IEC 61643-331:2020

(Main)Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV)

Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV)

IEC 61643-331:2020 is a test specification for metal oxide varistors (MOV), which are used for applications up to 1 000 V AC or 1 500 V DC in power lines, or telecommunication, or signalling circuits. They are designed to protect apparatus or personnel, or both, from high transient voltages. This document applies to MOVs having two electrodes and hybrid surge protection components. This document also does not apply to mountings and their effect on the MOV’s characteristics. Characteristics given apply solely to the MOV mounted only in the ways described for the tests. This third edition cancels and replaces the second edition published in 2017. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- a Varistor MCOV rating assurance test;

- an energy rating test (2ms);

- revised Dielectric strength and insulation resistance tests.

Composants pour parafoudres basse tension - Partie 331: Exigences de performance et méthodes d'essai pour les varistances à oxyde métallique (MOV)

IEC 61643-331:2020 est une spécification d'essai pour les varistances à oxyde métallique (MOV, Metal Oxide Varistor) utilisées dans des applications jusqu'à 1 000 V en courant alternatif ou 1 500 V en courant continu sur les lignes électriques ou de télécommunication, ou dans les circuits de signalisation. Elles sont conçues pour protéger l'appareillage et/ou le personnel contre les hautes tensions transitoires. Le présent document s'applique aux MOV comportant deux électrodes et des composants pour parafoudres hybrides. Le présent document ne s'applique pas aux montages et à leurs effets sur les caractéristiques des MOV. Les caractéristiques indiquées s'appliquent exclusivement aux MOV montées uniquement dans le sens décrit pour les essais. Cette troisième édition annule et remplace la deuxième édition parue en 2017. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- un essai d'assurance des caractéristiques MCOV assignées de la varistance a été ajouté;

- un essai des caractéristiques assignées d'énergie (2 ms) a été ajouté;

- les essais de rigidité diélectrique et de résistance d'isolement ont été revus.

General Information

- Status

- Published

- Publication Date

- 18-Mar-2020

- Technical Committee

- SC 37B - Components for low-voltage surge protection

- Drafting Committee

- MT 1 - TC 37/SC 37B/MT 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Mar-2020

- Completion Date

- 13-Mar-2020

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61643-331:2020 - Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV) - is the third edition (technical revision) of the MOV test specification. It applies to two‑electrode and hybrid MOV components used in applications up to 1 000 V AC or 1 500 V DC for power lines, telecommunications or signalling circuits. The standard defines performance criteria and laboratory test methods intended to verify MOV behaviour for protection of equipment and personnel against high transient voltages. This edition introduces significant updates including a Varistor MCOV rating assurance test, an energy rating test (2 ms) and revised dielectric strength and insulation resistance tests.

Key topics and technical requirements

Scope and applicability

- MOVs with two electrodes and hybrid surge protection components for low-voltage systems (power, telecom, signalling).

- Excludes effects of mountings unless tests specify mounting arrangements.

Electrical characteristics and ratings

- Nominal varistor voltage (Vn), clamping voltage (Vc), maximum continuous operating voltage (MCOV), standby/leakage current, capacitance.

- New MCOV rating assurance to confirm continuous operating voltage claims.

- Energy rating (2 ms) test to quantify short-duration energy capability.

Performance and endurance tests

- Nominal discharge current (In) and single-impulse maximum current tests.

- Endurance / operating duty tests and accelerated endurance screening.

- Limited current temporary overvoltage and thermally protected varistor sequences.

- Dielectric strength and insulation resistance measurements (revised in this edition).

- ESD testing for SMD MOV types.

Quality and reliability

- Annexes address test methods for operating duty, accelerated endurance, and a proposed MTTF determination method.

- Marking, solderability and mechanical robustness requirements are included.

Practical applications and users

Who uses IEC 61643-331:

- MOV manufacturers validating product performance and ratings.

- Certification and independent test laboratories performing compliance testing.

- Designers and engineers of surge protective devices (SPDs), power distribution, telecommunications and signalling equipment.

- Procurement/specification writers and regulatory bodies that require traceable performance criteria for surge protection components.

Practical value:

- Ensures MOVs meet minimum safety and functional performance under transient stress.

- Guides designers in selecting MOVs with verified MCOV, energy handling and clamping behaviour.

- Supports consistent testing for product qualification and comparative evaluation.

Related standards

- IEC 61643-11 - Surge protective devices for Class I, II and III (referenced in annex A).

- IEC 61051 - Varistors for use in electronic equipment (referenced in annex B).

For complete test procedures, pass/fail criteria and normative details, obtain the full IEC 61643-331:2020 text from the IEC Webstore.

Buy Documents

IEC 61643-331:2020 - Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV) Released:3/19/2020 Isbn:9782832279052

IEC 61643-331:2020 RLV - Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV) Released:3/19/2020 Isbn:9782832280232

IEC 61643-331:2020 - Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV) Released:3/19/2020 Isbn:9782832285589

Frequently Asked Questions

IEC 61643-331:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Components for low-voltage surge protection - Part 331: Performance requirements and test methods for metal oxide varistors (MOV)". This standard covers: IEC 61643-331:2020 is a test specification for metal oxide varistors (MOV), which are used for applications up to 1 000 V AC or 1 500 V DC in power lines, or telecommunication, or signalling circuits. They are designed to protect apparatus or personnel, or both, from high transient voltages. This document applies to MOVs having two electrodes and hybrid surge protection components. This document also does not apply to mountings and their effect on the MOV’s characteristics. Characteristics given apply solely to the MOV mounted only in the ways described for the tests. This third edition cancels and replaces the second edition published in 2017. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - a Varistor MCOV rating assurance test; - an energy rating test (2ms); - revised Dielectric strength and insulation resistance tests.

IEC 61643-331:2020 is a test specification for metal oxide varistors (MOV), which are used for applications up to 1 000 V AC or 1 500 V DC in power lines, or telecommunication, or signalling circuits. They are designed to protect apparatus or personnel, or both, from high transient voltages. This document applies to MOVs having two electrodes and hybrid surge protection components. This document also does not apply to mountings and their effect on the MOV’s characteristics. Characteristics given apply solely to the MOV mounted only in the ways described for the tests. This third edition cancels and replaces the second edition published in 2017. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - a Varistor MCOV rating assurance test; - an energy rating test (2ms); - revised Dielectric strength and insulation resistance tests.

IEC 61643-331:2020 is classified under the following ICS (International Classification for Standards) categories: 31.040.20 - Potentiometers, variable resistors. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61643-331:2020 has the following relationships with other standards: It is inter standard links to IEC 61643-331:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61643-331:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61643-331 ®

Edition 3.0 2020-03

INTERNATIONAL

STANDARD

colour

inside

Components for low-voltage surge protection –

Part 331: Performance requirements and test methods for metal oxide varistors

(MOV)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and once 67 000 electrotechnical terminology entries in English and

a month by email. French extracted from the Terms and Definitions clause of IEC

publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or need CISPR.

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61643-331 ®

Edition 3.0 2020-03

INTERNATIONAL

STANDARD

colour

inside

Components for low-voltage surge protection –

Part 331: Performance requirements and test methods for metal oxide varistors

(MOV)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.040.20 ISBN 978-2-8322-7905-2

– 2 – IEC 61643-331:2020 © IEC 2020

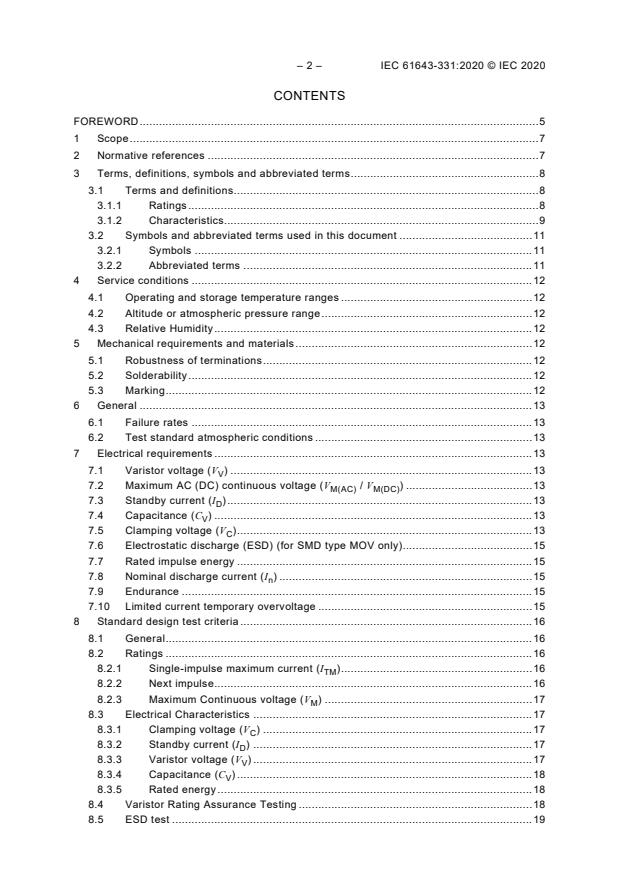

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviated terms . 8

3.1 Terms and definitions . 8

3.1.1 Ratings . 8

3.1.2 Characteristics. 9

3.2 Symbols and abbreviated terms used in this document . 11

3.2.1 Symbols . 11

3.2.2 Abbreviated terms . 11

4 Service conditions . 12

4.1 Operating and storage temperature ranges . 12

4.2 Altitude or atmospheric pressure range . 12

4.3 Relative Humidity . 12

5 Mechanical requirements and materials . 12

5.1 Robustness of terminations . 12

5.2 Solderability . 12

5.3 Marking . 12

6 General . 13

6.1 Failure rates . 13

6.2 Test standard atmospheric conditions . 13

7 Electrical requirements . 13

7.1 Varistor voltage (V ) . 13

V

7.2 Maximum AC (DC) continuous voltage (V / V ) . 13

M(AC) M(DC)

7.3 Standby current (I ) . 13

D

7.4 Capacitance (C ) . 13

V

7.5 Clamping voltage (V ) . 13

C

7.6 Electrostatic discharge (ESD) (for SMD type MOV only). 15

7.7 Rated impulse energy . 15

7.8 Nominal discharge current (I ) . 15

n

7.9 Endurance . 15

7.10 Limited current temporary overvoltage . 15

8 Standard design test criteria . 16

8.1 General . 16

8.2 Ratings . 16

8.2.1 Single-impulse maximum current (I ) . 16

TM

8.2.2 Next impulse . 16

8.2.3 Maximum Continuous voltage (V ) . 17

M

8.3 Electrical Characteristics . 17

8.3.1 Clamping voltage (V ) . 17

C

8.3.2 Standby current (I ) . 17

D

8.3.3 Varistor voltage (V ) . 17

V

8.3.4 Capacitance (C ) . 18

V

8.3.5 Rated energy . 18

8.4 Varistor Rating Assurance Testing . 18

8.5 ESD test . 19

9 Nominal discharge current and limited current temporary overvoltage. 19

9.1 Thermally protected varistors – Sequence of tests . 19

9.2 Temperature and humidity cycle conditioning . 19

9.3 Nominal discharge current (I ) test description . 20

n

9.3.1 General . 20

9.3.2 Pass/fail criteria . 22

9.4 Limited current temporary overvoltage test description and procedure for

thermally protected varistors . 22

9.4.1 General . 22

9.4.2 Sample preparation . 23

9.4.3 Test conditions . 23

9.4.4 Pass/fail criteria . 23

9.5 Dielectric testing . 24

9.5.1 Test conditions for thermally protected MOV . 24

9.5.2 Setup from foil to leads . 25

9.5.3 Pass criteria . 25

9.6 Insulation Resistance . 25

Annex A (informative) MOV testing according to the IEC 61643-11:2011 Surge

protective devices for the Class I, II and III . 26

A.1 General . 26

A.2 MOV selection . 26

A.3 Cross reference list of abbreviations, descriptions and definitions . 26

A.4 Operating duty test . 27

A.4.1 General . 27

A.4.2 Class I and II operating duty tests (8.4.4.3) . 32

A.4.3 Additional duty test for test class I . 33

A.4.4 Class III operating duty tests . 33

A.4.5 Pass criteria for all operating duty tests and for the additional duty test

for test class I . 34

A.4.6 Preferred parameters of impulse discharge current I used for Class I

imp

additional duty tests . 34

A.4.7 Preferred values of impulse discharge current I used for Class I and

n

Class II residual voltage and operating duty tests . 35

A.4.8 Preferred values of combination generator waveshape used for Class III

tests . 35

Annex B (informative) IEC 61051 Varistors for use in electronic equipment . 38

Annex C (normative) Accelerated Endurance screening test . 39

C.1 Accelerated endurance screening test . 39

C.2 Preparation of sample . 39

C.3 Test conditions . 39

C.4 Refer to test circuit diagram as shown in Figure C.1. . 39

C.5 Pass criteria . 40

Annex D (informative) Proposed test method of MTTF – Mean time to failure (MTTF) . 41

D.1 Sampling plans . 41

D.2 Total test hours . 41

D.3 Samples. 41

D.4 Test set-up . 42

D.5 Intermediate measurements . 42

D.6 Failure criteria . 42

– 4 – IEC 61643-331:2020 © IEC 2020

D.7 Acceptance criteria . 42

Figure 1 – V-I characteristic of an MOV . 10

Figure 2 – Symbol for MOV . 11

Figure 3 – Symbol for thermally protected MOV . 11

Figure 4 – Test circuit for single-impulse maximum current . 16

Figure 5 – Test circuit for measuring standby current . 17

Figure 6 – Test circuit for measuring varistor voltage (V ) . 18

V

Figure 7 – Varistor rating assurance test setup . 19

Figure 8 – Nominal discharge current test flowchart . 21

Figure 9 – Sequence of the I Test . 22

n

Figure 10 – Temporary overvoltage limited current test procedure flowchart . 24

Figure A.1 – Flow chart of the operating duty test . 28

Figure A.2 – Test set-up for operating duty test . 29

Figure A.3 – Flow chart of testing to determine the measured limiting voltage . 31

Figure A.4 – Operating duty test timing diagram for test classes I and II . 32

Figure A.5 – Additional duty test timing diagram for test class I . 33

Figure A.6 – Operating duty test timing diagram for test class III . 34

Figure C.1 – Circuit of accelerated ageing test . 39

Figure D.1 – Test Circuit of MTTF . 42

Table 1 – Typical Voltage ratings for disc types . 14

Table 2 – Typical Voltage Ratings for SMD types . 15

Table 3 – Test voltages for dielectric strength Between Test voltage . 25

Table A.1 – Abbreviations, descriptions and definitions . 27

Table A.2 – Preferred parameters for class I test . 34

Table A.3 – Preferred values for class I and class II tests . 35

Table A.4 – Preferred values for class III tests . 36

Table C.1 – Current in V measurement . 39

T

Table D.1 – Sampling plans . 41

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMPONENTS FOR LOW-VOLTAGE SURGE PROTECTION –

Part 331: Performance requirements and test methods

for metal oxide varistors (MOV)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61643-331 has been prepared by subcommittee 37B: Components

for low-voltage surge protection, of IEC technical committee 37: Surge arresters.

This third edition cancels and replaces the second edition published in 2017. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) a Varistor MCOV rating assurance test;

b) an energy rating test (2ms);

c) revised Dielectric strength and insulation resistance tests.

– 6 – IEC 61643-331:2020 © IEC 2020

The text of this International Standard is based on the following documents:

FDIS Report on voting

37B/211/FDIS 37B/214/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 61643 series, under the general title Components for low-voltage

surge protective devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

COMPONENTS FOR LOW-VOLTAGE SURGE PROTECTION –

Part 331: Performance requirements and test methods

for metal oxide varistors (MOV)

1 Scope

This part of IEC 61643 is a test specification for metal oxide varistors (MOV), which are used

for applications up to 1 000 V AC or 1 500 V DC in power lines, or telecommunication, or

signalling circuits. They are designed to protect apparatus or personnel, or both, from high

transient voltages.

This document applies to MOVs having two electrodes and hybrid surge protection

components. This document also does not apply to mountings and their effect on the MOV’s

characteristics. Characteristics given apply solely to the MOV mounted only in the ways

described for the tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:2008, Environmental testing – Part 2-27: Tests – Test Ea and guidance:

Shock

IEC 60068-2-52:2017 Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 61643-11:2011, Low-voltage surge protective devices – Part 11: Surge protective devices

connected to low-voltage power systems – Requirements and test methods

IEC 61000-4-2:2008, Electromagnetic compatibility (EMC) – Part 4-2: Testing and

measurement techniques – Electrostatic discharge immunity test

– 8 – IEC 61643-331:2020 © IEC 2020

3 Terms, definitions, symbols and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Terms and definitions

3.1.1 Ratings

3.1.1.1

absolute maximum ratings

limiting values of operating and environmental conditions applicable to a component, device,

equipment or machine as defined by its published specification data, which should not be

exceeded under the worst possible conditions

Note 1 to entry: A limiting condition may be either a maximum or a minimum or both.

[SOURCE: IEC 62240-1:2013, 3.1.1, modified ("any semiconductor device of a specific type"

replaced by "a component, device, equipment or machine", addition of Note 1 to entry)]

3.1.1.2

single-impulse [transient] maximum current

I

TM

rated maximum value of current which may be applied for a single impulse of specified

waveform

Note 1 to entry: For power distribution SPDs, IEC 61643-11, Maximum Discharge Current I is used.

MAX

3.1.1.3

nominal discharge current

I

n

crest value of the current through the MOV having a current waveshape of 8/20

3.1.1.4

impulse life characteristic

graphical representation between impulse current peak (I), equivalent rectangular pulse width

(T), and impulse numbers (n) which the MOV can withstand

Note 1 to entry: Unless otherwise specified, the range of T shall be 20 µs to 10 ms, the range of n shall be 10 ,

5 4 3 2 1 0

10 ,10 , 10 , 10 , 10 and 10 .

3.1.1.5

temperature derating curve

graphical representation of parameter derating against temperature

Note 1 to entry: Typical parameters are rated voltage, impulse current, energy and average power dissipation.

3.1.1.6

single-pulse [transient] maximum energy

W

TM

rated maximum value which may be absorbed for a single pulse of a specified waveform

Note 1 to entry: Unless otherwise specified, 2 ms rectangular pulse is used (IEC 60060).

3.1.1.7

maximum continuous voltage

V

M

voltage that may be applied continuously at a specified temperature

Note 1 to entry: May also be called U or MCOV.

C

Note 2 to entry: See Figure 1.

3.1.1.8

maximum continuous AC voltage

V

M(AC)

value of RMS power frequency voltage (less than 5 % total harmonic distortion) that may be

applied continuously at a specified temperature

3.1.1.9

maximum continuous DC voltage

V

M(DC)

DC voltage that may be applied continuously at a specified temperature

3.1.1.10

mean time to failure

MTTF

basic measure of reliability for non-repairable items, the total number of life units of an item

divided by the total number of failures within that population ,during a particular measurement

interval under stated conditions

3.1.2 Characteristics

3.1.2.1

characteristic

inherent and measurable properties of an MOV

3.1.2.2

standby current

I

D

current passing through MOV at maximum continuous voltage V

M

Note 1 to entry: The current passing through the MOV at less than V is called leakage current.

M

3.1.2.3

varistor voltage

V

V

voltage across the MOV measured at a specified current (typically 1 mA) for a specific

duration

3.1.2.4

varistor test current

I

N

test current (typically 1 mA) to determine the varistor voltage V

V

Note 1 to entry: See Figure 1.

3.1.2.5

clamping voltage

V

C

peak voltage across the MOV measured under conditions of a specified peak pulse current

(I ) and specified waveform

P

Note 1 to entry: See Figure 1.

– 10 – IEC 61643-331:2020 © IEC 2020

Note 2 to entry: Unless otherwise specified, a typical value of this parameter is measured with a pulsed current

8/20 waveform.

Note 3 to entry: Clamping voltage, V , is referred to as measured limiting voltage in IEC 61643-11.

C

Figure 1 – V-I characteristic of an MOV

3.1.2.6

capacitance

C

V

capacitance across the MOV measured at a specified frequency, voltage and time

3.1.2.7

metal oxide varistor (MOV)

component whose conductance during static state, at a given temperature, increases rapidly

with increasing voltage

Note 1 to entry: This is also known as a voltage dependant resistor (VDR).

3.1.2.8

thermally protected metal oxide varistor

varistor which includes a series non-resettable element that will disconnect the MOV when it

is overheated due to excessive dissipation

3.1.2.9

DC standby current

I

DC

current passing through MOV at maximum continuous voltage DC V

M(DC)

3.2 Symbols and abbreviated terms used in this document

3.2.1 Symbols

Figure 2 and Figure 3 represent the IEC 60617 symbols for MOV and thermally protected

MOV, respectively.

Figure 2 – Symbol for MOV

Figure 3 – Symbol for thermally protected MOV

NOTE IEC 60027 recommends the letters V and v only as reserve symbols for voltage; however, in the field of

MOV components, these are so widely used that in this document they are preferred to U and u.

3.2.2 Abbreviated terms

CUT Component Under Test

ESD Electrostatic Discharge

MCOV Maximum Continuous Operating Voltage

MOV Metal Oxide Varistor

MTTF Mean Time To Failure

SMD Surface Mount Device

SPD Surge Protective Device

VDR Voltage Dependent Resistor

– 12 – IEC 61643-331:2020 © IEC 2020

4 Service conditions

4.1 Operating and storage temperature ranges

Operating range

– Normal: –5 °C to +55 °C

– Extended: −40 °C to +85 °C

Storage range MOV

– Normal: –40 °C to +85 °C

– Extended: −40 °C to +125 °C

Storage range Thermally protected MOV

– Normal: –40 °C to +85 °C

– Extended: −40 °C to +85 °C

NOTE Temperature range (operating or storage) could be different than the normal or extended values shown

above.

4.2 Altitude or atmospheric pressure range

The altitude of air pressure is within 80 kPa to 106 kPa (refer to IEC 60068-1).

4.3 Relative Humidity

Normal range: 5 % to 95 % at 25 °C (refer to IEC 60068-1 and IEC 60068-2-78).

5 Mechanical requirements and materials

5.1 Robustness of terminations

If applicable, the user shall specify a suitable test from IEC 60068-2-21.

5.2 Solderability

Solder terminations shall meet the requirements of IEC 60068-2-20, test Ta, method 1.

5.3 Marking

Legible and permanent marking shall be applied to the MOV as necessary to ensure that the

user can determine the following information by inspection.

Each MOV shall be marked with the following information:

– Date of manufacture or batch number

– Manufacturer name or trademark

– part number

– safety approval markings

NOTE 1 The necessary information can also be coded.

NOTE 2 When the space is not sufficient for printing this data, it could be provided on the smallest unit container

in which the product is packaged or as agreed upon between the manufacturer and the purchaser.

6 General

6.1 Failure rates

Sampling size, electrical characteristics to be tested, etc. should be covered by the quality

assurance requirements, which are not covered by this document.

6.2 Test standard atmospheric conditions

The following tests shall be performed on the MOVs as required by the application. Unless

otherwise specified, ambient test conditions shall be as follows:

• Temperature: 15 °C to 35 °C;

• Relative humidity 25 % to 75 %;

MOVs of various types should have the characteristics listed in Table 1 when tested in

accordance with Clause 8.

7 Electrical requirements

7.1 Varistor voltage (V )

V

When tested according to 8.3.3, varistor voltage should be within the manufacturer’s specified

limits. Table 1 shows the varistor voltages of high voltage and low voltage disc types that are

commonly used; their allowable tolerances are ±10 %.

The varistor voltages and tolerances listed in Table 2 are typical for SMD types.

7.2 Maximum AC (DC) continuous voltage (V / V )

M(AC) M(DC)

Unless otherwise specified, MOVs shall have a maximum AC (DC) continuous voltage

V / (V ) as given in Table 1 and Table 2, the conformity shall be evaluated according

M(AC) M(DC)

to 8.2.3.

NOTE Maximum AC (DC) continuous voltage V / (V ) is sometimes referred to as U .

M(AC) M(DC) C

7.3 Standby current (I )

D

When tested according to 8.3.2, the standby current I under maximum continuous DC

DC

voltage V , shall be less than the maximum value specified by the manufacturer and there

M(DC)

shall be no upward drifting during the application of the test voltage V .

M(DC)

7.4 Capacitance (C )

V

When tested according to 8.3.4, the measured value of capacitance shall not exceed the

value specified by the manufacturer.

)

7.5 Clamping voltage (V

C

The measured clamping voltage (see 8.3.1) at a specified impulse current shall be no more

than the specified values or the values indicated in Table 1. Unless otherwise specified, an

8/20 impulse current having the peak as specified shall be used.

NOTE Clamping voltage V is referred to as Measured Limiting Voltage in IEC 61643-11.

C

– 14 – IEC 61643-331:2020 © IEC 2020

Table 1 – Typical Voltage ratings for disc types

Max. continuous voltage (V ) Clamping voltage (NOTE), V (V)

M C

Varistor

voltage V (V)

V AC (RMS) V DC V 8/20, V

M(AC) M(DC) C

18 11 14 36

22 14 18 43

27 17 22 53

33 20 26 65

39 25 31 77

47 30 38 93

56 35 45 110

68 40 56 135

82 50 65 135

100 60 85 165

120 75 100 200

150 95 125 250

180 115 150 300

200 130 170 340

220 140 180 360

240 150 200 395

275 175 225 455

300 195 250 505

330 210 270 545

360 230 300 595

390 250 320 650

430 275 350 710

470 300 385 775

510 320 410 845

560 350 450 930

620 385 505 1 025

680 420 560 1 120

715 440 585 1 180

750 460 615 1 240

820 510 670 1 355

910 550 745 1 500

1 000 625 825 1 650

1 100 680 895 1 815

1 200 750 970 2 000

1 600 1 000 1 280 2 650

1 800 1 100 1 465 2 970

NOTE Clamping voltage V is referred to as measured limiting voltage in IEC 61643-11.

C

During the tests, there shall be no flashover or puncture of the samples, the clamping voltage

(V ) of the samples shall be tested prior to and after the tests, the change of which shall not

C

exceed ±10 %, when tested according to 8.3.1.

7.6 Electrostatic discharge (ESD) (for SMD type MOV only)

The requirement of Table 2 is only applicable for surface mount devices (for SMD varistors

ONLY). SMD MOV shall be tested as in 8.5.

Table 2 – Typical Voltage Ratings for SMD types

Varistor Maximum continuous voltage (V )

M

Voltage V (V)

AC (RMS) V DC V

V

AC DC

5,6 ±20 % 2,5 4

6,8±20 % 3,5 4,5

8,2 ±20 % 4 5,5

10 ± 20 % 5 7

12± 20 % 6 8,5

15± 20 % 7,5 10,5

18 ± 20 % 9 13

22 ± 10 % 14 18

27 ± 10 % 17 22

33 ± 10 % 20 26

39 ± 10 % 25 31

47 ± 10 % 30 38

56 ± 10 % 35 45

68 ± 10 % 40 56

82 ± 10 % 50 65

7.7 Rated impulse energy

The MOV shall be capable of absorbing the impulse energy specified by the manufacturer

when subjected to one impulse current of 2 ms rectangular pulse or 10/1000 or 8/20 and

tested according to 8.2.1.

7.8 Nominal discharge current (I )

n

The MOV shall be subjected to 15 applications of impulse currents of 8/20 wave with the peak

specified by the manufacturer, and tested according to 9.3.

7.9 Endurance

The MOV shall be subjected to an endurance test under the conditions of specified

temperature and maximum continuous voltage for 1 000 h and tested according to 8.4. If all

concerned parties agree, the optional accelerated endurance screening test in Annex C may

be used.

7.10 Limited current temporary overvoltage

This is an AC step stress test to evaluate thermally protected MOVs for potential ignition

sources when the thermally protected MOV is subjected to AC overload (see 9.4).

– 16 – IEC 61643-331:2020 © IEC 2020

8 Standard design test criteria

8.1 General

The design tests described in 8.3 provide standardized methods for measuring specified

parameters of an MOV for the purpose of component selection. These parameters may vary

from MOV to MOV, making it necessary to measure all components. MOVs are bi-directional

and they shall be tested with both positive and negative voltages.

8.2 Ratings

8.2.1 Single-impulse maximum current (I )

TM

In the absence of specified requirements, the test current shall be an 8/20 waveshape. An

oscilloscope is used to record the clamping voltage (V ) of the CUT. Rated voltage, V

c M(AC)

or V as appropriate, shall be applied continuously for a minimum of 2 s before impulse

M(DC)

and a minimum of 30 s after the impulse.

Measurement techniques for high-current and high-frequency testing should be observed,

such as four-point Kelvin contact, differential oscilloscope, short leads, etc.

NOTE See Figure 4.

Components

C Energy storage capacitor R3 Impulse-shaping resistor

L Impulse-shaping inductor R2 Impulse-shaping and current-limiting resistor

MOV Component under test (MOV) R4 Current-sensing resistor (coaxial).

Alternatively, a current transformer probe of

adequate rating may be used

Oscilloscope for observing current and

OSC S1 Charging switch

voltage

PS DC charging power supply S2 Discharge switch

R1 Charging resistor

NOTE Caution: The circuit shown is for description only.

Figure 4 – Test circuit for single-impulse maximum current

8.2.2 Next impulse

The next impulse shall be applied after the CUT has returned to thermal equilibrium (for

example, the initial conditions before the impulses were applied). In the absence of specified

requirements, the test current shall be an 8/20 waveshape.

NOTE 1 MOVs intended for service in IEC 61643-11 surge protective devices require special class I, class II and

class III testing procedures and waveforms. These tests are covered in Annex A.

NOTE 2 See Figure 4.

8.2.3 Maximum Continuous voltage (V )

M

This rating is verified in 8.3.2.

8.3 Electrical Characteristics

8.3.1 Clamping voltage (V )

C

Clamping voltage shall be measured during the single impulse current (I ), clause 8.2.1. The

P

peak clamping voltage and peak test current are not necessarily coincident in time. In the

absence of specified requirements, the test current shall be an 8/20 waveshape.

NOTE 1 MOVs intended for service in IEC 61643-11 surge protective devices require special class II or class III

testing procedures and waveforms. These tests are covered in Annex A.

NOTE 2 See Figure 4.

8.3.2 Standby current (I )

D

In this measurement, voltage should be maintained at a steady value regardless of the load

impedance. A power supply of constant voltage source shall be used. It is not recommended

that the voltmeter be connected across the CUT due to the current bleeding through the

meter. The standby current reading would be inaccurate. The power supply PS should be set

to the specified Maximum Continuous Voltage V of the MOV under test.

M(DC)

NOTE 1 See Figure 5.

NOTE 2 The test duration of standby current depends mainly on the electrode area of the MOV; the larger the

electrode area, the longer the test duration needs to be if other conditions remain the same. The test duration can

be sufficiently long for the standby current to stabilize.

Components

A Current meter

PS Power Supply (shall be a DC voltage

source)

V Voltmeter

Figure 5 – Test circuit for measuring standby current

8.3.3 Varistor voltage (V )

V

In this measurement, current should be maintained at a steady value regardless of the load

impedance. A power supply of constant current source should be used. The time of applied

test current (I ) shall be between 20 ms to 100 ms. Unless otherwise specified, the test

N

current shall be 1 mA DC.

NOTE 1 See Figure 6.

NOTE 2 The test duration cannot be too long in order to avoid a thermal effect when the temperature of the MOV

rises appreciably during the measurement. However, for very large varistor sizes, it may be necessary to go above

100 ms.

– 18 – IEC 61643-331:2020 © IEC 2020

Components

A Current meter

P Bipolar pulsed current source

V Voltmeter

Figure 6 – Test circuit for measuring varistor voltage (V )

V

8.3.4 Capacitance (C )

V

This should be measured at a specified sinusoidal frequency and voltage at a specified

temperature. Unless otherwise specified, a signal of <1 V RMS of 1 kHz at 25 C without DC

°

bias is recommended.

NOTE If the capacitance test is performed on MOV samples which have undergone other tests previously, then a

waiting period of 48 h may be observed.

8.3.5 Rated energy

The compliance of the rated energy specified in the MOV datasheet shall be verified with the

current pulse whose waveform is prescribed in the MOV datasheet. Unless otherwise

specified, the current pulse shall be of 2 ms rectangular waveform or 10/1 000 waveform.

8.4 Varistor Rating Assurance Testing

The purpose of this testing is to verify that the Maximum Continuous Operating Voltage V

M

rating of the varistor is appropriately specified.

The varistor voltage V and the standby current of the samples are measured and recorded

V

prior to this test. The varistors that are to be tested shall be connected as in Figure 7.

The MOV is heated to its maximum operating normal temperature rating for the duration of

1 000 h.

The test voltage shall be V for AC and/or V for DC. The test should be performed in

M(AC) M(DC)

a chamber, at a temperature variation within 5 K. When the test is finished, the samples

should be cooled down for not less than 1 h nor more than 2 h. The varistor voltage, V , and

V

the standby current I should be within the specified limits when measured at ambient

DC

temperature.

This endurance test may be increased to the maximum operating extended temperature rating

for the duration of 1 000 h for more robust MOVs.

Figure 7 – Varistor rating assurance test setup

8.5 ESD test

Initial measurements: Varistor voltage and clamping voltage for SMD type varistor only.

The samples shall be mounted on a circuit board with a large ground plane. The circuit board

shall have a convenient discharge point for the ESD gun in contact mode and the SMD shall

be mounted between the ESD gun discharge point and the board ground. The circuit board is

then placed at the center of a minimum 0,5 m metal ground plane as described in ANSI/ESD

SP5.6. The ground plane of the circuit board and the metallic ground plane shall make good

electrical contact

...

IEC 61643-331 ®

Edition 3.0 2020-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Components for low-voltage surge protective devices protection –

Part 331: Performance requirements and test methods for metal oxide varistors

(MOV)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61643-331 ®

Edition 3.0 2020-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Components for low-voltage surge protective devices protection –

Part 331: Performance requirements and test methods for metal oxide varistors

(MOV)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 31.040.20 ISBN 978-2-8322-8023-2

– 2 – IEC 61643-331:2020 RLV © IEC 2020

CONTENTS

FOREWORD . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviated terms . 8

3.1 Terms and definitions . 8

3.1.1 Ratings . 8

3.1.2 Characteristics. 9

3.2 Symbols and abbreviated terms used in this document . 11

3.2.1 Symbols . 11

3.2.2 Abbreviated terms . 11

4 Service conditions . 12

4.1 Operating and storage temperature ranges . 12

4.2 Altitude or atmospheric pressure range . 12

4.3 Relative Humidity . 12

5 Mechanical requirements and materials . 12

5.1 Robustness of terminations . 12

5.2 Solderability . 12

5.3 Marking . 12

6 General . 13

6.1 Failure rates . 13

6.2 Test standard atmospheric conditions . 13

7 Electrical requirements . 13

7.1 Nominal Varistor voltage (V ) . 13

V

7.2 Maximum AC (DC) continuous operating voltage (V / V ) . 13

M(AC) M(DC)

7.3 Standby current I (I ) . 13

DC

D

7.4 Capacitance (C ) . 13

V

7.5 Clamping voltage (V ) . 13

C

7.6 Electrostatic discharge (ESD) (for SMD type MOV only). 15

7.7 Rated impulse energy (W ) . 15

TM

7.8 Nominal discharge current (I ) . 15

n

7.9 Endurance . 15

7.10 Limited current temporary overvoltage . 16

8 Standard design test criteria . 16

8.1 General . 16

8.2 Ratings . 16

8.2.1 Single-impulse maximum current (I ) . 16

TM

8.2.2 Next impulse . 17

8.2.3 Maximum Continuous rated voltage (V ) . 17

M

8.3 Electrical Characteristics . 17

8.3.1 Clamping voltage (V ) . 17

C

8.3.2 Standby current (I ) . 17

D

8.3.3 Nominal Varistor voltage (V ) (V ) . 18

N V

8.3.4 Capacitance (C ) . 18

V

8.3.5 Rated energy . 18

8.4 Endurance Varistor Rating Assurance Testing . 18

8.5 ESD test Method . 19

9 Nominal discharge current and limited current temporary overvoltage. 19

9.1 Thermally protected varistors – Sequence of tests . 19

9.2 Temperature and humidity cycle conditioning . 20

9.3 Nominal discharge current I(n) (I ) test description . 20

n

9.3.1 General . 20

9.3.2 Pass/fail criteria . 22

9.4 Limited current temporary overvoltage test description and procedure for

thermally protected varistors . 22

9.4.1 General . 22

9.4.2 Sample preparation . 23

9.4.3 Test conditions . 23

9.4.4 Pass/fail criteria . 23

9.5 Dielectric testing . 24

9.5.1 Test conditions for thermally protected MOV . 24

9.5.2 Setup from foil to leads . 25

9.5.3 Pass criteria . 25

9.6 Insulation Resistance . 25

Annex A (informative) MOV testing according to the IEC 61643-11:2011 Surge

protective devices for the Class I, II and III . 26

A.1 General . 26

A.2 MOV selection . 26

A.3 Cross reference list of abbreviations, descriptions and definitions . 26

A.4 Operating duty test . 27

A.4.1 General . 27

A.4.2 Class I and II operating duty tests (8.3.4.3) . 32

A.4.3 Additional duty test for test class I . 33

A.4.4 Class III operating duty tests . 33

A.4.5 Pass criteria for all operating duty tests and for the additional duty test

for test class I . 34

A.4.6 Preferred parameters of impulse discharge current I used for Class I

imp

additional duty tests . 34

A.4.7 Preferred values of impulse discharge current I used for Class I and

n

Class II residual voltage and operating duty tests . 35

A.4.8 Preferred values of combination generator waveshape used for Class III

tests . 36

Annex B (informative) IEC 61051 Varistors for use in electronic equipment . 38

Annex C (informative normative) Accelerated Endurance screening test . 39

C.1 Accelerated endurance screening test . 39

C.2 Preparation of sample . 39

C.3 Test conditions . 39

C.4 Refer to test circuit diagram as shown in Figure C.1. . 39

C.5 Pass criteria . 40

Annex D (informative) Proposed test method for determination of MTTF – Mean time

to failure (MTTF) . 41

D.1 Sampling plans . 41

D.2 Total test hours . 41

D.3 Samples. 41

D.4 Test set-up . 42

D.5 Intermediate measurements . 42

– 4 – IEC 61643-331:2020 RLV © IEC 2020

D.6 Failure criteria . 42

D.7 Acceptance criteria . 42

Bibliography .

Figure 1 – V-I characteristic of an MOV . 10

Figure 2 – Symbol for MOV . 11

Figure 3 – Symbol for thermally protected MOV . 11

Figure 4 – Test circuit for single-impulse maximum current . 16

Figure 5 – Test circuit for measuring leakage standby current . 17

Figure 6 – Test circuit for measuring nominal varistor voltage (V ) (V ) . 18

N V

Figure 7 – Varistor rating assurance test setup . 18

Figure 8 – Nominal discharge current test flowchart . 21

Figure 9 – Sequence of the I Test . 22

n

Figure 10 – Temporary overvoltage limited current test procedure flowchart . 24

Figure A.1 – Flow chart of the operating duty test . 28

Figure A.2 – Test set-up for operating duty test . 29

Figure A.3 – Flow chart of testing to determine the measured limiting voltage . 31

Figure A.4 – Operating duty test timing diagram for test classes I and II . 32

Figure A.5 – Additional duty test timing diagram for test class I . 33

Figure A.6 – Operating duty test timing diagram for test class III . 34

Figure C.1 – Circuit of accelerated ageing test . 39

Figure D.1 – Test Circuit of MTTF . 42

Table 1 – Typical Voltage ratings for disc types . 14

Table 2 – Typical Voltage Ratings for SMD types . 14

Table 3 – Test voltages for dielectric strength Between Test voltage . 25

Table A.1 – Comparison of IEC 61643-11 and IEC 61643-311 Abbreviations,

descriptions and definitions . 27

Table A.2 – Preferred parameters for class I test . 34

Table A.3 – Preferred values for class I and class II tests . 35

Table A.4 – Preferred values for class III tests . 36

Table C.1 – Current in V measurement . 39

T

Table D.1 – Sampling plans . 41

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMPONENTS FOR LOW-VOLTAGE SURGE PROTECTIVE DEVICES

PROTECTION –

Part 331: Performance requirements and test methods

for metal oxide varistors (MOV)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

– 6 – IEC 61643-331:2020 RLV © IEC 2020

International Standard IEC 61643-331 has been prepared by subcommittee 37B: Components

for low-voltage surge protection, of IEC technical committee 37: Surge arresters.

This third edition cancels and replaces the second edition published in 2017. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) a Varistor MCOV rating assurance test;

b) an energy rating test (2ms);

c) revised Dielectric strength and insulation resistance tests.

The text of this International Standard is based on the following documents:

FDIS Report on voting

37B/211/FDIS 37B/214/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of IEC 61643 series, under the general title Components for low-voltage

surge protective devices, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

COMPONENTS FOR LOW-VOLTAGE SURGE PROTECTIVE DEVICES

PROTECTION –

Part 331: Performance requirements and test methods

for metal oxide varistors (MOV)

1 Scope

This part of IEC 61643 is a test specification for metal oxide varistors (MOV), which are used

for applications up to 1 000 V AC or 1 500 V DC in power lines, or telecommunication, or

signalling circuits. They are designed to protect apparatus or personnel, or both, from high

transient voltages.

This document applies to MOVs having two electrodes and hybrid overvoltage surge

protection components. This document also does not apply to mountings and their effect on

the MOV’s characteristics. Characteristics given apply solely to the MOV mounted only in the

ways described for the tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60068-1:2013, Environmental testing – Part 1: General and guidance

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 60068-2-14:2009, Environmental testing – Part 2-14: Tests – Test N: Change of

temperature

IEC 60068-2-20:2008, Environmental testing – Part 2-20: Tests – Test T: Test methods for

solderability and resistance to soldering heat of devices with leads

IEC 60068-2-21:2006, Environmental testing – Part 2-21: Tests – Test U: Robustness of

terminations and integral mounting devices

IEC 60068-2-27:2008, Environmental testing – Part 2-27: Tests – Test Ea and guidance:

Shock

IEC 60068-2-52:2017 Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic

(sodium chloride solution)

IEC 60068-2-78:2012, Environmental testing – Part 2-78: Tests – Test Cab: Damp heat,

steady state

IEC 61643-11:2011, Low-voltage surge protective devices – Part 11: Surge protective devices

connected to low-voltage power systems – Requirements and test methods

IEC 61000-4-2:2008, Electromagnetic compatibility (EMC) – Part 4-2: Testing and

measurement techniques – Electrostatic discharge immunity test

– 8 – IEC 61643-331:2020 RLV © IEC 2020

3 Terms, definitions, symbols and abbreviated terms

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 Terms and definitions

3.1.1 Ratings

3.1.1.1

absolute maximum ratings

limiting values of operating and environmental conditions applicable to a component, device,

equipment or machine as defined by its published specification data, which should not be

exceeded under the worst possible conditions

Note 1 to entry: A limiting condition may be either a maximum or a minimum or both.

[SOURCE: MODIFIED: IEC 62240-1:2013, 3.1.1, modified ("any semiconductor device of a

specific type" replaced by "a component, device, equipment or machine", addition of Note 1 to

entry)]

3.1.1.2

single-impulse [transient] maximum current

I

TM

rated maximum value of current which may be applied for a single impulse of specified

waveform

Note 1 to entry: For power distribution surge protective devices ( SPDs), IEC 61643-11, Maximum Discharge

Current I is used.

MAX

3.1.1.3

nominal discharge current

I

n

crest value of the current through the MOV having a current waveshape of 8/20

3.1.1.4

impulse life characteristic

graphical representation between impulse current peak (I), equivalent rectangular pulse width

(T), and impulse numbers (n) for which the varistor MOV can withstand

Note 1 to entry: Unless otherwise specified, the range of T shall be 20 µs to 10 ms, the range of n shall be 10 ,

5 4 3 2 1 0

10 ,10 , 10 , 10 , 10 and 10 temperature derating curve.

3.1.1.5

temperature derating curve

graphical representation of parameter derating against temperature

Note 1 to entry: Typical parameters are rated voltage, impulse current, energy and average power dissipation.

3.1.1.6

single-pulse [transient] maximum energy

W

TM

rated maximum value which may be absorbed for a single pulse of a specified waveform

Note 1 to entry: Unless otherwise specified, 2 ms rectangular pulse is used (IEC 60060).

3.1.1.7

maximum continuous voltage

V

M

voltage that may be applied continuously at a specified temperature

Note 1 to entry: May also be called U or maximum continuous operating voltage (MCOV).

C

Note 2 to entry: See Figure 1.

3.1.1.8

maximum continuous AC voltage

V

M(AC)

value of RMS power frequency voltage (less than 5 % total harmonic distortion) that may be

applied continuously at a specified temperature

3.1.1.9

maximum continuous DC voltage

V

M(DC)

DC voltage that may be applied continuously at a specified temperature

3.1.1.10

mean time to failure

MTTF

basic measure of reliability for non-repairable items, the total number of life units of an item

divided by the total number of failures within that population ,during a particular measurement

interval under stated conditions

3.1.2 Characteristics

3.1.2.1

characteristic

inherent and measurable property properties of an MOV

3.1.2.2

standby current

I

D

current passing through MOV at maximum continuous voltage V

M

Note 1 to entry: The current passing through the MOV at less than V is called leakage current.

M

3.1.2.3

nominal varistor voltage

V V

N V

voltage across the MOV measured at a specified current (typically 1 mA) for a specific

duration

Note 1 to entry: See Figure 1.

3.1.2.4

varistor test current

I

N

test current (typically 1 mA) to determine the varistor voltage V

V

Note 1 to entry: See Figure 1.

3.1.2.5

clamping voltage

V

C

peak voltage across the MOV measured under conditions of a specified peak pulse current

) and specified waveform

(I

P

– 10 – IEC 61643-331:2020 RLV © IEC 2020

Note 1 to entry: See Figure 1.

Note 2 to entry: Unless otherwise specified, a typical value of this parameter is measured with a pulsed current

8/20 waveform.

Note 3 to entry: Clamping voltage, V , is referred to as measured limiting voltage in IEC 61643-11.

C

Figure 1 – V-I characteristic of an MOV

3.1.2.6

capacitance

C

V

capacitance across the MOV measured at a specified frequency, voltage and time

3.1.2.7

metal oxide varistor (MOV)

component whose conductance during static state, at a given temperature, increases rapidly

with increasing voltage

Note 1 to entry: This is also known as a voltage dependant resistor (VDR).

3.1.2.8

thermally protected metal oxide varistor

varistor which includes a series non-resettable element that will disconnect the MOV when it

is overheated due to excessive dissipation

3.1.2.9

DC standby current

I

DC

current passing through MOV at maximum continuous voltage DC V

M(DC)

3.2 Symbols and abbreviated terms used in this document

3.2.1 Symbols

Figure 2 and Figure 3 represent the IEC 60617 symbols for MOV and thermally protected

MOV, respectively.

Figure 2 – Symbol for MOV

Figure 3 – Symbol for thermally protected MOV

NOTE IEC 60027 recommends the letters V and v only as reserve symbols for voltage; however, in the field of

MOV components, these are so widely used that in this document they are preferred to U and u.

3.2.2 Abbreviated terms

CUT Component Under Test

DUT Device Under Test

ESD Electrostatic Discharge

MCOV Maximum Continuous Operating Voltage

MOV Metal Oxide Varistor

MTTF Mean Time To Failure

SMD Surface Mount Device

SPD Surge Protective Device

VDR Voltage Dependent Resistor

– 12 – IEC 61643-331:2020 RLV © IEC 2020

4 Service conditions

4.1 Operating and storage temperature ranges

Operating range

– Normal: –5 °C to +55 °C

– Extended: −40 °C to +85 °C

Storage range MOV

– Normal: –40 °C to +85 °C

– Extended: −40 °C to +125 °C

Storage range Thermally protected MOV

– Normal: –40 °C to +85 °C

– Extended: −40 °C to +85 °C

NOTE Temperature range (operating or storage) could be different than the normal or extended values shown

above.

4.2 Altitude or atmospheric pressure range

The altitude of air pressure is within 80 kPa to 106 kPa (refer to IEC 60068-1).

4.3 Relative Humidity

Normal range: 5 % to 95 % at 25 °C (refer to IEC 60068-1 and IEC 60068-2-78).

5 Mechanical requirements and materials

5.1 Robustness of terminations

If applicable, the user shall specify a suitable test from IEC 60068-2-21.

5.2 Solderability

Solder terminations shall meet the requirements of IEC 60068-2-20, test Ta, method 1.

5.3 Marking

Legible and permanent marking shall be applied to the MOV as necessary to ensure that the

user can determine the following information by inspection.

Each MOV shall be marked with the following information:

– Date of manufacture or batch number

– Manufacturer name or trademark

– part number

– safety approval markings

NOTE 1 The necessary information can also be coded.

NOTE 2 When the space is not sufficient for printing this data, it should be provided in the technical

documentation after agreement between the manufacturer and the purchaser it could be provided on the smallest

unit container in which the product is packaged or as agreed upon between the manufacturer and the purchaser.

6 General

6.1 Failure rates

Sampling size, electrical characteristics to be tested, etc. should be covered by the quality

assurance requirements, which are not covered by this document.

6.2 Test standard atmospheric conditions

The following tests shall be performed on the MOVs as required by the application. Unless

otherwise specified, ambient test conditions shall be as follows:

• Temperature: 15 °C to 35 °C;

• Relative humidity 25 % to 75 %;

MOVs of various types should have the characteristics listed in Table 1 when tested in

accordance with Clause 8.

7 Electrical requirements

7.1 Nominal Varistor voltage (V )

V

When tested according to 8.3.3, varistor voltage should be within the specified manufacturer’s

specified limits. Table 1 shows the nominal varistor voltages of high voltage and low voltage

disc types that are commonly used; their allowable tolerances are ±10 %.

The nominal varistor voltages and tolerances listed in Table 2 are typical for surface mount

Device ( SMD) types.

7.2 Maximum AC (DC) continuous operating voltage (V / V )

M(AC) M(DC)

Unless otherwise specified, MOVs shall have a maximum AC (DC) continuous voltage

V / (V ) as given in Table 1 and Table 2, the conformity shall be evaluated according

M(AC) M(DC)

to 8.2.3.

NOTE Maximum AC (DC) continuous operating voltage V / (V ) is sometimes referred to as U .

M(AC) M(DC) C

7.3 Standby current I (I )

DC

D

When tested according to 8.3.2, the standby current DC I under maximum continuous DC

DC

voltage V V , shall be less than the maximum value specified by the manufacturer and

DC M(DC)

there shall be no upward drifting during the application of the test voltage V V .

DC M(DC)

7.4 Capacitance (C )

V

When tested according to 8.3.4, the measured value of capacitance shall not exceed the

value specified by the manufacturer.

7.5 Clamping voltage (V )

C

The measured clamping voltage (see 8.3.1) at a specified impulse current shall be no more

than the specified values or the values indicated in Table 1 and 2. Unless otherwise specified,

an 8/20 impulse current having the peak as specified shall be used.

NOTE Clamping voltage V is referred to as Measured Limiting Voltage in IEC 61643-11.

C

– 14 – IEC 61643-331:2020 RLV © IEC 2020

Table 1 – Typical Voltage ratings for disc types

Nominal Max. continuous voltage (V ) Clamping voltage (NOTE), V (V)

M C

Varistor

AC (RMS)

voltage V V

N V DC V V 8/20, V

DC M(DC) C

V /VM(DC

(V) )

M(AC)

18 11 14 36

22 14 18 43

27 17 22 53

33 20 26 65

39 25 31 77

47 30 38 93

56 35 45 110

68 40 56 135

82 50 65 135

100 60 85 165

120 75 100 200

150 95 125 250

180 115 150 300

200 130 170 340

220 140 180 360

240 150 200 395

275 175 225 455

300 195 250 505

330 210 270 545

360 230 300 595

390 250 320 650

430 275 350 710

470 300 385 775

510 320 410 845

560 350 450 930

620 385 505 1 025

680 420 560 1 120

715 440 585 1 180

750 460 615 1 240

820 510 670 1 355

910 550 745 1 500

1 000 625 825 1 650

1 100 680 895 1 815

1 200 750 970 2 000

1 600 1 000 1 280 2 650

1 800 1 100 1 465 2 970

NOTE Clamping voltage V is referred to as measured limiting voltage in IEC 61643-11.

C

During the tests, there shall be no flashover or puncture of the samples, the MOV clamping

voltage (V ) of the samples shall be tested prior to and after the tests, the change of which

C

shall not exceed ±10 %, when tested according to 8.3.31.

7.6 Electrostatic discharge (ESD) (for SMD type MOV only)

The SMD MOVs shall be subjected to electrostatic discharge (ESD) contact discharge test of

8 kV for 10 applications with an interval of 1 s according to 8.5.

During the tests, there shall be no evidence of flashover or puncture of the samples, and the

Varistor voltage of the samples shall be tested prior to and after the tests, the change of

which shall not exceed ±30 %.

The requirement of Table 2 is only applicable for surface mount devices (for SMD varistors

ONLY). SMD MOV shall be tested as in 8.5.

Table 2 – Typical Voltage Ratings for SMD types

Maximum continuous voltage (V )

Nominal Varistor

M

Voltage V V (V) AC (RMS) V DC V

N V AC DC

5,6 ±20 % 2,5 4

6,8±20 % 3,5 4,5

8,2 ±20 % 4 5,5

10 ± 20 % 5 7

12± 20 % 6 8,5

15± 20 % 7,5 10,5

18 ± 20 % 9 13

22 ± 10 % 14 18

27 ± 10 % 17 22

33 ± 10 % 20 26

39 ± 10 % 25 31

47 ± 10 % 30 38

56 ± 10 % 35 45

68 ± 10 % 40 56

82 ± 10 % 50 65

NOTE Clamping voltage V is referred to as Measured Limiting Voltage in

C

IEC 61643-11.

7.7 Rated impulse energy (W )

TM

The MOV shall be capable of absorbing the impulse energy specified by the manufacturer

when subjected to one impulse current of 2 ms rectangular pulse or 10/1000 wave or 8/20 and

tested according to 8.2.1.

7.8 Nominal discharge current (I )

n

The MOV shall be subjected to 15 applications of impulse currents of 8/20 wave with the peak

specified by the manufacturer, and tested according to 9.3.

7.9 Endurance

The MOV used for power supply circuitry shall be subjected to an endurance test under the

conditions of maximum operating specified temperature and maximum continuous operating

voltage for 1 000 h and tested according to 8.4. If all concerned parties agree, the optional

accelerated endurance screening test in Annex C may be used.

– 16 – IEC 61643-331:2020 RLV © IEC 2020

7.10 Limited current temporary overvoltage