IEC 61851-25:2020

(Main)Electric vehicle conductive charging system - Part 25: DC EV supply equipment where protection relies on electrical separation

Electric vehicle conductive charging system - Part 25: DC EV supply equipment where protection relies on electrical separation

IEC 61851-25:2020 applies to the DC EV supply equipment for charging electric road vehicles with a rated supply voltage of up to 480 V AC or up to 600 V DC, with rated output voltage not exceeding 120 V DC and output currents not exceeding 100 A DC.

This document provides the requirements for the DC EV supply equipment where the secondary circuit is protected from the primary circuit by electrical separation.

Requirements for bi-directional power flow are not covered in this document.

This document also provides the requirements for the control and the communication between DC EV supply equipment and an EV.

This document also applies to DC EV supply equipment supplied from on-site storage systems.

The aspects covered in this document include:

• characteristics and operating conditions of the DC EV supply equipment;

• specification of the connection between the DC EV supply equipment and the EV;

• requirements for electrical safety for the DC EV supply equipment.

Additional requirements can apply to equipment designed for specific environments or conditions, for example:

• DC EV supply equipment located in hazardous areas where flammable gas or vapour and/or combustible materials, fuels or other combustible, or explosive materials are present;

• DC EV supply equipment designed to be installed at an altitude of more than 2 000 m;

• DC EV supply equipment intended to be used on-board ships.

Requirements for electrical devices and components used in DC EV supply equipment are not included in this document and are covered by their specific product standards.

This document does not apply to:

• safety aspects related to maintenance;

• charging of trolley buses, rail vehicles, industrial trucks and vehicles designed primarily for use off-road;

• equipment on the EV;

• EMC requirements for equipment on the EV while connected, which are covered in IEC 61851-21-1;

• charging the RESS off-board the EV.

Système de charge par conduction pour véhicules électriques - Partie 25: Système d'alimentation en courant continu pour véhicules électriques dont la protection s'appuie sur la séparation électrique

L'IEC 61581-25:2020 s'applique aux systèmes d'alimentation en courant continu pour VE pour la charge des véhicules électriques destinés à circuler sur la voie publique, avec une tension d'alimentation assignée maximale de 480 V en courant alternatif ou de 600 V en courant continu, une tension de sortie assignée maximale de 120 V en courant continu et des courants de sortie continus maximaux de 100 A.

Le présent document fournit les exigences relatives aux systèmes d'alimentation en courant continu pour VE dont le circuit secondaire est protégé du circuit primaire par une séparation électrique.

Les exigences relatives au flux de puissance bidirectionnel ne sont pas traitées dans le présent document.

Le présent document fournit également les exigences relatives à la commande et à la communication entre un système d'alimentation en courant continu pour VE et un VE.

Le présent document s'applique également aux systèmes d'alimentation en courant continu pour VE alimentés par des systèmes de stockage sur site.

Les aspects couverts par le présent document incluent:

• les caractéristiques et les conditions de fonctionnement du système d'alimentation en courant continu pour VE;

• la spécification de la connexion entre le système d'alimentation en courant continu pour VE et le VE;

• les exigences relatives à la sécurité électrique du système d'alimentation en courant continu pour VE.

Des exigences supplémentaires peuvent s'appliquer au matériel conçu pour des environnements ou conditions spécifiques, par exemple:

• les systèmes d'alimentation en courant continu pour VE situés dans des zones dangereuses contenant du gaz ou de la vapeur inflammable et/ou des matières combustibles, des carburants ou d'autres combustibles, ou des matières explosives;

• les systèmes d'alimentation en courant continu pour VE conçus pour être installés à au moins 2 000 m d'altitude;

• les systèmes d'alimentation en courant continu pour VE destinés à être utilisés à bord de navires.

Les exigences relatives aux appareils et composants électriques utilisés dans le système d'alimentation en courant continu pour VE ne sont pas incluses dans le présent document et sont couvertes par leurs normes de produits spécifiques.

Le présent document ne s'applique pas:

• aux aspects de sécurité relatifs à la maintenance;

• à la charge des trolleybus, des véhicules ferroviaires, des chariots de manutention et des véhicules principalement tout-terrain;

• au matériel installé sur le VE;

• aux exigences CEM du matériel installé sur le VE connecté, qui sont couvertes par l'IEC 61851-21-1;

• à la charge du RESS hors du VE.

General Information

- Status

- Published

- Publication Date

- 03-Dec-2020

- Technical Committee

- TC 69 - Electrical power/energy transfer systems for electrically propelled road vehicles and industrial trucks

- Drafting Committee

- PT 61851-25 - TC 69/PT 61851-25

- Current Stage

- PPUB - Publication issued

- Start Date

- 04-Dec-2020

- Completion Date

- 02-Jan-2021

Overview

IEC 61851-25:2020 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies the requirements for direct current (DC) electric vehicle supply equipment (EVSE) where protection relies on electrical separation. This standard applies specifically to DC charging systems designed to charge electric road vehicles with rated supply voltages up to 480 V AC or 600 V DC and rated output voltages not exceeding 120 V DC, with maximum output currents up to 100 A DC.

This document provides essential guidelines for the design, operation, and safety of DC EV supply equipment that utilizes electrical separation to protect the secondary circuit from the primary power source. It also covers the control and communication protocols between the DC EVSE and the electric vehicle (EV). Notably, requirements for bi-directional power flow and charging of specialized vehicles like trolley buses or off-road vehicles are excluded from this standard.

Key Topics

Electrical Separation for Safety: The core aspect of IEC 61851-25 is ensuring that the secondary circuit (connected to the EV) is electrically isolated from the primary supply circuit. This separation enhances user and equipment safety by minimizing risk of electric shock.

Operating Conditions & Characteristics: Specifies the rated supply voltages, output current limits, and electrical characteristics necessary for the reliable and safe functioning of DC EVSE under different operational environments.

Control and Communication Requirements: Defines the communication interface and protocols required between the EV supply equipment and the electric vehicle to manage charging operations safely and effectively.

Protection Against Electric Shock: Outlines measures for preventing electric shock incidents, including design, construction, and testing of the supply equipment, in compliance with IEC 61140.

Environmental Considerations: Includes additional requirements for DC EVSE operating in special conditions such as hazardous areas with combustible gases, high-altitude locations above 2000 meters, and onboard ships, ensuring versatility and safety in diverse settings.

Construction and Testing: Establishes structural design requirements and verification tests for overload, short-circuit protection, automatic reclosing, marking, instructions, and emergency disconnection features.

Exclusions and Limitations: Clarifies that the standard does not cover electrical devices and components within the EVSE (subject to their own product standards), safety aspects related to maintenance, electromagnetic compatibility (EMC) for equipment on the EV, or off-board energy storage systems.

Applications

IEC 61851-25:2020 is crucial for manufacturers, engineers, and operators involved in:

- Designing DC charging stations for electric road vehicles where electrical separation provides protection.

- Ensuring compliance with international safety and interoperability standards for DC EV supply equipment up to specified voltage and current ratings.

- Deploying DC EVSE in various challenging environments such as industrial sites with hazardous materials, high-altitude areas, and maritime vessels.

- Developing control and communication systems that interface securely and reliably between charging equipment and electric vehicles.

- Implementing safety measures that prevent electric shock and other electrical hazards during EV charging operations.

This standard supports the global growth of electric vehicle infrastructure by promoting safe, reliable, and standardized DC conductive charging solutions.

Related Standards

- IEC 61851-1:2017: General requirements for electric vehicle conductive charging systems, which IEC 61851-25 supplements by focusing on electrical separation for DC supply equipment.

- IEC 61140: Protection against electric shock – Common aspects for installation and equipment, providing foundational principles for electrical separation used in this part.

- IEC 61851-21-1: Electromagnetic compatibility (EMC) requirements for equipment on the EV while connected, referenced as complementary but excluded from this document.

- Other parts of IEC 61851 series addressing AC charging modes, communication protocols, and safety requirements for a comprehensive framework of EV conductive charging.

Keywords: IEC 61851-25, DC EV supply equipment, electric vehicle charging standard, electrical separation, electric vehicle conductive charging, DC charging safety, electric vehicle supply equipment, EVSE standards, electric shock protection, DC charging communication, hazardous environment charging.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

IEC 61851-25:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric vehicle conductive charging system - Part 25: DC EV supply equipment where protection relies on electrical separation". This standard covers: IEC 61851-25:2020 applies to the DC EV supply equipment for charging electric road vehicles with a rated supply voltage of up to 480 V AC or up to 600 V DC, with rated output voltage not exceeding 120 V DC and output currents not exceeding 100 A DC. This document provides the requirements for the DC EV supply equipment where the secondary circuit is protected from the primary circuit by electrical separation. Requirements for bi-directional power flow are not covered in this document. This document also provides the requirements for the control and the communication between DC EV supply equipment and an EV. This document also applies to DC EV supply equipment supplied from on-site storage systems. The aspects covered in this document include: • characteristics and operating conditions of the DC EV supply equipment; • specification of the connection between the DC EV supply equipment and the EV; • requirements for electrical safety for the DC EV supply equipment. Additional requirements can apply to equipment designed for specific environments or conditions, for example: • DC EV supply equipment located in hazardous areas where flammable gas or vapour and/or combustible materials, fuels or other combustible, or explosive materials are present; • DC EV supply equipment designed to be installed at an altitude of more than 2 000 m; • DC EV supply equipment intended to be used on-board ships. Requirements for electrical devices and components used in DC EV supply equipment are not included in this document and are covered by their specific product standards. This document does not apply to: • safety aspects related to maintenance; • charging of trolley buses, rail vehicles, industrial trucks and vehicles designed primarily for use off-road; • equipment on the EV; • EMC requirements for equipment on the EV while connected, which are covered in IEC 61851-21-1; • charging the RESS off-board the EV.

IEC 61851-25:2020 applies to the DC EV supply equipment for charging electric road vehicles with a rated supply voltage of up to 480 V AC or up to 600 V DC, with rated output voltage not exceeding 120 V DC and output currents not exceeding 100 A DC. This document provides the requirements for the DC EV supply equipment where the secondary circuit is protected from the primary circuit by electrical separation. Requirements for bi-directional power flow are not covered in this document. This document also provides the requirements for the control and the communication between DC EV supply equipment and an EV. This document also applies to DC EV supply equipment supplied from on-site storage systems. The aspects covered in this document include: • characteristics and operating conditions of the DC EV supply equipment; • specification of the connection between the DC EV supply equipment and the EV; • requirements for electrical safety for the DC EV supply equipment. Additional requirements can apply to equipment designed for specific environments or conditions, for example: • DC EV supply equipment located in hazardous areas where flammable gas or vapour and/or combustible materials, fuels or other combustible, or explosive materials are present; • DC EV supply equipment designed to be installed at an altitude of more than 2 000 m; • DC EV supply equipment intended to be used on-board ships. Requirements for electrical devices and components used in DC EV supply equipment are not included in this document and are covered by their specific product standards. This document does not apply to: • safety aspects related to maintenance; • charging of trolley buses, rail vehicles, industrial trucks and vehicles designed primarily for use off-road; • equipment on the EV; • EMC requirements for equipment on the EV while connected, which are covered in IEC 61851-21-1; • charging the RESS off-board the EV.

IEC 61851-25:2020 is classified under the following ICS (International Classification for Standards) categories: 43.120 - Electric road vehicles. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61851-25:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61851-25 ®

Edition 1.0 2020-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric vehicle conductive charging system –

Part 25: DC EV supply equipment where protection relies on electrical

separation

Systeme de charge par conduction pour vehicules electriques –

Partie 25: Système d'alimentation en courant continu pour véhicules électriques

dont la protection s'appuie sur la séparation électrique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61851-25 ®

Edition 1.0 2020-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric vehicle conductive charging system –

Part 25: DC EV supply equipment where protection relies on electrical

separation

Systeme de charge par conduction pour vehicules electriques –

Partie 25: Système d'alimentation en courant continu pour véhicules électriques

dont la protection s'appuie sur la séparation électrique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 43.120 ISBN 978-2-8322-9122-1

– 2 – IEC 61851-25:2020 © IEC 2020

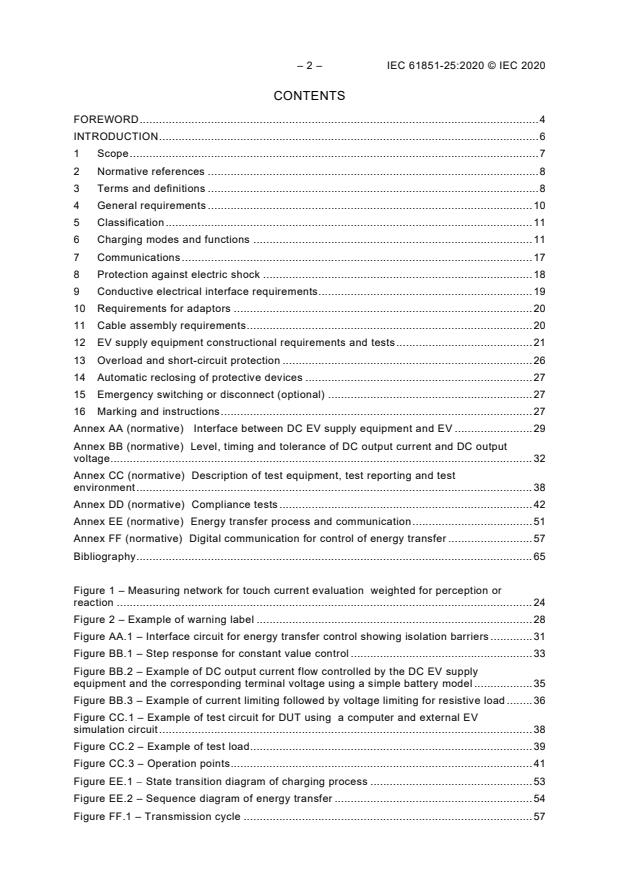

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 8

4 General requirements . 10

5 Classification . 11

6 Charging modes and functions . 11

7 Communications . 17

8 Protection against electric shock . 18

9 Conductive electrical interface requirements. 19

10 Requirements for adaptors . 20

11 Cable assembly requirements . 20

12 EV supply equipment constructional requirements and tests . 21

13 Overload and short-circuit protection . 26

14 Automatic reclosing of protective devices . 27

15 Emergency switching or disconnect (optional) . 27

16 Marking and instructions . 27

Annex AA (normative) Interface between DC EV supply equipment and EV . 29

Annex BB (normative) Level, timing and tolerance of DC output current and DC output

voltage . 32

Annex CC (normative) Description of test equipment, test reporting and test

environment . 38

Annex DD (normative) Compliance tests . 42

Annex EE (normative) Energy transfer process and communication . 51

Annex FF (normative) Digital communication for control of energy transfer . 57

Bibliography . 65

Figure 1 – Measuring network for touch current evaluation weighted for perception or

reaction . 24

Figure 2 – Example of warning label . 28

Figure AA.1 – Interface circuit for energy transfer control showing isolation barriers . 31

Figure BB.1 – Step response for constant value control . 33

Figure BB.2 – Example of DC output current flow controlled by the DC EV supply

equipment and the corresponding terminal voltage using a simple battery model . 35

Figure BB.3 – Example of current limiting followed by voltage limiting for resistive load . 36

Figure CC.1 – Example of test circuit for DUT using a computer and external EV

simulation circuit . 38

Figure CC.2 – Example of test load . 39

Figure CC.3 – Operation points . 41

Figure EE.1 − State transition diagram of charging process . 53

Figure EE.2 – Sequence diagram of energy transfer . 54

Figure FF.1 – Transmission cycle . 57

Table 1 – Normal shutdown events and conditions . 16

Table 2 – Error shutdown events and conditions . 16

Table AA.1 – Voltage of control pilot circuit . 29

Table AA.2 – Parameter values for interface circuit . 31

Table BB.1 – Requirements for the output response performance of DC EV supply

equipment . 34

Table BB.2 – Current ripple limit of DC EV supply equipment. 37

Table DD.1 – Correspondence between requirements and test descriptions . 42

Table DD.2 – Initial switch and parameter values for a normal start-up sequence . 43

Table DD.3 – The test value for control pilot circuit . 46

Table DD.4 – Shutdown requirements . 49

Table EE.1– Energy transfer state of DC EV supply equipment . 51

Table FF.1 – Physical/data link layer specification . 57

Table FF.2 – Received parameters during energy transfer (1 of 3) . 59

Table FF.3 – Transmitted parameters during DC charging (1 of 2) . 62

– 4 – IEC 61851-25:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC VEHICLE CONDUCTIVE CHARGING SYSTEM –

Part 25: DC EV supply equipment where protection

relies on electrical separation

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61851-25 has been prepared by IEC technical committee 69:

Electrical power/energy transfer systems for electrically propelled road vehicles and industrial

trucks.

The text of this International Standard is based on the following documents:

FDIS Report on voting

69/735/FDIS 69/740/RVD

Full information on the voting for the approval of this International Standard can be found in the

report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

This document is to be read in conjunction with IEC 61851-1:2017.

This document supplements or modifies clauses in IEC 61851-1:2017. Where the text of

subsequent clauses indicates an "addition" to or a "replacement" of the relevant requirement,

test specification or explanation of IEC 61851-1:2017, these changes are made to the relevant

text of IEC 61851-1:2017, which then becomes part of this document. Where no change is

necessary, the words "Clause X of IEC 61851-1:2017 is applicable" are used. Additional

clauses, tables and figures which are not included in IEC 61851-1:2017 have a number starting

from 101. Additional annexes are lettered AA, BB, etc.

A list of all parts in the IEC 61851 series, published under the general title Electric vehicle

conductive charging system, can be found on the IEC website.

In this document, the following print types are used:

– test specifications: italic type.

– notes: smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 61851-25:2020 © IEC 2020

INTRODUCTION

This document describes the specific requirements for DC EV supply equipment whose

secondary circuit and EV are protected from the primary power supply circuit by electrical

separation as defined in IEC 61140, where the connection to the separated circuit is limited to

a single connection.

ELECTRIC VEHICLE CONDUCTIVE CHARGING SYSTEM –

Part 25: DC EV supply equipment where protection

relies on electrical separation

1 Scope

This document applies to the DC EV supply equipment for charging electric road vehicles with

a rated supply voltage of up to 480 V AC or up to 600 V DC, with rated output voltage not

exceeding 120 V DC and output currents not exceeding 100 A DC.

This document provides the requirements for the DC EV supply equipment where the secondary

circuit is protected from the primary circuit by electrical separation.

Requirements for bi-directional power flow are not covered in this document.

This document also provides the requirements for the control and the communication between

DC EV supply equipment and an EV.

This document also applies to DC EV supply equipment supplied from on-site storage systems.

The aspects covered in this document include:

• characteristics and operating conditions of the DC EV supply equipment;

• specification of the connection between the DC EV supply equipment and the EV;

• requirements for electrical safety for the DC EV supply equipment.

Additional requirements can apply to equipment designed for specific environments or

conditions, for example:

• DC EV supply equipment located in hazardous areas where flammable gas or vapour and/or

combustible materials, fuels or other combustible, or explosive materials are present;

• DC EV supply equipment designed to be installed at an altitude of more than 2 000 m;

• DC EV supply equipment intended to be used on-board ships.

Requirements for electrical devices and components used in DC EV supply equipment are not

included in this document and are covered by their specific product standards.

This document does not apply to:

• safety aspects related to maintenance;

• charging of trolley buses, rail vehicles, industrial trucks and vehicles designed primarily for

use off-road;

• equipment on the EV;

• EMC requirements for equipment on the EV while connected, which are covered in

IEC 61851-21-1;

• charging the RESS off-board the EV.

NOTE In the following countries electrical separation can only be handled by skilled people: CH

– 8 – IEC 61851-25:2020 © IEC 2020

2 Normative references

Clause 2 of IEC 61851-1:2017 is applicable with the following additions.

IEC 60068-2-30:2005, Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic

(12 h + 12 h cycle)

IEC 61140:2016, Protection against electric shock – Common aspects for installations and

equipment

IEC 61180:2016, High-voltage test techniques for low-voltage equipment – Definitions, test and

procedure requirements, test equipment

IEC 61439-7:2018, Low-voltage switchgear and controlgear assemblies –Part 7: Assemblies

for specific applications such as marinas, camping sites, market squares, electric vehicle

charging stations

IEC 61851-1:2017, Electric vehicle conductive charging system – Part 1: General

requirements

IEC 62477-1:2012, Safety requirements for power electronic converter systems and equipment

– Part 1: General

IEC 62893-4-1:2020, Charging cables for electric vehicles of rated voltages up to and including

0,6/1 kV – Part 4-1: Cables for DC charging according to mode 4 of IEC 61851-1 – DC charging

without use of a thermal management system

ISO 3297:2017, Information and documentation – International standard serial number (ISSN)

ISO 11898-1:2015, Road vehicles – Controller area network (CAN) – Part 1: Data link layer and

physical signalling

ISO 11898-2:2016, Road vehicles – Controller area network (CAN) – Part 2: High-speed

medium access unit

3 Terms and definitions

Clause 3 of IEC 61851-1:2017 is applicable with the following additions to 3.2, 3.3 and 3.7.

ISO and IEC maintain terminological data bases for use in standardization at the following

addresses:

• ISO Online browsing platform: available at https: //www.iso.org/obp

• IEC Electropedia: available at http: //www.electropedia.org/

3.2 Insulation

3.2.101

electrical separation

protective measure in which hazardous-live-parts are insulated from all other electric circuits

and parts, from local earth and from touch

[SOURCE: IEC 60050-826:2004, 826-12-27]

3.3 Functions

3.3.101

normal start-up sequence

beginning of an energy transfer sequence with the commands and parameters that are used to

transfer energy to an EV when no error condition arises during the energy transfer sequence

3.3.102

normal shutdown

termination of the energy transfer process initiated by the user, by the EV or by the DC EV

supply equipment, and not caused by a failure

3.3.103

error shutdown

termination of the energy transfer process caused by a failure detected by the DC EV supply

equipment or the EV

3.3.104

emergency shutdown

termination of the energy transfer process caused by a failure detected by the DC EV supply

equipment or the EV that may present a safety hazard

3.3.105

control pilot wire

insulated wire incorporated in a cable assembly which is part of the control pilot circuit

3.3.106

digital communication

digitally encoded information exchanged between DC EV supply equipment and an EV, as well

as the method by which it is exchanged

[SOURCE: IEC 61851-24:2014, 3.1, modified – The term "charging station" has been replaced

with "supply equipment".]

3.3.107

signal

data element that is communicated between DC EV supply equipment and an EV using any

means other than digital communication

[SOURCE: IEC 61851-24:2014, 3.2, modified – The term "charging station" has been replaced

with "supply equipment".]

3.3.108

device under test

DUT

sample of DC EV supply equipment that is submitted for testing

3.7 General terms

3.7.101

available DC output power

maximum DC output power that the DC EV supply equipment can supply

3.7.102

available DC output power parameter

parameter transmitted to the EV indicating the available DC output power

– 10 – IEC 61851-25:2020 © IEC 2020

3.7.103

DC output current

DC current supplied to the EV by the DC EV supply equipment

3.7.104

available DC output current

value of the highest DC current that the DC EV supply equipment can supply to the EV at a

given time

3.7.105

available DC output current parameter

parameter sent by the EV supply equipment to the vehicle that indicates the highest current

that can be supplied to the EV

3.7.106

rated DC output current

output current assigned to the DC EV supply equipment by the manufacturer under normal

operating conditions

3.7.107

requested DC output current

value of the DC output current that is requested by the EV

3.7.108

requested DC output current parameter

parameter sent by the EV to the DC EV supply equipment indicating the requested DC output

current

3.7.109

DC output voltage

voltage present between the DC+ and DC− terminals at the vehicle connector

3.7.110

rated DC output voltage

output voltage assigned to the DC EV supply equipment by the manufacturer

3.7.111

rated DC output voltage parameter

parameter sent by the DC EV supply equipment to indicate the rated DC output voltage

3.7.112

DC output voltage target parameter

value sent by the EV to the DC EV supply equipment that indicates the requested value of the

DC output voltage

3.7.113

DC output voltage limit parameter

value sent by the EV to the DC EV supply equipment that indicates the allowable DC output

voltage

4 General requirements

Clause 4 of IEC 61851-1:2017 is applicable.

5 Classification

Clause 5 of IEC 61851-1:2017 is applicable, except as follows.

5.1.2 Characteristics of power supply output

Replacement:

The EV supply equipment shall be classified as DC EV supply equipment.

5.6 Protection against electric shock

Subclause 5.6 of IEC 61851-1:2017 is not applicable.

5.7 Charging modes

Subclause 5.7 of IEC 61851-1:2017 is not applicable.

6 Charging modes and functions

Clause 6 of IEC 61851-1:2017 is applicable, except as follows.

6.1 General

Replacement:

Clause 6 describes the functions for energy transfer to EVs.

6.2 Charging modes

Subclause 6.2 of IEC 61851-1:2017 is not applicable.

6.3 Functions provided in Mode 2, 3 and 4

Subclause 6.3 of IEC 61851-1:2017 is replaced by the following:

6.3 Mandatory functions

6.3.1 General

The DC EV supply equipment shall supply a DC output current to the EV in accordance with the

requested DC output current parameter from the EV, subject to the requirements of the

mandatory functions as indicated below.

NOTE The DC EV supply equipment acts as a slave to the EV. Further details are given in Annex AA, Annex BB

and Annex EE.

The following functions shall be provided by the DC EV supply equipment:

• verification that the EV is properly connected to the DC EV supply equipment in accordance

with 6.3.2;

• verification of the latching of the vehicle coupler in accordance with 6.3.3;

• latching and unlatching of the vehicle coupler in accordance with 6.3.4;

• communication with the vehicle in accordance with 6.3.5;

• monitoring of the continuity of the control pilot circuit in accordance with 6.3.6;

• verification function before energy transfer in accordance with 6.3.7;

– 12 – IEC 61851-25:2020 © IEC 2020

• energization and control of the power supply to the EV in accordance with 6.3.8;

• protection against overvoltage in accordance with 6.3.9;

• de-energization of the power supply to the EV in accordance with 6.3.10;

• shutdown of DC EV supply equipment in accordance with 6.3.10.2, 6.3.10.3 and 6.3.10.4.

Values, timing and tolerances for the DC output current and the DC output voltages shall be

tested in accordance with Annex BB.

6.3.2 Verification that the EV is properly connected to the DC EV supply equipment

The DC EV supply equipment shall determine that the EV is properly connected to the DC EV

supply equipment.

Proper connection is assumed when the continuity of the control pilot circuit is detected.

Compliance is checked in accordance with DD.3.1.

6.3.3 Verification of the latching of the vehicle coupler

The DC EV supply equipment shall determine that the vehicle connector is properly latched to

the vehicle inlet.

The DC EV supply equipment shall not energize the conductors in the cable assembly when

the vehicle connector is not latched to a vehicle inlet.

The DC EV supply equipment shall enter into an emergency shutdown if the vehicle connector

is disconnected from the vehicle inlet while under power.

Compliance is checked in accordance with DD.3.8.6.

6.3.4 Latching and unlatching of the vehicle coupler

A mechanical or electromechanical means shall be provided to prevent intentional and

unintentional disconnection under load of the vehicle connector according to IEC 62196-1.

Compliance is checked by inspection.

6.3.5 Communication with the EV

6.3.5.1 General

Digital communication shall be established between the EV and the DC EV supply equipment

to validate and control the energy transfer.

The DC EV supply equipment shall be able to receive and interpret all mandatory digital

communication data as described in Annex FF.

Compliance is checked in accordance with Clause DD.3.

The vehicle connector shall not be energized until the compatibility assessment is successfully

completed in accordance with 6.3.7.2.

Compliance is checked by the test in Annex DD applying the messages defined in Table FF.2

and Table FF.3 of Annex FF.

6.3.5.2 Available DC output current parameter

The EV supply equipment shall inform the EV of the value of the available DC output current

that can be provided by the EV supply equipment.

The value may be changed and retransmitted during energy transfer, to adapt to power

limitations, (e.g. for load management), without exceeding the rated DC output current.

The DC EV supply equipment shall limit the DC output current to the available output current

parameter or interrupt the energy supply if the DC output current drawn by the EV exceeds the

available DC output current parameter.

Compliance is checked in accordance with DD.3.7 and DD.3.8.

6.3.5.3 Available DC output power parameter

A means shall be provided to inform the EV on the available DC output power of the DC EV

supply equipment.

The DC EV supply equipment may decrease the DC output current if the power demand exceeds

this value.

Compliance is checked in accordance with DD.3.7.

NOTE Available DC output power is indicated before the beginning of energy transfer. Dynamic power limitation

due to the AC supply network limitations is an option that could modify the available DC output power during energy

transfer on some DC EV supply equipment (see Clause EE.5).

6.3.5.4 DC output voltage target parameter and DC output voltage limit parameter

The DC EV supply equipment shall compare the DC output voltage with the values of the DC

output voltage target parameter and the DC output voltage limit parameter received from the

EV, and with the rated DC output voltage.

Shutdown conditions are in accordance with 6.3.10 if one of these values is exceeded.

Timing and tolerances that are applicable are indicated in Annex BB.

NOTE The values of the DC output voltage target parameter and the DC output voltage limit parameter are set

before the beginning of the energy transfer. They can be modified during energy transfer.

6.3.5.5 Monitoring of energy transfer requirements of the EV and adjustment of energy

supply conditions

A means shall be provided to continuously monitor the data transmitted by the EV and to adjust

the DC output current and/or DC output voltage and all associated parameters.

The DC EV supply equipment shall initiate an error shutdown if valid data is not received for

more than 1 s. An energy transfer cycle can be reinitiated by the EV after such shutdown.

The DC EV supply equipment shall be able to deliver DC output power up to the rated DC output

voltage and up to the rated DC output current within the limit of its rated DC output power at

the ambient temperature 0 °C to 40 °C below 2 000 m above sea level. The DC EV supply

equipment shall not exceed its available DC output power, even if the power requested by the

EV is higher than the available DC output power. Outside this operating range the DC EV supply

equipment is allowed to reduce the power.

NOTE 1 National or industrial codes and regulations can require different operating temperature ranges.

NOTE 2 Tolerances and timing for the DC output current are given in Annex BB.

– 14 – IEC 61851-25:2020 © IEC 2020

Compliance is checked in accordance with DD.3.7.

6.3.6 Monitoring of the continuity of the control pilot circuit

The EV supply equipment shall monitor the continuity of the control pilot circuit. The EV supply

equipment shall initiate an emergency shutdown on detection of interruption of the control pilot

circuit. Re-initialisation of the complete energy transfer procedure according to DD.3.5 shall be

required in order to restart the energy transfer cycle.

Compliance is checked in accordance with DD.3.5 and DD.3.8.6.

6.3.7 Verification function before energy transfer

6.3.7.1 General

The verification function is carried out when the vehicle connector has been fully inserted,

latched and the control pilot circuit verified (see DD.3.5 and EE.1.2), and before energy is

supplied to the EV.

6.3.7.2 Compatibility assessment before energy transfer

The DC EV supply equipment shall complete a compatibility assessment with the EV before

starting the energy transfer cycle. The check shall include at least the following elements:

• Reception of energy transfer requirements from the EV:

– DC output voltage target parameter;

– DC output voltage limit parameter;

• Validation by the DC EV supply equipment of information received from the EV;

• Transmission of DC EV supply equipment energy transfer parameters:

– available DC output current;

– rated DC output voltage;

– available DC output power;

• Transmission by DC EV supply equipment of the confirmed DC output voltage limit

parameter;

• Reception of validation information transmitted by the EV indicating that the information is

accepted.

Energy transfer shall only proceed if the compatibility assessment is completed correctly.

Compliance is checked in accordance with DD.3.3 applying the messages defined in Table FF.2

and Table FF.3.

6.3.7.3 Verification of the absence of a short-circuit on the cable assembly

With the EV connected to the DC EV supply equipment and before the EV contactor is closed,

the DC EV supply equipment shall have a means to check for a short circuit between DC+ and

DC− of the output circuit, the cable and vehicle coupler.

Compliance is checked in accordance with DD.3.4.

6.3.8 Energization of the power supply to the EV

The vehicle connector shall not be energized unless energy exchange has been allowed by the

control pilot function.

Compliance is checked in accordance with DD.3.5.

The DC output current and the DC output voltage of the DC EV supply equipment shall not

exceed the values of the parameters transmitted by the EV.

Compliance is checked in accordance with DD.3.6 and DD.3.8.

Requirements on the rate change of current, timing and tolerance are given in Annex BB.

6.3.9 Protection against overvoltage

The DC output voltage of the DC EV supply equipment shall not be greater than +2 % of the

rated DC output voltage.

The DC EV supply equipment shall perform an error shutdown if the measured DC output

voltage exceeds for more than 2 s the rated DC output voltage of the DC EV supply equipment

by 2 %, or the DC output voltage limit parameter sent by the EV by 1,5 V or 2 %, whichever is

the greater.

The DC EV supply equipment shall perform an emergency shutdown if the DC output voltage

exceeds the DC output voltage limit parameter sent by the EV by 1 % for 1 s or exceeds 150 V

for more than 30 ms.

Compliance is checked in accordance with DD.3.7 and DD.3.8.

6.3.10 De-energization of the power supply to the EV

6.3.10.1 General

If the signal status from the EV control energy transfer function no longer allows energization,

the power supply to the EV shall be interrupted but the control pilot circuit may remain in

operation.

Three shutdown procedures are possible:

• normal shutdown;

• error shutdown;

• emergency shutdown.

The DC EV supply equipment shall have a means to allow the user to initiate normal or

emergency shutdown.

Compliance is checked by inspection.

6.3.10.2 Normal shutdown

The DC EV supply equipment shall stop energy transfer by controlled interruption of DC output

current to the EV, where DC output current descends with a controlled slope under the control

of the EV and the DC EV supply equipment.

The data exchange and protocol are indicated in Annex EE.

Table 1 shows events and reducing conditions for normal shutdown.

– 16 – IEC 61851-25:2020 © IEC 2020

Table 1 – Normal shutdown events and conditions

Event Particular Time for starting to Minimum rate of DC

reduce DC output output current ramp

current down

Normal shutdown request Shutdown signal from Within 1 s after reception 100 A/s

a

from EV of the digital data frame

EV is received.

Normal shutdown by DC DC EV supply equipment According to the 100 A/s

b

EV supply equipment manufacturer's definition

detects internal events

and less than 1 min

Normal shutdown by DC User pushes on the stop Within 1 s 100 A/s

EV supply equipment button

a

Signal definitions are given in Annex FF.

b

For example, time limit exceeded.

Compliance is tested in accordance with DD.3.8.4.

6.3.10.3 Error shutdown

The DC EV supply equipment shall stop the energy transfer by controlled interruption of the DC

output current to the EV, where the DC output current descends with a controlled slope, after

the error shutdown is triggered by the DC EV supply equipment or by a message from the EV.

Table 2 indicates the main events and reducing conditions for error shutdown.

Table 2 – Error shutdown events and conditions

Event Particular Time for starting to Minimum rate of DC

reduce DC output current output current ramp down

Pilot wire voltage error State of CP is "Error" in Less than 100 ms 200 A/s

a

Table AA.1

Digital communication A valid digital data frame is Less than 100 ms after the 200 A/s

reception error not received for more than 1 s time-out

1 s

Overvoltage DC output voltage exceeds Less than 100 ms after the 200 A/s

rated DC output voltage of

2 s time-out

DC EV supply equipment

for more than 2 s

Or

DC output voltage exceeds

DC output voltage limit

parameter sent by EV

equipment for more than

2 s

Reception of shutdown Shutdown signal from EV is Within 1 s after reception of 200 A/s

signal from EV received the digital data frame

a

This error becomes emergency shutdown when the voltage is < 2,0 V DC (see 6.3.10.4).

b

The error signals are defined in Annex FF.

Compliance is tested in accordance with DD.3.8.5.

6.3.10.4 Emergency shutdown

The DC EV supply equipment shall stop power transfer within 30 ms after the emergency

shutdown was triggered. The DC output voltage shall fall (between DC+ and DC−) ≤ 60 V DC

within 1 s after the emergency shutdown was triggered.

The emergency shutdown shall be initiated by:

– the voltage of the control pilot circuit < 2,0 V DC;

– disconnection of vehicle connector under load;

– the DC output voltage exceeds DC output voltage limit sent by the EV or exceeds 150 V

DC for more than 30 ms, as described in 6.3.9;

– reception of emergency shutdown signal from EV or initiated by the user.

The DC output voltage of the DC EV supply equipment shall not be greater than +2 % of the

rated DC output voltage.

Compliance is tested in accordance with DD.3.8.6.

7 Communications

Clause 7 of IEC 61851-1:2017 is replaced with the following.

Replacement:

7.1 General

This Clause 7 provides a general description and the basic requirements for the control

communication function. The specific procedure and protocol is described in Annex EE.

The DC EV supply equipment supplies energy in response to digital information received by the

EV.

NOTE This implies that the EV manages the battery charging. The corresponding desired voltage and current levels

are transmitted to the DC EV supply equipment by the EV.

7.2 System configuration

The communication between the DC EV supply equipment and the EV is established using the

pilot control function and via digital communication, as described in Annex EE. The DC EV

supply equipment supplies energy to the EV according to the parameters sent by the EV,

provided all conditions required as indicated in Clause 6 are satisfied.

NOTE This implies that the EV controls the energy transfer. The DC EV supply system acts as a slave to the EV.

The detailed operational procedure is given in Clause 6 and in Annex EE.

7.3 Digital communication between the DC EV supply equipment and the management

system

The telecommunication network or telecommunication port of the DC EV supply equipment,

connected to the telecommunication network, if any, shall comply with the requirements for

connection to telecommunication networks according to IEC 60950-1:2005, Clause 6,

IEC 60950-1:2005/AMD1:2009, Clause 6 and IEC 60950-1:2005/AMD2:2013, Clause 6.

– 18 – IEC 61851-25:2020 © IEC 2020

8 Protection against electric shock

Clause 8 of IEC 61851-1 is applicable except as follows:

8.1 Degrees of protection against access to hazardous-live-parts

Replacement:

The EV supply equipment shall fulfil the following IP ratings for protection against electric shock:

– vehicle connector when mated with vehicle inlet: IPXXD;

– IP rating for dedicated DC accessories: IPXXB.

NOTE IP ratings for the enclosure are indicated in 12.3.1.

Compliance is checked by inspection and measurement in accordance with IEC 60529.

8.3 Fault protection

Subclause 8.3 of IEC 61851-1:2017 is replaced by the following:

8.3 Protective measures

8.3.1 General

Electrical separation between the primary and the secondary circuit according to IEC 61140

shall be provided. The following requirements shall be met:

• basic protection is provided by basic insulation, rated for the highest voltage present in the

equipment, between hazardous-live-parts, other circuits and exposed conductive parts of

the separated circuit;

and,

• fault protection is provided:

– by simple separation of the separated circuit from other circuits and earth;

and

– by a protective equipotential bonding interconnecting exposed conductive parts of the

separated circuit where more than one item of equipment is connected to the separated

circuit. This protective equipotential bonding system shall not be earthed.

Intentional connection of exposed-conductive-parts to a protective earthing conductor or to an

earthing conductor is not permitted.

DC EV supply equipment shall be fitted with a single cable and single

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...