IEC 62024-1:2008

(Main)High frequency inductive components - Electrical characteristics and measuring methods - Part 1: Nanohenry range chip inductor

High frequency inductive components - Electrical characteristics and measuring methods - Part 1: Nanohenry range chip inductor

IEC 62024-1:2008 specifies electrical characteristics and measuring methods for the nanohenry range chip inductor that is normally used in high frequency (over 100 kHz) range. This edition includes the following significant technical changes with respect to the previous edition:

a) sizes 0402 added in Table 1 and Table 2;

b) contents of 4.4 reviewed for easier understanding;

c) correct errors in 3.1.4.2.

Composants inductifs à haute fréquence - Caractéristiques électriques et méthodes de mesure - Partie 1: Inductance pastille de l'ordre du nanohenry

La CEI 62024-1:2008 spécifie les caractéristiques électriques et les méthodes de mesure pour l'inductance pastille de l'ordre du nanohenry qui est normalement utilisée dans la gamme des hautes fréquences (supérieures à 100 kHz). Par rapport à l'édition précédente, les principales modifications techniques sont les suivantes:

a) tailles 0402 ajoutées dans le Tableau 1 et le Tableau 2;

b) contenu de 4.4 révisé pour en faciliter la compréhension;

c) erreurs de 3.1.4.2 corrigées.

General Information

- Status

- Published

- Publication Date

- 21-Feb-2008

- Technical Committee

- TC 51 - Magnetic components, ferrite and magnetic powder materials

- Drafting Committee

- MT 9 - TC 51/MT 9

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 13-Dec-2017

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62024-1:2008 - "High frequency inductive components – Electrical characteristics and measuring methods – Part 1: Nanohenry range chip inductor" - specifies electrical characteristics and standardized measuring methods for nanohenry-range chip inductors intended for high-frequency use (over 100 kHz). This second edition updates test sizes (adds 0402), clarifies measurement-by-analyser content, and corrects measurement notes, ensuring reliable characterization of small surface-mount inductors for RF and high-frequency applications.

Key topics and requirements

- Scope and purpose: Defines how to measure and report inductance, Q‑factor, impedance, self‑resonance frequency and DC resistance for nanohenry chip inductors.

- Measuring methods:

- Vector voltage/current method for inductance measurement.

- Q‑factor and impedance measurement procedures with dedicated circuits.

- Self‑resonance frequency measurement using minimum-output, reflection and analyser methods.

- DC resistance measurement (bridge method) and temperature considerations.

- Test fixtures and mounting:

- Specified test fixtures (Fixture A and Fixture B) and mounting guidance to preserve characteristic impedance (≈50 Ω).

- Mechanical contact force and fixture dimensions (Table 1 includes sizes 1608, 1005, 0603, 0402).

- Annex A provides mounting methods for surface‑mount coils.

- Calibration and compensation:

- Requirements for open‑short compensation and electrical length correction of test fixtures.

- Formulas and notes for accurate impedance compensation and reporting.

- Edition updates:

- Addition of 0402 size in Tables 1 and 2.

- Clarified section 4.4 (measurement by analyser).

- Corrections in clause 3.1.4.2.

Applications and practical value

- Standardizes test procedures used in:

- Component manufacturers (characterization, datasheets, production QA).

- Independent test labs and certification bodies.

- RF/microwave designers and PCB engineers evaluating chip inductors for filters, matching networks, EMI suppression and small wireless modules (IoT, mobile devices).

- Ensures repeatable, comparable measurements across suppliers and labs, improving component selection, design reliability and supplier negotiation.

Who should use this standard

- Magnetic component and ferrite material manufacturers

- RF/component test laboratories

- Electronics design engineers (RF, high-frequency systems)

- Quality assurance and compliance teams

- Standards committees and procurement specialists

Related standards and references

- IEC 62024 series (other parts for high-frequency inductive components)

- Normative references cited: IEC 61249-2-7, ISO 6353-3, ISO 9453

- Useful keywords for search: IEC 62024-1:2008, nanohenry chip inductor, high frequency inductive components, inductance measurement, Q-factor, self-resonance frequency, SMD inductor test methods.

IEC 62024-1:2008 - High frequency inductive components - Electrical characteristics and measuring methods - Part 1: Nanohenry range chip inductor Released:2/22/2008 Isbn:2831896312

IEC 62024-1:2008 - High frequency inductive components - Electrical characteristics and measuring methods - Part 1: Nanohenry range chip inductor Released:2/22/2008 Isbn:9782832203507

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62024-1:2008 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "High frequency inductive components - Electrical characteristics and measuring methods - Part 1: Nanohenry range chip inductor". This standard covers: IEC 62024-1:2008 specifies electrical characteristics and measuring methods for the nanohenry range chip inductor that is normally used in high frequency (over 100 kHz) range. This edition includes the following significant technical changes with respect to the previous edition: a) sizes 0402 added in Table 1 and Table 2; b) contents of 4.4 reviewed for easier understanding; c) correct errors in 3.1.4.2.

IEC 62024-1:2008 specifies electrical characteristics and measuring methods for the nanohenry range chip inductor that is normally used in high frequency (over 100 kHz) range. This edition includes the following significant technical changes with respect to the previous edition: a) sizes 0402 added in Table 1 and Table 2; b) contents of 4.4 reviewed for easier understanding; c) correct errors in 3.1.4.2.

IEC 62024-1:2008 is classified under the following ICS (International Classification for Standards) categories: 29.100.10 - Magnetic components. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62024-1:2008 has the following relationships with other standards: It is inter standard links to IEC 62024-1:2008/COR1:2008, IEC 62024-1:2017, IEC 62024-1:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62024-1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62024-1

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

High frequency inductive components – Electrical characteristics and measuring

methods –

Part 1: Nanohenry range chip inductor

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62024-1

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

High frequency inductive components – Electrical characteristics and measuring

methods –

Part 1: Nanohenry range chip inductor

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

R

ICS 29.100.10 ISBN 2-8318-9631-2

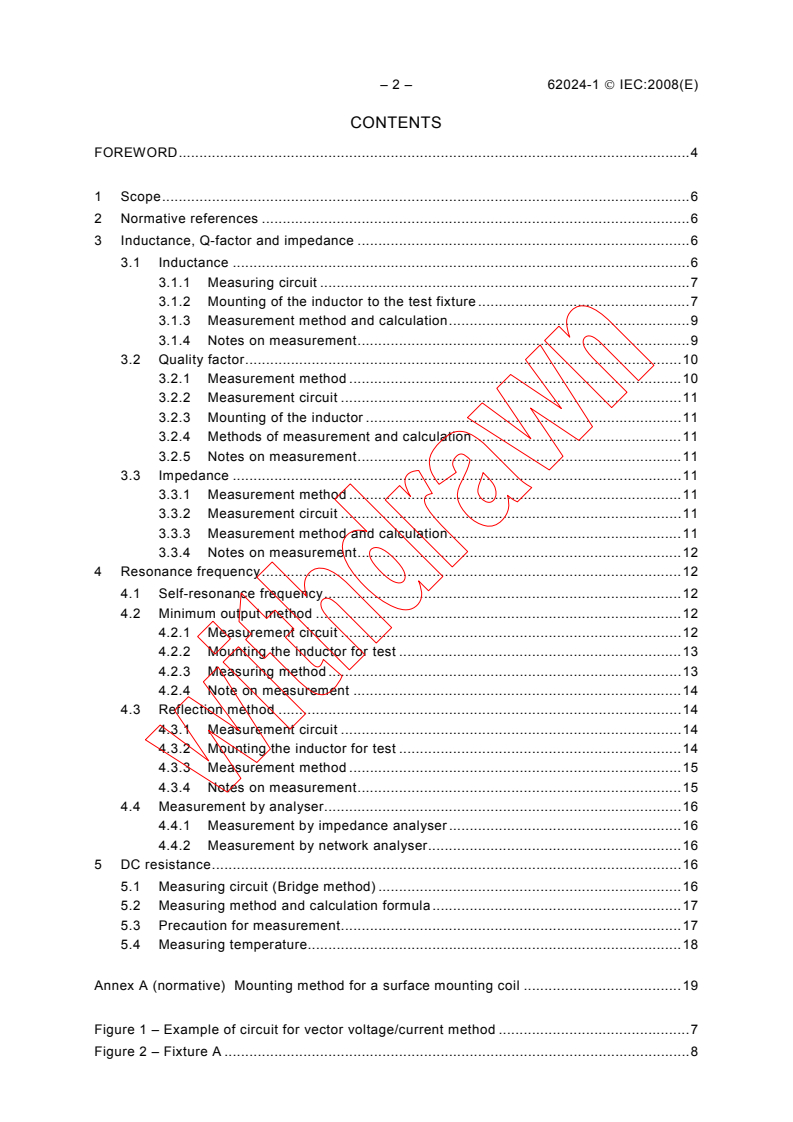

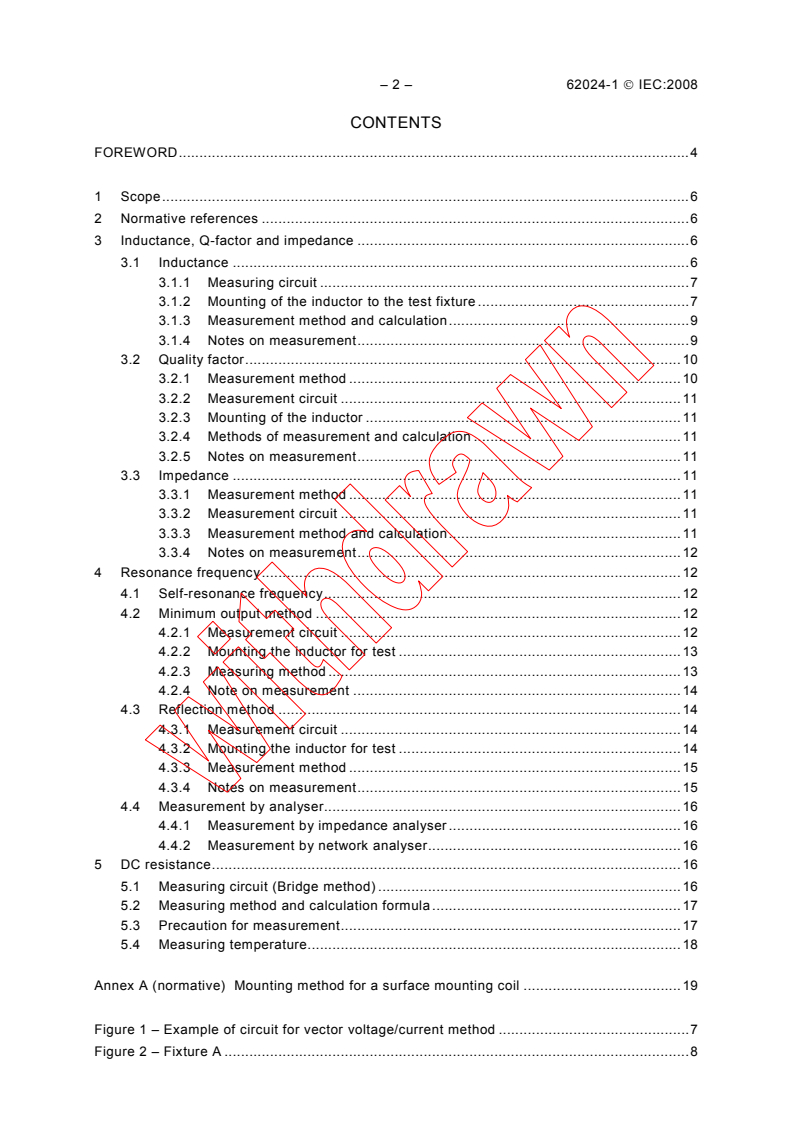

– 2 – 62024-1 © IEC:2008(E)

CONTENTS

FOREWORD.4

1 Scope.6

2 Normative references .6

3 Inductance, Q-factor and impedance .6

3.1 Inductance .6

3.1.1 Measuring circuit .7

3.1.2 Mounting of the inductor to the test fixture .7

3.1.3 Measurement method and calculation.9

3.1.4 Notes on measurement.9

3.2 Quality factor.10

3.2.1 Measurement method .10

3.2.2 Measurement circuit .11

3.2.3 Mounting of the inductor .11

3.2.4 Methods of measurement and calculation .11

3.2.5 Notes on measurement.11

3.3 Impedance .11

3.3.1 Measurement method .11

3.3.2 Measurement circuit .11

3.3.3 Measurement method and calculation.11

3.3.4 Notes on measurement.12

4 Resonance frequency.12

4.1 Self-resonance frequency.12

4.2 Minimum output method .12

4.2.1 Measurement circuit .12

4.2.2 Mounting the inductor for test .13

4.2.3 Measuring method .13

4.2.4 Note on measurement .14

4.3 Reflection method .14

4.3.1 Measurement circuit .14

4.3.2 Mounting the inductor for test .14

4.3.3 Measurement method .15

4.3.4 Notes on measurement.15

4.4 Measurement by analyser.16

4.4.1 Measurement by impedance analyser.16

4.4.2 Measurement by network analyser.16

5 DC resistance.16

5.1 Measuring circuit (Bridge method) .16

5.2 Measuring method and calculation formula.17

5.3 Precaution for measurement.17

5.4 Measuring temperature.18

Annex A (normative) Mounting method for a surface mounting coil .19

Figure 1 – Example of circuit for vector voltage/current method .7

Figure 2 – Fixture A .8

62024-1 © IEC:2008(E) – 3 –

Figure 3 – Fixture B .8

Figure 4 – Short device shape .10

Figure 5 – Example of test circuit for the minimum output method.12

Figure 6 – Self-resonance frequency test board (minimum output method) .13

Figure 7 – Example of test circuit for the reflection method .14

Figure 8 – Self-resonance frequency test board (reflection method).15

Figure 9 – Suitable test fixture for measuring self-resonance frequency.16

Figure 10 – Example of measuring circuit of d.c. resistance.17

Table 1 – Dimensions of l and d.8

Table 2 – Short device dimensions and inductances .10

– 4 – 62024-1 © IEC:2008(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH FREQUENCY INDUCTIVE COMPONENTS –

ELECTRICAL CHARACTERISTICS AND MEASURING METHODS –

Part 1: Nanohenry range chip inductor

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)“). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62024-1 has been prepared by IEC technical committee 51:

Magnetic components and ferrite materials.

This second edition cancels and replaces the first edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) sizes 0402 added in Table 1 and Table 2;

b) contents of 4.4 reviewed for easier understanding;

c) correct errors in 3.1.4.2.

62024-1 © IEC:2008(E) – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

51/908/FDIS 51/915/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 62024 series, published under the general title High frequency

inductive components – Electrical characteristics and measuring methods, can be found on

the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

The contents of the corrigendum of July 2008 have been included in this copy.

– 6 – 62024-1 © IEC:2008(E)

HIGH FREQUENCY INDUCTIVE COMPONENTS –

ELECTRICAL CHARACTERISTICS AND MEASURING METHODS –

Part 1: Nanohenry range chip inductor

1 Scope

This part of IEC 62024 specifies electrical characteristics and measuring methods for the

nanohenry range chip inductor that is normally used in high frequency (over 100 kHz) range.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 61249-2-7, Materials for printed boards and other interconnecting structures – Part 2-7:

Reinforced base materials clad and unclad – Epoxide woven E-glass laminated sheet of

defined flammability (vertical burning test) copper-clad

ISO 6353-3, Reagents for chemical analysis – Part 3: Specifications – Second series

ISO 9453, Soft solder alloys – Chemical compositions and forms

3 Inductance, Q-factor and impedance

3.1 Inductance

The inductance of an inductor is measured by the vector voltage/current method.

62024-1 © IEC:2008(E) – 7 –

3.1.1 Measuring circuit

EV

L

x

R

R

g

L

s

C

d

EV

R

s

G

IEC 317/08

Components

R source resistance (50 Ω)

g

R resistor

L inductor under test

x

C distributed capacitance of inductor under test

d

L series inductance of inductor under test

s

R series resistance of inductor under test

s

phase reference signal

Ev , Ev vector voltmeter

1 2

G signal generator

Figure 1 – Example of circuit for vector voltage/current method

3.1.2 Mounting of the inductor to the test fixture

The inductor shall be measured in a test fixture as specified in the relevant standard. If no

fixture is specified, one of the following test fixtures A or B shall be used. The fixture used

shall be reported.

– 8 – 62024-1 © IEC:2008(E)

3.1.2.1 Fixture A

The shape and dimensions of fixture A shall be as shown in Figure 2.

Electrical Structure of connection

length to the measurement circuit

l

External electrode

Central electrode

Dielectric material

Inductor under test

IEC 318/08

Figure 2 – Fixture A

Table 1 – Dimensions of l and d

l d

Size of inductor under test

mm mm

1608 1,6 0,95

1005 1,0 0,60

0603 0,6 0,36

0402 0,4 0,26

The electrodes of test fixture shall contact the electrodes of inductor under test by mechanical

force provided by an appropriate method. This force shall be chosen so as to provide

satisfactory measurement stability without influencing the characteristics of the inductor. The

electrode force shall be specified. The structure between the measurement circuit and test

fixture shall maintain a characteristic impedance as near as possible to 50 Ω.

3.1.2.2 Fixture B

The test fixture B as shown in Figure 3 shall be used.

External electrode

Inductor under test

Central electrode

d

Dielectric material

Structure of connection with

measurement circuit

IEC 319/08

Figure 3 – Fixture B

d

62024-1 © IEC:2008(E) – 9 –

The electrodes of the test fixture shall be in contact with the electrodes of the inductor under

test by mechanical force provided by an appropriate method. This force shall be chosen so as

to provide satisfactory measurement stability without influencing the characteristics of the

inductor. The electrode force shall be specified.

The structure between the measurement circuit and test fi

...

IEC 62024-1 ®

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

High frequency inductive components – Electrical characteristics and measuring

methods –

Part 1: Nanohenry range chip inductor

Composants inductifs à haute fréquence – Caractéristiques électriques et

méthodes de mesure –

Partie 1: Inductance pastille de l'ordre du nanohenry

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62024-1 ®

Edition 2.0 2008-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

High frequency inductive components – Electrical characteristics and measuring

methods –

Part 1: Nanohenry range chip inductor

Composants inductifs à haute fréquence – Caractéristiques électriques et

méthodes de mesure –

Partie 1: Inductance pastille de l'ordre du nanohenry

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX R

ICS 29.100.10 ISBN 978-2-83220-350-7

– 2 – 62024-1 IEC:2008

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Inductance, Q-factor and impedance . 6

3.1 Inductance . 6

3.1.1 Measuring circuit . 7

3.1.2 Mounting of the inductor to the test fixture . 7

3.1.3 Measurement method and calculation . 9

3.1.4 Notes on measurement . 9

3.2 Quality factor . 10

3.2.1 Measurement method . 10

3.2.2 Measurement circuit . 11

3.2.3 Mounting of the inductor . 11

3.2.4 Methods of measurement and calculation . 11

3.2.5 Notes on measurement . 11

3.3 Impedance . 11

3.3.1 Measurement method . 11

3.3.2 Measurement circuit . 11

3.3.3 Measurement method and calculation . 11

3.3.4 Notes on measurement . 12

4 Resonance frequency . 12

4.1 Self-resonance frequency . 12

4.2 Minimum output method . 12

4.2.1 Measurement circuit . 12

4.2.2 Mounting the inductor for test . 13

4.2.3 Measuring method . 13

4.2.4 Note on measurement . 14

4.3 Reflection method . 14

4.3.1 Measurement circuit . 14

4.3.2 Mounting the inductor for test . 14

4.3.3 Measurement method . 15

4.3.4 Notes on measurement . 15

4.4 Measurement by analyser. 16

4.4.1 Measurement by impedance analyser . 16

4.4.2 Measurement by network analyser . 16

5 DC resistance . 16

5.1 Measuring circuit (Bridge method) . 16

5.2 Measuring method and calculation formula . 17

5.3 Precaution for measurement . 17

5.4 Measuring temperature. 18

Annex A (normative) Mounting method for a surface mounting coil . 19

Figure 1 – Example of circuit for vector voltage/current method . 7

Figure 2 – Fixture A . 8

62024-1 IEC:2008 – 3 –

Figure 3 – Fixture B . 8

Figure 4 – Short device shape . 10

Figure 5 – Example of test circuit for the minimum output method . 12

Figure 6 – Self-resonance frequency test board (minimum output method) . 13

Figure 7 – Example of test circuit for the reflection method . 14

Figure 8 – Self-resonance frequency test board (reflection method) . 15

Figure 9 – Suitable test fixture for measuring self-resonance frequency . 16

Figure 10 – Example of measuring circuit of d.c. resistance . 17

Table 1 – Dimensions of l and d . 8

Table 2 – Short device dimensions and inductances . 10

– 4 – 62024-1 IEC:2008

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

HIGH FREQUENCY INDUCTIVE COMPONENTS –

ELECTRICAL CHARACTERISTICS AND MEASURING METHODS –

Part 1: Nanohenry range chip inductor

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)“). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62024-1 has been prepared by IEC technical committee 51:

Magnetic components and ferrite materials.

This second edition cancels and replaces the first edition published in 2002. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) sizes 0402 added in Table 1 and Table 2;

b) contents of 4.4 reviewed for easier understanding;

c) correct errors in 3.1.4.2.

This bilingual version (2012-09) corresponds to the monolingual English version, published in

2008-02.

62024-1 IEC:2008 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

51/908/FDIS 51/915/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

The French version of this standard has not been voted upon.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 62024 series, published under the general title High frequency

inductive components – Electrical characteristics and measuring methods, can be found on

the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of July 2008 have been included in this copy.

– 6 – 62024-1 IEC:2008

HIGH FREQUENCY INDUCTIVE COMPONENTS –

ELECTRICAL CHARACTERISTICS AND MEASURING METHODS –

Part 1: Nanohenry range chip inductor

1 Scope

This part of IEC 62024 specifies electrical characteristics and measuring methods for the

nanohenry range chip inductor that is normally used in high frequency (over 100 kHz) range.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 61249-2-7, Materials for printed boards and other interconnecting structures – Part 2-7:

Reinforced base materials clad and unclad – Epoxide woven E-glass laminated sheet of

defined flammability (vertical burning test) copper-clad

ISO 6353-3, Reagents for chemical analysis – Part 3: Specifications – Second series

ISO 9453, Soft solder alloys – Chemical compositions and forms

3 Inductance, Q-factor and impedance

3.1 Inductance

The inductance of an inductor is measured by the vector voltage/current method.

62024-1 IEC:2008 – 7 –

3.1.1 Measuring circuit

EV

L

x

R

R

g

L

s

C

d

EV

R

s

G

IEC 317/08

Components

R source resistance (50 Ω)

g

R resistor

L inductor under test

x

C distributed capacitance of inductor under test

d

L series inductance of inductor under test

s

R series resistance of inductor under test

s

phase reference signal

Ev , Ev vector voltmeter

1 2

G signal generator

Figure 1 – Example of circuit for vector voltage/current method

3.1.2 Mounting of the inductor to the test fixture

The inductor shall be measured in a test fixture as specified in the relevant standard. If no

fixture is specified, one of the following test fixtures A or B shall be used. The fixture used

shall be reported.

– 8 – 62024-1 IEC:2008

3.1.2.1 Fixture A

The shape and dimensions of fixture A shall be as shown in Figure 2.

Electrical Structure of connection

to the measurement circuit

length

l

External electrode

Central electrode

Dielectric material

Inductor under test

IEC 318/08

Figure 2 – Fixture A

Table 1 – Dimensions of l and d

l d

Size of inductor under test

mm mm

1608 1,6 0,95

1005 1,0 0,60

0603 0,6 0,36

0402 0,4 0,26

The electrodes of test fixture shall contact the electrodes of inductor under test by mechanical

force provided by an appropriate method. This force shall be chosen so as to provide

satisfactory measurement stability without influencing the characteristics of the inductor. The

electrode force shall be specified. The structure between the measurement circuit and test

fixture shall maintain a characteristic impedance as near as possible to 50 Ω.

3.1.2.2 Fixture B

The test fixture B as shown in Figure 3 shall be used.

External electrode

Inductor under test

Central electrode

d

Dielectric material

Structure of connection with

measurement circuit

IEC 319/08

Figure 3 – Fixture B

d

62024-1 IEC:2008 – 9 –

The electrodes of the test fixture shall be in contact with the electrodes of the inductor under

test by mechanical force provided by an appropriate method. This force shall be chosen so as

to provide satisfactory measurement stability without influencing the characteristics of the

inductor. The electrode force shall be specified.

The structure between the measurement circuit and test fixture shall maintain a characteristic

impedance as near as possible to 50 Ω.

Dimension d shall be specified between parties concerned.

3.1.3 Measurement method and calculation

of the inductor L is defined by the vector sum of reactance caused by L and

Inductance L

x

x s

C (see Figure 1). The frequency f of the signal generator output signal shall be set to a

d

frequency as separately specified. The inductor under test shall be connected to the

measurement circuit by using the test fixture as described above. Vector voltage E and E

1 2

shall be measured by vector voltage meters Ev and Ev , Respectively. The inductance L

1 2 x

shall be calculated by the following formula:

E

lm R

E

2

L = (1)

x

ω

where

L is the inductance of inductor under test;

x

lm is the imaginary part of the complex value;

R is the resistance of resistor;

E is the value indicated on vector voltmeter Ev ;

1 1

E is the value indicated on vector voltmeter Ev ;

2 2

ω is the angular frequency: 2πf.

3.1.4 Notes on measurement

The electrical length of the test fixture shall be compensated by an appropriate method

followed by open-short compensation. If an electrical length that is not commonly accepted is

used, it shall be specified. Open-short compensation shall be calculated by the following

formulae:

Z − B

m c

Z = A (2)

x c

1− Z C

m c

A = 1 + j0 (3)

c

Z −(1− Y Z )Z − Z Y Z

sm om sm ss sm os ss

B = (4)

c

−

1 Y Z Y Z

om sm os ss

Y −(1− Y Z )Y − Y Y Z

om om sm os om os ss

C = (5)

c

−

1 Y Z Y Z

om sm os ss

where

Z is impedance measurement value after compensation;

x

Z is impedance measurement value before compensation;

m

– 10 – 62024-1 IEC:2008

Z is the impedance measurement value of short device;

sm

Z is the short device inductance as defined in 3.1.4.1;

ss

Y is the admittance measurement value of the fixture with test device absent;

om

Y is the admittance measurement value of the test fixture as defined in 3.1.4.2.

os

3.1.4.1 Short compensation

For test fixture A, the applicable short device dimension and shape are as shown in Figure 4

and Table 2. The appropriate short device inductance shall be selected from Table 2

depending on the dimension of the inductor under test. The inductance of the selected short

device shall be used as a compensation value.

d

Gold-plated copper or

gold-plated equivalent metal

IEC 320/08

Figure 4 – Short device shape

Table 2 – Short device dimensions and inductances

l d Inductance value

Size of inductor under test

mm mm nH

1608 1,6 0,95 0,43

1005 1,0 0,60 0,27

0603 0,6 0,36 0,16

0402 0,4 0,26 0,11

If an inductance value other than defined in Table 2 is used for test fixture A, the employed

value shall be specified. For test fixture B, short device dimension, shape and inductance

values shall be specified.

3.1.4.2 Open compensation

Open compensation for test fixture A shall be performed with test fixture electrodes at the

same distance apart from each other as with the inductor under test mounted in the fixture.

The admittance Y is defined as 0S (zero Siemens) unless otherwise specified.

os

Open compensation for test fixture B shall be performed without mounting the inductor. The

admittance Y is defined as 0S (zero Siemens) unless otherwise specified.

os

3.2 Quality factor

3.2.1 Measurement method

The Q of the inductor shall be measured by the vector voltage/current method.

l

62024-1 IEC:2008 – 11 –

3.2.2 Measurement circuit

The measurement circuit is as shown in Figure 1.

3.2.3 Mounting of the inductor

Mounting of the inductor is described in 3.1.2.

3.2.4 Methods of measurement and calculation

The frequency of the signal generator (Figure 1) output signal shall be set to a frequency as

separately specified. The inductor shall be connected to the measurement circuit by using the

test fixture as described above. Vector voltage E and E shall be measured by vector voltage

1 2

meters Ev and Ev respectively. The Q value shall be calculated by the following formula:

1 2

Im[E / E ]

1 2

Q= (6)

Re[E / E ]

1 2

where

Q is the Q of the inductor under test;

Re is the real part of the complex value;

lm is the imaginary part of the complex value;

E is the value indicated on vector voltmeter Ev ;

1 1

E is the value indicated on vector voltmeter Ev .

2 2

3.2.5 Notes on measurement

Refer to 3.1.4 in the inductance measurement part.

3.3 Impedance

3.3.1 Measurement method

The impedance of an inductor shall be measured by the vector voltage/current method. The

vector voltage/current method is as follows:

3.3.2 Measurement circuit

The measurement circuit is as shown in Figure 1. Mounting of the inductor to the test fixture

as described in 3.1.2.

3.3.3 Measurement method and calculation

The frequency of the signal generator (Figure 1) output signal shall be set to a frequency f as

separately specified. The inductor shall be connected to the measurement circuit by using the

and E shall be measured by vector voltage

test fixture as described above. Vector voltage E

1 2

meters Ev and Ev , respectively.

1 2

The impedance shall be calculated by the following formula:

E

Z = R (7)

E

where

Z is the absolute value of the impedance;

– 12 – 62024-1 IEC:2008

R is the resistance;

E is the absolute value of Ev ;

1 1

E is the absolute value of Ev .

2 2

3.3.4 Notes on measurement

Refer to 3.1.4 in the inductance measurement part.

4 Resonance frequency

4.1 Self-resonance frequency

The self-resonance frequency of the inductor shall be measured by the minimum output

method 4.2 or by the reflection method 4.3 or by the impedance analyser 4.4.

4.2 Minimum output method

The minimum output method is as follows:

4.2.1 Measurement circuit

The measurement circuit is as shown in Figure 5 below.

L

L

x

R

g

C

d

R

L V

E G L L E

1 2

1 2

Earth

Test board

IEC 321/08

Components

G signal generator

R source resistance of signal generator (50 Ω)

g

L inductance under test

x

Cd distributed capacitance of inductor under test

L inductance of inductor under test

L , L 50 Ω micro-strip line

1 2

V RF voltmeter

R input resistance of RF voltmeter (50 Ω)

L

NOTE A suitably calibrated network analyser may be used for the minimum output method in place of the signal

generator and RF voltmeter.

Figure 5 – Example of test circuit for the minimum output method

62024-1 IEC:2008 – 13 –

4.2.2 Mounting the inductor for test

The inductor shall be mounted on the self-resonance frequency test board prescribed in the

individual standard for the particular inductor by the method prescribed in Annex A. If there is

no individual standard, the self-resonance frequency test board shall be as shown in Figure 6.

Dimensions in millimetres

50 Ω micro-strip line

l

l

19,3

Earth plane covering whole bottom area

IEC 322/08

Key

Board material 96 % alumina ceramic board (ε ≅ 9,4)

Conductive material paste-printed or plated Cu, Ag-Pd to a total thickness of (15 to 30) µm

W 0,62 mm (reference value)

Solder joint field dimensions: hatched area

W same width as 50 Ω micro-strip line

l 1/2 length of the inductor under test

l length of the inductor under test + 0,4 mm

Figure 6 – Self-resonance frequency test board (minimum output method)

4.2.3 Measuring method

Using a circuit of the kind shown in Figure 5, keeping E fixed, the oscillating frequency of the

signal generator should be gradually increased until resonance is obtained as indicated by E

assuming its minimum value, which is then taken as the self-resonant value.

However, if the range of frequencies where E is minimal, is wide, and the frequency of the

minimal value is not easily determined, the two frequencies f and f at which E is greater

1 2 2

than the minimum by A [dB] (A ≤ 3) shall be measured, and the self-resonance frequency

shall be obtained using the following formula:

f + f

1 2

Self-resonance frequency = (8)

W

5,0

t = 0,635

– 14 – 62024-1 IEC:2008

4.2.4 Note on measurement

The width W of the micro-strip line shall be such that the characteristic impedance is as close

value of the micro-strip line selected shall also allow easy

as possible to 50 Ω. The E

identification of the minimum value of E .

4.3 Reflection method

The reflection method is as follows:

4.3.1 Measurement circuit

The measurement circuit is as shown in Figure 7. The network analyser circuit used for

measurement shall be configured as shown in Figure 7, or have equivalent circuit functions. In

single port (S ) reflection measurement mode, phase measurement shall be possible and the

analyser shall be suitably calibrated.

Phase adj.

C L

d

x

Phase

comp.

L

L

Power splitter

Directional

coupler

Earth

RF network analyser

Test board

IEC 323/08

Components

G signal generator

L inductor under test

x

C distributed capacitance of inductor under test

d

L inductance of inductor under test

L 50 Ω micro-strip line

Figure 7 – Example of test circuit for the reflection method

4.3.2 Mounting the inductor for test

The inductor shall be mounted on the self-resonance frequency test board prescribed in the

individual standard for the particular inductor by the method prescribed in Annex A. If there is

no individual standard, the self-resonance frequency test board shall be as in Figure 8.

62024-1 IEC:2008 – 15 –

Dimensions in millimetres

50 Ω micro-strip line

l

l

19,3

Earth plane covering whole bottom area

IEC 324/08

Key

Board material: 96 % alumina ceramic board (ε ≅ 9,4)

Conductive material: paste-printed or plated Cu, Ag-Pd to a total thickness of (15 to 30) µm

W 0,62 mm (reference value)

Solder joint field dimensions: hatched area

W same width as 50 Ω micro-strip line

l 1/2 length of the inductor under test

l length of the inductor under test + 0,4 mm

Figure 8 – Self-resonance frequency test board (reflection method)

4.3.3 Measurement method

The test board (on which the inductor has not yet been mounted) shall be connected to a

suitably calibrated network analyser, and the phase adjuster shall be adjusted so that within

the range of oscillating frequencies of the scanning signal generator, the output of the phase

comparator shows the minimum phase difference (absolute value) between the incident and

reflected waves.

The inductor for test shall then be mounted on the test board, and the oscillating frequency of

the scanning signal generator shall gradually be swept from the low end to the high end.

The oscillating frequency of the scanning signal generator when the output of the phase

comparator shows the minimum phase difference (absolute value) between the incident and

reflected waves shall be taken as the self-resonance frequency.

4.3.4 Notes on measurement

The width W of the micro-strip line shall be such that the characteristics impedance is as

close as possible to 50 Ω. The output of the scanning signal generator shall be set within a

range that ensures stable operation of the phase comparator.

W

5,0

t = 0,635

– 16 – 62024-1 IEC:2008

4.4 Measurement by analyser

4.4.1 Measurement by impedance analyser

Self-resonance frequency can be measured by measuring the impedance of the inductor

using the impedance analyser. When measuring self-resonance frequency, after

compensating for the unwanted capacitance (refer to 3.1.4.2), the inductor for test shall be

connected to the test fixture.

The exact value of the self-resonance frequency shall be the frequency where the first

imaginary part value of impedance equals 0, when sweeping the frequency of the impedance

analyser from the lower value to the higher value.

The test fixture for the measurement of the self-resonance frequency shall be the same as

that of the inductance.

4.4.2 Measurement by network analyser

The self-resonance frequency of the inductor can be measured by the power attenuation

method using the network analyser. During the measurement of the self-resonance frequency,

care shall be taken to avoid the influence of electromagnetic interference from other

electronic equipments. The sweeping frequency range of the network analyser shall include

the self-resonance frequency of the inductor.

The self-resonance frequency of the inductor shall be the frequency where the power

attenuation becomes a maximum. It shall be confirmed that the measured self-resonance

frequency is not the resonance of the test fixture.

An example of a test fixture for measurement of self-resonance frequency by the power

attenuation method is shown in Figure 9.

Placement force

Micro-strip line

Receptacles to be adjusted

to measuring equipment

Inductor

under test

l

Earth plane covering

whole bottom area

Glass epoxy:

FR4 (ε = 4,3 to 4,5)

2,25 mm

l: 1/2 length of the inductor under test IEC 325/08

Figure 9 – Suitable test fixture for measuring self-resonance frequency

5 DC resistance

5.1 Measuring circuit (Bridge method)

An example of measuring circuit for DC resistance is shown in Figure 10.

1,6 mm

62024-1 IEC:2008 – 17 –

5.2 Measuring method and calculation formula

Use the circuit as shown in Figure 10, balance the bridge by adjusting the proportional arm

resistors R and R and standard variable resister R and calculate DC resistance R of the

1 2 3 x

coil from the following formula:

R

R = × R (9)

x 3

R

R

R

E D

R

L

x

IEC 326/08

Components

R , R resistance of proportional arm resistors R , R

1 2 1 2

R resistance of standard variable resistor R

3 3

L inductor under test

x

E DC power supply

D detector

Figure 10 – Example of measuring circuit of d.c. resistance

5.3 Precaution for measurement

The precautions for measurements are as follows:

– measurement of resistance shall be made by using a direct voltage of a small magnitude

for as short a time as practicable, in order that the temperature of the resistance element

will not rise appreciably during measurement;

– measuring voltage: ≤ 0,5 V;

– measurement uncertainty ± 0,5 % of measured value or ± 0,001 Ω, whichever is greater;

– take care so that the temperature of the specimen coincides with the ambient temperature;

– keep the current passed through the specimen within a range so that the resistance of coil

will not change so much;

– use of double bridge is desirable for measuring especially low resistance.

– 18 – 62024-1 IEC:2008

5.4 Measuring temperature

The d.c. resistance shall meet the specified limits at a temperature of (20 ± 1)°C. When the

test is made at a temperature T other than 20 °C, the result shall be corrected to 20 °C by

e

means of the formula:

R

Te

R = ;T in °C (10)

20 e

0,92+ 0,004T

e

62024-1 IEC:2008 – 19 –

Annex A

(normative)

Mounting method

for a surface mounting coil

This annex specifies the method for mounting a surface mounting coil to be tested

(hereinafter referred to as “specimen”) to the testing printed-circuit board.

A.1 Mounting printed-circuit board and mounting land

A mounting printed-circuit board suitable to the construction of the specimen shall be used,

and it shall be specified in the detail specification. If there is no provision in the detail

+0,010

specification, the board [thickness (1,6 ± 0,19) mm, copper foil 0,035 mm mm] of

−0,005

epoxide woven glass fabric copper-clad laminate sheet specified in IEC 61249-2-7 shall be

used. It shall be a printed-circuit board on which the land for mounting the specimen is

previously located. The configuration of the land is indicated by the detail specification.

A.2 Solder

The solder shall be a solder paste prepared in such a way that a weakly active flux of

colophonium system is added to the solder of composition H60A or H63A specified in

ISO 9453 having a grain size 200 mesh or more to form a creamy paste. The viscosity is

subjected to agreement between the parties concerned with acceptance.

A.3 Preparation

The solder paste shall be coated on the lands of the testing printed-circuit board specified in

the detail specification to a thickness of (200 ± 50) µm and the specimen shall be placed so

that its terminations or electrodes are positioned on the pasted lands.

A.4 Pre-heating

The printed-circuit board on which the specimen is placed shall be heated at (150 ± 10) °C for

(60 to 120) s.

A.5 Soldering

After the pre-heating, the soldering shall be carried out immediately by using the reflow

soldering device. The soldering temperature shall be (235 ± 5) °C, and the time shall be within

10 s.

A.6 Cleaning

After the soldering, the printed-circuit board shall be cleaned by using the 2-propanol

specified in ISO 6353-3 to remove the flux. If necessary, the precaution for the cleaning

method shall be specified in the detail specification.

___________

– 20 – 62024-1 CEI:2008

SOMMAIRE

AVANT-PROPOS . 22

1 Domaine d’application . 24

2 Références normatives . 24

3 Inductance, facteur Q et impédance . 24

3.1 Inductance . 24

3.1.1 Circuit de mesure . 25

3.1.2 Montage de la bobine au support d'essai . 25

3.1.3 Méthode de mesure et calcul . 27

3.1.4 Notes sur la mesure . 27

3.2 Facteur de qualité . 29

3.2.1 Méthode de mesure . 29

3.2.2 Circuit de mesure . 29

3.2.3 Montage de la bobine . 29

3.2.4 Méthodes de mesure et calcul . 29

3.2.5 Notes sur la mesure . 29

3.3 Impédance . 29

3.3.1 Méthode de mesure . 29

3.3.2 Circuit de mesure . 29

3.3.3 Méthode de mesure et calcul . 29

3.3.4 Notes sur la mesure . 30

4 Fréquence de résonance . 30

4.1 Fréquence de résonance propre . 30

4.2 Méthode de la sortie minimale . 30

4.2.1 Circuit de mesure . 31

4.2.2 Montage de la bobine pour essai . 31

4.2.3 Méthode de mesure . 32

4.2.4 Note sur la mesure . 32

4.3 Méthode de réflexion . 33

4.3.1 Circuit de mesure . 33

4.3.2 Montage de la bobine pour essai . 33

4.3.3 Méthode de mesure . 34

4.3.4 Notes sur la mesure . 34

4.4 Mesure par un analyseur . 35

4.4.1 Mesure par l'analyseur d'impédance . 35

4.4.2 Mesure par un analyseur de réseau . 35

5 Résistance en courant continu . 35

5.1 Circuit de mesure (méthode du pont) . 35

5.2 Méthode de mesure et formule de calcul . 36

5.3 Précautions de mesure . 36

5.4 Température de mesure . 37

Annexe A (normative) Méthode de montage d’une bobine de montage en surface . 38

62024-1 CEI:2008 – 21 –

Figure 1 – Exemple de circuit pour la méthode tension/courant vectorielle . 25

Figure 2 – Support A . 26

Figure 3 – Support B . 26

Figure 4 – Forme du dispositif de court-circuit . 28

Figure 5 – Exemple de circuit d'essai pour la méthode de sortie minimale . 31

Figure 6 – Table d'essai de fréquence de résonance propre (méthode de sortie

minimale) . 32

Figure 7 – Exemple de circuit d'e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...