ISO 15557:1998

(Main)Practice for use of a radiochromic film dosimetry system

Practice for use of a radiochromic film dosimetry system

Pratique de l'utilisation d'un système dosimétrique à film radiochromique

General Information

Relations

Standards Content (Sample)

INTERNATIONAL

IS0

STANDARD

15557

First edition

1998-l 2-l 5

Practice for use of a radiochromic film

dosimetry system

Pra tique de I’u tilisa tion d ’un sys t@me dosim6 trique 2 film radiochromique

Reference number

IS0 15557: 1998(E)

---------------------- Page: 1 ----------------------

IS0 15557: 1998(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of national standards bodies

(IS0 member bodies). The work of preparing International Standards is normally carried out through IS0 technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. IS0 collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

bodies for voting.

Draft International Standards adopted by the technical committees are circulated to the member

casting a vote.

Publication as an International Standard requires approval by at least 75 % of the member bodies

International Standard IS0 15557 was prepared by the American Society for Testing and Materials (ASTM)

Subcommittee E1O.O1 (as E 1275-93) and was adopted, under a special “fast-track procedure ”, by Technical

Committee ISOmC 85, Nuclear energy, in parallel with its approval by the IS0 member bodies.

A new lSO/TC 85 Working Group WG 3, High-level dosimetry for radiation processing, was formed to review the

voting comments from the IS0 “Fast-track procedure” and to maintain these standards. The USA holds the

convenership of this working group.

International Standard IS0 15557 is one of 20 standards developed and published by ASTM. The 20 fast-tracked

standards and their associated ASTM designations are listed below:

IS0 Designation ASTM Designation Title

E 1204-93 Practice for dosimetry in gamma irradiation facilities for food

15554

processing

Practice for use of a ceric-cerous sulfate dosimetry system

15555 E 1205-93

15556 E 1261-94 Guide for selection and calibration of dosimetry systems for

radiation processing

15557 E 1275-93 Practice for use of a radiochromic film dosimetry system

E 1276-96 Practice for use of a polymethylmethacryaylate dosimetry system

15558

15559 E 1310-94 Practice for use of a radiochromic optica/ waveguide dosimetry

sys tern

15560 E 1400-95a Practice for characterization and performance of a high-dose

radiation dosimetry calibration laboratory

15561 E 1401-96 Practice for use of a dichromate dosimetry system

0 IS0 1998

Unless otherwise specified, no pa publication may be reproduced or utilized in any form or by any means, electronic

All rights reserved. rt of this

or mechanical, incl uding photocopying and microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case postale 56 l CH-1211 Geneve 20 l Switzerland

Internet iso @ iso.ch

Printed in Switzerland

ii

---------------------- Page: 2 ----------------------

IS0 15557: 1998(E)

@ IS0

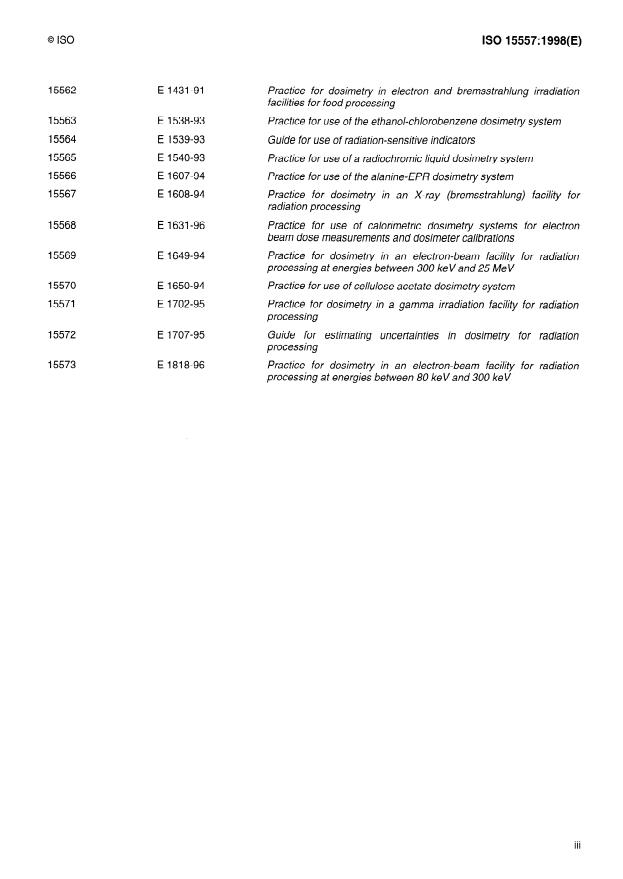

E1431-91 Practice for dosimetry in electron and bremsstrahlung irradiation

15562

facilities for food processing

Practice for use of the ethanol-chlorobenzene dosimetry system

15563 E 1538-93

15564 E 1539-93 Guide for use of radiation-sensitive indicators

15565 E 1540-93 Practice for use of a radiochromic liquid dosimetry system

15566 E 1607-94 Practice for use of the alanine-EPR dosimetry system

Practice for dosimetry in an X-ray (bremsstrahlung) facility for

15567 E 1608-94

radiation processing

for electron

15568 E 1631-96 Practice for use of calorimetric dosimetry systems

beam dose measurements and dosimeter calibrations

Practice for dosimetry in an electron-beam facility for radiation

15569 E 1649-94

processing at energies between 300 keV and 25 MeV

E 1650-94 Practice for use of cellulose acetate dosimetry system

15570

Practice for dosimetry in a gamma irradiation facility for radiation

1557-l E 1702-95

processing

Guide for estimating uncertainties in dosimetry for radiation

15572 E 1707-95

processing

Practice for dosimetry in an electron-beam facility for radiation

15573 E 1818-96

processing at energies between 80 keV and 300 keV

. . .

Ill

---------------------- Page: 3 ----------------------

IS0 15557: 1998(E)

@ IS0

AMERICAN SOCIETY FOR TESTING AND MATERIALS

Designation: E 1275 - 93

1916 Race St Philadelphia, Pa 19103

clSTb

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

If not listed in the current combined index, will appear in the next edition.

Standard Practice for

Use of a Radiochromic Film Dosimetry System’

This standard is issued under the fixed designation E 1275; the number immediately following the designation indicates the year of

original adoption or, in *he case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

2.2 International Commission on Radiation Units and

1. Scope

Measurements (ICR U) Reports:

1.1 This practice covers the handling, testing, and proce-

ICRU Report 14-Radiation Dosimetry: X Rays and

dure for using a radiochromic film dosimetry system to

Gamma Rays with Maximum Photon Energies Between

measure absorbed dose in materials irradiated by photons or

0.6 and 50 MeV6

electrons in terms of absorbed dose in water.

ICRU Report 17-Radiation Dosimetry: X Rays Gener-

1.2 This practice applies to radiochromic film dosimeters

ated at Potentials of 5 to 150 kV6

that can be used within part or all of the specified ranges as

ICRU Report 33-Radiation Quantities and Units6

follows:

ICRU Report 34-The Dosimetry of Pulsed Radiation6

1.2.1 The absorbed dose range is 1 x lOa2 to 1 x lo* kGy.

ICRU Report 35-Radiation Dosimetry: Electron Beams

1.2.2 The absorbed dose rate is 1 x lo-* to 1 X 1O*3 Gy/s

with Energies Between 1 and 50 MeV6

(l-4).*

1.2.3 The radiation energy range for both photons and

3. Terminology

electrons is 0.1 to 50 MeV.

3.1 Definitions:

1.2.4 The irradiation temperature range is -78 to +6O ”C.

3.1.1 absorbed dose, D-the quotient of de’ by dm, where

1.3 This standard does not purport to address all of the

d? is the mean energy imparted by ionizing radiation to the

safety problems, if any, associated with its use. It is the

matter of mass dm (see ICRU Report 33).

responsibility of the user of this standard to establish appro-

de’

priate safety and health practices and determine the applica-

- D==

bility of regulatory limitations prior to use.

The special name for the unit for absorbed dose is the gray

.

.

GY)

2. Referenced Documents

1 Gy = 1 Jekg-’

2.1 ASTM Standards:

Formerly, the special unit for absorbed dose was the rad:

170 Terminology Relating to Radiation Measurements

1 rad = 1O-2 Jmkg-’ = 1O-2 Gy

and Dosimet$

178 Practice for Dealing with Outlying Observations4

3.1.2 analysis wavelength-wavelength used for calibra-

275 Practice for Describing and Measuring Performance

tion and routine application.

of Ultraviolet, Visible, and Near Infrared Spectro-

3.1.3 batch-quantity of dosimeters made from a specific

photometers5

mass of material with uniform composition, fabricated in a

668 Practice for Application of Thermoluminescence-

single production run, and having a unique identification

Dosimetry (TLD) Systems for Determining Absorbed

code.

Dose in Radiation-I-Iardness Testing of Electronic De-

3.1.4 \ calibration curve-graphical or mathematical rela-

vices3

tionship between the specific net absorbance and the ab

1026 Practice for Using the Fricke Reference Standard

sorbed dose for a given dosimetry system. The calibration

Dosimetry System3

curve can also serve as the response function.

1204 Practice for Dosimetry in Gamma Irradiation

3.1.5 calibration ficility-combination of an ionizing ra-

Facilities for Food Processing3

diation source and its associated instrumentation that pro-

1205 Practice for Use of a Ceric-Cerous Sulfate

vides uniform and reproducible absorbed dose rates at

.Dosimetry System3

specific locations and in a specific material traceable to

126 1 Guide for Selection and Application of Dosimetry

national standards, and therefore, may be used to calibrate

Systems for Radiation Processing of Food3

the absorbed dose response of routine or other types of

dosimeters.

3.1.6 dosimetry system-system used for determining ab-

* This practice is under the jurisdiction of ASTM Committee E-18 on Nuclear

sorbed dose, consisting of dosimeters, measurement instru-

Technology and Applications and is the direct responsibility of Subcommittee

mentation, the calibration curve, reference standards, and

E1O.O 1 on Dosimetry for Radiation Processing.

Current edition approved April 15, 1993. Published July 1993. Originally

procedures for the system ’s use.

published as E 1275 - 88. Last previous edition E 1275 - 88 ”.

3.1.7 measurement quality assurance plan-a docu-

2 The boldface numbers in parentheses refer to the list of references at the end

of this practice.

3 Annual Book of ASTM Standards, Vol 12.02.

’ Annual Book o/ASTM Standards, Vol 14.02. 6 Available from International Commission on Radiation Units and Measure-

ments, 79 10 Woodmont Ave., Suite 800, Bethesda, 208

5 Annual Book o/ASTM Standards, Vol 14.0 1. MD 14.

1

---------------------- Page: 4 ----------------------

0 1so

IS0 15557: 1998(E)

ClsIE, E 1275

width, and stray light rejection.

mented program for the measurement process that qualifies

51.3 Holder, to position the dosimeter reproducibly in

the total uncertainty of the measurements (both random and

and perpendicular to the measuring light beam.

systematic error components); this plan shall demonstrate

5.1.4 Calibrated Thickness Gage, with- a precision of

traceability to national standards and shall show that the

22 % of the film thickness (at a 95 % confidence level).

total uncertainty meets the requirements of the specific

application.

NOTE 2-Documentation provided by the manufacturer of the

3.1.8 net absorbance, &&radiation-induced change in

radiochromic film dosimeter with regard to the fdrn thickness and its

measured absorbance at a selected wavelength(s) determined variability may be substituted for direct measurement of thickness by

the user. This information should be verified by the user by analyzing a

by subtracting the pre-irradiation absorbance, AO, from the

representative sample of films

post-irradiation absorbance, Ar as follows:

NOTE 3-Some radiochromic fflrn dosimeters contain a substrate

AA = A, - A0

which is not radiochromic. With such dosimeters the thickness is not

measured.

This term is also referred to as induced absorbance.

3.1.9 radiochromic film dosimeter-specially prepared

6. Performance Check of Instrumentation

film containing ingredients that undergo an ionizing radia-

6.1 The performance of the photometer or spectropho-

tion-induced change in optical absorbance. This change in

tometer shah be checked and documented. (See Practices

optical absorbance can be related to absorbed dose in water.

E 275 and E 1026.)

3. I. 10 specific net absorbance, k-net absorbance, AA, at

6.1.1 When using a spectrophotometer, check and docu-

a selected wavelength(s) divided by the thickness, t, of the

dosimeter as follows: ment the bias and precision of the wavelength scale and

absorbance scale at or near the analysis wavelength(s) at

k=hA/t

intervals not to exceed one month during periods of use, or

3.1.11 traceability-ability to show that a measurement is

whenever there are indications of poor performance.

consistent with appropriate national standards through an

6.1.2 When using a photometer, check and document the

unbroken chain of comparisons.

bias and precision of the absorbance scale at intervals not to

3.2 Other appropriate terms may be found in Termi-

exceed one month during periods of use, or whenever there

nology E 170.

are indications of poor performance.

6.1.3 Compare the information obtained in 6.1. I or 6.1.2

4. Significance and Use

with the original instrument specifications to ensure ade-

4.1 The radiochromic film dosimetry system provides a

quate performance.

means of determining absorbed dose in materials. Under the

6.2 Check the thickness gage before, during, and after use

influence of ionizing radiation, chemical reactions take place

to assure reproducibility and lack of zero drift. Check and

in the radiochromic film creating or enhancing, or both,

document the calibration of the gage at intervals not to

optical absorption bands. Absorbance is determined at the

exceed six months. Use gage blocks, traceable to national

selected wavelength(s) within these radiation-induced ab

standards for this purpose.

sorption bands. Examples of appropriate wavelengths for

analysis for specific dosimetry systems are provided by the 7. Calibration of Dosimeters

manufacturer and in Refs. 3 through 14.

7.1 To calibrate a dosimetry system, use an electron or

4.2 In the application of a specific dosimetry system,

gamma irradiation facility, as appropriate, whose dose rate is

absorbed dose is determined by use of a calibration curve

traceable to national standards and which meets the fol-

traceable to national standards.

lowing requirements:

4.3 The absorbed dose determined is usually specified in

7.1.1 Specify the calibration absorbed dose in terms of

water. Absorbed dose in other materials may be determined

absorbed dose in water, or in another material appropriate

by applying the conversion factors discussed in Guide

for the specific application (see 4.3).

E 1261.

7.1.2 Determine the absorbed dose rate of the calibration

field by use of a reference or transfer dosimetry system (see

NOTE l-For comprehensive discussion of various dosimetry

methods applicable to the radiation types and energies discussed in this

Guide E 126 1, Practice E 1026, and Practice E 1205).

test method, see ICRU Reports 14, 17, 34, and 35.

7.2 Provide the conditions for calibration of dosimeters as

follows:

4.4 Radiochromic film dosimetry systems are commonly

7.2.1 Position the dosimeter in the calibration radiation

applied in the industrial radiation processing of a variety of

field in a defined, reproducible location.

products, for example, sterilization of medical devices and

7.2.2 When using a gamma-ray source for calibration,

processing of foods (11, 13).

surround the dosimeters with a sufficient amount of material

to ensure electron equilibrium conditions.

5. Apparatus

NOTE 4-For example, in determining absorbed dose in water with a

5.1 Components of the Dosimetry System-The following

Yo source, approximately 3 to 5 mm of polystyrene (or equivalent

shall be used to determine absorbed dose with radiochromic

polymeric material) should surround the dosimeters in all directions.

film dosimetry systems:

5.1.1 Radiochromic Film Dosimeters.

7.2.3 Make the calibration field within the volume occu-

5.1.2 Spectrophotometer or Photometer, having documen- pied by the dosimeter(s) as uniform as possible. The varia-

tation covering analysis wavelength range, accuracy of w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.