IEC 60981:2019

(Main)Extra heavy-duty electrical rigid steel conduits

Extra heavy-duty electrical rigid steel conduits

IEC 60981:2019 specifies requirements for extra heavy-duty electrical rigid steel (EHDERS) conduits, couplings, nipples and elbows for electrical installations, including communications and fibre optics. This document also specifies threads for these components. It is not applicable to the conduits specified in IEC 60423. This third edition cancels and replaces the second edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the second edition:

- addition of provisions for alternative coatings to zinc;

- addition of elasticity test for organic coatings;

- new Annex B on tests for evaluating alternative exterior coatings applied on extra heavyduty electrical rigid steel (EHDERS) conduits.

Conduits électriques très lourds rigides en acier

General Information

- Status

- Published

- Publication Date

- 19-Aug-2019

- Technical Committee

- SC 23A - Cable management systems

- Drafting Committee

- MT 1 - TC 23/SC 23A/MT 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Aug-2019

- Completion Date

- 20-Sep-2019

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 05-Sep-2023

Overview

IEC 60981:2019 - Extra heavy-duty electrical rigid steel conduits (EHDERS) - is the third edition international standard that defines requirements for extra heavy‑duty electrical rigid steel conduits, couplings, nipples and elbows, including thread forms and protective coatings. It applies to conduits used in electrical installations - including communications and fibre‑optics - and replaces the 2004 edition. The standard is explicit that it does not apply to the conduits covered by IEC 60423.

Key topics and technical requirements

- Scope and components: Requirements for EHDERS conduits, couplings, nipples and 90° elbows; thread specifications for these parts.

- Dimensions & threads: Specified conduit wall thicknesses, diameters and thread forms to ensure interchangeability and mechanical integrity.

- Protective coatings: Detailed rules for zinc coatings and provisions for alternative exterior coatings (new in 2019). Annex B provides test methods for evaluating alternative corrosion‑resistant coatings.

- Coating tests: Inclusion of an elasticity test for organic coatings and other test programs (e.g., salt spray, UV, and oven conditioning referenced via ISO/IEC methods) to verify adhesion and durability.

- Mechanical and manufacturing requirements: Welding, cleaning, chamfering, coupling dimensions, ductility and bending performance, and marking requirements for traceability.

- Test methods & annexes: Normative Annex A covers zinc thickness testing; Annex B contains a new, systematic test program for alternative exterior coatings. Normative references include IEC 60695‑11‑3, IEC 61950, ISO 9227, ISO 4892‑2, among others.

Practical applications and users

Who uses IEC 60981:2019:

- Conduit and fittings manufacturers - to design and certify EHDERS products that meet international performance and interchangeability requirements.

- Electrical engineers and specifiers - to select compatible conduits and fittings for robust electrical and communications installations.

- Procurement and compliance teams - to set procurement criteria and verify supplier conformity.

- Certifiers and test laboratories - to perform the standardized coating, mechanical and thread tests required by the standard.

Typical applications:

- Heavy‑duty electrical installations in industrial and commercial buildings.

- Conduit runs that enclose power, communications and fibre‑optics cabling where enhanced mechanical protection and corrosion resistance are required.

Related standards

- IEC 60423 (different conduit types - not covered by IEC 60981)

- IEC 61950 (conduit fittings and accessories)

- IEC 60695‑11‑3, ISO 9227, ISO 4892‑2 (referenced test methods)

IEC 60981:2019 provides manufacturers, engineers and compliance teams with a clear, updated technical framework for specifying and testing extra heavy‑duty steel conduit systems, including modern options for corrosion protection and validated test procedures for alternative coatings.

IEC 60981:2019 - Extra heavy-duty electrical rigid steel conduits

REDLINE IEC 60981:2019 - Extra heavy-duty electrical rigid steel conduits Released:8/20/2019 Isbn:9782832273319

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60981:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Extra heavy-duty electrical rigid steel conduits". This standard covers: IEC 60981:2019 specifies requirements for extra heavy-duty electrical rigid steel (EHDERS) conduits, couplings, nipples and elbows for electrical installations, including communications and fibre optics. This document also specifies threads for these components. It is not applicable to the conduits specified in IEC 60423. This third edition cancels and replaces the second edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the second edition: - addition of provisions for alternative coatings to zinc; - addition of elasticity test for organic coatings; - new Annex B on tests for evaluating alternative exterior coatings applied on extra heavyduty electrical rigid steel (EHDERS) conduits.

IEC 60981:2019 specifies requirements for extra heavy-duty electrical rigid steel (EHDERS) conduits, couplings, nipples and elbows for electrical installations, including communications and fibre optics. This document also specifies threads for these components. It is not applicable to the conduits specified in IEC 60423. This third edition cancels and replaces the second edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the second edition: - addition of provisions for alternative coatings to zinc; - addition of elasticity test for organic coatings; - new Annex B on tests for evaluating alternative exterior coatings applied on extra heavyduty electrical rigid steel (EHDERS) conduits.

IEC 60981:2019 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60981:2019 has the following relationships with other standards: It is inter standard links to EN IEC 60947-1:2021, IEC 60981:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60981:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60981 ®

Edition 3.0 2019-08

INTERNATIONAL

STANDARD

colour

inside

Extra heavy-duty electrical rigid steel conduits

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60981 ®

Edition 3.0 2019-08

INTERNATIONAL

STANDARD

colour

inside

Extra heavy-duty electrical rigid steel conduits

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.10 ISBN 978-2-8322-7310-4

– 2 – IEC 60981:2019 © IEC 2019

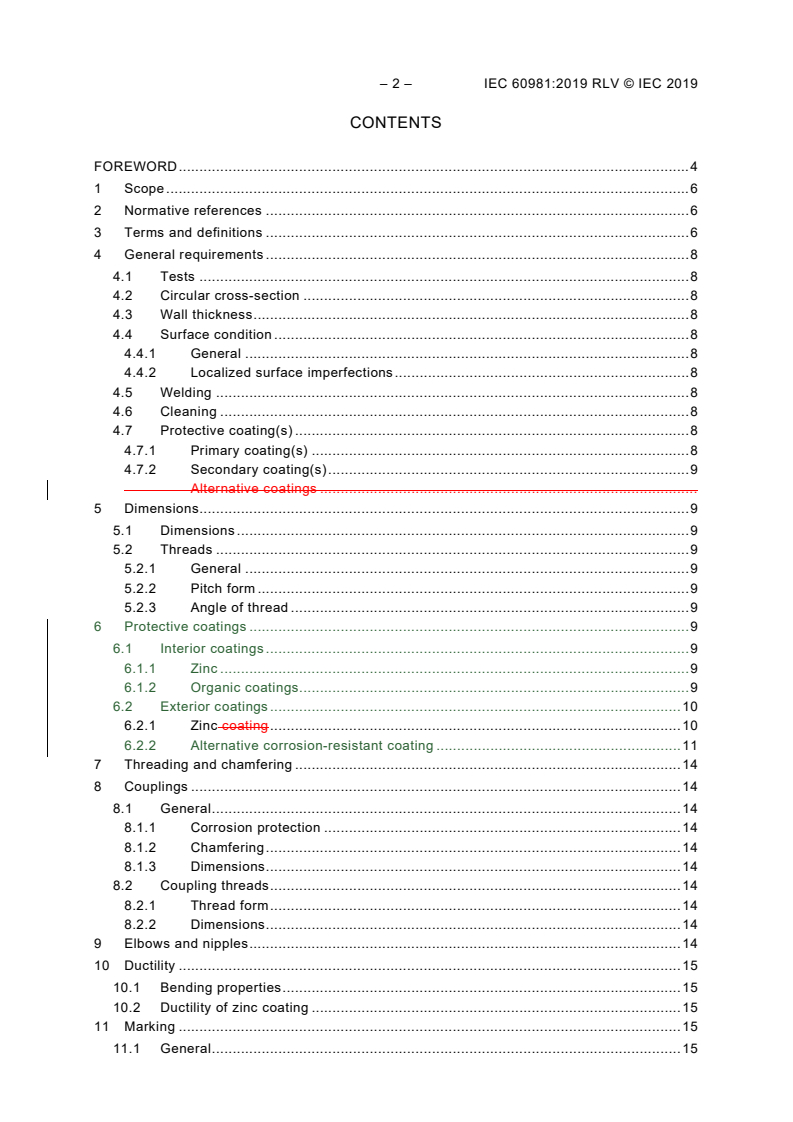

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 8

4.1 Tests . 8

4.2 Circular cross-section . 8

4.3 Wall thickness . 8

4.4 Surface condition . 8

4.4.1 General . 8

4.4.2 Localized surface imperfections . 8

4.5 Welding . 8

4.6 Cleaning . 8

4.7 Protective coating(s) . 8

4.7.1 Primary coating(s) . 8

4.7.2 Secondary coating(s) . 9

5 Dimensions. 9

5.1 Dimensions . 9

5.2 Threads . 9

5.2.1 General . 9

5.2.2 Pitch form . 9

5.2.3 Angle of thread . 9

6 Protective coatings . 9

6.1 Interior coatings . 9

6.1.1 Zinc . 9

6.1.2 Organic coatings. 9

6.2 Exterior coatings . 10

6.2.1 Zinc . 10

6.2.2 Alternative corrosion-resistant coating . 10

7 Threading and chamfering . 13

8 Couplings . 14

8.1 General . 14

8.1.1 Corrosion protection . 14

8.1.2 Chamfering . 14

8.1.3 Dimensions . 14

8.2 Coupling threads . 14

8.2.1 Thread form . 14

8.2.2 Dimensions . 14

9 Elbows and nipples . 14

10 Ductility . 14

10.1 Bending properties . 14

10.2 Ductility of zinc coating . 14

11 Marking . 15

11.1 General . 15

11.2 Required information . 15

Annex A (normative) Test for thickness of zinc coating on extra heavy-duty electrical

rigid steel (EHDERS) conduits . 24

A.1 Requirement . 24

A.2 Solutions required . 24

A.3 Preparation of samples . 24

A.4 Specimen surface condition . 24

A.5 Test method . 24

A.6 Results . 25

Annex B (normative) Tests for evaluating alternative exterior coatings applied on extra

heavy-duty electrical rigid steel (EHDERS) conduits . 26

B.1 Alternative corrosion-resistant coatings . 26

B.2 Preparation of specimens . 26

B.3 Air oven conditioning exposure . 28

B.4 Resistance to ultraviolet light and water exposure . 29

B.5 Resistance to salt spray (fog) exposure . 29

B.6 Resistance to moist carbon dioxide-sulfur dioxide-air exposure . 29

Bibliography . 30

Figure 1 – Dimensions of threads for EHDERS conduits . 18

Figure 2 – Basic form of taper thread . 19

Figure 3 – Limits on crest and root truncation of external and internal threads . 20

Figure 4 – Dimensions of a ferrous metal coupling . 21

Figure 5 – Dimensions of wedge . 22

Figure 6 – Essential dimensions for flame test . 23

Figure B.1 – Alternative corrosion program flowchart with sample requirements . 27

Figure B.2 – Scribe pattern . 28

Table 1 – Dimensions and mass of EHDERS conduits . 16

Table 2 – Dimensions of couplings . 17

Table 3 – Dimensions of 90° elbows . 17

– 4 – IEC 60981:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXTRA HEAVY-DUTY ELECTRICAL RIGID STEEL CONDUITS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60981 has been prepared by subcommittee 23A: Cable

management systems, of IEC technical committee 23: Electrical accessories.

This third edition cancels and replaces the second edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the second

edition:

a) addition of provisions for alternative coatings to zinc;

b) addition of elasticity test for organic coatings;

c) new Annex B on tests for evaluating alternative exterior coatings applied on extra

heavy-duty electrical rigid steel (EHDERS) conduits.

The text of this International Standard is based on the following documents:

FDIS Report on voting

23A/886/FDIS 23A/888/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this document, the following print types are used:

• requirements proper: in roman type;

• test specifications: in italic type;

• explanatory matter: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60981:2019 © IEC 2019

EXTRA HEAVY-DUTY ELECTRICAL RIGID STEEL CONDUITS

1 Scope

This document specifies requirements for extra heavy-duty electrical rigid steel (EHDERS)

conduits, couplings, nipples and elbows for electrical installations, including communications

and fibre optics. This document also specifies threads for these components.

It is not applicable to the conduits specified in IEC 60423.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60695-11-3, Fire hazard testing – Part 11-3: Test flames – 500 W flames – Apparatus and

confirmational test methods

IEC 61950, Cable management systems – Specifications for conduit fittings and accessories

for cable installations for extra heavy duty electrical steel conduit

ISO 527 (all parts), Plastics – Determination of tensile properties

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 9227, Corrosion tests in artificial atmospheres – Salt spray tests

ISO 13263, Thermoplastics piping systems for non-pressure underground drainage and

sewerage – Thermoplastics fittings – Test method for impact strength

ISO 19095-3, Plastics – Evaluation of the adhesion interface performance in plastic-metal

assemblies – Part 3: Test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

extra heavy-duty electrical rigid steel conduit

EHDERS conduit

part of a closed wiring system of circular cross-section made of welded steel construction

capable of providing extra heavy mechanical protection to conductors or cables in electrical

installations and used as an equipment earthing conductor when installed utilizing appropriate

fittings

3.2

straight conduit

straight length of EHDERS, greater than 0,6 m long and threaded at each end, without a

coupling

3.3

finished conduit

straight length of EHDERS with one coupling attached

3.4

threaded coupling

internally threaded steel cylinder for connecting two sections of an EHDERS conduit

3.5

elbow

factory-curved section of an EHDERS conduit threaded at each end

3.6

glowing combustion

combustion of a material in the solid phase without flame but with emission of light from the

combustion zone

3.7

nipple

straight section of an EHDERS conduit not more than 0,6 m long and threaded at each end

3.8

type test

test made on a specimen for the conformity of the design of a given product to the

requirements of the relevant document

3.9

alternative corrosion-resistant coating

exterior primary coating(s) other than one consisting solely of zinc

Note 1 to entry: The coating(s) may include zinc. See Annex B.

3.10

organic coating

coating(s) other than one consisting solely of zinc

Note 1 to entry: The coating(s) may include zinc.

3.11

zinc coating

interior or exterior primary coating consisting solely of zinc

– 8 – IEC 60981:2019 © IEC 2019

4 General requirements

4.1 Tests

Tests according to this document shall be type tests.

Unless otherwise specified, the tests shall be carried out at an ambient temperature of

(20 ± 5) °C.

Unless otherwise specified, each test shall be carried out on two new samples. If a sample

tested in accordance with this document fails, two additional samples shall be tested, both of

which shall comply with all the requirements of this document.

4.2 Circular cross-section

An EHDERS conduit shall have a circular cross-section sufficiently accurate to allow the

cutting of threads in accordance with Figure 1.

4.3 Wall thickness

The wall thickness shall comply with the dimensions given in Table 1.

4.4 Surface condition

4.4.1 General

Surfaces of a conduit shall be free from slivers, burrs, scale and other defects likely to cause

damage to conductors or cables.

Compliance shall be checked by visual inspection of the external and internal surfaces.

4.4.2 Localized surface imperfections

Localized surface imperfections shall not exceed a depth of 12,5 % of the nominal wall

thickness given in Table 1.

Compliance of localized surface imperfections shall be checked by measurement.

4.5 Welding

The welding of all seams shall be continuous and carried out in a professional manner.

Compliance is checked by visual inspection.

4.6 Cleaning

The conduit shall be adequately cleaned before the application of the protective coating. The

cleaning process shall leave the exterior and interior surfaces of the conduit in such a

condition that the protective coating will be firmly adherent and smooth, as defined in 4.4.

4.7 Protective coating(s)

4.7.1 Primary coating(s)

The exterior surface shall be thoroughly and evenly coated with either a metallic zinc or an

alternative corrosion protection coating applied directly to the surface of the steel so that

metal-to-metal contact and galvanic protection against corrosion are provided. Zinc coatings

or alternative corrosion protection coatings having a zinc component shall be in metal-to-

metal contact with the steel.

The interior surface shall be protected by a zinc or organic or other suitable corrosion-

resistant coating.

4.7.2 Secondary coating(s)

When (an) additional coating(s) is(are) applied to enhance the primary coating, the evaluation

for each additional coating's degree of corrosion protection shall be optional.

5 Dimensions

5.1 Dimensions

The dimensions and mass of the EHDERS conduit shall be in accordance with those given in

Table 1.

5.2 Threads

5.2.1 General

The pitch and the length of the threaded portion at each end of each length of conduit, nipple,

and elbow shall be as indicated in Figure 1 and shall be compatible with IEC 61950. The

complete thread shall be tapered for its entire length, and the taper shall have a ratio of

1 to 16.

5.2.2 Pitch form

The form of the thread profile, the dimensional relationships for the form of the thread and the

general notation are shown in Figure 2.

5.2.3 Angle of thread

The angle between the sides of the thread, measured in the axial plane, shall be 60°. The line

bisecting this angle is perpendicular to the axis.

6 Protective coatings

6.1 Interior coatings

6.1.1 Zinc

The presence of a zinc coating on the interior surface shall be verified.

Compliance shall be checked by the method described in Annex A for one test cycle only.

6.1.2 Organic coatings

6.1.2.1 Elasticity test

An organic coating used to protect the interior of the conduit shall not crack, flake off or be

otherwise damaged.

Compliance shall be checked by the following test:

The coating shall be applied to a sheet-steel test piece and baked in an oven for 5 h, and

shall withstand without damage ten successive bends of the test piece back and forth through

an angle of 180° against an edge having a radius of 1,6 mm.

– 10 – IEC 60981:2019 © IEC 2019

The apparatus shall consist of flat test pieces of sheet steel of a width of 75 mm by a length of

125 mm and a thickness of approximately 0,25 mm, an oven for baking the test pieces, and a

vice with jaws of a width of at least 75 mm for holding the test pieces during the bending test.

The 75-mm edge of each jaw shall be rounded to a radius of 1,6 mm.

Two test pieces shall be cleaned with a suitable organic solvent to remove any grease and

foreign material and shall then be dipped in the organic coating. After air drying for 30 min,

the test pieces shall be suspended by means of short wires in the oven. Samples shall be

baked for 5 h at the normal baking temperature for the organic coating in question but, if the

normal baking temperature is lower than 135 °C or the enamel is regularly air dried, the oven

temperature shall be maintained between 135 °C and 150 °C.

At the end of 5 h, the test pieces shall be removed from the oven and cooled in still air to

room temperature. Each flat test piece shall be secured in the vice, gripped at its free end,

and then bent for 90° against one of the 75-mm edges of the vice jaws. Each test piece shall

then be bent back past its original position through 180° so that it ends bent 90° against the

other 75-mm edge of the vice jaws. It shall then be bent for 90° in the opposite direction,

ending with the test piece in its original position. This cycle shall be repeated five times.

6.1.2.2 Warm humid air test

No corrosion of the metal shall be present after 1 440 h of exposure to humidity.

Compliance shall be checked by the following test:

The test apparatus shall be an insulated chamber with inside dimensions of approximately

119 cm × 71 cm × 71 cm. It shall contain a temperature-controlled water reservoir, pump,

spray chamber for humidifying the air, an air-circulating fan, provisions for heating the air,

specimen supports, and the necessary means of control.

The dry bulb temperature of the test chamber shall be maintained at (60 ± 1) °C for 1 440 h

and at (98 ± 2) % relative humidity throughout the test. The specimens shall be supported in

racks at an angle of 15° from the vertical.

6.2 Exterior coatings

6.2.1 Zinc

A zinc coating on the outside surface shall have a minimum thickness of 0,02 mm.

Compliance shall be checked by measurement. In case of a dispute, the minimum acceptable

thickness shall be determined using the method described in Annex A.

6.2.2 Alternative corrosion-resistant coating

6.2.2.1 General

An alternative corrosion-resistant coating on the outside surface shall provide an equal or

greater protection from corrosion as a zinc coating.

Compliance shall be checked by the requirements in Clauses B.2 to B.6, 6.2.2.2 to 6.2.2.5 (as

applicable) and the electrical continuity and mechanical strength test sequence for fittings for

unthreaded EHDERS conduits in accordance with IEC 61950. Separate sets of assembled

specimens of the conduit, elbow, or nipple to both set-screw and compression-type couplings

shall be subjected to the fault current test, electrical continuity test, a bend test, an electrical

continuity test (repeated), and a pull-out test as specified in IEC 61950.

6.2.2.2 Tensile strength

The tensile strength of a polyvinyl chloride (PVC) alternative corrosion-resistant coating for

EHDERS conduits shall have a minimum tensile strength of 13,79 MPa (2 000 psi).

Compliance shall be checked by the tests in ISO 527 (all parts). Other materials shall be

subject to special investigation.

6.2.2.3 Adhesion

The adhesion of an alternative corrosion-resistant coating shall be greater than the strength of

the alternative corrosion-resistant coating itself. The coating may tear rather than separate

from the substrate.

Compliance for coatings of a thickness of 0,51 mm to 1,27 mm shall be checked by the

following test:

Two parallel circumferential cuts 38 mm long shall be made 13 mm apart through the

alternative corrosion-resistant coating to the substrate. A third cut shall be made

perpendicular to, and crossing, the circumferential cuts. The edge of the alternative corrosion-

resistant coating shall be carefully lifted with a knife to form a tab. To determine compliance,

this tab shall be pulled perpendicularly to the conduit with a pair of pliers.

Compliance for coatings with a thickness of 0,127 mm or less shall be checked by the test in

ISO 19095-3.

6.2.2.4 Cold impact

The coating shall not separate from the metal nor be damaged to the extent that bare metal is

exposed on each individual specimen.

Compliance shall be checked by inspection without magnification after the following test:

Ten 152 mm to 203 mm specimens of finished conduit provided with a non-metallic alternative

corrosion-resistant coating shall be conditioned at a temperature of 0 °C for a period of

60 min. Conduits intended for use in temperatur

...

IEC 60981 ®

Edition 3.0 2019-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Extra heavy-duty electrical rigid steel conduits

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60981 ®

Edition 3.0 2019-08

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Extra heavy-duty electrical rigid steel conduits

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.120.10 ISBN 978-2-8322-7331-9

– 2 – IEC 60981:2019 RLV © IEC 2019

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 General requirements . 8

4.1 Tests . 8

4.2 Circular cross-section . 8

4.3 Wall thickness . 8

4.4 Surface condition . 8

4.4.1 General . 8

4.4.2 Localized surface imperfections . 8

4.5 Welding . 8

4.6 Cleaning . 8

4.7 Protective coating(s) . 8

4.7.1 Primary coating(s) . 8

4.7.2 Secondary coating(s) . 9

Alternative coatings .

5 Dimensions. 9

5.1 Dimensions . 9

5.2 Threads . 9

5.2.1 General . 9

5.2.2 Pitch form . 9

5.2.3 Angle of thread . 9

6 Protective coatings . 9

6.1 Interior coatings . 9

6.1.1 Zinc . 9

6.1.2 Organic coatings. 9

6.2 Exterior coatings . 10

6.2.1 Zinc coating . 10

6.2.2 Alternative corrosion-resistant coating . 11

7 Threading and chamfering . 14

8 Couplings . 14

8.1 General . 14

8.1.1 Corrosion protection . 14

8.1.2 Chamfering . 14

8.1.3 Dimensions . 14

8.2 Coupling threads . 14

8.2.1 Thread form . 14

8.2.2 Dimensions . 14

9 Elbows and nipples . 14

10 Ductility . 15

10.1 Bending properties . 15

10.2 Ductility of zinc coating . 15

11 Marking . 15

11.1 General . 15

11.2 Required information . 15

Annex A (normative) Test for thickness of zinc coating on extra heavy-duty electrical

rigid steel (EHDERS) conduits . 24

A.1 Requirement . 24

A.2 Solutions required . 24

A.3 Preparation of samples . 24

A.4 Specimen surface condition . 24

A.5 Test method . 24

A.6 Results . 25

Annex B (normative) Tests for evaluating alternative exterior coatings applied on extra

heavy-duty electrical rigid steel (EHDERS) conduits . 26

B.1 Alternative corrosion-resistant coatings . 26

B.2 Preparation of specimens . 26

B.3 Air oven conditioning exposure . 28

B.4 Resistance to ultraviolet light and water exposure . 29

B.5 Resistance to salt spray (fog) exposure . 29

B.6 Resistance to moist carbon dioxide-sulfur dioxide-air exposure . 29

Bibliography . 30

Figure 1 – Dimensions of threads for EHDERS conduits . 18

Figure 2 – Basic form of taper thread . 19

Figure 3 – Limits on crest and root truncation of external and internal threads . 20

Figure 4 – Dimensions of a ferrous metal coupling . 21

Figure 5 – Dimensions of wedge . 22

Figure 6 – Essential dimensions for flame test . 23

Figure B.1 – Alternative corrosion program flowchart with sample requirements . 27

Figure B.2 – Scribe pattern . 28

Table 1 – Dimensions and mass of EHDERS conduits . 16

Table 2 – Dimensions of couplings . 17

Table 3 – Dimensions of 90° elbows . 17

– 4 – IEC 60981:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXTRA HEAVY-DUTY ELECTRICAL RIGID STEEL CONDUITS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60981 has been prepared by subcommittee 23A: Cable

management systems, of IEC technical committee 23: Electrical accessories.

This third edition cancels and replaces the second edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the second

edition:

a) addition of provisions for alternative coatings to zinc;

b) addition of elasticity test for organic coatings;

c) new Annex B on tests for evaluating alternative exterior coatings applied on extra

heavy-duty electrical rigid steel (EHDERS) conduits.

The text of this International Standard is based on the following documents:

FDIS Report on voting

23A/886/FDIS 23A/888/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

In this document, the following print types are used:

• requirements proper: in roman type;

• test specifications: in italic type;

• explanatory matter: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60981:2019 RLV © IEC 2019

EXTRA HEAVY-DUTY ELECTRICAL RIGID STEEL CONDUITS

1 Scope

This document specifies requirements for extra heavy-duty electrical rigid steel (EHDERS)

conduits, couplings, nipples and elbows for electrical installations, including communications

and fibre optics. This document also specifies threads for these components.

1)

It is not applicable to the conduits specified in IEC 60423 .

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60695-11-3, Fire hazard testing – Part 11-3: Test flames – 500 W flames – Apparatus and

confirmational test methods

IEC 61950, Cable management systems – Specifications for conduit fittings and accessories

for electrical cable installations for extra heavy duty metal electrical steel conduit

ISO 527 (all parts), Plastics – Determination of tensile properties

ISO 4892-2, Plastics – Methods of exposure to laboratory light sources – Part 2: Xenon-arc

lamps

ISO 9227, Corrosion tests in artificial atmospheres – Salt spray tests

ISO 13263, Thermoplastics piping systems for non-pressure underground drainage and

sewerage – Thermoplastics fittings – Test method for impact strength

ISO 19095-3, Plastics – Evaluation of the adhesion interface performance in plastic-metal

assemblies – Part 3: Test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

___________

1)

IEC 60423, Conduits for electrical purposes – Outside diameters of conduits for electrical installations and

threads for conduits and fittings

3.1

extra heavy-duty electrical rigid steel conduit

EHDERS conduit

part of a closed wiring system of circular cross-section made of welded steel construction

capable of providing extra heavy mechanical protection to conductors or cables in electrical

installations and used as an equipment earthing conductor when installed utilizing appropriate

fittings

3.2

straight conduit

straight length of EHDERS, greater than 0,6 m long and threaded at each end, without a

coupling

3.3

finished conduit

straight length of EHDERS with one coupling attached

3.4

threaded coupling

internally threaded steel cylinder for connecting two sections of an EHDERS conduit

3.5

elbow

factory-curved section of an EHDERS conduit threaded at each end

3.6

glowing combustion

combustion of a material in the solid phase without flame but with emission of light from the

combustion zone

3.7

nipple

straight section of an EHDERS conduit not more than 0,6 m long and threaded at each end

3.8

type test

test made on a specimen for the conformity of the design of a given product to the

requirements of the relevant document

3.9

alternative corrosion-resistant coating

exterior primary coating(s) other than one consisting solely of zinc

Note 1 to entry: The coating(s) may include zinc. See Annex B.

3.10

organic coating

coating(s) other than one consisting solely of zinc

Note 1 to entry: The coating(s) may include zinc.

3.11

zinc coating

interior or exterior primary coating consisting solely of zinc

– 8 – IEC 60981:2019 RLV © IEC 2019

4 General requirements

4.1 Tests

Tests according to this document shall be type tests.

Unless otherwise specified, the tests shall be carried out at an ambient temperature of

(20 ± 5) °C.

Unless otherwise specified, each test shall be carried out on two new samples. If a sample

tested in accordance with this document fails, two additional samples shall be tested, both of

which shall comply with all the requirements of this document.

4.2 Circular cross-section

An EHDERS conduit shall have a circular cross-section sufficiently accurate to permit allow

the cutting of threads in accordance with Figure 1.

4.3 Wall thickness

The wall thickness shall comply with the dimensions given in Table 1.

4.4 Surface condition

4.4.1 General

Surfaces of a conduit shall be free from slivers, burrs, scale and other defects likely to cause

damage to conductors or cables.

Compliance shall be checked by visual inspection of the external and internal surfaces.

4.4.2 Localized surface imperfections

Localized surface imperfections shall not exceed a depth of 12,5 % of the nominal wall

thickness given in Table 1.

Compliance of localized surface imperfections shall be checked by measurement.

4.5 Welding

The welding of all seams shall be continuous and carried out in a workmanlike professional

manner.

Compliance is checked by visual inspection.

4.6 Cleaning

The conduit shall be adequately cleaned before the application of the protective coating. The

cleaning process shall leave the exterior and interior surfaces of the conduit in such a

condition that the protective coating will be firmly adherent and smooth, as defined in 4.4.

4.7 Protective coating(s)

4.7.1 Primary coating(s)

The exterior surface shall be thoroughly and evenly coated with either a metallic zinc or an

alternative corrosion protection coating applied directly to the surface of the steel so that

metal-to-metal contact and galvanic protection against corrosion are provided. Zinc coatings

or alternative corrosion protection coatings having a zinc component shall be in metal-to-

metal contact with the steel.

The interior surface shall be protected by a zinc or organic or other suitable corrosion-

resistant coating.

4.7.2 Secondary coating(s)

When (an) additional coating(s) is(are) applied to enhance the primary coating, the evaluation

for its each additional coating's degree of corrosion protection shall be optional.

4.7.3 Alternative coating

When an alternative coating is applied to enhance or replace the primary coating, the

evaluation of the amount of corrosion protection provided shall be the subject of a separate

standard.

5 Dimensions

5.1 Dimensions

The dimensions and mass of the EHDERS conduit shall be in accordance with those given in

Table 1.

5.2 Threads

5.2.1 General

The pitch and the length of the threaded portion at each end of each length of conduit, nipple,

and elbow shall be as indicated in Figure 1 and shall be compatible with IEC 61950. The

complete thread shall be tapered for its entire length, and the taper shall have a ratio of

1 to 16.

5.2.2 Pitch form

The form of the thread profile, the dimensional relationships for the form of the thread and the

general notation are shown in Figure 2.

5.2.3 Angle of thread

The angle between the sides of the thread, measured in the axial plane, shall be 60°. The line

bisecting this angle is perpendicular to the axis.

6 Protective coatings

6.1 Interior coatings

6.1.1 Zinc

The presence of a zinc coating on the interior surface shall be verified.

Compliance shall be checked by the method described in Annex A for one test cycle only.

– 10 – IEC 60981:2019 RLV © IEC 2019

6.1.2 Organic coatings

6.1.2.1 Elasticity test

An organic coating used to protect the interior of the conduit shall not crack, flake off or be

otherwise damaged.

Compliance shall be checked by the following test:

The coating shall be applied to a sheet-steel test piece and baked in an oven for 5 h, and

shall withstand without damage ten successive bends of the test piece back and forth through

an angle of 180° against an edge having a radius of 1,6 mm.

The apparatus shall consist of flat test pieces of sheet steel of a width of 75 mm by a length of

125 mm and a thickness of approximately 0,25 mm, an oven for baking the test pieces, and a

vice with jaws of a width of at least 75 mm for holding the test pieces during the bending test.

The 75-mm edge of each jaw shall be rounded to a radius of 1,6 mm.

Two test pieces shall be cleaned with a suitable organic solvent to remove any grease and

foreign material and shall then be dipped in the organic coating. After air drying for 30 min,

the test pieces shall be suspended by means of short wires in the oven. Samples shall be

baked for 5 h at the normal baking temperature for the organic coating in question but, if the

normal baking temperature is lower than 135 °C or the enamel is regularly air dried, the oven

temperature shall be maintained between 135 °C and 150 °C.

At the end of 5 h, the test pieces shall be removed from the oven and cooled in still air to

room temperature. Each flat test piece shall be secured in the vice, gripped at its free end,

and then bent for 90° against one of the 75-mm edges of the vice jaws. Each test piece shall

then be bent back past its original position through 180° so that it ends bent 90° against the

other 75-mm edge of the vice jaws. It shall then be bent for 90° in the opposite direction,

ending with the test piece in its original position. This cycle shall be repeated five times.

6.1.2.2 Warm humid air test

No corrosion of the metal shall be present after 1 440 h of exposure to humidity.

Compliance shall be checked by the following test:

The test apparatus shall be an insulated chamber with inside dimensions of approximately

119 cm × 71 cm × 71 cm. It shall contain a temperature-controlled water reservoir, pump,

spray chamber for humidifying the air, an air-circulating fan, provisions for heating the air,

specimen supports, and the necessary means of control.

The dry bulb temperature of the test chamber shall be maintained at (60 ± 1) °C for 1 440 h

and at (98 ± 2) % relative humidity throughout the test. The specimens shall be supported in

racks at an angle of 15° from the vertical.

6.2 Exterior coatings

6.2.1 Zinc coating

A zinc coating on the outside surface shall have a minimum thickness of 0,02 mm.

Compliance shall be checked by measurement. In case of a dispute, the minimum acceptable

thickness shall be determined using the method described in Annex A.

6.2.2 Alternative corrosion-resistant coating

6.2.2.1 General

An alternative corrosion-resistant coating on the outside surface shall provide an equal or

greater protection from corrosion as a zinc coating.

Compliance shall be checked by the requirements in Clauses B.2 to B.6, 6.2.2.2 to 6.2.2.5 (as

applicable) and the electrical continuity and mechanical strength test sequence for fittings for

unthreaded EHDERS conduits in accordance with IEC 61950. Separate sets of assembled

specimens of the conduit, elbow, or nipple to both set-screw and compression-type couplings

shall be subjected to the fault current test, electrical continuity test, a bend test, an electrical

continuity test (repeated), and a pull-out test as specified in IEC 61950.

6.2.2.2 Tensile strength

The tensile strength of a polyvinyl chloride (PVC) alternative corrosion-resistant coating for

EHDERS conduits shall have a minimum tensile strength of 13,79 MPa (2 000 psi).

Compliance shall be checked by the tests in ISO 527 (all parts). Other materials shall be

subject to special investigation.

6.2.2.3 Adhesion

The adhesion of an alternative corrosion-resistant coating shall be greater than the strength of

the alternative corrosion-resistant coating itself. The coating may tear rather than separate

from the substrate.

Compliance for coatings of a thickness of 0,51 mm to 1,27 mm shall be checked by the

following test:

Two parallel circumferential cuts 38 mm long shall be made 13 mm apart through the

alternative corrosion-resistant coating to the substrate. A third cut shall be made

perpendicular to, and crossing, the circumferential cuts. The edge of the alternative corrosion-

resistant coating shall be carefully lifted with a knife to form a tab. To determine compliance,

this tab shall be pulled perpendicularly to the conduit with a pair of pliers.

Compliance for coatings with a thickness of 0,127 mm or less shall be checked by the test in

ISO 19095-3.

6.2.2.4 Cold impact

The coating shall not separate from the metal nor be damaged to the extent that bare metal is

exposed on each individual specimen.

Compliance shall be checked by inspection without magnification after the following test:

Ten 152 mm to 203 mm specimens of finished conduit provided with a non-metallic alternative

corrosion-resistant coating shall be conditioned at a temperature of 0 °C for a period of

60 min. Conduits intended for use in temperatures below 0 °C shall be conditioned at the

rated temperature, for which the rated temperature shall be any temperature below 0 °C in

5 °C increments. The specimens shall then be subjected to an impact force of 12,2 J. A

combination of any height and weight resulting in this impact force shall be considered

equivalent if the impact face remains unchanged.

The impact shall be performed according to the apparatus, falling mass and method specified

in ISO 13263. The test shall be conducted inside the cold chamber or within 15 s of removal

from the cold chamber.

– 12 – IEC 60981:2019 RLV © IEC 2019

6.2.2.5 Flammability

The finished conduit provided with a non-metallic alternative corrosion-resistant coating shall

be flame resistant.

The finished conduit shall not flame for longer than 5 s following any of three 60-s

applications of flame, the period between applications being 30 s. A specimen shall not:

• emit flaming or glowing particles or flaming drops at any time that ignite the cotton on the

burner, wedge, or floor of the enclosure (flameless charring of the cotton shall be ignored);

• continue to flame longer than 5 s after any application of the gas flame; or

• have the coating completely consumed during or after any application of the gas flame.

NOTE When an alternative corrosion protection system employs a thin exterior organic topcoat measuring less

than or equal to 0,125 mm in thickness, over a confirmed three-dips worth of zinc, a specimen can display a total

consumption of the top coat at the point of flame contact to the conduit without any measureable flame propagation

as long as it meets the requirements of 6.2.2.5, first and second bullet points. Confirmation of the presence of

three-dips worth of zinc coating is accomplished using the zinc coating test of Annex A as part of a separate test.

Compliance is checked by the following test:

Materials and reactants shall consist of the following:

a) Methane, at 98 % minimum purity, having a heat content of (37 ± 1) MJ/m at 25 °C and

101 kPa; or natural gas, with a heat content of (37 ± 1) MJ/m at 25 °C and 101 kPa;

Alternative gases, such as propane, at a 95 % minimum purity, having a heat content of

(94 ± 2) MJ/m at 25 °C and 101 kPa or butane, at 99 % minimum purity, having a heat

content of (120 ± 3) MJ/m at 25 °C and 101 kPa, may be used if a stable flame is

obtained and the heat evolution profile complies with IEC 60695-11-3.

WARNING Propane and butane gases are denser than air and can settle and become an

explosion hazard. Consult the gas supplier for special precautions to be taken.

b) Surgical cotton, dry and untreated.

The apparatus and a means for supporting the test specimen in a vertical position shall

consist of the following:

1) A three-sided metal enclosure in an exhaust hood or cabinet. The metal enclosure shall

be 305 mm wide, 355 mm deep, and 610 mm high, and the top and front shall be open. A

457-mm specimen of finished conduit shall be secured with its longitudinal axis vertical in

the centre of the enclosure. A flat, horizontal layer of untreated surgical cotton of a

thickness between 6 mm and 25 mm shall cover the floor of the enclosure. The upper

surface of the cotton shall be between 229 mm and 241 mm below point B, which is the

point at which the tip of the blue inner cone of the test flame touches the specimen. See

Figure 6.

2) An angle block, wedge, (see Figure 5) to which the base of the burner can be secured,

shall be provided for tilting the barrel 20° from the vertical while the longitudinal axis of

the barrel remains in a vertical plane. The burner shall be secured to the wedge and the

assembly shall be placed in an adjustable support jig. A layer of untreated surgical cotton

of a thickness between 6 mm and 25 mm shall be placed on the wedge and around the

base of the burner. The jig shall be adjusted toward one side or the other of the enclosure

to place the longitudinal axis of the barrel in the vertical plane that contains the

longitudinal axis of the specimen. The plane shall be parallel to the sides of the enclosure.

The jig shall also be adjusted toward the rear or front of the enclosure to position the

point A, which is the intersection of the longitudinal axis of the barrel with the plane of the

tip of the barrel, 38 mm from the point B at which the extended longitudinal axis of the

barrel meets the outer surface of the specimen. Point B is the point at which the tip of the

blue inner cone touches the centre of the front of the specimen. The specimen shall be

adjusted vertically to keep point B from being any closer than 76 mm to the lower clamp or

other support for the specimen.

3) A laboratory burner in conformance with IEC 60695-11-3, suitable for the calorific value of

the gas and having an inside diameter of (9,5 ± 0,3) mm and a length of (100 ± 10) mm

above the primary-air inlets. The burner shall be calibrated in accordance with

IEC 60695-11-3 each time a cylinder of gas, when used, is changed or refilled, or any of

the apparatus is changed.

The burner flame shall be calibrated at least every 30 days and each time that a cylinder

of gas is changed or if any of the apparatus is changed. If using gas different from the

grade of methane specified for referee purposes, the burner flame shall be calibrated

immediately before testing.

4) A length-measuring device accurate to within 5 % of char length requirements.

5) A flame height gauge capable of measuring the specified flame heights.

6) A timing device capable of measuring the specified times in seconds, having a resolution

of 1 s and an accuracy of ±0,5 s.

Three specimens having a minimum length of 457 mm taken from a sample of finished

conduit shall be conditioned at room temperature for a minimum of 6 h.

When conducting the test, the specimens, apparatus, and surrounding air shall be at room

temperature.

The specimens shall be mounted vertically in the supports in the chamber (see Figure 6).

A continuous horizontal layer of cotton between 6 mm and 25 mm shall be placed on the

floor of the test chamber, centred on the vertical axis of the test specimen, extending from

75 mm to 100 mm outward in all directions except in the direction of the burner, where it

shall extend to just contact the angle block. The upper surface of the cotton shall be

between 229 mm and 241 mm, (235 ± 6) mm below the point at which the tip of the blue

inner cone of the flame shall impinge on the specimen. There shall be no cotton on the

burner, or on or under the angle block.

With the burner in vertical position, the height of the test flame shall be adjusted to

(125 ± 10) mm, with an inner blue cone of a length of (40 ± 2) mm. The burner shall then

be positioned on the angle block, with its barrel at an angle of 20° to the vertical.

The alignment of the angle block shall be such that the axis of the burner barrel and the

longitudinal axis of the specimen are in the same plane.

The motion of the angle block, which allows smooth removal of the flame from the

specimen and smooth reapplication of the flame, shall not disturb the layer of cotton on

the floor of the enclosure.

The angle block shall be moved into position such that the tip of the inner blue cone of the

flame impinges on the outer surface of the specimen for 60 s, and is then moved away for

30 s. This cycle shall be repeated until three applications of the flame have been

completed. In all cases, the movement of the angle block shall be smooth and quick, with

minimum disturbance of the chamber air. On a flat specimen, the flame shall impinge on

the centre of the broad face of the specimen. If the specimen changes location due to

heating or burning, the position of the burner shall be adjusted so that the point of

impingement remains on the same location of the specimen.

When any specimen emits flaming or glowing particles or flaming drops that fall outside

the area of the testing surface covered by the cotton, or fall onto the wedge or burner, or

both, the test results shall be discarded and the test repeated. For the repeat test, the

area covered by the cotton may be increased, placed over the wedge, or both.

When flaming of the specimen persists for longer than 5 s after removal of the burner

flame, the burner flame shall not be re-applied until immediately after the flaming ceases.

If flaming ceases and only glowing combustion continues after 30 s, the burner flame shall

be re-applied.

After the test is completed, the exhaust system shall be activated to remove all smoke and

fumes from the chamber.

During and after the test, occurrence of the following shall be recorded:

– 14 – IEC 60981:2019 RLV © IEC 2019

– flaming or glowing particles or flaming drops at any time that ignite the cotton on the

burner, wedge, or floor of the enclosure (flameless charring of the cotton shall be ignored);

– non-metallic alternative corrosion-resistant coating flaming longer than 5 s following any of

three 60-s applications of gas flame; or

– complete consumption of the coating during or after any application of the gas flame.

7 Threading and chamfering

7.1 Each length of conduit, as well as each nipple and elbow shall be threaded at both ends.

Each end shall be chamfered or otherwise treated to remove burrs and sharp edges.

7.2 Threads shall comply with the requirements of 5.2. If threads are cut after the zinc

coating has been applied, the threads, before installation, shall be treated with a protective

coating to prevent corrosion. This treatment shall not impair electrical continuity through the

joint after installation.

8 Couplings

8.1 General

8.1.1 Corrosion protection

The exterior surface of couplings shall be protected by means of a zinc coating or alternative

corrosion protection coating, which shall comply with the requirements of Clause 6, and the

interior surface shall be treated to keep corrosion from taking place prior to installation onto

the conduit.

8.1.2 Chamfering

Both ends of couplings shall be chamfered between 11° and 15°, to prevent damage to the

start of the thread (see Figure 4).

8.1.3 Dimensions

The outside diameter and length of couplings shall be as indicated in Table 2. Each length of

conduit shall be supplied with one coupling attached.

8.2 Coupling threads

8.2.1 Thread form

Coupling threads in accordance with this document shall be straight (parallel) threads of the

same thread form as the taper thread specified in 5.2.1.

8.2.2 Dimensions

The dimensions and pitch diameter limits shall be as indicated in Table 2, and the truncation

shall be as indicated in Figure 3.

The major and minor diameters vary with the pitch diameter. The thread form shall be as

indicated in Figure 2.

9 Elbows and nipples

Conduit elbows and conduit nipples shall have the same dimensions and quality employed in

the straight lengths of the EHDERS conduit, and shall be treated, coated, threaded and

marked for identification according to the requirements of this document. The dimensions of

90° elbows shall be as indicated in Table 3.

10 Ductility

10.1 Bending properties

The specimen is deemed to have passed the test if after bending there is no cracking on the

surface, or opening of the weld, visible under normal or corrected-to-normal vision.

10.2 Ductility of zinc coating

The ductility of protective coatings used on the exterior or interior surfaces of an EHDERS

conduit shall be checked by the following test, which shall be carried out within one year of

manufacture.

A specimen of conduit shall be bent at ambient temperature around a mandrel to a radius

specified in Table 3.

Conduits designated as 12H and 16H are bent at 180°. Conduits of other designators are bent

at 90°.

The specimen is deemed to have passed the test if after bending there is no visible cracking

or flaking of the coating, visible under normal or corrected-to-normal vision.

11 Marking

11.1 General

Marking shall be durable and easily legible.

Test for compliance under consideration.

11.2 Required information

Each length of conduit, nipple and elbow shall be marked with the name of the manufacturer

or responsible vendor or trademark or other identifying symbols, as well as the words “Extra

Heavy-Duty Electrical Rigid Steel Conduit”, or “EHDERS Conduit”, or “EHDERS” being

marked with at least one of the following:

a) "extra heavy-duty electrical rigid steel conduit";

b) "EHDERS conduit";

c) "EHDERS";

d) "electrical rigid metal conduit"; or

e) "ERMC-S".

Nipples, where the unthreaded portion is less than 25 mm long, need not be marked.

Each finished length of conduit, elbow, or nipple shall be legibly and durably marked with

"Consult manufacturer for proper installation" or equivalent marking. Elbows and nipples of

trade sizes 53 or smaller may be marked on the smallest shipping container instead of the

product.

The conduits provided with a non-metallic alternative corrosion-resistant coating shall be

allowed to be marked with a maximum use temperature of "90°C". A conduit tested for use at

a maximum ambient temperature higher than 90 °C shall be marked "____°C" with the rated

– 16 – IEC 60981:2019 RLV © IEC 2019

temperat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...