IEC 60800:2021

(Main)Heating cables with a rated voltage up to and including 300/500 V for comfort heating and prevention of ice formation

Heating cables with a rated voltage up to and including 300/500 V for comfort heating and prevention of ice formation

IEC 60800:2021 is applicable to, and specifies requirements for resistive heating cables for low temperature applications such as comfort heating and the prevention of ice formation. These heating cables and heating cable sets can comprise either factory assembled or field (work-site) assembled units, and are heating cables assembled in accordance with manufacturer’s instructions. Bare conductors and protected conductors to be supplied at voltages equal to, or less than, 50 V are excluded from the scope of this document.

Typical applications include, but are not limited to:

- surface heating installed in or under surfaces;

- direct and storage heating;

- snow melting and frost protection of roofs, gutters, pipes, etc.

Electrical resistance trace heating systems for industrial and commercial applications are specified in the IEC 62395 series [1] and for explosive atmospheres applications in the IEC/IEEE 60079-30 series [2], as are mineral insulated heating cables. Applications in which the sheath temperature exceeds 100 °C are outside the scope of this document.

Câbles chauffants de tension assignée jusques et y compris 300 V/500 V pour le chauffage des locaux et la protection contre la formation de glace

L'IEC 60800:2021 s’applique aux câbles chauffants résistifs utilisés dans des applications basse température telles que le chauffage des locaux et la protection contre la formation de glace, et spécifie les exigences qui s’y appliquent. Ces câbles chauffants et câbles chauffants équipés peuvent comprendre soit des unités fabriquées en usine, soit des unités assemblées sur site (chantier), et sont des câbles chauffants assemblés conformément aux instructions du fabricant. Les conducteurs nus et les conducteurs protégés destinés à être alimentés à des tensions inférieures ou égales à 50 V sont exclus du domaine d’application du présent document.

Les applications typiques comprennent entre autres:

- le chauffage superficiel interne aux surfaces ou situé sous les surfaces;

- le chauffage direct et à accumulation;

- la fonte de neige et le dégivrage des toits, gouttières, chéneaux, etc.

Les systèmes de traçage par résistance électrique pour applications industrielles et commerciales sont spécifiés dans la série IEC 62395 [1] et ceux pour applications en atmosphères explosives dans la série IEC/IEEE 60079-30 [1], tout comme les câbles chauffants à isolation minérale. Les applications pour lesquelles la température de la gaine dépasse 100 °C ne relèvent pas du domaine d'application du présent document.

General Information

- Status

- Published

- Publication Date

- 21-Nov-2021

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 17 - TC 20/WG 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Nov-2021

- Completion Date

- 26-Nov-2021

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60800:2021 - Edition 4.0 is the international standard that specifies requirements for resistive heating cables with a rated voltage up to and including 300/500 V, intended for comfort heating and prevention of ice formation. The standard applies to both factory‑assembled and field‑assembled heating cables and cable sets assembled according to the manufacturer’s instructions. It defines construction, marking, installation information and a comprehensive suite of testing requirements to verify electrical, thermal and mechanical durability in normal use.

Key topics and technical requirements

- Scope and exclusions: Covers low‑temperature resistive heating cables; excludes bare/protected conductors supplied at ≤50 V and applications where sheath temperature exceeds 100 °C. Terminations and gland fittings are outside the scope.

- Mechanical classification and marking: Requirements for mechanical class, durable identification and installation instructions to ensure safe selection and use.

- Construction requirements: Rules for conductors, insulation, electrically conductive screens (e.g., metallic braid or sheath for protective purposes), armouring, sheaths and moisture resistance.

- Comprehensive testing regime - type, routine and sample tests include:

- Electrical resistance and rated output verification

- Water immersion and temperature cycling tests (with mechanical property checks)

- Flammability and heat‑shock tests

- Cold impact, cold bend and reverse winding tests

- Ageing tests for insulation and sheath, cyclic ageing, hot set and tensile tests

- Weathering and UV resistance testing (ISO 4892‑2 Annex A)

- Splice and end‑seal cyclic ageing tests and abrasion/penetration checks

- Durability and safety focus: Ensures cables operate at safe temperatures relative to materials and installations and can include electrically conductive components for fault protection.

Practical applications and users

Typical applications:

- Surface and under‑surface heating (e.g., underfloor systems)

- Direct and storage heating

- Snow melting and frost protection for roofs, gutters, walkways and pipes Who uses IEC 60800:2021:

- Heating cable manufacturers designing products for comfort or anti‑icing use

- Test laboratories performing type and routine testing

- Specifiers, procurement teams and consulting engineers writing product requirements for buildings and infrastructure

- Installers, compliance officers and safety engineers ensuring installations meet required markings and instructions

Related standards

- IEC 62395 series - electrical resistance trace heating systems for industrial/commercial applications

- IEC/IEEE 60079‑30 series - trace heating in explosive atmospheres

- IEC 60811 - referenced for cable test methods and material evaluations

IEC 60800:2021 consolidates construction, marking and test criteria to support safe, durable heating cable installations for low‑voltage comfort heating and ice prevention applications.

Buy Documents

IEC 60800:2021 RLV - Heating cables with a rated voltage up to and including 300/500 V for comfort heating and prevention of ice formation Released:11/22/2021 Isbn:9782832210567

IEC 60800:2021 - Heating cables with a rated voltage up to and including 300/500 V for comfort heating and prevention of ice formation Released:11/22/2021 Isbn:9782832246719

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60800:2021 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Heating cables with a rated voltage up to and including 300/500 V for comfort heating and prevention of ice formation". This standard covers: IEC 60800:2021 is applicable to, and specifies requirements for resistive heating cables for low temperature applications such as comfort heating and the prevention of ice formation. These heating cables and heating cable sets can comprise either factory assembled or field (work-site) assembled units, and are heating cables assembled in accordance with manufacturer’s instructions. Bare conductors and protected conductors to be supplied at voltages equal to, or less than, 50 V are excluded from the scope of this document. Typical applications include, but are not limited to: - surface heating installed in or under surfaces; - direct and storage heating; - snow melting and frost protection of roofs, gutters, pipes, etc. Electrical resistance trace heating systems for industrial and commercial applications are specified in the IEC 62395 series [1] and for explosive atmospheres applications in the IEC/IEEE 60079-30 series [2], as are mineral insulated heating cables. Applications in which the sheath temperature exceeds 100 °C are outside the scope of this document.

IEC 60800:2021 is applicable to, and specifies requirements for resistive heating cables for low temperature applications such as comfort heating and the prevention of ice formation. These heating cables and heating cable sets can comprise either factory assembled or field (work-site) assembled units, and are heating cables assembled in accordance with manufacturer’s instructions. Bare conductors and protected conductors to be supplied at voltages equal to, or less than, 50 V are excluded from the scope of this document. Typical applications include, but are not limited to: - surface heating installed in or under surfaces; - direct and storage heating; - snow melting and frost protection of roofs, gutters, pipes, etc. Electrical resistance trace heating systems for industrial and commercial applications are specified in the IEC 62395 series [1] and for explosive atmospheres applications in the IEC/IEEE 60079-30 series [2], as are mineral insulated heating cables. Applications in which the sheath temperature exceeds 100 °C are outside the scope of this document.

IEC 60800:2021 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60800:2021 has the following relationships with other standards: It is inter standard links to IEC 60800:2009, IEC 60800:2009/COR1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60800:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60800 ®

Edition 4.0 2021-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Heating cables with a rated voltage of up to and including 300/500 V for comfort

heating and prevention of ice formation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 18 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60800 ®

Edition 4.0 2021-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Heating cables with a rated voltage of up to and including 300/500 V for comfort

heating and prevention of ice formation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-1056-7

– 2 – IEC 60800:2021 RLV © IEC 2021

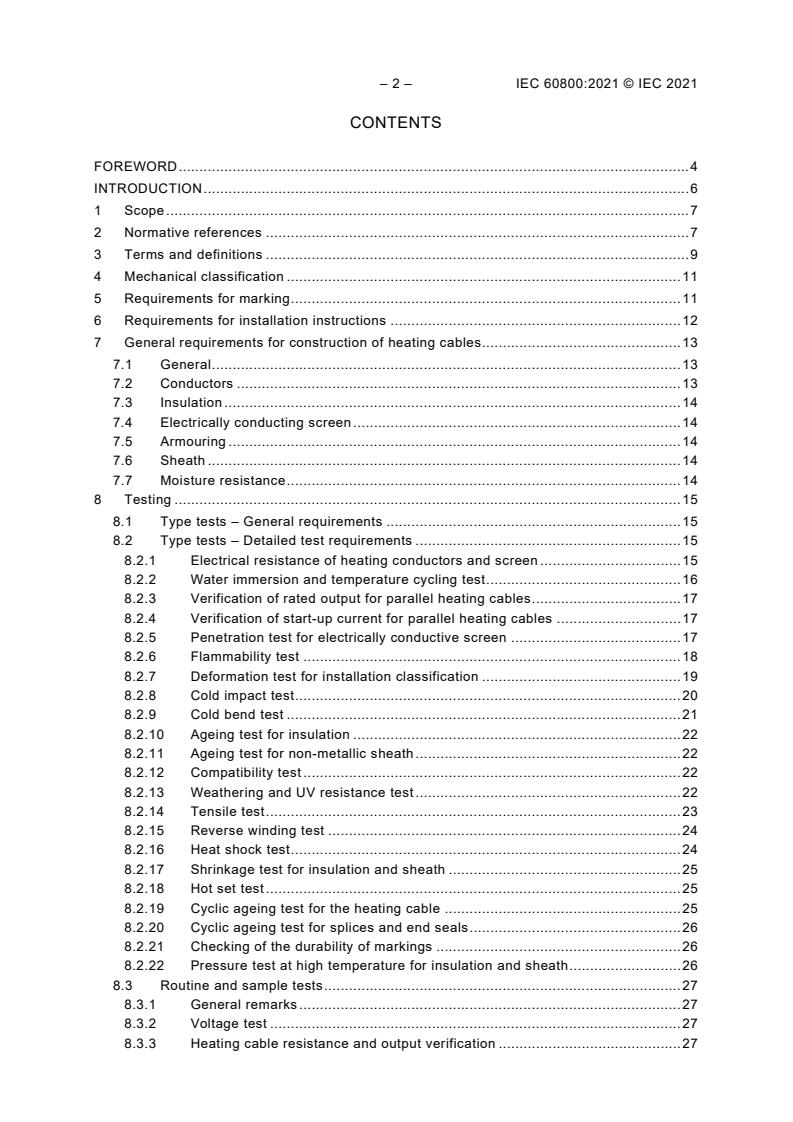

CONTENTS

FOREWORD . 4

INTRODUCTION . 2

1 Scope and object . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Mechanical classification . 10

5 Requirements for marking . 12

6 Requirements for installation instructions . 13

7 General requirements for construction of heating cables . 14

7.1 General . 14

7.2 Conductors . 14

7.3 Insulation . 14

7.4 Electrically conducting screen . 15

7.5 Armouring . 15

7.6 Sheath . 15

7.7 Moisture resistance . 16

8 Testing . 16

8.1 Type tests – General requirements . 16

8.2 Type tests – Detailed test requirements . 16

8.2.1 Electrical resistance of heating conductors and screen . 16

8.2.2 Water immersion and temperature cycling test . 17

8.2.3 Verification of rated output for parallel heating cables . 18

8.2.4 Verification of start-up current for parallel heating cables . 18

8.2.5 Penetration test for electrically conductive screen . 18

8.2.6 Flammability test . 18

8.2.7 Deformation test for installation classification . 20

8.2.8 Cold impact test . 21

8.2.9 Cold bend test . 22

8.2.10 Ageing test for insulation . 23

8.2.11 Ageing test for non-metallic sheath . 23

8.2.12 Compatibility test . 24

8.2.13 Weathering and UV resistance test . 24

8.2.14 Tensile test . 25

8.2.15 Reverse winding test . 26

8.2.16 Heat shock test . 27

8.2.17 Shrinkage test for insulation and sheath . 27

8.2.18 Hot set test . 27

8.2.19 Cyclic ageing test for the heating cable . 27

8.2.20 Cyclic ageing test for splices and end seals . 28

8.2.21 Checking of the durability of markings . 28

8.2.22 Abrasion test .

8.2.23 Deformation test for insulation and sheathing materials .

8.2.22 Pressure test at high temperature for insulation and sheath . 29

8.3 Routine and sample tests . 29

8.3.1 General remarks . 29

8.3.2 Voltage test . 29

8.3.3 Heating cable resistance and output verification . 29

8.3.4 Insulation thickness . 30

8.3.5 Sheath thickness . 30

8.3.6 Hot set test . 30

Annex A (normative) Weathering and UV resistance test . 31

Bibliography . 32

Figure 1 – Typical arrangement for splice testing the splice . 20

Figure 2 – Typical arrangement for testing the end seal testing . 20

Figure 3 – Cold bend test . 23

Figure 4 – Jaws for tensile machine . 26

– 4 – IEC 60800:2021 RLV © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HEATING CABLES WITH A RATED VOLTAGE OF UP TO

AND INCLUDING 300/500 V FOR COMFORT HEATING AND

PREVENTION OF ICE FORMATION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60800:2009. A vertical bar appears in the margin wherever a change has

been made. Additions are in green text, deletions are in strikethrough red text.

IEC 60800 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This fourth edition cancels and replaces the third edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modification of the title: "up to and including", has been introduced;

b) update of IEC 60811 references;

c) introduction of a test for mechanical properties of sheaths after the water immersion and

temperature cycling test;

d) introduction of a weathering and UV resistance test according to ISO 4892-2:2013, Annex A.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/1972/FDIS 20/1991/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 60800:2021 RLV © IEC 2021

INTRODUCTION

This document is intended to provide a comprehensive overview of the essential requirements

and testing appropriate to electrical resistance heating cables used for comfort heating and

prevention of ice formation. While some of this work already exists in national standards or

international standards, this document has collated much of this existing work.

This document provides a means to verify the electrical, thermal and mechanical durability of

resistive heating cables, so that in normal use their performance is without danger to the user

or surroundings. Compliance is checked by carrying out all the tests specified in this document.

HEATING CABLES WITH A RATED VOLTAGE OF UP TO

AND INCLUDING 300/500 V FOR COMFORT HEATING AND

PREVENTION OF ICE FORMATION

1 Scope and object

This document is applicable to, and specifies requirements for resistive heating cables for low

temperature applications such as comfort heating and the prevention of ice formation. These

heating cables and heating cable sets may can comprise either factory fabricated assembled

or field (work-site) assembled units, and are heating cables assembled in accordance with

manufacturer’s instructions.

Bare conductors and protected conductors to be supplied at voltages equal to, or less than,

50 V are excluded from the scope of this document.

NOTE Terminations and gland fittings are outside the scope of this standard.

Typical applications include, but are not limited to:

• surface heating installed in or under surfaces;

• direct and storage heating;

• snow melting and frost protection of roofs, gutters, pipes, etc.

Heating cables Electrical resistance trace heating systems for industrial and commercial

applications are specified in the IEC 62395 series [1] and for explosive atmospheres

applications in the IEC/IEEE 60079-30 series [2], as are mineral insulated heating cables.

Applications in which the operating sheath temperature exceeds 100 °C are outside the scope

of this document.

The object of this document is to ensure that electrical resistance heating cables operate safely

under their normal defined conditions of use. This is achieved by:

• employing heating cables of the appropriate construction that meet the test criteria detailed

in this document;

• including, for heating cables with an electrical protective component, a metallic braid,

concentric wires or sheath, or other suitable electrically conductive material for protective

purposes in case of fault;

• ensuring that the heating cables operate at safe temperatures with respect to the materials

used in the construction of the cables and their installations according to national

regulations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

____________

Numbers in square brackets refer to the bibliography.

– 8 – IEC 60800:2021 RLV © IEC 2021

IEC 60050-461, International Electrotechnical Vocabulary (IEV) – Part 461: Electric cables

(available at http://www.electropedia.org)

IEC 60228, Conductors of insulated cables

IEC 60332-1-1, Tests on electric and optical fibre cables under fire conditions – Part 1-1: Test

for vertical flame propagation for a single insulated wire or cable – Apparatus

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60364-7-701, Low-voltage electrical installations – Part 7-701: Requirements for special

installations or locations – Locations containing a bath or shower

IEC 60364-7-753, Low-voltage electrical installations – Part 7-753: Requirements for special

installations or locations – Heating cables and embedded heating systems

IEC 62230, Electric cables – Spark test method

IEC 60811-1-1, Common test methods for insulating and sheathing materials of electric cables

and optical cables – Part 1-1: Methods for general application –Measurement of thickness and

overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

and optical cables – Part 1-2: Methods for general application – Thermal ageing methods

Amendment 1 (1989)

Amendment 2 (2000)

IEC 60811-1-3, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 1-3: General application – Methods for determining the density – Water

absorption tests – Shrinkage test

IEC 60811-1-4, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 1-4: Methods for general application – Tests at low temperature

IEC 60811-2-1, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 2-1: Methods specific to elastomeric compounds – Ozone resistance, hot

set and mineral oil immersion tests

IEC 60811-3-1, Common test methods for insulating and sheathing materials of electric and

optical cables – Part 3-1: Methods specific to PVC compounds – Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in air oven

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials-

Part 502: Mechanical tests – Shrinkage test for insulations

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 62395-1:20062013, Electrical resistance trace heating systems for industrial and

commercial applications – Part 1: General and testing requirements

ISO 4892-3:20062016, Plastics – Methods of exposure to laboratory light sources – Part 3:

Fluorescent UV lamps

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-461 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

armouring

mechanical reinforcement of the heating cable

Note 1 to entry: The reinforcement can be made of one or more layers of steel wires or braid, or of a metallic sheath

or other suitable material.

3.2

cold lead

electrically insulated conductor or conductors used to connect a heating cable to the branch

circuit and designed so that it does not produce significant heat

3.3

connection splice

sealed splice, connecting the heating cable to the cold lead, or an identical heating cable

3.4

earthing conductor

uninsulated conductor (drain wire) which is in good electric contact with the electrical screen

along practically the whole length

– 10 – IEC 60800:2021 RLV © IEC 2021

3.5

electrically conductive screen

metallic braid, concentric wires, metallic sheath, or alternative covering with sufficient

conductivity so that, when bonded to ground, will cause a residual current device (RCD) to

operate under fault conditions

3.6

end termination

sealed termination, which may be heat producing, connected to the heating cable at the end

opposite to that where the power is supplied

3.7

factory assembled unit or heating cable set

heating cable, including the necessary integral components, set (unit) supplied with

components, which are assembled by the manufacturer

3.8

field assembled unit or set heating cable

heating cable supplied in bulk, with the integral components to be assembled at the work site

during installation

3.9

heating cable

cable, with or without an electrically conductive screen, metallic or equivalent, sheath or armour

intended for emitting heat for heating purposes

3.10

heating cable set

heating cable with suitable power connection and end termination included

3.11

heating conductor

part of a serial heating cable in which the electrical energy is transformed into heat

3.12

insulation

material which insulates each conductor from other conductors or from conducting parts at earth

potential

3.13

integral components

factory-fabricatedassembled or field-assembled electrical terminations and connections, such

as heat shrink terminations, moulded end seals or splices, which conform to the general shape

of the heating cable and are exposed to the same environments as the heating cable

3.14

linear power density

power output in watts per linear metre for the heating cable and heating cable sets

3.15

operating conductor temperature

highest allowable continuous temperature of the cable conductor

3.16

operating surface temperature

highest allowable continuous temperature of the cable surface

3.17

operating voltage

actual voltage applied to the heating cable when in service

3.18

rated temperature

temperature assigned to any insulated and sheathed cable which does not result in either the

insulation or the sheath being operated in excess of the appropriate operating surface

temperature

3.14

maximum sheath temperature

maximum temperature of the outermost covering of a heating cable

3.15

nominal voltage

actual voltage applied to the heating cable when in service

3.16

parallel heating cable

heating elements electrically connected in parallel, with the heating element either continuous

or in discrete units or zones, such that the watt density per unit length is not significantly

changed with any change in circuit length

3.17

rated resistance of individual conductor(s)

resistance at 20 °C of 1 m of cable conductor

Note 1 to entry: Most heating cables contain more than one conductor and the resistance is measured for all

conductors.

3.18

rated voltage

highest allowable voltage between the conductors in a twin and multi conductor cable, or

between one conductor and an electrical conductive screen, or between the two ends of a single

core cable, or earth in unscreened cables

reference voltage for which the heating cable is designed

Note 1 to entry: The rated voltage is expressed by the combination of two values U /U, expressed in volts:

U being the RMS value between any insulated conductor and "earth" (metal covering of the cable or the

surrounding medium);

U being the RMS value between any two-phase conductors of a multicore cable or of a system of single-core

cables.

Note 2 to entry: See IEC 62440:2008, 5.2 [3].

3.19

routine test

test made by the manufacturer on each manufactured length of cable to check that each length

meets the specified requirements

3.20

sample test

test made by the manufacturer on samples of completed cable or components taken from a

complete cable, at specified frequency, so as to verify that the finished product meets the

specified requirements

– 12 – IEC 60800:2021 RLV © IEC 2021

3.21

sheath

uniform and continuous tubular covering, metallic or non-metallic, enclosing the insulated

conductor(s), used for mechanical protection and to protect the cable against influences from

the surroundings (corrosion, moisture etc.)

3.22

type test

test made before supplying, on a general commercial basis, a type of cable covered by this

document, in order to demonstrate satisfactory performance characteristics to meet the

intended application

Note 1 to entry: These Type tests are of such a nature that, after they have been made, they need not be repeated,

unless changes are made in the cable materials or design or manufacturing process which might change the

performance characteristics.

4 Mechanical classification

The heating cables in this document have been divided into two classes which indicate their

ability to withstand mechanical forces during and after installation. These classes are as follows:

– mechanical class M1: for heating cables intended for installation with low risk of mechanical

damage;

– mechanical class M2: for heating cables intended for installation with higher risk of

mechanical damage.

The class of any heating cable is determined by its performance as measured against the

requirements in 8.2.7, 8.2.8 and 8.2.14.

NOTE 1 Mechanical class M1: for heating cables intended for use in applications with low risk of mechanical

damage, as for example installed the installation on even surfaces like flat, smooth sub-floors of concrete or wooden

materials or thermal insulations, embedded in screeds with no sharp objects, etc.

NOTE 2 Mechanical class M2: for heating cables intended for use in applications with higher risk of mechanical

damage, such as the installation on steel reinforcing grids, direct embedding in soil, in concrete with sharp objects,

on roofs and gutters, etc.

5 Requirements for marking

The product shall be marked identified by printing, embossing or indenting on the sheath or on

a label attached to the product or on a component inside the heating cable.

NOTE 1 Embossing is shall not recommended be used on the insulation.

A label shall be attached to the product in a permanent way and be clearly detectable to the

electrical installer.

NOTE 2 The label should preferably shall be attached to the part of the product which is clearly

visible when unpacking the product ready for installation.

The marking shall at least contain:

• the identification of the manufacturer by name and/or a symbol;

• the type reference;

• the resistance per metre of heating cable at 20°C in ohms per metre if for single or twin

conductor series resistive heating cables, or and for a parallel heating cable, the power

output in watts per metre at a reference temperature. For series resistive cables with more

than two conductors the resistance of each conductor shall be clearly marked This is not

required for heating cable sets;

• the mechanical classification;

• the rated voltage for parallel heating cables or maximum operating nominal voltage for

series heating cables;

• if applicable, “only for installation in concrete” the indication "not flame-retardant".

The distance between the end of one complete set of marks and the beginning of the next shall

not exceed:

– 550 mm, if the marking is on the sheath;

– 275 mm, if the marking is on a component inside the heating cable.

If the units are factory assembled, the following additional information shall be provided:

For series resistive units sets:

– nominal voltage;

– total wattage and wattage per metre;

– total resistance.

For parallel resistive units sets:

– nominal voltage;

– power output in watts per metre at a reference temperature or total wattage.

Printed marking shall be durable. Compliance with this requirement shall be checked by the

test given in 8.2.21.

The above are the minimum requirements and suppliers are free to add any additional

information which may be useful, such as the following:

Traceability identification shall be added such as week and year of manufacture, or batch

number.

NOTE 3 Traceability is recommended, for example week/year.

NOTE 4 National or regional regulations may can give other requirements.

6 Requirements for installation instructions

The manufacturer shall provide product-specific installation instructions for heating cables,

heating cable sets and components. The instructions shall be clearly identified as to the

products and locations that apply, and shall include the following information:

a) the intended use(s), either by general application type or by specific listed application;

b) a means of isolating all line conductors from the supply;

c) the indication that over-current protection is provided;

d) the statement "Residual current device (RCD) protection having a residual current not

exceeding 30 mA is required";

e) for mechanical classification M1 heating cables, intended for reduced levels of mechanical

forces, the statement "Caution: Do not use in areas subject to high mechanical loads or

impact";

f) an applicable statement to indicate that any metal sheath, braid, screen or equivalent

electrically conductive covering of the heating cable shall be connected to an earth terminal;

g) if unscreened heating cables are installed, the indication that they shall be covered by an

electrically earthed mesh or equivalent and protected by a 30 mA RCD according to the

installation standard. See also IEC 60364-7-701 and IEC 60364-7-753;

– 14 – IEC 60800:2021 RLV © IEC 2021

h) minimum installation temperature;

i) minimum bending radius;

j) maximum sheath temperature, if applicable;

k) the a statement such as: "The presence of the heating cable shall be made evident by the

posting of caution signs or markings, such as in the fuse box, at appropriate locations, such

as at the power connection fittings and/or at frequent intervals along the circuit and be part

of any electrical documentation following the installation";

l) if applicable, the statement "The heating cable shall only be installed in concrete or other

non-combustible materials".

m) for series resistive heating cables with more than two conductors, the indication that the

resistance of each conductor shall be given.

The above are the minimum requirements and suppliers are free to add any additional

information which may be useful.

NOTE National regulations, or in their absence, the IEC 60364 series [4], may can give other additional

requirements.

7 General requirements for construction of heating cables

7.1 General

The heating cables shall be designed and constructed so as to give electrical, thermal and

mechanical durability, and so that, in normal use, their performance is without danger to the

user or surroundings.

Tapes, fillers, filler strings, etc. may be used in the heating cable.

All integral components shall comply with this document. All others shall comply with relevant

product standards.

Compliance is checked by all the requirements and tests specified in this document.

It is presupposed that all exposed parts of a heating cable and heating cable set intended for

use in contact with potable tap water shall be are constructed of materials that meet relevant

national or local requirements.

7.2 Conductors

Conductors shall consist of one or more wires of pure or alloyed metal, or other suitable

material. In the case of conductors consisting of pure copper coated with a metallic coating, the

metallic coating shall be appropriate to the conductor operating temperature.

The resistance of the heating conductors at 20 °C ± 1 °C shall be in accordance with the values

+10

given by the manufacturer with a maximum tolerance of %.

−5

The heating conductor-material used shall not have a negative temperature coefficient of

resistance. Compliance shall be checked according to the test in 8.2.1.

7.3 Insulation

The insulating materials used in heating cables shall be suitable for the intended use. This shall

be verified by meeting the tests and the requirements given in this document.

The minimum average mean value of the insulation thickness shall be stated by the

manufacturer and measured in accordance with IEC 60811-1-1 IEC 60811-201, and meet the

minimum requirements specified in 8.3.4.

7.4 Electrically conducting screen

When applicable and required, heating cables shall be provided with an evenly distributed

electrically conductive metallic screen, or electrically conductive metallic sheath, tape or

laminate or other suitable electrically conductive material. The metallic screen or electrically

conductive material shall enable protection device(s) to operate as intended.

NOTE 1 For heating cables without an electrically conducting screen, additional national requirements may can

apply.

The resistance of the conductive sheath or screen, inclusive of a separate earthing conductor

which shall be in contact with the sheath or screen, shall be not higher than the resistance of

each conductor in the heating cable or higher than the resistance of a plain copper conductor

having a 0,5 mm cross-sectional area as given for a class 1 conductor according to IEC 60228,

whichever is the lesser. The combined resistance of any earthing conductor included with this

screen or sheath shall not be greater than that of a 0,5 mm copper conductor. A number of

copper wires may be included in order to comply with the requirements.

NOTE 2 In some countries, national regulations require the resistance to be less than that of 0,5 mm copper

conductors.

Compliance shall be checked as described in 8.2.1.

If a conductive sheath or screen alone is used as the earthing conductor, the resistance

measured shall be the total resistance including the earthing connections delivered with the

cable connection wire (drain wire).

Electrically conductive screens shall be so constructed as to prevent the penetration of foreign

substances greater than 1 mm in diameter into the insulation without touching the screen.

Compliance shall be checked by the test specified in 8.2.5.

7.5 Armouring

Separate armouring, if any, may consist of metallic or non-metallic wires, sheath, tape or

laminate. If metallic, it shall not be applied directly on to the metallic sheath if any, but shall be

separated from this by a protective layer of suitable insulating material which can withstand the

mechanical abuse and the temperatures which can occur under normal use, and protects the

metallic sheath against corrosion.

Electrically conductive armouring shall be so constructed as to prevent the penetration of

foreign substances greater than 1 mm in diameter into the insulation without touching the

armouring. Compliance shall be checked by the test specified in 8.2.5.

If the armouring is based on a conductive material the same requirements as specified for the

electrically conductive screen shall apply.

NOTE National regulations may can give other requirements.

7.6 Sheath

The sheathing materials used in heating cables shall be suitable for the intended use. This shall

be verified by meeting the tests and the requirements given in this document. A non-metallic

outer sheath shall give mechanical and/or corrosion protection dependent on the type of heating

cable.

The minimum average mean value of the sheath thickness shall be stated by the manufacturer

and measured in accordance with IEC 60811-1-1 IEC 60811-202, and meet the minimum

requirements specified in 8.3.5.

– 16 – IEC 60800:2021 RLV © IEC 2021

7.7 Moisture resistance

Heating cables shall comply with the requirements as stated in 8.2.2.

NOTE This requirement is regarded at least comparable with class IPX7 as defined in IEC 60529 [5].

8 Testing

8.1 Type tests – General requirements

All described routine and sample tests shall be included in the type test, except for the spark

test specified in 8.3.1.

For heating cables intended to be supplied in bulk, a sample of suitable length, for example a

5 m sample of the heating cable, shall be used for testing, if not otherwise specified.

For heating cable sets which are factory assembled, including cold lead, connection splice and

end seal termination, the complete heating cable set shall be used for testing. Alternatively, a

5 m sample of heating cable may be tested. The various parts (components) such as cold lead,

connection splice and end termination may be assembled on a dummy length of heating cable

and tested separately.

For heating cables intended to be field assembled, the cold lead, connection splice and end

terminations to be used and specified by the manufacturer shall be assembled, according to

the manufacturer’s instructions, with the heating cable to form a heating cable set. The complete

heating cable set shall be tested. Alternatively, a 5 m sample of heating cable may be tested.

The various parts such as cold lead, connection splice and end termination may be assembled

on a 5 m dummy length of heating cable and tested separately, if not otherwise specified.

All sample components used shall be typical examples from what is supplied to the market or

intended to be supplied to the market.

Tests shall be conducted at a room temperature between 20 °C and 25 (23 ± 5) °C, unless

otherwise specified.

Unless otherwise specified, the test voltage shall be alternating current at a frequency between

49 Hz and 61 Hz of approximately sinusoidal waveform.

For a parallel resistive heating cable, the power output in watts per metre shall be checked

according to the test in 8.2.3.

For a parallel resistive heating cable, the start-up current shall be checked according to the test

in 8.2.4.

Separate samples may be used for each test unless otherwise specified. These shall be

prepared in accordance with the manufacturer’s recommendations.

If a sample does not meet a specified requirement, two new complete sets of samples shall be

tested. If both pass the test requirement, the cable shall be deemed to meet the test.

8.2 Type tests – Detailed test requirements

8.2.1 Electrical resistance of heating conductors and screen

The resistance of the conductor(s) and screen, if any, shall be measured by any suitable means

on samples at least 1,0 m long. Two measurements shall be taken for the each individual

conductor, the first at ambient temperature and the second at a temperature of (100 ± 2) °C.

The measurement at ambient temperature, corrected to (20 ± 1) °C, shall determine whether or

not the resistance value specified by the manufacturer has been achieved, both for the

conductors and the screen.

The measurement at the higher temperature shall be compared with that at ambient temperature

to confirm that the each individual conductor(s) does not have a negative temperature

coefficient of resistance.

8.2.2 Water immersion and temperature cycling test

8.2.2.1 General remark

A (5 ± 0,1) m sample shall be subjected to two ageing cycles a cycle ageing test and shall be

immersed for a total of 56 h in potable tap water at a temperature of (20 ± 5) °C for 8 h,

(80 ± 5) °C for 16 h, (20 ± 5) °C for 8 h, (80 ± 5) °C for 16 h and (20 ± 5) °C for 8 h, i.e. 8 h +

16 h + 8 h + 16 h + 8 h. The sample shall be transferred to preheated water containers between

each sub-cycle. The temperature in the water containers must shall be controlled, for example

by placing them in preheated cabinets in accordance with IEC 60811-1-2 IE

...

IEC 60800 ®

Edition 4.0 2021-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Heating cables with a rated voltage up to and including 300/500 V for comfort

heating and prevention of ice formation

Câbles chauffants de tension assignée jusques et y compris 300 V/500 V pour le

chauffage des locaux et la protection contre la formation de glace

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC online collection - oc.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 000 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 18 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 000 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 16 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC online collection - oc.iec.ch

IEC 60800 ®

Edition 4.0 2021-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Heating cables with a rated voltage up to and including 300/500 V for comfort

heating and prevention of ice formation

Câbles chauffants de tension assignée jusques et y compris 300 V/500 V pour le

chauffage des locaux et la protection contre la formation de glace

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20 ISBN 978-2-8322-1042-3

– 2 – IEC 60800:2021 © IEC 2021

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Mechanical classification . 11

5 Requirements for marking . 11

6 Requirements for installation instructions . 12

7 General requirements for construction of heating cables . 13

7.1 General . 13

7.2 Conductors . 13

7.3 Insulation . 14

7.4 Electrically conducting screen . 14

7.5 Armouring . 14

7.6 Sheath . 14

7.7 Moisture resistance . 14

8 Testing . 15

8.1 Type tests – General requirements . 15

8.2 Type tests – Detailed test requirements . 15

8.2.1 Electrical resistance of heating conductors and screen . 15

8.2.2 Water immersion and temperature cycling test . 16

8.2.3 Verification of rated output for parallel heating cables . 17

8.2.4 Verification of start-up current for parallel heating cables . 17

8.2.5 Penetration test for electrically conductive screen . 17

8.2.6 Flammability test . 18

8.2.7 Deformation test for installation classification . 19

8.2.8 Cold impact test . 20

8.2.9 Cold bend test . 21

8.2.10 Ageing test for insulation . 22

8.2.11 Ageing test for non-metallic sheath . 22

8.2.12 Compatibility test . 22

8.2.13 Weathering and UV resistance test . 22

8.2.14 Tensile test . 23

8.2.15 Reverse winding test . 24

8.2.16 Heat shock test . 24

8.2.17 Shrinkage test for insulation and sheath . 25

8.2.18 Hot set test . 25

8.2.19 Cyclic ageing test for the heating cable . 25

8.2.20 Cyclic ageing test for splices and end seals . 26

8.2.21 Checking of the durability of markings . 26

8.2.22 Pressure test at high temperature for insulation and sheath . 26

8.3 Routine and sample tests . 27

8.3.1 General remarks . 27

8.3.2 Voltage test . 27

8.3.3 Heating cable resistance and output verification . 27

8.3.4 Insulation thickness . 27

8.3.5 Sheath thickness . 27

8.3.6 Hot set test . 28

Annex A (normative) Weathering and UV resistance test . 29

Bibliography . 30

Figure 1 – Typical arrangement for splice testing . 18

Figure 2 – Typical arrangement for end seal testing . 19

Figure 3 – Cold bend test . 21

Figure 4 – Jaws for tensile machine . 24

– 4 – IEC 60800:2021 © IEC 2021

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HEATING CABLES WITH A RATED VOLTAGE UP TO

AND INCLUDING 300/500 V FOR COMFORT HEATING AND

PREVENTION OF ICE FORMATION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60800 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This fourth edition cancels and replaces the third edition published in 2009. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modification of the title: "up to and including", has been introduced;

b) update of IEC 60811 references;

c) introduction of a test for mechanical properties of sheaths after the water immersion and

temperature cycling test;

d) introduction of a weathering and UV resistance test according to ISO 4892-2:2013, Annex A.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/1972/FDIS 20/1991/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60800:2021 © IEC 2021

INTRODUCTION

This document is intended to provide a comprehensive overview of the essential requirements

and testing appropriate to electrical resistance heating cables used for comfort heating and

prevention of ice formation. While some of this work already exists in national standards or

international standards, this document has collated much of this existing work.

This document provides a means to verify the electrical, thermal and mechanical durability of

resistive heating cables, so that in normal use their performance is without danger to the user

or surroundings. Compliance is checked by carrying out all the tests specified in this document.

HEATING CABLES WITH A RATED VOLTAGE UP TO

AND INCLUDING 300/500 V FOR COMFORT HEATING AND

PREVENTION OF ICE FORMATION

1 Scope

This document is applicable to, and specifies requirements for resistive heating cables for low

temperature applications such as comfort heating and the prevention of ice formation. These

heating cables and heating cable sets can comprise either factory assembled or field (work-

site) assembled units, and are heating cables assembled in accordance with manufacturer’s

instructions.

Bare conductors and protected conductors to be supplied at voltages equal to, or less than,

50 V are excluded from the scope of this document.

Typical applications include, but are not limited to:

• surface heating installed in or under surfaces;

• direct and storage heating;

• snow melting and frost protection of roofs, gutters, pipes, etc.

Electrical resistance trace heating systems for industrial and commercial applications are

specified in the IEC 62395 series [1] and for explosive atmospheres applications in the

IEC/IEEE 60079-30 series [2], as are mineral insulated heating cables.

Applications in which the sheath temperature exceeds 100 °C are outside the scope of this

document.

The object of this document is to ensure that electrical resistance heating cables operate safely

under their normal defined conditions of use. This is achieved by:

• employing heating cables of the appropriate construction that meet the test criteria detailed

in this document;

• including, for heating cables with an electrical protective component, a metallic braid,

concentric wires or sheath, or other suitable electrically conductive material for protective

purposes in case of fault;

• ensuring that the heating cables operate at safe temperatures with respect to the materials

used in the construction of the cables and their installations according to national

regulations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-461, International Electrotechnical Vocabulary (IEV) – Part 461: Electric cables

(available at http://www.electropedia.org)

____________

Numbers in square brackets refer to the bibliography.

– 8 – IEC 60800:2021 © IEC 2021

IEC 60228, Conductors of insulated cables

IEC 60332-1-1, Tests on electric and optical fibre cables under fire conditions – Part 1-1: Test

for vertical flame propagation for a single insulated wire or cable – Apparatus

IEC 60332-1-2, Tests on electric and optical fibre cables under fire conditions – Part 1-2: Test

for vertical flame propagation for a single insulated wire or cable – Procedure for 1 kW pre-

mixed flame

IEC 60364-7-701, Low-voltage electrical installations – Part 7-701: Requirements for special

installations or locations – Locations containing a bath or shower

IEC 60364-7-753, Low-voltage electrical installations – Part 7-753: Requirements for special

installations or locations – Heating cables and embedded heating systems

IEC 62230, Electric cables – Spark test method

IEC 60811-201, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 201: General tests – Measurement of insulation thickness

IEC 60811-202, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 202: General tests – Measurement of thickness of non-metallic sheath

IEC 60811-401, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 401: Miscellaneous tests – Thermal ageing methods – Ageing in air oven

IEC 60811-501, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 501: Mechanical tests – Tests for determining the mechanical properties of insulating and

sheathing compounds

IEC 60811-502, Electric and optical fibre cables – Test methods for non-metallic materials-

Part 502: Mechanical tests – Shrinkage test for insulations

IEC 60811-503, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 503: Mechanical tests – Shrinkage test for sheaths

IEC 60811-506, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 506: Mechanical tests – Impact test at low temperature for insulations and sheaths

IEC 60811-507, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 507: Mechanical tests – Hot set test for cross-linked materials

IEC 60811-508, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 508: Mechanical tests – Pressure test at high temperature for insulation and sheaths

IEC 60811-509, Electric and optical fibre cables – Test methods for non-metallic materials –

Part 509: Mechanical tests – Test for resistance of insulations and sheaths to cracking (heat

shock test)

IEC 62395-1:2013, Electrical resistance trace heating systems for industrial and commercial

applications – Part 1: General and testing requirements

ISO 4892-3:2016, Plastics – Methods of exposure to laboratory light sources – Part 3:

Fluorescent UV lamps

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-461 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

armouring

mechanical reinforcement of the heating cable

Note 1 to entry: The reinforcement can be made of one or more layers of steel wires or braid, or of a metallic sheath

or other suitable material.

3.2

cold lead

electrically insulated conductor or conductors used to connect a heating cable to the branch

circuit and designed so that it does not produce significant heat

3.3

connection splice

sealed splice, connecting the heating cable to the cold lead, or an identical heating cable

3.4

earthing conductor

uninsulated conductor (drain wire) which is in good electric contact with the electrical screen

along the length

3.5

electrically conductive screen

metallic braid, concentric wires, metallic sheath, or alternative covering with sufficient

conductivity so that, when bonded to ground, will cause a residual current device (RCD) to

operate under fault conditions

3.6

end termination

sealed termination, which may be heat producing, connected to the heating cable at the end

opposite to that where the power is supplied

3.7

factory assembled heating cable set

heating cable set (unit) supplied with components, which are assembled by the manufacturer

3.8

field assembled heating cable

heating cable supplied in bulk with components to be assembled during installation

3.9

heating cable

cable, with or without an electrically conductive screen, metallic or equivalent, sheath or armour

intended for emitting heat for heating purposes

– 10 – IEC 60800:2021 © IEC 2021

3.10

heating cable set

heating cable with suitable power connection and end termination included

3.11

heating conductor

part of a serial heating cable in which the electrical energy is transformed into heat

3.12

insulation

material which insulates each conductor from other conductors or from conducting parts at earth

potential

3.13

integral components

factory-assembled or field-assembled electrical terminations and connections, such as heat

shrink terminations, moulded end seals or splices, which conform to the general shape of the

heating cable and are exposed to the same environments as the heating cable

3.14

maximum sheath temperature

maximum temperature of the outermost covering of a heating cable

3.15

nominal voltage

actual voltage applied to the heating cable when in service

3.16

parallel heating cable

heating elements electrically connected in parallel, with the heating element either continuous

or in discrete units or zones, such that the watt density per unit length is not significantly

changed with any change in circuit length

3.17

rated resistance

resistance at 20 °C of 1 m of conductor

Note 1 to entry: Most heating cables contain more than one conductor and the resistance is measured for all

conductors.

3.18

rated voltage

reference voltage for which the heating cable is designed

Note 1 to entry: The rated voltage is expressed by the combination of two values U /U, expressed in volts:

U being the RMS value between any insulated conductor and "earth" (metal covering of the cable or the

surrounding medium);

U being the RMS value between any two-phase conductors of a multicore cable or of a system of single-core

cables.

Note 2 to entry: See IEC 62440:2008, 5.2 [3].

3.19

routine test

test made by the manufacturer on each manufactured length of cable to check that each length

meets the specified requirements

3.20

sample test

test made by the manufacturer on samples of completed cable or components taken from a

complete cable, at specified frequency, so as to verify that the finished product meets the

specified requirements

3.21

sheath

uniform and continuous covering, metallic or non-metallic, enclosing the insulated conductor(s),

used for mechanical protection and to protect the cable against influences from the

surroundings

3.22

type test

test made before supplying, on a general commercial basis, a type of cable covered by this

document, in order to demonstrate satisfactory performance characteristics to meet the

intended application

Note 1 to entry: Type tests are of such a nature that, after they have been made, they need not be repeated, unless

changes are made in the cable materials or design or manufacturing process which might change the performance

characteristics.

4 Mechanical classification

The heating cables in this document have been divided into two classes which indicate their

ability to withstand mechanical forces during and after installation. These classes are as follows:

– mechanical class M1: for heating cables intended for installation with low risk of mechanical

damage;

– mechanical class M2: for heating cables intended for installation with higher risk of

mechanical damage.

The class of any heating cable is determined by its performance as measured against the

requirements in 8.2.7 and 8.2.14.

NOTE 1 Mechanical class M1: for heating cables intended for use in applications with low risk of mechanical

damage, for example the installation on even surfaces like flat, smooth sub-floors of concrete or wooden materials

or thermal insulations, embedded in screeds with no sharp objects.

NOTE 2 Mechanical class M2: for heating cables intended for use in applications with higher risk of mechanical

damage, such as the installation on steel reinforcing grids, direct embedding in soil, in concrete with sharp objects,

on roofs and gutters.

5 Requirements for marking

The product shall be identified by printing, embossing or indenting on the sheath or on a label

attached to the product or on a component inside the heating cable.

Embossing shall not be used on the insulation.

A label shall be attached to the product in a permanent way and be clearly detectable to the

electrical installer.

The label shall be attached to the part of the product which is clearly visible when unpacking

the product ready for installation.

– 12 – IEC 60800:2021 © IEC 2021

The marking shall at least contain:

• the identification of the manufacturer by name and/or a symbol;

• the type reference;

• the resistance per metre of heating cable at 20°C in ohms per metre for single or twin

conductor series resistive heating cables and for a parallel heating cable, the power output

in watts per metre at a reference temperature. This is not required for heating cable sets;

• the mechanical classification;