ISO 21925-1:2018

(Main)Fire resistance tests — Fire dampers for air distribution systems — Part 1: Mechanical dampers

Fire resistance tests — Fire dampers for air distribution systems — Part 1: Mechanical dampers

This document specifies a test method for the determination of the resistance of fire dampers to heat, and for the evaluation of their ability to prevent fire and smoke spreading from one fire compartment to another through an air distribution system. It is applicable to mechanical fire dampers. It is not intended to be used for dampers used only in smoke control systems, for testing fire protection devices which only deal with air transfer applications, or for dampers used in suspended ceilings, as the installation of the damper and duct can have an adverse effect on the performance of the suspended ceiling, requiring other methods of evaluation. NOTE "Air transfer" is a low-pressure application through a fire separation door (or wall, floor) without any connection to an air duct.

Essais de résistance au feu — Clapets résistant au feu pour dessystèmes de distribution d’air — Partie 1: Titre manque

General Information

- Status

- Published

- Publication Date

- 27-Nov-2018

- Technical Committee

- ISO/TC 92/SC 2 - Fire containment

- Drafting Committee

- ISO/TC 92/SC 2/WG 4 - Ventilation ducts and fire dampers

- Current Stage

- 9060 - Close of review

- Completion Date

- 04-Jun-2029

Relations

- Effective Date

- 23-Apr-2020

- Effective Date

- 23-Apr-2020

- Effective Date

- 23-Sep-2017

- Effective Date

- 23-Sep-2017

- Effective Date

- 15-Apr-2017

- Effective Date

- 15-Apr-2017

Overview

ISO 21925-1:2018 - Fire resistance tests - Fire dampers for air distribution systems - Part 1: Mechanical dampers - defines a standardized test method to determine how mechanical fire dampers resist heat and prevent the spread of fire and smoke through ducted air distribution systems. The standard applies to mechanical fire dampers (not dampers used only for smoke control, air-transfer-only devices, or dampers in suspended ceilings). It consolidates earlier ISO 10294 parts into a single document and includes safety notes about possible release of toxic gases during testing.

Key topics and technical requirements

- Scope and applicability: Tests mechanical dampers for fire and smoke spread between fire compartments via air ducts; excludes smoke-only systems and suspended-ceiling installations.

- Test principles: Damper installed representative of real practice, test starts with damper in the open position to expose the actuating/thermal release mechanism to furnace conditions; measures integrity, insulation (for insulated dampers), and leakage.

- Leakage measurement: Tightness of the closed damper measured by direct flow at a constant pressure differential (commonly 300 Pa, higher permitted for special applications).

- Apparatus:

- Furnace meeting ISO 834-1 heating and pressure conditions.

- Connecting duct (welded steel, ~1.5 ± 0.1 mm thickness, length = 2× diagonal dimension up to 2 m) with gas-tight observation port.

- Measuring station using orifice, Venturi or equivalent and straightening as per ISO 5167 to determine volumetric flow.

- Exhaust fan system capable of maintaining test underpressure and control within ±5%.

- Test construction & installation: Details on specimen size, installation, supporting construction (walls/floors), separation and mounting options (within openings, mounted on face, remote), conditioning and instrumentation.

- Actuating & thermal release mechanisms: Tests assess the ability of fusible links, memory metals, frangible bulbs or sensors to trigger closure under fire conditions; annexes provide alternative mechanisms and reliability tests.

- Reporting, classification & field of application: Specifies test report contents, classification criteria, number of tests, and direct field application guidance (size limits, mounting conditions, separation considerations).

Practical applications - who uses this standard

- Fire test laboratories and certification bodies for validating damper performance.

- Fire safety engineers and consultants specifying compliant fire dampers in building designs.

- HVAC and ductwork manufacturers to design and test mechanical fire dampers.

- Regulatory authorities and code officials assessing compliance with fire-resistance requirements.

- Facilities managers and specifiers selecting dampers for compartmentation and life-safety systems.

Related standards

- ISO 834-1 - fire resistance furnace requirements (referenced)

- ISO 5167-7 / ISO 5167 series - flow measurement (referenced)

- Earlier series consolidated: ISO 10294-1 to -4

Using ISO 21925-1:2018 helps ensure repeatable, internationally recognized fire resistance testing for mechanical dampers, improving safety, regulatory compliance, and comparability of test results.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

ISO 21925-1:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Fire resistance tests — Fire dampers for air distribution systems — Part 1: Mechanical dampers". This standard covers: This document specifies a test method for the determination of the resistance of fire dampers to heat, and for the evaluation of their ability to prevent fire and smoke spreading from one fire compartment to another through an air distribution system. It is applicable to mechanical fire dampers. It is not intended to be used for dampers used only in smoke control systems, for testing fire protection devices which only deal with air transfer applications, or for dampers used in suspended ceilings, as the installation of the damper and duct can have an adverse effect on the performance of the suspended ceiling, requiring other methods of evaluation. NOTE "Air transfer" is a low-pressure application through a fire separation door (or wall, floor) without any connection to an air duct.

This document specifies a test method for the determination of the resistance of fire dampers to heat, and for the evaluation of their ability to prevent fire and smoke spreading from one fire compartment to another through an air distribution system. It is applicable to mechanical fire dampers. It is not intended to be used for dampers used only in smoke control systems, for testing fire protection devices which only deal with air transfer applications, or for dampers used in suspended ceilings, as the installation of the damper and duct can have an adverse effect on the performance of the suspended ceiling, requiring other methods of evaluation. NOTE "Air transfer" is a low-pressure application through a fire separation door (or wall, floor) without any connection to an air duct.

ISO 21925-1:2018 is classified under the following ICS (International Classification for Standards) categories: 13.220.50 - Fire-resistance of building materials and elements. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 21925-1:2018 has the following relationships with other standards: It is inter standard links to ISO 10294-4:2001/Amd 1:2014, ISO 10294-1:1996/Amd 1:2014, ISO 10294-2:1999, ISO 10294-3:1999, ISO 10294-1:1996, ISO 10294-4:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 21925-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 21925-1

First edition

2018-11

Fire resistance tests — Fire dampers

for air distribution systems —

Part 1:

Mechanical dampers

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

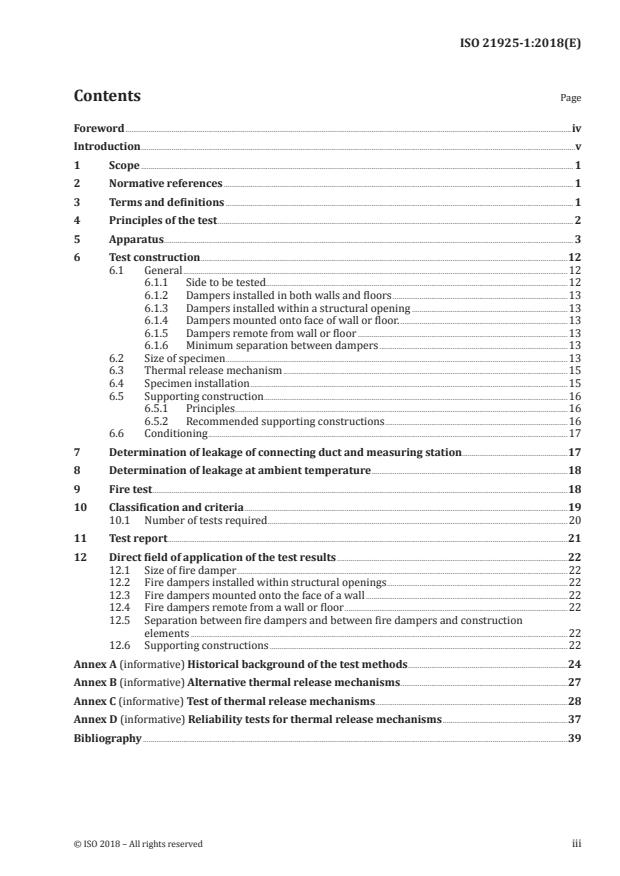

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principles of the test . 2

5 Apparatus . 3

6 Test construction .12

6.1 General .12

6.1.1 Side to be tested.12

6.1.2 Dampers installed in both walls and floors .13

6.1.3 Dampers installed within a structural opening .13

6.1.4 Dampers mounted onto face of wall or floor. .13

6.1.5 Dampers remote from wall or floor .13

6.1.6 Minimum separation between dampers .13

6.2 Size of specimen .13

6.3 Thermal release mechanism .15

6.4 Specimen installation .15

6.5 Supporting construction .16

6.5.1 Principles .16

6.5.2 Recommended supporting constructions .16

6.6 Conditioning .17

7 Determination of leakage of connecting duct and measuring station.17

8 Determination of leakage at ambient temperature .18

9 Fire test .18

10 Classification and criteria .19

10.1 Number of tests required .20

11 Test report .21

12 Direct field of application of the test results .22

12.1 Size of fire damper .22

12.2 Fire dampers installed within structural openings .22

12.3 Fire dampers mounted onto the face of a wall .22

12.4 Fire dampers remote from a wall or floor .22

12.5 Separation between fire dampers and between fire dampers and construction

elements .22

12.6 Supporting constructions .22

Annex A (informative) Historical background of the test methods .24

Annex B (informative) Alternative thermal release mechanisms .27

Annex C (informative) Test of thermal release mechanisms .28

Annex D (informative) Reliability tests for thermal release mechanisms .37

Bibliography .39

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 2, Fire

containment.

This first edition of ISO 21925-1 cancels and replaces ISO 10294-1:1996, ISO 10294-2:1999,

ISO 10294-3:1999 and ISO 10294-4:2001, which have been technically revised.

The main changes are as follows:

— integration of the requirements for mechanical dampers, which were published as four separate

parts in the former ISO 10294-series, into a single document.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

iv © ISO 2018 – All rights reserved

Introduction

The material in the former ISO 10294-series was used to assess the fire resistance of mechanical fire

dampers. The separate publications required multiple maintenance work and resources to keep them

current and up-to-date. By having the requirements in a single volume, ISO 21925-1 is intended to

improve efficiency and to be more user friendly. It is also anticipated that a single volume will serve

the continued efforts to promote the alignment of the requirements contained in regional and national

standards for testing fire dampers against this document.

ISO 10294-1:1996 addressed the spread of fire and smoke in buildings through ventilation ducts and

other openings in fire-separating walls and floors.

ISO 10294-2:1999 provided classification, criteria and field of application for the test method given in

ISO 10294-1:1996.

ISO 10294-3:1999 provided a background to the test method and a rationale to the procedures and the

criteria selected with respect to the testing of fire dampers, as given in ISO 10294-1:1996.

ISO 10294-4:2001 provided a test method to evaluate the performance of fire damper-operating

mechanisms.

A list of all parts in the ISO 21925-series can be found on the ISO website.

INTERNATIONAL STANDARD ISO 21925-1:2018(E)

Fire resistance tests — Fire dampers for air distribution

systems —

Part 1:

Mechanical dampers

SAFETY WARNING — For suitable health precautions to be taken, the attention is drawn to the

possibility that toxic or harmful gases can be released while the test is being conducted.

1 Scope

This document specifies a test method for the determination of the resistance of fire dampers to heat,

and for the evaluation of their ability to prevent fire and smoke spreading from one fire compartment

to another through an air distribution system.

It is applicable to mechanical fire dampers. It is not intended to be used for dampers used only in smoke

control systems, for testing fire protection devices which only deal with air transfer applications, or

for dampers used in suspended ceilings, as the installation of the damper and duct can have an adverse

effect on the performance of the suspended ceiling, requiring other methods of evaluation.

NOTE "Air transfer" is a low-pressure application through a fire separation door (or wall, floor) without any

connection to an air duct.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 834-1, Fire resistance tests — Elements of building construction — Part 1: General requirements

ISO 5167-7, Measurement of fluid flow by means of pressure differential devices — Part 7: Orifice plates,

nozzles and Venturi tubes inserted in circular cross-section conduits running full

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

3.1

test construction

complete test assembly, consisting of the separating element, damper and duct sections and penetration

seals (if any)

3.2

supporting construction

wall partition or floor into which the damper and duct section are installed for the test

3.3

separating element

wall, partition or floor into which the damper and duct are installed in the building

3.4

connecting duct

duct section between the damper or separating element and the measuring station

3.5

measuring station

equipment consisting of pipe system with an orifice plate or venturi and an air flow straightener (if

any), installed between the connecting duct and the exhaust equipment to determine the volume flow

rate of gases passing through the damper under test

3.6

exhaust equipment

equipment consisting of a fan and balancing or dilution dampers (if any), to apply and maintain the

underpressure in the connecting duct

3.7

fire damper

mobile closure within a duct which is operated automatically or manually and is designed to prevent

the spread of fire

3.8

actuating mechanism

mechanism, integral or directly associated with the damper which, when initiated by the

damper triggering device, causes the movable component of the damper to change from the "open" to

the "closed" position

3.9

insulated damper

damper which satisfies the integrity, leakage and insulation requirements of this document

3.10

uninsulated damper

damper which satisfies the integrity and leakage requirements of this document

3.11

thermal release mechanism

system which evaluates the parameters of temperature in the airflow of the ventilation duct and

initiates the closing of the fire damper before a predicted threshold limit is reached

Note 1 to entry: The sensing element may be, for example, a fusible link, memory metal, frangible bulb or

electrical sensor.

3.12

threshold limit

maximum operational temperature of the thermal release mechanism

4 Principles of the test

The damper with its fixing device is built into, or attached directly, or remotely via a section of ducting,

to a fire-separating building element in a manner representative of good practice. Tests are performed

starting with the damper in the open position so as to expose the actuating mechanism of the damper

to furnace conditions. Temperature and integrity measurements are carried out in various parts of

the test construction during the test. The tightness of the damper system is measured by direct flow

measurements whilst maintaining a constant pressure differential across the closed damper of 300 Pa.

For special applications, higher underpressures may be employed. The tightness of the damper in the

closed position is also measured at ambient temperature prior to the start of the furnace test.

2 © ISO 2018 – All rights reserved

As the test conditions and tolerances for the beginning of the fire test are not specified in detail, the fire

test enables only a limited assessment of the actuating mechanism to be carried out.

Annex A gives the historical background of the test.

5 Apparatus

The test apparatus specified in 5.1 to 5.8, including the instrumentation, shall be in accordance with

ISO 834-1 except where specifically stated otherwise.

An example of a test arrangement is shown in Figure 1.

5.1 Furnace, capable of achieving the heating and pressure conditions specified in ISO 834-1.

5.2 Damper under test, attached to the connecting duct in accordance with the manufacturer’s

instructions.

5.3 Connecting duct, of all welded construction fabricated from (1,5 ± 0,1) mm thick steel with a

width and height appropriate to the size of the damper under test. The duct shall have a length of 2× the

diagonal dimension of the damper, up to a maximum of 2 m. The connecting duct shall be provided with

a gas-tight observation port.

5.4 Measuring station, consisting of an orifice plate, venturi, or other suitable device, an air flow

straightener (if required) and straight lengths of pipe sized in accordance with ISO 5167-1 installed

between the connecting duct and the exhaust fan to determine the volume flow rate of gases passing

through the damper under test. When testing dampers installed in floors, it is still possible to use the

measuring station horizontally. A suitable mounting detail is shown in Figure 2.

5.5 Exhaust fan system, capable of controlling flow rates and maintaining a pressure difference

between the connecting duct and the furnace, as required, when the damper is closed.

Regardless of what test pressure is chosen, the fan should be capable of achieving a 200 Pa pressure

difference higher than the test pressure difference chosen for the test.

Regulation of the 300 Pa (or higher pressure differential) may be by means of a dilution damper installed

just before the fan inlet. The pressure shall be controlled to within ±5 % of the required pressure. A

balancing damper shall be fitted at the outlet of the fan to adjust the pressure range of the systems to

suit the damper under test. A variable speed fan may be used instead of the dilution damper.

5.6 Instrumentation for measuring and recording the furnace temperature, in accordance with

ISO 834-1. Locations of the furnace thermocouples for a number of different test arrangements are

shown in Figures 3, 4, 5, 6, 7 and 8.

The gas temperature adjacent to the flow measuring device shall be measured by a 0,25 mm bare

wire thermocouple enclosed in a 6 mm diameter porcelain twin wall tube with its measuring junction

located at the centreline of the measuring duct and at a distance equal to twice the diameter of the

measuring duct downstream from the flow measuring device. A similar thermocouple shall be located

at the exit from the connecting duct plenum (see Figures 1 and 2). Alternative thermocouples may be

used provided it can be shown that they have equivalent response time.

5.7 Instrumentation for measuring and recording surface temperature, in accordance with

ISO 834-1.

It shall be located, depending on the method of mounting the damper selected, in the positions shown in

Figures 3, 4, 5, 6, 7 or 8.

5.8 Instrumentation for measuring pressure differential between the furnace and the

connecting duct.

A pressure tapping shall be located on the centreline of one vertical side wall of the connecting duct.

Instrumentation shall have a 300 Pa measurement capacity higher than the test pressure chosen for the

test. Instrumentation shall also be provided for measuring the pressure difference between inside and

outside (ambient) of the furnace.

5.9 Timing device, capable of running throughout the test period.

5.10 Gap gauges and cotton pad, according to ISO 834-1, to judge the integrity of the joints between

the damper and its connecting duct and the damper assembly and the supporting construction of the test

arrangement.

4 © ISO 2018 – All rights reserved

Key

1 supporting construction (wall)

2 2× diagonal (to a maximum of 2 m)

3 pressure sensor (on centreline)

4 observation port

5 orifice plate or venturi

6 pressure differential (300 Pa)

7 pressure differential control box

8 pressure sensor in laboratory

9 pressure control dilution damper

10 pneumatic actuator or manual control

11 balancing damper

12 fan

13 flexible connecting duct

14 support

15 thermocouple

16 support

17 flow straightener

18 flange

19 support

20 thermocouple at exit from plenum

21 connecting duct

22 test damper

23 furnace chamber

24 pressure sensor (on centreline of damper)

25 distance: thermocouple to orifice plate = 2 d

Figure 1 — Example of general test arrangement

Key

1 dimension equal to the diameter of the measuring station

2 pressure sensor

3 pressure differential (300 Pa)

4 pressure sensor in laboratory

5 pressure differential control box

6 pressure control dilution damper

7 balancing damper

8 fan

9 pneumatic actuator or manual control

10 flexible connecting duct

11 distance: thermocouple to orifice plate = 2 d

12 thermocouple

13 support

14 orifice plate or venturi

15 flange

16 connecting duct

17 thermocouple at exit from plenum

18 flow straightener

19 support

20 supporting construction {floor)

21 furnace chamber

22 test damper

23 pressure sensor

24 2× diagonal (to a maximum of 2 m)

Figure 2 — Example of an alternative arrangement when testing dampers in floors

6 © ISO 2018 – All rights reserved

Dimensions in millimetres

Key

1 furnace

2 supporting construction

3 support

4 connecting duct

5 connecting angle

6 length "L" to be specified by damper manufacturer

7 infill material, provided it is necessary

8 damper

9 insulated ductwork

10 furnace thermocouples, 4 places

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 3 — Position of surface thermocouples when damper is installed in an insulated duct

Dimensions in millimetres

Key

1 furnace

2 supporting construction

3 support

4 connecting duct

5 connecting angle

6 infill material, provided it is necessary

7 damper

8 furnace thermocouples, 4 places

L length to be specified by damper manufacturer

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 4 — Position of surface thermocouples when damper is installed in a non-insulated duct

8 © ISO 2018 – All rights reserved

Dimensions in millimetres

Key

1 furnace

2 supporting construction

3 support

4 connecting duct

5 damper

6 furnace thermocouples, 4 places

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 5 — Damper mounted onto face of supporting construction within the furnace

Dimensions in millimetres

Key

1 supporting construction

2 support

3 connecting duct

4 damper

5 connecting angle

6 furnace

7 furnace thermocouples, 4 places

L length to be specified by damper manufacturer

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 6 — Damper mounted onto face of supporting construction outside the furnace

10 © ISO 2018 – All rights reserved

Dimensions in millimetres

Key

1 furnace

2 floor for example

3 suitable attachment as in practice

4 insulation, provided it is necessary

5 insulated duct

6 supporting construction

7 support

8 connecting duct

9 connecting angle

10 damper

11 furnace thermocouples, 4 places

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 7 — Damper mounted remote from the supporting construction and within the

furnace chamber

Dimensions in millimetres

Key

1 furnace

2 supporting construction

3 damper insulation, provided it is necessary

4 damper

5 support

6 connecting duct

7 connecting angle

8 connecting angle

9 insulated duct

10 furnace thermocouples, 4 places

L length to be specified by damper manufacturer

L length of insulation where insulation is necessary

i

T , T , T unexposed surface thermocouples (minimum of one each side)

s 1 2

Figure 8 — Damper mounted remote from the supporting construction and outside the

furnace chamber

6 Test construction

6.1 General

The test construction shall contain all construction details relevant for test results. Only a maximum of

two dampers may be tested at one time.

6.1.1 Side to be tested

Where dampers are asymmetrical, they shall be tested from both sides, as it is probably not possible to

determine which side will give the worse result. Symmetrical dampers need only be tested from one

12 © ISO 2018 – All rights reserved

side. For the purposes of determining whether a damper is symmetrical, the presence of the actuating

mechanism can be ignored. However, in such a case, the damper shall be installed so that the actuating

mechanism is on the side away from the furnace, as this is considered to be the more onerous condition

because, as it will be further from the furnace, the time to its operation will be consequently longer.

If testing is carried out from one side only (i.e. one specimen) the reason for this shall be clearly stated

in the report.

6.1.2 Dampers installed in both walls and floors

Dampers which are to be employed in both walls and floors shall be tested in both orientations, unless

it can be demonstrated that one is more onerous.

6.1.3 Dampers installed within a structural opening

Dampers to be positioned within a structural opening shall be tested as shown in Figure 1 when

installed in a wall and as shown in Figure 2 when installed in a floor.

6.1.4 Dampers mounted onto face of wall or floor.

Uninsulated dampers mounted on a wall or floor and attached to the face of a structure shall be tested

with the damper positioned within the furnace as shown in Figure 5. Insulated dampers shall be tested

from both sides so that the insulation properties of the damper body and where appropriate the duct

can be evaluated. An example of a damper mounted to the wall/floor outside the furnace is shown in

Figure 6.

6.1.5 Dampers remote from wall or floor

6.1.5.1 Within the furnace

Dampers mounted remote from the wall or floor and separate from the structure shall be attached to

a length of ductwork. For test purposes, the duct shall be attached to the supporting construction with

the damper installed at the duct end within the furnace, as shown in Figure 7. This length of ductwork

shall be (150 ± 50) mm long and insulated to the extent necessary to ensure that it remains intact

throughout the test. The distance between the outer surface of the duct and the furnace wall or floor

shall not be less than 500 mm.

6.1.5.2 Outside the furnace

For dampers that are to be mounted onto a section of duct outside the furnace, as shown in Figure 8, the

length of duct shall be (500 ± 50) mm.

NOTE In the case of an uninsulated damper, mounted on a section of a duct outside the furnace, this does not

need to be tested.

6.1.6 Minimum separation between dampers

Where two dampers are to be tested at the same time, the distance between the dampers shall not be

less than 200 mm, as shown in Figure 9. Where the dampers are mounted in a wall or partition, but are

not located in the same horizontal plane, the required furnace pressure is determined at the horizontal

plane of the lower damper [see 9.8 a) and Figure 1.

6.2 Size of specimen

The largest size damper should be fire tested and, provided the damper satisfies the appropriate fire

leakage criteria, the results can be extended to smaller sizes of dampers whose dimensions relative

to width, height and length are smaller than that tested, subject to the following verification that all

components, in particular the damper blade(s), are the same thickness and cross-sectional shape with

respect to curtain and multi-blade dampers and blade width.

Dimensions in millimetres

Key

1 supporting construction

2 damper

Figure 9 — Maximum separation between two dampers

14 © ISO 2018 – All rights reserved

Dimensions in millimetres

Key

1 supporting construction (wall)

2 damper

3 pressure of 15 Pa maintained on this plane

Figure 10 — Dampers mounted in different horizontal planes

6.3 Thermal release mechanism

The thermal release mechanism shall be included in the specimen construction. If there are alternative

release mechanisms where these are in series with the basic thermal release and can be shown to not

inhibit the basic release then only the one thermal release mechanism is required to be tested. (See

optional requirements in Annexes B, C and D)

NOTE Where a damper design is modified solely with respect to the thermal release mechanism, it is not

necessary to continue the test after closure provided that the release mechanism does not affect the maintenance

of the closed state of damper.

6.4 Specimen installation

The dampers shall be installed as in practice in a supporting construction using methods which are in

accordance with the manufacturer's instructions. Damper manufacturers requiring the damper to be

tested in a length of insulated ductwork shall specify the length over which the duct is to be insulated

as shown in Figure 3.

6.5 Supporting construction

6.5.1 Principles

6.5.1.1 The supporting construction shall be a wall, partition or floor of the type to be used in practice.

6.5.1.2 A test result obtained for a fire damper mounted in a supporting construction made of masonry,

concrete or solid partition (without any cavity) is applicable for the same type of supporting construction

with a thickness and density equal to or greater than those of the supporting construction used for the test.

6.5.1.3 The supporting construction selected shall have fire resistance slightly greater than the

required fire resistance of the damper being tested.

6.5.1.4 If a specific supporting construction different than those described above is selected, the test

results obtained are applicable only to that specific wall, partition or floor.

6.5.2 Recommended supporting constructions

Where the type of supporting construction used in normal practice is not known, then one of the

standard supporting constructions described in Tables 1, 2 or 3 shall be used.

Table 1 — Standard rigid wall construction

Type of construction Thickness Density Test duration

mm kg/m t

h

Normal concrete/masonry 110 ± 10 2 200 ± 200 t = 2

150 ± 10 2 200 ± 200 2 < t ≤ 3

175 ± 10 2 200 ± 200 3 < t ≤ 4

a

Aerated concrete 110 ± 10 650 ± 200 t = 2

150 ± 10 650 ± 200 2 < t ≤ 4

a

This supporting construction may be made from blocks bonded together with mortar or adhesive.

Table 2 — Standard flexible-wall constructions (gypsum plasterboard)

Fire resistance Wall constructions

a b

Number of layers Thickness Insulation Thickness

min

on each side

mm D/ρ mm

30 1 12,5 40/40 75

60 2 12,5 40/40 100

90 2 12,5 60/50 125

120 2 12,5 60/100 150

180 3 12,5 60/100 175

240 3 15,0 80/100 190

a 3

D is the thickness in mm of mineral wool insulation inside the wall; ρ is the density in kg/m of mineral wool insulation

inside the wall.

b

Tolerance of ±10 %.

16 © ISO 2018 – All rights reserved

Table 3 — Standard floor constructions

Type of construction Thickness Density Test duration

mm kg/m t

h

Normal concrete 110 ± 10 2 200 ± 200 t = 1,5

150 ± 10 2 200 ± 200 1,5 < t ≤ 3

175 ± 10 2 200 ± 200 3 < t ≤ 4

Aerated concrete 125 ± 10 650 ± 200 t = 2

150 ± 10 650 ± 200 2 < t ≤ 4

6.5.2.1 Non-standard supporting constructions

When the test specimen is intended for use in a form of construction not covered by the standard

supporting constructions, it shall be tested in the supporting construction intended for use.

6.6 Conditioning

After installation of the damper into a supporting construction the assembly shall be subject to a

conditioning procedure in accordance with the requirements of ISO 834-1. The moisture content of the

supporting construction and any infill material used between the damper and supporting construction

may have an influence on the performance of the damper, in particular in relation to the insulation

criterion. Where practical, the moisture content of all the component items, including any infill material,

shall be controlled to ensure that equilibrium has been reached, and the final value measured and

recorded. If the supporting construction has been assembled and has been fully conditioned prior to

the installation of the test specimen and if a water based infill material (or other similar infill material

which requires curing) is used to seal any small gaps between the supporting construction and the

damper, then a minimum of 14 days shall be allowed for the assembly to reach equilibrium.

7 Determination of leakage of connecting duct and measuring station

7.1 Shut the damper manually and seal the inlet aperture using impervious material.

7.2 Assemble the connecting duct measuring station and exhaust fan as shown in Figure 1. The joints

between each component shall be well sealed with high temperature gaskets and/or sealants.

7.3 Connect an orifice plate, venturi or other suitable device to a suitable recording instrument

calibrated and complying with the requirements of ISO 5167-1. It may be necessary to use a different size

of orifice plate, venturi or other suitable device for the determination of the leakage of the connecting

duct and measuring standard to that used for the leakage tests described in Clauses 7 and 8. The leakage

is calculated from the recorded pressure differential from the orifice plate, venturi or other suitable

device using the formulae for volume flow rates given in ISO 5167-1.

7.4 Adjust the exhaust fan so that the air leakage through the connecting duct and measuring station

can be measured at 200 Pa, 300 Pa, 400 Pa and 500 Pa. The pressure differential at each value should

be maintained for 60 s before the leakage is recorded. For higher pressure differential than 300 Pa, the

control of leakage shall be performed at a test pressure 200 Pa higher than the test pressure chosen, in

five equal increments.

7.5 Plot the values on graph paper to determine the leakage at 300 Pa, or at a higher selected pressure

differential.

7.6 If the leakage at 300 Pa is more than 12 m /h, improve the sealing of joints and stability of test

construction until the leakage criterion referred to above can be met. For pressure differentials higher

than 300 Pa the leakage of 12 m /h may be increased by a factor (P /300) 0,5.

test

7.7 Remove sealing from the inlet aperture of the damper.

8 Determination of leakage at ambient temperature

8.1 Subject the damper to 50 opening and closing cycles.

8.2 After the 50th cycle, check that the damper still locks in the closed position and that it shows no

mechanical damage that will affect the operation of the damper.

8.3 Close the damper.

8.4 Adjust the exhaust fan to maintain an underpressure of 300 Pa (or higher underpressure) in the

connecting duct relative to the laboratory.

8.5 Record the pressure differential across the orifice plate, venturi or other suitable device at not

more than 2-min intervals for a period of 20 min or until stable readings are reached.

8.6 Calculate the leakage from the recorded pressure differential from the orifice plate, venturi or

other suitable device using the formulae for volume flow rates given in ISO 5167-1. Deduct the value

for the leakage of the connecting duct and measuring station determined in Clause 7 from the measured

leakage.

9 Fire test

9.1 Latch the damper into its open position, then if not already in position, mount the test specimen

onto the furnace.

9.2 Connect all instrumentation required by this document.

9.3 With the damper fully open, set the exhaust fan system to produce an air velocity of 0,15 m/s

across the damper opening. This may be measured by the orifice plate, venturi or other suitable device

located within the measuring duct. The air velocity shall be maintained to an accuracy of ±15 %.

9.4 Switch off the exhaust fan, but leave at its pre-set value given in 9.3.

9.5 Ignite the furnace. Start the timing device and switch on all measuring devices.

9.6 Switch on the exhaust fan as soon as the furnace has ignited.

9.7 When the damper has closed, adjust the exhaust fan to maintain an underpressure of 300 Pa (or

higher) in the connecting duct, relative to the furnace. Record the time at which the damper closes. If the

damper fails to close after 2 min from igniting the furnace, discontinue the test.

9.8 During the test, carry out the following.

a) Control and record the furnace temperature and pressure in accordance with ISO 834-1. The

furnace pressure at the horizontal centreline of a vertical damper shall be maintained at (15 ± 2) Pa.

18 © ISO 2018 – All rights reserved

b) Maintain a pressure differential between the connecting duct and furnace of (−300 ± 15) Pa, (or

higher underpressure}.

c) Record the pressure differential across the orifice plate, venturi or other suitable device and the

local gas temperature at not more than 2-min intervals.

Constants for orifice plate, venturi or other suitable devices shall be calculated in accordance with

ISO 5167-1 over the range of anticipated gas temperatures. As a function of time and measured gas

temperatures, select the corresponding orifice plate, venturi or other suitable device constants and

calculate the volume flow rate at the measuring station gas temperatures using the formulae for

volume flow rates given in ISO 5167-1. Correct the measured volume flow rate to 20 °C. Deduct the

value for the leakage of the connecting duct and measuring station determined in Clause 7 from the

measured leakages.

d) Record the temperature on the external surface of the connecting duct at the time intervals

specified in ISO 834-1.

e) The effect of gaps, orifices or openings on the integrity at the junction between the supporting

construction and connecting duct shall be determined by the use of the cotton pad and/or gap

gauges as defined in ISO 834-1.

f) Where practical, record any observations of the general behaviour of the damper assembly during

the test. In practice this is limited to observations taken on the furnace side and to the duct/damper

junction and adjacent area on the non-furnace side.

10 Classification and criteria

Depending on the classification required, the size of the fire damper to be tested and the criteria to be

applied are given in Table 4.

Table 4 — Fire test performance criteria

a

Classification Size to be tested Leakage at Fire test

ambient tempera-

Leakage limit Temperature Perimeter

ture

3 2 b

m /(h · m ) rise limit integrity

3 2

m /(h · m )

°C

Mean/Max.

c

E max. Not required 360 Not required GG/SF

c

ES max. 200 200 Not required GG/SF

min. 200 Not required Not required Not required

c

EI max. Not required 360 140/180 CP/GG/SF

c

EIS max. 200 200 140/180 CP/GG/SF

min. 200 Not required Not required Not required

In relation to the criteria for leakage (S), the values given shall be satisfied in both the ambient temperature (smallest

damper and largest damper in the range) and the fire test (largest damper in the range).

NOTE 1 The maximum temperature rise limit (180 °C) can be determined at any of the thermocouples T , T and T (or

1 2 s

the roving thermocouple described in ISO 834-1) and the mean (average) temperature rise (140 °C) is determined from

thermocouples T . Locations of the thermocouples are shown in Figures 3 to 8.

NOTE 2 For the purposes of calculating compliance with the leakage criteria in this table, the area of a damper can be

taken to be the cross-sectional area of the duct to which the damper is connected.

NOTE 3 Classification of integrity is according to whether or not the damper is also classified for insulation. Where a

damper is classified for integrity E and insulation I, the integrity is that determined by whichever of the three criteria fails

first. Where a damper is classified E but without an I classification, the integrity value is defined as the time to failure of

only the cracks/openings or sustained flaming criteria, whichever fails first.

a

E is the integrity (gas flow corrected to 20 °C);

I is the insulation (see note 1);

S is the leakage classification (see note 2) (gas leakage corrected to 20 °C).

b

CP is the cotton pad (see note 3);

GG is the gap gauge (see note 3);

SF is the sustained flaming (see note 3).

c

Leakage limits only apply after 5 min from the start of the test.

10.1 Number of tests required

The test method has been designed to cover as many potential applications for damper installation as

possible. It is not intended that all the options have to be covered in a test programme.

Guidance is given below in Tables 5 and 6 on the number of tests that may be required. Experience may

show that not all tests need to be undertaken, as some installation options may be found to represent

the most onerous condition, in which case the number of tests required can be reduced.

Table 5 — Fire damper standard installation application

Fire damper installation application in prac- Number of tests asymmetri- Number of tests symmet-

tice standard application cal fire damper rical fire damper

Installed within a wall 2 1

Installed within a floor 2 1

20 © ISO 2018 – All rights reserved

Table 6 — Fire damper special installation application

Fire damper installation application in Number of tests asymmetri- Number of tests symmetri-

practice special application cal fire damper cal fire damper

Installed on face of wall 2 1

Installed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...