ISO 15016:2015

(Main)Ships and marine technology — Guidelines for the assessment of speed and power performance by analysis of speed trial data

Ships and marine technology — Guidelines for the assessment of speed and power performance by analysis of speed trial data

The primary purpose of speed and power trials is to determine a ship's performance in terms of ship's speed, power and propeller shaft speed under prescribed ship's conditions and thereby verify the satisfactory attainment of a ship's speed stipulated by EEDI regulations and/or contract. ISO 15016:2015 defines and specifies the following procedures to be applied in the preparation, execution, analysis and reporting of speed trials for ships, with reference to the effects which may have an influence upon the speed, power and propeller shaft speed relationship: · the responsibility of each party involved, · the trial preparations, · the ship's condition, · the limiting weather and sea conditions, · the trial procedure, · the execution of the trial, · the measurements required, · the data acquisition and recording, · the procedures for the evaluation and correction, · the processing of the results. The contracted ship's speed and the ship's speed for EEDI are determined for stipulated conditions and at specific draughts (contract draught and/or EEDI draught). For EEDI, the environmental conditions are: no wind, no waves, no current and deep water of 15°C. Normally, such stipulated conditions are unlikely to be experienced in part or in full during the actual trials. In practice, certain corrections for the environmental conditions such as water depth, surface wind, waves, current and deviating ship draught, have to be considered. For this purpose, during the speed and power trials, not only are shaft power and ship's speed measured, but also relevant ship data and environmental conditions. The applicability of ISO 15016:2015 is limited to ships of the displacement type.

Navires et technologie maritime — Lignes directrices pour l'évaluation des performances de vitesse et de puissance par analyse des données d'essais de vitesse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15016

Second edition

2015-04-01

Ships and marine technology —

Guidelines for the assessment of

speed and power performance by

analysis of speed trial data

Navires et technologie maritime — Lignes directrices pour

l’évaluation des performances de vitesse et de puissance par analyse

des données d’essais de vitesse

Reference number

©

ISO 2015

© ISO 2015

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2015 – All rights reserved

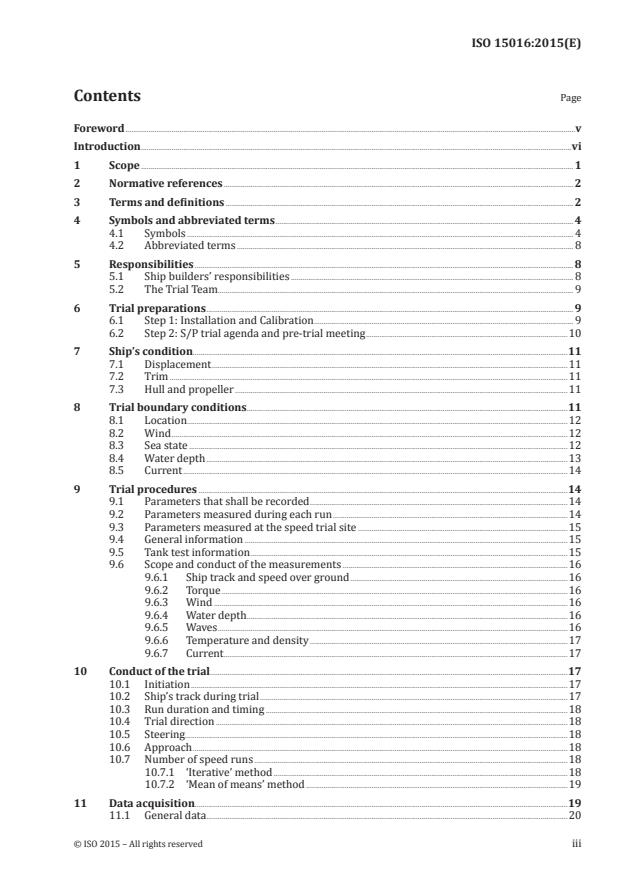

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Symbols and abbreviated terms . 4

4.1 Symbols . 4

4.2 Abbreviated terms . 8

5 Responsibilities . 8

5.1 Ship builders’ responsibilities . 8

5.2 The Trial Team. 9

6 Trial preparations . 9

6.1 Step 1: Installation and Calibration . 9

6.2 Step 2: S/P trial agenda and pre-trial meeting .10

7 Ship’s condition.11

7.1 Displacement .11

7.2 Trim .11

7.3 Hull and propeller .11

8 Trial boundary conditions .11

8.1 Location .12

8.2 Wind .12

8.3 Sea state .12

8.4 Water depth .13

8.5 Current .14

9 Trial procedures .14

9.1 Parameters that shall be recorded .14

9.2 Parameters measured during each run .14

9.3 Parameters measured at the speed trial site .15

9.4 General information .15

9.5 Tank test information .15

9.6 Scope and conduct of the measurements .16

9.6.1 Ship track and speed over ground .16

9.6.2 Torque .16

9.6.3 Wind .16

9.6.4 Water depth . .16

9.6.5 Waves .16

9.6.6 Temperature and density .17

9.6.7 Current.17

10 Conduct of the trial .17

10.1 Initiation .17

10.2 Ship’s track during trial .17

10.3 Run duration and timing .18

10.4 Trial direction .18

10.5 Steering .18

10.6 Approach .18

10.7 Number of speed runs .18

10.7.1 ‘Iterative’ method .18

10.7.2 ‘Mean of means’ method .19

11 Data acquisition.19

11.1 General data .20

11.2 Data on each run .20

11.3 Acquisition system .21

11.3.1 Minimum data .21

11.3.2 System requirements .21

11.3.3 Location .22

11.4 Manual data collection .22

12 Analysis procedure .24

12.1 General remarks .24

12.2 Description of the analysis procedure .24

12.2.1 Resistance data derived from the acquired data .25

12.2.2 Evaluation of the acquired data .25

12.2.3 Evaluation based on Direct Power Method .26

12.2.4 Correction of the measured ship’s speed due to the effect of current .29

12.2.5 Correction of the ship’s speed due to the effects of shallow water .30

12.2.6 Correction of the ship’s performance due to the effects of displacement .30

12.2.7 Conversion of power curve from trial condition to full load/

stipulated condition .30

13 Processing of the results .30

14 Reporting .31

15 Example of speed trial data analysis .32

Annex A (normative) General information and trial log sheet .34

Annex B (normative) Beaufort scale for wind velocity .35

Annex C (normative) Resistance increase due to wind .38

Annex D (normative) Resistance increase due to waves .48

Annex E (normative) Effect of water temperature and water density.61

Annex F (normative) Effect of current .62

Annex G (normative) Effect of shallow water .66

Annex H (normative) Effect of displacement .67

Annex I (normative) Conversion from trial condition to other stipulated load conditions .68

Annex J (normative) Derivation of load variation coefficients .70

Annex K (informative) Analysis of direct power method .75

Bibliography .85

iv © ISO 2015 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 8, Ships and marine technology, Subcommittee

SC 6, Navigation and ship operations.

This second edition cancels and replaces the first edition (ISO 15016:2002), which has been

technically revised.

Annexes A, B, C, D, E, F, G, H, I and J form a normative part of this International Standard, whereas

Annex K is informative.

Introduction

This International Standard concerns the method of analysing the results obtained from speed trials.

The primary purpose of speed and power trials is to determine a ship’s performance in terms of

ship’s speed, power and propeller shaft speed under prescribed ship’s conditions and thereby verify

the satisfactory attainment of a ship’s speed stipulated by Energy Efficiency Design Index (EEDI)

regulations and/or contract. Ship’s speed is that realized under conditions stipulated by contract and/or

EEDI regulations, which are usually; smooth hull and propeller surfaces, no wind, no waves, no current

and deep water of 15°C.

In general it cannot be expected that all such stipulated conditions will be met during the actual trials. In

practice, certain corrections for the environmental conditions have to be considered, such as for water

[1][2]

depth, wind, waves and current .

The purpose of this International Standard is to define the basic requirements for the performance

of speed trials, and provide procedures for evaluation and correction of speed trial data, covering all

influences which may be relevant to the individual trial runs based on sound scientific grounds, thereby

enabling owners and others to have confidence in the validity of the final results.

This International Standard is intended to help the interested parties achieve the desired target accuracy

of, within 2 % in shaft power and 0,1 kn in speed.

The procedure specified in this International Standard has been developed largely on the basis of published

data on speed trials and on ship’s performance, the more important among them being listed in Clause 2.

ISO has invited the International Towing Tank Conference (ITTC) to co-operate on the development

of a new standard for speed/power trials taking into account the new guidelines issued by ITTC and

approved by MEPC65 for EEDI. The contribution of the STA-group and the ITTC is highly appreciated.

Substitution of terms clause

This International Standard is generally applied to those ships for which survey and certification of EEDI

is required under International Maritime Organization (IMO) Resolution MEPC.214(63) [as amended

by MEPC.234(65)]. In the case of other ships, to which the above IMO resolutions are not applicable,

the terms or phrases of this International Standard are deemed to be replaced as necessary (e.g.

“agreement between the Shipbuilder, the Owner and the Verifier” shall be read as “agreement between

the Shipbuilder and the Owner” etc.)

vi © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 15016:2015(E)

Ships and marine technology — Guidelines for the

assessment of speed and power performance by analysis of

speed trial data

1 Scope

The primary purpose of speed and power trials is to determine a ship’s performance in terms of ship’s

speed, power and propeller shaft speed under prescribed ship’s conditions and thereby verify the

satisfactory attainment of a ship’s speed stipulated by EEDI regulations and/or contract.

This International Standard defines and specifies the following procedures to be applied in the

preparation, execution, analysis and reporting of speed trials for ships, with reference to the effects

which may have an influence upon the speed, power and propeller shaft speed relationship:

— the responsibility of each party involved,

— the trial preparations,

— the ship’s condition,

— the limiting weather and sea conditions,

— the trial procedure,

— the execution of the trial,

— the measurements required,

— the data acquisition and recording,

— the procedures for the evaluation and correction,

— the processing of the results.

The contracted ship’s speed and the ship’s speed for EEDI are determined for stipulated conditions and

at specific draughts (contract draught and/or EEDI draught). For EEDI, the environmental conditions

are: no wind, no waves, no current and deep water of 15°C.

Normally, such stipulated conditions are unlikely to be experienced in part or in full during the actual

trials. In practice, certain corrections for the environmental conditions such as water depth, surface

wind, waves, current and deviating ship draught, have to be considered. For this purpose, during the

speed and power trials, not only are shaft power and ship’s speed measured, but also relevant ship data

and environmental conditions.

The applicability of this International Standard is limited to ships of the displacement type.

In this International Standard, it was decided that the unit to express the amount of an angle should be

“rad” (radian) and that the unit of speed should be “m/s” (metres per second). Nevertheless, “°” (degree)

as a unit for an angle and “knots” as a unit for speed may be used. However, the units for the angles and

speeds which appear in calculation formulas are to be “rad” and “m/s” without exception. Moreover, for

the convenience of the users of this International Standard, numerical values using the units of degree

and knots are stated jointly at appropriate places.

If it is physically impossible to meet the conditions in this International Standard, a practical treatment is

allowed based on the documented mutual agreement among the Owner, the Verifier and the Shipbuilder.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ITTC 7.5-04-01-01.4:2002, ITTC Recommended Procedures and Guidelines, Speed and Power Trials, Part 4:

Instrumentation Installation and Calibration

ITTC 7.5-02-07-02.2, ITTC Recommended Procedures and Guidelines, Prediction of Power Increase in

Irregular Waves from Model Test

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

brake power

power delivered by the output coupling of the propulsion machinery before passing through any speed-

reducing and transmission devices

3.2

contract power

brake power or shaft power that is stipulated in the new build or conversion contract between the

Shipbuilder and the Owner

3.3

contract speed

ship’s speed to be achieved as agreed within the terms of the new build/conversion contract

3.4

Double Run

two consecutive speed runs at the same power setting on reciprocal headings

Note 1 to entry: See 3.16 for speed runs.

3.5

EEDI

Energy Efficiency Design Index as formulated by IMO

3.6

EEDI power

brake power that is stipulated by the Energy Efficiency Design Index (EEDI) regulations

3.7

EEDI Speed

ship’s speed achieved under the conditions specified by the IMO Resolution MEPC.245(66) (as amended)

3.8

ideal conditions

ideal weather and sea conditions: no wind, no waves, no current and deep water of 15°C

3.9

measured ship’s speed

ship’s speed during a speed run derived from the headway distance between start and end position and

the elapsed time of the speed run

3.10

Owner

party that signed the new building or conversion contract with the Shipbuilder

2 © ISO 2015 – All rights reserved

3.11

power setting

setting of engine throttle and propeller shaft speed for fixed pitch propellers and setting of the pitch

angle for controllable pitch propellers

3.12

propeller pitch

design pitch for a fixed pitch propeller

3.13

pitch angle

operating pitch angle of a Controllable Pitch Propeller (CPP)

3.14

shaft power

net power supplied by the propulsion machinery to the propulsion shafting after passing through all

speed-reducing and other devices and after power for all attached auxiliaries has been taken off and

accounting for losses in shaft between propeller and the location of power measurement at the shaft

3.15

Shipbuilder

shipyard that signed the new building or conversion contract with the Owner

3.16

ship’s speed

speed of the ship that is realised under the stipulated conditions

Note 1 to entry: See also measured ship’s speed, contract speed and EEDI speed.

3.17

sister ships

ships with identical main dimensions, body lines, appendages and propulsion system built in a series by

the same Shipyard

3.18

S/P trials

speed and power trials to establish the relationship between power and speed for a particular ship

3.19

S/P trial agenda

document outlining the scope of a particular S/P trial

3.20

speed run

ship’s track with specified heading, distance and duration for which the measured ship’s speed and shaft

power are calculated

Note 1 to entry: This International Standard contains the procedures on how to conduct the trial and table(s)

portraying the runs to be conducted.

3.21

tank tests

model tank tests for the prediction of the speed power relation for the stipulated conditions

3.22

trial baseline

the track of the first S/P run

3.23

Trial Leader

duly authorised (Shipbuilder’s representative) person responsible for the execution of all phases of the

S/P trials including the pre-trial preparation

3.24

trial log

all the data recorded before, during and after the S/P trial

3.25

Trial Team

team that consists of the Trial Leader, the Owner’s representative, the appointed persons responsible for

the S/P trial measurements and, if the ship requires EEDI, the Verifier

3.26

Verifier

third party responsible for verification of the EEDI

3.27

zero pitch

Controllable Pitch Propeller (CPP) blade angle at which the pitch angle at the representative radius is

equivalent to zero

4 Symbols and abbreviated terms

4.1 Symbols

A is the lateral projected area above the waterline including superstructures

LV

A is the midship section area under water

M

A is the lateral projected area of superstructures above upper deck

OD

a , b , c are the factors for the torque coefficient curve

Q Q Q

a , b , c are the factors for the thrust coefficient curve

T T T

A is the transverse projected area above the waterline including superstructures in square metres

XV

B is the ship’s breadth

B(x) is the sectional breadth

B is the bluntness coefficient

f

C is the wind resistance coefficient; C (0) means the wind resistance coefficient in head wind

AA AA

C is the block coefficient

B

C is the frictional resistance coefficient for the actual water temperature and water density

F

C is the frictional resistance coefficient for the reference water temperature and water density

F0

C is the horizontal distance from midship section to centre of lateral projected area A , where +

MC LV

means forward from midship

C is the vertical prismatic coefficient

Pv

C is the total resistance coefficient for the reference water temperature and water density

T0

C is the coefficient of advance speed

U

D is the propeller diameter

E is the directional spectrum

e is the scale correlation factor of the wake fraction

i

F is the skin friction correction force same as in the normal self-propulsion tests

D

Fr is the Froude number

4 © ISO 2015 – All rights reserved

F is the external tow force measured during load variation test

X

g is the acceleration of gravity

G is the angular distribution function

h is the water depth

H (m) is the function to be determined by the distribution of singularities σ(x) which represents a

periodical disturbance by the ship

H is the significant wave height

1/3

H is the height of top of superstructure (bridge etc.)

BR

H is the height from waterline to centre of lateral projected area A

C LV

H is the significant height of local swell

S1/3

H is the significant height of local wind driven waves

W1/3

(i) is the run number

I is the modified Bessel function of the first kind of order 1

J is the propeller advance coefficient

J is the propeller advance coefficient in the ideal condition

id

J is the propeller advance coefficient in the trial condition

ms

k is the wave number

K is the modified Bessel function of the second kind of order 1

K is the torque coefficient

Q

K is the torque coefficient in the ideal condition

Qid

K is the torque coefficient in the trial condition

Qms

K is the thrust coefficient

T

K is the thrust coefficient in the ideal condition

Tid

K is the thrust coefficient in the trial condition

Tms

k is the non-dimensional radius of gyration in the lateral direction

yy

L is the distance of the bow to 95 % of maximum breadth on the waterline

BWL

L is the ship’s length overall

OA

L is the ship’s length between perpendiculars

PP

MCR is the Maximum Continuous Rating

th

m is the n moment of frequency spectrum

n

n is the corrected propeller shaft speed

id

n is the measured propeller shaft speed

ms

P

is the power corresponding to displacement volume ∇ during the S/P trial

P

is the power corresponding to displacement volume ∇ used in the tank test

P is the measured brake power

Bms

P is the delivered power in the ideal condition

Did

P is the delivered power in the trial condition

Dms

P is the power at full load/stipulated condition predicted by the tank tests

Full,P

P is the power at full load/stipulated condition obtained by the S/P trials

Full,S

P is the measured shaft power

Sms

P is the power at the trial condition predicted by the tank tests

Trial,P

P is the power at the trial condition obtained by the S/P trials

Trial,S

R is the resistance increase due to relative wind

AA

R is the resistance increase due to deviation of water temperature and water density

AS

R is the resistance increase due to waves

AW

R is the mean resistance increase in long crested irregular waves, as substitute for R

AWL AW

R is the mean resistance increase in regular waves based on Maruo’s theory, which is calculated

AWM

from the radiation and diffraction components

R is the correction term of R

AWR AWM

R is the frictional resistance for the actual water temperature and water density

F

R is the frictional resistance for the reference water temperature and water density

F0

R is the resistance in the ideal condition

id

R is the resistance in the trial condition

ms

R is the total resistance for the reference water temperature and water density

T0

R is the mean resistance increase in regular waves

wave

is the mean resistance increase in regular waves measured in the tank tests

EXP

R

wave

s is the directional spreading parameter

S is the wetted surface area

S is the full scale wetted surface, the same value as used in the normal self-propulsion test

S

S is the frequency spectrum

η

t is the thrust deduction factor

T is the period of variation of current speed

C

T is the draught; for a trim condition T is the deepest draught

deep deep

t is the thrust deduction factor in the ideal condition

id

T is the draught at midships

M

t is the thrust deduction factor in the trial condition

ms

V’ is the corrected relative wind velocity at the vertical position of the anemometer

WR

V’ is the averaged true wind velocity at the vertical position of the anemometer

WT

V is the speed of flow into propeller

A

V is the current speed

C

V is the measured ship’s speed over ground

G

V is the measured ship’s speed over the ground on the first of four runs

G1

V is the measured ship’s speed over the ground on the second of four runs

G2

V is the measured ship’s speed over the ground on the third of four runs

G3

V is the measured ship’s speed over the ground on the fourth of four runs

G4

V is the ship’s speed through the water

S

V is the relative wind velocity

WR

V is the relative wind velocity at the reference height

WRref

V is the true wind velocity

WT

V is the true wind velocity at the reference height

WTref

w is the model wake fraction

M

w is the model wake fraction in the ideal condition

Mid

w is the model wake fraction in the trial condition

Mms

w is the full-scale wake fraction

S

6 © ISO 2015 – All rights reserved

w is the full-scale wake fraction in the ideal condition

Sid

w is the full-scale wake fraction in the trial condition

Sms

x is the longitudinal coordinate

Z is the vertical position of the anemometer

a

Z is the reference height for the wind resistance coefficients

ref

Z is the vertical displacement relative to waves in steady motion

Γ

α is the power ratio

P

α is the effect of draught and encounter frequency

T

α is the angle between ship’s heading and component waves; 0 means head waves

β is the slope of the line element dl along the water line

W

Γ is the Gamma function

ΔP is the required correction for power

ΔR is the total resistance increase

Δt is the deviation of the thrust deduction factor

ΔV is the decrease of ship’s speed due to shallow water

Δw is the deviation of the wake fraction

M

Δη is the deviation of the relative rotative efficiency

R

ζ is the wave amplitude

A

η is the propulsive efficiency coefficient

D

η is the propulsive efficiency coefficient in ideal condition

Did

η is the propulsive efficiency coefficient in trial condition

Dms

η is the transmission efficiency

M

η is the propeller open water efficiency

O

η is the propeller efficiency in the ideal condition

Oms

η is the relative rotative efficiency

R

η is the relative rotative efficiency in the ideal condition

Rid

η is the relative rotative efficiency in the trial condition

Rms

η is the shaft efficiency

S

θ is the angle between ship’s heading and wave direction relative to the bow; 0 means head waves

m

λ is the scale factor

μ is the smoothing range

ξ , ξ are derived considering the load variation effect as described in Annex J

n V

ξ is derived considering the load variation effect as described in Annex J

P

ρ is the mass density of air

A

ρ is the water density in the model test

M

ρ is the water density for the actual water temperature and salt content

S

ρ is the water density for the reference water temperature and salt content

S0

τ is the load factor equal to K /J

P T

τ is the load factor in the ideal condition

Pid

τ is the load factor in the trial condition

Pms

ψ is the ship’s heading

ψ’

is the corrected relative wind direction at the vertical position of the anemometer

WR

ψ’ is the averaged true wind direction at the vertical position of the anemometer

WT

ψ is the relative wind direction; 0 means head winds

WR

ψ is the relative wind direction at the reference height

WRref

ψ is the true wind direction in Earth system

WT

ω is the circular frequency of regular waves

ω is the circular wave frequency of encounter

E

is the displacement volume during the S/P trial

∇

is the displacement volume used in the tank test

∇

4.2 Abbreviated terms

CPP Controllable Pitch Propeller

IMO International Maritime Organization

ITTC International Towing Tank Conference

JASNAOE The Japan Society of Naval Architects and Ocean Engineers

JONSWAP Joint North Sea Wave Project

MEPC Marine Environmental Protection Committee in IMO

SNAJ The Society of Naval Architects of Japan

SNAME The Society of Naval Architects and Marine Engineers, USA

STA-Group An international group of owners, shipyards, research institutes, classification societies and

universities studying and improving sea trial procedures and Sea Trial Analyses (STA)

5 Responsibilities

5.1 Ship builders’ responsibilities

The Shipbuilder is responsible for the planning, conduct and evaluation of the S/P trials. The Shipbuilder

shall ensure that:

— an appropriately authorized Trial Leader is appointed to oversee all aspects of the S/P trial,

— all permits and certificates required for the ship to go to sea are provided,

— all qualified personnel necessary for operating the ship and all engines, systems and equipment

required during the sea trials, are on board,

— all regulatory bodies: the Classification Society; the Owner; ship agents; suppliers; subcontractors;

harbour facilities; departments organizing the supply of provisions, fuel, water, towage, etc.,

necessary for conducting these trials; have been informed, are available and on board when required,

— all safety measures have been checked,

— all fixed, portable and individual material (for crew, trial personnel and guests) is on board and operative,

— any safety systems for conducting safe S/P trials have been checked in accordance with the

administrative requirements,

— an inclining test has been performed and/or at least a preliminary stability booklet including the

S/P trials condition has been approved, in accordance with the SOLAS Convention,

— all ship data relevant for the S/P trials Preparation, Conduct, Analysis and Reporting are made

available to the Trial Team prior to the S/P trials. This data shall include the information requested

8 © ISO 2015 – All rights reserved

in Annex A as well as the results of the tank tests for this ship at trial draught and trim, EEDI draught

and trim and Contract draught and trim.

Speed and power measurements and analysis shall be conducted by persons acknowledged as competent

to perform those tasks, as agreed between the Shipbuilder, the Owner and the (where applicable) Verifier.

The Shipbuilder shall arrange for divers to inspect the ship’s hull and propulsor(s) if necessary.

The Shipbuilder is responsible for the overall trial co-ordination. A pre-trial meeting between the Trial Team

and the ship’s crew shall be held to discuss the various trial events and to resolve any outstanding issues.

The Trial Leader shall maintain contact with the Trial Team on the preparation, execution and results

of the S/P trials.

5.2 The Trial Team

The Trial Team is responsible for correct measurements and reporting of the S/P trials according to this

International Standard and for the analysis of the measured data to derive the ship’s speed and power

at the stipulated conditions.

The Trial Team is responsible for the following:

— conducting an inspection of the ship, including the condition of the hull and propeller(s)/propulsor(s),

prior to the commencement of the S/P trial,

— the provision, installation, operation and removal of all necessary trial instrumentation and

temporary cabling,

— providing the ship’s Master and the Owner’s representative with a preliminary data package and

initial analysis before disembarking,

— delivering a final report on completion of full analysis of the measurements taken during the trial.

6 Trial preparations

The success of the S/P trials largely depends on the preparations. In this Clause the most important

steps are summarized.

6.1 Step 1: Installation and Calibration

Assemble all the trials instrumentation in the configuration that is to be used on the ship. Test the

instrumentation system for any malfunctioning or other complications.

Apart from the obvious inputs such as; shaft torque, propeller shaft speed and DGPS, it is important to check:

a) gyrocompasses,

b) anemometer system,

c) propeller pitch (of each propeller),

d) ship’s draught measurement system (if available),

e) water depth measuring system.

After the trial instrumentation is installed, all shipboard input signals to be recorded during the S/P

trials shall be calibrated prior to the trials. For this purpose the sensors shall be cycled throughout the

full operating range of the system.

This is accomplished by:

— slewing the gyrocompasses,

— changing the propeller pitch.

Prior to departure for S/P trials and with the ship in a steady loading condition, all draught marks, water

temperature and specific density, and ship’s draught measuring system (if available) shall be measured

and recorded. If no ship’s draught measuring system is available, all tank sounding data shall be recorded.

The shaft power shall be derived from torque and propeller shaft speed.

Shaft torque shall be measured by means of a calibrated permanent torque sensor or strain gauges on the

shaft. The measurement system shall be certified for power measurements with a bias error smaller than

1 % so that an overall bias error smaller than 2 % (on board the ship undergoing trials) can be achieved.

Alternative shaft torque measurement devices with a certified accuracy equal to or better than the

above figures are acceptable.

As part of the S/P trial preparation, the torsion meter’s zero torque readings shall be determined since

there is a residual torque in the shaft, which is resting on the line shaft bearings. The torsion meter zero

setting is to be carried out in accordance with its maker’s instructions. If not specified otherwise, the

zero torque value is determined with the ship at rest by turning the shaft ahead and astern and taking

the mean of these two readings as the zero value (refer to ITTC 7.5-04-01-01.4 2002).

The shaft material properties, e.g. the G-Modulus shall be fully described and documented by the

Shipbuilder. If no certificate based on an actual shaft torsional test is available, the G-Modulus of 82

400 N/mm shall be used. The shaft diameter used in the power calculation shall be derived from the

shaft circumference measured at the location of the torsion meter. In the case of controllable pitch

propeller(s) there might be a drilling diameter to be taken into account (to be supplied by Shipbuilder).

When shaft torque measurement is not possible, an alte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...