IEC 62453-303-1:2009

(Main)Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2

Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2

IEC 62453-303-1:2009 provides information for integrating the PROFIBUS protocol into the FDT interface specification (IEC 62453-2). This part of the IEC 62453 specifies communication and other services.

Spécification des interfaces des outils des dispositifs de terrain (FDT) - Partie 303-1: Intégration des profils de communication - CEI 61784 CP 3/1 et CP 3/2

La CEI 62453-303-1:2009 donne des informations pour intégrer le protocole PROFIBUS dans la spécification d'interface FDT (CEI 62453-2). La présente partie de la CEI 62453 spécifie les services de communication et autres services.

General Information

- Status

- Published

- Publication Date

- 29-Jun-2009

- Technical Committee

- SC 65E - Devices and integration in enterprise systems

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Jun-2009

- Completion Date

- 15-Jul-2009

Relations

- Replaces

IEC PAS 62453-4:2006 - Field Device Tool (FDT) interface specification - Part 4: HART communication - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62453-303-1:2009 is part of the IEC 62453 series (Field Device Tool - FDT) and defines how the PROFIBUS communication profiles (IEC 61784 CP 3/1 and CP 3/2) are integrated into the FDT interface specification (IEC 62453-2). This part specifies protocol-specific communication and supporting services used by Device Type Managers (DTMs) and FDT hosts to access, configure and manage PROFIBUS field devices in industrial automation systems.

Key Topics

- PROFIBUS integration into FDT: mapping PROFIBUS semantics to FDT interfaces and data types.

- Protocol-specific behavior: PROFIBUS device model, configuration and parameterization strategies, and handling of modular vs. monolithic devices.

- Communication profiles: support and handling for DPV0 and DPV1 services (cyclic and acyclic communication).

- DTM services and Process Channel objects: access to instance and device data through standardized DTM services.

- Bus Master Configuration (BMCP): structures and data needed for master and slave configuration and parameter sets.

- Network management & GSD handling: network topology scans, GSD (device description) information and gateway device support.

- Data types and channel parameters: protocol-specific use of general FDT data types, communication and channel parameter definitions.

- Device identification and I&M: structured device identification, topology scan results and device type identification for PROFIBUS.

- Safety integration: provisions for ProfiSafe parameter handling and individual device safety parameters.

Practical Applications

- For DTM developers: provides the specification needed to implement PROFIBUS DTMs that interoperate with FDT hosts.

- For system integrators and automation engineers: ensures consistent configuration, parameterization and diagnostics of PROFIBUS devices within engineering tools.

- For control system and tool vendors: guides integration of PROFIBUS communication profiles into enterprise engineering and asset-management systems.

- For device manufacturers: clarifies how to expose device parameters, identification and network information via FDT-compatible DTMs.

Who Uses This Standard

- Device vendors creating PROFIBUS-compatible DTMs

- Industrial automation tool vendors (FDT hosts, engineering systems)

- System integrators deploying heterogeneous PROFIBUS networks

- QA and test teams validating interoperability in distributed control systems

Related Standards

- IEC 62453-2 (FDT interface specification - core)

- IEC 61784 (PROFIBUS/PROFINET communication profiles) - CP 3/1 and CP 3/2

- PROFIBUS device specification (GSD files and I&M)

This standard is essential for reliable PROFIBUS device integration using FDT technology, enabling unified device configuration, diagnostics and lifecycle management across diverse automation environments. Keywords: FDT, IEC 62453, PROFIBUS, IEC 61784 CP 3/1, CP 3/2, DTM, DPV0, DPV1, GSD, ProfiSafe.

Buy Documents

IEC 62453-303-1:2009 - Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2 Released:6/30/2009 Isbn:9782889107216

IEC 62453-303-1:2009 - Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2

IEC 62453-303-1:2009+AMD1:2016 CSV - Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2 Released:6/22/2016 Isbn:9782832234983

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

Sponsored listings

Frequently Asked Questions

IEC 62453-303-1:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Field device tool (FDT) interface specification - Part 303-1: Communication profile integration - IEC 61784 CP 3/1 and CP 3/2". This standard covers: IEC 62453-303-1:2009 provides information for integrating the PROFIBUS protocol into the FDT interface specification (IEC 62453-2). This part of the IEC 62453 specifies communication and other services.

IEC 62453-303-1:2009 provides information for integrating the PROFIBUS protocol into the FDT interface specification (IEC 62453-2). This part of the IEC 62453 specifies communication and other services.

IEC 62453-303-1:2009 is classified under the following ICS (International Classification for Standards) categories: 25.040.40 - Industrial process measurement and control; 35.100.05 - Multilayer applications; 35.110 - Networking. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62453-303-1:2009 has the following relationships with other standards: It is inter standard links to IEC PAS 62453-4:2006, IEC PAS 62453-5:2006, IEC PAS 62453-3:2006, IEC PAS 62453-2:2006, IEC PAS 62453-1:2006, IEC 62453-303-1:2009/AMD1:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62453-303-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62453-303-1 ®

Edition 1.0 2009-06

INTERNATIONAL

STANDARD

Field device tool (FDT) interface specification –

Part 303-1: Communication profile integration – IEC 61784 CP 3/1 and CP 3/2

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62453-303-1 ®

Edition 1.0 2009-06

INTERNATIONAL

STANDARD

Field device tool (FDT) interface specification –

Part 303-1: Communication profile integration – IEC 61784 CP 3/1 and CP 3/2

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

XA

ICS 25.040.40; 35.100.05; 35.110 ISBN 978-2-88910-721-6

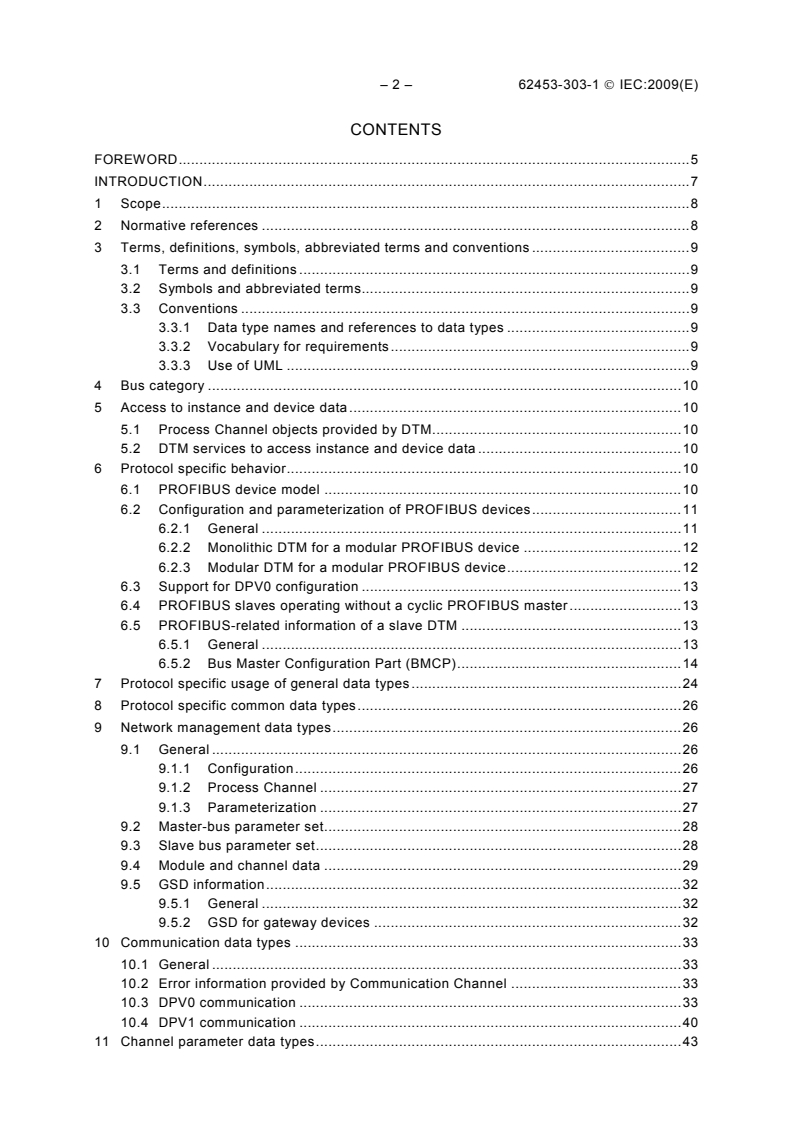

– 2 – 62453-303-1 © IEC:2009(E)

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope.8

2 Normative references .8

3 Terms, definitions, symbols, abbreviated terms and conventions .9

3.1 Terms and definitions .9

3.2 Symbols and abbreviated terms.9

3.3 Conventions .9

3.3.1 Data type names and references to data types .9

3.3.2 Vocabulary for requirements.9

3.3.3 Use of UML .9

4 Bus category .10

5 Access to instance and device data.10

5.1 Process Channel objects provided by DTM.10

5.2 DTM services to access instance and device data .10

6 Protocol specific behavior.10

6.1 PROFIBUS device model .10

6.2 Configuration and parameterization of PROFIBUS devices.11

6.2.1 General .11

6.2.2 Monolithic DTM for a modular PROFIBUS device .12

6.2.3 Modular DTM for a modular PROFIBUS device.12

6.3 Support for DPV0 configuration .13

6.4 PROFIBUS slaves operating without a cyclic PROFIBUS master .13

6.5 PROFIBUS-related information of a slave DTM .13

6.5.1 General .13

6.5.2 Bus Master Configuration Part (BMCP).14

7 Protocol specific usage of general data types .24

8 Protocol specific common data types.26

9 Network management data types.26

9.1 General .26

9.1.1 Configuration.26

9.1.2 Process Channel .27

9.1.3 Parameterization .27

9.2 Master-bus parameter set.28

9.3 Slave bus parameter set.28

9.4 Module and channel data .29

9.5 GSD information.32

9.5.1 General .32

9.5.2 GSD for gateway devices .32

10 Communication data types .33

10.1 General .33

10.2 Error information provided by Communication Channel .33

10.3 DPV0 communication .33

10.4 DPV1 communication .40

11 Channel parameter data types.43

62453-303-1 © IEC:2009(E) – 3 –

12 Device identification .46

12.1 General .46

12.2 Protocol specific handling of the data type STRING.46

12.3 Common device type identification data types .46

12.4 Topology scan data types.51

12.5 Scan identification data types.52

12.6 Device type identification data types – provided by DTM .54

12.7 Identification information in GUI .57

13 ProfiSafe .57

13.1 Motivation .57

13.2 General parameter handling .57

13.3 ProfiSafe individual device parameter .58

Bibliography.60

Figure 1 – Part 303-1 of the IEC 62453 series .7

Figure 2 – FDT PROFIBUS device model.11

Figure 3 – Example for IO data within datagrams.30

Figure 4 – F-Parameter and individual device parameter .58

Figure 5 – Data structure of ProfiSafe individual device parameters.59

Table 1 – Protocol identifiers .10

Table 2 – Physical layer identifiers.10

Table 3 – BMPC Part1 – General configuration.15

Table 4 – BMPC Part2 – Parameter data .15

Table 5 – BMPC Part3 – Configuration data.16

Table 6 – Part 4: Address table and slave user parameters .17

Table 7 – Part 4: Extended Prm data .17

Table 8 – Complete BMCP.18

Table 9 – Protocol specific usage of general data types.24

Table 10 – Bus parameter set for master device .28

Table 11 – Bus parameter set for slave device.29

Table 12 – Signal channels within the data frame .31

Table 13 – Simple DPV0 communication data types.34

Table 14 – Structured DPV0Communication data types .34

Table 15 – Availability of services for Master Class1 (C1).39

Table 16 – Availability of services for Master Class2 (C2).39

Table 17 – Simple DPV1 communication data types.40

Table 18 – Structured DPV1 communication data types .41

Table 19 – Mapping of DPV1 data types to FDT data types.43

Table 20 – Simple ChannelParameter data types.44

Table 21 – Structured ChannelParameter data types .45

Table 22 – Identification data types with Profibus DP specific mapping.47

Table 23 – Identification data types with Profibus I&M specific mapping .48

Table 24 – Identification data types with Profibus PA specific mapping .50

– 4 – 62453-303-1 © IEC:2009(E)

Table 25 – Simple identification data types with protocol independent semantics.51

Table 26 – Structured identification data types with protocol independent semantics .51

Table 27 – Simple topology scan data types .51

Table 28 – Structured topology scan data types.51

Table 29 – Simple scan identification data types.52

Table 30 – Structured scan identification data types .52

Table 31 – Structured device identification data types.55

62453-303-1 © IEC:2009(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIELD DEVICE TOOL (FDT) INTERFACE SPECIFICATION –

Part 303-1: Communication profile integration –

IEC 61784 CP 3/1 and CP 3/2

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62453-303-1 been prepared by subcommittee 65E: Devices and

integration in enterprise systems, of IEC technical committee 65: Industrial-process

measurement, control and automation.

This part, in conjunction with the other parts of the first edition of the IEC 62453 series

cancels and replaces IEC/PAS 62453-1, IEC/PAS 62453-2, IEC/PAS 62453-3, IEC/PAS

62453-4 and IEC/PAS 62453-5 published in 2006, and constitutes a technical revision.

Each part of the IEC 62453-3xy series is intended to be read in conjunction with IEC 62453-2.

– 6 – 62453-303-1 © IEC:2009(E)

The text of this standard is based on the following documents:

FDIS Report on voting

65E/127/FDIS 65E/140/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62453 series, under the general title Field Device Tool (FDT)

interface specification, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

62453-303-1 © IEC:2009(E) – 7 –

INTRODUCTION

This part of IEC 62453 is an interface specification for developers of FDT (Field Device Tool)

components for function control and data access within a client/server architecture. The

specification is a result of an analysis and design process to develop standard interfaces to

facilitate the development of servers and clients by multiple vendors that need to interoperate

seamlessly.

With the integration of fieldbusses into control systems, there are a few other tasks which

need to be performed. In addition to fieldbus- and device-specific tools, there is a need to

integrate these tools into higher-level system-wide planning- or engineering tools. In

particular, for use in extensive and heterogeneous control systems, typically in the area of the

process industry, the unambiguous definition of engineering interfaces that are easy to use for

all those involved is of great importance.

A device-specific software component, called DTM (Device Type Manager), is supplied by the

field device manufacturer with its device. The DTM is integrated into engineering tools via the

FDT interfaces defined in this specification. The approach to integration is in general open for

all kinds of fieldbusses and thus meets the requirements for integrating different kinds of

devices into heterogeneous control systems.

Figure 1 shows how IEC 62453–303-1 is aligned in the structure of the IEC 62453 series.

Part 303-1

Communication

profile integration –

IEC 61784 CP 3/1

and CP 3/2

IEC 1127/09

Figure 1 – Part 303-1 of the IEC 62453 series

– 8 – 62453-303-1 © IEC:2009(E)

FIELD DEVICE TOOL (FDT) INTERFACE SPECIFICATION –

Part 303-1: Communication profile integration –

IEC 61784 CP 3/1 and CP 3/2

1 Scope

Communication Profile 3/1 and Communication Profile 3/2 (commonly known as

PROFIBUS™ ) defines communication profiles based on IEC 61158-2 Type 3, IEC 61158-3-3,

IEC 61158-4-3, IEC 61158-5-3, and IEC 61158-6-3. The basic profiles CP 3/1 (PROFIBUS

DP) and CP 3/2 (PROFIBUS PA) are defined in IEC 61784-1.

This part of IEC 62453 provides information for integrating the PROFIBUS protocol into the

FDT interface specification (IEC 62453–2).

This part of the IEC 62453 specifies communication and other services.

This specification neither contains the FDT specification nor modifies it.

2 Normative references

The following referenced documents are indispensable for the application of this specification.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies

IEC 61131-3:2003, Programmable controllers – Part 3: Programming languages

IEC 61158 (all parts), Industrial communication networks – Fieldbus specifications

IEC 61158-2, Industrial communication networks – Fieldbus specifications – Part 2: Physical

layer specification and service definition

IEC 61158-3-3, Industrial communication networks – Fieldbus specifications – Part 3-3: Data-

link layer service definition – Type 3 elements

IEC 61158-4-3 Industrial communication networks – Fieldbus specifications – Part 4-3: Data-

link layer protocol specification – Type 3 elements

IEC 61158-5-3: Industrial communication networks – Fieldbus specifications – Part 5-3:

Application layer service definition – Type 3 elements

IEC 61158-6-3, Industrial communication networks – Fieldbus specifications – Part 6-3:

Application layer protocol specification – Type 3 elements

IEC 61784-1, Industrial communication networks – Profiles – Part 1: Fieldbus profiles

—————————

PROFIBUS™ is a trade names of the non-profit organization PROFIBUS Nutzerorganisation e.V. (PNO). This

information is given for the convenience of users of this International Standard and does not constitute an

endorsement by IEC of the trade name holder or any of its products. Compliance to this standard does not

require use of the registered logos for PROFIBUS™. Use of the registered logos for PROFIBUS™ requires

permission of PNO.

62453-303-1 © IEC:2009(E) – 9 –

IEC 62453-1:2009, Field Device Tool (FDT) interface specification – Part 1: Overview and

guidance

IEC 62453–2:2009, Field Device Tool (FDT) interface specification – Part 2: Concepts and

detailed description

3 Terms, definitions, symbols, abbreviated terms and conventions

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62453–1 and

IEC 62453–2 apply.

3.1.1

bus interface module

module of a field device that provides the connection to the fieldbus

3.1.2

CP 3/1

Communication profile of CPF3, featuring asynchronous transmission; RS 485 (ANSI TIA/EIA

RS-485-A); optional RS 485-IS; plastic fiber; glass multi mode fiber or glass single mode

fiber; PCF fiber

3.1.3

CP 3/2

Communication profile of CPF3, featuring synchronous transmission; manchester coded and

bus powered (MBP); optional intrinsically safe (MBP-IS) and lower power (MBP-LP)

3.2 Symbols and abbreviated terms

For the purposes of this document, the symbols and abbreviations given in IEC 62453–1,

IEC 62453–2 and the following apply.

BIM Bus Interface Module

BMCP Bus Master Configuration Part

GSD General Station Description

3.3 Conventions

3.3.1 Data type names and references to data types

The conventions for naming and referencing of data types are explained in IEC 62453-2,

Clause A.1

3.3.2 Vocabulary for requirements

The following expressions are used when specifying requirements.

Usage of “shall” or “mandatory” No exceptions allowed.

Usage of “should” or “recommended” Strong recommendation. It may make sense in special

exceptional cases to differ from the described behaviour.

Usage of “can’ or “optional’ Function or behaviour may be provided, depending on defined

conditions.

3.3.3 Use of UML

Figures in this document are using the UML notation as defined in Annex A of IEC 62453–1.

– 10 – 62453-303-1 © IEC:2009(E)

4 Bus category

CP 3/1 and CP 3/2 protocols are identified in the protocolId element of the structured data

type 'fdt:BusCategory' by the following unique identifiers (Table 1):

Table 1 – Protocol identifiers

Identifier value ProtocolId name Description

036D1497-387B-11D4-86E1-00E0987270B9 'Profibus DP/V0' Support of Profibus DP V0 protocol

036D1499-387B-11D4-86E1-00E0987270B9 'Profibus DP/V1' Support of Profibus DP V1 protocol

CP 3/1 AND CP 3/2 protocols are using the following unique identifiers in physicalLayer

members within PhysicalLayer data type (Table 2):

Table 2 – Physical layer identifiers

Identifier value Description

036D1590-387B-11D4-86E1-00E0987270B9 IEC 61158-2 (Profibus PA)

036D1591-387B-11D4-86E1-00E0987270B9 RS485

036D1592-387B-11D4-86E1-00E0987270B9 Fiber

036D1593-387B-11D4-86E1-00E0987270B9 Ethernet

5 Access to instance and device data

5.1 Process Channel objects provided by DTM

The minimum set of provided data should be: Process values modelled as channel objects

including the ranges and scaling

5.2 DTM services to access instance and device data

The services InstanceDataInformation and DeviceDataInformation shall provide access to at

least all parameters of the Physical Block and the status and Out value of the Function Blocks

shall be exposed.

According to IEC 62453-2, at least one set of semantic information (one per supported

fieldbus protocol) shall be provided for each accessible data object, using the

‘SemanticInformation’ general data type. The corresponding data type ‘applicationDomain’

shall have a value defined for Profibus and the data type ‘semanticId’ shall have an

appropriate value, as specified in Table 9.

6 Protocol specific behavior

6.1 PROFIBUS device model

FDT extends the PROFIBUS device model by using Process Channels for description of I/O

values (see Figure 2).

62453-303-1 © IEC:2009(E) – 11 –

IEC 1128/09

Figure 2 – FDT PROFIBUS device model

6.2 Configuration and parameterization of PROFIBUS devices

6.2.1 General

In a GSD-based configuration tool the user defines the configuration and sets the appropriate

parameters for the modules. The configuration tool creates the configuration string and the

parameter string that are used to set up the slave properly.

With FDT the configuration and parameterization of the devices is no longer executed only by

a central component; it moved partly into the DTMs. A DTM is responsible for providing

configuration and parameterization information for the cyclic master that puts the PROFIBUS

slaves in operation.

A DTM is used to adjust a field device to its specific application. Within PROFIBUS, there are

three different aspects of adjustment:

• parameterization: usr prm data (used in the PROFIBUS service SET_PRM for setting up

the cyclic communication and the specific behavior of the device);

– 12 – 62453-303-1 © IEC:2009(E)

• application parameterization: application specific parameters (transmitted via acyclic

read/write PROFIBUS services);

• configuration: configuration data (used in the PROFIBUS service CHK_CFG for definition

of the format and length of the input/output data that are transmitted within cyclic

communication).

The application parameterization transmitted via acyclic communication is not in the scope of

this document. Within this document the term parameterization represents communication

parameterization (SET_PRM).

6.2.2 Monolithic DTM for a modular PROFIBUS device

A monolithic DTM is one single DTM that represents the complete device with its Bus

Interface Module (BIM) and its I/O modules. In general, such a DTM offers a configuration

dialog (presentation object) that allows definition of the used BIM and modules. The

configuration dialog must be available via the FDT standard function “Configure” (see [1] 4.3

Operation Configuration).

Not all PROFIBUS devices require a configuration dialog. That is why not all DTMs provide

the “Configure” function. This is valid only for non-modular PROFIBUS devices if the usr prm

data cannot be changed.

The configuration dialog allows changing the data only in offline mode if the data set can be

locked.

6.2.3 Modular DTM for a modular PROFIBUS device

Separate DTMs represent the BIM (Device DTM) and the particular I/O modules (Module

DTMs). The effort developing such a modular DTM is normally higher than in the case of a

monolithic DTM, because:

• a private protocol has to be implemented between BIM and I/O modules to ensure that

only a Module DTM can be added to the BIM DTM. This requires an own protocol ID and

the adaptation / creation of communication;

• in some cases, additional private interfaces are necessary to exchange information

between Device DTM for BIM and Module DTMs.

Implementing a Modular DTM results in the following advantages:

• the project represents the device structure;

• the user is able to access module-related information directly as a function of the Module

DTM;

• the FDT specification defines a mechanism to identify DTMs. With these mechanisms it is

possible to provide support for scanning the modules below the BIM and generate the

topology automatically;

• supporting a new type of BIM or I/O module requires an additional DTM “only” and does

not affect existing components. This may result in reduced test effort.

The configuration data to set up the PROFIBUS configuration must be provided by the Device

DTM (representing the BIM). This configuration data may be generated from information of

the instantiated Child DTMs and by using a configuration dialog.

Modular DTMs should be provided for modular devices (e.g. a plant operator may add/remove

modules). Monolithic DTMs are used to represent devices that show no modularity (e.g. PA

devices).

62453-303-1 © IEC:2009(E) – 13 –

6.3 Support for DPV0 configuration

A PROFIBUS slave is configured by a cyclic master and communicates via PROFIBUS DP. In

addition to this the slave may support DPV1 communication.

A Gateway DTM for a PROFIBUS slave does not have to provide communication for the DPV0

communication schema. For example, there is a remote I/O system with HART modules. It

may have a Gateway DTM that requires the DPV1 protocol and provides the HART protocol

(defined in the information document and in the parameter document). This enables HART

Device DTMs to communicate with their devices via the Gateway DTM and via

Communication DTM for DPV1. Following the specification the Gateway DTM delivers channel

parameter documents for both protocols DPV1 and HART. The protocolId is a member of

NetworkManagementInfo data type.

The Process Channels must provide ChannelParameter documents for DPV1 including all

information to allow integration into the control system (e.g. DPAddress of the IO value if

available).

6.4 PROFIBUS slaves operating without a cyclic PROFIBUS master

In most cases, a PROFIBUS slave is configured and parameterized by a cyclic PROFIBUS

master device. So a running master device in the network is required.

Some slaves are able to allow acyclic communication without a running cyclic master.

Especially in the case of gateway functionality this is an eminent advantage because they

allow the parameterization of field devices connected to them by using an acyclic bus master.

So instrument specialists are able to work with field devices also in case the controller is not

yet working.

If a master starts communication, these devices start to detect bus speed and settings to

react properly. This may take some time.

In the following, two cases are described that a user may keep in mind when working with

such devices.

Use case 1:

The user performs a network scan. The Communication DTM tries to read diagnostic data via

a GetDiagnose Request but does not receive a response. The device is not detected by the

Communication DTM. This occurs mostly when the device has a low PROFIBUS address. The

reason is that the device has not completed bus speed / bus setting detection as it was asked

for their diagnostic data. The workaround is to give these devices a higher PROFIBUS

address.

Use Cases 2:

The user tries to connect a field device linked to the gateway that supports DPV1 without a

running cyclic master. This can lead to an error message because the gateway device has not

completed bus speed / bus setting detection as it was asked for a connection. So the user has

to try to connect again. This happens only in very rare situations.

6.5 PROFIBUS-related information of a slave DTM

6.5.1 General

The information used by a cyclic master device to set up the PROFIBUS network properly and

allow cyclic communication between control system and slave devices is provided by a DTM

in

– 14 – 62453-303-1 © IEC:2009(E)

• Bus Master Configuration Part (BMCP);

• GSD information;

• internal topology,

• pocess channels.

A DTM of a PROFIBUS slave must deliver these parts of PROFIBUS-related information to

get integrated into a FDT-based Engineering System. In the next subclauses, a more detailed

description is given on how to generate and how to provide this information. This depends on

the kind of DTM (see 6.2 Configuration and parameterization of PROFIBUS devices).

6.5.2 Bus Master Configuration Part (BMCP)

6.5.2.1 BMCP introduction

The BMCP of one single DTM instance describes the actual parameter and configuration data

of the corresponding PROFIBUS slave. Each DTM representing a PROFIBUS slave device

must provide a Bus Master Configuration Part. The BMCP is provided in the

busMasterConfigurationPart member of NetworkManagementInfo data type. This information

is obtained by calling service NetworkManagementInfoRead.

The BMCP includes information about the configuration and the parameters for the slave. The

BMCP is provided by the DTM and is required in order to generate the master configuration.

The BMCP contains data which might be changed during master configuration. That means

that the BMCP may be changed and transferred back to the slave DTM by calling

NetworkManagementInfoWrite. A Slave DTM must accept the new information and recompute

the configuration / internal parameters to match the new BMCP.

DTM must check whether the new values are according to the capabilities of the device. The

NetworkManagementInfoWrite call will be refused if the device can not handle the new values.

6.5.2.2 Creating the BMCP

This subclause explains the meaning of the individual elements of the BMCP in details.

The BCMP may be generated from the GSD information of a PROFIBUS device.

The BMCP is divided into four parts that are explained in the following subclauses.

The explanations use the GSD keywords and reference the PROFIBUS specification. See

also the table with complete BMCP in 6.5.2.2.1 .

6.5.2.2.1 Part 1: From Slave_Para_Len to Octet 15

The first part consists of a fixed set of bytes described in the table below.

62453-303-1 © IEC:2009(E) – 15 –

Table 3 – BMPC Part1 – General configuration

Byte Name Defined in Notice

0 Slave_Para_Len [5] 6.2.12.1

Length of the BMCP including this value

2 Sl_Flag [5] 6.2.12.2 The following GSD values are used [6]:

• Bit 0 : reserved,

• Bit 1: Extra_Alarm_SAP,

• Bit 2: DPV1_Data_Types,

• Bit 3: DPV1_Supported,

• Bit 4: Publisher_Enable,

• Bit 5 : Fail_Safe, .

The following bits are not based on GSD values:

• Bit 6 : New_Prm,

• Bit 7 : Active

3 Slave Type [5] 6.2.12.3

Value is 0 (= DP-Slave)

4 Max_Diag_Data_Len [5] 6.2.12.4 The following GSD value is used [6]: Max_Diag_Data_Len

5 Max_Alarm_Len [5] 6.2.12.5

6 Max_Channel_Data_Len [5] 6.2.12.6 This field defines how much data can be transferred between

slave and master. In this case, the maximum of these GSD

values [6] must be calculated:

• Max_Data_Len,

• C1_Max_Data_Len plus 4 Bytes (Function Num,

Slot_Number, Length)

7 Diag_Update_Delay [5] 6.2.12.7 The following GSD value is used [6]:Diag_Update_Delay

8 Alarm_Mode [5] 6.2.12.8

9 Add_Sl_Flag [5] 6.2.12.9

10 C1_Timeout [5] 6.2.12.10 The following GSD value is used [6]:C1_Response_Timeout

12 Reserved

6.5.2.2.2 Part 2: Parameter data

Part 2 of the BMCP are the slave parameter data.

Table 4 – BMPC Part2 – Parameter data

Byte Name Defined in Notice

16 Prm_Data_Len [5] 6.2.12.11 Length of the Parameter Data including this value

18 Station Status [5] 6.2.4.1 The following GSD values are used [6]:

• Bit 0-2: reserved,

• Bit 3: WD_On,

• Bit 4: Freeze_Req,

• Bit 5: Sync_Req,

• Bit 6,7(Lock/Unlock Request): [5] Table 402

19 WatchDog1 [5] 6.2.4.2 These values (WD_Fact_1 and WD_Fact_2) depend on the baud rate.

A master should set these values and slaves should handle new

values

20 WatchDog2 [5] 6.2.4.3

21 Min Tsdr [5] 6.2.4.4 Default value is 11 bit times [1]

22 Ident_Number [5] 6.2.3.5 The following GSD value is used [6]: Ident_Number

– 16 – 62453-303-1 © IEC:2009(E)

Byte Name Defined in Notice

24 Group_Ident [5] 6.2.4.5 Indicates the group assignment of the slave in a bitwise coded form

25 DPV1_Status_1 [5] 6.2.4.7 The following GSD values are used [6]:

• Bit 0,1: reserved,

• Bit 2: WD_Base_1ms,

• Bit 3 – 5: reserved,

• Bit 6: Fail_Safe,

• Bit 7 : DPV1_Enable,

These bits report the slave capabilities to the master and are

changed by the MS0 master following its capabilities

26 DPV1_Status_2 [5] 6.2.4.8 The following GSD values are used [6]:

• Bit 0: Check_Cfg_Mode,

• Bit 1: reserved,

• Bit 2: Enable_Update_Alarm,

• Bit 3: Enable_Status_Alarm,

• Bit 4: Enable_Manufacturer_Specific_Alarm,

• Bit 5: Enable_Diagnostic_Alarm,

• Bit 6: Enable_Process_Alarm,

• Bit 7: Enable_Pull_Plug_Alarm,

These bits report the slave capabilities to the master and are

changed by the MS0 master following its capabilities

• Bit 0-2: - ,

27 DPV1_Status_3 [5] 6.2.4.9

• Bit 3: Prm Structure,

• Bit 4: IsoM_Req,

• Bit 5-6: reserved,

• Bit 7: Prm_Cmd

28 User_Prm_Data From Byte 28 of the BMCP, a DTM has to insert additional user

parameter data. The information is given in the GSD file via value of

…

User_Prm_Data

NOTE 1 It is possible that a module does not have user parameter data. In this case, no parameter string is

inserted into the BMCP for this module.

NOTE 2 Some slaves have some fixed modules besides the BIM. Even if these modules do not appear in the

configuration dialog or are not represented as Module DTMs, they have to be considered in the BCMP if they have

parameters.

NOTE 3 The three DPV1 status bytes are defined by the MS0 master.

6.5.2.2.3 Part 3: Configuration data

The configuration data are provided as part 3:

Table 5 – BMPC Part3 – Configuration data

Byte Name Source Notice

16+Prm_Data_Len Cfg_Data_Len [5] 6.2.12.13 Length including this value

16+Prm_Data_Len + 1

16+Prm_Data_Len +2 Cfg_Data Configuration data (if available)

…

From byte position (16+Prm_Data_Len +2), the configuration strings for the BIM and the

modules are provided in ascending order. The information is given in the GSD file via value

module.

NOTE 1 Some slaves have some fixed modules besides the BIM. Even if these modules do not appear in the

configuration dialog or are not represented as Module DTMs, they have to be considered in the BCMP if they have

parameters.

NOTE 2 Empty slots have to be considered in the configuration data. Refer to the GSD file as to which

configuration string has to be used.

62453-303-1 © IEC:2009(E) – 17 –

6.5.2.2.4 Part 4: Address table and slave user parameters

In Part 4 of the BMCP, the address table and the slave user parameter section is provided.

Table 6 – Part 4: Address table and slave user parameters

Byte Name Source Hints

[5] 6.2.12.15

16 + Prm_Data_Len + Cfg_Data_Len Add_Tab_Len Length including this

value

16 + Prm_Data_Len + Cfg_Data_Len + 1

16 + Prm_Data_Len + Cfg_Data_Len + Slave_User_Data_Len [6] 6.2.12.21 Length including this

Add_Tab_Len value

16 + Prm_Data_Len + Cfg_Data_Len +

Add_Tab_Len + 1

16 + Prm_Data_Len + Cfg_Data_Len + Slave_User_Data Slave user parameter (if

Add_Tab_Len + 2 availablbe)

…

After Add_Tab_Len the address table data is inserted into the BMCP. If the master does not

support this table the Add_Tab_Len is set to 2 and no data is inserted.

After Slave_UserDataLen the slave user data is inserted into the BMCP. If the master does

not support this data the Slave_User_Data_Len is set to 2 and no data is inserted.

Table 7 – Part 4: Extended Prm data

Byte Name Source Hints

16 + Prm_Data_Len + Cfg_Data_Len + Ext_Prm_Data_Len [5] 6.2.12.23 Length including this

Add_Tab_Len + Slave_User_Data_Len value

16 + Prm_Data_Len + Cfg_Data_Len +

Add_Tab_Len + Slave_User_Data_Len + 1

After Ext_Prm_Data_Len the extended prm data is inserted into the BMCP. If the master does

not support this data the Ext_Prm_Data_Len is set to 2 and no data is inserted.

6.5.2.2.5 Complete slave bus parameter set

All values are provided from the Slave DTM. It is responsibility of the Slave DTM to be

compatible with the Slave GSD. The Master DTM could change some of these initial values

sent by Slave DTM if they depend on the capabilities of the master.

Example

Within the GSD file, it is stated that the device supports the Freeze Mode by the keyword “Freeze_Mode_supp”.

The master sets the value “Freeze_Mode_Req” within the Slave Bus Parameter Set because only the master

knows whether it supports this mode.

The following table explains which component is the source of the parameter values (“Parameter provided by”).

Some of the values can be changed by the system or by user interaction. For those values it is indicated which

component is allowed to change the values (“Configuration by”.) If possible, the default values for the parameters

are defined (“Default Value”).

– 18 – 62453-303-1 © IEC:2009(E)

Table 8 – Complete BMCP

Byte Name Note Parameter provided by Configuration Default Value

by

0 Slave_Para_Len Length of the BMCP including this Calculated by Slave DTM - -

value

2 Sl_Flag Bit coded. The meaning of the - - -

bits:

Bit 0: reserved - - 0

Bit 1: Extra_Alarm_SAP Slave DTM shows with this bit that the feature is supported Master DTM Extra_Alarm_SAP_sup

p within GSD

Bit 2: DPV1_Data_Types Slave DTM shows what data types are used by the slave DTM Master DTM DPV1_Data_Types

within Slave GSD

Bit 3: DPV1_Supported Slave DTM shows with this bit that the feature is supported Master DTM DPV1_Slave within

GSD

Bit 4: Publisher_enable Slave DTM shows with this bit that the feature is supported Master DTM Publisher_supp within

GSD

Bit 5: Fail_Safe Slave DTM can show by this flag that the slave needs fail safe Master DTM Value within Slave

(Fail_Safe or Fail_Safe_Required of the GSD) GSD

Bit 6: New_Prm If the Slave DTM set this value, it requests that the MS0 master should - 0

set the changed slave parameter. (see [5] 6.2.12.2)

Bit 7: Active If the Slave DTM has finished the module configuration set it to 1. - 0

3 Slave Type 0 = DP-Slave Slave DTM shows that i

...

IEC 62453-303-1 ®

Edition 1.0 2009-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Field device tool (FDT) interface specification –

Part 303-1: Communication profile integration – IEC 61784 CP 3/1 and CP 3/2

Spécification des interfaces des outils des dispositifs de terrain (FDT) –

Partie 303-1: Intégration des profils de communication – CEI 61784 CP 3/1

et CP 3/2

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62453-303-1 ®

Edition 1.0 2009-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Field device tool (FDT) interface specification –

Part 303-1: Communication profile integration – IEC 61784 CP 3/1 and CP 3/2

Spécification des interfaces des outils des dispositifs de terrain (FDT) –

Partie 303-1: Intégration des profils de communication – CEI 61784 CP 3/1

et CP 3/2

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX XA

ICS 25.040.40; 35.100.05; 35.110 ISBN 978-2-83220-379-8

– 2 – 62453-303-1 IEC:2009

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions, symbols, abbreviated terms and conventions . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviated terms. 9

3.3 Conventions . 9

3.3.1 Data type names and references to data types . 9

3.3.2 Vocabulary for requirements . 9

3.3.3 Use of UML . 9

4 Bus category . 10

5 Access to instance and device data . 10

5.1 Process Channel objects provided by DTM . 10

5.2 DTM services to access instance and device data . 10

6 Protocol specific behavior . 10

6.1 PROFIBUS device model . 10

6.2 Configuration and parameterization of PROFIBUS devices . 11

6.2.1 General . 11

6.2.2 Monolithic DTM for a modular PROFIBUS device . 12

6.2.3 Modular DTM for a modular PROFIBUS device . 12

6.3 Support for DPV0 configuration . 13

6.4 PROFIBUS slaves operating without a cyclic PROFIBUS master . 13

6.5 PROFIBUS-related information of a slave DTM . 13

6.5.1 General . 13

6.5.2 Bus Master Configuration Part (BMCP) . 14

7 Protocol specific usage of general data types . 24

8 Protocol specific common data types . 26

9 Network management data types . 26

9.1 General . 26

9.1.1 Configuration . 26

9.1.2 Process Channel . 27

9.1.3 Parameterization . 27

9.2 Master-bus parameter set . 28

9.3 Slave bus parameter set . 28

9.4 Module and channel data . 29

9.5 GSD information . 32

9.5.1 General . 32

9.5.2 GSD for gateway devices . 32

10 Communication data types . 33

10.1 General . 33

10.2 Error information provided by Communication Channel . 33

10.3 DPV0 communication . 33

10.4 DPV1 communication . 40

11 Channel parameter data types . 43

62453-303-1 IEC:2009 – 3 –

12 Device identification . 46

12.1 General . 46

12.2 Protocol specific handling of the data type STRING . 46

12.3 Common device type identification data types . 46

12.4 Topology scan data types . 51

12.5 Scan identification data types . 52

12.6 Device type identification data types – provided by DTM . 54

12.7 Identification information in GUI . 57

13 ProfiSafe . 57

13.1 Motivation . 57

13.2 General parameter handling . 57

13.3 ProfiSafe individual device parameter . 58

Bibliography . 60

Figure 1 – Part 303-1 of the IEC 62453 series . 7

Figure 2 – FDT PROFIBUS device model . 11

Figure 3 – Example for IO data within datagrams . 30

Figure 4 – F-Parameter and individual device parameter . 58

Figure 5 – Data structure of ProfiSafe individual device parameters . 59

Table 1 – Protocol identifiers . 10

Table 2 – Physical layer identifiers . 10

Table 3 – BMPC Part1 – General configuration . 15

Table 4 – BMPC Part2 – Parameter data . 15

Table 5 – BMPC Part3 – Configuration data . 16

Table 6 – Part 4: Address table and slave user parameters . 17

Table 7 – Part 4: Extended Prm data . 17

Table 8 – Complete BMCP . 18

Table 9 – Protocol specific usage of general data types . 24

Table 10 – Bus parameter set for master device . 28

Table 11 – Bus parameter set for slave device . 29

Table 12 – Signal channels within the data frame . 31

Table 13 – Simple DPV0 communication data types . 34

Table 14 – Structured DPV0Communication data types . 34

Table 15 – Availability of services for Master Class1 (C1) . 39

Table 16 – Availability of services for Master Class2 (C2) . 39

Table 17 – Simple DPV1 communication data types . 40

Table 18 – Structured DPV1 communication data types . 41

Table 19 – Mapping of DPV1 data types to FDT data types . 43

Table 20 – Simple ChannelParameter data types . 44

Table 21 – Structured ChannelParameter data types . 45

Table 22 – Identification data types with Profibus DP specific mapping . 47

Table 23 – Identification data types with Profibus I&M specific mapping . 48

Table 24 – Identification data types with Profibus PA specific mapping . 50

– 4 – 62453-303-1 IEC:2009

Table 25 – Simple identification data types with protocol independent semantics . 51

Table 26 – Structured identification data types with protocol independent semantics . 51

Table 27 – Simple topology scan data types . 51

Table 28 – Structured topology scan data types . 51

Table 29 – Simple scan identification data types . 52

Table 30 – Structured scan identification data types . 52

Table 31 – Structured device identification data types. 55

62453-303-1 IEC:2009 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIELD DEVICE TOOL (FDT) INTERFACE SPECIFICATION –

Part 303-1: Communication profile integration –

IEC 61784 CP 3/1 and CP 3/2

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62453-303-1 been prepared by subcommittee 65E: Devices and

integration in enterprise systems, of IEC technical committee 65: Industrial-process

measurement, control and automation.

This part, in conjunction with the other parts of the first edition of the IEC 62453 series

cancels and replaces IEC/PAS 62453-1, IEC/PAS 62453-2, IEC/PAS 62453-3, IEC/PAS

62453-4 and IEC/PAS 62453-5 published in 2006, and constitutes a technical revision.

Each part of the IEC 62453-3xy series is intended to be read in conjunction with IEC 62453-2.

This bilingual version (2012-12) corresponds to the monolingual English version, published in

2009-06.

– 6 – 62453-303-1 IEC:2009

The text of this standard is based on the following documents:

FDIS Report on voting

65E/127/FDIS 65E/140/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62453 series, under the general title Field Device Tool (FDT)

interface specification, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication

indicates that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

62453-303-1 IEC:2009 – 7 –

INTRODUCTION

This part of IEC 62453 is an interface specification for developers of FDT (Field Device Tool)

components for function control and data access within a client/server architecture. The

specification is a result of an analysis and design process to develop standard interfaces to

facilitate the development of servers and clients by multiple vendors that need to interoperate

seamlessly.

With the integration of fieldbusses into control systems, there are a few other tasks which

need to be performed. In addition to fieldbus- and device-specific tools, there is a need to

integrate these tools into higher-level system-wide planning- or engineering tools. In

particular, for use in extensive and heterogeneous control systems, typically in the area of the

process industry, the unambiguous definition of engineering interfaces that are easy to use for

all those involved is of great importance.

A device-specific software component, called DTM (Device Type Manager), is supplied by the

field device manufacturer with its device. The DTM is integrated into engineering tools via the

FDT interfaces defined in this specification. The approach to integration is in general open for

all kinds of fieldbusses and thus meets the requirements for integrating different kinds of

devices into heterogeneous control systems.

Figure 1 shows how IEC 62453–303-1 is aligned in the structure of the IEC 62453 series.

Part 303-1

Communication

profile integration –

IEC 61784 CP 3/1

and CP 3/2

IEC 1127/09

Figure 1 – Part 303-1 of the IEC 62453 series

– 8 – 62453-303-1 IEC:2009

FIELD DEVICE TOOL (FDT) INTERFACE SPECIFICATION –

Part 303-1: Communication profile integration –

IEC 61784 CP 3/1 and CP 3/2

1 Scope

Communication Profile 3/1 and Communication Profile 3/2 (commonly known as

PROFIBUS™ ) defines communication profiles based on IEC 61158-2 Type 3, IEC 61158-3-3,

IEC 61158-4-3, IEC 61158-5-3, and IEC 61158-6-3. The basic profiles CP 3/1 (PROFIBUS

DP) and CP 3/2 (PROFIBUS PA) are defined in IEC 61784-1.

This part of IEC 62453 provides information for integrating the PROFIBUS protocol into the

FDT interface specification (IEC 62453–2).

This part of the IEC 62453 specifies communication and other services.

This specification neither contains the FDT specification nor modifies it.

2 Normative references

The following referenced documents are indispensable for the application of this specification.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies

IEC 61131-3:2003, Programmable controllers – Part 3: Programming languages

IEC 61158 (all parts), Industrial communication networks – Fieldbus specifications

IEC 61158-2, Industrial communication networks – Fieldbus specifications – Part 2: Physical

layer specification and service definition

IEC 61158-3-3, Industrial communication networks – Fieldbus specifications – Part 3-3: Data-

link layer service definition – Type 3 elements

IEC 61158-4-3 Industrial communication networks – Fieldbus specifications – Part 4-3: Data-

link layer protocol specification – Type 3 elements

IEC 61158-5-3: Industrial communication networks – Fieldbus specifications – Part 5-3:

Application layer service definition – Type 3 elements

IEC 61158-6-3, Industrial communication networks – Fieldbus specifications – Part 6-3:

Application layer protocol specification – Type 3 elements

IEC 61784-1, Industrial communication networks – Profiles – Part 1: Fieldbus profiles

—————————

PROFIBUS™ is a trade names of the non-profit organization PROFIBUS Nutzerorganisation e.V. (PNO). This

information is given for the convenience of users of this International Standard and does not constitute an

endorsement by IEC of the trade name holder or any of its products. Compliance to this standard does not

require use of the registered logos for PROFIBUS™. Use of the registered logos for PROFIBUS™ requires

permission of PNO.

62453-303-1 IEC:2009 – 9 –

IEC 62453-1:2009, Field Device Tool (FDT) interface specification – Part 1: Overview and

guidance

IEC 62453–2:2009, Field Device Tool (FDT) interface specification – Part 2: Concepts and

detailed description

3 Terms, definitions, symbols, abbreviated terms and conventions

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62453–1 and

IEC 62453–2 apply.

3.1.1

bus interface module

module of a field device that provides the connection to the fieldbus

3.1.2

CP 3/1

Communication profile of CPF3, featuring asynchronous transmission; RS 485 (ANSI TIA/EIA

RS-485-A); optional RS 485-IS; plastic fiber; glass multi mode fiber or glass single mode

fiber; PCF fiber

3.1.3

CP 3/2

Communication profile of CPF3, featuring synchronous transmission; manchester coded and

bus powered (MBP); optional intrinsically safe (MBP-IS) and lower power (MBP-LP)

3.2 Symbols and abbreviated terms

For the purposes of this document, the symbols and abbreviations given in IEC 62453–1,

IEC 62453–2 and the following apply.

BIM Bus Interface Module

BMCP Bus Master Configuration Part

GSD General Station Description

3.3 Conventions

3.3.1 Data type names and references to data types

The conventions for naming and referencing of data types are explained in IEC 62453-2,

Clause A.1

3.3.2 Vocabulary for requirements

The following expressions are used when specifying requirements.

Usage of “shall” or “mandatory” No exceptions allowed.

Usage of “should” or “recommended” Strong recommendation. It may make sense in special

exceptional cases to differ from the described behaviour.

Usage of “can’ or “optional’ Function or behaviour may be provided, depending on defined

conditions.

3.3.3 Use of UML

Figures in this document are using the UML notation as defined in Annex A of IEC 62453–1.

– 10 – 62453-303-1 IEC:2009

4 Bus category

CP 3/1 and CP 3/2 protocols are identified in the protocolId element of the structured data

type 'fdt:BusCategory' by the following unique identifiers (Table 1):

Table 1 – Protocol identifiers

Identifier value ProtocolId name Description

036D1497-387B-11D4-86E1-00E0987270B9 'Profibus DP/V0' Support of Profibus DP V0 protocol

036D1499-387B-11D4-86E1-00E0987270B9 'Profibus DP/V1' Support of Profibus DP V1 protocol

CP 3/1 AND CP 3/2 protocols are using the following unique identifiers in physicalLayer

members within PhysicalLayer data type (Table 2):

Table 2 – Physical layer identifiers

Identifier value Description

036D1590-387B-11D4-86E1-00E0987270B9 IEC 61158-2 (Profibus PA)

036D1591-387B-11D4-86E1-00E0987270B9 RS485

036D1592-387B-11D4-86E1-00E0987270B9 Fiber

036D1593-387B-11D4-86E1-00E0987270B9 Ethernet

5 Access to instance and device data

5.1 Process Channel objects provided by DTM

The minimum set of provided data should be: Process values modelled as channel objects

including the ranges and scaling

5.2 DTM services to access instance and device data

The services InstanceDataInformation and DeviceDataInformation shall provide access to at

least all parameters of the Physical Block and the status and Out value of the Function Blocks

shall be exposed.

According to IEC 62453-2, at least one set of semantic information (one per supported

fieldbus protocol) shall be provided for each accessible data object, using the

‘SemanticInformation’ general data type. The corresponding data type ‘applicationDomain’

shall have a value defined for Profibus and the data type ‘semanticId’ shall have an

appropriate value, as specified in Table 9.

6 Protocol specific behavior

6.1 PROFIBUS device model

FDT extends the PROFIBUS device model by using Process Channels for description of I/O

values (see Figure 2).

62453-303-1 IEC:2009 – 11 –

IEC 1128/09

Figure 2 – FDT PROFIBUS device model

6.2 Configuration and parameterization of PROFIBUS devices

6.2.1 General

In a GSD-based configuration tool the user defines the configuration and sets the appropriate

parameters for the modules. The configuration tool creates the configuration string and the

parameter string that are used to set up the slave properly.

With FDT the configuration and parameterization of the devices is no longer executed only by

a central component; it moved partly into the DTMs. A DTM is responsible for providing

configuration and parameterization information for the cyclic master that puts the PROFIBUS

slaves in operation.

A DTM is used to adjust a field device to its specific application. Within PROFIBUS, there are

three different aspects of adjustment:

• parameterization: usr prm data (used in the PROFIBUS service SET_PRM for setting up

the cyclic communication and the specific behavior of the device);

– 12 – 62453-303-1 IEC:2009

• application parameterization: application specific parameters (transmitted via acyclic

read/write PROFIBUS services);

• configuration: configuration data (used in the PROFIBUS service CHK_CFG for definition

of the format and length of the input/output data that are transmitted within cyclic

communication).

The application parameterization transmitted via acyclic communication is not in the scope of

this document. Within this document the term parameterization represents communication

parameterization (SET_PRM).

6.2.2 Monolithic DTM for a modular PROFIBUS device

A monolithic DTM is one single DTM that represents the complete device with its Bus

Interface Module (BIM) and its I/O modules. In general, such a DTM offers a configuration

dialog (presentation object) that allows definition of the used BIM and modules. The

configuration dialog must be available via the FDT standard function “Configure” (see [1] 4.3

Operation Configuration).

Not all PROFIBUS devices require a configuration dialog. That is why not all DTMs provide

the “Configure” function. This is valid only for non-modular PROFIBUS devices if the

Usr_Prm-Data cannot be changed.

The configuration dialog allows changing the data only in offline mode if the data set can be

locked.

6.2.3 Modular DTM for a modular PROFIBUS device

Separate DTMs represent the BIM (Device DTM) and the particular I/O modules (Module

DTMs). The effort developing such a modular DTM is normally higher than in the case of a

monolithic DTM, because:

• a private protocol has to be implemented between BIM and I/O modules to ensure that

only a Module DTM can be added to the BIM DTM. This requires an own protocol ID and

the adaptation / creation of communication;

• in some cases, additional private interfaces are necessary to exchange information

between Device DTM for BIM and Module DTMs.

Implementing a Modular DTM results in the following advantages:

• the project represents the device structure;

• the user is able to access module-related information directly as a function of the Module

DTM;

• the FDT specification defines a mechanism to identify DTMs. With these mechanisms it is

possible to provide support for scanning the modules below the BIM and generate the

topology automatically;

• supporting a new type of BIM or I/O module requires an additional DTM “only” and does

not affect existing components. This may result in reduced test effort.

The configuration data to set up the PROFIBUS configuration must be provided by the Device

DTM (representing the BIM). This configuration data may be generated from information of

the instantiated Child DTMs and by using a configuration dialog.

Modular DTMs should be provided for modular devices (e.g. a plant operator may add/remove

modules). Monolithic DTMs are used to represent devices that show no modularity (e.g. PA

devices).

62453-303-1 IEC:2009 – 13 –

6.3 Support for DPV0 configuration

A PROFIBUS slave is configured by a cyclic master and communicates via PROFIBUS DP. In

addition to this the slave may support DPV1 communication.

A Gateway DTM for a PROFIBUS slave does not have to provide communication for the DPV0

communication schema. For example, there is a remote I/O system with HART modules. It

may have a Gateway DTM that requires the DPV1 protocol and provides the HART protocol

(defined in the information document and in the parameter document). This enables HART

Device DTMs to communicate with their devices via the Gateway DTM and via

Communication DTM for DPV1. Following the specification the Gateway DTM delivers channel

parameter documents for both protocols DPV1 and HART. The protocolId is a member of

NetworkManagementInfo data type.

The Process Channels must provide ChannelParameter documents for DPV1 including all

information to allow integration into the control system (e.g. DPAddress of the IO value if

available).

6.4 PROFIBUS slaves operating without a cyclic PROFIBUS master

In most cases, a PROFIBUS slave is configured and parameterized by a cyclic PROFIBUS

master device. So a running master device in the network is required.

Some slaves are able to allow acyclic communication without a running cyclic master.

Especially in the case of gateway functionality this is an eminent advantage because they

allow the parameterization of field devices connected to them by using an acyclic bus master.

So instrument specialists are able to work with field devices also in case the controller is not

yet working.

If a master starts communication, these devices start to detect bus speed and settings to

react properly. This may take some time.

In the following, two cases are described that a user may keep in mind when working with

such devices.

Use case 1:

The user performs a network scan. The Communication DTM tries to read diagnostic data via

a GetDiagnose Request but does not receive a response. The device is not detected by the

Communication DTM. This occurs mostly when the device has a low PROFIBUS address. The

reason is that the device has not completed bus speed / bus setting detection as it was asked

for their diagnostic data. The workaround is to give these devices a higher PROFIBUS

address.

Use Cases 2:

The user tries to connect a field device linked to the gateway that supports DPV1 without a

running cyclic master. This can lead to an error message because the gateway device has not

completed bus speed / bus setting detection as it was asked for a connection. So the user has

to try to connect again. This happens only in very rare situations.

6.5 PROFIBUS-related information of a slave DTM

6.5.1 General

The information used by a cyclic master device to set up the PROFIBUS network properly and

allow cyclic communication between control system and slave devices is provided by a DTM

in

– 14 – 62453-303-1 IEC:2009

• Bus Master Configuration Part (BMCP);

• GSD information;

• internal topology,

• pocess channels.

A DTM of a PROFIBUS slave must deliver these parts of PROFIBUS-related information to

get integrated into a FDT-based Engineering System. In the next subclauses, a more detailed

description is given on how to generate and how to provide this information. This depends on

the kind of DTM (see 6.2 Configuration and parameterization of PROFIBUS devices).

6.5.2 Bus Master Configuration Part (BMCP)

6.5.2.1 BMCP introduction