ISO 22095:2020

(Main)Chain of custody — General terminology and models

Chain of custody — General terminology and models

This document defines a framework for chain of custody by providing: — a consistent generic approach to the design, implementation and management of chains of custody; — harmonized terminology; — general requirements for different chain of custody models; — general guidance on the application of the defined chain of custody models, including initial guidance on the circumstances under which each chain of custody model might be appropriate. This document is applicable to all materials and products. It does not apply to services as final outputs. This document can be used by any organization operating at any step in a supply chain, as well as by standard setting organizations as a reference point for specific chain of custody standards. This document can enhance the transparency of specific claims regarding materials or products and thereby support the reliability of these claims. It is not intended to be used on its own to make or verify such claims. This document is not, on its own, able to support claims about an organization's materials or products. This is misleading, especially to consumers and other end customers, as the existence of a chain of custody system alone does not specify the characteristics or the conditions under which materials or products are produced. This document includes requirements and guidance regarding this issue.

Chaîne de contrôle — Terminologie générale et modèles

General Information

- Status

- Published

- Publication Date

- 18-Oct-2020

- Technical Committee

- ISO/TC 308 - Chain of custody

- Drafting Committee

- ISO/TC 308 - Chain of custody

- Current Stage

- 9020 - International Standard under periodical review

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Amended By

ISO 22095:2020/Amd 1:2026 - Chain of custody — General terminology and models — Amendment 1 - Effective Date

- 07-Jan-2025

Overview

ISO 22095:2020 defines a harmonized framework for chain of custody (CoC) systems across sectors. It provides consistent terminology, a generic approach to design, implementation and management of chains of custody, general requirements for different chain of custody models, and guidance on when each model is appropriate. The standard applies to all materials and products (not to services as final outputs) and is intended as a reference for organizations at any step in a supply chain and for standard-setting bodies.

Key takeaway: ISO 22095 promotes supply chain transparency and consistent traceability practices but is not, on its own, sufficient to make or verify product claims-CoC systems must be implemented and assessed according to relevant scheme requirements.

Key Topics and Requirements

- Harmonized terminology: Definitions for chain of custody, chain of custody system, inputs, outputs, specified characteristics, traceability and related roles/responsibilities to reduce confusion across sectors.

- Chain of custody models: Clear descriptions and requirements for main models:

- Identity Preserved - maintains the unique identity of a material/product through the supply chain.

- Segregated - keeps certified materials physically separate from others.

- Controlled Blending - allows blending under defined controls to preserve specified characteristics.

- Mass Balance - permits mixing but tracks quantities to match certified inputs with outputs.

- Book and Claim - decouples physical flows from associated claims via trading of credits or documentation.

- Design and governance: Roles and responsibilities, top management commitment, competence, documented information, and communication.

- Operational controls: Traceability, conversion factors, inventory balancing, outsourcing, complaints handling and measures for dealing with non-conformities.

- Assurance and conformity assessment: Guidance on evidencing CoC implementation and limitations of CoC systems for supporting claims.

Applications

- Use ISO 22095 to design or align chain of custody systems for sectors such as forestry, agriculture, food, fisheries, mining, manufacturing, recycling and construction.

- Support harmonization across certification schemes to reduce complexity, improve trust in sustainability or origin claims, and facilitate market access.

- Serve as a reference for auditors, scheme owners, supply chain managers, certification bodies and policy makers developing CoC requirements.

Who should use ISO 22095

- Supply chain managers, sustainability officers, certification and compliance professionals, standard-setting organizations, auditors, and manufacturers or traders seeking consistent CoC design and traceability practices.

Related standards

- ISO 14044 (life cycle assessment terminology referenced)

- ISO 9000 (quality management vocabulary)

- Applicable sector-specific CoC standards and certification scheme requirements

Keywords: ISO 22095, chain of custody, chain of custody models, traceability, mass balance, identity preserved, segregated model, book and claim, supply chain transparency, chain of custody system.

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

ISO 22095:2020 is a standard published by the International Organization for Standardization (ISO). Its full title is "Chain of custody — General terminology and models". This standard covers: This document defines a framework for chain of custody by providing: — a consistent generic approach to the design, implementation and management of chains of custody; — harmonized terminology; — general requirements for different chain of custody models; — general guidance on the application of the defined chain of custody models, including initial guidance on the circumstances under which each chain of custody model might be appropriate. This document is applicable to all materials and products. It does not apply to services as final outputs. This document can be used by any organization operating at any step in a supply chain, as well as by standard setting organizations as a reference point for specific chain of custody standards. This document can enhance the transparency of specific claims regarding materials or products and thereby support the reliability of these claims. It is not intended to be used on its own to make or verify such claims. This document is not, on its own, able to support claims about an organization's materials or products. This is misleading, especially to consumers and other end customers, as the existence of a chain of custody system alone does not specify the characteristics or the conditions under which materials or products are produced. This document includes requirements and guidance regarding this issue.

This document defines a framework for chain of custody by providing: — a consistent generic approach to the design, implementation and management of chains of custody; — harmonized terminology; — general requirements for different chain of custody models; — general guidance on the application of the defined chain of custody models, including initial guidance on the circumstances under which each chain of custody model might be appropriate. This document is applicable to all materials and products. It does not apply to services as final outputs. This document can be used by any organization operating at any step in a supply chain, as well as by standard setting organizations as a reference point for specific chain of custody standards. This document can enhance the transparency of specific claims regarding materials or products and thereby support the reliability of these claims. It is not intended to be used on its own to make or verify such claims. This document is not, on its own, able to support claims about an organization's materials or products. This is misleading, especially to consumers and other end customers, as the existence of a chain of custody system alone does not specify the characteristics or the conditions under which materials or products are produced. This document includes requirements and guidance regarding this issue.

ISO 22095:2020 is classified under the following ICS (International Classification for Standards) categories: 03.100.01 - Company organization and management in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22095:2020 has the following relationships with other standards: It is inter standard links to ISO 22095:2020/Amd 1:2026. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 22095:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22095

First edition

2020-10

Chain of custody — General

terminology and models

Chaîne de contrôle — Terminologie générale et modèles

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

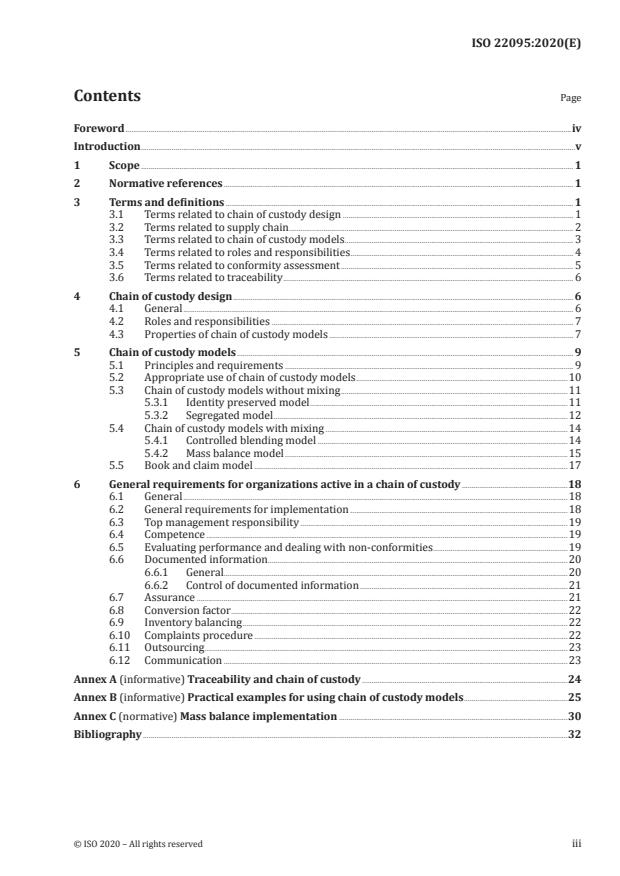

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Terms related to chain of custody design . 1

3.2 Terms related to supply chain . 2

3.3 Terms related to chain of custody models . 3

3.4 Terms related to roles and responsibilities . 4

3.5 Terms related to conformity assessment . 5

3.6 Terms related to traceability . 6

4 Chain of custody design . 6

4.1 General . 6

4.2 Roles and responsibilities . 7

4.3 Properties of chain of custody models . 7

5 Chain of custody models . 9

5.1 Principles and requirements . 9

5.2 Appropriate use of chain of custody models .10

5.3 Chain of custody models without mixing .11

5.3.1 Identity preserved model .11

5.3.2 Segregated model .12

5.4 Chain of custody models with mixing .14

5.4.1 Controlled blending model .14

5.4.2 Mass balance model .15

5.5 Book and claim model .17

6 General requirements for organizations active in a chain of custody .18

6.1 General .18

6.2 General requirements for implementation .18

6.3 Top management responsibility .19

6.4 Competence .19

6.5 Evaluating performance and dealing with non-conformities .19

6.6 Documented information .20

6.6.1 General.20

6.6.2 Control of documented information .21

6.7 Assurance .21

6.8 Conversion factor .22

6.9 Inventory balancing .22

6.10 Complaints procedure .22

6.11 Outsourcing.23

6.12 Communication .23

Annex A (informative) Traceability and chain of custody .24

Annex B (informative) Practical examples for using chain of custody models .25

Annex C (normative) Mass balance implementation .30

Bibliography .32

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Project Committee ISO/PC 308, Chain of custody — General terminology

and models.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

Introduction

Understanding the origin of input materials, product components, product outputs and the conditions

under which they are produced is becoming increasingly important. Manufacturers want to

demonstrate compliance with requirements regarding health and safety, as well as environmental,

social and quality-related aspects, while consumers or other end users need to be able to trust the claims

made for these products. The main drivers are government policies, consumer and business demand.

Companies directly active in a chain of custody (e.g. manufacturers, traders, logistic and transport

service providers, retailers) as well as those investing in such companies (e.g. financial institutions,

governments) need transparency to understand and manage risks, to secure quality and to facilitate

the implementation of a reliable chain of custody system.

Chain of custody systems have become an indispensable element of many different applications, such as

certification schemes for food safety, sustainable agriculture, forestry, aquaculture or fisheries, social

compliance, manufacturing, construction and mineral mining. They enable information associated with

a product and/or production characteristics to be shared among various organizations active in the chain

of custody such as material and ingredient suppliers, processors, contractors, transportation companies,

(private or regulatory) scheme owners, financial institutions, companies active in refurbishing and

recycling, governmental organizations, end customers, and consumers or other end users.

Although these many systems differ in scope and use terminology relevant to the sector and product-

specific needs, and might also diverge on semantics and presentation, they deal with the same

challenges and are based on the same range of chain of custody models. The proliferation of systems and

definitions causes unnecessary confusion, complexity and inconsistency. It also reduces the degree of

trustworthiness of information (e.g. related claims) and increases costs for organizations active in the

chain of custody. These complexities and resulting costs can be a barrier to market access, especially

for smaller companies and developing countries.

The aim of this document is to provide

— unambiguous definitions of the different chain of custody models, and

— the corresponding requirements, which are independent of sectors, materials, products, and issues

addressed.

These requirements are applicable to any organization operating at any step in the supply chain. Chain

of custody models are also referred to as "chain of custody methods" or "chain of custody concepts". In

this document, the term "chain of custody models" is used to describe the approach taken to control

inputs and outputs and associated information in a particular chain of custody system. This multi-

sector globally applicable International Standard serves as a reference point for existing and future

commodity or sector specific chain of custody standards.

As each chain of custody model represents a different level of physical presence of the specified

characteristic in the output, this document provides general guidance on the application of the defined

chain of custody models, including initial guidance on the circumstances under which each chain of

custody model might be appropriate.

This document does not specify or recommend a management system. Users can refer to this document,

clearly stating which models of chain of custody described in this document are used as a basis in their

chain of custody systems.

INTERNATIONAL STANDARD ISO 22095:2020(E)

Chain of custody — General terminology and models

1 Scope

This document defines a framework for chain of custody by providing:

— a consistent generic approach to the design, implementation and management of chains of custody;

— harmonized terminology;

— general requirements for different chain of custody models;

— general guidance on the application of the defined chain of custody models, including initial guidance

on the circumstances under which each chain of custody model might be appropriate.

This document is applicable to all materials and products. It does not apply to services as final outputs.

This document can be used by any organization operating at any step in a supply chain, as well as by

standard setting organizations as a reference point for specific chain of custody standards.

This document can enhance the transparency of specific claims regarding materials or products and

thereby support the reliability of these claims. It is not intended to be used on its own to make or verify

such claims.

This document is not, on its own, able to support claims about an organization’s materials or products.

This is misleading, especially to consumers and other end customers, as the existence of a chain of

custody system alone does not specify the characteristics or the conditions under which materials or

products are produced. This document includes requirements and guidance regarding this issue.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1 Terms related to chain of custody design

3.1.1

chain of custody

process by which inputs (3.2.2) and outputs (3.2.3) and associated information are transferred,

monitored and controlled as they move through each step in the relevant supply chain (3.2.1)

3.1.2

chain of custody system

set of measures designed to implement a chain of custody (3.1.1), including documentation of these

measures

Note 1 to entry: The purpose of a chain of custody system is to provide credibility that the given material or

product has a set of specified characteristics (3.2.5).

Note 2 to entry: The information linked to materials or products is transferred, monitored and controlled

throughout the entire supply chain (3.2.1) or parts of it.

3.1.3

chain of custody model

approach taken to control inputs (3.2.2) and outputs (3.2.3) and associated information in a particular

chain of custody system (3.1.2)

Note 1 to entry: A chain of custody model is typically designed to preserve a set of specified characteristics (3.2.5).

Note 2 to entry: The chain of custody models are defined in 3.3 and summarized in Table 1.

3.2 Terms related to supply chain

3.2.1

supply chain

series of processes or activities involved in the production and distribution of a material or product

through which it passes from the source (3.2.8)

Note 1 to entry: A supply chain is typically composed of a series of different organizations.

3.2.2

input

material or product that enters an organization or part of an organization

Note 1 to entry: Input may be used at any stage of the supply chain (3.2.1).

Note 2 to entry: Input may also include reused and recycled materials or products.

Note 3 to entry: Input will have associated information.

[SOURCE: ISO 14044:2006+A1: 2017, 3.21, modified — The wording and Note 1 to entry have been

modified. Notes 2 and 3 to entry have been added.]

3.2.3

output

material or product that leaves an organization or part of an organization

Note 1 to entry: Output can be created at any stage of the supply chain (3.2.1).

Note 2 to entry: Output might include other products resulting from production processes.

Note 3 to entry: Output will have associated information.

[SOURCE: ISO 14044:2006+A1: 2017, 3.25, modified — The wording and Note 1 to entry has been

modified. Notes 2 and 3 to entry have been added.]

3.2.4

characteristic

distinguishing feature

[SOURCE: ISO 9000:2015, 3.10.1, modified — Notes 1 to 3 to entry have been deleted.]

2 © ISO 2020 – All rights reserved

3.2.5

specified characteristic

set of product characteristics (3.2.6) and/or production characteristics (3.2.7) that the chain of custody

is designed to maintain

3.2.6

product characteristic

distinguishing feature of a material or product

Note 1 to entry: A product characteristic can be qualitative or quantitative.

3.2.7

production characteristic

distinguishing feature of one or more production processes in the supply chain (3.2.1)

Note 1 to entry: Production characteristics sometimes create product characteristics (3.2.6). Examples include

the grinding of wood, the chemical treatment of wood for pulp production and food cooked at a low temperature.

Examples of production characteristics that do not normally create a product characteristic include production

according to a particular specification, such as the sustainable production of the material; the absence of child

labour; particular human rights standards or the identity of the primary processor.

Note 2 to entry: Production characteristics can include the type of transportation and storage.

3.2.8

source

specific originator at a location of a material or product with a specified characteristic (3.2.5)

Note 1 to entry: The originator is typically a specific supplier but can also be a specific manufacturer or specific

processor adding a particular characteristic.

3.2.9

site

location with geographical boundaries at which defined activities under the control of an organization

are carried out

Note 1 to entry: Sites may be in one geographical area but need not be contiguous. For example, a road can

separate two geographical areas that are operated as a single site.

Note 2 to entry: Activities can include material extraction, production, manufacturing, recycling, storage, trade

and/or transportation.

3.2.10

process

set of interrelated or interacting activities that use inputs (3.2.2) to deliver an intended output (3.2.3)

Note 1 to entry: A process can include services.

[SOURCE: ISO 9000:2015, 3.4.1, modified — The word “result” has been replaced by “output”. Notes 1 to

6 to entry have been deleted.]

3.3 Terms related to chain of custody models

3.3.1

identity preserved model

chain of custody model (3.1.3) in which the materials or products originate from a single source (3.2.8)

and their specified characteristics (3.2.5) are maintained throughout the supply chain (3.2.1)

3.3.2

segregated model

chain of custody model (3.1.3) in which specified characteristics (3.2.5) of a material or product are

maintained from the initial input (3.2.2) to the final output (3.2.3)

Note 1 to entry: Addition of material with different characteristics and/or grade to the input is not allowed.

Note 2 to entry: Commonly, material from more than one source contributes to a chain of custody under the

segregated model.

3.3.3

controlled blending model

chain of custody model (3.1.3) in which materials or products with a set of specified characteristics (3.2.5)

are mixed according to certain criteria with materials or products without that set of characteristics

resulting in a known proportion of the specified characteristics in the final output (3.2.3)

Note 1 to entry: This chain of custody model is also referred to as the "single percentage method".

3.3.4

mass balance model

chain of custody model (3.1.3) in which materials or products with a set of specified characteristics (3.2.5)

are mixed according to defined criteria with materials or products without that set of characteristics

Note 1 to entry: The proportion of the input (3.2.2) with specified characteristics might only match the initial

proportions on average and will typically vary across different outputs (3.2.3).

3.3.5

book and claim model

chain of custody model (3.1.3) in which the administrative record flow is not necessarily connected to

the physical flow of material or product throughout the supply chain (3.2.1)

Note 1 to entry: This chain of custody model is also referred to as "certificate trading model" or "credit trading".

Note 2 to entry: This is often used where the certified/specified material cannot, or only with difficulty, be kept

separate from the non-certified/specified material, such as green credits in an electricity supply.

3.4 Terms related to roles and responsibilities

3.4.1

organization

entity or group of people and facilities with an arrangement of responsibilities, authorities and

relationships and identifiable objectives

Note 1 to entry: An organization may encompass multiple (production /geographical) sites.

[SOURCE: ISO 26000:2010, 2.12]

3.4.2

top management

person or group of people who directs and controls an organization at the highest level

[SOURCE: ISO 9000:2015, 3.1.1, modified — Notes 1 to 3 to entry have been deleted.]

3.4.3

requirements setter

person or organization that specifies the requirements for a particular chain of custody

4 © ISO 2020 – All rights reserved

3.5 Terms related to conformity assessment

3.5.1

conformity

fulfillment of a specified requirement

[SOURCE: ISO 9000:2015, 3.6.11, modified — The definition has been modified.]

3.5.2

conformity assessment

demonstration that specified requirements are fulfilled

Note 1 to entry: Conformity assessment can be performed as first-party activity (3.5.3), second-party activity(3.5.4)

or third-party activity (3.5.5).

[SOURCE: ISO/IEC 17000:2020, 4.1, modified — Notes 1 to 4 to entry have been deleted. A new Note 1 to

entry has been added.]

3.5.3

first-party conformity assessment activity

conformity assessment (3.5.2) activity that is performed by the person or organization that provides or

that is the object of conformity assessment

[SOURCE: ISO/IEC 17000:2020, 4.3, modified — Notes 1 and 2 to entry have been deleted.]

3.5.4

second-party conformity assessment activity

conformity assessment (3.5.2) activity that is performed by a person or organization that has a user

interest in the object of conformity assessment

[SOURCE: ISO/IEC 17000:2020, 4.4, modified — Notes 1 and 2 to entry have been deleted.]

3.5.5

third-party conformity assessment activity

conformity assessment (3.5.2) activity that is performed by a person or organization that is independent

of the provider of the object and has no user interest in the object

[SOURCE: ISO/IEC 17000:2020, 4.5, modified — Note 1 to entry has been deleted.]

3.5.6

audit

process (3.2.10) for obtaining relevant information about an object of conformity assessment (3.5.2) and

evaluating it objectively to determine the extent to which specified requirements are fulfilled

[SOURCE: ISO/IEC 17000:2020, 6.4, modified — Notes 1 to 3 to entry have been deleted.]

3.5.7

inspection

examination of an object of conformity assessment (3.5.2) and determination of its conformity with

detailed requirements or, on the basis of professional judgement, with general requirements

[SOURCE: ISO/IEC 17000:2020, 6.3, modified — Notes 1 to 3 to entry have been deleted.]

3.5.8

verification

confirmation of truthfulness, through the provision of objective evidence that specified requirements

have been fulfilled

Note 1 to entry: The objective evidence needed for a verification can be the result of an inspection (3.5.7), audit

(3.5.6) or other forms of determination such as performing alternative calculations or reviewing documents.

Note 2 to entry: The activities carried out for verification are sometimes called a "qualification process" and can

result in certification (3.5.9).

Note 3 to entry: The word “verified” is used to designate the corresponding status.

[SOURCE: ISO 9000:2015, 3.8.12, modified — In Note 2 to entry, the wording has been modified.]

3.5.9

certification

third-party attestation related to an object of conformity assessment (3.5.2), with the exception of

accreditation

[SOURCE: ISO/IEC 17000:2020, 7.6]

3.5.10

claim

declared information regarding the specified characteristics (3.2.5) of a material or product

3.6 Terms related to traceability

3.6.1

traceability

ability to trace the history, application, location or source(s) of a material or product throughout the

supply chain (3.2.1)

[SOURCE: ISO 9000:2015, 3.6.13, modified — The wording has been modified. Notes 1 and 2 to entry

have been deleted.]

3.6.2

traceability system

manual or electronic system that provides the ability to access any or all information relating to the

material or product under consideration throughout their life cycle, by means of accessing documented

information

Note 1 to entry: "Life cycle" should be understood in the broadest possible sense, to include, for example, raw

material extraction, agricultural production, final disposal, and reuse or recycling, as well as all other stages

connected with product manufacture and use.

4 Chain of custody design

4.1 General

Although frequently considered as interchangeable, the concepts of traceability and chain of custody

are not identical. The difference between these two concepts is described in Annex A.

A chain of custody system encompasses the set of measures supporting responsibility for the custody of

materials and products as ownership or control is transferred from one organization to another within

the relevant supply chain. A chain of custody usually involves more than one organization.

This document provides a framework and fundamental requirements for a chain of custody system.

Depending on, for example, the sector of application, material or product handled, product characteristics

and/or specific claim, additional and more specific chain of custody requirements might need to be

implemented. When using this document, the organization shall check and evaluate this need.

This document can enhance the transparency of specific claims regarding materials or products by

providing common terminology and chain of custody models, and thereby support the reliability of

these claims. However, organizations shall not use this document on its own to make or verify such

claims. This would be misleading, especially to consumers and other end customers, as the existence

of a chain of custody system alone does not specify characteristics or the conditions under which

products are produced and therefore cannot support the characteristics or the conditions under which

materials or products are produced. Also, any communication associated with materials or products

solely concerning conformity to this document shall be avoided, especially towards consumers and

other end customers.

6 © ISO 2020 – All rights reserved

In order to make claims about an organization’s materials or products, rather than the chain of custody

itself, further evidence on conformity with specified characteristics shall be provided.

When materials or products come with a claim of adherence to a certification scheme, which has its

own chain of custody rules, for example third-party assessment as certification or verification, and

an organization aims to use that claim for its materials or products, the rules of that scheme shall be

followed unless that scheme allows the use of this document instead.

4.2 Roles and responsibilities

The identification of actors (e.g. organizations), locations (including sites), inputs, outputs and

associated information in the chain of custody is needed to implement any chain of custody model.

Understanding which organizations play a role, and sometimes their relationship to each other, in the

supply chain is important. In any chain of custody system, it is necessary to distinguish the various

actors which play a particular role in the chain of custody or supply chain. Examples of actors in the

supply chain include a manufacturer, trader, distributor, carrier, or retailer.

Since a chain of custody is intended to maintain specified characteristics, the functions in such an

organized chain of custody are:

— Organizing: overseeing and managing the chain of custody so that there is an unbroken chain that

complies with the requirements;

— Requirements setting: setting the specific requirements for the organized chain of custody;

NOTE 1 The specific requirements typically take into account:

— the sector in which the chain of custody system is implemented;

— the specific role of an organization in the supply chain, the materials or products handled;

— their characteristics and/or the type of claims an organization is allowed to make depending on the chain

of custody model chosen.

— Conformity assessment: evaluating whether specific requirements are met;

NOTE 2 Verification of the assessment can be performed by the party organizing the chain of custody,

managed by a scheme owner, or outsourced to the market. The conformity assessment of the fulfilment of

the specific requirements can be a first-party conformity assessment activity (self-assessment), second-

party conformity asessment activity (peer assessment) or third-party conformity assessment activity

(independent body).

— Implementing: Implementation by individual organizations active in the chain of custody.

Control procedures shall be put in place to avoid materials or products that do not conform to the

minimum requirements from entering the chain of custody.

4.3 Properties of chain of custody models

This document defines five different chain of custody models for chain of custody systems. Each model

has specific requirements that allow different claims to be made about materials or products and/or

production processes that are delivered using that chain of custody model.

The five chain of custody models are:

1) identity preserved model;

2) segregated model;

3) controlled blending model;

4) mass balance model;

5) book and claim model.

One of the basic purposes of this document is to ensure that, whichever chain of custody model or

combination of chain of custody models is adopted, its integrity is safeguarded. This subclause provides

basic guidance on what the particular chain of custody models achieve.

The choice as to which chain of custody model is appropriate will depend on the benefits and quality

the actors in the supply chain aim to achieve. This choice will affect the claims that can be made about

materials or products delivered through a particular chain of custody model and how well they match

the corresponding expectations of actors in the chain of custody including the consumer or other end

users. It will also affect the implementation of administration, logistical and organizational aspects.

Table 1 summarizes the key properties of the five chain of custody models. Examples of the different

chain of custody models are given in Annex B.

Table 1 — Summary of the properties of the chain of custody models in this document

Models without mixing Models with mixing

Properties of Identity Segregated Controlled Mass Book and

chain of custody models preserved blending balance claim

Connection between Yes Yes Yes Yes No

administrative document

flow and the physical flow

of materials and products

Item-based expectations Yes Yes Yes, for the No No

satisfied percentage

with specified

characteristics

Market-based expectations Yes Yes Yes Yes Yes

satisfied

Mixing material with specified No No Yes Yes Yes

characteristics and material

with non-specified

characteristics is possible

Assurance that volumes with Yes Yes Yes Yes, within No, but

specified characteristics sold the specified claimed

match (or do not exceed) time period volumes

volumes of material with shall be in

specified characteristics bought balance

with the

associated

credits

Specified characteristics No No Yes Yes Yes

preservation linked to volume

reconciliation over a set time

period

Physical separation of material Yes Yes Yes, for the No No

or products to ensure that the part with the

specified characteristics are specified

physically present in the output characteristics

Identify source of a material or Yes No No No No

product (or material component

or product component)

While there can be a great variety in the expectations of those using chain of custody protected

materials or products, two main types of expectation can typically be identified:

1) Item-based: the material or product received bears all the characteristics identified by associated

information;

8 © ISO 2020 – All rights reserved

2) Market-based: taken as a whole, the market for the material or product received delivers the

characteristics identified by associated information.

The identity preserved model satisfies item-based expectations of organizations active in the

chain of custody, consumers, or other end users. The segregated model will also satisfy item-based

expectations, provided that the exact origin of the received material or product is not one of the claimed

characteristics.

Market-based expectations imply that the organizations active in the chain of custody, consumers

or other end users are satisfied that on average or in the proportions specified, the purchase of such

materials or products will deliver the claimed characteristics. The controlled blending and mass

balance models ensure that one of the following applies, as appropriate:

— the claimed proportion of the material or product received will bear the characteristics described

in the claim;

— the claimed proportion of a large sample of similar materials or products received (e.g. products

within a product group) will bear the characteristics specified in the claim.

The book and claim model is also market-based. While there is no physical custody of material or

products involved, the book and claim model aims to ensure that for each purchase for which a claim

is made, materials or products with the same specified characteristics have been produced. The book

and claim model is most suitable for intangible materials or products and in circumstances where the

entire market is controlled.

Market-based expectations can be founded on a desire to promote the production and trade of the

material or product with the desired characteristics, independent of any desire actually to purchase

materials or products bearing them. Satisfying market-based expectations can lead to, for example, a

particular instance of a material or product that may not physically contain the specified characteristics.

It is very important that the relevant labelling or other associated information makes such facts clear.

Claims regarding specified characteristics may be based on schemes (e.g. certification schemes or

programmes for labels), which specify requirements (e.g. for chain of custody rules or third-party

conformity assessment). If the organization aims to use these claims for its outputs, the requirements

of that scheme shall be applied, unless the scheme allows the use of this document instead.

5 Chain of custody models

5.1 Principles and requirements

The general requirements when implementing chain of custody models, as defined in Clause 6, apply

to all organizations active in a chain of custody and to all chain of custody models that are applied. The

organization shall implement and maintain a chain of custody system adequate to the organization's type

and complexity to ensure the continuous conformity to all applicable chain of custody requirements.

Organizations active in the chain of custody shall fulfill the requirements of the requirements setter.

The organization shall establish and implement one or more of the chain of custody models for all

materials or products with specified characteristics and shall be transparent about the model chosen.

The organization shall only use the same chain of custody model as its supplier or a model with lower

physical presence of the specified characteristic in the output. The list of chain of custody models,

ranked from highest to lowest physical presence of the specified characteristics is illustrated in

Figure 1.

NOTE In the book and claim model, the administrative flow is not connected to the physical flows throughout

the chain of custody. Within the same chain of custody, it is not possible to switch from the book and claim model

to other chain of custody models.

Figure 1 — Indicative illustration of chain of custody models ranked according to the physical

presence of specified characteristics

Each of the chain of custody models is linked to different options for making claims regarding the

specified characteristics. When using any chain of custody model involving mixing, the requirements

setter shall define relevant minimum requirements for all inputs based on associated risks.

NOTE Examples of associated risks are child labour, forced labour, working conditions, environment, etc.

To assess and address risk is a significant task and cannot be solved by the implementation of a sound chain of

[16] [1] [17]

custody system. Further guidance can be found in ISO 26000 , ISO Guide 73 and the ISO 31000 series.

5.2 Appropriate use of chain of custody models

In some industries, the existing chain of custody definitions require the physical presence of the

specified characteristics of a product or material to be maintained. In these industries, only the identity

preserved, the segregated and the controlled blending model are considered as appropriate chain of

custody model.

In some private and regulatory frameworks, claims regarding the content can be generated by the mass

balance approach. In these cases, it shall be transparently shown how the claimed content is calculated.

For communication, it shall be clear that this content does not necessarily correspond directly to

physical content in the product.

An organization should apply the rules for ethical claims and supporting information when using chain

of custody models to prevent misleading claims on the material or product.

NOTE For applicable requirements for ethical claims and supporting information, refer to, for example,

[26] [23]

ISO/TS 17033 , the ISEAL claims good practice guide and national legislation.

10 © ISO 2020 – All rights reserved

5.3 Chain of custody models without mixing

5.3.1 Identity preserved model

5.3.1.1 General

The identity preserved model is a chain of custody model, in which the inputs originate from a single

source. In the identity preserved model, the material or product is kept physically separated and

its characteristics are maintained throughout the supply chain. Materials or products are clearly

identifiable throughout the supply chain as originating from the single source.

The specified characteristics of the material or product determined by the specific source it originates

from shall be maintained by the organizations active in the chain of custody. The material or product

can be traced all the way back to the source from which it originates. A simplified illustration of the

identity preserved model for a single tier in the supply chain is shown in Figure 2.

Key

outputs with specified

inputs with specified characteristics

characteristics

The specified characteristics are clearly

a

organization

identifiable as originating from a single source.

Figure 2 — Simplified illustration of the identity preserved model

5.3.1.2 Supply chain requirements

An organization active in the chain of custody applying the identity preserved model shall ensure that

the material or product with specified characteristics is physically separated and clearly identifiable

throughout all stages of the production and transportation and the trading process. It shall ensure that

the material or product is clearly identifiable to a particular single source.

This shall be achieved by:

— physical separation of inputs and outputs with specified characteristics including single source

from any other inputs and outputs during, for example, production, transport and storage;

— clear identification of the materials or products during the process;

— the output quantities corresponding to the input quantities are in line with an appropriate conversion

factor (see 6.8).

5.3.1.3 Specified characteristics

The organization active in the chain of custody shall define which specified characteristics of the

material or product are maintained (including the source) and which materials or products are kept

physically separated f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...