IEC 61537:2023

(Main)Cable management - Cable tray systems and cable ladder systems

Cable management - Cable tray systems and cable ladder systems

IEC 61537:2023 specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication systems installations. Where necessary, cable tray systems and cable ladder systems can be used for the arrangement of cables into groups.

This document does not apply to conduit systems, cable trunking systems and cable ducting systems or to any current-carrying parts.

This third edition cancels and replaces the second edition published in 2006. This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous edition:

new, repositioned and renumbered figures,

revised classification for corrosion,

revised SWL test types and procedures,

new tests for lengths mounted vertical running horizontal and mounted vertical running vertical,

tests for support devices: cantilevers, pendants, C shape ceiling supports and trapeze systems,

new and revised annexes including use of tray as a protective earth conductor.

Systèmes de câblage - Systèmes de chemin de câbles et systèmes d'échelle à câbles

L'IEC 61537:2023 spécifie les exigences et les essais pour les systèmes de chemin de câbles et les systèmes d'échelle à câbles prévus pour le support, le logement des câbles et éventuellement d'autres équipements électriques dans des installations électriques et/ou des systèmes de communication. Si nécessaire, les systèmes de chemin de câbles et les systèmes d'échelle à câbles peuvent être utilisés pour le regroupement de câbles.

Le présent document ne s'applique pas aux systèmes de conduits, systèmes de goulottes et systèmes de conduits-profilés ou toutes parties transportant le courant.

Cette troisième édition annule et remplace la deuxième édition parue en 2006. Cette édition constitue une révision technique.

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

des figures ont été ajoutées, déplacées et renumérotées;

la classification pour la corrosion a été révisée;

les types d'essais sous CPS et les procédures d'essai associées ont été révisés;

des essais ont été ajoutés pour les longueurs montées verticalement et cheminant horizontalement et pour les longueurs montées verticalement et cheminant verticalement;

essais des dispositifs de support: cantilevers, pendards, supports de plafond en C et systèmes de trapèze;

des annexes ont été ajoutées et révisées, y compris l'utilisation du chemin comme conducteur de terre de protection.

General Information

- Status

- Published

- Publication Date

- 23-Jan-2023

- Technical Committee

- SC 23A - Cable management systems

- Drafting Committee

- MT 12 - TC 23/SC 23A/MT 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Jan-2023

- Completion Date

- 17-Feb-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61537:2023 is the latest international standard specifying comprehensive requirements and testing methods for cable tray and cable ladder systems used in electrical and communication infrastructure. This third edition replaces the 2006 version with critical technical updates, ensuring modern cable management installations meet heightened safety, durability, and performance criteria.

The standard targets the support and organization of cables, enabling grouping where necessary. Importantly, it excludes conduit, trunking, and ducting systems and does not cover any live current-carrying components.

Key Topics

Material and Construction Classes

- Classification by material type including metals and non-metallic components

- Fire resistance and flame propagation characteristics

- Electrical conductivity and continuity requirements

- Corrosion resistance classifications for various materials such as steel, aluminum, and composites

Mechanical and Structural Testing

- Safe Working Load (SWL) test procedures for multiple mounting orientations: horizontal, vertical, and combined configurations

- Strength tests of fittings including bends, tees, and crosses

- Evaluations for support devices like cantilever brackets, pendants, ceiling supports, and trapeze systems

- Impact resistance testing to simulate real-world mechanical stresses

Electrical and Thermal Properties

- Tests ensuring proper electrical continuity, including low impedance requirements

- Assessment of non-conductive materials for insulation performance

- Thermal durability with minimum and maximum operating temperatures defined

Fire Safety Measures

- Reaction to fire assessments focusing on ignition, flame spread, and contribution to fire

- Resistance to fire ensuring system integrity under thermal stress

Corrosion and Environmental Resistance

- Salt spray testing and environmental durability for outdoor and harsh conditions

- Specific guidelines for coatings and metallic treatments to extend service life

Marking and Documentation

- Durable marking standards for traceability and identification

- Documentation requirements to support installation, inspection, and maintenance

Applications

IEC 61537:2023 facilitates reliable cable management solutions across diverse industries including:

- Telecommunications: Structured cabling systems in data centers and communication networks

- Industrial Facilities: Power distribution and control cable support in factories and process plants

- Commercial and Residential Buildings: Organized routing and secure support of electrical wiring

- Infrastructure Projects: Transportation hubs, airports, and utility installations requiring robust cable support

The standard ensures cable tray and ladder systems deliver mechanical stability, electrical safety, and corrosion resistance essential for longevity and compliance in installations exposed to mechanical loads and environmental influences.

Related Standards

- IEC 60529 – Degrees of protection provided by enclosures (IP Code)

- IEC 60364 Series – Electrical Installations of Buildings, addressing wiring methods and safety

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles, complementing corrosion requirements

- IEC 61000-4-5 – Surge immunity testing, relevant to cable system electromagnetic compatibility

- IEC 60439 Series – Low-voltage switchgear and control gear assemblies

IEC 61537:2023 represents the authoritative benchmark for cable tray system manufacturers, designers, and installers, helping ensure cable infrastructure is safe, durable, and compliant with international best practices. Adherence to this standard optimizes cable routing efficiency and protects electrical communication systems from mechanical and environmental hazards.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 61537:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Cable management - Cable tray systems and cable ladder systems". This standard covers: IEC 61537:2023 specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication systems installations. Where necessary, cable tray systems and cable ladder systems can be used for the arrangement of cables into groups. This document does not apply to conduit systems, cable trunking systems and cable ducting systems or to any current-carrying parts. This third edition cancels and replaces the second edition published in 2006. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: new, repositioned and renumbered figures, revised classification for corrosion, revised SWL test types and procedures, new tests for lengths mounted vertical running horizontal and mounted vertical running vertical, tests for support devices: cantilevers, pendants, C shape ceiling supports and trapeze systems, new and revised annexes including use of tray as a protective earth conductor.

IEC 61537:2023 specifies requirements and tests for cable tray systems and cable ladder systems intended for the support and accommodation of cables and possibly other electrical equipment in electrical and/or communication systems installations. Where necessary, cable tray systems and cable ladder systems can be used for the arrangement of cables into groups. This document does not apply to conduit systems, cable trunking systems and cable ducting systems or to any current-carrying parts. This third edition cancels and replaces the second edition published in 2006. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: new, repositioned and renumbered figures, revised classification for corrosion, revised SWL test types and procedures, new tests for lengths mounted vertical running horizontal and mounted vertical running vertical, tests for support devices: cantilevers, pendants, C shape ceiling supports and trapeze systems, new and revised annexes including use of tray as a protective earth conductor.

IEC 61537:2023 is classified under the following ICS (International Classification for Standards) categories: 29.120.10 - Conduits for electrical purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61537:2023 has the following relationships with other standards: It is inter standard links to IEC 61537:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61537:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61537 ®

Edition 3.0 2023-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Cable management – Cable tray systems and cable ladder systems

Systèmes de câblage – Systèmes de chemin de câbles et systèmes d'échelle à

câbles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 61537 ®

Edition 3.0 2023-01

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Cable management – Cable tray systems and cable ladder systems

Systèmes de câblage – Systèmes de chemin de câbles et systèmes d'échelle à

câbles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.120.10 ISBN 978-2-8322-6364-8

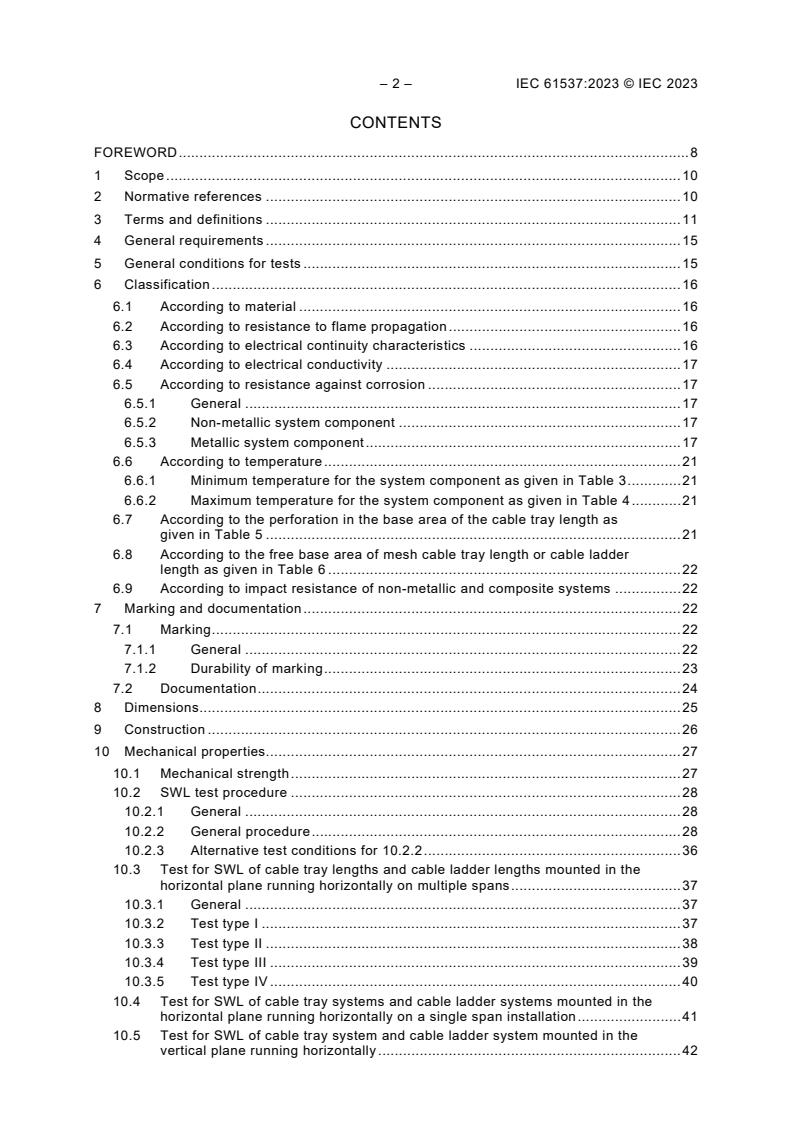

– 2 – IEC 61537:2023 © IEC 2023

CONTENTS

FOREWORD . 8

1 Scope . 10

2 Normative references . 10

3 Terms and definitions . 11

4 General requirements . 15

5 General conditions for tests . 15

6 Classification . 16

6.1 According to material . 16

6.2 According to resistance to flame propagation . 16

6.3 According to electrical continuity characteristics . 16

6.4 According to electrical conductivity . 17

6.5 According to resistance against corrosion . 17

6.5.1 General . 17

6.5.2 Non-metallic system component . 17

6.5.3 Metallic system component . 17

6.6 According to temperature . 21

6.6.1 Minimum temperature for the system component as given in Table 3 . 21

6.6.2 Maximum temperature for the system component as given in Table 4 . 21

6.7 According to the perforation in the base area of the cable tray length as

given in Table 5 . 21

6.8 According to the free base area of mesh cable tray length or cable ladder

length as given in Table 6 . 22

6.9 According to impact resistance of non-metallic and composite systems . 22

7 Marking and documentation . 22

7.1 Marking . 22

7.1.1 General . 22

7.1.2 Durability of marking . 23

7.2 Documentation . 24

8 Dimensions. 25

9 Construction . 26

10 Mechanical properties. 27

10.1 Mechanical strength . 27

10.2 SWL test procedure . 28

10.2.1 General . 28

10.2.2 General procedure . 28

10.2.3 Alternative test conditions for 10.2.2 . 36

10.3 Test for SWL of cable tray lengths and cable ladder lengths mounted in the

horizontal plane running horizontally on multiple spans . 37

10.3.1 General . 37

10.3.2 Test type I . 37

10.3.3 Test type II . 38

10.3.4 Test type III . 39

10.3.5 Test type IV . 40

10.4 Test for SWL of cable tray systems and cable ladder systems mounted in the

horizontal plane running horizontally on a single span installation . 41

10.5 Test for SWL of cable tray system and cable ladder system mounted in the

vertical plane running horizontally . 42

10.5.1 Multiple span test . 42

10.5.2 Single span test . 45

10.6 Test for SWL of cable tray system and cable ladder system mounted in the

vertical plane running vertically . 51

10.7 Test for SWL of cable tray fittings and cable ladder fittings mounted in the

horizontal plane running horizontally . 56

10.7.1 General . 56

10.7.2 Test for SWL of 90° bend. 57

10.7.3 Test for SWL of equal tee and equal cross . 57

10.8 Test for SWL of support devices . 59

10.8.1 General . 59

10.8.2 Test for SWL of cantilever brackets . 59

10.8.3 Test for SWL of pendants ceiling mounted . 76

10.9 Test for impact resistance . 94

11 Electrical properties . 98

11.1 Electrical continuity . 98

11.1.1 General . 98

11.1.2 Electrical impedance tests . 98

11.2 Electrical non-conductivity . 104

11.2.1 General . 104

11.2.2 Preparation of samples . 105

11.2.3 Preparation of electrodes . 105

11.2.4 Humidity treatment of samples . 105

11.2.5 Mounting of electrodes on samples . 105

11.2.6 Measurement of surface resistance . 106

11.2.7 Calculation of surface resistivity . 106

12 Thermal properties . 107

13 Fire hazards . 107

13.1 Reaction to fire . 107

13.1.1 Initiation of fire . 107

13.1.2 Contribution to fire . 107

13.1.3 Spread of fire . 107

13.1.4 Additional reaction to fire characteristics . 110

13.2 Resistance to fire . 111

14 External influences . 111

14.1 Resistance against environmental forces . 111

14.2 Resistance against corrosion . 111

14.2.1 General . 111

14.2.2 Non-metallic system components . 112

14.2.3 System components made of mild steel with metallic coating or

stainless steel . 112

14.2.4 Salt spray test . 113

14.2.5 System components made from aluminium alloys . 113

14.2.6 System components made of steel with organic coating . 113

15 Electromagnetic compatibility (EMC) . 114

Annex A (informative) Sketches of typical types of cable tray lengths and cable ladder

lengths . 115

Annex B (informative) Sketches of typical support devices . 117

Annex C (normative) Protective Earth (PE) function . 120

– 4 – IEC 61537:2023 © IEC 2023

C.1 General . 120

C.2 Cable tray system or cable ladder system with electrical continuity

characteristics and with PE function . 120

C.2.1 Construction . 120

C.2.2 Marking and documentation . 121

C.2.3 Requirements for periodic inspection . 121

C.2.4 Electrical properties . 122

C.2.5 Validation test of the calculated equivalent copper cross-sectional area

of the system . 123

Annex D (normative) Methods of applying and distributing a UDL for SWL tests using

load distribution plates . 126

D.1 General . 126

D.2 Dimensions of load distribution plates for cable tray and cable ladder

mounted in the horizontal plane . 126

D.3 Distribution of point loads across the width of cable tray, cable ladder and

support . 126

D.4 Distribution of point loads along the length of cable tray . 127

D.5 Distribution of point loads along the length of the cable ladder . 129

Annex E (informative) Typical methods of applying a UDL for SWL tests . 131

E.1 UDL applied through a mechanical linkage . 131

E.2 UDL applied through individual loads . 132

E.3 UDL applied through load blocks . 132

Annex F (xxx) Not Used . 133

Annex G (informative) Example for clarification of permitted creep. 134

Annex H (informative) Information for a safe installation of pendants with cantilever

brackets . 135

Annex I (informative) Summary of compliance checks . 137

Annex J (normative) Compliance checks to be carried out for cable tray systems and

cable ladder systems already complying with IEC 61537:2006 . 139

Annex K (informative) Number of samples required for tests . 141

Annex L (informative) Illustrative flow chart for the SWL tests . 142

L.1 Lengths . 142

L.2 Fittings . 143

L.3 Supports . 144

L.4 Cantilever brackets . 145

L.5 Pendants for cantilever bracket . 146

L.6 Centrally supported bracket . 146

L.7 Trapeze supports . 147

Annex M (normative) Application of a point load to a support . 148

Bibliography . 149

Figure 1 – Flame propagating symbol . 22

Figure 2 – Piston for durability of marking test . 23

Figure 3 – Safe working load test – General arrangement . 30

Figure 4 – Load and temperature diagrams with respect to time for test 10.2.2.4 . 34

Figure 5 – Test type I . 38

Figure 6 – Test type II . 39

Figure 7 – Test type III . 40

Figure 8 – Test type IV . 40

Figure 9 – Safe working load for single span test . 42

Figure 10 – Test conditions: Multi-span cable tray mounted in the vertical plane

running horizontally . 43

Figure 11 – Test conditions: Multi-span cable ladder mounted in the vertical plane

running horizontally . 44

Figure 12 – Test conditions: Single span cable tray mounted in the vertical plane

running horizontally . 46

Figure 13 – Test conditions: Single span cable ladder mounted in the vertical plane

running horizontally . 47

Figure 14 – Measurement example of the resultant deflection for Figure 10, Figure 11,

Figure 12 and Figure 13 . 48

Figure 15 – Load position for cable tray or cable ladder mounted in the vertical plane

running horizontal . 49

Figure 16 – Example of applying the test load for cable tray or cable ladder mounted in

the vertical plane running horizontally . 51

Figure 17 – Examples of test arrangements for systems mounted vertically running

vertically . 55

Figure 18 – Safe working load test for 90° bend . 57

Figure 19 – Safe working load test for equal tee . 58

Figure 20 – Safe working load test for equal cross . 58

Figure 21 – Typical examples of length and position of the mid-line of fittings . 59

Figure 22 – Test set-up for cantilever brackets intended for use with unspecified cable

tray of widths at least 80 % of the useable length of the cantilever bracket . 61

Figure 23 – Test set-up for cantilever brackets intended for use with unspecified cable

tray of widths less than 80 % of the useable length of the cantilever bracket . 62

Figure 24 – Test set-up for cantilever brackets intended for use with unspecified cable

ladder systems . 63

Figure 25 – Test set-up for cantilever brackets intended for use with a specified cable

tray system . 65

Figure 26 – Example of test set-up for cantilever brackets intended for use with a

specified cable tray system – Positioning of load . 66

Figure 27 – Test set-up for cantilever brackets intended for use with a specified cable

ladder system only, or with both cable tray systems and cable ladder systems . 67

Figure 28 – Example of test set-up for cantilever brackets intended for use with

specified cable ladder systems . 68

Figure 29 – Test set-up for cantilever brackets: end view showing measurement of

deflection when the bracket twists . 68

Figure 30 – Test set-up for cantilever brackets: end view showing alternative weight

positioning . 69

Figure 31 – Test set-up for cantilever brackets for use with unspecified cable tray

mounted vertically running vertically with widths at least 80 % of the useable length of

the cantilever bracket . 70

Figure 32 – Test set-up for cantilever brackets for use with unspecified cable tray or

cable ladder mounted vertically running vertically with widths less than 80 % of the

useable length of the cantilever bracket . 71

Figure 33 – Test set-up for cantilever brackets for use with unspecified cable ladder

mounted vertically running vertically with widths at least 80 % of the useable length of

the cantilever bracket . 72

Figure 34 – Example of test arrangement on cantilever bracket with a cable tray length . 74

– 6 – IEC 61537:2023 © IEC 2023

Figure 35 – Example of test arrangement on cantilever bracket with a cable ladder

length . 76

Figure 36 – Test set-up – Pendants for cantilever brackets . 78

Figure 37 – Example test set-up for pendant with centrally supported bracket for evenly

and unevenly loaded specified cable ladder systems . 80

Figure 38 – Example test set-up for pendant with centrally supported bracket for evenly

and unevenly loaded specified cable tray systems . 81

Figure 39 – Load positioning for centrally supported bracket for unevenly loaded

specified cable tray or cable ladder systems . 82

Figure 40 – Deflection of a centrally supported bracket for unevenly loaded specified

cable tray or cable ladder systems . 83

Figure 41 – Load positioning and deflection for a centrally supported bracket for evenly

loaded specified cable tray or cable ladder systems . 84

Figure 42 – Test set up for unevenly loaded centrally supported brackets intended for

unspecified use . 86

Figure 43 – Deflection and alternative method of unevenly loading a centrally

supported bracket for use with unspecified cable ladder and cable tray systems . 87

Figure 44 – Test set up for evenly loaded centrally supported brackets intended for

unspecified use . 89

Figure 45 – Test set-up for a C shape ceiling support . 91

Figure 46 – Test set-up for trapeze system designed for supporting cable ladder only . 92

Figure 47 – Test set-up for trapeze system designed for supporting cable tray or cable

ladder . 93

Figure 48 – Alternative test set-up for trapeze systems . 94

Figure 49 – Impact test stroke arrangement . 97

Figure 50 – Test set-up impedance along the length . 99

Figure 51 – Test set-up impedance across the width . 100

Figure 52 – Test set-up impedance of a joint . 103

Figure 53 – Test set-up impedance of an earthing terminal or termination . 103

Figure 54 – Test set-up impedance of the connection between an access cover and a

cable tray or cable ladder. 104

Figure 55 – Typical arrangement of surface resistivity test . 106

Figure 56 – Arrangement for the flame test . 109

Figure 57 – Enclosure for the flame test . 110

Figure A.1 – Solid bottom cable tray lengths . 115

Figure A.2 – Perforated cable tray lengths . 115

Figure A.3 – Mesh cable tray lengths . 115

Figure A.4 – Cable ladder lengths . 116

Figure B.1 – Cantilever brackets . 117

Figure B.2 – Pendants . 118

Figure B.3 – Fixing brackets . 119

Figure B.4 – C shape ceiling support . 119

Figure C.1 – Arrangement for the test of 5 s current carrying capability . 125

Figure D.1 – Examples of distribution load points across the width . 127

Figure D.2 – Typical arrangement of load distribution plates . 128

Figure D.3 – Example of equispaced point loads along the length . 129

Figure D.4 – Examples of test load distribution on cable ladder lengths . 130

Figure E.1 –UDL applied through a mechanical linkage . 131

Figure E.2 –UDL applied through individual loads . 132

Figure E.3 – UDL applied through load blocks . 132

Figure G.1 – Example for clarification of permitted creep . 134

Figure H.1 – Forces on pendant and cantilever bracket. 135

Figure H.2 – Illustration of the safe area . 136

Figure L.1 – Lengths . 142

Figure L.2 – Fittings . 143

Figure L.3 – Supports . 144

Figure L.4 – Cantilever brackets . 145

Figure L.5 – Pendants for cantilever bracket . 146

Figure L.6 – Centrally supported bracket . 146

Figure L.7 – Trapeze supports . 147

Figure M.1 – Maximum area of the applied point load to a support . 148

Table 1 – Classification for resistance against corrosion for zinc electroplated,

pre-galvanised and post-galvanised mild steel products . 18

Table 2 – Classification for resistance against corrosion for stainless steel products . 19

Table 3 – Minimum temperature classification . 21

Table 4 – Maximum temperature classification . 21

Table 5 – Perforation base area classification . 21

Table 6 – Free base area classification . 22

Table 7 – Use of test type IV . 41

Table 8 – Load distribution plates for the SWL test of the cable tray lengths and cable

ladder lengths mounted in the vertical plane running horizontally . 45

Table 9 – Impact test values . 95

Table 10 – System component compliance and classification for resistance against

corrosion . 111

Table 11 – Salt spray test duration. 112

Table C.1 – Calculated and declared cross sectional area of the system used for the

PE function equivalent to copper conductors . 123

Table D.1 – Number of point loads across the width of a cable tray, a cable ladder or a

support . 126

Table D.2 – Number of point loads along the length of a cable tray . 128

Table I.1 – Summary of compliance checks . 137

Table J.1 – Required compliance checks . 139

Table K.1 – Number of samples required for tests . 141

– 8 – IEC 61537:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CABLE MANAGEMENT –

CABLE TRAY SYSTEMS AND CABLE LADDER SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 61537 has been prepared by subcommittee 23A: Cable management systems, of IEC

technical committee 23: Electrical accessories. It is an International Standard.

This third edition cancels and replaces the second edition published in 2006. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) new, repositioned and renumbered figures,

b) revised classification for corrosion,

c) revised SWL test types and procedures,

d) new tests for lengths mounted vertical running horizontal and mounted vertical running

vertical,

e) tests for support devices: cantilevers, pendants, C shape ceiling supports and trapeze

systems,

f) new and revised annexes including use of tray as a protective earth conductor.

The text of this International Standard is based on the following documents:

Draft Report on voting

23A/1032/FDIS 23A/1039/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/standardsdev/publications.

The following differences exist in some countries:

In the USA it is permitted to use cable tray systems and cable ladder systems as a PE conductor,

in which case national wiring regulations have to be adhered to.

In France it is not permitted to use cable tray systems and cable ladder systems as a PE

conductor.

In France the use of flame propagating cable tray and cable ladder systems is not permitted.

In this document, the following print types are used:

– Requirements proper: in roman type.

– Test specifications: in italic type.

– Explanatory matter: in smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 10 – IEC 61537:2023 © IEC 2023

CABLE MANAGEMENT –

CABLE TRAY SYSTEMS AND CABLE LADDER SYSTEMS

1 Scope

This document specifies requirements and tests for cable tray systems and cable ladder

systems intended for the support and accommodation of cables and possibly other electrical

equipment in electrical and/or communication systems installations. Where necessary, cable

tray systems and cable ladder systems can be used for the arrangement of cables into groups.

This document does not apply to conduit systems, cable trunking systems and cable ducting

systems or to any current-carrying parts.

NOTE Cable tray systems and cable ladder systems are designed for use as supports for cables and not as

enclosures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60068-2-75:2014, Environmental testing – Part 2-75: Tests – Test Eh: Hammer tests

IEC 60287 (all parts), Elec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...