IEC 60096-0-1:2012

(Main)Radio frequency cables - Part 0-1: Guide to the design of detail specifications - Coaxial cables

Radio frequency cables - Part 0-1: Guide to the design of detail specifications - Coaxial cables

IEC 60096-0-1:2012 provides guidance for the design of radio frequency coaxial cables with braid, metallic tapes or tubular outer conductors. This third edition cancels and replaces the second edition published in 1990. It constitutes a technical revision. The significant changes with respect to the previous edition are as follows:

- tables of material constants and factors and have been updated, different equations have been updated and corrected;

- a subclause dealing with the calculation of "Current carrying capacity of coaxial cables has been added as Subclause 7.7.

Câbles pour fréquences radioélectriques - Partie 0-1: Lignes directrices pour la conception des spécifications particulières - Câbles coaxiaux

La CEI 60096-0-1:2012 donne des lignes directrices pour la conception des câbles coaxiaux pour fréquences radioélectriques à tresse, ruban métallique ou conducteurs extérieurs tubulaires. Cette troisième édition annule et remplace la deuxième édition parue en 1990. Elle constitue une révision technique. Les principales modifications par rapport à l'édition précédente sont les suivantes:

- les tableaux contenant les constantes et les facteurs relatifs aux matériaux ont été mis à jour, un certain nombre d équations ont été mises à jour et corrigées;

- un paragraphe traitant du calcul du «courant admissible dans les câbles coaxiaux» a été ajouté en tant que Paragraphe 7.7.

General Information

- Status

- Published

- Publication Date

- 29-Oct-2012

- Technical Committee

- SC 46A - Coaxial cables

- Drafting Committee

- WG 3 - TC 46/SC 46A/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 30-Oct-2012

- Completion Date

- 15-Jan-2012

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

IEC 60096-0-1:2012 - Radio Frequency Coaxial Cable Design Guide

Overview

IEC 60096-0-1:2012 is an international standard issued by the International Electrotechnical Commission (IEC) that provides comprehensive guidelines for the design of detailed specifications for radio frequency (RF) coaxial cables. This third edition updates the 1990 second edition with technical revisions to reflect advancements in materials and calculation methods for coaxial cables featuring braid, metallic tapes, or tubular outer conductors.

The standard targets engineers, designers, and manufacturers involved in the development of coaxial cables used in RF applications, ensuring industry-wide uniformity and performance reliability. It incorporates updated tables of material constants, corrected equations, and introduces new subclauses such as the calculation of current carrying capacity of coaxial cables.

Key Topics

- Material Constants and Properties

Detailed tables provide material constants related to dielectrics, sheaths, inner and outer conductors. These updated values are critical for accurate electromagnetic and mechanical design of coaxial cables. - Construction Elements and Numbering

Guidelines for systematically identifying cable components using standard symbols and numbering aid in precise specification drafting and product cataloging. - Design Parameters and Electrical Properties

The standard guides the calculation of DC resistance, attenuation, characteristic impedance, capacitance per unit length, and permissible voltages. This encompasses formulas and correction factors to optimize cable performance in specific environments. - Mechanical Dimensions and Weight

Standard nominal diameters for cable dielectrics, sheath diameters, and cable weight calculations enable designers to meet mechanical and installation requirements. - Power Rating and Current Capacity

Updated methods to assess maximum permissible input power and the newly added subclause 7.7 focuses on calculating the current carrying capacity essential for safe cable operation under various load conditions. - Testing and Compliance

Test voltages for dielectric and sheath materials such as PVC are specified, ensuring durability and operational safety in high-frequency applications.

Applications

IEC 60096-0-1:2012 is fundamental for the design and manufacturing of coaxial cables used in:

- Telecommunication networks including cellular and broadband systems

- Broadcast and satellite communications

- RF transmission lines in industrial and scientific equipment

- Military and aerospace communication systems requiring high signal integrity

- Infrastructure supporting wireless sensor networks and IoT devices

Following this standard ensures cables meet global performance expectations for attenuation, impedance, power handling, and durability, facilitating interoperability and long-term reliability.

Related Standards

The IEC 60096 series complements other IEC and ISO standards, including:

- IEC 61196 series - Specifications for RF coaxial cables for various usage conditions and frequency ranges.

- IEC 60050-732 - Electrotechnical vocabulary relevant to communication cables.

- ISO/IEC 14763 - Testing and installation guidelines for communication cabling.

Adherence to IEC 60096-0-1:2012 facilitates integration with these standards, promoting standardized quality and design consistency across different international markets.

Keywords: IEC 60096-0-1, radio frequency cables, coaxial cable design, electromagnetic properties, RF cables, coaxial cable specification, current carrying capacity, IEC standards, telecommunications cables, coaxial cable attenuation

Buy Documents

IEC 60096-0-1:2012 - Radio frequency cables - Part 0-1: Guide to the design of detail specifications - Coaxial cables

IEC 60096-0-1:2012+AMD1:2017 CSV - Radio frequency cables - Part 1- 0: Guide to the design of detail specifications - Coaxial cables Released:1/25/2017 Isbn:9782832239117

Get Certified

Connect with accredited certification bodies for this standard

TL 9000 QuEST Forum

Telecommunications quality management system.

ANCE

Mexican certification and testing association.

Intertek Slovenia

Intertek testing, inspection, and certification services in Slovenia.

Sponsored listings

Frequently Asked Questions

IEC 60096-0-1:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Radio frequency cables - Part 0-1: Guide to the design of detail specifications - Coaxial cables". This standard covers: IEC 60096-0-1:2012 provides guidance for the design of radio frequency coaxial cables with braid, metallic tapes or tubular outer conductors. This third edition cancels and replaces the second edition published in 1990. It constitutes a technical revision. The significant changes with respect to the previous edition are as follows: - tables of material constants and factors and have been updated, different equations have been updated and corrected; - a subclause dealing with the calculation of "Current carrying capacity of coaxial cables has been added as Subclause 7.7.

IEC 60096-0-1:2012 provides guidance for the design of radio frequency coaxial cables with braid, metallic tapes or tubular outer conductors. This third edition cancels and replaces the second edition published in 1990. It constitutes a technical revision. The significant changes with respect to the previous edition are as follows: - tables of material constants and factors and have been updated, different equations have been updated and corrected; - a subclause dealing with the calculation of "Current carrying capacity of coaxial cables has been added as Subclause 7.7.

IEC 60096-0-1:2012 is classified under the following ICS (International Classification for Standards) categories: 33.120.10 - Coaxial cables. Waveguides. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60096-0-1:2012 has the following relationships with other standards: It is inter standard links to EN 50117-1:2019, EN 4604-010:2018, EN 4604-003:2025, EN 6049-001:2015, EN 4604-007:2025, EN 6049-008:2013, EN 6049-001:2018, EN 4604-005:2015, EN 4604-010:2017, EN 4604-006:2025, EN 4604-008:2025, IEC 60096-0-1:2012/AMD1:2017, IEC 60096-0-1:1990, IEC 60096-0-1:1990/AMD1:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60096-0-1:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60096-0-1 ®

Edition 3.0 2012-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Radio frequency cables –

Part 0-1: Guidelines to the design of detail specifications – Coaxial cables

Câbles pour fréquences radioélectriques –

Partie 0-1: Lignes directrices pour la conception des spécifications particulières

‒ Câbles coaxiaux

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60096-0-1 ®

Edition 3.0 2012-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Radio frequency cables –

Part 0-1: Guidelines to the design of detail specifications – Coaxial cables

Câbles pour fréquences radioélectriques –

Partie 0-1: Lignes directrices pour la conception des spécifications particulières

‒ Câbles coaxiaux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 33.120.10 ISBN 978-2-83220-473-3

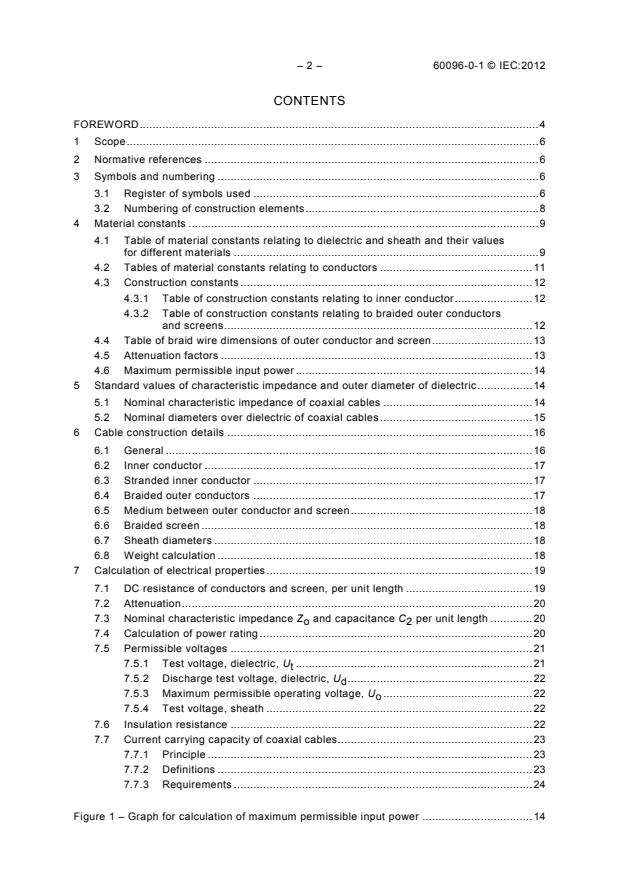

– 2 – 60096-0-1 © IEC:2012

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Symbols and numbering . 6

3.1 Register of symbols used . 6

3.2 Numbering of construction elements . 8

4 Material constants . 9

4.1 Table of material constants relating to dielectric and sheath and their values

for different materials . 9

4.2 Tables of material constants relating to conductors . 11

4.3 Construction constants . 12

4.3.1 Table of construction constants relating to inner conductor . 12

4.3.2 Table of construction constants relating to braided outer conductors

and screens . 12

4.4 Table of braid wire dimensions of outer conductor and screen . 13

4.5 Attenuation factors . 13

4.6 Maximum permissible input power . 14

5 Standard values of characteristic impedance and outer diameter of dielectric . 14

5.1 Nominal characteristic impedance of coaxial cables . 14

5.2 Nominal diameters over dielectric of coaxial cables . 15

6 Cable construction details . 16

6.1 General . 16

6.2 Inner conductor . 17

6.3 Stranded inner conductor . 17

6.4 Braided outer conductors . 17

6.5 Medium between outer conductor and screen . 18

6.6 Braided screen . 18

6.7 Sheath diameters . 18

6.8 Weight calculation . 18

7 Calculation of electrical properties . 19

7.1 DC resistance of conductors and screen, per unit length . 19

7.2 Attenuation . 20

7.3 Nominal characteristic impedance Z and capacitance C per unit length . 20

o 2

7.4 Calculation of power rating . 20

7.5 Permissible voltages . 21

7.5.1 Test voltage, dielectric, U . 21

t

7.5.2 Discharge test voltage, dielectric, U . 22

d

7.5.3 Maximum permissible operating voltage, U . 22

o

7.5.4 Test voltage, sheath . 22

7.6 Insulation resistance . 22

7.7 Current carrying capacity of coaxial cables . 23

7.7.1 Principle . 23

7.7.2 Definitions . 23

7.7.3 Requirements . 24

Figure 1 – Graph for calculation of maximum permissible input power . 14

60096-0-1 © IEC:2012 – 3 –

Table 1 – Example of use of k factor . 8

x

Table 2 – Example of use of k factor . 8

xy

Table 3 – Material constants relating to dielectric and sheath and their values for

different materials . 9

Table 4 – Conductivity (at 20 °C) and density . 11

a

Table 5 – Coating factor . 11

Table 6 – Tinned copper wire . 11

Table 7 – Copper clad steel wire . 12

Table 8 – Construction constants relating to inner conductor . 12

Table 9 – Construction constants relating to braided outer conductors and screens . 13

Table 10 – Braid wire dimensions of outer conductor and screen . 13

Table 11 – Factor relating to calculation of attenuation – examples . 13

Table 12 – Nominal diameters D over dielectric and the tolerances . 15

Table 13 – Special design features . 16

Table 14 – Special design features . 17

Table 15 – Braided outer conductors . 17

Table 16 – Medium between outer conductor and screen . 18

Table 17 – Braided screen . 18

Table 18 – Sheath diameters . 18

Table 19 – Weight calculation . 19

Table 20 – Electrical properties. 19

Table 21 – Factors for calculation of attenuation . 20

Table 22 – Test voltages for PVC sheaths . 22

– 4 – 60096-0-1 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RADIO FREQUENCY CABLES –

Part 0-1: Guidelines to the design of detail specifications –

Coaxial cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International standard IEC 60096-0-1 has been prepared by subcommittee 46A: Coaxial

cables, of IEC technical committee 46: Cables, wires, waveguides, R.F. connectors, R.F. and

microwave passive components and accessories.

This third edition cancels and replaces the second edition published in 1990 and its

Amendment 1 (2000). It constitutes a technical revision.

The significant changes with respect to the previous edition are as follows:

– tables of material constants and factors and have been updated, different equations have

been updated and corrected;

– a subclause dealing with the calculation of “Current carrying capacity of coaxial cables”

has been added as Subclause 7.7.

60096-0-1 © IEC:2012 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

46A/1043/FDIS 46A/1064/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

A list of all the parts in the IEC 60096 series, published under the general title Radio

frequency cables, can be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60096-0-1 © IEC:2012

RADIO FREQUENCY CABLES –

Part 0-1: Guidelines to the design of detail specifications –

Coaxial cables

1 Scope

This part of IEC 60096 provides guidance for the design of radio frequency coaxial cables

with braid, metallic tapes or tubular outer conductors.

2 Normative references

Void.

3 Symbols and numbering

3.1 Register of symbols used

Symbol Designation Unit

α Total attenuation per unit length, 20 °C . dB/100 m

α Total attenuation per unit length, T ≠ 20 °C . dB/100 m

T

α Attenuation due to element x, 20 °C . dB/100 m

x

β Braid angle of element x . ° (degree)

x

γ Density of the material of element x . g/cm

x

δ Loss angle of the material of element x . rad

x

ε Relative dielectric permittivity of the material of element x . –

x

χ Conductivity of the material of element x, 20 °C . m/Ωmm

x

σ Thermal resistivity of the material of element x . K⋅m/W

x

B Braid coverage concerning element x. –

x

c Velocity of propagation in free space . m/s

o

C Dielectric diameter mm

C Capacitance of element x, per unit length . pF/m

x

d Diameter of individual wires of element x . mm

x

D Outer diameter of element x . mm

x

D Electrical effective diameter of element x . mm

xe

D Mean diameter of element x . mm

xm

D Sheath diameter mm

D Outer conductor diameter mm

s

d Center conductor diameter mm

E Maximum permissible voltage gradient of dielectric (peak value). kV/mm

ε Surface emissivity (sheathed=0,95, bare=0,35)

f Frequency . MHz

h Coating thickness concerning element x . mm

x

I Current carrying capacity (Amperes)

k , k Calculation factors according to Tables 1 and 2 . –

x xy

L Braid lay length concerning element x . mm

x

60096-0-1 © IEC:2012 – 7 –

Symbol Designation Unit

ln Natural logarithm

m Total weight of cable per unit length . g/m

m Weight of element x . g/m

x

N Number of stranded wires of inner conductors . –

N Number of wires to each spindle concerning braid x . –

x

n Number of cables

n Number of spindles in the braid concerning element x . –

x

P Maximum permissible input power, ambient temperature 40 °C . W

P Thermal resistivity of the dielectric material, Typically =

i

13,0 K·m/W for both foam,

disc and air dielectrics

P Thermal resistivity of the sheath material,

j

Typically = 3,5 K·m/W for polyethylene

Typically = 7,0 K·m/W for polyvinylchloride (PVC) sheaths

P Maximum permissible input power, ambient temperature T ≠ 40 °C . W

T

P Maximum permissible dissipation power per unit length . W/m

d

q Filling factor of braid concerning element x . –

x

R DC resistance of conductive element x, per unit length . Ω/m

x

and insulation resistance of insulating element x respectively . MΩ·km

R Inner conductor resistance Ω/m at t

ic a

R Inner conductor resistance at conductor operating temperature (t )

ictc c

R Outer conductor resistance Ω/m at t

oc a

R Outer conductor resistance at conductor operating temperature (t )

octc c

R Increase in R due to effect of outer conductor

eoc ic

R Total thermal resistance of circuit K.m/W

th

R Thermal resistance of dielectric K.m/W

i

R Thermal resistance of sheath K.m/W

j

s Nominal thickness of element x . mm

x

s Minimal thickness of element x . mm

xmin.

T Temperature of element x . °C

x

T Ambient temperature. °C

a

t Conductor operating temperature °C

c

t Ambient temperature °C

a

t Cable surface temperature °C

s

U Test voltage (40 Hz - 60 Hz), rounded r.m.s. value . kV

t

U Test voltage (40 Hz - 60 Hz), rounded r.m.s. value . kV

tc

U Discharge test voltage, r.m.s. value . kV

d

U Maximum permissible operating voltage, rounded r.m.s. value . kV

o

U Maximum permissible operating voltage, calculated r.m.s. value . kV

oc

ν Velocity ratio . –

r

z Characteristic impedance, nominal value . Ω

o

– 8 – 60096-0-1 © IEC:2012

3.2 Numbering of construction elements

Numbering of construction elements in the following tables are as follows:

1 Inner conductor

2 Dielectric

3 Outer conductor

4 Sheath

5 Medium between outer conductor and screen

6 Screen

7 Medium between first and second screen

8 Second screen

etc.

Examples of use of k factor are given in Table 1.

x

Table 1 – Example of use of k factor

x

Symbol Designation Unit

Factor dependent on inner conductor concerning the

k –

voltage gradient in the dielectric

2 1,25

k Thermal dissipation constant of sheath surface in air W/m K

Examples of use of k factor are given in Table 2.

xy

Table 2 – Example of use of k factor

xy

Construction element

concerned

Factor

1 3 6 8

Coating factor k k

1c 3c

Stranding or braiding factor:

– concerning attenuation k k

1a 3a

– concerning d.c. resistance and weight k k k k

1r 3r 6r 8r

Ratio between overall diameter and diameter of

k

1d

individual wires

Effective diameter factor concerning characteristic

k

1z

impedance

60096-0-1 © IEC:2012 – 9 –

4 Material constants

4.1 Table of material constants relating to dielectric and sheath and their values for different materials

Material constants relating to dielectric and sheath and their values for different materials are given in Table 3.

Table 3 – Material constants relating to dielectric and sheath and their values for different materials

a

Symbol Designation Unit Value for

b b

Solid PE Semi-air- Cellular PE PTFE FEP Cellular ETFE PFA PVC

spaced PE FEP

Permittivity of dielectric – 2,28 1,4 1,3 1,5 1,7 2,1 2,1 1,5 2,6 2,1

ε

c f e e

–4 –4 –4 –4 –4 –3

tan δ Dissipation factor – 2,5 × 10 2,5 × 10 4 × 10 6 × 10 6 × 10 1,2 × 10

of dielectric

e e

E Maximum permissible kV/mm 11 2 2 2 2 11 2

voltage gradient

of dielectric

3 b

Density of dielectric g/cm 0,93 0,36 0,28 0,44 0,58 2,2 2,2 0,90 1,7 2,2 1,4

γ , γ

2 4

and sheath

e e

σ , σ Thermal resistivity K • m/W 3,5 15 9 6 4,4 5,0 4,4 4,5 7,0

2 4

of dielectric and sheath

d d g g g g

T Maximum permissible °C 85/80 85/80 70 70 70 250 200 200 150 200 70

operating temperature

– 10 – 60096-0-1 © IEC:2012

Table 3 (continued)

a PE = polyethylene

PTFE = polytetrafluoroethylene

FEP = fluorinated ethylene propylene

ETFE = ethylenetetrafluoroethylene

PFA = perfluoroalcoxylalkane

PVC = polyvinylchloride

b Typical value(s).

c

Frequency tan δ2

MHz

–4

1 1×10

–4

1,5×10

–4

2,5×10

103 –4

4,3×10

104 –4

2×10

d 85 °C: high density material.

80 °C: other density material.

e Under consideration

f

Frequency

tan δ2

MHz

–4

4×10

–4

4×10

–4

8×10

–4

10×10

–4

2×103

10×10

104 –4

7×10

g In the case of silvered inner and outer conductors only.

60096-0-1 © IEC:2012 – 11 –

4.2 Tables of material constants relating to conductors

Material constants relating to conductors are given in Tables 4 to 7.

Table 4 – Conductivity (at 20 °C) and density

Conductor Symbols Unit Value Symbols Unit Value

2 3

Copper χ , χ , χ m/Ωmm 58 γ , γ , γ g/cm 8,9

1 3 6 1 3 6

Aluminium 35 2,7

Tin 8,3 7,3

Silver 61 10,5

a

Copper clad steel 30 % 17,4 8,15

a

Copper clad steel 40 % 23,2 8,20

a

For calculation of d.c. resistance only.

a

Table 5 – Coating factor

Conductor Symbol Value

Bare copper wire 1

Silvered copper wire 1

k and k

1c 3c

Tinned copper wire Table 6

Copper clad steel wire Table 7

a

RF resistance of coated wire in relation to bare

copper wire, dependent on frequency and coating

thickness

Table 6 – Tinned copper wire

k or k

h f or h f 1c 3c

1 3

0,01 1,01

0,02 1,03

0,03 1,06

0,04 1,11

0,06 1,25

0,08 1,44

0,10 1,67

0,12 1,91

0,15 2,24

0,18 2,46

0,20 2,60

2,70

≥0,25

– 12 – 60096-0-1 © IEC:2012

Table 7 – Copper clad steel wire

a

k

h

f 1c

0,005 11,04

0,010 6,06

0,015 4,16

0,020 3,17

0,025 2,57

0,030 2,16

0,035 1,87

0,040 1,65

0,050 1,35

0,060 1,16

0,070 1,04

0,080 1,00

a

Assumptions relating to steel:

χ = 8 m/Ωmm .

Relative permeability, µ = 200.

r

4.3 Construction constants

4.3.1 Table of construction constants relating to inner conductor

Construction constants relating to inner conductor are given in Table 8.

Table 8 – Construction constants relating to inner conductor

Value versus number of strands

N

Symbol Designation

1 7 12 19

Stranding factor for d.c. resistance and

k 1,00 1,03 1,03 1,03

1r

weight

k Standing factor for attenuation 1,00 1,25 1,25 1,25

1a

k Effective diameter factor 1,00 0,94 0,96 0,98

1z

Ratio between overall diameter

k 1,00 3,02 4,16 5,00

1d

and diameter of individual wires

k Voltage gradient factor 1,00 0,90 0,90 0,90

4.3.2 Table of construction constants relating to braided outer conductors

and screens

Construction constants relating to braided outer conductors and screens are given in Table 9.

60096-0-1 © IEC:2012 – 13 –

Table 9 – Construction constants relating to braided outer conductors

and screens

L L

3 6

k ; k

Braid angle β ; β ;

3r 6r

3 6

D D

3m 6m

20° 8,63 1,06

25° 6,74 1,10

30° 5,44 1,15

35° 4,49 1,22

40° 3,74 1,30

45° 3,14 1,41

Definitions: k = 1 + (π ⋅ D /L ) =

3r 3m 3

cosβ

k = 1 + (π ⋅ D /L ) =

6r 6m 6

cosβ

4.4 Table of braid wire dimensions of outer conductor and screen

Braid wire dimensions of outer conductor and screen are given in Table 10.

Table 10 – Braid wire dimensions of outer conductor and screen

Nominal diameter of braid wire (d , d )

3 6

Nominal outer diameter

mm

of dielectric (D )

mm

Single braid Double braid

0,87 and 1,5 0,09–0,11 –

2,95, 3,7, 4,8 and 6,4 0,13–0,15 0,13–0,15

7,25, 9,8 and 11,5 0,18–0,20 0,16–0,18

17,3 0,24–0,26 0,18–0,20

4.5 Attenuation factors

Examples of attenuation factors for the calculation of attenuation are given in Table 11.

Table 11 – Factor relating to calculation of attenuation – examples

Symbol Designation Feature Value

Solid wire 1,0

k

1a

Stranded wire 1,25

Attenuation due to

inner conductor

Tinned copper wires See Table 6

k

1c

Copper clad steel wire See Table 7

Tubular outer conductor 1,0

k

3a

a

Attenuation due to

Braided outer conductor 2,0

outer conductor

k Braid wires tinned copper See Table 6

3c

a

Rough approximation (in absence of a reliable theory).

– 14 – 60096-0-1 © IEC:2012

4.6 Maximum permissible input power

For the calculation of maximum permissible input power with respect to thermal dissipation

constant for surface in air, see Figure 1.

4 8 12 16 20 24

Outside diameter of cable D (mm)

IEC 2123/12

Figure 1 – Graph for calculation of maximum permissible input power

A more detailed description for the maximum permissible dissipation power related to ambient

temperature is given in 7.4.

5 Standard values of characteristic impedance and outer diameter of dielectric

5.1 Nominal characteristic impedance of coaxial cables

All impedances specified in this clause are defined at a frequency of 200 MHz and at the

reference temperature of 20 °C.

Standard values of nominal characteristic impedance are:

a) 50 Ω;

b) 93 Ω;

c) 75 Ω.

Thermal dissipation constant for surface in air K (W/m K)

60096-0-1 © IEC:2012 – 15 –

5.2 Nominal diameters over dielectric of coaxial cables

Nominal diameters D over dielectric and the tolerances are given in Table 12.

Table 12 – Nominal diameters D over dielectric and the tolerances

Dielectric Impedance Diameter over dielectric

a

Millimetres Inches

Ω

Rated Tolerance Rated Tolerance Rated Tolerance

value ± value ± value ±

1,50 0,10 0,060 0,004

2,95 0,13 0,116 0,005

2,0 3,70 0,15 0,146 0,006

4,80 0,20 0,189 0,008

50 6,40 0,20 0,252 0,008

7,25 0,25 0,285 0,010

b

1,0 7,25 0,15 0,285 0,006

11,50 0,30 0,453 0,012

Solid

2,0 17,30 0,40 0,680 0,016

polyethylene

23,70 0,30 0,933 0,012

1,50 0,10 0,060 0,004

3,0 2,95 0,13 0,116 0,005

3,70 0,13 0,146 0,005

b

1,5 3,70 0,10 0,146 0,004

75 3,0 4,80 0,20 0,189 0,008

7,25 0,25 0,285 0,010

b

1,5 7,25 0,15 0,285 0,006

3,0 17,30 0,40 0,680 0,016

23,70 0,30 0,933 0,012

1,50 0,10 0,060 0,004

5,0 2,30 0,10 0,090 0,004

2,95 0,13 0,116 0,005

50 4,80 0,20 0,189 0,008

5,85 0,20 0,230 0,008

Cellular

4,0 6,25 0,20 0,246 0,008

polyethylene

7,25 0,25 0,285 0,010

3,70 0,15 0,146 0,005

75 5,0 4,80 0,20 0,189 0,008

7,25 0,25 0,285 0,010

a

For information only.

b

Close tolerance cables.

– 16 – 60096-0-1 © IEC:2012

Table 12 (continued)

Dielectric Impedance Diameter over dielectric

a

Millimetres Inches

Ω

Rated Tolerance Rated Tolerance Rated Tolerance

value ± value ± value ±

50 2,5 7,25 0,25 0,285 0,010

Semi-air-spaced

2,50 0,15 0,098 0,006

polyethylene

93 5,5 3,70 0,13 0,146 0,005

3,5 0,87 0,07 0,034 0,003

1,50 0,10 0,060 0,004

50 2,5 2,95 0,13 0,116 0,005

2,0 7,25 0,15 0,285 0,006

Polytetrafluoro-ethylene

11,50 0,30 0,453 0,012

5,0 1,50 0,10 0,060 0,004

75 3,0 3,70 0,13 0,146 0,005

7,25 0,25 0,285 0,010

93 5,5 2,60 0,13 0,102 0,005

50 2,5 2,40 0,08 0,095 0,003

Cellular fluorinated 3,40 0,13 0,135 0,005

ethylene-

75 3,5 4,30 0,08 0,170 0,003

propylene

7,25 0,25 0,285 0,010

93 5,5 3,70 0,13 0,146 0,005

NOTE This table is a reference guide to some cable sizes but does not limit the manufacture of smaller or

larger designs.

a

For information only.

6 Cable construction details

6.1 General

The starting point is to determine:

(according to 5.1);

a) the nominal characteristic impedance, z

o

b) the outer diameter of dielectric, D (according to 5.2);

NOTE Other diameters outside the scope of this document can be calculated using the formula provided in 6.3.

c) the permittivity of dielectric, ε (Table 3).

Calculate the effective diameter of outer conductor, D .

3e

Special design features are given in Table 13.

Table 13 – Special design features

Outer conductor Diameter D

3e

Tubular D = D

3e 2

Braided D > D (see 6.4)

3e 2

60096-0-1 © IEC:2012 – 17 –

6.2 Inner conductor

The electrical effective diameter D of the inner conductor follows from:

1e

ε

1)

D = D ⋅ exp( −Z ⋅ )

1e 1e 0

Special design features are given in Table 14.

Table 14 – Special design features

Solid inner conductor Diameter D as calculated

Stranded inner conductor Diameter D > D (see 6.3)

1 1e

6.3 Stranded inner conductor

The diameter D is to be calculated from the effective diameter D :

1 1e

D = D / k

1 1e 1z

The wire diameter d is to be calculated from D :

1 1

d = D / k

1 1 1d

k and k according to Table 8.

1d 1z

6.4 Braided outer conductors

Equations for the calculation of braided outer conductors are given in Table 15.

Table 15 – Braided outer conductors

The effective diameter D

3e

outer diameter D

mean diameter D

3m

are to be calculated from the outer diameter D and the diameter of the braid wires d :

2 3

D = D + 1,5 · d

3e 2 3

D = D + 4,5 · d

3 2 3

D = D + 2,25 · d d according to Table 10

3m 2 3 3

The filling factor of the braid is:

N ⋅ n ⋅ d ⋅ k

3 3 3 3r

q =

2 ⋅ π ⋅ D

3m

d and D as above

3 3m

k according to Table 9

3r

The coverage and the braid angle of the outer conductor are given by:

B = 2q – q β = arc tan πD /L

3 3 3 3 3m 3

___________

1)

Rounded up from 59,96.

– 18 – 60096-0-1 © IEC:2012

6.5 Medium between outer conductor and screen

Medium between outer conductor and screen is given in Table 16.

Table 16 – Medium between outer conductor and screen

The outer diameter of the interposed medium is:

D = D + 2 s

5 3 5

6.6 Braided screen

Equations for the calculation of braided screens are given in Table 17.

Table 17 – Braided screen

The outer diameter D and the mean diameter D are to be calculated from the outer diameter of the interposed

6 6m

medium D and the diameter of the braid wires, d :

5 6

D = D + 4,5 d

6 5 6

D = D + 2,25 d

6m 5 6

according to Table 10

d

The filling factor of the braid is:

N ⋅ n ⋅ d ⋅ k

6 6 6 6r

q =

2 ⋅ π ⋅ D

6m

d and D as above

6 6m

k according to Table 9

6r

The coverage and the braid angle of the screen are given by:

B = 2q – q β = arc tan πD /L

6 6 6 6 6m 6

6.7 Sheath diameters

Sheath diameters are given in Table 18.

Table 18 – Sheath diameters

Material Outer diameter of Nominal thickness Minimum thickness

a

screen D s s min.

6 4 4

FEP 0,25 mm 0,15 mm

<2,5

2,5 – 5,9 0,25 mm

PTFE 0,38 mm

6,0 – 9,0 0,30 mm

a

PE <2,5 0,07 D + 0,3 mm

0,9 s – 0,1 mm

a

PVC 0,07 D + 0,5 mm

≥2,5

a

Cables without screen: to be replaced by outer diameter of outer conductor D .

6.8 Weight calculation

.

The approximate total weight of the cable is to be calculated from m = Σ m

x

For the calculation of the individual weights, formulae are given in Table 19:

60096-0-1 © IEC:2012 – 19 –

Table 19 – Weight calculation

π

Solid inner conductor =

m ⋅D ⋅γ

1 1

γ according to Table 4

k according to Table 8

1r

π

Stranded inner conductor m = ⋅ d ⋅ N ⋅ k ⋅ γ

1 1 1r 1

γ according to Table 3

π 2

2 2

Insulation m = ⋅ (D − D )⋅ γ

2 1

4 D according to 6.3

Tubular outer conductor m = π ·(D + s ) · s ·γ γ according to Table 4

3 2 3 3 3 3

π

Braided outer conductor m = ⋅ d ⋅ N ⋅ n ⋅ k ⋅ γ k according to Table 9

3 3r

3 3 3 3r 3

m = π •(D + s )· s ·γ γ dependent on the material used

Interposed medium between outer 5 3 5 5 5 5

conductor and screen

D according to Table 16

γ according to Table 4

π 6

Braided screen m = ⋅ d ⋅ N ⋅ n ⋅ k ⋅ γ

6 6 6 6r 6

k according to Table 9

6r

a

Sheath

m = π · (D + s ) · s · γ γ according to Table 3

4 6 4 4 4 4

a

For cables without screen, D is to be replaced by D .

6 3

7 Calculation of electrical properties

7.1 DC resistance of conductors and screen, per unit length

The values are to be calculated from the formulae in Table 20:

Table 20 – Electrical properties

R =

Solid inner conductor

π ⋅ D ⋅ χ

4 k

1r

Stranded inner conductor R =

N ⋅ π ⋅ d ⋅ χ

1 1 1

χ , χ , χ according to Table 4

R = 1 3 6

Tubular inner conductor

π ⋅ (D − S )⋅ S ⋅ χ

1 1 1

1 k according to Table 8

1r

and k according to Table 9

k

3r 6r

R =

Tubular outer conductor

d and d according to Table 10

π ⋅ (D + s )⋅ S ⋅ χ 3 6

2 3 3 3

4 k

3r

R =

Braided outer conductor

N ⋅ n ⋅ π ⋅ d ⋅ χ

3 3 3 3

4 ⋅k

6r

R =

Braided screen 6

N ⋅ n ⋅ π ⋅ d ⋅ χ

6 6 6 6

– 20 – 60096-0-1 © IEC:2012

7.2 Attenuation

The total attenuation per unit length is to be calculated from:

α = α + α + α

1 2 3

where α , α and α are the attenuation components due to the inner conductor, dielectric

1 2 3

and outer conductor. The attenuation is related to a cable temperature of 20 °C. For

temperatures T ≠ 20 °C, the attenuation shall be calculated by:

α = (α + α ) 1+ 0,00393 (T − 20 °C) + α

T 1 3 2

NOTE α may be temperature-dependent for some dielectric materials.

Formulae for calculation of α , α and α are given in Table 21. These formulae are

1 2 3

applicable for frequencies ≥10 MHz. Formulae for lower frequencies are under consideration.

Table 21 – Factors for calculation of attenuation

4,58 ⋅ k ⋅ k ε ⋅ f

1c 1a 2

α = ⋅

χ

D ⋅ln D /D χ and χ , k and k according to Tables 4 and 5

1e 3e 1e 1 1 3 1c 3c

k and k according to Table 11

1a 3a

α = 9,1⋅ ε ⋅ tan δ f

2 2 2

ε and tan δ according to Table 3

2 2

D and D according to 6.2 and to Table 14 or to 6.4

4,58 ⋅ k ⋅ k ε ⋅ f

1e 3e

3c 3a

α = ⋅

χ

D ⋅lnD /D

3e 3e 1e 3

7.3 Nominal characteristic impedance Z and capacitance C per unit length

o 2

2)

D

3e

z = ln

o

D

ε

1e

2)

ε

C = ⋅10 (pF/m)

3z

o

ε according to Table 3 or as provided by the manufacturer;

D according to Table 14 or to 6.4 or as provided by the manufacturer;

3e

D according to 6.2.

1e

7.4 Calculation of power rating

The power rating shall be calculated from the attenuation and the maximum permissible

dissipation power for an ambient temperature of 40 °C.

For most practical purposes, the maximum permissible dissipation power per unit length (P )

d

of the inner conductor, given by the

is dependent on the maximum permissible temperature T

maximum permissible temperature of dielectric (see Table 3).

___________

2)

Rounded up from 59,96 and 2,9979 respectively.

60096-0-1 © IEC:2012 – 21 –

The temperature rise of the inner conductor above that of the stagnant ambient air is:

0,8

P α + 1 / 2 α D D 1 000 P

d 1 2 2 4 d

T − 40 °C = σ ln + σ ln +

1 2 4

2π α D D π D k

1 6 4 4

σ and σ according to Table 3;

2 4

k according to Figure 1.

For cables without screen, D is to be replaced by D .

6 3

The first term of the sum is the temperature rise of inner conductor above sheath surface

(T – T ). The second term is the temperature rise of sheath above ambient air (T – T ).

1 4 4 a

Having found P , the maximum permissible input power is given by:

d

868,6 P 395 P

d d

P = =

2,2 α α

T T

α according to 7.2.

T

The maximum attenuation may be 10 % above the nominal value. Because of the unknown

temperature of the outer conductor, the calculation assumes equality with the temperature of

the inner conductor. The resulting error is negligible.

For ambient temperatures T ≠ 40 °C, the power rating shall be calculated from P by the

a 40

empirical formula:

1,14

T −T

1 a

P = P ⋅

T 40

T − 40 °C

1

7.5 Permissible voltages

7.5.1 Test voltage, dielectric, U

t

The maximum value of voltage gradient is to be found at the surface of the inner conductor. It

is limited by the maximum permissible voltage E of the dielectric. Hence the test voltage U

2 tc

(r.m.s. value) is to be calculated from the formula:

E D ⋅ k D

3e

2 1 2

U = ⋅ ln

tc

2 D

1e

E according to Table 3; or as provided by the manufacturer;

k according to Table 8; or as provided by the manufacturer;

D according to 6.3;

D according to 6.2;

1e

D according to Table 14 or to 6.4; or as provided by the manufacturer.

3e

– 22 – 60096-0-1 © IEC:2012

The value of U shall then be rounded to the nearest 0,2 kV for values below 5 kV and to

tc

the nearest 0,5 kV for values of 5 kV and more. The rounded test voltage is designated U .

t

The rounded test voltage shall be applied for 2 min at a frequency of 40 Hz to 60 Hz.

7.5.2 Discharge test voltage, dielectric, U

d

The discharge test voltage U (r.m.s. value) is given by the formula U = 0,5 U except in the

d d t

case for polytetrafluoroethylene.

U = 0,4 U with a minimum of 1 kV

d t

7.5.3 Maximum permissible operating voltage, U

o

The maximum permissible operating voltage U (r.m.s. value) is derived from the test voltage

o

U

t

U = 0,45 U

oc t

as far as the maximum permissible input power P will not be exceeded.

The condition

U ≤ z ⋅P / 1000

o o 40

has to be met in each case. The value of U shall then be rounded to the nearest 0,2 kV for

oc

values below 5 kV and to the nearest 0,5 kV for values of 5 kV and more. The rounded

maximum permissible operating voltage is designated U .

o

7.5.4 Test voltage, sheath

For PVC sheaths, see Table 22:

Table 22 – Test voltages for PVC sheaths

Nominal thickness of the sheath Test voltage

(s ) kV r.m.s.

mm

Immersion test Spark test

Up to and including 0,5 No test No test

Over 0,5 up to and including 0,8 2 3

Over 0,8 up to and

...

IEC 60096-0-1 ®

Edition 3.1 2017-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Radio frequency cables –

Part 0-1: Guidelines to the design of detail specifications – Coaxial cables

Câbles pour fréquences radioélectriques –

Partie 0-1: Lignes directrices pour la conception des spécifications particulières ‒

Câbles coaxiaux

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 16

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC

65 000 entrées terminologiques électrotechniques, en anglais

en utilisant différents critères (numéro de référence, texte,

et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les

publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées.

antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Restez informé sur les nouvelles publications IEC. Just Service Clients - webstore.iec.ch/csc

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60096-0-1 ®

Edition 3.1 2017-01

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Radio frequency cables –

Part 0-1: Guidelines to the design of detail specifications – Coaxial cables

Câbles pour fréquences radioélectriques –

Partie 0-1: Lignes directrices pour la conception des spécifications particulières ‒

Câbles coaxiaux

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 33.120.10 ISBN 978-2-8322-3911-7

IEC 60096-0-1 ®

Edition 3.1 2017-01

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Radio frequency cables –

Part 0-1: Guidelines to the design of detail specifications – Coaxial cables

Câbles pour fréquences radioélectriques –

Partie 0-1: Lignes directrices pour la conception des spécifications particulières ‒

Câbles coaxiaux

– 2 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Symbols and numbering . 6

3.1 Register of symbols used . 6

3.2 Numbering of construction elements . 8

4 Material constants . 9

4.1 Table of material constants relating to dielectric and sheath and their values

for different materials . 9

4.2 Tables of material constants relating to conductors . 11

4.3 Construction constants . 12

4.3.1 Table of construction constants relating to inner conductor . 12

4.3.2 Table of construction constants relating to braided outer conductors

and screens . 12

4.4 Table of braid wire dimensions of outer conductor and screen . 13

4.5 Attenuation factors . 13

4.6 Maximum permissible input power . 14

5 Standard values of characteristic impedance and outer diameter of dielectric . 14

5.1 Nominal characteristic impedance of coaxial cables . 14

5.2 Nominal diameters over dielectric of coaxial cables . 15

6 Cable construction details . 16

6.1 General . 16

6.2 Inner conductor . 17

6.3 Stranded inner conductor . 17

6.4 Braided outer conductors . 17

6.5 Medium between outer conductor and screen . 18

6.6 Braided screen. 18

6.7 Sheath diameters . 18

6.8 Weight calculation . 18

7 Calculation of electrical properties . 19

7.1 DC resistance of conductors and screen, per unit length . 19

7.2 Attenuation . 20

7.3 Nominal characteristic impedance Z and capacitance C per unit length . 20

o 2

7.4 Calculation of Power rating . 20

7.4.1 Average power rating . 20

7.4.2 Peak power rating . 21

7.5 Permissible voltages . 22

7.5.1 Test voltage, dielectric, U . 22

t

7.5.2 Discharge test voltage, dielectric, U . 22

d

7.5.3 Maximum permissible operating voltage, U . 22

o

7.5.4 Test voltage, sheath . 23

7.6 Insulation resistance . 23

7.7 Current carrying capacity of coaxial cables . 23

7.7.1 Principle . 23

7.7.2 Definitions . 23

7.7.3 Requirements . 24

© IEC 2017

Figure 1 – Graph for calculation of maximum permissible input power . 14

Table 1 – Example of use of k factor . 8

x

Table 2 – Example of use of k factor . 8

xy

Table 3 – Material constants relating to dielectric and sheath and their values for

different materials . 9

Table 4 – Conductivity (at 20 °C) and density . 11

a

Table 5 – Coating factor . 11

Table 6 – Tinned copper wire . 11

Table 7 – Copper clad steel wire . 12

Table 8 – Construction constants relating to inner conductor . 12

Table 9 – Construction constants relating to braided outer conductors and screens . 13

Table 10 – Braid wire dimensions of outer conductor and screen . 13

Table 11 – Factor relating to calculation of attenuation – examples . 13

Table 12 – Nominal diameters D over dielectric and the tolerances . 15

Table 13 – Special design features . 16

Table 14 – Special design features . 17

Table 15 – Braided outer conductors . 17

Table 16 – Medium between outer conductor and screen . 18

Table 17 – Braided screen . 18

Table 18 – Sheath diameters . 18

Table 19 – Weight calculation . 19

Table 20 – Electrical properties. 19

Table 21 – Factors for calculation of attenuation . 20

Table 22 – Test voltages for PVC sheaths . 23

– 4 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RADIO FREQUENCY CABLES –

Part 0-1: Guidelines to the design of detail specifications –

Coaxial cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60096-0-1 edition 3.1 contains the third edition (2012-10) [documents 46A/1043/FDIS and

46A/1064/RVD] and its amendment 1 (2017-01) [documents 46A/1317/FDIS and 46A/1321/RVD].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text.

A separate Final version with all changes accepted is available in this publication.

© IEC 2017

International standard IEC 60096-0-1 has been prepared by subcommittee 46A: Coaxial

cables, of IEC technical committee 46: Cables, wires, waveguides, R.F. connectors, R.F. and

microwave passive components and accessories.

This third edition constitutes a technical revision.

The significant changes with respect to the previous edition are as follows:

– tables of material constants and factors and have been updated, different equations have

been updated and corrected;

– a subclause dealing with the calculation of “Current carrying capacity of coaxial cables”

has been added as Subclause 7.7.

A list of all the parts in the IEC 60096 series, published under the general title Radio

frequency cables, can be found on the IEC website.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

RADIO FREQUENCY CABLES –

Part 0-1: Guidelines to the design of detail specifications –

Coaxial cables

1 Scope

This part of IEC 60096 provides guidance for the design of radio frequency coaxial cables

with braid, metallic tapes or tubular outer conductors.

2 Normative references

Void.

3 Symbols and numbering

3.1 Register of symbols used

Symbol Designation Unit

α Total attenuation per unit length, 20 °C . dB/100 m

α Total attenuation per unit length, T ≠ 20 °C . dB/100 m

T

α Attenuation due to element x, 20 °C . dB/100 m

x

β Braid angle of element x . ° (degree)

x

γ Density of the material of element x . g/cm

x

δ Loss angle of the material of element x . rad

x

e Relative dielectric permittivity of the material of element x . –

x

χ Conductivity of the material of element x, 20 °C . m/Ωmm

x

σ Thermal resistivity of the material of element x . K⋅m/W

x

B Braid coverage concerning element x. –

x

c Velocity of propagation in free space . m/s

o

C Dielectric diameter mm

C Capacitance of element x, per unit length . pF/m

x

d Diameter of individual wires of element x . mm

x

D Outer diameter of element x . mm

x

D Electrical effective diameter of element x . mm

xe

D Mean diameter of element x . mm

xm

D Sheath diameter mm

D Outer conductor diameter mm

s

d Center conductor diameter mm

E Maximum permissible voltage gradient of dielectric (peak value). kV/mm

ε Surface emissivity (sheathed=0,95, bare=0,35)

f Frequency . MHz

h Coating thickness concerning element x . mm

x

I Current carrying capacity (Amperes)

k , k Calculation factors according to Tables 1 and 2 . –

x xy

L Braid lay length concerning element x . mm

x

© IEC 2017

Symbol Designation Unit

ln Natural logarithm

m Total weight of cable per unit length . g/m

m Weight of element x . g/m

x

N Number of stranded wires of inner conductors . –

N Number of wires to each spindle concerning braid x . –

x

n Number of cables

n Number of spindles in the braid concerning element x . –

x

P Maximum permissible input power, ambient temperature 40 °C . W

P Thermal resistivity of the dielectric material, Typically =

i

13,0 K·m/W for both foam,

disc and air dielectrics

P Thermal resistivity of the sheath material,

j

Typically = 3,5 K·m/W for polyethylene

Typically = 7,0 K·m/W for polyvinylchloride (PVC) sheaths

P Maximum permissible input power, ambient temperature T ≠ 40 °C . W

T

P Maximum permissible dissipation power per unit length . W/m

d

q Filling factor of braid concerning element x . –

x

R DC resistance of conductive element x, per unit length . Ω/m

x

and insulation resistance of insulating element x respectively . MΩ·km

R Inner conductor resistance Ω/m at t

ic a

R Inner conductor resistance at conductor operating temperature (t )

ictc c

R Outer conductor resistance Ω/m at t

oc a

R Outer conductor resistance at conductor operating temperature (t )

octc c

R Increase in R due to effect of outer conductor

eoc ic

R Total thermal resistance of circuit K.m/W

th

R Thermal resistance of dielectric K.m/W

i

R Thermal resistance of sheath K.m/W

j

s Nominal thickness of element x . mm

x

s Minimal thickness of element x . mm

xmin.

T Temperature of element x . °C

x

T Ambient temperature. °C

a

t Conductor operating temperature °C

c

t Ambient temperature °C

a

t Cable surface temperature °C

s

U Test voltage (40 Hz - 60 Hz), rounded r.m.s. value . kV

t

U Test voltage (40 Hz - 60 Hz), rounded r.m.s. value . kV

tc

U Discharge test voltage, r.m.s. value . kV

d

U Maximum permissible operating voltage, rounded r.m.s. value . kV

o

U Maximum permissible operating voltage, calculated r.m.s. value . kV

oc

ν Velocity ratio . –

r

z Characteristic impedance, nominal value . Ω

o

– 8 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

3.2 Numbering of construction elements

Numbering of construction elements in the following tables are as follows:

1 Inner conductor

2 Dielectric

3 Outer conductor

4 Sheath

5 Medium between outer conductor and screen

6 Screen

7 Medium between first and second screen

8 Second screen

etc.

Examples of use of k factor are given in Table 1.

x

Table 1 – Example of use of k factor

x

Symbol Designation Unit

Factor dependent on inner conductor concerning the

k –

voltage gradient in the dielectric

2 1,25

k Thermal dissipation constant of sheath surface in air W/m K

Examples of use of k factor are given in Table 2.

xy

Table 2 – Example of use of k factor

xy

Construction element

concerned

Factor

1 3 6 8

Coating factor k k

1c 3c

Stranding or braiding factor:

– concerning attenuation k k

1a 3a

– concerning d.c. resistance and weight k k k k

1r 3r 6r 8r

Ratio between overall diameter and diameter of

k

1d

individual wires

Effective diameter factor concerning characteristic

k

1z

impedance

© IEC 2017

4 Material constants

4.1 Table of material constants relating to dielectric and sheath and their values for different materials

Material constants relating to dielectric and sheath and their values for different materials are given in Table 3.

Table 3 – Material constants relating to dielectric and sheath and their values for different materials

a

Symbol Designation Unit Value for

b b

Solid PE Semi-air- Cellular PE PTFE FEP Cellular ETFE PFA PVC

spaced PE FEP

Permittivity of dielectric – 2,28 1,4 1,3 1,5 1,7 2,1 2,1 1,5 2,6 2,1

e

c f e e

–4 –4 –4 –4 –4 –3

tan δ Dissipation factor – 2,5 × 10 2,5 × 10 4 × 10 6 × 10 6 × 10 1,2 × 10

of dielectric

e e

E Maximum permissible kV/mm 11 2 2 2 2 11 2

voltage gradient

of dielectric

3 b

Density of dielectric g/cm 0,93 0,36 0,28 0,44 0,58 2,2 2,2 0,90 1,7 2,2 1,4

γ , γ

2 4

and sheath

e e

σ , σ Thermal resistivity K • m/W 3,5 15 9 6 4,4 5,0 4,4 4,5 7,0

2 4

of dielectric and sheath

d d g g g g

T Maximum permissible °C 85/80 85/80 70 70 70 250 200 200 150 200 70

operating temperature

– 10 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

Table 3 (continued)

a PE = polyethylene

PTFE = polytetrafluoroethylene

FEP = fluorinated ethylene propylene

ETFE = ethylenetetrafluoroethylene

PFA = perfluoroalcoxylalkane

PVC = polyvinylchloride

b Typical value(s).

c

Frequency tan δ2

MHz

–4

1 1×10

–4

1,5×10

–4

2,5×10

103 –4

4,3×10

104 –4

2×10

d 85 °C: high density material.

80 °C: other density material.

e Under consideration

f

Frequency

tan δ2

MHz

–4

4×10

–4

4×10

–4

8×10

–4

10×10

–4

2×103

10×10

104 –4

7×10

g In the case of silvered inner and outer conductors only.

© IEC 2017

4.2 Tables of material constants relating to conductors

Material constants relating to conductors are given in Tables 4 to 7.

Table 4 – Conductivity (at 20 °C) and density

Conductor Symbols Unit Value Symbols Unit Value

2 3

Copper χ , χ , χ m/Ωmm 58 γ , γ , γ g/cm 8,9

1 3 6 1 3 6

Aluminium 35 2,7

Tin 8,3 7,3

Silver 61 10,5

a

Copper clad steel 30 % 17,4 8,15

a

Copper clad steel 40 % 23,2 8,20

a

For calculation of d.c. resistance only.

a

Table 5 – Coating factor

Conductor Symbol Value

Bare copper wire 1

Silvered copper wire 1

k and k

1c 3c

Tinned copper wire Table 6

Copper clad steel wire Table 7

a

RF resistance of coated wire in relation to bare

copper wire, dependent on frequency and coating

thickness

Table 6 – Tinned copper wire

k or k

h f or h f 1c 3c

1 3

0,01 1,01

0,02 1,03

0,03 1,06

0,04 1,11

0,06 1,25

0,08 1,44

0,10 1,67

0,12 1,91

0,15 2,24

0,18 2,46

0,20 2,60

2,70

≥0,25

– 12 – IEC 60096-0-1:2012+AMD1:2017 CSV

© IEC 2017

Table 7 – Copper clad steel wire

a

k

h

f 1c

0,005 11,04

0,010 6,06

0,015 4,16

0,020 3,17

0,025 2,57

0,030 2,16

0,035 1,87

0,040 1,65

0,050 1,35

0,060 1,16

0,070 1,04

0,080 1,00

a

Assumptions relating to steel:

χ = 8 m/Ωmm .

Relative permeability, µ = 200.

r

4.3 Construction constants

4.3.1 Table of construction constants relating to inner conductor

Construction constants relating to inner conductor are given in Table 8.

Table 8 – Construction constants relating to inner conductor

Value versus number of strands

N

Symbol Designation

1 7 12 19

Stranding factor for d.c. resistance and

k 1,00 1,03 1,03 1,03

1r

weight

k Standing factor for attenuation 1,00 1,25 1,25 1,25

1a

k Effective diameter factor 1,00 0,94 0,96 0,98

1z

Ratio between overall diameter

k 1,00 3,02 4,16 5,00

1d

and diameter of individual wires

k Voltage gradient factor 1,00 0,90 0,90 0,90

4.3.2 Table of construction constants relating to braided outer conductors

and screens

Construction constants relating to braided outer conductors and screens are given in Table 9.

© IEC 2017

Table 9 – Construction constants relating to braided outer conductors

and screens

L L

3 6

k ; k

Braid angle β ; β ;

3r 6r

3 6

D D

3m 6m

20° 8,63 1,06

25° 6,74 1,10

30° 5,44 1,15

35° 4,49 1,22

40° 3,74 1,30

45° 3,14 1,41

Definitions: k = 1 + (π ⋅ D /L ) =

3r 3m 3

cosβ

k = 1 + (π ⋅ D /L ) =

6r 6m 6

cosβ

4.4 Table of braid wire dimensions of outer conductor and screen

Braid wire dimensions of outer conductor and screen are given in Table 10.

Table 10 – Braid wire dimensions of outer conductor and screen

Nominal diameter of braid wire (d , d )

3 6

Nominal outer diameter

mm

of dielectric (D )

mm

Single braid Double braid

0,87 and 1,5 0,09–0,11 –

2,95, 3,7, 4,8 and 6,4 0,13–0,15 0,13–0,15

7,25, 9,8 and 11,5 0,18–0,20 0,16–0,18

17,3 0,24–0,26 0,18–0,20

4.5 Attenuation factors

Examples of attenuation factors for the calculation of attenuation are given in Table 11.