IEC 60812:2006

(Main)Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA)

Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA)

This International Standard describes Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects and Criticality Analysis (FMECA), and gives guidance as to how they may be applied to achieve various objectives by: providing the procedural steps necessary to perform analysis; identifying appropriate terms; defining basic principles; providing examples of the necessary worksheets or other tabular forms.

Techniques d'analyse de la fiabilité du système - Procédure d'analyse des modes de défaillance et de leurs effets (AMDE)

La présente Norme Internationale décrit l'analyse des modes de défaillance et de leurs effets (AMDE) et l'analyse des modes de défaillance, de leurs effets et de leur criticité (AMDEC), et apporte des conseils sur l'application de ces méthodes selon les divers objectifs recherchés, de la façon suivante: en fournissant la procédure à suivre pour réaliser une analyse, en spécifiant les termes pertinents, les hypothèses, les mesures de criticité, les modes de défaillance, en déterminant les principes de base, en fournissant des exemples-types de documents et tableaux.

General Information

- Status

- Published

- Publication Date

- 24-Jan-2006

- Technical Committee

- TC 56 - Dependability

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 10-Aug-2018

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60812:2006 - Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA) describes how to perform Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects and Criticality Analysis (FMECA). The standard gives procedural steps, defines terms and basic principles, and provides examples of worksheets and tabular forms. It emphasizes early, iterative application during design or process development to identify potential failure modes, their causes and effects, and to support cost‑effective mitigation and risk reduction.

Key topics and requirements

- FMEA / FMECA procedure: step‑by‑step analysis workflow from system decomposition to reporting, including guidance for preparing and updating analyses as designs evolve.

- System decomposition: hierarchical representation (hardware, software, processes) using block diagrams to determine analysis levels.

- Terms and definitions: consistent definitions for item, failure, fault, failure mode, failure effect, severity, occurrence and criticality.

- Severity, occurrence and detection: qualitative and (where applicable) quantitative considerations for assessing failure mode impact and likelihood; criticality combines severity with frequency or probability attributes.

- Worksheets and examples: illustrative FMEA/FMECA worksheet formats and example analyses (annexes include sample worksheets, RPN examples and criticality matrices).

- Special considerations: treatment of common‑cause failures, human factors, software errors and consequences of system failure.

- Outputs and reporting: guidance on documenting results, recommended corrective actions and tracking design changes.

- Method relationships: guidance on how FMEA/FMECA relates to other dependability methods (e.g., Fault Tree Analysis and Reliability Block Diagrams).

Practical applications and users

IEC 60812 is used to support reliability, safety and quality engineering across industries:

- Who uses it: design and reliability engineers, system architects, safety engineers, process engineers, quality teams, maintainers and regulatory bodies.

- Typical applications: product development and design reviews, process FMEA for manufacturing, safety analysis for automotive/electronics/aerospace, maintenance planning, and supplier or component qualification.

- Benefits: early identification of design weaknesses, prioritization of mitigation actions, improved documentation for audits and regulatory compliance, and inputs to risk management and maintenance strategies.

Related standards

- IEC 60300-3-1 - Dependability management: application guide for analysis techniques

- IEC 61025 - Fault tree analysis (FTA)

- IEC 61078 - Reliability block diagram method

Keywords: IEC 60812, FMEA, FMECA, failure modes and effects analysis, reliability, criticality, risk assessment, FMEA worksheet, failure severity.

IEC 60812:2006 - Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA) Released:1/25/2006

IEC 60812:2006 - Techniques d'analyse de la fiabilité du système - Procédure d'analyse des modes de défaillance et de leurs effets (AMDE) Released:1/25/2006

IEC 60812:2006 - Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA) Released:1/25/2006 Isbn:283188425X

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

IEC 60812:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Analysis techniques for system reliability - Procedure for failure mode and effects analysis (FMEA)". This standard covers: This International Standard describes Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects and Criticality Analysis (FMECA), and gives guidance as to how they may be applied to achieve various objectives by: providing the procedural steps necessary to perform analysis; identifying appropriate terms; defining basic principles; providing examples of the necessary worksheets or other tabular forms.

This International Standard describes Failure Mode and Effects Analysis (FMEA) and Failure Mode, Effects and Criticality Analysis (FMECA), and gives guidance as to how they may be applied to achieve various objectives by: providing the procedural steps necessary to perform analysis; identifying appropriate terms; defining basic principles; providing examples of the necessary worksheets or other tabular forms.

IEC 60812:2006 is classified under the following ICS (International Classification for Standards) categories: 03.120.01 - Quality in general; 03.120.30 - Application of statistical methods; 21.020 - Characteristics and design of machines, apparatus, equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60812:2006 has the following relationships with other standards: It is inter standard links to IEC 60812:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60812:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60812

Second edition

2006-01

Analysis techniques for system reliability –

Procedure for failure mode

and effects analysis (FMEA)

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60812

Second edition

2006-01

Analysis techniques for system reliability –

Procedure for failure mode

and effects analysis (FMEA)

© IEC 2006 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

X

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

For price, see current catalogue

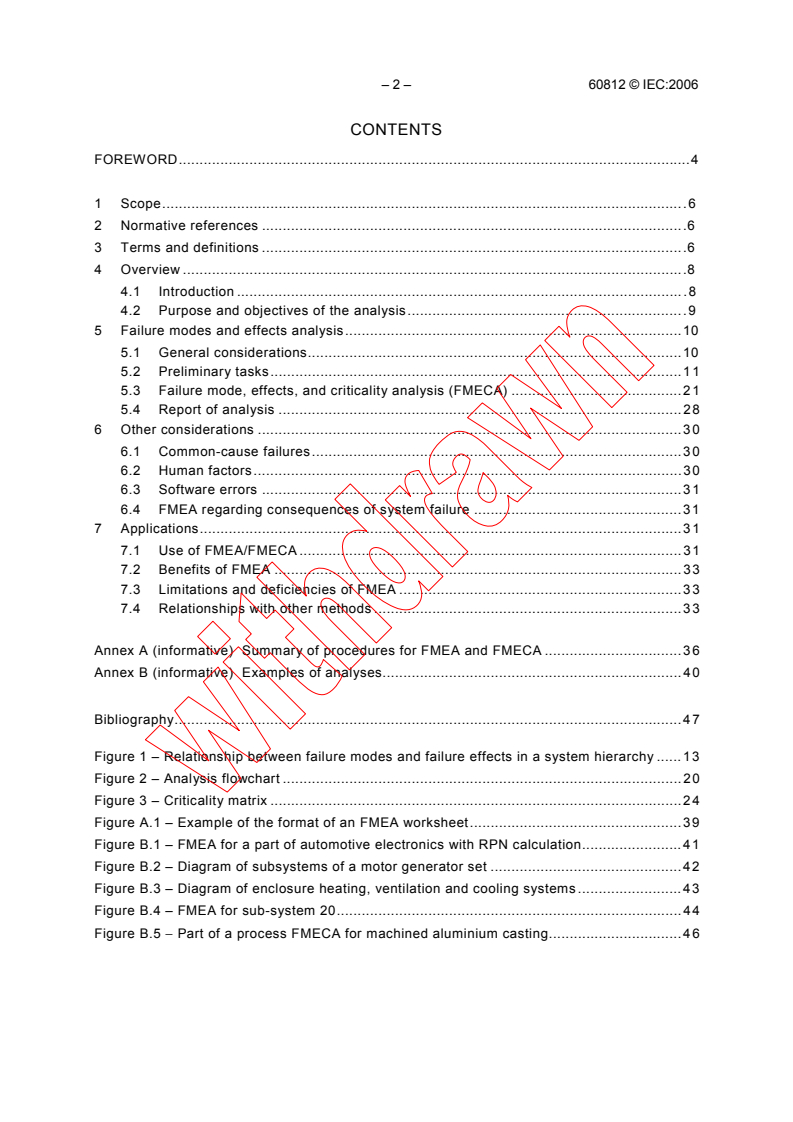

60812 IEC:2006 – 3 –

CONTENTS

FOREWORD.7

1 Scope.11

2 Normative references .11

3 Terms and definitions .11

4 Overview .15

4.1 Introduction .15

4.2 Purpose and objectives of the analysis.17

5 Failure modes and effects analysis.19

5.1 General considerations.19

5.2 Preliminary tasks.21

5.3 Failure mode, effects, and criticality analysis (FMECA) .41

5.4 Report of analysis .55

6 Other considerations .59

6.1 Common-cause failures.59

6.2 Human factors.59

6.3 Software errors .61

6.4 FMEA regarding consequences of system failure .61

7 Applications.61

7.1 Use of FMEA/FMECA .61

7.2 Benefits of FMEA .65

7.3 Limitations and deficiencies of FMEA .65

7.4 Relationships with other methods .67

Annex A (informative) Summary of procedures for FMEA and FMECA .71

Annex B (informative) Examples of analyses.79

Bibliography.93

Figure 1 – Relationship between failure modes and failure effects in a system hierarchy .25

Figure 2 – Analysis flowchart .39

Figure 3 – Criticality matrix .47

Figure A.1 – Example of the format of an FMEA worksheet.77

Figure B.1 – FMEA for a part of automotive electronics with RPN calculation.81

Figure B.2 – Diagram of subsystems of a motor generator set .83

Figure B.3 – Diagram of enclosure heating, ventilation and cooling systems .85

Figure B.4 – FMEA for sub-system 20.87

Figure B.5 − Part of a process FMECA for machined aluminium casting.91

60812 IEC:2006 – 5 –

Table 1 – Example of a set of general failure modes.29

Table 2 – Illustrative example of a severity classification for end effects .35

Table 3 – Risk/criticality matrix .49

Table 4 – Failure mode severity.51

Table 5 – Failure mode occurrence related to frequency and probability of occurrence .51

Table 6 – Failure mode detection evaluation criteria .53

Table 7 – Example of a set of failure effects (for a motor vehicle starter) .57

Table 8 – Example of a failure effects probability .57

Table B.1 – Definition and classification of the severity of the effects of failures on the

complete M-G system .83

60812 IEC:2006 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ANALYSIS TECHNIQUES FOR SYSTEM RELIABILITY –

PROCEDURE FOR FAILURE MODE

AND EFFECTS ANALYSIS (FMEA)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60812 has been prepared by IEC technical committee 56:

Dependability.

This second edition cancels and replaces the first edition published in 1985 and constitutes a

technical revision.

The main changes from the previous edition are as follows:

– introduction of the failure modes effects and criticality concepts;

– inclusion of the methods used widely in the automotive industry;

– added references and relationships to other failure modes analysis methods;

– added examples;

– provided guidance of advantages and disadvantages of different FMEA methods.

60812 IEC:2006 – 9 –

The text of this standard is based on the following documents:

FDIS Report on voting

56/1072/FDIS 56/1091/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60812 IEC:2006 – 11 –

ANALYSIS TECHNIQUES FOR SYSTEM RELIABILITY –

PROCEDURE FOR FAILURE MODE

AND EFFECTS ANALYSIS (FMEA)

1 Scope

This International Standard describes Failure Mode and Effects Analysis (FMEA) and Failure

Mode, Effects and Criticality Analysis (FMECA), and gives guidance as to how they may be

applied to achieve various objectives by

− providing the procedural steps necessary to perform an analysis;

− identifying appropriate terms, assumptions, criticality measures, failure modes;

− defining basic principles;

− providing examples of the necessary worksheets or other tabular forms.

All the general qualitative considerations presented for FMEA will apply to FMECA, since the

latter is an extension of the other.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60300-3-1:2003, Dependability management – Part 3-1: Application guide – Analysis

techniques for dependability – Guide on methodology

IEC 61025, Fault tree analysis (FTA)

IEC 61078, Analysis techniques for dependability – Reliability block diagram method

3 Terms and definitions

For the purposes of this document, the following definitions apply.

3.1

item

any part, component, device, subsystem, functional unit, equipment or system that can be

individually considered

NOTE 1 An item may consist of hardware, software or both, and may also in particular cases include people.

NOTE 2 A number of items, e.g. a population of items or a sample, may itself be considered as an item.

[IEV 191-01-01]

60812 IEC:2006 – 13 –

A process can also be defined as an item which carries out a predetermined function and for

which a process FMEA or FMECA is carried out. Normally, a hardware FMEA does not

address people and their interactions with hardware/software, while a process FMEA normally

includes actions of people.

3.2

failure

termination of the ability of an item to perform a required function

[IEV 191-04-01]

3.3

fault

state of an item characterized by the inability to perform a required function, excluding the

inability during preventive maintenance or other planned actions, or due to lack of external

resources

NOTE 1 A fault is often the result of a failure of the item itself, but may exist without prior failure.

[IEV 191-05-01]

NOTE 2 In this document “fault” is used interchangeably with the term “failure” for historical reasons.

3.4

failure effect

consequence of a failure mode in terms of the operation, function or status of the item

3.5

failure mode

manner in which an item fails

3.6

failure criticality

combination of the severity of an effect and the frequency of its occurrence or other attributes

of a failure as a measure of the need for addressing and mitigation

3.7

system

set of interrelated or interacting elements

NOTE 1 In the context of dependability, a system will have

a) defined purposes expressed in terms of required functions;

b) stated conditions of operation use (see 191-01-12);

c) a defined boundary.

NOTE 2 The structure of a system is hierarchical.

[ISO 9000:2000]

3.8

failure severity

significance or grading of the failure mode’s effect on item operation, on the item surrounding,

or on the item operator; failure mode effect severity as related to the defined boundaries of

the analysed system

60812 IEC:2006 – 15 –

4 Overview

4.1 Introduction

Failure Modes and Effect Analysis (FMEA) is a systematic procedure for the analysis of a

system to identify the potential failure modes, their causes and effects on system performance

(performance of the immediate assembly and the entire system or a process). Here, the term

system is used as a representation of hardware, software (with their interaction) or a process.

The analysis is successfully performed preferably early in the development cycle so that

removal or mitigation of the failure mode is most cost effective. This analysis can be initiated

as soon as the system is defined enough to be presented as a functional block diagram where

performance of its elements can be defined.

FMEA timing is essential; if done early enough in the development cycle, then incorporating

the design changes to overcome deficiencies identified by the FMEA may be cost effective. It

is therefore important that the FMEA task and its deliverables be incorporated into the

development plan and schedule. Thus, FMEA is an iterative process that takes place

coincidentally with design process.

FMEA is applicable at various levels of system decomposition from the highest level of block

diagram down to the functions of discrete components or software commands. The FMEA is

also an iterative process that is updated as the design develops. Design changes will require

that relevant parts of the FMEA be reviewed and updated.

A thorough FMEA is a result of a team composed of individuals qualified to recognize and

assess the magnitude and consequences of various types of potential inadequacies in the

product design that might lead to failures. Advantage of the team work is that it stimulates

thought process, and ensures necessary expertise.

FMEA is considered to be a method to identify the severity of potential failure modes and to

provide an input to mitigating measures to reduce risk. In some applications however, FMEA

also includes an estimation of the probability of occurrence of the failure modes. This

enhances the analysis by providing a measure of the failure mode’s likelihood.

Application of FMEA is preceded by a hierarchical decomposition of the system (hardware

with software, or a process) into its more basic elements. It is useful to employ simple block

diagrams to illustrate this decomposition (IEC 61078). The analysis then starts with lowest

level elements. A failure mode effect at a lower level may then become a failure cause of a

failure mode of an item in the next higher level. The analysis proceeds in a bottom-up fashion

until the end effect on the system is identified. Figure 1 illustrates this relationship.

FMECA (Failure Modes, Effects and Criticality Analysis) is an extension to the FMEA to

include a means of ranking the severity of the failure modes to allow prioritization of

countermeasures. This is done by combining the severity measure and frequency of occur-

rence to produce a metric called criticality.

The principles of an FMEA may be applied outside of engineering design. FMEA procedure

can be applied to a manufacturing or any other work process such as in hospitals, medical

laboratories, school systems, or others. When FMEA is applied to a manufacturing process,

60812 IEC:2006 – 17 –

this procedure is known in industry as the Process FMEA, or PFMEA. For an FMEA to be

effective, adequate resources for a team work have to be committed. A thorough

understanding of the system under analysis may not be essential for a preliminary FMEA.

With development of design, a detailed failure mode analysis requires thorough knowledge of

the design performance and its specifications. Complex engineering designs usually require

the involvement of multiple areas of design expertise (e.g. mechanical engineering, electrical

engineering, systems engineering, software engineering, maintenance support, etc).

FMEA generally deals with individual failure modes and the effect of these failure modes on

the system. Each failure mode is treated as independent. The procedure is therefore

unsuitable for consideration of dependent failures or failures resulting from a sequence of

events. To analyse these situations other methods and techniques, such as Markov analysis

(see IEC 61165) or fault tree analysis (see IEC 61025), may be required.

In determining the impact of a failure, one must consider higher level induced – resultant

failures and possibly the same level of induced failures. The analysis should indicate,

wherever possible the combination of failure modes or their sequence that was a cause of a

higher level effect. In that case additional modelling is required to estimate the magnitude or

probability of occurrence of such an effect.

FMEA is a flexible tool that can be tailored to meet specific industry or product needs.

Specialized worksheets requiring specific entries may be adapted for certain applications. If

severity levels of failure modes are defined, they may be defined differently for different

systems or different system levels.

4.2 Purpose and objectives of the analysis

The reasons for undertaking Failure Mode Effects Analysis (FMEA) or Failure Mode Effects

and Criticality Analysis (FMECA) may include the following:

a) to identify those failures which have unwanted effects on system operation, e.g. preclude

or significantly degrade operation or affect the safety of the user;

b) to satisfy contractual requirements of a customer, as applicable;

c) to allow improvements of the system’s reliability or safety (e.g. by design modifications or

quality assurance actions);

d) to allow improvement of the system’s maintainability (by highlighting areas of risk or

nonconformity for maintainability).

In view of the above reasons for undertaking a FMEA effort, the objectives of an FMEA (or

FMECA) may include the following:

a) a comprehensive identification and evaluation of all the unwanted effects within the

defined boundaries of the system being analysed, and the sequences of events brought

about by each identified item failure mode, from whatever cause, at various levels of the

system’s functional hierarchy;

b) the determination of the criticality or priority for addressing/mitigation (see Clause 6) of

each failure mode with respect to the system’s correct function or performance and the

impact on the process concerned;

60812 IEC:2006 – 19 –

c) a classification of identified failure modes according to relevant characteristics, including

their ease of detection, capability to be diagnosed, testability, compensating and operating

provisions (repair, maintenance, logistics, etc.);

d) identification of system functional failures and estimation of measures of the severity and

probability of failure;

e) development of design improvement plan for mitigation of failure modes;

f) support the development of an effective maintenance plan to mitigate or reduce likelihood

of failure (see IEC 60300-3-11).

NOTE When criticality or probability of occurrence is addressed, the comments regard FMECA methodology.

5 Failure modes and effects analysis

5.1 General considerations

Traditionally there have been wide variations in the manner in which FMEA is conducted and

presented. The analysis is usually done by identifying the failure modes, their respective

causes and immediate and final effects. The analytical results can be presented on a

worksheet that contains a core of essential information for entire system and details

developed for that specific system. It shows the ways the system could potentially fail, the

components and their failure modes that would be the cause of system failure, and the

cause(s) of occurrence of each individual failure mode.

The FMEA effort applied to the complex products might be very extensive. This effort may be

sometimes reduced by having in mind that design of some subassemblies or their parts may

not be entirely new and by identifying parts of the product design that are a repetition or a

modification of a previous product design. The newly constructed FMEA should use

information on those existing subassemblies to the highest possible extent. It must also point

to the need for eventual test or full analysis of the new features and items. Once a detailed

FMEA is created for one design, it can be updated and improved for the succeeding

generations of that design, which constitutes a significantly less effort than the entirely new

analysis.

When using an existing FMEA from a previous product version, it is essential to make sure

that the repeated design is indeed used in the same manner and under the same stresses as

the previous design. The new operational or environmental stresses may require review of the

previously completed FMEA. Different environmental and operational stresses may require an

entirely new FMEA to be created in view of the new operational conditions.

The FMEA procedure consists of the following four main stages:

a) establishment of the basic ground rules for the FMEA and planning and scheduling to

ensure that the time and expertise is available to do the analysis;

b) executing the FMEA using the appropriate worksheet or other means such as a logic

diagrams or fault trees;

c) summarizing and reporting of the analysis to include any conclusions and

recommendations made;

d) updating the FMEA as the development activity progresses.

60812 IEC:2006 – 21 –

5.2 Preliminary tasks

5.2.1 Planning for the analysis

FMEA activities, follow up activities, procedures, relationship with other reliability activities,

processes for management of corrective actions and for their closure, and milestones, should

be integrated into the overall program plan.

The reliability program plan should describe the FMEA analysis method to be used. This

description may be a summary description or a reference to a source document containing the

method description.

This plan should contain the following points.

− clear definition of the specific purposes of the analysis and expected results;

− the scope of the present analysis in terms of how the FMEA should focus on certain

design elements. The scope should reflect the design maturity, elements of the design

that may be considered to be a risk because they perform a critical function or because of

immaturity of the technology used;

− description of how the present analysis supports the overall project dependability;

− identified measures used for control of the FMEA revisions and the relevant

documentation. Revision control of the analysis documents and worksheets and archive

methods should be specified;

− participation of design experts in the analysis so that they are available when needed;

− key project schedule milestones clearly marked to ensure the analysis is executed in a

timely manner;

− manner of closure of all actions identified in the process of mitigation of identified failure

modes that need to be addressed.

The plan should reflect the consensus of all participants and should be approved by project

management. Final review of the completed FMEA in the final stage of the design of a product

or its manufacturing process (process FMEA) identifies all of the recorded actions for

mitigation of failure modes of concern and the manner of their closure.

5.2.2 System structure

5.2.2.1 Information on system structure

The following items need to be included into the information on system structure:

a) different system elements with their characteristics, performances, roles and functions;

b) logical connections between elements;

c) redundancy level and nature of the redundancies;

d) position and importance of the system within the whole facility (if possible);

e) inputs and outputs of the system;

f) changes in system structure for varying operational modes.

Information pertaining to functions, characteristics and performances are required for all

system levels considered up to the highest level so that FMEA could properly address failure

modes that preclude any of those functions.

60812 IEC:2006 – 23 –

5.2.2.2 Defining system boundary for the analysis

The system boundary forms the physical and functional interface between the system and its

environment, including other systems with which the analysed system interacts. The definition

of the system boundary for the analysis should correspond to the boundary as defined for

design and maintenance. This should apply to a system at any level. Systems and/or

components outside the boundaries should explicitly be defined for exclusion.

The definition of the system boundary is more likely to be influenced by design, intended use,

source of supply, or commercial criteria rather than the optimum requirements of the FMEA.

However, where it is possible to define the boundaries to facilitate the system FMEA and its

integration with other related studies in the programme, such action is preferable. This is

especially so if the system is functionally complex with multiple interconnections between

items within the boundary and multiple outputs crossing the boundary. In such cases it could

be advantageous to define a study boundary from functional rather than hardware and

software point of view to limit the number of input and output links to other systems. This

would tend to reduce the number of system failure effects.

Care should be taken to ensure that other systems or components outside the boundaries of

the subject system are not forgotten, by explicitly stating that they are excluded from the

particular study.

5.2.2.3 Levels of analysis

It is important to determine the indenture level in the system that will be used for the analysis.

For example, systems can be broken down by function or into subsystems, replaceable units,

or individual components (see Figure 1). Ground rules for selecting the system indenture

levels for analysis depend on the results desired and the availability of design information.

The following guidelines are useful.

a) The highest level within the system is selected from the design concept and specified

output requirements.

b) The lowest level within the system at which the analysis is effective is that level for which

information is available to establish definition and description of functions. The selection

of the appropriate system level is influenced by previous experience. Less detailed

analysis may be justified for a system based on a mature design, with a good reliability,

maintainability and safety record. Conversely, greater details and a correspondingly lower

system level are indicated for any newly designed system or a system with unknown

reliability history.

c) The specified or intended maintenance and repair level may be a valuable guide in

determining lower system levels.

60812 IEC:2006 – 25 –

Subsystem

Subsystem Subsystem Subsystem

1 4 5

Subsystem

System failure cause

System

Failure modes

Effect: subsystem 4 failure

Module Module Module Module

1 2 3 4

Subsystem 4 failure cause

Subsystem 4

Failure modes

Effect: module 3 failure

Module 3

Part

Part Part Part

1 2 5

Part

Module 3 failure cause

Failure modes

Effect: part 2 failure

Mode Mode Mode

1 2 3

Part 2 failure cause

Part 2

Failure causes

Effect: failure mode 3 occurrence

Cause Cause Cause

1 2 3

Part 2, Mode 3 failure causes

IEC 2640/05

Figure 1 – Relationship between failure modes and failure effects in a system hierarchy

60812 IEC:2006 – 27 –

In the FMEA, the definitions of failure modes, failure causes and failure effects depend on the

level of analysis and system failure criteria. As the analysis progresses, the failure effects

identified at the lower level may become failure modes at the higher level. The failure modes

at the lower level may become the failure causes at the higher level, and so on.

When a system is broken down into its elements, effects of one or more of the failure mode

causes make a failure mode, which in turn is a cause of the higher level effect, a part failure.

Part failure is then the cause of a module failure (effect), which in itself is a cause of a

subsystem failure. The effect of a cause of one system level thus becomes a cause of another

effect at a higher level. The above rationale is shown in Figure 1.

5.2.2.4 Representation of system structure

Symbolic representations of the system structure and operation, especially diagrams, are very

useful to aid the analysis.

Simple diagrams should be created, highlighting all the functions essential to the system. In

the diagram, the blocks are linked together by lines that represent the inputs and outputs for

each function. Usually, the nature of each function and each input needs to be precisely

described. There may be several diagrams to cover different phases of system operation.

As the system design progresses, a component block diagram can be created with blocks

representing actual components or parts. With this additional knowledge more precise

identification of potential failure modes and causes becomes possible.

The diagrams should display any series and redundant relationships among the elements and

the functional interdependencies between them. This allows the functional failures to be

tracked through the system. More than one diagram may be needed to display the alternative

modes of system operation. Separate diagrams may be required for each operational mode.

As a minimum, the block diagram should contain the following:

a) breakdown of the system into major subsystems including functional relationships;

b) all appropriately labelled inputs and outputs and identification numbers by which each

subsystem is consistently referenced;

c) all redundancies, alternative signal paths and other engineering features which provide

protection against system failures.

5.2.2.5 System initiation, operation, control and maintenance

The status of the different operating conditions of the system should be specified, as well as

the changes in the configuration or the position of the system and its components during the

different operational phases. The minimum performances demanded of the system should be

defined such that success and/or failure criteria can be clearly understood. Such specific

requirements as availability or safety should be considered in terms of specified minimum

levels of performance to be achieved and maximum levels of damage or harm to be accepted.

It is necessary to have an accurate knowledge of

a) the duration of each function the system may be called upon to perform;

b) the time interval between periodic tests;

60812 IEC:2006 – 29 –

c) the time available for corrective action before serious consequences occur to the system;

d) the entire facility, the environment and/or the personnel, including interfaces and

interactions with operators;

e) operating procedures during system start-up, shut-down and other operational transitions;

f) control during the operational phases;

g) preventive and/or corrective maintenance;

h) procedures for routine testing, if employed.

It has been stated that one of the uses of FMEA is to assist in the development of the

maintenance strategy. However, if the latter has been pre-determined, information on

maintenance facilities, equipment and spares should be known for both preventive and

corrective maintenance.

5.2.2.6 System environment

The environmental conditions of the system should be specified, including ambient conditions

and those created by other systems in the vicinity. The system should be delineated with

respect to its relationships, dependencies, or interconnections with auxiliary or other systems

and human interfaces.

At the design stage these facts are usually not all known and therefore approximations and

assumptions will be needed. As the project progresses, the data will have to be augmented

and the FMEA modified to allow for new information or changed assumptions or approxi-

mations. Often the FMEA will be helpful in defining the required conditions.

5.2.3 Failure mode determination

Successful operation of a given system is subject to the performance of certain critical system

elements. The key to evaluation of system performance is the identification of those critical

elements. The procedures for identifying failure modes, their causes and effects can be

effectively enhanced by the preparation of a list of failure modes anticipated in the light of the

following:

a) the use of the system;

b) the particular system element involved;

c) the mode of operation;

d) the pertinent operational specifications;

e) the time constraints;

f) the environmental stresses;

g) the operational stresses.

An example list of general failure modes is given in Table 1.

Table 1 – Example of a set of general failure modes

1 Failure during operation

2 Failure to operate at a prescribed time

3 Failure to cease operation at a prescribed time

4 Premature operation

NOTE This listing is an example only. Different lists would be required for different types of systems.

60812 IEC:2006 – 31 –

Virtually every type of failure mode can be classified into one or more of these categories.

However, these general failure mode categories are too broad in scope for definitive analysis;

consequently, the list needs to be expanded to make the categories more specific. When used

in conjunction with performance specifications governing the inputs and outputs on the

reliability block diagram, all potential failure modes can be identified and described. It should

be noted that a given failure mode may have several causes.

It is important that evaluation of all items within the system boundaries at the lowest level

commensurately with the objectives of the analysis is undertaken to identify all potential

failure modes. Investigation to determine possible failure causes and also failure effects on

subsystem and system function can then be undertaken.

Item suppliers should identify the potential item failure modes within their products. To assist

this function typical failure mode data can be sought from the following areas:

a) for new items, reference can be made to other items with similar function and structure

and to the results of tests performed on them under appropriate stress levels;

b) for new items, the design intent and detailed functional analysis yields the potential failure

modes and their causes. This method is preferred to the one in a), because the stresses

and the operation itself might be different from the similar items. An example of this

situation may be the use of a signal processor different than the one used in the similar

design;

c) for items in use, in-service records and failure data may be consulted;

d) potential failure modes can be deduced from functional and physical parameters typical of

the operation of the item.

It is important that item failure modes are not omitted for lack of data and that initial estimates

are improved by test results and design progression. The FMEA should record the status of

such estimates.

The identification of failure modes and, where necessary, the determination of remedial

design actions, preventative quality assurance actions or preventative maintenance actions is

of prime importance. It is more important to identify and, if possible, to mitigate the failure

modes effects by design measures, than to know their probability of occurrence. When it is

difficult to assign priorities, criticality analysis may be required.

5.2.4 Failure causes

The most likely causes for each potential failure mode should be identified and described.

Since a failure mode can have more than one cause, the most likely potential independent

causes for each failure mode need to be identified and described.

The identification and description of failure causes is not always necessary for all failure

modes identified in the analysis. Identification and description of failure causes, as well as

suggestions for their mitigation should be done on the basis of the failure effects and their

severity. The more severe the effects of failure modes, the more accurately failure causes

should be identified and described. Otherwise, the analyst may dedicate unnecessary effort

on the identification of failure causes of such failure modes that have no or a very minor effect

on system functionality.

60812 IEC:2006 – 33 –

Failure causes may be determined from analysis of field failures or failures in test units. When

the design is new and without precedent, failure causes may be established by eliciting the

opinion of experts.

When the causes of each failure mode are identified the recommended action will be

evaluated based on their estimated probability of occurrence and the severity of their effect.

5.2.5 Failure effects

5.2.5.1 Failure effects definition

A failure effect is the consequence of a failure mode in terms of the operation, function or

status of a system (see definition 3.4). A failure effect may be caused by one or more failure

modes of one or more items.

The consequences of each failure mode on system element operation, function, or status

need to be identified, evaluated and recorded. Maintenance activities and system objectives

should also be considered whenever pertinent. A failure effect may also influence the next

level up and ultimately the highest level under analysis. Therefore, at each level, the effect of

failures on the level above should be evaluated.

5.2.5.2 Local failure effects

The expression “local effects” refers to the effects of the failure mode on the system element

under consideration. The consequences of each possible failure on the output of the item

should be described. The purpose of identifying the local effects is to provide a basis for

judgement when evaluating existing alternative provisions or devising recommended

corrective actions. In certain instances, there may not be a local effect beyond the failure

mode itself.

5.2.5.3 Failure effects at the system level

When identifying end effects, the impact of a possible failure on the highest system level is

defined and evaluated by the analysis of all intermediate levels. The end effect described may

be the result of multiple failures. (For example, failure of a safety device results in a

catastrophic end effect only in the event that both the safety device fails and the prime

function for which the safety device is designed goes beyond allowed limits.)

...

NORME CEI

INTERNATIONALE 60812

Deuxième édition

2006-01

Techniques d’analyse de la fiabilité du système –

Procédure d’analyse des modes de défaillance

et de leurs effets (AMDE)

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 60812:2006(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2

Informations supplémentaires sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI

afin qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des

publications de la CEI (voir ci-dessous) en plus des nouvelles éditions, amende-

ments et corrigenda. Des informations sur les sujets à l’étude et l’avancement des

travaux entrepris par le comité d’études qui a élaboré cette publication, ainsi que la

liste des publications parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (www.iec.ch/searchpub) vous permet

de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations

en ligne sont également disponibles sur les nouvelles publications, les publications

remplacées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (www.iec.ch/online_news/justpub)

est aussi disponible par courrier électronique. Veuillez prendre contact avec le

Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE 60812

Deuxième édition

2006-01

Techniques d’analyse de la fiabilité du système –

Procédure d’analyse des modes de défaillance

et de leurs effets (AMDE)

© IEC 2006 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

X

Commission Electrotechnique Internationale

International Electrotechnical Commission

МеждународнаяЭлектротехническаяКомиссия

Pour prix, voir catalogue en vigueur

– 2 – 60812 CEI:2006

SOMMAIRE

AVANT-PROPOS.6

1 Domaine d'application .10

2 Références normatives.10

3 Termes et définitions .10

4 Vue d’ensemble.14

4.1 Introduction .14

4.2 But et objectifs de l’analyse.16

5 Analyses des modes de défaillance et de leurs effets .18

5.1 Approche générale .18

5.2 Tâches préliminaires .20

5.3 Mode de défaillance, effets, et analyses de criticité (AMDEC) .40

5.4 Rapport d’analyse .54

6 Autres considérations .58

6.1 Défaillances de cause commune .58

6.2 Facteurs humains.58

6.3 Erreurs logicielles.60

6.4 L’AMDE et les conséquences de la défaillance du système .60

7 Applications.60

7.1 Utilisation d’une AMDE/AMDEC .60

7.2 Avantages d’une AMDE.64

7.3 Limitations et inconvénients de l’AMDE .64

7.4 Relations avec les autres méthodes .66

Annexe A (informative) Récapitualtif des procédures pour AMDE et AMDEC .70

Annexe B (informative) Exemples d’analyses.78

Bibliographie.92

Figure 1 – Relation entre les modes de défaillance et les effets de défaillance dans la

hiérarchie d’un système .24

Figure 2 – Schéma fonctionnel d’analyse .38

Figure 3 – Matrice de criticité.46

Figure A.1 – Exemple de formulaire de document AMDE .76

Figure B.1 – FMEA pour une partie de dispositif électronique d’automobile avec calcul

de NPR.80

Figure B.2 – Diagramme des sous-systèmes d’un ensemble générateur-moteur .82

Figure B.3 – Diagramme d’enveloppe chauffante, ventilation et systèmes de

refroidissement .84

Figure B.4 – AMDE pour sous-système 20.86

Figure B.5 – Partie du processus AMDEC pour coulage d’aluminium par machine .90

– 4 – 60812 CEI:2006

Tableau 1 – Exemple d’un ensemble de modes de défaillance généraux .28

Tableau 2 – Exemple illustré de classification de la sévérité pour effets finaux .34

Tableau 3 – Matrice risque/criticité .48

Tableau 4 – Sévérité du mode de défaillance.50

Tableau 5 – Apparition du mode de défaillance reliée à la fréquence et probabilité

d’apparition.50

Tableau 6 – Critère d’évaluation de la détection du mode de défaillance .52

Tableau 7 – Exemple d’un ensemble d’effets de défaillance (pour un démarreur de

véhicule à moteur) .56

Tableau 8 – Exemple de probabilités d’effets de défaillance .56

Tableau B.1 – Définition et classification de la sévérité des effets de défaillance sur le

système G-M complet .82

– 6 – 60812 CEI:2006

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

TECHNIQUES D’ANALYSE DE LA FIABILITÉ DU SYSTÈME –

PROCÉDURE D’ANALYSE DES MODES DE DÉFAILLANCE

ET DE LEURS EFFETS (AMDE)

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur élaboration est confiée à des

comités d'études, aux travaux desquels tout Comité national intéressé par le sujet traité peut participer. Les

organisations internationales, gouvernementales et non gouvernementales, en liaison avec la CEI, participent

également aux travaux. La CEI collabore étroitement avec l'Organisation Internationale de Normalisation (ISO),

selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'uniformité internationale, les Comités nationaux de la CEI s'engagent, dans toute la

mesure possible, à appliquer de façon transparente les Publications de la CEI dans leurs publications

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60812 a été établie par le comité d’études 56 de la CEI: Sûreté

de fonctionnement.

Cette deuxième édition annule et remplace la première édition publiée en 1985 et constitue

une révision technique.

Les modifications majeures par rapport à l’édition précédente sont les suivantes:

– introduction des concepts d’effets des modes de défaillance et de leur criticité ;

– introduction des méthodes largement utilisées dans l’industrie automobile;

– ajout de références et de relations aux autres méthodes d’analyse des modes de

défaillance;

– ajout d’exemples;

– fourniture de guides sur les avantages et les inconvénients des différentes méthodes

AMDE.

– 8 – 60812 CEI:2006

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

56/1072/FDIS 56/1091/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

– 10 – 60812 CEI:2006

TECHNIQUES D’ANALYSE DE LA FIABILITÉ DU SYSTÈME –

PROCÉDURE D’ANALYSE DES MODES DE DÉFAILLANCE

ET DE LEURS EFFETS (AMDE)

1 Domaine d'application

La présente Norme Internationale décrit l’analyse des modes de défaillance et de leurs effets

(AMDE) et l’analyse des modes de défaillance, de leurs effets et de leur criticité (AMDEC), et

apporte des conseils sur l’application de ces méthodes selon les divers objectifs recherchés,

de la façon suivante:

− en fournissant la procédure à suivre pour réaliser une analyse,

− en spécifiant les termes pertinents, les hypothèses, les mesures de criticité, les modes de

défaillance,

− en déterminant les principes de base,

− en fournissant des exemples-types de documents et tableaux.

Etant donné que l’AMDEC est une suite logique de l’AMDE, toutes les remarques générales

d’ordre qualitatif se rapportant à l’une sont applicables à l’autre.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60300-3-1:2003, Gestion de la sûreté de fonctionnement – Partie 3-1: Guide d’application

– Techniques d’analyse de la sûreté de fonctionnement – Guide méthodologique (disponible

en anglais seulement)

CEI 61025, Analyse par arbre de panne (AAP)

CEI 61078, Techniques d’analyses pour la sûreté de fonctionnement – Méthode du bloc-

diagramme de fiabilité

3 Termes et définitions

Pour les besoins du présent document, les définitions suivantes s’appliquent:

3.1

dispositif / entité

tout élément, composant, sous-système, unité fonctionnelle, équipement ou système que l’on

peut considérer individuellement

NOTE 1 Un dispositif/entité peut être constitué de matériel, de logiciel ou des deux à la fois, et peut aussi dans

certains cas comprendre du personnel.

NOTE 2 Un ensemble déterminé de dispositifs/entités, par exemple une population ou un échantillon, peut lui-

même être considéré comme un dispositif/entité.

[VEI 191-01-01]

– 12 – 60812 CEI:2006

Un procédé peut aussi être considéré comme un dispositif/entité qui accomplit une fonction

prédéterminée et pour lequel un processus AMDE ou AMDEC peut être mené. Normalement,

une AMDE d’un matériel ne traite pas des personnes et de leurs interactions avec les

matériels/logiciels, alors qu’une AMDE portant sur un procédé inclut normalement les actions

des personnes.

3.2

défaillance

cessation de l'aptitude d'une entité à accomplir une fonction requise

[VEI 191-04-01]

3.3

panne

état d'une entité inapte à accomplir une fonction requise, non comprise l'inaptitude due à la

maintenance préventive ou à d’autres actions programmées, ou due à un manque de moyens

extérieurs

NOTE 1 Une panne est souvent le résultat d’une défaillance du dispositif lui-même, mais peut exister sans une

défaillance préalable.

[VEI 191-05-01]

NOTE 2 Pour des raisons historiques, le mot «panne» est aussi utilisé dans ce document à la place du terme

« défaillance ».

3.4

effet de défaillance

conséquence du mode de défaillance en termes de fonctionnement, fonction ou état du

dispositif

3.5

mode de défaillance

manière dont un dispositif tombe en panne

3.6

criticité d’une défaillance

combinaison de la sévérité d’un effet et de la fréquence de son apparition, ou d’autres

attributs d’une défaillance comme une mesure de la nécessité d’un traitement ou d’une

atténuation

3.7

système

ensemble d’éléments interactifs ou reliés entre eux

NOTE 1 Dans un contexte de sûreté de fonctionnement, un système aura

a) divers objectifs exprimés en termes de fonctions requises,

b) l’indication des conditions d’exploitation (voir 191-01-12),

c) une limite définie.

NOTE 2 La structure d’un système est hiérarchique.

[ISO 9000:2000]

3.8

sévérité de la défaillance

signification ou classement de l’effet d’un mode de défaillance sur le fonctionnement du

dispositif, sur l'environnement du dispositif, ou sur l’opérateur du dispositif; la sévérité de

l’effet d’un mode de défaillance est liée aux limites définies pour le système analysé

– 14 – 60812 CEI:2006

4 Vue d’ensemble

4.1 Introduction

L’analyse des modes de défaillance et de leurs effets (AMDE) est une procédure systé-

matique, formelle, d’analyse d’un système pour identifier les modes de défaillance potentiels,

leurs causes et les effets sur l’aptitude à la fonction du système (aptitude à la fonction de

l’assemblage hiérarchiquement au-dessus et du système global ou d’un procédé). Ici, le

terme « système » représente un matériel, un logiciel (avec leurs interactions) ou un procédé.

L’analyse est menée de préférence tôt dans le cycle de développement de sorte que le retrait

ou l’atténuation du mode de défaillance soit le plus efficace. Cette analyse peut être initiée

dès que le système est suffisamment défini pour pouvoir être représenté sous forme d’un

bloc-diagramme fonctionnel dont l’aptitude à la fonction des éléments peut être définie.

Le moment où a lieu l’AMDE est essentiel; si elle n’est pas faite suffisamment tôt dans le

cycle de développement, l’incorporation des modifications de conception pour maîtriser les

déficiences identifiées par l’AMDE peut ne pas être efficace. Par conséquent, il est important

d’inclure l’AMDE et ses conclusions dans le plan et le programme de développement. Ainsi,

l’AMDE est un processus itératif qui est mené conjointement au processus de conception.

L’AMDE est applicable aux différents niveaux de décomposition d’un système, du niveau le

plus haut du bloc-diagramme jusqu’aux fonctions des composants discrets et des instructions

logicielles. L’AMDE est aussi un processus itératif qui est mis à jour au fur et à mesure de la

progression de la conception. Pour les modifications de conception, les parties concernées de

l’AMDE doivent être revues et mises à jour.

Une AMDE menée rigoureusement est le résultat obtenu par une équipe composée

d’individus qualifiés pour identifier et évaluer l’ampleur et les conséquences de types variés

d’inadéquations dans la conception du produit, pouvant conduire à des défaillances. Le travail

en équipe a l’avantage de stimuler les processus de réflexion, et d’assurer l’expertise

nécessaire.

L’AMDE est considérée comme une méthode pour identifier la sévérité de modes de

défaillance potentiels et pour introduire dans la conception des mesures pour réduire les

risques. Cependant, dans certaines applications, l’AMDE inclut également une estimation de

la probabilité d’apparition des modes de défaillance. Cela améliore l’analyse en fournissant

une mesure de la probabilité du mode de défaillance.

L’application de l’AMDE est précédée d’une décomposition hiérarchique du système (matériel

et logiciel, ou un procédé) dans ses moindres éléments de base. L’utilisation de blocs-

diagrammes simples pour illustrer cette décomposition est utile (CEI 61078). L’analyse

débute donc avec les éléments du niveau le plus bas. Un effet du mode de défaillance à bas

niveau peut devenir une cause de défaillance d’un mode de défaillance d’un dispositif du

niveau juste au-dessus. L’analyse est réalisée du bas vers le haut jusqu’à ce que l’effet final

soit identifié sur le système. La Figure 1 illustre ces concepts.

L’AMDEC (Analyses des Modes de Défaillance, de leurs Effets et de leur Criticité) est une

extension de l’AMDE qui comprend un moyen de classer les modes de défaillance par

sévérité pour permettre de donner la priorité aux contre-mesures. Cela est obtenu en

combinant la mesure de la sévérité et la fréquence d’apparition pour fournir une criticité dite

métrique.

Les principes de l’AMDE peuvent s’appliquer en dehors de la conception d’ingénierie. La

procédure AMDE peut s’appliquer à un procédé de fabrication ou à d’autres processus de

travail, telles que dans les hôpitaux, les laboratoires médicaux, les scolarités, ou autres.

– 16 – 60812 CEI:2006

Lorsque l’AMDE est appliquée à un procédé de fabrication, cette procédure est identifiée

comme AMDE de procédé ou PAMDE. Pour qu’une AMDE soit efficace, des ressources

adéquates pour un travail en équipe doivent être attribuées. Une compréhension approfondie

du système sous analyse n’est pas indispensable pour une AMDE préliminaire. Avec le

développement de la conception, l’analyse détaillée d’un mode de défaillance nécessite une

connaissance approfondie de la conception et de ses spécifications. Les conceptions

d’ingénierie complexes nécessitent généralement l’implication de multiples domaines

d’expertise de conception (ex.: ingénierie mécanique, ingénierie électrique, ingénierie des

systèmes, ingénierie logicielle, support de maintenance, etc.).

L’AMDE porte généralement sur les modes de défaillance individuels et les effets de ces

modes de défaillance sur le système. Chaque mode de défaillance est traité en étant

considéré comme indépendant. La procédure n’est donc pas adaptée à la prise en

considération de défaillance dépendant ou résultant d’une suite d’événements. D’autres

méthodes et techniques, telles que l’analyse de Markov (voir CEI 61165) ou Analyse par

Arbre de Panne (voir CEI 61025) peuvent être nécessaires pour analyser ces situations.

Lors de la détermination de l’impact d’une défaillance, il faut considérer le niveau plus élevé

concerné – défaillances résultantes et éventuellement le même niveau de défaillances

induites. Il convient que l’analyse mentionne la combinaison possible de modes de défaillance

ou leur succession qui ont été une cause d’un effet de niveau élevé. Dans ce cas, une

modélisation complémentaire est requise pour estimer l’ampleur ou la probabilité d’apparition

de tels effets.

AMDE est un outil souple qui peut être adapté pour répondre à des besoins spécifiques de

l’industrie ou à des produits. Des documents spécialisés avec des données spécifiques

peuvent être adaptés à certaines applications. Si des niveaux de sévérité des modes de

défaillance sont définis, ils peuvent l’être différemment pour des systèmes différents ou des

niveaux de systèmes différents.

4.2 But et objectifs de l’analyse

Les raisons d’entreprendre l’analyse des modes de défaillance et de leurs effets (AMDE) ou

l’analyse des modes de défaillance, de leurs effets et de leur criticité (AMDEC) peuvent être

les suivantes:

a) identifier les défaillances qui ont des effets non souhaités sur le fonctionnement du

système, ex.: empêcher ou dégrader significativement le fonctionnement ou affecter la

sécurité de l’opérateur;

b) satisfaire aux exigences contractuelles d’un client, si applicable;

c) permettre des améliorations de la fiabilité ou de la sécurité du système (ex. des

modifications de la conception ou des actions d’assurance-qualité);

d) permettre des améliorations de la maintenabilité du système (en mettant en évidence les

zones de risque ou de non-conformité pour la maintenabilité).

Compte tenu des raisons données ci-dessus pour entreprendre une AMDE, les objectifs d’une

AMDE (ou AMDEC) peuvent être les suivants:

a) une évaluation et identification détaillée de tous les effets indésirables dans les limites

définies du système sous analyse, et les séquences d’événements amenées par chaque

mode de défaillance du dispositif identifié, quelle que soit la cause, à divers niveaux de la

hiérarchie fonctionnelle du système,

b) la détermination de la criticité ou de la priorité pour traiter/atténuer (voir Article 6) chaque

mode de défaillance par rapport à la fonction correcte du système ou aptitude et l’impact

sur le processus concerné,

– 18 – 60812 CEI:2006

c) une classification des modes de défaillance identifiés d’après les caractéristiques en

question, comprenant l’aptitude à la détection, au diagnostic, aux essais, au remplace-

ment du dispositif, les provisions de fonctionnement et de compensation (réparation,

maintenance, logistique, etc.),

d) l’identification des défaillances fonctionnelles du système et estimation des mesures de la

sévérité et de la probabilité de défaillance,

e) le développement d’un plan d’amélioration de la conception pour la réduction des modes

de défaillance,

f) le soutien du développement d’un plan de maintenance effectif pour atténuer ou réduire la

probabilité de défaillance (voir CEI 60300-3-11).

NOTE Quand il s’agit de criticité ou probabilité d’apparition, les commentaires concernent la méthodologie

AMDEC.

5 Analyses des modes de défaillance et de leurs effets

5.1 Approche générale

Traditionnellement, la manière de mener et de présenter l’AMDE a subi de grandes

évolutions. L’analyse est généralement faite en identifiant les modes de défaillance, leurs

causes respectives et leurs effets immédiats et finaux. Les résultats analytiques peuvent être

présentés sur un document contenant un noyau d’informations essentielles pour l’intégralité

du système et des éléments détaillés spécifiques à ce système. Ce document expose les

potentialités de tomber en panne, les composants et leurs modes de défaillance à l’origine de

défaillance du système, et la ou les causes d’apparition de chaque mode de défaillance

individuel.

Une AMDE appliquée à des produits complexes peut demander un effort considérable. Cet

effort peut parfois être réduit en considérant que la conception de certains sous-ensembles

ou des parties de ceux-ci n’est pas entièrement nouvelle et en identifiant les parties de la

conception du produit qui sont une répétition ou une modification d’une conception

précédente. Il convient que la nouvelle AMDE construite se serve au maximum des

informations des sous-ensembles existants. Il faut aussi qu’elle indique le besoin éventuel

d’essais ou d’analyse complète des nouveaux dispositifs. Une fois qu’une AMDE détaillée est

créée pour une conception, elle peut être mise à jour et améliorée pour les générations

futures de cette conception, ce qui consiste en un effort nettement moindre que l’analyse

d’origine.

Quand on se sert d’une AMDE d’une version de produit précédente, il est indispensable de

s’assurer que la conception reprise est bien utilisée de la même manière et sous les mêmes

contraintes que précédemment. Les nouvelles contraintes environnementales et opération-

nelles peuvent exiger une révision de l’AMDE précédemment effectuée. Des contraintes

environnementales et opérationnelles différentes peuvent exiger la création d’une AMDE

entièrement nouvelle au vu des nouvelles conditions opérationnelles.

La procédure AMDE consiste en quatre étapes principales:

a) établissement des règles de bases pour l’AMDE, planification et programmation pour

s’assurer que le temps et l’expertise sont disponibles pour mener l’analyse,

b) réaliser l’AMDE en se servant des documents appropriés ou de tout autre moyen tel qu’un

diagramme logique ou un arbre de panne,

c) résumer et établir un rapport de l’analyse incluant les conclusions et recommandations

faites,

d) mettre à jour l’AMDE au fur et à mesure de la progression de l’activité de développement.

– 20 – 60812 CEI:2006

5.2 Tâches préliminaires

5.2.1 Planification des analyses

Il convient que les actions de l’AMDE, les actions en découlant, les procédures, les liens avec

les autres actions relatives à la fiabilité, les processus de gestion des actions correctives et

de leur finalisation, les planning soient intégrés dans le plan global du programme.

Il convient que le plan du programme de fiabilité décrive la méthode d‘AMDE à appliquer.

Cette description peut être un résumé ou une référence à un document source décrivant la

méthode.

Ce plan comporte les points suivants:

− une définition claire des objectifs spécifiques de l’analyse et les résultats attendus;

− le domaine d’application de la présente analyse, c’est-à-dire comment il convient que

l’AMDE se concentre sur certains éléments de conception. Il convient que le domaine

d’application reflète la maturité de la conception et les éléments de celle-ci qui peuvent

présenter des risques car ils accomplissent une fonction critique ou parce que la

technologie est nouvelle;

− la description de comment la présente analyse soutient la sûreté de fonctionnement de