IEC 60664-3:2003

(Main)Insulation coordination for equipment within low-voltage systems - Part 3: Use of coating, potting or moulding for protection against pollution

Insulation coordination for equipment within low-voltage systems - Part 3: Use of coating, potting or moulding for protection against pollution

Applies to assemblies protected against pollution by the use of coating, potting or moulding, thus allowing a reduction of clearance and creepage distances as described in Part 1 or Part 5. This standard describes the requirements and test procedures for two methods of protection: - type 1 protection improves the microenvironment of the parts under the protection; - type 2 protection is considered to be similar to solid insulation. This standard also applies to all kinds of protected printed boards, including the surface of inner layers of multi-layer boards, substrates and similarly protected assemblies. In the case of multi-layer printed boards, the distances through an inner layer are covered by the requirements for solid insulation in Part 1. This standard refers only to permanent protection. It does not cover assemblies that are subjected to mechanical adjustment or repair. The principles of this standard are applicable to functional, basic, supplementary and reinforced insulation. Has the status of a basic safety publication in accirdance with IEC Guide 104. The major changes made during the revision of IEC 60664-3 were the following: - Part 3 has been exactly aligned with Part 1 (including amendments 1 and 2). It has been made clear that Part 3 can only be used as a whole document together with Part 1 of IEC 60664. - The scope of Part 3 has been greatly extended including now also potting and moulding and similar procedures providing protection against pollution. The standard also applies to all kinds of coated printed boards including the surface of inner-layers of multi-layer boards, substrates and similar protected assemblies. The distances through an inner layer of multi-layer boards however are covered by the requirements for solid insulation in Part 1. - The difference between the two types of protection has been clarified. Type 1 (formerly type A) protection leads to a reduction of the pollution degree present beyond the protection to pollution degree 1. Type 2 (formerly type B) protection introduces protection systems which can be considered similar to solid insulation. Consequently the dimensioning and test requirements have been aligned more correctly. - The area of application has been extended including now functional, basic, supplementary and reinforced insulation. - Type 1 and type 2 protection now can both be used under the conditions of pollution degree 3 (formerly only type B). - Not only type 2 protection but also type 1 protection requires that between two conductive parts 100 % of the distance across the spacing shall be covered by the protection. - For type 2 protection minimum distances have been introduced. In any case the spacings shall not be lower than the minimum value of 10 µm. - Also the new Part 5 of IEC 60664 is referred to. - The tests follow much more closely the different requirements for type 1 and type 2 protection. The protected assembly shall withstand the electrical tests for solid insulation in 4.1.2 of IEC 60664-1. For type 1 protection, the partial discharge test is not applicable. For type 2 protection, the partial discharge test is required. The required partial discharge extinction voltage and the test method are specified in 4.1.2.4 of IEC 60664-1. - The requirements for the test specimen have been aligned with the extended scope. - The tests for the "adhesion of coating" and the "scratch resistance test" have been updated.

Coordination de l'isolement des matériels dans les systèmes (réseaux) à basse tension - Partie 3: Utilisation de revêtement, d'empotage ou de moulage pour la protection contre la pollution

Applicable aux ensembles protégés contre la pollution au moyen de revêtement, d'empotage ou de moulage, permettant ainsi une réduction des distances d'isolement et des lignes de fuite décrites dans la Partie 1 ou la Partie 5. Cette norme décrit les prescriptions et procédures d'essai pour deux méthodes de protection: - la protection de type 1 améliore le micro-environnement des parties sous protection; - la protection de type 2 est considérée comme similaire à l'isolation solide. La présente norme s'applique également à toutes sortes de cartes imprimées protégées, y compris la surface de couches internes de cartes multicouches, de substrats et d'ensembles protégés de manière similaire. Dans le cas de cartes imprimées multicouches, les distances à travers une couche interne sont couvertes par les prescriptions pour l'isolation solide dans la Partie 1. La présente norme fait uniquement référence à une protection permanente. Elle n'englobe pas les ensembles soumis à une mise au point mécanique ou à des réparations. Les principes de cette norme sont applicables à l'isolation fonctionnelle, principale, supplé-mentaire et renforcée. A le statut d'une publication fondamentale de sécurité conformément au Guide 104 de la CEI. Les modifications majeures effectuées au cours de la révision de la CEI 60664-3 ont été les suivantes: - La Partie 3 a été alignée exactement à la Partie 1 (y compris les amendements 1 et 2). Il a été précisé que la Partie 3 ne peut être utilisée que comme un document entier ainsi que la Partie 1 de la CEI 60664. - Le domaine d'application de la Partie 3 a été considérablement élargi, en incluant à présent le moulage et l'empotage et les procédures similaires fournissant une protection contre la pollution. La norme s'applique également à toutes sortes de cartes imprimées enduites, y compris la surface de couches internes de cartes multicouches, de substrats et d'ensembles protégés similaires. Les distances à travers une couche interne de cartes multicouches sont cependant couvertes par les prescriptions pour l'isolation solide de la Partie 1. - La différence entre les deux types de protection a été clarifiée. La protection de type 1 (précédemment type A) aboutit à une réduction du degré de pollution présente au-delà de la protection pour le degré 1 de pollution. La protection de type 2 (précédemment type B) introduit des systèmes de protection qui peuvent être considérés comme similaires à l'isolation solide. Par conséquent, les prescriptions de dimensionnement et d'essais ont été alignées d'une meilleure façon. - Le domaine d'application a été élargi, en incluant à présent l'isolation fonctionnelle, principale, supplémentaire et renforcée. - Les protections de type 1 et type 2 peuvent maintenant être utilisées dans des conditions de degré 3 de pollution (précédemment type B). - Non seulement la protection de type 2 mais également la protection de type 1 nécessitent que, entre les deux parties conductrices, 100 % de la distance à travers l'espacement soient couverts par la protection. - Pour la protection de type 2, des distances minimales ont été introduites. Dans tous les cas, les espacements ne doivent pas être inférieurs à la valeur minimale de 10 µm. - Il est également fait référence à la nouvelle Partie 5 de la CEI 60664. - Les essais suivent de beaucoup plus près les différentes prescriptions pour les protections de type 1 et type 2. L'ensemble protégé doit résister aux essais électriques concernant l'isolation solide de 4.1.2 de la CEI 60664-1. Pour la protection de type 1, l'essai de décharge partielle n'est pas applicable. Pour la protection de type 2, l'essai de décharge partielle est exigé. La tension d'extinction de décharge partielle prescrite et la méthode d'essai sont spécifiées en 4.1.2.4 de la CEI 60664-1. - Les prescriptions pour l'éprouvette d'essai ont été alignées en élargissant le domaine d'application. - Les essais concernant «l'adhérence du revêtement» et «l'essai de résistance aux éraflur

General Information

- Status

- Published

- Publication Date

- 22-Aug-2010

- Technical Committee

- TC 109 - Insulation co-ordination for low-voltage equipment

- Drafting Committee

- WG 2 - TC 109/WG 2

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 04-Nov-2016

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60664-3:2003 (amended 2010) is an international standard published by the International Electrotechnical Commission (IEC) that focuses on insulation coordination for equipment within low-voltage systems. Specifically, Part 3 of this standard addresses the use of coating, potting, or moulding as protective measures against pollution impacting insulation performance.

This standard is essential for manufacturers, designers, and engineers involved in electrical and electronic equipment operating in low-voltage environments, aiming to reduce clearance and creepage distances safely by employing protective encapsulation methods. It extends and complements the requirements set out in IEC 60664-1 and IEC 60664-5, ensuring consistent compatibility and enhanced safety in insulation.

Key Topics

Scope and Application

IEC 60664-3 applies to permanent protective measures, such as coatings, potting compounds, or moulding materials, used on assemblies including printed circuit boards (PCBs), multi-layer boards, and other substrates. This enables reduction of electrical clearance and creepage distances necessary to withstand pollution effects.Types of Protection

- Type 1 Protection: Enhances the microenvironment under the protective layer, effectively lowering pollution degree to pollution degree 1 beyond the protection.

- Type 2 Protection: Provides performance comparable to solid insulation, meeting stricter dimensioning and electrical test requirements including minimum distance rules and partial discharge testing.

Design Requirements

The standard clarifies that 100% of the spacing between conductive parts must be covered with the protective material for both Type 1 and Type 2 protections. Additionally, it sets minimum spacing requirements, with a minimum thickness of 10 µm for Type 2 protection.Testing and Validation

IEC 60664-3 specifies comprehensive tests for confirming the reliability of coatings, potting, and moulding:- Mechanical tests like adhesion and scratch resistance.

- Electrical tests to withstand stress similar to solid insulation.

- Partial discharge tests mandatory for Type 2 protection to ensure insulation integrity.

Extended Application Fields

The standard applies to various forms of insulation-functional, basic, supplementary, and reinforced insulation-broadening its relevance across a wide range of low-voltage equipment.

Applications

Low-Voltage Electrical Equipment Manufacturing

Use of protective coatings, potting, or moulding materials ensures safe and reliable insulation coordination. This is critical in applications such as control panels, switchgear, power supplies, and electronic assemblies.Printed Circuit Board Protection

Coating and potting processes improve pollution resistance on PCBs, including multi-layer designs, where the standard complements solid insulation requirements for inner layers, enabling compact and durable electrical layouts.Pollution-Prone Environments

Agricultural, industrial, and outdoor electrical equipment benefit from reduced leakage currents and enhanced dielectric protection when IEC 60664-3 compliant coatings or encapsulation methods are employed.Equipment Design for Compactness

By allowing reduced clearance and creepage distances through validated protective methods, the standard facilitates designing smaller and more integrated devices without compromising safety.

Related Standards

IEC 60664-1: Principles, Requirements, and Tests

The foundational part of IEC 60664, providing the general rules on clearance, creepage distances, and insulation coordination principles. IEC 60664-3 is intended to be used in conjunction with Part 1.IEC 60664-5: Method for Determining Clearances and Creepage Distances ≤ 2 mm

Part 5 complements Part 3 by detailing measures where very small insulation distances are necessary and supports dimensioning when coatings or mouldings are employed.IEC Guide 104: Basic Safety Publications

This IEC guide emphasizes the safety role IEC 60664-3 plays as a fundamental publication, underscoring its importance in protecting users and equipment.Other Parts of IEC 60664 Series

Including Part 2 (application guide) and Part 4 (high-frequency voltage stress considerations), which complement the understanding and application of insulation coordination.

Summary

IEC 60664-3:2003+A1:2010 is a critical standard for ensuring the safety and reliability of insulation in low-voltage electrical systems through the use of coating, potting, or moulding to protect against pollution. It defines two types of protection methods, aligned testing procedures, and design rules to ensure permanent and effective insulation coordination. This facilitates reduced insulation distances, enabling compact and robust electrical equipment suitable for diverse industrial and environmental conditions while meeting stringent safety requirements.

Adopting IEC 60664-3 compliance supports manufacturers and engineers in delivering high-quality electrical products with enhanced durability against pollution, aiding global harmonization and improving operational safety across low-voltage systems worldwide.

Buy Documents

IEC 60664-3:2003 - Insulation coordination for equipment within low-voltage systems - Part 3: Use of coating, potting or moulding for protection against pollution Released:2/17/2003 Isbn:2831868831

IEC 60664-3:2003+AMD1:2010 CSV - Insulation coordination for equipment within low-voltage systems - Part 3: Use of coating, potting or moulding for protection against pollution Released:8/23/2010 Isbn:9782889121

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60664-3:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Insulation coordination for equipment within low-voltage systems - Part 3: Use of coating, potting or moulding for protection against pollution". This standard covers: Applies to assemblies protected against pollution by the use of coating, potting or moulding, thus allowing a reduction of clearance and creepage distances as described in Part 1 or Part 5. This standard describes the requirements and test procedures for two methods of protection: - type 1 protection improves the microenvironment of the parts under the protection; - type 2 protection is considered to be similar to solid insulation. This standard also applies to all kinds of protected printed boards, including the surface of inner layers of multi-layer boards, substrates and similarly protected assemblies. In the case of multi-layer printed boards, the distances through an inner layer are covered by the requirements for solid insulation in Part 1. This standard refers only to permanent protection. It does not cover assemblies that are subjected to mechanical adjustment or repair. The principles of this standard are applicable to functional, basic, supplementary and reinforced insulation. Has the status of a basic safety publication in accirdance with IEC Guide 104. The major changes made during the revision of IEC 60664-3 were the following: - Part 3 has been exactly aligned with Part 1 (including amendments 1 and 2). It has been made clear that Part 3 can only be used as a whole document together with Part 1 of IEC 60664. - The scope of Part 3 has been greatly extended including now also potting and moulding and similar procedures providing protection against pollution. The standard also applies to all kinds of coated printed boards including the surface of inner-layers of multi-layer boards, substrates and similar protected assemblies. The distances through an inner layer of multi-layer boards however are covered by the requirements for solid insulation in Part 1. - The difference between the two types of protection has been clarified. Type 1 (formerly type A) protection leads to a reduction of the pollution degree present beyond the protection to pollution degree 1. Type 2 (formerly type B) protection introduces protection systems which can be considered similar to solid insulation. Consequently the dimensioning and test requirements have been aligned more correctly. - The area of application has been extended including now functional, basic, supplementary and reinforced insulation. - Type 1 and type 2 protection now can both be used under the conditions of pollution degree 3 (formerly only type B). - Not only type 2 protection but also type 1 protection requires that between two conductive parts 100 % of the distance across the spacing shall be covered by the protection. - For type 2 protection minimum distances have been introduced. In any case the spacings shall not be lower than the minimum value of 10 µm. - Also the new Part 5 of IEC 60664 is referred to. - The tests follow much more closely the different requirements for type 1 and type 2 protection. The protected assembly shall withstand the electrical tests for solid insulation in 4.1.2 of IEC 60664-1. For type 1 protection, the partial discharge test is not applicable. For type 2 protection, the partial discharge test is required. The required partial discharge extinction voltage and the test method are specified in 4.1.2.4 of IEC 60664-1. - The requirements for the test specimen have been aligned with the extended scope. - The tests for the "adhesion of coating" and the "scratch resistance test" have been updated.

Applies to assemblies protected against pollution by the use of coating, potting or moulding, thus allowing a reduction of clearance and creepage distances as described in Part 1 or Part 5. This standard describes the requirements and test procedures for two methods of protection: - type 1 protection improves the microenvironment of the parts under the protection; - type 2 protection is considered to be similar to solid insulation. This standard also applies to all kinds of protected printed boards, including the surface of inner layers of multi-layer boards, substrates and similarly protected assemblies. In the case of multi-layer printed boards, the distances through an inner layer are covered by the requirements for solid insulation in Part 1. This standard refers only to permanent protection. It does not cover assemblies that are subjected to mechanical adjustment or repair. The principles of this standard are applicable to functional, basic, supplementary and reinforced insulation. Has the status of a basic safety publication in accirdance with IEC Guide 104. The major changes made during the revision of IEC 60664-3 were the following: - Part 3 has been exactly aligned with Part 1 (including amendments 1 and 2). It has been made clear that Part 3 can only be used as a whole document together with Part 1 of IEC 60664. - The scope of Part 3 has been greatly extended including now also potting and moulding and similar procedures providing protection against pollution. The standard also applies to all kinds of coated printed boards including the surface of inner-layers of multi-layer boards, substrates and similar protected assemblies. The distances through an inner layer of multi-layer boards however are covered by the requirements for solid insulation in Part 1. - The difference between the two types of protection has been clarified. Type 1 (formerly type A) protection leads to a reduction of the pollution degree present beyond the protection to pollution degree 1. Type 2 (formerly type B) protection introduces protection systems which can be considered similar to solid insulation. Consequently the dimensioning and test requirements have been aligned more correctly. - The area of application has been extended including now functional, basic, supplementary and reinforced insulation. - Type 1 and type 2 protection now can both be used under the conditions of pollution degree 3 (formerly only type B). - Not only type 2 protection but also type 1 protection requires that between two conductive parts 100 % of the distance across the spacing shall be covered by the protection. - For type 2 protection minimum distances have been introduced. In any case the spacings shall not be lower than the minimum value of 10 µm. - Also the new Part 5 of IEC 60664 is referred to. - The tests follow much more closely the different requirements for type 1 and type 2 protection. The protected assembly shall withstand the electrical tests for solid insulation in 4.1.2 of IEC 60664-1. For type 1 protection, the partial discharge test is not applicable. For type 2 protection, the partial discharge test is required. The required partial discharge extinction voltage and the test method are specified in 4.1.2.4 of IEC 60664-1. - The requirements for the test specimen have been aligned with the extended scope. - The tests for the "adhesion of coating" and the "scratch resistance test" have been updated.

IEC 60664-3:2003 is classified under the following ICS (International Classification for Standards) categories: 29.080.30 - Insulation systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60664-3:2003 has the following relationships with other standards: It is inter standard links to EN ISO 17409:2017, IEC 60664-3:2003/AMD1:2010, IEC 60664-3:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60664-3:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

60664-3

INTERNATIONAL

Deuxième édition

STANDARD

Second edition

2003-02

PUBLICATION FONDAMENTALE DE SÉCURITÉ

BASIC SAFETY PUBLICATION

Coordination de l'isolement des matériels

dans les systèmes (réseaux) à basse tension –

Partie 3:

Utilisation de revêtement, d'empotage ou de

moulage pour la protection contre la pollution

Insulation coordination for equipment

within low-voltage systems –

Part 3:

Use of coating, potting or moulding

for protection against pollution

Numéro de référence

Reference number

CEI/IEC 60664-3:2003

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(http://www.iec.ch/searchpub/cur_fut.htm) vous permet (http://www.iec.ch/searchpub/cur_fut.htm) enables

de faire des recherches en utilisant de nombreux you to search by a variety of criteria including text

critères, comprenant des recherches textuelles, par searches, technical committees and date of

comité d’études ou date de publication. Des publication. On-line information is also available

informations en ligne sont également disponibles sur on recently issued publications, withdrawn and

les nouvelles publications, les publications rempla- replaced publications, as well as corrigenda.

cées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published • IEC Just Published

Ce résumé des dernières publications parues This summary of recently issued publications

(http://www.iec.ch/online_news/justpub/jp_entry.htm) (http://www.iec.ch/online_news/justpub/jp_entry.htm)

est aussi disponible par courrier électronique. is also available by email. Please contact the

Veuillez prendre contact avec le Service client Customer Service Centre (see below) for further

(voir ci-dessous) pour plus d’informations. information.

• Service clients • Customer Service Centre

Si vous avez des questions au sujet de cette If you have any questions regarding this

publication ou avez besoin de renseignements publication or need further assistance, please

supplémentaires, prenez contact avec le Service contact the Customer Service Centre:

clients:

Email: custserv@iec.ch Email: custserv@iec.ch

Tél: +41 22 919 02 11 Tel: +41 22 919 02 11

Fax: +41 22 919 03 00 Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

60664-3

INTERNATIONAL

Deuxième édition

STANDARD

Second edition

2003-02

PUBLICATION FONDAMENTALE DE SÉCURITÉ

BASIC SAFETY PUBLICATION

Coordination de l'isolement des matériels

dans les systèmes (réseaux) à basse tension –

Partie 3:

Utilisation de revêtement, d'empotage ou de

moulage pour la protection contre la pollution

Insulation coordination for equipment

within low-voltage systems –

Part 3:

Use of coating, potting or moulding

for protection against pollution

IEC 2003 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in any

utilisée sous quelque forme que ce soit et par aucun procédé, form or by any means, electronic or mechanical, including

électronique ou mécanique, y compris la photo-copie et les photocopying and microfilm, without permission in writing from

microfilms, sans l'accord écrit de l'éditeur. the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

T

Commission Electrotechnique Internationale

PRICE CODE

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

For price, see current catalogue

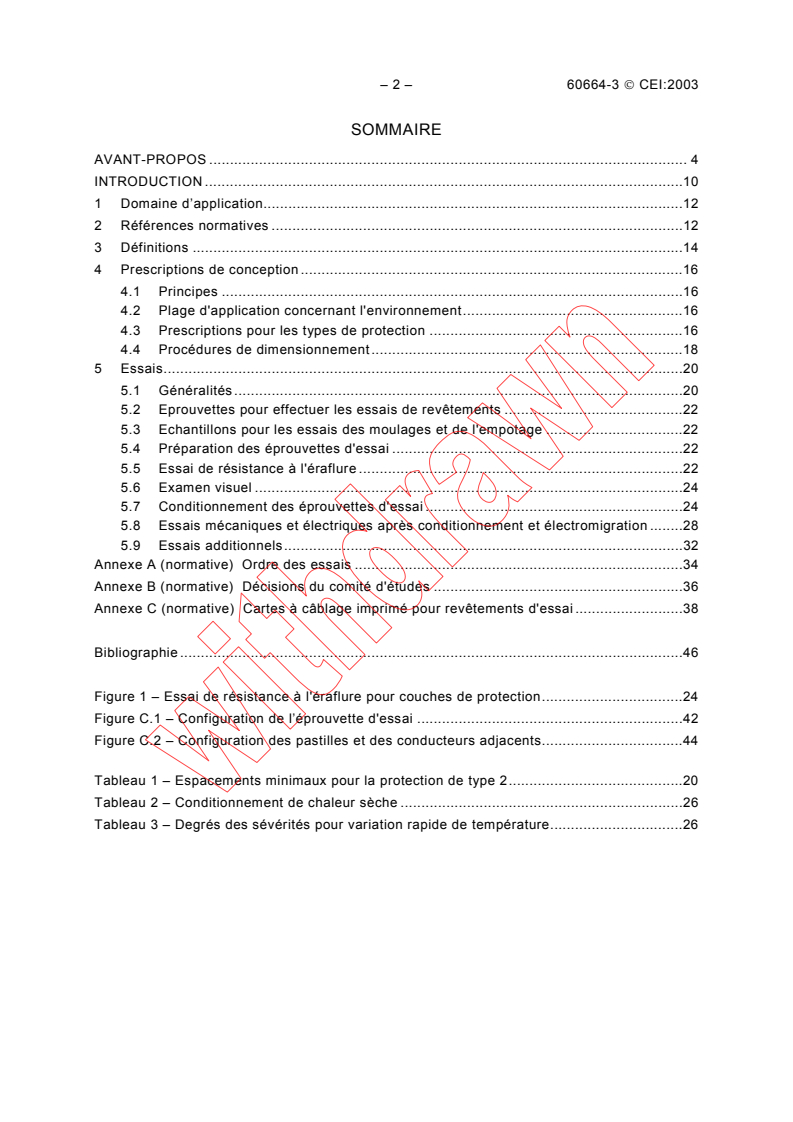

– 2 – 60664-3 CEI:2003

SOMMAIRE

AVANT-PROPOS . 4

INTRODUCTION .10

1 Domaine d’application.12

2 Références normatives .12

3 Définitions .14

4 Prescriptions de conception .16

4.1 Principes .16

4.2 Plage d'application concernant l'environnement.16

4.3 Prescriptions pour les types de protection .16

4.4 Procédures de dimensionnement.18

5 Essais.20

5.1 Généralités.20

5.2 Eprouvettes pour effectuer les essais de revêtements .22

5.3 Echantillons pour les essais des moulages et de l'empotage .22

5.4 Préparation des éprouvettes d'essai .22

5.5 Essai de résistance à l'éraflure .22

5.6 Examen visuel .24

5.7 Conditionnement des éprouvettes d'essai .24

5.8 Essais mécaniques et électriques après conditionnement et électromigration .28

5.9 Essais additionnels.32

Annexe A (normative) Ordre des essais .34

Annexe B (normative) Décisions du comité d'études .36

Annexe C (normative) Cartes à câblage imprimé pour revêtements d'essai .38

Bibliographie .46

Figure 1 – Essai de résistance à l'éraflure pour couches de protection.24

Figure C.1 – Configuration de l’éprouvette d'essai .42

Figure C.2 – Configuration des pastilles et des conducteurs adjacents.44

Tableau 1 – Espacements minimaux pour la protection de type 2.20

Tableau 2 – Conditionnement de chaleur sèche .26

Tableau 3 – Degrés des sévérités pour variation rapide de température.26

60664-3 IEC:2003 – 3 –

CONTENTS

FOREWORD . 5

INTRODUCTION .11

1 Scope .13

2 Normative references.13

3 Definitions .15

4 Design requirements.17

4.1 Principles .17

4.2 Application range regarding environment .17

4.3 Requirements for the types of protection.17

4.4 Dimensioning procedures .19

5 Tests .21

5.1 General .21

5.2 Specimens for testing coatings .23

5.3 Specimens for testing mouldings and potting .23

5.4 Preparation of test specimens.23

5.5 Scratch resistance test .23

5.6 Visual examination .25

5.7 Conditioning of the test specimens .25

5.8 Mechanical and electrical tests after conditioning and electromigration.29

5.9 Additional tests.33

Annex A (normative) Test sequence.35

Annex B (normative) Technical committees' decisions.37

Annex C (normative) Printed wiring board for testing coatings.39

Bibliography.47

Figure 1 – Scratch resistance test for protecting layers .25

Figure C.1 – Configuration of the test specimen .43

Figure C.2 – Configuration of lands and adjacent conductors .45

Table 1 − Minimum spacings for type 2 protection .21

Table 2 – Dry heat conditioning.27

Table 3 – Degrees of severities for rapid change of temperature.27

– 4 – 60664-3 CEI:2003

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COORDINATION DE L’ISOLEMENT DES MATÉRIELS

DANS LES SYSTÈMES (RÉSEAUX) À BASSE TENSION –

Partie 3: Utilisation de revêtement, d'empotage ou de moulage

pour la protection contre la pollution

AVANT-PROPOS

1) La CEI (Commission Electrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les

deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60664-3 a été établie par le comité d’études 109 de la CEI:

Coordination de l'isolement pour le matériel à basse tension.

Cette seconde édition annule et remplace la première édition parue en 1992, dont elle

constitue une révision technique.

Elle a le statut de publication fondamentale de sécurité, conformément au Guide CEI 104.

Le texte de la présente norme est issu des documents suivants:

FDIS Rapport de vote

109/24/FDIS 109/31/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

60664-3 IEC:2003 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATION COORDINATION FOR EQUIPMENT

WITHIN LOW-VOLTAGE SYSTEMS –

Part 3: Use of coating, potting or moulding

for protection against pollution

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60664-3 has been prepared by IEC technical committee 109:

Insulation coordination for low-voltage equipment.

This second edition cancels and replaces the first edition, published in 1992, and constitutes

a technical revision.

It has the status of a basic safety publication in accordance with IEC Guide 104.

The text of this standard is based on the following documents:

FDIS Report on voting

109/24/FDIS 109/31/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 6 – 60664-3 CEI:2003

Les modifications majeures effectuées au cours de la révision de la CEI 60664-3 ont été les

suivantes:

• La Partie 3 a été alignée exactement à la Partie 1 (y compris les amendements 1 et 2).

Il a été précisé que la Partie 3 ne peut être utilisée que comme un document entier ainsi

que la Partie 1 de la CEI 60664.

• Le domaine d’application de la Partie 3 a été considérablement élargi, en incluant à

présent le moulage et l’empotage et les procédures similaires fournissant une protection

contre la pollution. La norme s'applique également à toutes sortes de cartes imprimées

enduites, y compris la surface de couches internes de cartes multicouches, de substrats

et d'ensembles protégés similaires. Les distances à travers une couche interne de cartes

multicouches sont cependant couvertes par les prescriptions pour l'isolation solide de la

Partie 1.

• La différence entre les deux types de protection a été clarifiée. La protection de type 1

(précédemment type A) aboutit à une réduction du degré de pollution présente au-delà de

la protection pour le degré 1 de pollution. La protection de type 2 (précédemment type B)

introduit des systèmes de protection qui peuvent être considérés comme similaires à

l’isolation solide. Par conséquent, les prescriptions de dimensionnement et d’essais ont

été alignées d’une meilleure façon.

• Le domaine d’application a été élargi, en incluant à présent l’isolation fonctionnelle,

principale, supplémentaire et renforcée.

• Les protections de type 1 et type 2 peuvent maintenant être utilisées dans des conditions

de degré 3 de pollution (précédemment type B).

• Non seulement la protection de type 2 mais également la protection de type 1 nécessitent

que, entre les deux parties conductrices, 100 % de la distance à travers l’espacement

soient couverts par la protection.

• Pour la protection de type 2, des distances minimales ont été introduites. Dans tous les

cas, les espacements ne doivent pas être inférieurs à la valeur minimale de 10 µm.

• Il est également fait référence à la nouvelle Partie 5 de la CEI 60664.

• Les essais suivent de beaucoup plus près les différentes prescriptions pour les

protections de type 1 et type 2. L’ensemble protégé doit résister aux essais électriques

concernant l’isolation solide de 4.1.2 de la CEI 60664-1. Pour la protection de type 1,

l’essai de décharge partielle n’est pas applicable. Pour la protection de type 2, l’essai de

décharge partielle est exigé. La tension d'extinction de décharge partielle prescrite et la

méthode d’essai sont spécifiées en 4.1.2.4 de la CEI 60664-1.

• Les prescriptions pour l’éprouvette d’essai ont été alignées en élargissant le domaine

d’application.

• Les essais concernant «l’adhérence du revêtement» et «l’essai de résistance aux

éraflures» ont été mis à jour.

La CEI 60664 comprend les parties suivantes, présentées sous le titre général Coordination

de l'isolement des matériels dans les systèmes (réseaux) à basse tension:

Partie 1: Principes, prescriptions et essais

Partie 2: Guide d’application

Partie 3: Utilisation de revêtement, d'empotage ou de moulage pour la protection contre la

pollution

Partie 4: Considérations sur les contraintes de tension à hautes fréquences

Partie 5: Méthode détaillée de détermination des distances d’isolement dans l’air et des

lignes de fuite inférieures ou égales à 2 mm

60664-3 IEC:2003 – 7 –

The major changes made during the revision of IEC 60664-3 were the following:

• Part 3 has been exactly aligned with Part 1 (including amendments 1 and 2). It has been

made clear that Part 3 can only be used as a whole document together with Part 1 of

IEC 60664.

• The scope of Part 3 has been greatly extended including now also potting and moulding

and similar procedures providing protection against pollution. The standard also applies to

all kinds of coated printed boards including the surface of inner-layers of multi-layer

boards, substrates and similar protected assemblies. The distances through an inner

layer of multi-layer boards however are covered by the requirements for solid insulation

in Part 1.

• The difference between the two types of protection has been clarified. Type 1 (formerly

type A) protection leads to a reduction of the pollution degree present beyond the

protection to pollution degree 1. Type 2 (formerly type B) protection introduces protection

systems which can be considered similar to solid insulation. Consequently the

dimensioning and test requirements have been aligned more correctly.

• The area of application has been extended including now functional, basic, supplementary

and reinforced insulation.

• Type 1 and type 2 protection now can both be used under the conditions of pollution

degree 3 (formerly only type B).

• Not only type 2 protection but also type 1 protection requires that between two conductive

parts 100 % of the distance across the spacing shall be covered by the protection.

• For type 2 protection minimum distances have been introduced. In any case the spacings

shall not be lower than the minimum value of 10 µm.

• Also the new Part 5 of IEC 60664 is referred to.

• The tests follow much more closely the different requirements for type 1 and type 2

protection. The protected assembly shall withstand the electrical tests for solid insulation

in 4.1.2 of IEC 60664-1. For type 1 protection, the partial discharge test is not applicable.

For type 2 protection, the partial discharge test is required. The required partial discharge

extinction voltage and the test method are specified in 4.1.2.4 of IEC 60664-1.

• The requirements for the test specimen have been aligned with the extended scope.

• The tests for the “adhesion of coating” and the “scratch resistance test” have been

updated.

IEC 60664 consists of the following parts under the general title Insulation coordination for

equipment within low-voltage systems:

Part 1: Principles, requirements and tests

Part 2: Application guide

Part 3: Use of coating, potting or moulding for protection against pollution

Part 4: Consideration of high-frequency voltage stress

Part 5: A comprehensive method for determining clearances and creepage distances equal

to or less than 2 mm

– 8 – 60664-3 CEI:2003

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2008.

A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60664-3 IEC:2003 – 9 –

The committee has decided that the contents of this publication will remain unchanged until 2008.

At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 10 – 60664-3 CEI:2003

INTRODUCTION

La présente partie de la CEI 60664 précise les conditions dans lesquelles la réduction des

distances d’isolement dans l’air et des lignes de fuite peuvent s'appliquer aux ensembles

rigides, tels que les cartes imprimées ou les bornes des composants. La protection contre la

pollution peut être obtenue par toutes sortes d'encapsulage, telles que le revêtement,

l'empotage ou le moulage. La protection peut être appliquée sur une face ou sur les deux

faces de l'ensemble. La présente norme spécifie les propriétés isolantes du matériau de

protection.

Entre deux parties conductrices quelconques non protégées, les prescriptions de distances

d'isolement et de lignes de fuite de la CEI 60664-1 ou de la CEI 60664-5 s'appliquent.

La présente norme fait uniquement référence à une protection permanente. Elle n'englobe

pas les ensembles après réparation.

Il est nécessaire que les comités d'études prennent en considération l'influence sur la

protection des conducteurs et composants surchauffés, en particulier dans des conditions de

défaut, et qu’ils décident si toute prescription additionnelle est nécessaire.

Une performance en toute sécurité des ensembles dépend d'un procédé de fabrication précis

et contrôlé pour l'application du système de protection. Il convient que les prescriptions pour

le contrôle de la qualité, par exemple par des essais par échantillonnage, soient prises en

considération par les comités d'études.

60664-3 IEC:2003 – 11 –

INTRODUCTION

This part of IEC 60664 details the conditions in which the reduction of clearance and

creepage distances can apply to rigid assemblies such as printed boards or terminals of

components. Protection against pollution can be achieved by any kind of encapsulation such

as coating, potting or moulding. The protection may be applied to one or both sides of the

assembly. This standard specifies the insulating properties of the protecting material.

Between any two unprotected conductive parts, the clearance and creepage distance

requirements of IEC 60664-1 or IEC 60664-5 apply.

This standard refers only to permanent protection. It does not cover assemblies after repair.

Technical committees need to consider the influence on the protection of overheated

conductors and components, especially under fault conditions, and to decide if any additional

requirements are necessary.

Safe performance of assemblies is dependent upon a precise and controlled manufacturing

process for the application of the protective system. Requirements for quality control, e.g. by

sampling tests, should be considered by technical committees.

– 12 – 60664-3 CEI:2003

COORDINATION DE L’ISOLEMENT DES MATÉRIELS

DANS LES SYSTÈMES (RÉSEAUX) À BASSE TENSION –

Partie 3: Utilisation de revêtement, d'empotage ou de moulage

pour la protection contre la pollution

1 Domaine d’application

La présente partie de la CEI 60664 est applicable aux ensembles protégés contre la pollution

au moyen de revêtement, d'empotage ou de moulage, permettant ainsi une réduction des

distances d'isolement et des lignes de fuite décrites dans la Partie 1 ou la Partie 5.

NOTE 1 Lorsqu’il est fait référence à la Partie 1 ou la Partie 5, on sous-entend la CEI 60664-1 ou la CEI 60664-5.

Cette norme décrit les prescriptions et procédures d'essai pour deux méthodes de protection:

– la protection de type 1 améliore le micro-environnement des parties sous protection;

– la protection de type 2 est considérée comme similaire à l'isolation solide.

La présente norme s'applique également à toutes sortes de cartes imprimées protégées,

y compris la surface de couches internes de cartes multicouches, de substrats et d'ensembles

protégés de manière similaire. Dans le cas de cartes imprimées multicouches, les distances

à travers une couche interne sont couvertes par les prescriptions pour l'isolation solide dans

la Partie 1.

NOTE 2 À titre d'exemples de substrats on peut citer les circuits intégrés hybrides et la technologie

à couches épaisses.

La présente norme fait uniquement référence à une protection permanente. Elle n'englobe

pas les ensembles soumis à une mise au point mécanique ou à des réparations.

Les principes de cette norme sont applicables à l'isolation fonctionnelle, principale, supplé-

mentaire et renforcée.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60068-2-1:1990, Essais d’environnement – Partie 2: Essais – Essais A: Froid

Amendement 1 (1993)

Amendement 2 (1994)

CEI 60068-2-2:1974, Essais fondamentaux climatiques et de robustesse mécanique –

Partie 2: Essais – Essais B: Chaleur sèche

Amendement 1 (1993)

Amendement 2 (1994)

CEI 60068-2-14:1984, Essais fondamentaux climatiques et de robustesse mécanique –

Partie 2: Essais – Essai N: Variation de température

Amendement 1 (1986)

CEI 60068-2-78:2001, Essais d’environnement – Partie 2-78: Essais – Essai Cab: Chaleur

humide, essai continu

60664-3 IEC:2003 – 13 –

INSULATION COORDINATION FOR EQUIPMENT

WITHIN LOW-VOLTAGE SYSTEMS –

Part 3: Use of coating, potting or moulding

for protection against pollution

1 Scope

This part of IEC 60664 applies to assemblies protected against pollution by the use of

coating, potting or moulding, thus allowing a reduction of clearance and creepage distances

as described in Part 1 or Part 5.

NOTE 1 When reference is made to Part 1 or Part 5, IEC 60664-1 or IEC 60664-5 are meant.

This standard describes the requirements and test procedures for two methods of protection:

– type 1 protection improves the microenvironment of the parts under the protection;

– type 2 protection is considered to be similar to solid insulation.

This standard also applies to all kinds of protected printed boards, including the surface of

inner layers of multi-layer boards, substrates and similarly protected assemblies. In the case

of multi-layer printed boards, the distances through an inner layer are covered by the

requirements for solid insulation in Part 1.

NOTE 2 Examples of substrates are hybrid integrated circuits and thick-film technology.

This standard refers only to permanent protection. It does not cover assemblies that are

subjected to mechanical adjustment or repair.

The principles of this standard are applicable to functional, basic, supplementary and

reinforced insulation.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068-2-1:1990, Environmental testing − Part 2: Tests − Tests A: Cold

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-2:1974, Basic environmental testing procedures − Part 2: Tests − Tests B:

Dry heat

Amendment 1 (1993)

Amendment 2 (1994)

IEC 60068-2-14:1984, Basic environmental testing procedures − Part 2: Tests − Test N:

Change of temperature

Amendment 1 (1986)

IEC 60068-2-78:2001, Environmental testing − Part 2-78: Tests − Test Cab: Damp heat,

steady state

– 14 – 60664-3 CEI:2003

CEI 60249-1:1982, Matériaux de base pour circuits imprimés – Partie 1: Méthodes d'essai

Amendement 4 (1993)

CEI 60249-2 (toutes les parties), Matériaux de base pour circuits imprimés – Partie 2:

Spécifications

IEC 60326-2:1990, Cartes imprimées – Partie 2: Méthodes d'essai

Amendement 1 (1992)

IEC 60454-3-1:1998, Rubans adhésifs sensibles à la pression à usages électriques –

Partie 3: Spécifications pour matériaux particuliers – Feuille 1: Rubans en PVC avec un

adhésif sensible à la pression

CEI 60664-1:1992, Coordination de l'isolement des matériels dans les systèmes (réseaux) à

basse tension – Partie 1: Principes, prescriptions et essais

Amendement 1 (2000)

Amendement 2 (2002)

CEI 60664-5:, Coordination de l'isolement des matériels dans les systèmes (réseaux) à

basse tension – Partie 5: Méthode détaillée de détermination des distances d'isolement dans

1)

l'air et des lignes de fuite inférieures ou égales à 2 mm

Guide CEI 104:1997, Élaboration des publications de sécurité et utilisation des publications

fondamentales de sécurité et des publications groupées de sécurité

3 Définitions

Pour les besoins du présent document, les définitions de la CEI 60664-1 s’appliquent, ainsi

que les définitions suivantes.

3.1

matériau de base

matériau isolant sur lequel peut être réalisée une impression conductrice

NOTE Le matériau de base peut être rigide ou souple, ou encore les deux. Il peut s'agir d'un diélectrique ou d'une

feuille de métal isolée.

(CEI 60194, traduction de la définition 40.1334)

3.2

carte imprimée

terme général pour configurations de câblage imprimé et circuit imprimé entièrement traités

NOTE Cela comprend les cartes simple face, double face et multicouches à matériaux rigides, souples et

flexorigides.

(CEI 60194, traduction de la définition 60.1485)

3.3

conducteur

chemin conducteur simple d’une impression conductrice

(CEI 60194, traduction de la définition 22.0251)

3.4

protection

toute mesure qui réduit l’influence de l’environnement

———————

1)

A publier.

60664-3 IEC:2003 – 15 –

IEC 60249-1:1982, Base materials for printed circuits – Part 1: Test methods

Amendment 4 (1993)

IEC 60249-2 (all parts), Base materials for printed circuit – Part 2: Specifications

IEC 60326-2:1990, Printed boards – Part 2: Test methods

Amendment 1 (1992)

IEC 60454-3-1:1998, Pressure-sensitive adhesive tapes for electrical purposes – Part 3:

Specifications for individual materials – Sheet 1: PVC film tapes with pressure-sensitive

adhesive

IEC 60664-1:1992, Insulation coordination for equipment within low-voltage systems – Part 1:

Principles, requirements and tests

Amendment 1 (2000)

Amendment 2 (2002)

IEC 60664-5:, Insulation coordination for equipment within low-voltage systems – Part 5:

A comprehensive method for determining clearance and creepage distances equal to or less

1)

than 2 mm

IEC Guide 104:1997, The preparation of safety publications and the use of basic safety

publications and group safety publications

3 Definitions

For the purposes of this document, the definitions given in IEC 60664-1 as well as the

following definitions apply.

3.1

base material

insulating material upon which a conductive pattern may be formed

NOTE The base material may be rigid or flexible, or both. It may be a dielectric or an insulated metal sheet.

(IEC 60194, definition 40.1334)

3.2

printed board

general term for completely processed printed circuit and printed wiring configurations

NOTE This includes single-sided, double-sided and multilayer boards with rigid, flexible, and rigid-flex base

materials

(IEC 60194, definition 60.1485)

3.3

conductor

single conductive path in a conductive pattern

(IEC 60194, definition 22.0251)

3.4

protection

any kind of measure which reduces the influence of the environment

———————

1)

To be published.

– 16 – 60664-3 CEI:2003

3.5

revêtement

matériau isolant tel que vernis ou film sec posé sur la surface de l'ensemble

NOTE Le revêtement et le matériau de base d'une carte imprimée forment un système isolant qui peut avoir des

propriétés similaires à l'isolation solide.

3.6

isolation solide

matériau isolant solide placé entre deux parties conductrices

NOTE Dans le cas d’une carte imprimée à revêtement, l’isolation solide est constituée de la carte elle-même ainsi

que du revêtement. Dans les autres cas, l’isolation solide est constituée du matériau d’encapsulation.

3.7

espacement

toute combinaison de distances d'isolement, de lignes de fuite et des distances à travers

l'isolation

4 Prescriptions de conception

4.1 Principes

Le dimensionnement des espacements entre les conducteurs dépend du type de protection

utilisé.

Lorsque la protection de type 1 est utilisée, le dimensionnement des distances d'isolement et

des lignes de fuite doivent suivre les prescriptions de la Partie 1 ou de la Partie 5. Si les

prescriptions de cette norme sont satisfaites, le degré 1 de pollution s'applique sous la

protection.Lorsque la protection de type 2 est utilisée, les espacements entre les parties

conductrices doivent satisfaire aux prescriptions et aux essais pour l'isolation solide de la

Partie 1 et leurs dimensions ne doivent pas être inférieures aux distances d'isolement

minimales spécifiées dans la Partie 1 ou la Partie 5 pour des conditions de champ

homogènes.

4.2 Plage d'application concernant l'environnement

Les prescriptions de conception sont applicables dans tous les micro-environnements.

Les contraintes, telles que celles de température, chimiques, mécaniques, ou bien celles

énumérées en 3.3.2.3 de la Partie 1, doivent être prises en compte lorsque l'on sélectionne le

matériau de protection.

L'absorption d'humidité par le matériau de protection ne doit pas affecter les propriétés

d'isolation des parties protégées.

NOTE L'absorption d'humidité peut être vérifiée par une mesure de résistance d'isolement dans des conditions

humides.

4.3 Prescriptions pour les types de protection

La protection est obtenue des manières suivantes:

– la protection de type 1 améliore le micro-environnement des parties sous protection. Les

prescriptions de distance d'isolement et de lignes de fuite de la Partie 1 ou de la Partie 5

pour le degré 1 de pollution s'appliquent sous la protection. Entre deux parties conduc-

trices, il est prescrit qu'une partie conductrice ou les deux ainsi que tous les espacements

entre elles soient couverts par la protection;

60664-3 IEC:2003 – 17 –

3.5

coating

insulating material such as varnish or dry film laid on the surface of the assembly

NOTE Coating and base material of a printed board form an insulating system that may have properties similar to

solid insulation.

3.6

solid insulation

solid insulating material interposed between two conductive parts

NOTE In the case of a printed board with a coating, solid insulation consists of the board itself as well as the

coating. In other cases, solid insulation consists of the encapsulating material.

3.7

spacing

any combination of clearances, creepage distances and insulation distances through

insulation

4 Design requirements

4.1 Principles

Dimensioning of spacings between conductors depends on the type of protection used.

When type 1 protection is used, dimensioning of clearances and creepage distances shall

follow the requirements of Part 1 or Part 5. If the requirements of this standard are met,

pollution degree 1 applies under the protection.

When type 2 protection is used, spacings between conductive parts shall meet the

requirements and tests for solid insulation of Part 1 and their dimensions shall not be less

than the minimum clearances specified in Part 1 or Part 5 for homogeneous field conditions.

4.2 Application range regarding environment

The design requirements are applicable in all microenvironments.

Stresses such as temperature, chemical, mechanical or those listed in 3.3.2.3 of Part 1 shall

be taken into account when the protective material is selected.

Absorption of humidity by the protective material shall not impair the insulation properties of

the parts being protected.

NOTE Absorption of humidity can be checked by an insulation resistance measurement under humid conditions.

4.3 Requirements for the types of protection

Protection is achieved in the following ways:

– type 1 protection improves the microenvironment of the parts under the protection. The

clearance and creepage distance requirements of Part 1 or Part 5 for pollution degree 1

apply under the protection. Between two conductive parts, it is a requirement that one or

both conductive parts, together with all the spacings between them, are covered by the

protection;

– 18 – 60664-3 CEI:2003

– la protection de type 2 est considérée comme similaire à l'isolation solide. Sous protection,

les prescriptions pour isolation solide spécifiées dans la Partie 1 sont applicables et les

espacements ne doivent pas être inférieurs à ceux qui sont spécifiés dans le Tableau 1.

Les prescriptions pour distances d'isolement et lignes de fuite de la Partie 1 ou de la

Partie 5 ne s'appliquent pas. Entre deux parties conductrices, il est prescrit que les deux

parties conductrices ainsi que tous les espacements entre elles soient couverts par la

protection de sorte qu'il n'existe aucun entrefer entre le matériau de protection, les parties

conductrices et la carte imprimée.

Les prescriptions de distance d'isolement et de ligne de fuite conformément à la Partie 1 ou

de la Partie 5 s'appliquent à toutes les parties non protégées des matériels.

4.4 Procédures de dimensionnement

Pour la protection de type 1, les prescriptions de dimensionnement de 3.1 et 3.2 de la Par-

tie 1 ou de la Partie 5 s'appliquent.

Pour la protection de type 2, l'espacement entre les conducteurs avant d'appliquer la

protection ne doit pas être inférieur aux valeurs spécifiées dans le Tableau 1. Ces valeurs

s'appliquent à l'isolation principale, l’isolation supplémentaire, ainsi que l’isolation renforcée.

NOTE Dans le cas des cartes multicouches, l’espacement entre les conducteurs à la surface des couches

internes est dimensionné comme spécifié pour la protection de type 1 ou la protection de type 2 en fonction du

résultat des essais sur la protection.

60664-3 IEC:2003 – 19 –

– type 2 protection is considered to be similar to solid insulation. Under the protection, the

requirements for solid insulation specified in Part 1 are applicable and the spacings shall

be not less than those specified in Table 1. The requirements for clearances and creepage

distances in Part 1 or

...

IEC 60664-3 ®

Edition 2.1 2010-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Insulation coordination for equipment within low-voltage systems –

Part 3: Use of coating, potting or moulding for protection against pollution

Coordination de l'isolement des matériels dans les systèmes (réseaux) à basse

tension –

Partie 3: Utilisation de revêtement, d'empotage ou de moulage pour la protection

contre la pollution

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60664-3 ®

Edition 2.1 2010-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Insulation coordination for equipment within low-voltage systems –

Part 3: Use of coating, potting or moulding for protection against pollution

Coordination de l'isolement des matériels dans les systèmes (réseaux) à basse

tension –

Partie 3: Utilisation de revêtement, d'empotage ou de moulage pour la

protection contre la pollution

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CK

CODE PRIX

ICS 29.080.30 ISBN 978-2-88912-119-9

– 2 – 60664-3 © IEC:2003+A1:2010

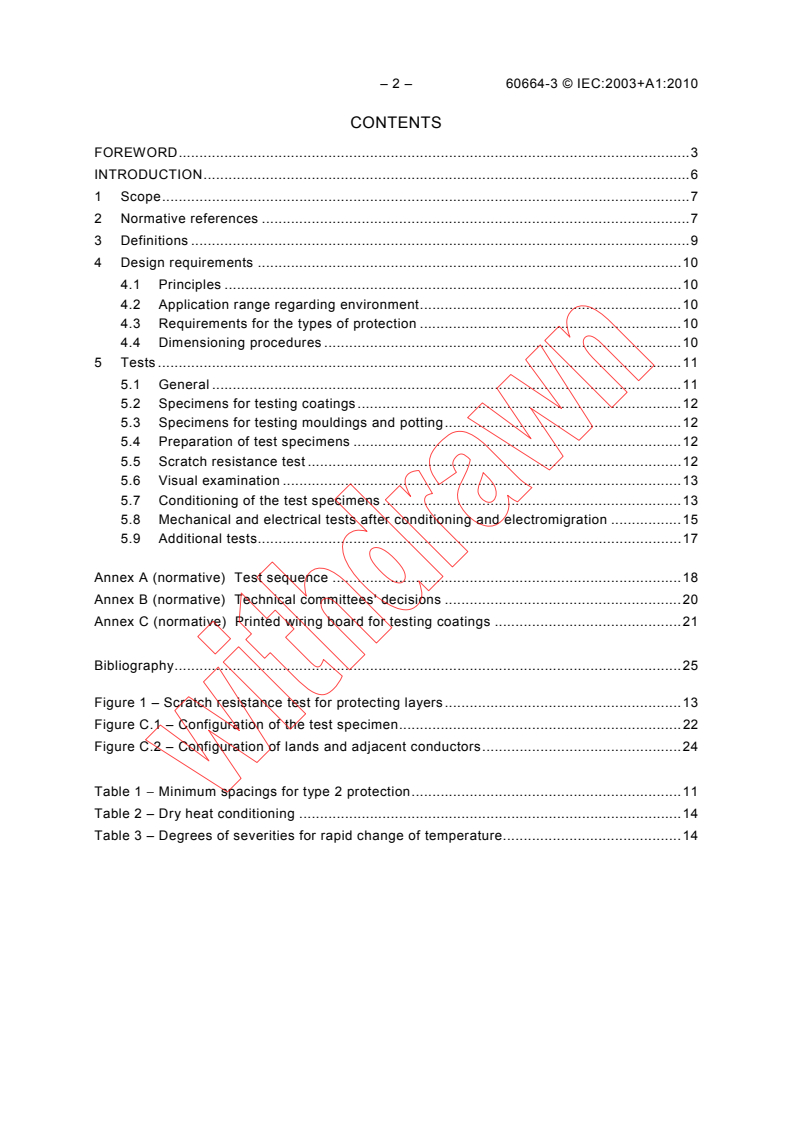

CONTENTS

FOREWORD.3

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Definitions.9

4 Design requirements.10

4.1 Principles.10

4.2 Application range regarding environment.10

4.3 Requirements for the types of protection .10

4.4 Dimensioning procedures.10

5 Tests.11

5.1 General.11

5.2 Specimens for testing coatings.12

5.3 Specimens for testing mouldings and potting.12

5.4 Preparation of test specimens .12

5.5 Scratch resistance test .12

5.6 Visual examination.13

5.7 Conditioning of the test specimens .13

5.8 Mechanical and electrical tests after conditioning and electromigration .15

5.9 Additional tests.17

Annex A (normative) Test sequence .18

Annex B (normative) Technical committees' decisions .20

Annex C (normative) Printed wiring board for testing coatings .21

Bibliography.25

Figure 1 – Scratch resistance test for protecting layers.13

Figure C.1 – Configuration of the test specimen.22

Figure C.2 – Configuration of lands and adjacent conductors.24

Table 1 − Minimum spacings for type 2 protection.11

Table 2 – Dry heat conditioning .14

Table 3 – Degrees of severities for rapid change of temperature.14

60664-3 © IEC:2003+A1:2010 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INSULATION COORDINATION FOR EQUIPMENT

WITHIN LOW-VOLTAGE SYSTEMS –

Part 3: Use of coating, potting or moulding

for protection against pollution

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of IEC 60664-3 consists of the second edition (2003)

[documents 109/24/FDIS and 109/31/RVD], its amendment 1 (2010) [documents

109/79/FDIS and 109/81/RVD] and its corrigendum of November 2010. It bears the

edition number 2.1.

The technical content is therefore identical to the base edition and its amendment and

has been prepared for user convenience. A vertical line in the margin shows where the

base publication has been modified by amendment 1. Additions and deletions are

displayed in red, with deletions being struck through.

– 4 – 60664-3 © IEC:2003+A1:2010

International Standard IEC 60664-3 has been prepared by IEC technical committee 109:

Insulation coordination for low-voltage equipment.

It has the status of a basic safety publication in accordance with IEC Guide 104.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The major changes made during the revision of IEC 60664-3 were the following:

• Part 3 has been exactly aligned with Part 1 (including amendments 1 and 2). It has been

made clear that Part 3 can only be used as a whole document together with Part 1 of

IEC 60664.

• The scope of Part 3 has been greatly extended including now also potting and moulding

and similar procedures providing protection against pollution. The standard also applies to

all kinds of coated printed boards including the surface of inner-layers of multi-layer

boards, substrates and similar protected assemblies. The distances through an inner

layer of multi-layer boards however are covered by the requirements for solid insulation

in Part 1.

• The difference between the two types of protection has been clarified. Type 1 (formerly

type A) protection leads to a reduction of the pollution degree present beyond the

protection to pollution degree 1. Type 2 (formerly type B) protection introduces protection

systems which can be considered similar to solid insulation. Consequently the

dimensioning and test requirements have been aligned more correctly.

• The area of application has been extended including now functional, basic, supplementary

and reinforced insulation.

• Type 1 and type 2 protection now can both be used under the conditions of pollution

degree 3 (formerly only type B).

• Not only type 2 protection but also type 1 protection requires that between two conductive

parts 100 % of the distance across the spacing shall be covered by the protection.

• For type 2 protection minimum distances have been introduced. In any case the spacings

shall not be lower than the minimum value of 10 µm.

• Also the new Part 5 of IEC 60664 is referred to.

• The tests follow much more closely the different requirements for type 1 and type 2

protection. The protected assembly shall withstand the electrical tests for solid insulation

in 4.1.2 of IEC 60664-1. For type 1 protection, the partial discharge test is not applicable.

For type 2 protection, the partial discharge test is required. The required partial discharge

extinction voltage and the test method are specified in 4.1.2.4 of IEC 60664-1.