IEC 62343-2:2014

(Main)Dynamic modules - Part 2: Reliability qualification

Dynamic modules - Part 2: Reliability qualification

IEC 62343-2:2014 applies to dynamic modules and devices (DMs) which are commercially available. Examples are tuneable chromatic dispersion compensators, wavelength selective switches and optical channel monitors. Optical amplifiers are not included in this list, but are treated in IEC 61291-5-2. For reliability qualification purposes, some information about the internal components, parts and interconnections is needed; these internal parts are treated as black boxes. This standard gives requirements for the evaluation of DM reliability by combining the reliability of such internal black boxes. The objectives of this standard are the following:

- to specify the requirements for the reliability qualification of DMs;

- to give the minimum list of reliability qualification tests, requirements on failure criteria during testing and on reliability predictions, and give the relevant normative references. This second edition cancels and replaces the first edition published in 2011 and constitutes a technical revision. The main change with respect to the previous edition is the addition of Annex A (informative), Reliability test items and their conditions. Keywords: dynamic modules and devices (DMs), tuneable chromatic dispersion compensators, wavelength selective switches, optical channel monitors

Modules dynamiques - Partie 2: Qualification de fiabilité

L'IEC 62343-2:2014 s'applique aux dispositifs et aux modules dynamiques disponibles sur le marché. Les exemples suivants peuvent être donnés:

- compensateurs de dispersion chromatique accordables,

- commutateurs sélectifs en longueur d'onde et

- contrôleurs de canal de transmission optique. Les amplificateurs optiques ne sont pas inclus dans cette liste, mais ils sont traités dans l'IEC 61291-5-2. Dans le cadre de la qualification de fiabilité, certaines informations sur les composants, les constituants et les interconnexions internes sont nécessaires; ces constituants internes sont traités comme des boîtes noires. La présente norme donne les exigences pour l'évaluation de la fiabilité des modules dynamiques en combinant la fiabilité de telles boîtes noires internes. Les objectifs de la présente norme sont les suivants:

- spécifier les exigences pour la qualification de fiabilité des modules dynamiques;

- donner la liste minimale des essais de qualification de fiabilité, les exigences concernant les critères de défaillance pendant un essai et les prévisions de fiabilité, et donner les références normatives appropriées. Cette deuxième édition annule et remplace la première édition parue en 2011 et constitue une révision technique. La principale modification par rapport à l'édition précédente consiste en l'ajout de l'Annexe A (informative), Eléments d'essai de fiabilité et leurs conditions. Mots clés: dispositifs et aux modules dynamiques, compensateurs de dispersion chromatique accordables, commutateurs sélectifs en longueur d'onde, canal de transmission optique.

General Information

- Status

- Replaced

- Publication Date

- 27-Jul-2014

- Technical Committee

- SC 86C - Fibre optic systems, sensing and active devices

- Drafting Committee

- WG 5 - TC 86/SC 86C/WG 5

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 16-Sep-2019

- Completion Date

- 13-Feb-2026

Relations

- Replaced By

IEC 62343-2-1:2019 - Dynamic modules - Part 2-1: Reliability qualification - Test template - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 62343-2:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Dynamic modules - Part 2: Reliability qualification". This standard covers: IEC 62343-2:2014 applies to dynamic modules and devices (DMs) which are commercially available. Examples are tuneable chromatic dispersion compensators, wavelength selective switches and optical channel monitors. Optical amplifiers are not included in this list, but are treated in IEC 61291-5-2. For reliability qualification purposes, some information about the internal components, parts and interconnections is needed; these internal parts are treated as black boxes. This standard gives requirements for the evaluation of DM reliability by combining the reliability of such internal black boxes. The objectives of this standard are the following: - to specify the requirements for the reliability qualification of DMs; - to give the minimum list of reliability qualification tests, requirements on failure criteria during testing and on reliability predictions, and give the relevant normative references. This second edition cancels and replaces the first edition published in 2011 and constitutes a technical revision. The main change with respect to the previous edition is the addition of Annex A (informative), Reliability test items and their conditions. Keywords: dynamic modules and devices (DMs), tuneable chromatic dispersion compensators, wavelength selective switches, optical channel monitors

IEC 62343-2:2014 applies to dynamic modules and devices (DMs) which are commercially available. Examples are tuneable chromatic dispersion compensators, wavelength selective switches and optical channel monitors. Optical amplifiers are not included in this list, but are treated in IEC 61291-5-2. For reliability qualification purposes, some information about the internal components, parts and interconnections is needed; these internal parts are treated as black boxes. This standard gives requirements for the evaluation of DM reliability by combining the reliability of such internal black boxes. The objectives of this standard are the following: - to specify the requirements for the reliability qualification of DMs; - to give the minimum list of reliability qualification tests, requirements on failure criteria during testing and on reliability predictions, and give the relevant normative references. This second edition cancels and replaces the first edition published in 2011 and constitutes a technical revision. The main change with respect to the previous edition is the addition of Annex A (informative), Reliability test items and their conditions. Keywords: dynamic modules and devices (DMs), tuneable chromatic dispersion compensators, wavelength selective switches, optical channel monitors

IEC 62343-2:2014 is classified under the following ICS (International Classification for Standards) categories: 33.180.01 - Fibre optic systems in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62343-2:2014 has the following relationships with other standards: It is inter standard links to IEC 62343-2-1:2019, IEC 62343-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62343-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62343-2 ®

Edition 2.0 2014-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dynamic modules –

Part 2: Reliability qualification

Modules dynamiques –

Partie 2: Qualification de fiabilité

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62343-2 ®

Edition 2.0 2014-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Dynamic modules –

Part 2: Reliability qualification

Modules dynamiques –

Partie 2: Qualification de fiabilité

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 33.180 ISBN 978-2-8322-1799-3

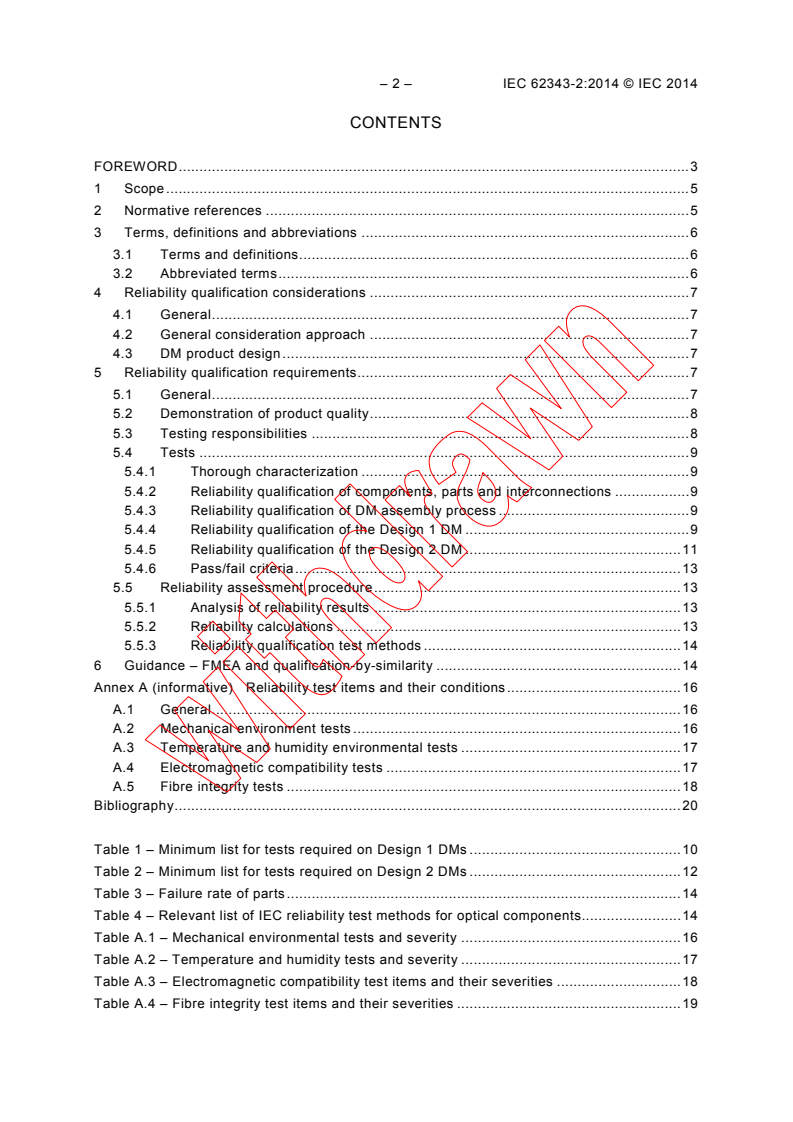

– 2 – IEC 62343-2:2014 © IEC 2014

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms, definitions and abbreviations . 6

3.1 Terms and definitions . 6

3.2 Abbreviated terms . 6

4 Reliability qualification considerations . 7

4.1 General . 7

4.2 General consideration approach . 7

4.3 DM product design . 7

5 Reliability qualification requirements. 7

5.1 General . 7

5.2 Demonstration of product quality . 8

5.3 Testing responsibilities . 8

5.4 Tests . 9

5.4.1 Thorough characterization . 9

5.4.2 Reliability qualification of components, parts and interconnections . 9

5.4.3 Reliability qualification of DM assembly process . 9

5.4.4 Reliability qualification of the Design 1 DM . 9

5.4.5 Reliability qualification of the Design 2 DM . 11

5.4.6 Pass/fail criteria . 13

5.5 Reliability assessment procedure . 13

5.5.1 Analysis of reliability results . 13

5.5.2 Reliability calculations . 13

5.5.3 Reliability qualification test methods . 14

6 Guidance – FMEA and qualification-by-similarity . 14

Annex A (informative) Reliability test items and their conditions . 16

A.1 General . 16

A.2 Mechanical environment tests . 16

A.3 Temperature and humidity environmental tests . 17

A.4 Electromagnetic compatibility tests . 17

A.5 Fibre integrity tests . 18

Bibliography . 20

Table 1 – Minimum list for tests required on Design 1 DMs . 10

Table 2 – Minimum list for tests required on Design 2 DMs . 12

Table 3 – Failure rate of parts . 14

Table 4 – Relevant list of IEC reliability test methods for optical components . 14

Table A.1 – Mechanical environmental tests and severity . 16

Table A.2 – Temperature and humidity tests and severity . 17

Table A.3 – Electromagnetic compatibility test items and their severities . 18

Table A.4 – Fibre integrity test items and their severities . 19

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DYNAMIC MODULES –

Part 2: Reliability qualification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62343-2 has been prepared by subcommittee 86C: Fibre optic

systems and active devices, of IEC technical committee 86: Fibre optics.

This second edition cancels and replaces the first edition published in 2011 and constitutes a

technical revision. The main change with respect to the previous edition is the addition of

Annex A (informative), Reliability test items and their conditions.

The text of this standard is based on the following documents:

CDV Report on voting

86C/1185/CDV 86C/1248/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

– 4 – IEC 62343-2:2014 © IEC 2014

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62343 series, published under the general title Dynamic modules,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

DYNAMIC MODULES –

Part 2: Reliability qualification

1 Scope

This part of IEC 62343 applies to dynamic modules and devices (DMs) which are

commercially available. Examples are tuneable chromatic dispersion compensators,

wavelength selective switches and optical channel monitors.

Optical amplifiers are not included in this list, but are treated in IEC 61291-5-2.

For reliability qualification purposes, some information about the internal components, parts

and interconnections is needed; these internal parts are treated as black boxes. This standard

gives requirements for the evaluation of DM reliability by combining the reliability of such

internal black boxes.

The objectives of this standard are the following:

• to specify the requirements for the reliability qualification of DMs;

• to give the minimum list of reliability qualification tests, requirements on failure criteria

during testing and on reliability predictions, and give the relevant normative references.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 61300-2-1, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 2-1: Tests – Vibration (sinusoidal)

IEC 61300-2-4, Fibre optic interconnecting devices and passive components – Basic test and

measurement procedures – Part 2-4: Tests – Fibre/cable retention

IEC 61300-2-12, Fibre optic interconnecting devices and passive components – Basic test

and measurement procedures – Part 2-12: Tests – Impact

IEC 62005-9-1, Fibre optic interconnecting devices and passive components – Reliability –

Part 9-1: Qualification of passive optical components

IEC 62005-9-2, Reliability of fibre optic interconnecting devices and passive optical

components – Part 9-2: Reliability qualification for single fibre optic connector sets – Single

mode

IEC 62572 (all parts), Fibre optic active components and devices – Reliability standards

ISO 9000: Quality management systems – Fundamentals and vocabulary

___________

To be published.

– 6 – IEC 62343-2:2014 © IEC 2014

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

failure

non-compliance to product specification or change in parameters as set by the standard or

agreed by the customer and supplier

3.1.2

qualification

commonly used as the abbreviation for reliability qualification

Note 1 to entry: It is used as a formal testing to determine whether or not the product is suitable for telecom

applications and, therefore, “pass or fail” is the expected outcome

Note 2 to entry: This is different from a reliability test, which is in nature a reliability “engineering test”. Reliability

tests are designed to understand the reliability consideration or estimate the reliability of the product. Pass or fail is

not the main output.

3.1.3

reliability

< time period > minimum period of DM continuous operation without failure at specified

operating and environmental conditions

3.1.4

probability to perform required functions at specified operating and

environmental conditions

Note 1 to entry: The reliability of a DM is expressed by either of the following two parameters: mean time between

failure (MTBF) and failures in time (FIT):

• the MTBF is the mean period of DM continuous operation without any failure at specified operating and

environmental conditions;

• the FIT is the number of failures expected in 10 device-hours at specified operating and environmental

conditions.

3.2 Abbreviated terms

DM dynamic module

DS detail specification

ESD electrostatic discharge

FIT failure in time

FMEA failure mode and effects analysis

LCD liquid crystal device

MTBF mean time between failure

RH relative humidity

UCL upper confidence level

VOA variable optical attenuators

4 Reliability qualification considerations

4.1 General

Since DMs are relatively new products in the commercial market and involve different

technologies, the requirements included in this standard will need to be reviewed as

technology progresses.

4.2 General consideration approach

It is worth emphasizing the fundamental approach of reliability qualification adopted in this

standard:

a) Any parts that can be effectively qualified on their individual levels shall be qualified at

that level. Their qualification shall be based on IEC standards or other industrial

standards in the absence of such IEC standards.

b) The qualification tests required at DM level shall be based on the degradation

mechanisms and failure modes that cannot be effectively detected in the lower part levels.

At the DM level, the qualification tests shall not attempt to discover or identify those

degradation mechanisms and failure modes that can be discovered in the lower assembly

levels than the final product level. For example, if all parts in the DM can be effectively

tested for damp heat-accelerated degradations, there is no need to repeat the damp heat

test at the DM level.

4.3 DM product design

A DM is an assembly of various components, parts and interconnections. There are two basic

designs in the current commercial DM market:

a) Design 1: parts (as a general term that includes components, parts and interconnections

used to build a DM from the of point of view of this standard) are packaged separately.

Their packages are usually either hermetic or moisture-resistant. They are integrated into

a housing (usually non-hermetic or not moisture-resistant).

b) Design 2: some parts used in DMs are unpackaged basic optical elements (e.g. crystals,

lenses, mirrors, etc.). These parts cannot be effectively qualified by themselves. These

parts/elements are integrated and packaged inside a hermetic box or moisture-resistant

box.

In Design 1, the individual parts can be tested and qualified individually and therefore, the DM

qualification does not have to repeat the tests that are performed in the part levels for the

same degradation mechanisms and failure modes.

In Design 2, the DM qualification is again focused on the tests that cannot be effectively

performed in the lower assembly levels (i.e., the basic part level). However, in this case there

are usually more tests required since the parts cannot be effectively tested at the part level

individually.

Due to the differences in the designs, and therefore different mechanisms and failure modes,

different qualification test approaches have to be developed separately. They are described in

5.4.4 for Design 1 and 5.4.5 for Design 2, respectively.

5 Reliability qualification requirements

5.1 General

For the purpose of this standard, each internal component, part and interconnection shall be

treated as a black box. It is also important to point out that the parts in the DM of this design

include the fibre splicing, fibre routing and fibre anchoring, as well as how the fibre exits from

the housing and how parts are mounted.

– 8 – IEC 62343-2:2014 © IEC 2014

This standard is based on the assumption that the reliability of a DM can be evaluated with

sufficient confidence from the FIT rates of its internal black boxes when the assembly process

of the constituents has been qualified.

There are degradation and failures not due to part failures. An example is the fibre routing

and fibre holders. The quality and reliability of the assembling, for example fibre routing, shall

be assessed and qualified through the process evaluation and qualification. The procedures

to qualify the assembly process are described in 5.4.3.

The internal black boxes often constituting a DM are listed below:

• passive optical components, including patch cords, pigtails, connectors and splices;

• active optical components;

• electronics, including PCBs, electrical connectors, etc.

• others (e.g. fibre splicing, fibre routing and fibre anchoring, as well as how the fibre exits

from the housing and how components are mounted).

The DM manufacturers shall declare the number and type of the internal black boxes

constituting the DM and give the failure rates (in FITs) for each black box.

The DM failure rate shall be calculated by suitably combining the failure rates in FITs of its

black boxes, as described in the 5.5.2. The model and assumptions used in DM failure rate

calculation shall be provided and justified for review, if the DM manufacturer has so requested.

5.2 Demonstration of product quality

Since the reliability qualification tests are performed on a limited number of units, it is

essential to have a quality management system in place to assure that the quality of all units

is consistent. Testing on a limited number of samples will be representative of the production

units to be delivered after the qualification is completed.

This standard (where required by the detailed specification) specifies the minimum mandatory

requirements to assess reliability qualification of a DM and is intended to be part of a total DM

reliability program and quality management system developed and implemented by the DM

manufacturer.

The DM manufacturer shall demonstrate:

• a documented and audited manufacturing process, including the reliability qualification of

purchased parts, in accordance with ISO 9000;

• performance data of production units shall be available for review, and its distribution shall

show processes are under adequate controls;

• a reliability qualification programme, including, for example, accelerated life testing, burn-

in and screening of parts and DMs;

• a reliability qualification maintenance programme to ensure continuity of qualification

status (this can be achieved by means of periodic reliability qualification tests of the

product or similar products);

• a procedure to ensure an appropriate feedback to development and production on

reliability issues.

5.3 Testing responsibilities

The DM manufacturer is responsible for performing reliability qualification testing.

The testing detailed in this standard shall be performed by the DM manufacturer. Additional

testing may be specified in the detailed specification.

5.4 Tests

5.4.1 Thorough characterization

A thorough characterization of the product for its performance (may be beyond those in the

performance specifications) and overall operating conditions (may be beyond those in the

operating condition specifications) shall be performed. The data shall be collected and

analysed (minimal for the mean and standard deviation), and be available for review.

5.4.2 Reliability qualification of components, parts and interconnections

All components, parts, and interconnections used to build DMs shall be qualified according to

the appropriate IEC standards for each of them. The components may include, but are not

limited to, variable optical attenuators (VOAs), taps/splitters, detectors, isolators, circulators,

electronic components, splicing connections (including the packaging or re-coating), crystals,

mirrors, prisms, etc.

If the IEC standards for the parts are under development or not yet available, the IEC

standards for parts of similar failure modes and degradation mechanisms should be adopted.

An analysis of similarity of failure modes and degradation mechanisms shall be provided to

support the approach.

Considerations shall be given to designs that use many pieces of same parts. The failure

rates of such parts may significantly contribute to the overall system failure rate or downtime.

The cumulative degradation from individual parts should also be investigated. The results may

require tests on additional samples or more stringent failure definitions.

Additionally, the pass/fail criteria of the part qualification shall be thoroughly examined to

determine whether or not the part qualification is adequate. For an example, if several 1x2

taps are used in a series design, not only the failure rate but also the degradation is multiplied

(i.e. 0,5 dB pass/fail criterion is multiplied), which may not be acceptable. The pass/fail

criterion of the parts commonly defined as 0,5 dB changes in insertion loss is much too loose

for the needs of a product such as a DM. The assessment of tighter criteria shall be carried

out and the qualification status justified.

5.4.3 Reliability qualification of DM assembly process

Fibre routing and component mounting are both important module assembling processes, and

they can be significant failure rate contributors if they are not done properly. Their designs

and processes shall be thoroughly documented and tested. Any changes shall be supported

by adequate experiment data.

If the fibre routing is thoroughly documented and controlled (e.g. through performance

measurements before and after routing) and the final DM is qualified, the fibre routing process

can be considered as a qualified process and can be used in other similar products to

produce a product that is claimed to be qualified by similarity.

5.4.4 Reliability qualification of the Design 1 DM

As described in 5.1 for Design 1, parts (components used to build a DM) are packaged

separately. Their packages are usually either hermetic or moisture-resistant. They are

integrated into a housing (usually non-hermetic or not moisture-resistant).

A reliability qualification procedure related to the complete DMs is described in Table 1. It

gives the minimum list of tests to be performed on DMs in order to assure reliability.

For the tests, no failures are allowed. The tests can be performed sequentially or in parallel.

For “operational” tests, relevant parameters should be monitored during the test.

– 10 – IEC 62343-2:2014 © IEC 2014

On the basis of the reliability assurance required for the reliability tests for the DM internal

black boxes, the sampling level is generally low (for example a few samples for each DM

type).

In some specific cases the use of adhesives in the DM can be considered as a critical process

and shall require separate qualification. Depending on the possible function of the adhesive

(mechanical anchoring, splice protection, index matching, etc.), the different failure modes

shall be addressed and supported by reliability/qualification data.

The main point in the reliability qualification of the Design 1 DMs is to ensure that the

reliability of each part is not degraded in the manufacturing process used.

Table 1 – Minimum list for tests required on Design 1 DMs

Test Condition Duration Samples

Active high temperature aging 85 °C 2 000 h 3

T /T

op, min op, max

Operational temperature cycling 100 cycles 3

>1 °C/min

100 mm height drop for

a

Drop (impact) <10 kg, 75 mm drop for 10 See table below 3

kg − 25 kg

Non-operational

mechanical test

10 Hz to 55Hz, 1,52 mm,

b

Vibration 2 h per direction 3

1 octave/min

c

Pull 5/10/100 N See table below 3

400 m/s , 5ms for

+/- z-axis,

200 m/s , 5ms for

d

Operational shock 3 times/direction 3

+/- x-axis,

100 m/s , 5 ms for

+/- y-axis

50 Hz to 500 Hz,

20 m/s for z-axis,

d

Operational vibration 2 sweeps/direction 3

10 m/s for x-axis,

5 m/s for y-axis

NOTE A reference to the temperature cycle test method is provided in Clause A.3.

a

Mechanical test: Impact (drop) (IEC 61300-2-12 for drop)

Mass Drop height

kg mm

0 to < 10 100

10 to < 25 75

b

Mechanical test: vibration(sinusoidal, IEC 61300-2-1).

c

Pigtail testing (pull test). The first figure in each row is the outer diameter of the buffered or cabled fibre to

which the specified test conditions apply.

2 mm: 20 N to100 N, 3 times, 5 s pulls

Cable

retention 900 µm 10 N, 3 times, 5 s pulls IEC 61300-2-4

(pull)

250 µm: 5 N, 3 times, 5 s pulls

d

The directions of the x, y and z axes are defined by mounting direction to a board in a equipment (x-axis: the

direction which is according to the front and back of the board to be mounted when the board is installed in a

piece of equipment; y-axis: the direction which is according to the gravity (up and down) of the board to be

mounted when the board is installed in a piece of equipment; z-axis: the direction which is perpendicular to

the board to be mounted.) If a tester cannot define the mounting direction, the test shall be carried out in the

most severe conditions for all directions.

It is essential that the evaluated DMs are entirely representative of standard production and

have passed all the production procedures and/or specified (where applicable in the DS) burn-

in and screening procedures.

Aspects of the test conditions not provided in the present standard are given in the relevant

detail specifications.

5.4.5 Reliability qualification of the Design 2 DM

A reliability qualification procedure related to design 2 DMs is described in Table 2. In this DM

design, Design 2, not all parts can be effectively tested by themselves (see 4.3). Therefore,

many of the long-term environmental tests can only be effectively tested and qualified in the

DM final product assembly level.

For the test, no failures are allowed. The tests can be performed sequentially or in parallel.

For “operational” tests, relevant parameters should be monitored during the test.

For example, some of the parts may have been qualified by the damp heat test but others

may not pass the damp heat test as required for telecommunications applications. Therefore,

the DM units with all the parts assembled shall be tested in damp heat conditions. This may

seem redundant, but it is necessary.

– 12 – IEC 62343-2:2014 © IEC 2014

Table 2 – Minimum list for tests required on Design 2 DMs

Test Condition Duration Samples

Active high temperature aging 85 °C 2 000 h 3

T /T

op, min op, max

Operational temperature cycling 100 cycles 3

>1 °C/min

a

Damp heat 85 °C/85 % RH 500 h 3

100 mm height drop for

b

Drop (impact) <10 kg, and 75 mm drop See table below 3

for 10 kg – 25 kg

Non-operational

mechanical test 10 Hz to 55 Hz,

c

Vibration 2 h per direction 3

1,52mm,1 octave/min

d

Pull 5/10/100 N See table below 3

400 m/s , 5ms for

± z-axis,

200 m/s , 5ms for

e

Operational shock 3 times/direction 3

± x-axis,

100 m/s , 5ms for

± y-axis

50 Hz to 500 Hz,

20 m/s for z-axis

e

Operational vibration 2 sweeps/direction 3

10 m/s for x-axis

5 m/s for y-axis

Hermeticity (checked before and after

∆T = 100 °C 15 cycles

liquid-to-liquid thermal shock)

dummy box

NOTE A reference to the temperature cycle test method is provided in Clause A.3.

a

Damp heat: the damp heat test at 85 °C/85 % RH for 100 h has been advocated by some manufacturers.

These test conditions may be used. Otherwise, the damp heat test at 40 °C/93 % RH for a much longer

duration may be used with the actual duration to be determined by the acceleration factor.

b

Mechanical test: impact (IEC 61300-2-12).

Mass Drop height

kg mm

0 to <10

10 to <25 75

c

Mechanical test: vibration (sinusoidal, IEC 61300-2-1).

d

Pigtail testing (pull test). The first figure in each row is the outer diameter of the buffered or cabled fibre to

which the specified test conditions do apply.

2 mm: 20 N to100 N, 3 times, 5 s pulls

Cable

retention 900 µm: 10 N, 3 times, 5 s pulls IEC 61300-2-4

(pull)

250 µm: 5 N, 3 times, 5 s pulls

e

The direction of the x, y and z axes are defined by mounting direction to a board in a piece of equipment (x-

axis: the direction which is according to the front and back of the board to be mounted when the board is

installed in a piece of equipment; y-axis: the direction which is according to the gravity (up and down) of the

board to be mounted when the board is installed in a piece of equipment; z-axis: the direction which is

perpendicular to the board to be mounted.) If a tester cannot define the mounting direction, the test shall be

done in the most severe conditions for all directions.

It is essential that the evaluated DMs are entirely representative of standard production and

have passed all the production procedures and/or specified (where applicable in the DS) burn-

in and screening procedures.

Aspects of the test conditions not provided in the present standard are given in the relevant

standards.

5.4.6 Pass/fail criteria

It should be noted that the commonly used failure criterion of a drift of higher than 0,5 dB in

insertion loss (IL) is a guideline. For DWDM DMs, such as wavelength blockers, centre

wavelength drift shall be defined as a failure criterion. The actual and practical criteria should

be developed based on the degradation allowed for the expected life of the product. An

example is provided below to illustrate the determination.

EXAMPLE:

• The acceleration factor of the testing condition to the operating condition is 50.

• The beginning-of-life parametric measurement is 1,0 dB below the end-of-life specification.

• Assume the expected life is 20 years.

• Allowed degradation for a 2 000 h testing is: (1,0*50*2 000)/(20*365,25*24) = 0,57 dB.

• Note that IL is not the only parameter considered for pass/fail; other parameters are included.

5.5 Reliability assessment procedure

5.5.1 Analysis of reliability results

The DM customer/SS shall have a procedure to analyse and verify reliability claims of a DM

manufacturer. In particular, the procedure should include the analysis of

• life test data for the complete dynamic module,

• life test data for internal parts,

• environmental test results.

The analysis of results leads to reporting the reliability parameters of the DM for each type of

device or sub-system. Minimum reliability parameters shall be presented as in Table 4 (see

below).

5.5.2 Reliability calculations

A reliability prediction regarding the complete DM is provided by the DM manufacturer, based

on the failure rates (in FIT “failure in time”) of the internal black boxes composed of the DM

(Design 1) or based on the data for the complete DM (Design 2).

The failure rates of the internal black boxes shall be given by the DM manufacturer taking into

account the basic values issued from the cumulated component-hours issued from the

different parts included in DM. The calculations for each internal black box shall be based on

the current standards regarding reliability calculations.

The reliability calculations will also include the wear-out failures. The FIT figures given for

each internal black box shall take into account all expected failure modes.

The FIT figures of the internal black boxes shall be combined to give the failure rate of the

Design 1 DM as explained in Table 3.

– 14 – IEC 62343-2:2014 © IEC 2014

Table 3 – Failure rate of parts

Number of

Element

Measured value (UCL 95 %)

elements

Splice n A FIT (random failure)

2 2

Connector n A FIT (random failure)

3 3

Electronics n A FIT (random failure)

4 4

Active component type 1 n A FIT (random and wear-out failure)

(4+1) (4+1)

Active component type 2 n A FIT (random and wear-out failure)

(4+2) (4+2)

………………………………………… …………………………………………………

Active component type m n A FIT (random and wear-out failure)

(4+m) (4+m)

Other internal component type 1 n A FIT (random failure)

(4+m+1) (4+m+1)

Other internal component type 2 n A FIT (random failure)

(4+m+2) (4+m+2)

………………………………………… ……………………………….

Other internal component type h n A FIT (random failure)

(4+m+h) (4+m+h)

Passive optical component type 1 n A FIT (random failure)

(4+m+h+1) (4+m+h+1)

Passive optical component type 2 n A FIT (random failure)

(4+m+h+2) (4+m+h+2)

………………………………………… ……………………………….

Passive optical component type k n A FIT (wear-out failure)

(4+m+h+k) (4+m+h+k)

Fibre routing

Optical component attachment n A FIT

(4+m+h+k) (4+m+h+k)

Any other failure modes identified in

n A FIT

(4+m+h+k) (4+m+h+k)

FMECA

Total failure rate ∑ A *n

i i I

NOTE n is the number of components of each type included in the DM.

i

5.5.3 Reliability qualification test methods

Table 4 shows a list of normative references relevant reliability qualification tests and test

conditions for constituting components used for DMs.

Table 4 – Relevant list of IEC reliability test methods for optical components

Constituting components IEC reference

(reliability qualification document number)

Passive optical components IEC 62005-9-1

Optical connectors IEC TR 62005-9-2

Active optical components IEC series 62572

6 Guidance – FMEA and qualification-by-similarity

It is worth emphasizing that the reliability assessment or qualification tests shall be based on

the degradation mechanisms and failure modes. The appropriate accelerated tests can be

developed once the degradation mechanisms, failure modes, and their acceleration factors

are understood. To begin with, the failure mode and effects analysis (FMEA) should be

developed. A set of reliability tests should be planned and conducted as the result of FMEA.

The testing results can be used to develop additional tests or refined tests to better

understand the degradation mechanisms or develop the acceleration models.

Where a range of dynamic modules is produced by a DM manufacturer, there may be some

significant similarity between different type codes. A combination of results from different test

programmes, where appropriate, is therefore permitted.

Consideration should be given to the fact that minor differences in technology or processing

can sometimes have a major impact on reliability, whilst not being apparent during quality

assessment.

As a minimum, FMEA shall be carried out for all varieties of products that are considered

“similar” and claimed to be “qualified” by “similarity”. FMEA shall be carried out thoroughly in

order to be an effective tool to consider “qualified-by-similarity”. Its thoroughness can be

checked against the failure mode analysis (FMA), based on manufacturing drop-out and

customer returns.

Evidence should be presented which demonstrates that all results are directly relevant.

– 16 – IEC 62343-2:2014 © IEC 2014

Annex A

(informative)

Reliability test items and their conditions

A.1 General

This annex provides information on reliability test items and conditions for DMs. The tester

can select reliability test items and conditions by referring to the following.

A.2 Mechanical environment tests

Table A.1 shows the severity of test items for the mechanical environmental tests. For a

dynamic module with moving parts, such as MEMS mirrors, it is strongly recommended to test

operating mechanical shock and vibration. Operating mechanical shock and vibration tests

are carried out by monitoring the performance of dynamic modules during the tests. The

transportation vibration and handling drop test should be carried out as packed modules.

Table A.1 – Mechanical environmental tests and severity

Groups Test items Severity References

M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...