IEC 60747-14-3:2009

(Main)Semiconductor devices - Part 14-3: Semiconductor sensors - Pressure sensors

Semiconductor devices - Part 14-3: Semiconductor sensors - Pressure sensors

IEC 60747-14-3:2009 specifies requirements for semiconductor pressure sensors measuring absolute, gauge or differential pressures. The major technical change with regard to the previous edition is the addition of a new subclause 5.9 (measuring method of linearity).

This publication should be read in conjunction with IEC 60747-1:2006.

Dispositifs à semiconducteurs - Partie 14-3: Capteurs à semiconducteurs - Capteurs de pression

La CEI 60747-14-3:2009 spécifie les exigences pour les capteurs de pression à semiconducteurs mesurant les pressions absolues, manométriques ou différentielles. Les modifications techniques majeures par rapport à l'édition précédente sont les suivantes: ajout d'un nouveau paragraphe 5.9 (méthode de mesure de la linéarité).

Cette publication doit être lue conjointement avec la CEI 60747-1:2006.

General Information

- Status

- Published

- Publication Date

- 28-Apr-2009

- Technical Committee

- SC 47E - Discrete semiconductor devices

- Drafting Committee

- WG 1 - TC 47/SC 47E/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 29-Apr-2009

- Completion Date

- 15-Jul-2009

Relations

- Revises

IEC 60747-14-3:2001 - Semiconductor devices - Part 14-3: Semiconductor sensors - Pressure sensors - Effective Date

- 05-Sep-2023

Overview

IEC 60747-14-3:2009 is an international standard developed by the International Electrotechnical Commission (IEC) focused on semiconductor pressure sensors. This standard specifies the requirements, terminology, essential ratings, characteristics, and measurement methods for semiconductor pressure sensors that measure absolute, gauge, or differential pressures. It plays a critical role in ensuring consistency, reliability, and performance in semiconductor pressure sensor technology.

The 2009 edition introduces a significant technical update with the addition of a new measuring method for linearity, detailed in subclause 5.9. This standard is intended to be used alongside IEC 60747-1:2006, which provides general guidance on semiconductor devices.

Key Topics

Scope and Application

IEC 60747-14-3 applies to semiconductor pressure sensors that convert pressure differences into electrical signals for measurement and control. The covered sensor types include both linear sensors and on-off (switch) sensors used across various industries.Terminology and Letter Symbols

The standard defines relevant terms such as absolute pressure, gauge pressure, and differential pressure. Precise definitions support clear communication and uniform understanding in device design and testing.Essential Ratings and Characteristics

Important parameters specified include:- Full-scale span and output voltage

- Sensitivity and temperature coefficients

- Offset voltage and its temperature dependence

- Pressure and temperature hysteresis effects

- Response time and mechanical dimensions

Measurement Methods

IEC 60747-14-3 outlines standardized methods to measure key sensor characteristics accurately. The latest addition covers the measurement of sensor linearity, which assesses how closely the sensor output follows a straight-line response to pressure changes, a critical factor for precision applications.Handling and Material Precautions

The standard includes guidelines for sensor material selection, particularly for piezoelectric sensors, and handling precautions to maintain sensor integrity and performance.

Applications

Semiconductor pressure sensors standardized under IEC 60747-14-3 are vital components in a broad range of applications:

Industrial Automation

Accurate pressure measurement for process control, safety monitoring, and equipment management.Automotive Industry

Monitoring engine and tire pressures, fuel systems, and emission controls.Medical Devices

Blood pressure monitoring, respiratory equipment, and other diagnostic tools requiring precise pressure sensing.Consumer Electronics

Devices like smartphones integrating pressure sensors for altitude detection and environmental monitoring.Environmental Monitoring

Measurement of atmospheric pressure and weather systems.

The standard ensures that devices used in these applications meet internationally recognized performance and reliability criteria, facilitating global interoperability.

Related Standards

IEC 60747-1:2006

Provides general rules, definitions, and test methods applying to semiconductor devices as a whole. It should be used in conjunction with IEC 60747-14-3 to provide a comprehensive framework.IEC 60747-14-1:2000

Establishes general principles and classification for semiconductor sensors, setting the foundation upon which the pressure sensor requirements are built.

Practical Value

Implementing IEC 60747-14-3:2009 helps manufacturers and users:

- Achieve consistent quality and repeatability in semiconductor pressure sensors.

- Facilitate product certification, regulatory compliance, and market acceptance.

- Enhance sensor performance through standard measurement methods, including the new linearity testing procedure.

- Minimize risk by following handling guidelines and accurate rating specifications.

- Support innovation by providing a clear framework for design and testing of pressure sensor devices.

By adhering to IEC 60747-14-3, stakeholders can ensure semiconductor pressure sensors deliver reliable, accurate, and safe operation, critical for modern industrial and technological ecosystems.

Frequently Asked Questions

IEC 60747-14-3:2009 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Semiconductor devices - Part 14-3: Semiconductor sensors - Pressure sensors". This standard covers: IEC 60747-14-3:2009 specifies requirements for semiconductor pressure sensors measuring absolute, gauge or differential pressures. The major technical change with regard to the previous edition is the addition of a new subclause 5.9 (measuring method of linearity). This publication should be read in conjunction with IEC 60747-1:2006.

IEC 60747-14-3:2009 specifies requirements for semiconductor pressure sensors measuring absolute, gauge or differential pressures. The major technical change with regard to the previous edition is the addition of a new subclause 5.9 (measuring method of linearity). This publication should be read in conjunction with IEC 60747-1:2006.

IEC 60747-14-3:2009 is classified under the following ICS (International Classification for Standards) categories: 31.080.99 - Other semiconductor devices. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60747-14-3:2009 has the following relationships with other standards: It is inter standard links to IEC 60747-14-3:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60747-14-3:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60747-14-3 ®

Edition 2.0 2009-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices –

Part 14-3: Semiconductor sensors – Pressure sensors

Dispositifs à semiconducteurs –

Partie 14-3: Capteurs à semiconducteurs – Capteurs de pression

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60747-14-3 ®

Edition 2.0 2009-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Semiconductor devices –

Part 14-3: Semiconductor sensors – Pressure sensors

Dispositifs à semiconducteurs –

Partie 14-3: Capteurs à semiconducteurs – Capteurs de pression

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

R

CODE PRIX

ICS 31.080.99 ISBN 978-2-88910-277-8

– 2 – 60747-14-3 © IEC:2009

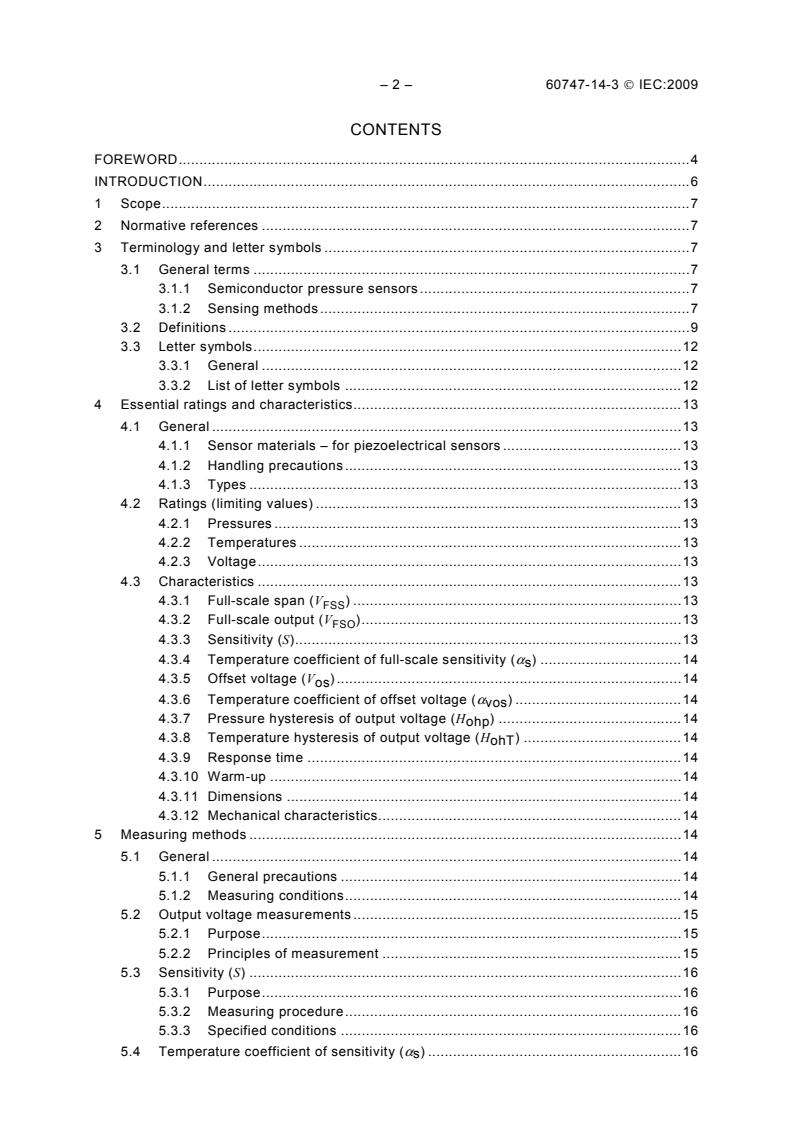

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references .7

3 Terminology and letter symbols .7

3.1 General terms .7

3.1.1 Semiconductor pressure sensors.7

3.1.2 Sensing methods.7

3.2 Definitions .9

3.3 Letter symbols.12

3.3.1 General .12

3.3.2 List of letter symbols .12

4 Essential ratings and characteristics.13

4.1 General .13

4.1.1 Sensor materials – for piezoelectrical sensors .13

4.1.2 Handling precautions.13

4.1.3 Types .13

4.2 Ratings (limiting values) .13

4.2.1 Pressures .13

4.2.2 Temperatures .13

4.2.3 Voltage.13

4.3 Characteristics .13

4.3.1 Full-scale span (V ) .13

FSS

4.3.2 Full-scale output (V ).13

FSO

4.3.3 Sensitivity (S).13

4.3.4 Temperature coefficient of full-scale sensitivity (α ) .14

s

4.3.5 Offset voltage (V ).14

os

4.3.6 Temperature coefficient of offset voltage (α ) .14

vos

4.3.7 Pressure hysteresis of output voltage (H ) .14

ohp

4.3.8 Temperature hysteresis of output voltage (H ) .14

ohT

4.3.9 Response time .14

4.3.10 Warm-up .14

4.3.11 Dimensions .14

4.3.12 Mechanical characteristics.14

5 Measuring methods .14

5.1 General .14

5.1.1 General precautions .14

5.1.2 Measuring conditions.14

5.2 Output voltage measurements .15

5.2.1 Purpose.15

5.2.2 Principles of measurement .15

5.3 Sensitivity (S) .16

5.3.1 Purpose.16

5.3.2 Measuring procedure.16

5.3.3 Specified conditions .16

5.4 Temperature coefficient of sensitivity (α ) .16

s

60747-14-3 © IEC:2009 – 3 –

5.4.1 Purpose.16

5.4.2 Specified conditions .16

5.5 Temperature coefficient of full-scale span (α V ) and maximum

FSS

temperature deviation of full-scale span (ΔV ) .17

FSS

5.5.1 Purpose.17

5.5.2 Specified conditions .17

5.6 Temperature coefficient of offset voltage (α ) and (ΔV ).17

Vos os

5.6.1 Purpose.17

5.6.2 Specified conditions .17

5.7 Pressure hysteresis of output voltage (H ) .18

ohp

5.7.1 Purpose.18

5.7.2 Circuit diagram and circuit description .18

5.7.3 Specified conditions .18

5.8 Temperature hysteresis of output voltage (H ) .18

ohT

5.8.1 Purpose.18

5.8.2 Measuring procedure.18

5.8.3 Specified conditions .18

5.9 Linearity .18

5.9.1 Purpose.18

5.9.2 Specified conditions .18

5.9.3 Measuring procedure.18

Figure 1 – Basic circuit for measurement of output voltage .15

Figure 2 – Linearity test .19

– 4 – 60747-14-3 © IEC:2009

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

SEMICONDUCTOR DEVICES –

Part 14-3: Semiconductor sensors –

Pressure sensors

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60747-14-3 has been prepared by subcommittee 47E: Discrete

semiconductor devices, of IEC technical committee 47: Semiconductor devices.

This second edition cancels and replaces the first edition, published in 2001, and constitutes

a technical revision.

The major technical changes with regard to the previous edition are as follows: added a new

Subclause 5.9 (measuring method of linearity) (technical)

60747-14-3 © IEC:2009 – 5 –

The text of this standard is based on the following documents:

CDV Report on voting

47E/362/CDV 47E/376/RVC

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

This part of IEC 60747 should be read in conjunction with IEC 60747-1:2006.

A list of all the parts in the IEC 60747 series, under the general title Semiconductor devices,

can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 60747-14-3 © IEC:2009

INTRODUCTION

This part of IEC 60747 provides basic information on semiconductors:

– terminology;

– letter symbols;

– essential ratings and characteristics;

– measuring methods;

– acceptance and reliability.

60747-14-3 © IEC:2009 – 7 –

SEMICONDUCTOR DEVICES –

Part 14-3: Semiconductor sensors –

Pressure sensors

1 Scope

This part of IEC 60747 specifies requirements for semiconductor pressure sensors measuring

absolute, gauge or differential pressures.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60747-1:2006, Semiconductor devices – Part 1: General

IEC 60747-14-1:2000, Semiconductor devices – Part 14-1: Semiconductor sensors – General

and classification

3 Terminology and letter symbols

3.1 General terms

3.1.1 Semiconductor pressure sensors

A semiconductor pressure sensor converts the difference between two pressures into an

electrical output quantity. One of the two pressures may be a reference pressure (see 3.2.3).

It includes linear and on-off (switch) types of sensors.

A linear sensor produces electrical output quantity changes linearly with the pressure

difference.

An on-off sensor switches an electrical output quantity on and off between two stable states

when the increasing or decreasing pressure differences cross given threshold values.

In this standard, the electrical output quantity is described as a voltage: output voltage.

However, the statements made in this standard are also applicable to other output quantities

such as those described in 3.8 of IEC 60747-14-1: changes in impedance, capacitance,

voltage ratio, frequency-modulated output or digital output.

3.1.2 Sensing methods

3.1.2.1 Piezoelectric sensing

The basic principle of piezoelectric devices is that a piezoelectric material induces a charge or

induces a voltage across itself when it is deformed by stress. The output from the sensor

is amplified in a charge amplifier which converts the charge generated by the transducer

sensor into a voltage that is proportional to the charge. The main advantages of piezoelectric

sensing are the wide operating temperature range (up to 300 °C) and high-frequency range

(up to 100 kHz).

– 8 – 60747-14-3 © IEC:2009

3.1.2.2 Piezoresistive sensing

The basic principle of a piezoresistor is the change of the resistor value when it is deformed

by stress. The sensing resistors can be either p- or n-type doped regions. The resistance of

piezoresistors is very sensitive to strain, and thus to pressure, when correctly placed on the

diaphragm of a pressure sensor. Four correctly oriented resistors are used to build a strain

gauge in the form of a resistor bridge.

An alternative to the resistor bridge is the transverse voltage strain gauge. It is a single

resistive element on a diaphragm, with voltage taps centrally located on either side of the

resistor. When a current is passed through the resistor, the voltages are equal when the

element is not under strain, but when the element is under strain, a differential voltage output

appears.

3.1.2.3 Capacitive sensing

A small dielectric gap between the diaphragm and a plate makes a capacitance which

changes with the diaphragm movement. Single capacitance or differential capacitance

techniques can be used in open- or closed-loop systems. Capacitance and capacitive

changes can be measured either in a bridge circuit or using switched-capacitor techniques.

Any of the capacitive sensing techniques used in a micromachined structure require an a.c.

voltage across the capacitor being measured. Capacitive sensing has the following

advantages: small size of elements, wide-operating temperature range, ease of trimming,

good linearity, and compatibility to CMOS signal conditioning.

3.1.2.4 Silicon vibrating sensing

The vibrating element of a silicon micromachined structure is maintained in oscillation, either

by piezoelectric or electrical field energy. The application of pressure to the silicon diaphragm

produces strain on the micromachined structure and the vibration frequency is measured to

determine applied pressure.

3.1.2.5 Signal conditioning

Semiconductor pressure sensors are mainly micromachined structures including a sensing

element. Other electrical components or functions can be performed at the same time and in

the same package on the process line. Most pressure sensors offer integrated signal

conditioning.

Signal conditioning transforms a raw sensor output into a calibrated signal. This process may

involve several functions, such as calibration of initial zero pressure offset and pressure

sensitivity, compensation of non-linear temperature errors of offset and sensitivity,

compensation of the non-linearity and output signal amplification of the pressure.

3.1.2.6 Temperature compensation

Semiconductor sensors are temperature sensitive. Some are temperature non-compensated

sensors while others are compensated with added circuitry or materials designed to

counteract known sources of error.

When non-compensated, the variations due to the temperature follow physical laws and a

temperature coefficient (α) is representative of this physical phenomena.

When compensated, the temperature remaining error is also dependant on the way the

compensation is performed. In this case, a maximum temperature deviation (Δ) better

represents this error.

60747-14-3 © IEC:2009 – 9 –

3.2 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60747-1 and the

following apply.

3.2.1

piezoresistance coefficient

measure of the piezoresistance effect derived from the semiconductor materials under the

application of strain

3.2.2

absolute pressure

pressure using absolute vacuum as the datum point

3.2.3

reference pressure

pressure against which pressures are defined, usually absolute vacuum or ambient atmo-

spheric pressure

3.2.4

differential pressure

difference between the two (absolute) pressures that act simultaneously on opposite sides of

the membrane

3.2.5

relative pressure

differential pressure when one of the two pressures is considered to be a reference pressure

with respect to which the other pressure is being measured

3.2.6

gauge pressure

relative pressure when the ambient atmospheric pressure is used as the reference pressure

3.2.7

system pressure (or common-mode pressure)

static pressure that acts on the sensor but does not represent the pressure to be converted, in

the case of a differential pressure sensor

3.2.8

over-pressure capability

maximum pressure that may be applied to the sensor without damage or loss of calibration

accuracy

3.2.9

differential output resistance

first derivative of output voltage as a function of output current at the specified pressure.

Refers to a basic sensor (without integrated signal amplification)

NOTE In practice, the differential resistance value can be expressed as the quotient of the change of the output

voltage over the change in output current resulting from a small change in output load resistance.

3.2.10

input resistance

supply voltage divided by the supply current

3.2.11

isolation resistance

resistance between all the connected electrical terminals of the sensor and the sensor part

which is in contact with the sensed element

– 10 – 60747-14-3 © IEC:2009

NOTE In practice, this is not applicable when the sensed element, such as gas or oil, is not conductive.

3.2.12

calibrated pressure range

range of pressure within which the device is designed to operate and for which limit values of

the conversion characteristics are specified

3.2.13

temperature coefficient of offset voltage

change in offset voltage relative to the change in temperature

3.2.14

temperature coefficient of full-scale span voltage

change in full-scale span voltage relative to the change in temperature

3.2.15

temperature coefficient of the pressure sensitivity

change in the pressure sensitivity relative to the change in temperature

3.2.16

maximum temperature deviation of the offset voltage

maximum deviation of the offset voltage for a specified temperature range, compared to the

output offset voltage at the reference temperature

3.2.17

maximum temperature deviation of the full-scale span voltage

maximum deviation of the full-scale span voltage in a specified temperature range, compared

to the full-scale span voltage at reference temperature

3.2.18

full-scale pressure

pressure that defines the upper limit for the calibrated pressure range

3.2.19

zero-scale pressure

pressure that defines the lower limit for the calibrated pressure range

3.2.20

null offset (also called zero pressure offset)

electrical output present when the pressure sensor is at null, i.e. when the pressure on each

side of the sensing diaphragm is equal

3.2.21

burst pressure

pressure that causes an irreversible damage of the sensor

3.2.22

(End-point) Linearity error

difference between the actual value of the output voltage and, at the given pressure, the value

that would result if the output voltage changed linearly with pressure between the zero-scale

pressure and the full-scale pressure

3.2.23

total error

difference between the actual value of the output voltage and, at the given pressure, the value

that would result if the actual voltages were equal to their nominal values at the zero-scale

pressure and at the full-scale pressure and changed linearly with pressure between these

points

60747-14-3 © IEC:2009 – 11 –

3.2.24

accuracy

maximum deviation of actual output from nominal output over the entire pressure range and

temperature range, as a percentage of the full-scale span at 25 °C, due to all sources of error

such as linearity, hysteresis, repeatability and temperature shifts

3.2.25

hysteresis

sensor’s ability to reproduce the same output for the same input, regardless of whether the

input is increasing or decreasing. Pressure hysteresis is measured at a constant temperature,

while temperature hysteresis is measured at a constant pressure within the operating range

3.2.25.1

pressure-cycle hysteresis

difference in the output at any given pressure in the operating pressure range when this

pressure is approached from the minimum operating pressure as compared to when

approached from the maximum operating pressure at room temperature

3.2.25.2

temperature-cycle hysteresis

difference in the output at any temperature in the operating pressure range when the

temperature is approached from the minimum operating temperature as compared to when

approached from the maximum operating temperature, with fixed pressure applied

3.2.26

pressure-cycling drift of output voltage

difference between the final value of the output voltage at a given pressure after a series of

pressure cycles and the initial value at that same pressure when all other operating conditions

are being held constant

3.2.27

temperature-cycling drift of output voltage

difference between the final value of the output voltage at a given temperature after a series

of temperature cycles and the initial value at that same temperature when all other operating

conditions are being held constant

3.2.28

pressure-cycling instability range of output voltage

difference between the extreme values of output voltage that were observed at a given

pressure during a series of pressure cycles when all other operating conditions are being held

constant

3.2.29

temperature-cycling instability range of output voltage

difference between the extreme values of output voltage that were observed at a given

temperature during a series of temperature cycles, when all other operating conditions are

being held constant

3.2.30

full-scale span sensitivity

quotient of the full-scale span voltage over the calibrated pressure range

3.2.31

temperature coefficient of full-scale span sensitivity

full-scale span sensitivity relative to the change in temperature

– 12 – 60747-14-3 © IEC:2009

3.3 Letter symbols

3.3.1 General

Subclauses 4.2, 4.4 and 4.5 of IEC 60747-1 apply.

3.3.2 List of letter symbols

Name and designation Letter symbol Remarks

π for the longitudinal component of the

l

Piezoresistance coefficient

π ,π

coefficient, π for the transverse component of

l t

t

the coefficient

Absolute pressure P

abs

Reference pressure P

ref

ΔP

Differential pressure

Relative pressure P

rel

Offset voltage V

os

Full-scale pressure P

fs

P

Zero-scale pressure

zs

Burst pressure P

burst

Differential output resistance R

do

R

Isolation resistance

iso

Full-scale span V

FSS

Response time t

resp

Sensitivity S

Temperature coefficient of

α

sensitivity

s

Total error E , E (p) E for any pressure, E (p) for a specified pressure

t t t t

(End-point) linearity error E , E (p) E for any pressure, E (p) for a specified pressure

l l l l

Pressure hysteresis of output

voltage H

ohp

Temperature hysteresis of output

voltage H

ohT

Temperature coefficient of offset

voltage α

vos

Temperature coefficient of full-

α

scale span

vFSS

Maximum temperature deviation

ΔV

of the offset voltage

os

Maximum temperature deviation

ΔV

of full-scale span

FSS

Pressure-cycling drift of output

voltage ΔV

otp

Temperature-cycling drift of

output voltage ΔV

otT

Pressure-cycling instability range

of output voltage ΔV

oip

Temperature-cycling instability

range of output voltage ΔV

oiT

60747-14-3 © IEC:2009 – 13 –

4 Essential ratings and characteristics

4.1 General

4.1.1 Sensor materials – for piezoelectrical sensors

Materials used for semiconductor pressure sensors are semiconductor materials having large

piezoresistance effects, such as Si, compound semiconductors and some of the metal oxide

semiconductors. Ratings of pressure sensors depend upon the materials used.

4.1.2 Handling precautions

When handling sensors, the handling precautions given in IEC 60747-1 Clause 8 must be

observed.

4.1.3 Types

Types of semiconductor pressure sensors in which pressure might be measured must be

specified, i.e. absolute, gauge or differential pressures.

4.2 Ratings (limiting values)

4.2.1 Pressures

4.2.1.1 Maximum pressure (P )

max

4.2.1.2 Burst pressure (P )

burst

4.2.1.3 Over-pressure capability

4.2.1.4 Maximum number of pressure cycles up to a specified pressure

4.2.2 Temperatures

4.2.2.1 Minimum and maximum storage temperatures (T )

stg

4.2.2.2 Minimum and maximum operating temperatures (T )

amb

4.2.3 Voltage

Maximum supply voltage (V ) or current (I )

smax smax

4.3 Characteristics

Except where otherwise stated, characteristics apply over the operating temperature range

given in 4.2.2.2.

4.3.1 Full-scale span (V )

FSS

The algebraic difference between the end points of the output, at an operating temperature

of +25 °C.

4.3.2 Full-scale output (V )

FSO

The upper limit of sensor output over the measuring range, at an operating temperature

of +25 °C.

NOTE V =V + V

FSO

off FSS

4.3.3 Sensitivity (S)

The change in output per unit change in pressure for a specified supply voltage or current.

– 14 – 60747-14-3 © IEC:2009

4.3.4 Temperature coefficient of full-scale sensitivity (α )

s

The per cent change in sensitivity per unit change in temperature relative to the sensitivity at

a specified temperature (typically +25 °C).

4.3.5 Offset voltage (V )

os

Maximum and minimum values, at specified supply voltage or current without any pressure

applied, at a fixed operating temperature.

4.3.6 Temperature coefficient of offset voltage (α )

vos

The per cent change in offset per unit change in temperature relative to the offset at a

specified temperature (typically +25 °C)

4.3.7 Pressure hysteresis of output voltage (H )

ohp

Maximum and minimum values as a percentage of full-scale output voltage, at specified

supply voltage or current under specified pressure range.

4.3.8 Temperature hysteresis of output voltage (H )

ohT

Maximum and minimum values as a percentage of full-scale output voltage, at specified

supply voltage or current under specified temperature range.

4.3.9 Response time

Time interval between the moment when a stimulus is subjected to a specified abrupt change

and the moment when the response reaches and remains within specified limits around its

final value.

4.3.10 Warm-up

Warm-up is defined as the time required for the device to meet the specified output voltage

after the pressure has been stabilized and the electrical supply has been applied.

4.3.11 Dimensions

Dimensions with specified tolerance shall be included on technical drawings.

4.3.12 Mechanical characteristics

– Weight

– Cavity volume

– Volumetric displacement

– Hermeticity

5 Measuring methods

5.1 General

5.1.1 General precautions

The general precautions listed in Subclause 6.4 of IEC 60747-1 apply.

5.1.2 Measuring conditions

The measurements shall be made over the operating pressure range at 25 °C, unless other-

wise specified.

60747-14-3 © IEC:2009 – 15 –

5.2 Output voltage measurements

5.2.1 Purpose

To measure output voltage under specific conditions.

5.2.2 Principles of measurement

a) Circuit diagram – piezo resistive types

b) Circuit description and requirements

Internal impedance of the meters and/or measuring instrument shall not affect the

performance and the test results of the circuit to be measured.

NOTE Semiconductor pressure sensors are very sensitive to temperature; always wait for thermal

stabilization of the device under test.

A

Ammeter

Constant

Constant 2

voltage

Voltmeter current

source

V 1 source 1

V

V

Voltmeter

Voltmeter

IEC 840/01 IEC 841/01

Key

1 Output +

2 Input +

3 Input –

4 Output –

Figure 1a – Constant voltage Figure 1b – Constant current

Figure 1 – Basic circuit for measurement of output voltage

5.2.2.1 Measurement procedure – Full-scale span

Ambient temperature is stabilized.

Apply a specified voltage or current to the input terminals of the device, using the circuit

shown in Figure 1.

Place the device with connected terminals to the circuit at a specified pressure. Wait for

thermal stabilization.

Measure full-scale output: V at P .

FSO max

Measure V at zero pressure applied.

os

Calculate the full-scale span V with the following equation:

FSS

V = V – V

FSS FSO os

– 16 – 60747-14-3 © IEC:2009

5.2.2.2 Specified conditions

Ambient or reference temperature.

Applied pressure.

Supply voltage or current.

5.3 Sensitivity (S)

5.3.1 Purpose

To measure the sensitivity of the device under specified conditions.

5.3.2 Measuring procedure

Measure the voltage output for two pressures, P and P , and calculate:

1 2

S = (V – V ) / (P – P )

2 1 2 1

NOTE In practice, P and P are the end-points of the pressure range; reference temperature is 25 °C. The

1 2

sensitivity can be called in that case full-scale sensitivity.

5.3.3 Specified conditions

Ambient or reference temperature.

Pressures at which the measurements are carried out.

Supply voltage or current.

5.4 Temperature coefficient of sensitivity (α )

s

5.4.1 Purpose

To measure the temperature coefficient of sensitivity of the device under specified conditions.

5.4.1.1 Non-compensated sensors

Calculate sensitivity at P over the temperature range, relative to 25 °C:

max

(α ) = [(S(T ) – S(T )) × 100] / [(T – T ) × S(25 °C)]

s

max min max min

NOTE In practice, T is the lower point of the measuring temperature range and T is the higher point of the

min max

measuring temperature range. The unit is % S/°C.

5.4.1.2 Compensated sensors

Output deviation over the measuring temperature range, relative to 25 °C.

5.4.2 Specified conditions

Temperatures at which the measurements are carried out.

Supply voltage or current.

60747-14-3 © IEC:2009 – 17 –

5.5 Temperature coefficient of full-scale span (α V ) and maximum temperature

FSS

deviation of full-scale span (ΔV )

FSS

5.5.1 Purpose

To measure the temperature coefficient of the full-scale span of the device under specified

conditions.

5.5.1.1 Non-compensated sensors

Measure full-scale span voltage at P over the temperature range, relative to 25 °C: V

max FSS

(αV ) = [(V (T ) – V (T )) × 100] / [(T – T ) × V (25 °C)]

FSS FSS max FSS min max min FSS

NOTE 1 In practice, T is the lower point of the measuring temperature range and T is the higher point of the

min max

measuring temperature range. The unit is % V /°C

FSS

5.5.1.2 Compensated sensors

Output deviation over the temperature range of maximum operating temperature to minimum

operating temperature, relative to 25 °C.

NOTE In practice, maximum deviation of the output full-scale span is used (ΔV ). This is the maximum

FSS

deviation of the output full-scale span at a given temperature range (for example 0-85 °C), compared to the output

full-scale span at 25 °C.

(ΔV ) = Max (V (T) – V (25 °C)), whatever T is in the complete temperature range.

FSS FSS FSS

5.5.2 Specified conditions

Temperatures at which the measurements are carried out.

Supply voltage or current.

5.6 Temperature coefficient of offset voltage (α ) and (ΔV )

Vos os

5.6.1 Purpose

To measure temperature coefficient of offset voltage.

5.6.1.1 Non-compensated sensors

Calculate offset at zero pressure applied at two temperatures TH and TL:

(α ) = (V (T ) – V (T )) / (T – T )

Vos os os

max min max min

NOTE In practice, T is the lower point of the measuring temperature range and T is the higher point of the

min max

measuring temperature range. The unit is μV/°C.

5.6.1.2 Compensated sensors

Output deviation, with zero pressure applied, over the measuring temperature range, relative

to 25 °C.

NOTE In practice, maximum deviation of the output offset voltage is used (ΔV ). This is the maximum deviation

os

of the output offset at a given temperature range (usually 0-85 °C), compared to the output offset voltage at 25 °C.

(ΔV ) = Max (V (T) – V (25 °C)), whatever T is in the complete temperature range.

os os os

5.6.2 Specified conditions

Temperatures at which the measurements are carried out.

– 18 – 60747-14-3 © IEC:2009

Supply voltage or current.

5.7 Pressure hysteresis of output voltage (H )

ohp

5.7.1 Purpose

To measure pressure hysteresis of output voltage.

5.7.2 Circuit diagram and circuit description

The same circuit as that described in the measuring procedure.

For the definition and description of H , refer to 3.3 and Figure 2 in IEC 60747-14-1, where

ohp

the variable is the pressure applied and the output is the output voltage in this case, under

specified conditions.

5.7.3 Specified conditions

Temperature at which the measurements are carried out.

Supply voltage or current.

5.8 Temperature hysteresis of output voltage (H )

ohT

5.8.1 Purpose

To measure temperature hysteresis of output voltage.

5.8.2 Measuring procedure

For the definition and description of H , refer to 3.3 and Figure 2 in IEC 60747-14-1, where

ohT

the variable is the temperature and the output is the output voltage in this case, under

specified conditions.

5.8.3 Specified conditions

Pressure at which the measurements are carried out.

Supply voltage or current.

5.9 Linearity

5.9.1 Purpose

To measure the variation of output value according to input pressure against the straight line

from start point to end point.

5.9.2 Specified conditions

Ambient or reference temperature.

Pressures at which the measurements are carried out.

Supply voltage or current.

5.9.3 Measuring procedure

Measure the voltage outputs for at least five input pressures within measuring pressure range

including end-points. From the graph as shown in Figure 2 plotted of voltage output against

60747-14-3 © IEC:2009 – 19 –

increase in measurand which usually appears as a curve, a straight line is drawn from the

zero point to the full scale output point.

Usually the point which deviates most from the simple straight line will be used to specify the

'linearity' of the pressure sensor. This is quoted as a percentage of the normal full scale

output of the pressure sensor.

Output

Ideal output

voltage (V )

o

value

Real output

value

Linearity error

Pressure (P)

IEC 613/09

Figure 2 – Linearity test

___________

– 20 – 60747-14-3 © CEI:2009

SOMMAIRE

AVANT-PROPOS.22

INTRODUCTION.24

1 Domaine d’application .25

2 Références normatives.25

3 Terminologie et symboles littéraux .25

3.1 Termes généraux .25

3.1.1 Capteurs de pression à semiconducteurs .25

3.1.2 Méthodes de détection .25

3.2 Définitions .27

3.3 Symboles littéraux.30

3.3.1 Généralité

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...