ISO/TS 14907-1:2015

(Main)Electronic fee collection — Test procedures for user and fixed equipment — Part 1: Description of test procedures

Electronic fee collection — Test procedures for user and fixed equipment — Part 1: Description of test procedures

ISO/TS 14907-1:2015 specifies the test procedures of EFC roadside equipment (RSE) and on-board equipment (OBE) with regard to the conformance to standards and requirements for type approval and acceptance testing which is within the realm of EFC application specifically. ISO/TS 14907-1:2015 is restricted to systems operating within the radio emission, electromagnetic compatibility (EMC) regulations, traffic, and other regulations of the countries in which they are operated. ISO/TS 14907-1:2015 identifies a set of suitable parameters and provides test procedures to enable the proof of a complete EFC system, as well as components of an EFC system, e.g. OBE, related to the defined requirements of an application. The defined parameter and tests are assigned to the following groups of parameters: ? functionality; ? quality; ? referenced pre-tests. An overview of the tests and parameters provided by this part of ISO/TS 14907 is given in 5.1 and 5.2. ISO/TS 14907-1:2015 describes procedures, methods and tools, and a test plan which shows the relation between all tests and the sequence of these tests. It lists all tests that are required to measure the performance of EFC equipment. It describes which EFC equipment is covered by the test procedures; the values of the parameters to be tested are not included. It also describes how the tests are to be performed and which tools and prerequisites are necessary before this series of tests can be undertaken. It is assumed that the security of the system is inherent in the communications and EFC functionality tests, therefore they are not addressed here. All tests in this part of ISO/TS 14907 provide instructions to evaluate the test results.

Perception du télépéage — Modes opératoires relatifs aux équipements embarqués et aux équipements fixes — Partie 1: Description des modes opératoires

General Information

- Status

- Withdrawn

- Publication Date

- 31-Aug-2015

- Withdrawal Date

- 31-Aug-2015

- Technical Committee

- ISO/TC 204 - Intelligent transport systems

- Drafting Committee

- ISO/TC 204/WG 5 - Fee and toll collection

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 18-Mar-2020

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Consolidates

ISO 17299-3:2014 - Textiles — Determination of deodorant property — Part 3: Gas chromatography method - Effective Date

- 06-Jun-2022

- Effective Date

- 23-Apr-2020

- Effective Date

- 05-Nov-2015

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

ISO/TS 14907-1:2015 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Electronic fee collection — Test procedures for user and fixed equipment — Part 1: Description of test procedures". This standard covers: ISO/TS 14907-1:2015 specifies the test procedures of EFC roadside equipment (RSE) and on-board equipment (OBE) with regard to the conformance to standards and requirements for type approval and acceptance testing which is within the realm of EFC application specifically. ISO/TS 14907-1:2015 is restricted to systems operating within the radio emission, electromagnetic compatibility (EMC) regulations, traffic, and other regulations of the countries in which they are operated. ISO/TS 14907-1:2015 identifies a set of suitable parameters and provides test procedures to enable the proof of a complete EFC system, as well as components of an EFC system, e.g. OBE, related to the defined requirements of an application. The defined parameter and tests are assigned to the following groups of parameters: ? functionality; ? quality; ? referenced pre-tests. An overview of the tests and parameters provided by this part of ISO/TS 14907 is given in 5.1 and 5.2. ISO/TS 14907-1:2015 describes procedures, methods and tools, and a test plan which shows the relation between all tests and the sequence of these tests. It lists all tests that are required to measure the performance of EFC equipment. It describes which EFC equipment is covered by the test procedures; the values of the parameters to be tested are not included. It also describes how the tests are to be performed and which tools and prerequisites are necessary before this series of tests can be undertaken. It is assumed that the security of the system is inherent in the communications and EFC functionality tests, therefore they are not addressed here. All tests in this part of ISO/TS 14907 provide instructions to evaluate the test results.

ISO/TS 14907-1:2015 specifies the test procedures of EFC roadside equipment (RSE) and on-board equipment (OBE) with regard to the conformance to standards and requirements for type approval and acceptance testing which is within the realm of EFC application specifically. ISO/TS 14907-1:2015 is restricted to systems operating within the radio emission, electromagnetic compatibility (EMC) regulations, traffic, and other regulations of the countries in which they are operated. ISO/TS 14907-1:2015 identifies a set of suitable parameters and provides test procedures to enable the proof of a complete EFC system, as well as components of an EFC system, e.g. OBE, related to the defined requirements of an application. The defined parameter and tests are assigned to the following groups of parameters: ? functionality; ? quality; ? referenced pre-tests. An overview of the tests and parameters provided by this part of ISO/TS 14907 is given in 5.1 and 5.2. ISO/TS 14907-1:2015 describes procedures, methods and tools, and a test plan which shows the relation between all tests and the sequence of these tests. It lists all tests that are required to measure the performance of EFC equipment. It describes which EFC equipment is covered by the test procedures; the values of the parameters to be tested are not included. It also describes how the tests are to be performed and which tools and prerequisites are necessary before this series of tests can be undertaken. It is assumed that the security of the system is inherent in the communications and EFC functionality tests, therefore they are not addressed here. All tests in this part of ISO/TS 14907 provide instructions to evaluate the test results.

ISO/TS 14907-1:2015 is classified under the following ICS (International Classification for Standards) categories: 35.240.60 - IT applications in transport; 43.040.15 - Car informatics. On board computer systems. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TS 14907-1:2015 has the following relationships with other standards: It is inter standard links to CEN ISO/TS 14907-1:2015, ISO 17299-3:2014, ISO 14907-1:2020, ISO/TS 14907-1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/TS 14907-1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 14907-1

Third edition

2015-09-01

Electronic fee collection — Test

procedures for user and fixed

equipment —

Part 1:

Description of test procedures

Perception du télépéage — Modes opératoires relatifs aux

équipements embarqués et aux équipements fixes —

Partie 1: Description des modes opératoires

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

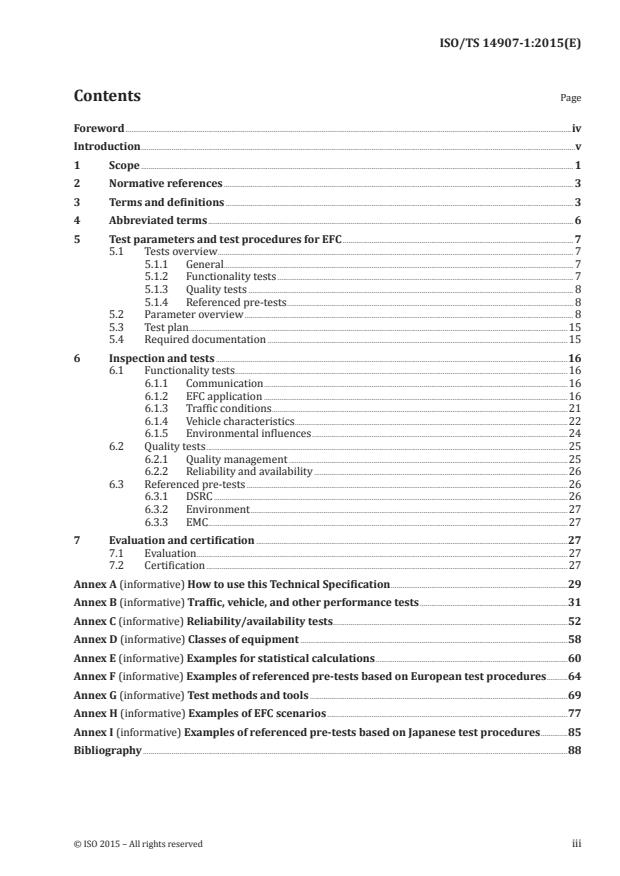

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 3

3 Terms and definitions . 3

4 Abbreviated terms . 6

5 Test parameters and test procedures for EFC . 7

5.1 Tests overview . 7

5.1.1 General. 7

5.1.2 Functionality tests . 7

5.1.3 Quality tests . 8

5.1.4 Referenced pre-tests . 8

5.2 Parameter overview . 8

5.3 Test plan .15

5.4 Required documentation .15

6 Inspection and tests .16

6.1 Functionality tests .16

6.1.1 Communication .16

6.1.2 EFC application .16

6.1.3 Traffic conditions . .21

6.1.4 Vehicle characteristics.22

6.1.5 Environmental influences .24

6.2 Quality tests .25

6.2.1 Quality management .25

6.2.2 Reliability and availability .26

6.3 Referenced pre-tests .26

6.3.1 DSRC .26

6.3.2 Environment .27

6.3.3 EMC.27

7 Evaluation and certification .27

7.1 Evaluation .27

7.2 Certification .27

Annex A (informative) How to use this Technical Specification .29

Annex B (informative) Traffic, vehicle, and other performance tests .31

Annex C (informative) Reliability/availability tests .52

Annex D (informative) Classes of equipment .58

Annex E (informative) Examples for statistical calculations .60

Annex F (informative) Examples of referenced pre-tests based on European test procedures .64

Annex G (informative) Test methods and tools .69

Annex H (informative) Examples of EFC scenarios .77

Annex I (informative) Examples of referenced pre-tests based on Japanese test procedures .85

Bibliography .88

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 204, Intelligent transport systems.

This third edition cancels and replaces the second edition (ISO/TS 14907-1:2010). It also incorporates

the Technical Corrigenda ISO/TS 14907-1:2010/Cor.1:2010. The main changes are related to the revision

of the references.

ISO/TS 14907 consists of the following parts, under the general title Electronic fee collection — Test

procedures for user and fixed equipment:

— Part 1: Description of test procedures

— Part 2: Conformance test for the onboard unit application interface

iv © ISO 2015 – All rights reserved

Introduction

For an electronic fee collection (EFC) system, approvals and tests are required to determine whether the

system (or individual components of the system) conforms to standards and application requirements

and to enable parameters such as quality, availability, and maintainability to be measured.

There are complete EFC systems available, including documentation and approvals, and these could

already be in operation in some European countries. This part of ISO/TS 14907 provides a toolbox

of tests and procedures for the assessment and proof of such EFC systems that they are suitable for

specified EFC applications under specific operational conditions. Dependent on a system to be tested

and based on the available documentation and the status of previously performed approvals, this part

of ISO/TS 14907 enables parties involved, e.g. system provider, operators, and test houses, to take into

consideration already proven references and to identify such parameters which still have to be tested

according to the specified applications.

At the time of publication of this part of ISO/TS 14907, the determination of common system requirements

for Europe (or any other region) has not been agreed. For this reason, this part of ISO/TS 14907 does

not specify any particular performance requirements, unless these are already determined elsewhere

(such as safety or radio regulations), but rather identifies the key parameters which will comprise such

requirements. Where reference to an existing test is available, this part of ISO/TS 14907 provides that

reference. This part of ISO/TS 14907 defines only the test and test procedures, not the benchmark

figures that these are to be measured against. Benchmark figures which the systems or components

under test can be compared with and validated against might form the subject of a future part of this

Technical Specification. Within the framework of the European Electronic Toll System (EETS), this part

of ISO/TS 14907 could provide inputs for the work of the notified bodies in view to certify the different

systems’ part of the EETS in particular to check the suitability for use.

This part of ISO/TS 14907 is furthermore limited to automated (electronic) payment using a

standardized dedicated short-range communication (DSRC). The scope of this part of ISO/TS 14907

does not include manual payment, conventional money transaction, nor payment by means of sticker,

vignettes, tickets, or magnetic-stripe cards, etc. The applications to which EFC is related are toll

collection, road pricing, parking, and individual traffic information.

This part of ISO/TS 14907 enables groups of operators to determine common specific performance levels

and operating conditions and to enable regional variation where appropriate. It provides operating and

environmental parameters (or classes of operating and environmental parameters) within which such

systems shall successfully function without impairing interoperability to ensure that the person who

specified the system can state their requirements clearly to implementation designers and integrators

and to enable the measurement of the performance of such systems.

The following guidelines have been followed when selecting the test procedures for test parameters:

— reference as far as possible to existing standardized test procedures;

— focusing on those tests that are essential to ensure that EFC equipment is able to exchange

information and mutually use the exchanged information.

A brief guide describing how to use this part of ISO/TS 14907 is provided by Annex A.

While this part of ISO/TS 14907 relates to general test procedures, certain provisions relate specifically

to test procedures for certification purposes. Many features of this part of ISO/TS 14907 are relevant

internationally; it is recognized that due to different regulatory requirements outside Europe,

extension may be required to make its applicability as comprehensive in non-EU countries, before this

International Standard can be reviewed for acceptance as in EU countries.

The ISO/TS 17444 series provides an examination framework for EFC charging performance.

TECHNICAL SPECIFICATION ISO/TS 14907-1:2015(E)

Electronic fee collection — Test procedures for user and

fixed equipment —

Part 1:

Description of test procedures

1 Scope

This part of ISO/TS 14907 specifies the test procedures of EFC roadside equipment (RSE) and on-board

equipment (OBE) with regard to the conformance to standards and requirements for type approval and

acceptance testing which is within the realm of EFC application specifically.

The scope of this part of ISO/TS 14907 is restricted to systems operating within the radio emission,

electromagnetic compatibility (EMC) regulations, traffic, and other regulations of the countries in

which they are operated.

This part of ISO/TS 14907 identifies a set of suitable parameters and provides test procedures to enable

the proof of a complete EFC system, as well as components of an EFC system, e.g. OBE, related to the

defined requirements of an application. The defined parameter and tests are assigned to the following

groups of parameters:

— functionality;

— quality;

— referenced pre-tests.

An overview of the tests and parameters provided by this part of ISO/TS 14907 is given in 5.1 and 5.2.

This part of ISO/TS 14907 describes procedures, methods and tools, and a test plan which shows

the relation between all tests and the sequence of these tests. It lists all tests that are required to

measure the performance of EFC equipment. It describes which EFC equipment is covered by the test

procedures; the values of the parameters to be tested are not included. It also describes how the tests

are to be performed and which tools and prerequisites are necessary before this series of tests can be

undertaken. It is assumed that the security of the system is inherent in the communications and EFC

functionality tests, therefore they are not addressed here. All tests in this part of ISO/TS 14907 provide

instructions to evaluate the test results.

The test procedures can be used for prototype testing, type approvals, test of installations, and

periodic inspections. Thus this part of ISO/TS 14907 defines only the test and test procedures, not the

benchmark figures that these are to be measured against.

Related to a conceptual model of an EFC system, this part of ISO/TS 14907 relates only to the equipment

of the user and the service provider as illustrated in Figure 1. Any other entities are outside the scope of

this part of ISO/TS 14907.

Figure 1 — Conceptual model of EFC

EFC systems for DSRC consist, in principle, of a group of technical components, which in combination

fulfil the functions required for the collection of fees by electronic automatic means. These components

comprise of all, or most, of the following:

— OBE within a vehicle;

— OBE containing the communications and computing sub-functions;

— optional integrated circuit card which may carry electronic money, service rights, and other

secured information;

— communication between OBE and RSE based on DSRC;

— equipment for the fee collection at the RSE containing the communications and computing sub-

functions;

— equipment for the enforcement at the roadside;

— central equipment for the administration and operation of the system.

The scope of this part of ISO/TS 14907 relates solely to OBE and RSE and the DSRC interface between

OBE and RSE including its functions to perform the fee collection as illustrated by Figure 2. All the

equipment used for enforcement (e.g. detection, classification, localization, and registration) and

central equipment are outside the scope of this part of ISO/TS 14907.

2 © ISO 2015 – All rights reserved

Figure 2 — OBE/RSE interface and associated environments

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO/IEC 17065:2012, Conformity assessment — Requirements for bodies certifying products, processes

and services

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

acceptance testing

examination that a product, process, or service is in conformity with the system specification

3.2

availability

property of being accessible and useable upon demand by an authorized entity

[SOURCE: ISO 7498-2:1989, 3.3.11]

3.3

certification

procedure by which a party gives written assurance that a product, process, or service conforms to

specified requirements

3.4

compatibility

suitability of products, processes, or services for use together under specific conditions to fulfil relevant

requirements without causing unacceptable interactions

3.5

EFC equipment

equipment comprising roadside equipment (RSE) and on-board equipment (OBE)

3.6

EFC system

system that enables electronic debiting for the use of transport services

3.7

evaluation

systematic process of determining how individuals, procedures, systems, or programs have met

formally agreed objectives and requirements

[SOURCE: ISO 10798:2011, 1.90]

3.8

evaluation assurance level

set of assurance requirements, usually involving documentation, analysis and testing, representing a

point on a predefined assurance scale, that form an assurance package

[SOURCE: ISO/IEC 15408-1:2009, 3.1.27, modified]

3.9

field test

test that is performed under real-life conditions

3.10

functionality test

assessing the performance of an EFC system, based on specific parameters

Note 1 to entry: Functionality parameters can include communication, application, and vehicle and traffic

characteristics.

3.11

inspection

conformity evaluation by observation and judgement accompanied, as appropriate, by measurement,

testing, or gauging

3.12

interoperability

ability of systems to exchange information and to make mutual use of the information that has

been exchanged

[SOURCE: ISO/IEC/TR 10000-1:1998, 3.2.1, modified]

3.13

laboratory test

test which is performed in a laboratory under specified conditions

3.14

maintainability

ability of a system or subsystem to be maintained or restored to specified conditions within a given

period of time

4 © ISO 2015 – All rights reserved

3.15

on-board equipment

OBE

equipment located on-board a vehicle including nomadic devices with the function of exchanging

information with external systems

Note 1 to entry: OBE is composed of the on-board unit (OBU) and other sub-units whose presence is considered

optional for the execution of the DSRC interface.

[SOURCE: ISO 14906:2011, 3.14]

3.16

quality

degree to which a set of inherent characteristics fulfils requirements

Note 1 to entry: User requirements can include ease of use, safety, availability, reliability, sturdiness, economy,

and environmental safety. Such requirements can be explicit or implicit.

[SOURCE: ISO 9000:2005, 3.1.1]

3.176

reliability

ability of a device or a system to perform its intended function under given conditions of use for a

specified period of time or number of cycles

3.18

roadside equipment

RSE

equipment located along the road, either fixed or mobile

3.19

simulation

representation of selected behavioural characteristics of one physical or abstract system by

another system

[SOURCE: ISO/IEC 2382-1:1993, definition 01.06.01]

3.20

test

procedure designed to measure characteristics of a component or system in specified conditions

3.21

test parameter

parameter that specifies one or more characteristics of a system to be tested

3.22

test procedure

instructions for the setup, execution, and evaluation of results for a given test case

[SOURCE: ISO/IEC 25051:2014, 4.1.22, modified]

3.23

test status

nature of a test, either basic or conditional

Note 1 to entry: A test labelled “conditional” is performed if, and only if, it is applicable to a feature identified in

the specification of the system or component, whereas a test labelled “basic” indicates a highly recommended

test as part of a foundation for meaningful evaluation. See 5.2.

3.24

test type

kind of test, such as inspection, simulation, lab test, and field test

3.25

test house

third party that carries out the test

3.26

type approval

approval based on conformity testing on the basis of one or more specimens of a product representative

of the production

3.27

validation

confirmation by examination and provision of objective evidence that the particular requirements for a

specific intended use are fulfilled

3.28

verification

confirmation by examination and provision of objective evidence that specified requirements have

been fulfilled

4 Abbreviated terms

ARIB Association of Radio Industries and Businesses

NOTE A Japanese standards development organisation.

DSRC dedicated short-range communication (ISO 14906)

EAL Evaluation Assurance Level

EFC electronic fee collection (ISO 17573)

EIRP equivalent isotropically radiated power

EMC electromagnetic compatibility

ETSI European Telecommunications Standards Institute

ICC integrated circuit card

IEC International Electrotechnical Commission

IUT implementation under test

MMI man-machine interface

MTBF mean time between failure

MTTF mean time to failure

MTTR mean time to repair

OBE onboard equipment (ISO 14906)

OBU onboard unit

RSE roadside equipment (ISO 14906)

SUT system under test

tbd to be determined

6 © ISO 2015 – All rights reserved

5 Test parameters and test procedures for EFC

5.1 Tests overview

5.1.1 General

The test parameters for EFC systems or components are categorized in three groups as follows:

a) functionality tests;

b) quality tests;

c) referenced pre-tests.

Figure 3 shows the general structure of all test parameter groups relevant for EFC systems and those

which are relevant to this part of ISO/TS 14907. The test parameters for pre-tests are referenced from

sources other than this part of ISO/TS 14907. The specific test parameters that are ultimately deemed

relevant for a specific EFC system shall be identified and listed in the test plan according to 5.3. The

individual test plan for type approval or acceptance testing shall take into account those pre-tests that

have already been passed, i.e. for EMC, DSRC, and environment.

Figure 3 — Test plan — Interdependencies

5.1.2 Functionality tests

The first category of tests is related to test procedures which aim to verify the functionality of the

EFC equipment.

The functionality tests are related to the essential test parameters that need to be applied to verify the

performance and capability of EFC equipment of different vendors and system operators.

The following parameters shall be tested:

— communication;

— EFC application;

— influence of vehicle characteristics;

— influence of traffic characteristics;

— environmental influences.

Communication and EFC application tests are described in 6.1. Tests related to vehicle and traffic

characteristics and environmental influences are listed in Annex B.

5.1.3 Quality tests

The second category of tests is related to procedures that aim to determine the quality of the EFC

equipment. These are relevant for both operators and users.

The following test parameters shall be tested:

— quality management;

— reliability;

— availability.

For some of these test parameters, there are some existing test procedures available, which are referenced.

These tests are described in 6.2 and Annex C.

5.1.4 Referenced pre-tests

The third category of tests is related to test parameters which are fundamental for the performance

of EFC equipment. The specific parameters and requirements are not within the scope of this part of

ISO/TS 14907. The parameters that are relevant can be assigned to the following groups:

— DSRC;

— EMC;

— environment.

5.2 Parameter overview

Tables 1 to 3 provide a comprehensive list of the parameters that are relevant for type approval or

acceptance testing of a complete EFC system, as well as components of an EFC system. The tables are

divided according to the subjects of 5.1.2, 5.1.3, and 5.1.4, namely functionality, quality, and referenced

pre-tests. The subclause in which the tests are described or referenced is shown. An indication as to the

nature of these tests (basic or conditional) is provided as not all tests are relevant to all operators and

their specific operating situations and environment.

As used in Tables 1 to 3,

— “basic” means that the identified tests are highly recommended as part of a foundation for meaningful

evaluation, and

— “conditional” means that the test shall be performed if, and only if, it is applicable to a feature

identified in the specification of the system or component under evaluation, for example, performing

the lane changing test (T6) if the RSE is characterized as multilane.

8 © ISO 2015 – All rights reserved

Table 1 provides an overview of the parameters for which tests are defined in this part of

ISO/TS 14907 to measure the performance and assess the level of conformance of an EFC system or

components under test.

Table 2 provides a list of the quality tests.

Table 3 provides a list of parameters that are necessary for pre-tests and whose performance and

conformance are tested by reference to existing standards or Technical Specifications.

NOTE The tests have been categorized into inspection tests, laboratory tests, simulation tests, and field

tests. The appropriate test or types of tests are indicated, in the following tables, for each parameter. It is not

expected that all the named types of tests for a parameter will be performed on that parameter. Where a set

of appropriate tools is available to a test house, it is up to the test house to decide which type of test is most

appropriate to meet its specific remit.

Where a particular category of test shall be performed to conform to this part of ISO/TS 14907, the test

is indicated in the following tables with a “p”. Where a particular category of test is optional, this is

indicated with an “o”.

10 © ISO 2015 – All rights reserved

Table 1 — Functionality

Applicable test type

Tests Location Test status

(p = shall be performed, o = optional)

Reference Basic/

Parameter Item Name Inspection Laboratory Simulation Field test

a

to subclause conditional

Category 1

Communication C1 Conformance assessment 6.1.1 B — p o o

F1 Validation of the specification 6.1.2 B p — — —

EFC

application F2 Implementation test 6.1.2 B p o o o

tests

F3 Functionality tests 6.1.2 B p o o p

T1 Longitudinal distance between vehicles 6.1.3, B.2 B — — o p

T2 Lateral distance between vehicles 6.1.3, B.2 C — — o o

T3 Lateral distance between OBEs 6.1.3, B.2 C — — o o

T4 Speed of vehicles 6.1.3, B.2 C — — o o

T5 Driving angle 6.1.3, B.2 C — — o o

Traffic

conditions

T6 Lane changing 6.1.3, B.2 C — — o o

T7 Shadowing 6.1.3, B.2 B — — o p

T8 Traffic scenarios — free flow 6.1.3, B.2 C — — o o

T9 Traffic scenarios — restricted flow 6.1.3, B.2 C — — o o

T10 Traffic volume 6.1.3, B.2 C — — o o

a

Test only to be applied if function or item is specified.

Table 1 — (continued)

Applicable test type

Tests Location Test status

(p = shall be performed, o = optional)

Reference Basic/

Parameter Item Name Inspection Laboratory Simulation Field test

a

to subclause conditional

Category 2

V1 Length of vehicle 6.1.4, B.3 C — — o o

V2 Height of vehicle 6.1.4, B.3 C — — o o

V3 Width of vehicle 6.1.4, B.3 C — — o o

V4 Length of bonnet 6.1.4, B.3 C — — o o

V5 Other vehicle features, weight, number of axles, 6.1.4, B.2 C — — o o

volume, shape, paintwork, colour, air

conditioner, mobile communication equipment

V6 Constructive elements, superstructures in 6.1.4, B.3 C — — o o

the windscreen area, lorries with external

sun visors, car transporters with projecting

Vehicle loading surface sun roof (open/closed)/roof

characteristics mountings

V7 Attenuation of windscreen, caused by e.g. 6.1.4, B.3 C — o o o

metallized, coated, heated, or dirty windscreen

V8 Angle of windscreens, horizontal plane cars, 6.1.4, B.3 C — o o o

small trucks and vans, trucks, buses, and

touring coaches

V9 Angle of windscreens, vertical plane location in 6.1.4, B.3 C — o o o

the outer curve area

V10 Mounting height of OBE antenna 6.1.4, B.3 C — o o o

V11 Lateral mounting of OBE antenna from middle 6.1.4, B.3 C — o o o

of windscreen

V12 OBE behaviour, variation of supply voltage, 6.1.4, B.3 C — o o o

operational state of OBE, fixing of OBE, ICC

behaviour

a

Test only to be applied if function or item is specified.

12 © ISO 2015 – All rights reserved

Table 1 — (continued)

Applicable test type

Tests Location Test status

(p = shall be performed, o = optional)

Reference Basic/

Parameter Item Name Inspection Laboratory Simulation Field test

to subclause conditionala

Category 3

I1 Width of pavement 6.1.5, B.4 C o — o o

I2 Number of lanes 6.1.5, B.4 C o — o o

I3 Other topographical influences 6.1.5, B.4 C o o o o

Environmental

influences

I4 Water and dust 6.1.5, B.4 C — o o o

I5 Temperature, humidity, and daylight 6.1.5, B.4 C — o o o

I6 Other weather conditions 6.1.5, B.4 C — o o o

a

Test only to be applied if function or item is specified.

Table 2 — Quality

Applicable test type

Tests Location Test status

(p = shall be performed, o = optional)

Reference Basic/

Parameter Item Name Inspection Laboratory Simulation Field test

a

to subclause conditional

Quality Q1 Design, development, production, installation, 6.2.1 B p — — —

management and servicing

R1 Components, equipment, system 6.2.2, C.1 B p o o o

R2 Transaction-level reliability 6.2.2, C.2 B p o o o

Reliability/

R3 OBE life duration 6.2.2, C.2 B p o o o

availability

R4 OBE battery duration 6.2.2, C.2 B p o o o

R5 OBE smart card life duration 6.2.2, C.2 B p o o o

a

Test only to be applied if function or item is specified.

14 © ISO 2015 – All rights reserved

Table 3 — Referenced pre-tests

Tests Location Test status Test type

Reference to Basic/ (R = refer to standards/regulations

Parameter Item Name

a

subclause conditional which specify these pre-tests)

D1 Layer 1 6.3.1, F.1 B R

DSRC D2 Layer 2 6.3.1, F.1 B R

D3 Layer 7 6.3.1, F.1 B R

ET1 Basic parameter 6.3.2, F.2 B R

ET2 Mechanical 6.3.2, F.2 B R

Environment ET3 Electrical 6.3.2, F.2 B R

ET4 Chemical/biological 6.3.2, F.2 B R

ET5 Safety 6.3.2, F.2 B R

E1.1 Emission 6.3.3, F.3 B R

EMC

E1.2 Immunity 6.3.3, F.3 B R

a

Test only to be applied if function or item is specified.

5.3 Test plan

The manufacturer or the test house carrying out the type approval or acceptance testing shall devise an

individual test plan for each tested EFC system or EFC component, in accordance with Figure 3, taking

into account the system-specific characteristics of the EFC application. With respect to type approval,

the requirements of applicable standards or other normative and referenced documents shall be tested

by the manufacturer or by a test house.

With respect to acceptance tests, only the features that are specified or implicit in the system

specification shall be tested. Where additional features are provided for contingent use at some future

date, these shall be tested only if such contingency is included in the system specification. Where

additional features are present in products supplied, but are neither used nor included in the system

specification or implementation, there is no requirement that they shall be tested unless they have an

effect on the operation of the system.

Results of pre-tests that have already been passed shall be compared with the application-specific

requirements. If deviations are detected, additional tests will need to be carried out. The test plan shall

make references to each listed test parameter with respect to the following details:

— identification of test parameter and item;

— reference of the related requirements/severity of the test;

— required equipment and documentation;

— selected test type;

— required test equipment, measurement equipment, interfaces, and tools;

— required test environment;

— department carrying out the test;

— required documentation of the tests and the results (see G.5).

Interdependencies between the results of the different tests are anticipated and shall be taken into

account by the manufacturer or the test house. An example test protocol form is given in G.5.

5.4 Required documentation

The following listed documentation shall be supplied by the manufacturer to carry out the tests defined

by a test plan:

— system description (overview, block diagrams);

— system specification including functions, timing, operational data on a detailed level;

— safety and security concept (threat analysis, implemented measures to detect and control failures,

threats, and manipulations);

— user documentation (service provider and user);

— specification of ambient conditions;

— operational directives;

— quality assurance directives, development rules;

— maintenance and installation directives;

— list of all available documents from the manufacturer relating to the EFC system under test created

during the design and manufacture of the equipment.

6 Inspection and tests

6.1 Functionality tests

6.1.1 Communication

The test specifications with regard to communication are defined in ISO/TS 14907-2. It specifies the

tests that verify OBU conformance of implemented communication (transaction) protocols to conform

with the specifications given in ISO 14906 to be used for EFC applications.

NOTE ISO/TS 14907-2 can also be used as a source of inspiration for roadside equipment testing in

accordance with ISO 14906.

ISO/TS 14907-2 describes general requirements for conformance testing and specific test procedures

for the following:

— basic DSRC L7 functionality;

— EFC application functions;

— EFC attributes;

— addressing procedures of EFC attributes and (hardware) components (e.g. ICC and MMI);

— EFC transaction model;

— behaviour of the interface.

6.1.2 EFC application

6.1.2.1 General

The tests are related to components or to a complete EFC system consisting of an OBE, RSE, or both

and RSE/OBE in combination. The objective of the tests is to validate that the equipment to be tested

fulfils the functional and technical requirements of the specification. The proof consists of inspections,

simulations, and tests which are to ensure that the system specifications and the equipment of EFC are

in conformance with the EFC requirements based on standards and regulations, national requirements,

and other requirements.

6.1.2.2 and 6.1.2.3 describe a set of tests (see also Annex B); which of those tests are relevant and sufficient

to prove the performance of an EFC system or its components shall be defined by a test plan (see 5.3).

The EFC application test is divided into two sections:

a) validation of the EFC specification;

b) inspection and test of the EFC system or component under test (SUT).

The relationship between the test sections is shown in Figure 4.

16 © ISO 2015 – All rights reserved

Figure 4 — Structure of application tests

6.1.2.2 addresses the validation of the EFC system specification with respect to the design specification.

The objective is a validation of the system specification to verify that it is in conformance with the EFC

requirements based on standards and regulations, national requirements, and other requirements. The

activity consists of inspection and analysis of the referenced documentation. The output of this phase is

an authorized and valid system specification of the SUT which meets the requirements of the selected

standards and regulations. Additionally, a test plan will be specified which identifies the required test

steps to prove the performance of the SUT.

6.1.2.3 addresses EFC equipment that is designed according to a validated system specification. The

activities of this section are inspections, simulations, and tests. Before the functionality test can start,

an implementation test (pre-test after installation) is carried out to ensure the principal performance of

the system. The implementation includes the activities of installation and commissioning. The objective

of the tests is to validate the conformity of the equipment with the specification and compliance with

the EFC requirements of standards and regulations, national requirements, and other requirements.

The inspection and test shall take into consideration results of tests that have been previously

performed, for example, quality tests and reference tests, and shall be detailed by a test plan (see 5.3).

Annex B contains a list of tests that are related to traffic conditions, vehicle characteristics, and other

environment influences. Annex H provides examples of EFC scenarios as part of a functionality test.

6.1.2.2 Validation of the SUT specification

EFC application test

Name: Validation of the specification (F1)

Group: EFC application

Purpose: To ensure that the specification of the SUT or component is in conformance with the EFC

requirements of standards and regulations, national requirements, and user requirements.

Requirement — National requirements for EFC.

reference:

— EFC requirements for a DSRC communication.

— User requirements of the specified EFC application.

Default: All specifications to be inspected shall be in conformance regarding the DSRC regulations

and DSRC standards applicable in the countries and regions in which the system or

component will be operated.

Test A set of documentation as listed in 5.4 is required.

configuration:

Behaviour The task consists of inspection and analysis (Annex G) of the provided documentation. The

description: details of the system specification of the SUT are compared with the requirements of the

EFC standards and regulations, national requirements, and user requirements.

The documentation is inspected concerning completeness, validity, unambiguity,

consistency, and understandability.

The analysis is carried out to evaluate the system structure, reliability figures, measures to

detect and control failures, timing behaviour, security and safety, maintenance, and other

technical and non-technical measures concerning system performance.

Constraints None

reference:

Verdict: Test result Verdict

Authorized and valid system specification of Pass

the SUT. Test plan for the performance proof. Fail

The system specification does not conform to

the requirements. List of discovered

deviations.

Comments:

18 © ISO 2015 – All rights reserved

6.1.2.3 Inspection and test of SUT

EFC application test

Name: Implementation test (F2)

Group: EFC application

Purpose: The objective of this test is to verify that the specified EFC system (SUT) or component is in

conformance with the fundamental requirements of the EFC application.

Requirement Validated system specification of the SUT.

reference:

Default: Certified DSRC equipment according to the requirements of DSRC regulations and DSRC

standards applicable in the countries and regions in which the system or component will

be operated.

Test — Documentation and equipment according

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...