IEC 60885-3:2015

(Main)Electrical test methods for electric cables - Part 3: Test methods for partial discharge measurements on lengths of extruded power cables

Electrical test methods for electric cables - Part 3: Test methods for partial discharge measurements on lengths of extruded power cables

IEC 60885-3:2015 specifies the test methods for partial discharge (PD) measurements on lengths of extruded power cable, but does not include measurements made on installed cable systems. Reference is made to IEC 60270 which gives the techniques and considerations applicable to partial discharge measurements in general. This second edition of IEC 60885-3 cancels and replaces the first edition, published in 1988 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- The definition of sensitivity as twice the background noise level has been removed and replaced by a practical assessment of sensitivity based on the minimum level of detectable discharge.

- References to measurements of pulse heights in mm on an oscilloscope have been replaced by measurements of partial discharge magnitude in pC.

- The order of the clauses has been revised in line with the general numbering scheme of IEC standards and to provide clarity in order to facilitate its practical use. Section 3 of the first edition (Application guide) has been removed as it is considered that background information is better obtained from the original references as listed in the bibliography.

Méthode d'essais électriques pour les cables électriques - Partie 3: Méthodes d'essais pour la mesure des décharges partielles sur des longueurs de câbles de puissance extrudés

IEC 60885-3:2015 spécifie les méthodes d'essai pour les mesures des décharges partielles sur des longueurs de câbles de puissance extrudés, mais ne traite pas des mesures effectuées sur des systèmes de câbles installés. Il est fait référence à l'IEC 60270 qui donne les techniques et considérations générales applicables aux mesures des décharges partielles. Cette deuxième édition de l'IEC 60885-3 annule et remplace la première édition parue en 1988. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- La définition de la sensibilité considérée comme le double du niveau de bruit de fond a été supprimée et remplacée par une évaluation pratique de la sensibilité en fonction du niveau minimum de décharge détectable.

- Les références aux mesures des hauteurs d'impulsions en mm sur un oscilloscope ont été remplacées par des mesures de la grandeur de la décharge partielle en pC.

- L'ordre des articles a été révisé pour reprendre le schéma de numérotation général des normes de l'IEC et pour clarifier le texte pour en faciliter l'utilisation pratique. La Section 3 de la première édition (Guide d'application) a été supprimée car il est considéré que les références originales telles qu'énumérées dans la bibliographie fournissent des informations de meilleure qualité sur l'environnement technique.

General Information

- Status

- Published

- Publication Date

- 08-Apr-2015

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Apr-2015

- Completion Date

- 30-Apr-2015

Overview - IEC 60885-3:2015 (Partial Discharge Tests for Extruded Power Cables)

IEC 60885-3:2015 defines standardized test methods for partial discharge (PD) measurements on lengths of extruded power cable. It is focused on laboratory and factory testing of cable lengths (type and production tests), and explicitly does not cover PD measurements on installed cable systems. The standard complements general PD measurement techniques given in IEC 60270 and represents a technical revision of the 1988 edition with updates to measurement sensitivity, charge units and clause structure.

Key topics and technical requirements

- Scope and purpose

- Test methods for PD measurement on extruded power cable lengths (not installed systems).

- Reference and normative link to IEC 60270 for general PD measurement techniques.

- Measurement units and sensitivity

- Partial discharge magnitude is specified and reported in picocoulombs (pC) (replacing older pulse-height-in-mm oscilloscope measures).

- The previous definition of sensitivity (twice background noise) was removed; sensitivity is now a practical assessment based on minimum detectable discharge.

- Test circuit setup and equipment

- Requirements for test apparatus: coupling capacitor, detector, calibrator, double pulse generator and measuring instruments.

- Procedures for calibration charge of the complete measuring system to ensure accurate PD magnitude in pC.

- Cable-specific effects

- Treatment of travelling waves, attenuation and superposition effects that occur in long cable lengths.

- Guidance on testing short cable lengths (including type test lengths) versus long cable lengths with or without terminal impedances or reflection suppressors.

- Terminal impedance and reflection control

- Requirements for terminal impedance (characteristic impedance) and use of reflection suppressors to control pulse reflections and measurement errors.

- Description of double pulse behaviour and plotting of double pulse diagrams to interpret superposition effects.

Practical applications - who uses IEC 60885-3

- Cable manufacturers performing type and routine PD testing on extruded power cable samples.

- High-voltage test laboratories validating cable insulation quality and PD inception/limits.

- Utilities and power system commissioning teams using factory test results during procurement and acceptance.

- R&D and QA engineers developing insulation systems and test procedures.

- Use cases: production acceptance, type qualification, diagnostic lab tests, calibration of PD measurement chains, and troubleshooting PD sources on cable samples.

Related standards and references

- IEC 60270 - High-voltage test techniques: Partial discharge measurements (normative reference for general PD techniques).

- Other parts of the IEC 60885 series (electrical test methods for electric cables) for complementary test procedures.

Keywords: IEC 60885-3, partial discharge (PD), extruded power cables, PD measurements, IEC 60270, pC calibration, terminal impedance, reflection suppressor, double pulse, travelling waves, cable testing.

Buy Documents

REDLINE IEC 60885-3:2015 - Electrical test methods for electric cables - Part 3: Test methods for partial discharge measurements on lengths of extruded power cables Released:4/9/2015 Isbn:9782832226179

IEC 60885-3:2015 - Electrical test methods for electric cables - Part 3: Test methods for partial discharge measurements on lengths of extruded power cables

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60885-3:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical test methods for electric cables - Part 3: Test methods for partial discharge measurements on lengths of extruded power cables". This standard covers: IEC 60885-3:2015 specifies the test methods for partial discharge (PD) measurements on lengths of extruded power cable, but does not include measurements made on installed cable systems. Reference is made to IEC 60270 which gives the techniques and considerations applicable to partial discharge measurements in general. This second edition of IEC 60885-3 cancels and replaces the first edition, published in 1988 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - The definition of sensitivity as twice the background noise level has been removed and replaced by a practical assessment of sensitivity based on the minimum level of detectable discharge. - References to measurements of pulse heights in mm on an oscilloscope have been replaced by measurements of partial discharge magnitude in pC. - The order of the clauses has been revised in line with the general numbering scheme of IEC standards and to provide clarity in order to facilitate its practical use. Section 3 of the first edition (Application guide) has been removed as it is considered that background information is better obtained from the original references as listed in the bibliography.

IEC 60885-3:2015 specifies the test methods for partial discharge (PD) measurements on lengths of extruded power cable, but does not include measurements made on installed cable systems. Reference is made to IEC 60270 which gives the techniques and considerations applicable to partial discharge measurements in general. This second edition of IEC 60885-3 cancels and replaces the first edition, published in 1988 and constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - The definition of sensitivity as twice the background noise level has been removed and replaced by a practical assessment of sensitivity based on the minimum level of detectable discharge. - References to measurements of pulse heights in mm on an oscilloscope have been replaced by measurements of partial discharge magnitude in pC. - The order of the clauses has been revised in line with the general numbering scheme of IEC standards and to provide clarity in order to facilitate its practical use. Section 3 of the first edition (Application guide) has been removed as it is considered that background information is better obtained from the original references as listed in the bibliography.

IEC 60885-3:2015 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60885-3:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60885-3 ®

Edition 2.0 2015-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical test methods for electric cables –

Part 3: Test methods for partial discharge measurements on lengths of extruded

power cables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60885-3 ®

Edition 2.0 2015-04

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Electrical test methods for electric cables –

Part 3: Test methods for partial discharge measurements on lengths of extruded

power cables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-2617-9

– 2 – IEC 60885-3:2015 RLV © IEC 2015

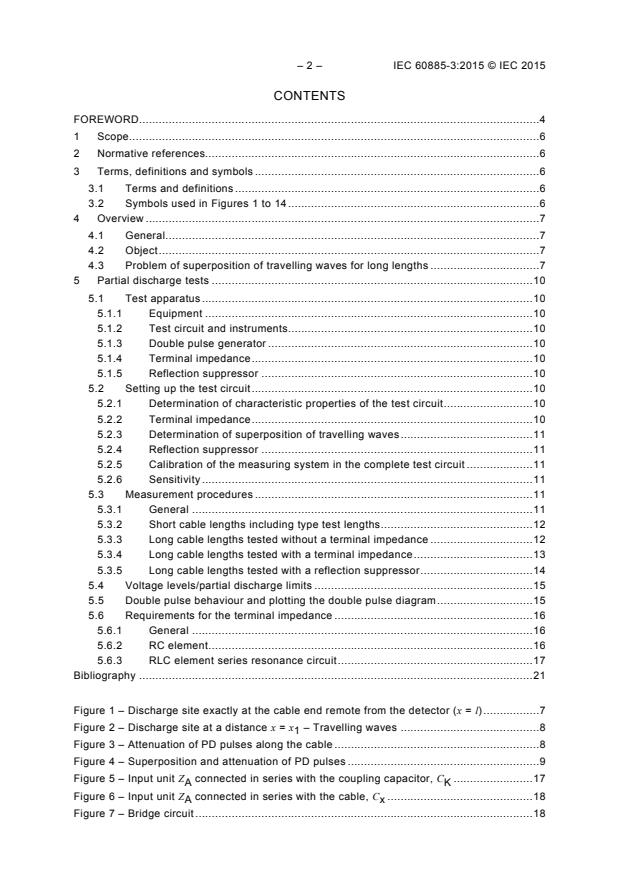

CONTENTS

FOREWORD . 4

1 SECTION ONE – GENERAL .

1 Scope . 6

2 Normative references . 6

2 SECTION TWO – PARTIAL DISCHARGE TESTS .

3 Terms, definitions and symbols. 6

3.1 Terms and definitions . 6

3.2 Symbols used in Figures 1 to 14 . 6

4 Overview . 7

4.1 General . 7

4.2 Object . 7

4.3 Problem of superposition of travelling waves for long lengths . 7

5 Partial discharge tests . 10

5.1 Test apparatus . 10

5.1.1 Equipment . 10

5.1.2 Test circuit and instruments . 10

5.1.3 Double pulse generator . 10

5.1.4 Terminal impedance (characteristic impedance) . 10

5.1.5 Reflection suppressor . 10

5.2 Setting up the test circuit . 11

5.2.1 Determination of characteristic properties of the test circuit . 11

5.2.2 Terminal impedance . 11

5.2.3 Superposition Determination of superposition of travelling waves . 11

5.2.4 Reflection suppressor . 11

5.2.5 Calibration charge of the measuring system in the complete test circuit . 11

5.2.6 Sensitivity . 12

5.3 Measurement procedures . 12

5.3.1 General . 13

5.3.2 Short cable lengths including type test lengths . 13

5.3.3 Long cable lengths tested without a terminal impedance . 14

5.3.4 Long cable lengths tested with a terminal impedance . 15

5.3.5 Long cable lengths tested with a reflection suppressor . 16

5.4 Voltage levels/partial discharge limits . 17

5.5 Double pulse behaviour and plotting the double pulse diagram . 17

5.6 Requirements for the terminal impedance . 18

5.6.1 General . 18

5.6.2 RC element . 18

5.6.3 RLC element series resonance circuit . 19

3 SECTION THREE – APPLICATION GUIDE.

3.1 Background information .

3.1.1 Introduction .

3.1.2 Superposition and attenuation .

3.2 Procedures and parameters .

3.2.1 Determination of characteristic properties of the test circuit (see 2.3) .

3.2.2 Measurement procedures (see 2.4) .

Bibliography . 31

LIST OF SYMBOLS .

Figure 1 – Discharge site exactly at the cable end remote from the detector (x = l) . 7

Figure 2 – Discharge site at a distance x = x – Travelling waves . 8

Figure 3 – Attenuation of PD pulses along the cable . 8

Figure 4 – Superposition and attenuation of PD pulses . 9

Figure 5 – Input unit Z connected in series with the coupling capacitor, C . 20

A K

Figure 6 – Input unit Z connected in series with the cable, C . 20

A x

Figure 7 – Bridge circuit . 20

Figure 8 – Connection of the terminal impedance Z . 21

w

Figure 9 – Connection of the reflection suppressor, RS . 21

Figure 10 – Connection of the double pulse generator into the measuring circuit in

Figure 5 . 21

Figure 11 – Double pulse diagram type 1 without negative superposition . 22

Figure 12 – Double pulse diagram type 2 with negative superposition between t and t . 22

1 2

Figure 13 – Double pulse diagram type 3 with negative and positive superpositions

between t and t . 22

1 2

Figure 14 – Connection of the double pulse generator for the test circuit in Figure 9

with the reflection suppressor . 23

Figure 15 – Maximum attenuation error, both cable ends connected together .

Figure 16 – Maximum attenuation error at the centre of the cable if measurements are

made from both ends .

Figure 17 – Double pulse diagram type 2. Negative superposition between l1 and l2

(forbidden length). .

Figure 18 – Measurement from both ends to avoid negative error .

Figure 19 – Negative superposition for 2l1 < l < 2l2 .

Figure 20 – Only positive superposition for l < 2l1 .

– 4 – IEC 60885-3:2015 RLV © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL TEST METHODS FOR ELECTRIC CABLES –

Part 3: Test methods for partial discharge measurements

on lengths of extruded power cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60885-3 has been prepared by IEC technical committee 20:

Electric cables.

This second edition of IEC 60885-3 cancels and replaces the first edition, published in 1988

and constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

• The definition of sensitivity as twice the background noise level has been removed and

replaced by a practical assessment of sensitivity based on the minimum level of

detectable discharge.

• References to measurements of pulse heights in mm on an oscilloscope have been

replaced by measurements of partial discharge magnitude in pC.

• The order of the clauses has been revised in line with the general numbering scheme of

IEC standards and to provide clarity in order to facilitate its practical use. Section 3 of the

first edition (Application guide) has been removed as it is considered that background

information is better obtained from the original references as listed in the bibliography.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1560/FDIS 20/1587/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60885 series, published under the general title Electrical test

methods for electric cables, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60885-3:2015 RLV © IEC 2015

ELECTRICAL TEST METHODS FOR ELECTRIC CABLES –

Part 3: Test methods for partial discharge measurements

on lengths of extruded power cables

1 SECTION ONE – GENERAL

1 Scope

This part of IEC 60885 specifies the essential requirements test methods for partial discharge

(PD) measurements on lengths of extruded power cable, but does not include measurements

made on installed cable systems.

Reference is made to IEC 60270 which gives the techniques and considerations applicable to

partial discharge measurements in general. The first edition of IEC 60270 appeared in 1968.

All references in this standard apply to the second edition (1981).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60270:2000, High-voltage test techniques – Partial discharge measurements

2 SECTION TWO – PARTIAL DISCHARGE TESTS

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60270 apply.

3.2 Symbols used in Figures 1 to 14

a discharge magnitude measured with the calibrator at the end near to the detector

a discharge magnitude measured with the calibrator at the end remote from the detector

Ccal calibrator

CK coupling capacitor

Cx power cable

D detector

I double pulse generator

l length of the power cable

M coaxial signal cable

Q discharge magnitude

R1R2 matching resistors

RS reflection suppressor

v propagation velocity of partial discharge

V voltage indicator

W power supply

Z impedance/filter

Z input unit

A

Z terminal impedance

W

4 Overview

4.1 General

Partial discharge measurements shall be carried out using the test techniques specified in

IEC 60270.

4.2 Object

The object of the test is to determine the discharge magnitude, or to check that the discharge

magnitude does not exceed a specified value, at a specified voltage with and a given declared

minimum sensitivity.

4.3 Problem of superposition of travelling waves for long lengths

Short lengths of cable behave in the same way as a single capacitor in that the discharge

magnitude can be measured directly by considering the cable as a single capacitor. However

longer cables behave like a transmission line and PD pulses travel away from their source in

both directions along the cable, in the form of a wave. On reaching the remote end from the

measuring equipment, the pulse will be reflected with the same polarity if the end is open

circuit. The reflected pulse will then travel back along the length of cable and arrive at the

detector at a time after the directly received pulse. If the time between the arrival of the two

pulses is short (the time difference depending on the length of the cable) then the detection

instrument may give a false response, indicating either a larger or smaller magnitude of

discharge than was actually the case. The methods detailed in this standard allow correct

measurement of partial discharges under these conditions.

Figures 1 to 4 illustrate the behaviour of travelling waves and possible superposition effects.

Q

V

C

K

Void

x

x = l

Z

A

IEC

Figure 1 – Discharge site exactly at the cable end remote from the detector (x = l)

– 8 – IEC 60885-3:2015 RLV © IEC 2015

a) at the time of the discharge V V

Q/2 Q/2

C

K

Void

l – x

x

x = x

x = l

Z

D

A

t = 2 (l – x )/V

V V

b) after reflection

Q/2 Q/2

C

K

Void

x = x

D

Z

A

IEC

Figure 2 – Discharge site at a distance x = x – Travelling waves

2,0

1,5

a (x = 0)

a (x = l)

1,0

0,8

0,6

0,5a

0,4

= end open

= end with characteristic impedance

0,2

0,1

x (m)

0 500 1 000 1 500 2 000

x = 0 x = l

IEC

Figure 3 – Attenuation of PD pulses along the cable

Relative response

a)

2,0

Positive superposition

1,5

(i) < 30%

a

1,0a

1,0

0,8

0,7a

0,6

0,5a

0,4

= end open

= end with characteristic impedance

0,2

0,1

x (m)

2 000

0 500 1 000 1 500

l = 440 D

k

b)

l = 640 m

2,0

1,5

Positive superposition

1,0

(i) < 30%

1,0a

0,8

0,6

0,7a

0,5a

0,4

Negative superposition

= end open

0,2

= end with characteristic impedance

0,1

x (m)

0 500 1 000 1 500 2 000

l = 190 m

k

l = 220 m

l = 600 m

IEC

Figure 4 – Superposition and attenuation of PD pulses

Relative response

Relative response

– 10 – IEC 60885-3:2015 RLV © IEC 2015

5 Partial discharge tests

5.1 Test apparatus

5.1.1 Equipment

The equipment consists of a high-voltage power alternating voltage supply having a kilovolt-

ampere capability rating adequate for to energise the length of cable under test, a voltmeter

for high voltages, a measuring circuit, a discharge calibrator, a double pulse generator and, if

necessary where applicable, a terminal impedance or reflection suppressor. All components

of the test equipment shall have a sufficiently low noise level to achieve the required

sensitivity. The frequency of the test supply is assumed to be the power frequency a.c. 49 Hz

to 61 Hz of approximately sine-wave form, the ratio peak value/r.m.s. being equal to with a

tolerance of ±7 %. The main subjects considered in this standard, calibration and attenuation

of partial discharge pulses, are not affected by using different frequencies of the power

supply. However, the partial discharge characteristics are affected by the test frequency; the

measurement procedure should take this fact into consideration.

The frequency of the test supply shall be in the range 45 Hz to 65 Hz with a waveshape

approximating to a sinusoid with the ratio of peak to r.m.s. values being equal to √2 with a

maximum tolerance of 5 %.

5.1.2 Test circuit and instruments

The test circuit includes the high voltage power supply, test object, the coupling capacitor and

the HV and PD measuring circuit equipment. The measuring circuit consists of the measuring

impedance (input impedance of the measuring instrument and the input unit which is selected

to match the cable impedance), the connecting lead and the measuring instrument. The

measuring instrument or detector includes a suitable amplifying device, an oscilloscope and, if

desired, an additional, or other instrument to indicate the existence of partial discharges and

to measure the apparent charge. The measuring system shall comply with IEC 60270.

5.1.3 Double pulse generator

The properties of the partial discharge test circuit shall be checked by means of A double

pulse generator is an instrument producing two equal pulses (with the same apparent charge)

following each other within a continuously time interval which can be varied between 0,2 µs to

100 µs. The rise time of the pulses shall not exceed 20 ns (10 % to 90 % of peak value); the

time between 10 % values of the front and the tail shall not exceed 150 ns. The pulses may

be synchronized with the power frequency.

5.1.4 Terminal impedance (characteristic impedance)

A terminal impedance is an impedance, equal in value to the characteristic impedance of the

test object may be, which is connected to the open end of the cable remote from the detector.

This will suppress the reflection of pulses at this end. It may be a combination of resistance

and capacitance (R & C) or resistance, capacitance and inductance (R, C & L). The

components shall be suitable for operation at the test voltage to be applied to the cable under

test. Additional requirements are specified in section 5.6.

5.1.5 Reflection suppressor

To avoid superposition effects when testing without a terminal impedance, a reflection

suppressor may be used. This is an electronic switch which in most cases can is designed to

block the input of the detector measuring instrument from pulses reflected from the open end

of the cable. However, when the partial discharge source is located at or near the open end

some positive superposition is unavoidable. This is achieved by blocking the input for a fixed

time after the first pulse is received.

5.2 Setting up the test circuit

5.2.1 Determination of characteristic properties of the test circuit

The characteristic properties of the test circuit should be determined under the conditions to

be used. The test circuits normally used for connections to a single cable end are those

shown in Figures 5, 6, 7, 8 and 9. Similar test circuits are also applicable when both ends of

the cable conductor are connected together; in this case the two ends of the metal cable

screen must shall also be connected together.

5.2.2 Terminal impedance

If a terminal impedance is used (see Figure 4) its suitability for the type of cable under test

should be demonstrated using the procedure described in 2.7. This check should be carried

out at least once a year and also upon request and when any significant circuit component

has been repaired or changed.

If a terminal impedance is connected to the remote end of the cable under test, with an

impedance value equal to the characteristic impedance of the cable then the cable will behave

as if it is of infinite length and there will be no reflected wave. The circuit for connection of a

terminal impedance is shown in Figure 8. The values (RC and L where applicable) of the

components of the terminal impedance and its suitability for the type of cable under test

should be demonstrated using the procedure described in 5.6. This check should be carried

out when the test circuit is set up and also when any changes are made to the circuit.

5.2.3 Superposition Determination of superposition of travelling waves

If a terminal impedance is not used, it is necessary to determine the properties of the test

circuit with respect to superposition of travelling waves. A double pulse generator is

connected according to Figure 10 and a double pulse diagram is plotted (see 5.5 and

Figures 11, 12 and 13). This check should be carried out at least once a year and also upon

request and when any significant circuit component has been repaired or changed when the

test circuit is set up and also when any changes are made to the circuit.

5.2.4 Reflection suppressor

The purpose of using a reflection suppressor is to obtain a double pulse diagram of Type 1

corresponding to Figure 11. Using the arrangement shown in Figure 14, the efficiency of the

reflection suppressor should be checked at least once per year and also upon request and

when any significant circuit component has been repaired or changed by plotting a double

pulse diagram (see 5.5 and Figures 11, 12 and 13), when the test circuit is set up and also

when any changes are made to the circuit.

5.2.5 Calibration charge of the measuring system in the complete test circuit

The "charge transfer" method of calibration shall be used in accordance with 5.2.1 of

IEC 60270. Further guidance for the use of discharge calibrators is given in CIGRÉ Report

1968-21-01, Appendix III. In this method, a calibrator is connected directly across one end of

the cable being tested to inject short current pulses of predetermined charge magnitude into

the test object as detailed in 2.4. The resulting pulse on the oscilloscope should have a height

of at least 10 mm.

Unless the calibrating capacitor is rated for use at the test voltages involved, it is necessary

to disconnect it before the high-voltage test transformer is energized. The amplifier gain shall

not be re-adjusted after this has been done, unless a means is provided for continuous

display of a suitable calibrating signal throughout the test.

Such a means may be as follows:

– 12 – IEC 60885-3:2015 RLV © IEC 2015

a) the calibrating capacitor may be full voltage rated and may form part of the test circuit. It

need not, in this case, be disconnected before the high-voltage test transformer is

energized, or

b) a secondary calibrator can be used additionally. This calibrator is connected to the input of

the detector. In this case, the amplitude of the secondary pulse response shall be pre-

calibrated against the primary calibrator before the latter is disconnected and the high-

voltage test transformer is energized in accordance with CIGRÉ Report 1968-21-01,

Appendix III, Section I, Sub-clause 1.2.

The calibration discharge, q (in picocoulombs), is equal to the product of the calibration

cal

pulse amplitude ∆U (in volts) and the calibrating capacitance C (in picofarads), of the

cal

calibrator as long as this capacitance is small compared with the capacitance of the test

object, C .

x

q = C ⋅ ∆U

cal cal

The characteristics of the calibrating pulse shall comply with 5.2 and 5.3 of IEC 60270 and

CIGRÉ Report 1968-21-01, Appendix III, Section III. For long lengths of cable there is an

additional requirement that the calibrating capacitance shall be not larger than 150 pF.

Calibration of the measuring system in the complete test circuit shall be carried out in

accordance with Clause 5 of IEC 60270:2000. The calibrator used shall comply with

IEC 60270. For long lengths of cable (> 100 m) there is an additional requirement that the

calibrating capacitance shall be not greater than 150 pF.

5.2.6 Sensitivity

a) The sensitivity of the test circuit (with the high-voltage supply and the instruments)

measuring system is defined as the minimum detectable discharge pulse, q , (in

min

picocoulombs – pC) that can be observed in the presence of background noise. Individual,

clearly identifiable interference pulses may be disregarded. An oscilloscope display is

required to monitor noise signal levels since a picocoulomb meter does not identify the source

of the signal indicated. In order to be detectable, a discharge pulse shall be of at least twice

the apparent noise height, h (h is the noise reading on the oscilloscope or the picocoulomb

n n

meter if this is used additionally).

Value of q shall be determined by evaluation of the background noise level and shall be no

min

more than twice the apparent noise level, h (h is the noise reading on the measuring

n n

instrument).

Therefore:

q = 2 k ⋅ h

min n

q = x × k × h

min n

where k is the scale factor and x is the ratio of the minimum detectable discharge to the

background noise. The maximum allowed value of x is 2. Typically values of x of between 1,25

and 1,5 should be achievable.

b) The maximum values of sensitivity shall be determined according to 5.4.

5.3 Measurement procedures

The test shall be carried out as a type test on short cable samples and as a routine test on

production lengths.

5.3.1 General

The selection of the test circuit depends on whether the cable sample may be considered as a

short length (see 5.3.2) or a long length (see 5.3.3, 5.3.4 and 5.3.5) depending on the double

pulse diagram (subclause 2.6). The test circuit has to shall be discharge free in order to

achieve the required sensitivity (see 5.2.6). Calibration does not necessarily have to be done

with the HV supply on (see 5.2.5). During the partial discharge measurement, individual

pulses clearly identifiable as interference may be disregarded.

5.3.2 Short cable lengths including type test lengths

5.3.2.1 Requirements

For short lengths the cable may be considered similar to a lumped capacitance. The limitation

on length where this is not acceptable depends upon the test circuit used, however it may be

assumed that cable lengths of up to 50 m (or 100 m, if both ends of the cable are connected

together) behave as a lumped capacitance and therefore superposition of reflected waves

need not be taken into account. The actual value would be determined using the double pulse

diagram described in 2.6 and defined as l . For longer lengths whether they can be treated as

k

a lumped capacitance shall be determined using the double pulse diagram as described in

5.5. The maximum length which can be considered as a lumped capacitance is defined as l

k;

This may be as low as 100 m or even greater than 1 000 m, depending on the particular

measuring system in use.

NOTE However, lengths up to 2l behave as short lengths when both ends of the cable are connected together.

k

(See 2.3.)

The test circuits normally used are those in Figures 5, 6 and 7.

5.3.2.2 Verification of sensitivity

The calibrator shall be connected in parallel with the cable and only at the end remote from

the detector. The calibration charge, q , is injected, and the respective measured deflection

cal

value a , is used to calculate the scale factor k = q /a (pC/ mm) and sensitivity, q (pC).

2 2 cal 2 min

q = 2k ⋅ h

min 2 n

where:

h is the deflection (mm) from background interference

n

The determination of the scale factor k for the measurement of the apparent charge shall be

carried out in accordance with Clause 5 of IEC 60270:2000. Therefore the partial discharge

calibrator shall be connected in parallel with the cable at the end remote from the detector.

5.3.2.3 Test procedure

The measurement shall be made only at one end of the cable. For the measured deflection A

(mm) the discharge magnitude q (pC) is

q = k ⋅ A

The voltage levels used shall be selected according to 2.5.

The measurement shall be made only at one end of the cable.

The test parameters shall be selected according to 5.4.

– 14 – IEC 60885-3:2015 RLV © IEC 2015

5.3.3 Long cable lengths tested without a terminal impedance

5.3.3.1 General

For long cable lengths (>50 m or >100 m with ends connected), tested without a terminal

impedance, it is necessary to plot a double pulse diagram.

5.3.3.2 Requirements

For cable lengths in excess of l it may still be possible to test without a terminal impedance

k

provided superposition and attenuation phenomena are taken into account. A test without

terminal impedance is permitted where the double pulse diagram (suclause 2.6) is either:

A double pulse generator is connected according to Figure 10 and a double pulse diagram is

plotted (see 5.5 and Figures 11, 12 and 13). This shall be carried out when the test circuit is

set up and also when any changes are made to the circuit.

A test without terminal impedance is permitted where the double pulse diagram is either

– type 1 (Figure 11) or

– type 2 and type 3 (Figures 12 and 13) but where the cable length, l, lies outside the limits

2l ≤ l ≤ 2l .

1 2

(See 5.5 for the determination of l and l .)

1 2

For lengths inside these limits an alternative test circuit should be used or the procedures

described in 5.3.4 or 5.3.5 should be adopted.

The test circuits normally used are those shown in Figures 5, 6, 7 and 9.

5.3.3.3 Verification of sensitivity

As shown in Figures 1, 2, 3 or 5, the calibrator shall be connected to each end in turn, in

parallel with the cable, at first to the end remote from the detector and then — with the same

setting of the amplifier and calibration charge — to the end near the detector.

The determination of the scale factor k for the measurement of the apparent charge shall be

carried out in accordance with Clause 5 of IEC 60270:2000. Therefore the partial discharge

calibrator shall be connected in parallel with the cable at the end near to the detector.

For the determination of the attenuation correction factor, the partial discharge calibrator shall

be connected to each end in turn in parallel with the cable with the same setting of the

amplifier and calibration charge. The following values shall be recorded:

– a (mm) the deflection discharge magnitude measured with the calibrator at the end near

to the detector;

– a (mm) the deflection discharge magnitude measured with the calibrator at the end

remote from the detector. a and the calibration charge q (pC) are used to determine the

1 cal

scale factor k (pC/mm):

k = q /a

1 cal 1

a and a are used to determine a correction factor F to allow for attenuation. It is given by:

1 2

F = 1 if a ≥ a

2 1

a

F= if a < a

2 1

a

5.3.3.4 Test procedure

The measurement shall be made twice by connecting the high voltage end of the coupling

capacitor to each end of the cable in turn. The measured deflections discharge magnitudes A

and A shall be determined and the higher value A (mm pC) selected. With the scale factor

2 max

k (pC/mm) and the correction factor F, the discharge magnitude q(pC) is:

q = k ⋅ A ⋅ F

1 max

q = A × F

max

The voltage levels used when measuring the highest deflection discharge magnitude A

max

shall be selected according to 5.4.

NOTE Only if the double pulse diagram is of type 1 (see Figure 11) and a ≥ a , a measurement of A(mm pC) is

2 1

sufficient when both cable ends are connected together (see 5.3.2).

The discharge magnitude is then: q = k ⋅ A q = A

5.3.4 Long cable lengths tested with a terminal impedance

5.3.4.1 General

For long cable lengths (>50 m or >100 m with ends connected), tested with a terminal

impedance, it is not necessary to plot a double pulse diagram.

5.3.4.2 Requirements

To eliminate superposition errors, cables of length greater than l may be tested with a

k

terminal impedance as shown in Figure 8. This method may be used with all detectors and all

cable lengths provided that the impedance Z meets the requirements specified in 5.6. The

w

suitability of the impedance for the cable under test shall be demonstrated using the

procedure described in 5.6.

5.3.4.3 Verification of sensitivity

As shown in Figure 4 the calibrator should be connected to each end in parallel with the cable

at first to the end remote from the detector and then — with the same amplifier setting and

calibration charge — to the end near to the detector.

The partial discharge calibrator shall be connected to each end in turn in parallel with the

cable with the same setting of the amplifier and calibration charge. The following values shall

be recorded:

– a (mm pC) the deflection discharge magnitude measured with the calibrator at the end

near to the detector. This need not be measured if the procedure in 5.3.4.4 b) is sufficient;

– a (mm pC) the deflection discharge magnitude measured with the calibrator at the end

remote from the detector.

The scale factor k (pC/mm) is determined, and sensitivity q (pC) calculated:

2 min

k = q /a

2 cal 2

q = 2 k ⋅ h

min 2 n

– 16 – IEC 60885-3:2015 RLV © IEC 2015

For the determination of the scale factor k for the measurement of the apparent charge in

accordance with Clause 5 of IEC 60270:2000, the value a (pC) with the partial discharge

calibrator connected in parallel with the cable at the end remote from the detector shall be

used.

5.3.4.4 Test procedure

The test procedure is as follows.

a) When it is required to determine the value of the partial discharge magnitude as closely as

possible, the high voltage end of the coupling capacitor shall be connected to each end of

the cable in turn and both measured deflections discharge magnitudes A (pC) and A (mm

1 2

pC) determined. The discharge magnitude q (pC) is given by:

A × A

1 2

q= q ×

cal

a × a

1 2

where q is the calibration discharge magnitude (pC).

cal

b) When it is sufficient to check that the discharge magnitude does not exceed a specified

value, the measurement may be made with the high voltage end of the coupling capacitor

connected to one end of the cable only. In this case the calibration pulse is injected only

at the end of the cable connected to the terminal impedance remote from the detector (a ).

(mm pC) and the scale factor k

With the measured deflection discharge magnitude A

1 2

(pC/mm) the discharge magnitude q (pC) is given by:

q = k × A

2 1

The voltage levels used when measuring the deflections discharge magnitudes A and if

necessary A shall be selected according to 5.4.

5.3.5 Long cable lengths tested with a reflection suppressor

5.3.5.1 General

For long cable lengths (>50 m or >100 m with ends connected), tested with a reflection

suppressor, it is necessary to plot a double pulse diagram.

The connection of the reflection suppressor is shown in Figure 9.

A double pulse generator is connected according to Figure 10 and a double pulse diagram is

plotted (see 5.5 and Figures 11, 12 and 13). This shall be carried out when the test circuit is

set up and also when any changes are made to the circuit.

5.3.5.2 Requirements

When using a reflection suppressor the double pulse diagram must shall be type 1 (see

Figure 11).

5.3.5.3 Verification of sensitivity

These are the same as those indicated for testing long lengths without a terminal impedance

(see 2.4.2).

See 5.3.2.2.

5.3.5.4 Test procedure

See 5.3.2.3.

5.4 Voltage levels/partial discharge limits

The test voltages, partial discharge sensitivity and partial discharge limits shall be determined

in accordance with the requirements in the standard for the type of cable.

5.5 Double pulse behaviour and plotting the double pulse diagram

A double pulse generator should be connected to the components of the measuring circuit as

shown in Figure 6.

The double pulse plot is affected by variations in each circuit component. It is important that

the double pulse plot be obtained for the precise conditions to be used in the high voltage

test.

NOTE The test cable is not connected whilst the double pulse plot is being plotted, the double pulse plot depends

solely on the measuring system and test circuit, excluding the cable.

The power cable is replaced by a resistive load having the maximum characteristic impedance

for extruded c

...

IEC 60885-3 ®

Edition 2.0 2015-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical test methods for electric cables –

Part 3: Test methods for partial discharge measurements on lengths of extruded

power cables

Méthodes d'essais électriques pour les câbles électriques –

Partie 3: Méthodes d'essais pour la mesure des décharges partielles sur des

longueurs de câbles de puissance extrudés

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 60 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60885-3 ®

Edition 2.0 2015-04

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical test methods for electric cables –

Part 3: Test methods for partial discharge measurements on lengths of extruded

power cables

Méthodes d'essais électriques pour les câbles électriques –

Partie 3: Méthodes d'essais pour la mesure des décharges partielles sur des

longueurs de câbles de puissance extrudés

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20 ISBN 978-2-8322-2582-0

– 2 – IEC 60885-3:2015 © IEC 2015

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references. 6

3 Terms, definitions and symbols . 6

3.1 Terms and definitions . 6

3.2 Symbols used in Figures 1 to 14 . 6

4 Overview . 7

4.1 General . 7

4.2 Object . 7

4.3 Problem of superposition of travelling waves for long lengths . 7

5 Partial discharge tests . 10

5.1 Test apparatus . 10

5.1.1 Equipment . 10

5.1.2 Test circuit and instruments. 10

5.1.3 Double pulse generator . 10

5.1.4 Terminal impedance . 10

5.1.5 Reflection suppressor . 10

5.2 Setting up the test circuit . 10

5.2.1 Determination of characteristic properties of the test circuit . 10

5.2.2 Terminal impedance . 10

5.2.3 Determination of superposition of travelling waves . 11

5.2.4 Reflection suppressor . 11

5.2.5 Calibration of the measuring system in the complete test circuit . 11

5.2.6 Sensitivity . 11

5.3 Measurement procedures . 11

5.3.1 General . 11

5.3.2 Short cable lengths including type test lengths . 12

5.3.3 Long cable lengths tested without a terminal impedance . 12

5.3.4 Long cable lengths tested with a terminal impedance . 13

5.3.5 Long cable lengths tested with a reflection suppressor . 14

5.4 Voltage levels/partial discharge limits . 15

5.5 Double pulse behaviour and plotting the double pulse diagram . 15

5.6 Requirements for the terminal impedance . 16

5.6.1 General . 16

5.6.2 RC element . 16

5.6.3 RLC element series resonance circuit . 17

Bibliography . 21

Figure 1 – Discharge site exactly at the cable end remote from the detector (x = l) . 7

Figure 2 – Discharge site at a distance x = x – Travelling waves . 8

Figure 3 – Attenuation of PD pulses along the cable . 8

Figure 4 – Superposition and attenuation of PD pulses . 9

Figure 5 – Input unit Z connected in series with the coupling capacitor, C . 17

A K

Figure 6 – Input unit Z connected in series with the cable, C . 18

A x

Figure 7 – Bridge circuit . 18

Figure 8 – Connection of the terminal impedance Z . 18

w

Figure 9 – Connection of the reflection suppressor, RS . 19

Figure 10 – Connection of the double pulse generator into the measuring circuit in

Figure 5 . 19

Figure 11 – Double pulse diagram type 1 without negative superposition . 19

Figure 12 – Double pulse diagram type 2 with negative superposition between t and t . 20

1 2

Figure 13 – Double pulse diagram type 3 with negative and positive superpositions

between t and t . 20

1 2

Figure 14 – Connection of the double pulse generator for the test circuit in Figure 9

with the reflection suppressor . 20

– 4 – IEC 60885-3:2015 © IEC 2015

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRICAL TEST METHODS FOR ELECTRIC CABLES –

Part 3: Test methods for partial discharge measurements

on lengths of extruded power cables

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60885-3 has been prepared by IEC technical committee 20:

Electric cables.

This second edition of IEC 60885-3 cancels and replaces the first edition, published in 1988

and constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

• The definition of sensitivity as twice the background noise level has been removed and

replaced by a practical assessment of sensitivity based on the minimum level of

detectable discharge.

• References to measurements of pulse heights in mm on an oscilloscope have been

replaced by measurements of partial discharge magnitude in pC.

• The order of the clauses has been revised in line with the general numbering scheme of

IEC standards and to provide clarity in order to facilitate its practical use. Section 3 of the

first edition (Application guide) has been removed as it is considered that background

information is better obtained from the original references as listed in the bibliography.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1560/FDIS 20/1587/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60885 series, published under the general title Electrical test

methods for electric cables, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60885-3:2015 © IEC 2015

ELECTRICAL TEST METHODS FOR ELECTRIC CABLES –

Part 3: Test methods for partial discharge measurements

on lengths of extruded power cables

1 Scope

This part of IEC 60885 specifies the test methods for partial discharge (PD) measurements on

lengths of extruded power cable, but does not include measurements made on installed cable

systems.

Reference is made to IEC 60270 which gives the techniques and considerations applicable to

partial discharge measurements in general.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60270:2000, High-voltage test techniques – Partial discharge measurements

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60270 apply.

3.2 Symbols used in Figures 1 to 14

a discharge magnitude measured with the calibrator at the end near to the detector

a discharge magnitude measured with the calibrator at the end remote from the detector

Ccal calibrator

CK coupling capacitor

Cx power cable

D detector

I double pulse generator

l length of the power cable

M coaxial signal cable

Q discharge magnitude

R1R2 matching resistors

RS reflection suppressor

v propagation velocity of partial discharge

V voltage indicator

W power supply

Z impedance/filter

Z input unit

A

Z terminal impedance

W

4 Overview

4.1 General

Partial discharge measurements shall be carried out using the test techniques specified in

IEC 60270.

4.2 Object

The object of the test is to determine the discharge magnitude, or to check that the discharge

magnitude does not exceed a specified value, at a specified voltage and a declared minimum

sensitivity.

4.3 Problem of superposition of travelling waves for long lengths

Short lengths of cable behave in the same way as a single capacitor in that the discharge

magnitude can be measured directly by considering the cable as a single capacitor. However

longer cables behave like a transmission line and PD pulses travel away from their source in

both directions along the cable, in the form of a wave. On reaching the remote end from the

measuring equipment, the pulse will be reflected with the same polarity if the end is open

circuit. The reflected pulse will then travel back along the length of cable and arrive at the

detector at a time after the directly received pulse. If the time between the arrival of the two

pulses is short (the time difference depending on the length of the cable) then the detection

instrument may give a false response, indicating either a larger or smaller magnitude of

discharge than was actually the case. The methods detailed in this standard allow correct

measurement of partial discharges under these conditions.

Figures 1 to 4 illustrate the behaviour of travelling waves and possible superposition effects.

Q

V

C

K

Void

x

x = l

D Z

A

IEC

Figure 1 – Discharge site exactly at the cable end remote from the detector (x = l)

– 8 – IEC 60885-3:2015 © IEC 2015

a) at the time of the discharge V V

Q/2 Q/2

C

K

Void

l – x

x

x = x

x = l

Z

D

A

t = 2 (l – x )/V

V V

b) after reflection

Q/2 Q/2

C

K

Void

x = x

D

Z

A

IEC

Figure 2 – Discharge site at a distance x = x – Travelling waves

2,0

1,5

a (x = 0)

a (x = l)

1,0

0,8

0,6

0,5a

0,4

= end open

= end with characteristic impedance

0,2

0,1

x (m)

2 000

0 500 1 000 1 500

x = 0 x = l

IEC

Figure 3 – Attenuation of PD pulses along the cable

Relative response

a)

2,0

Positive superposition

1,5

(i) < 30%

a

1,0a

1,0

0,8

0,7a

0,6

0,5a

0,4

= end open

= end with characteristic impedance

0,2

0,1

x (m)

0 500 1 000 1 500 2 000

l = 440 m

k

b)

l = 640 m

2,0

1,5

Positive superposition

1,0

(i) < 30%

1,0a

0,8

0,6

0,7a

0,5a

0,4 2

Negative superposition

= end open

0,2

= end with characteristic impedance

0,1

x (m)

2 000

0 500 1 000 1 500

l = 190 m

k

l = 220 m

l = 600 m

IEC

Figure 4 – Superposition and attenuation of PD pulses

Relative response

Relative response

– 10 – IEC 60885-3:2015 © IEC 2015

5 Partial discharge tests

5.1 Test apparatus

5.1.1 Equipment

The equipment consists of a high-voltage alternating voltage supply having a rating adequate

to energise the length of cable under test, a voltmeter for high voltages, a measuring circuit, a

discharge calibrator, a double pulse generator and, where applicable, a terminal impedance or

reflection suppressor. All components of the test equipment shall have a sufficiently low noise

level to achieve the required sensitivity. The frequency of the test supply shall be in the range

45 Hz to 65 Hz with a waveshape approximating to a sinusoid with the ratio of peak to r.m.s.

values being equal to √2 with a maximum tolerance of 5 %.

5.1.2 Test circuit and instruments

The test circuit includes the high voltage power supply, test object, the coupling capacitor and

the HV and PD measuring equipment. The measuring circuit consists of the measuring

impedance (input impedance of the measuring instrument and the input unit which is selected

to match the cable impedance), the connecting lead and the measuring instrument. The

measuring instrument or detector includes a suitable amplifying device, an oscilloscope, or

other instrument to indicate the existence of partial discharges and to measure the apparent

charge. The measuring system shall comply with IEC 60270.

5.1.3 Double pulse generator

A double pulse generator is an instrument producing two equal pulses (with the same

apparent charge) following each other within a time interval which can be varied between

0,2 µs to 100 µs. The rise time of the pulses shall not exceed 20 ns (10 % to 90 % of peak

value); the time between 10 % values of the front and the tail shall not exceed 150 ns. The

pulses may be synchronized with the power frequency.

5.1.4 Terminal impedance

A terminal impedance is an impedance, equal in value to the characteristic impedance of the

test object, which is connected to the open end of the cable remote from the detector. It may

be a combination of resistance and capacitance (R & C) or resistance, capacitance and

inductance (R, C & L). The components shall be suitable for operation at the test voltage to

be applied to the cable under test. Additional requirements are specified in section 5.6.

5.1.5 Reflection suppressor

This is an electronic switch which is designed to block the input of the measuring instrument

from pulses reflected from the open end of the cable. This is achieved by blocking the input

for a fixed time after the first pulse is received.

5.2 Setting up the test circuit

5.2.1 Determination of characteristic properties of the test circuit

The characteristic properties of the test circuit should be determined under the conditions to

be used. The test circuits normally used for connections to a single cable end are those

shown in Figures 5, 6, 7, 8 and 9. Similar test circuits are also applicable when both ends of

the cable conductor are connected together; in this case the two ends of the metal cable

screen shall also be connected together.

5.2.2 Terminal impedance

If a terminal impedance is connected to the remote end of the cable under test, with an

impedance value equal to the characteristic impedance of the cable then the cable will behave

as if it is of infinite length and there will be no reflected wave. The circuit for connection of a

terminal impedance is shown in Figure 8. The values (RC and L where applicable) of the

components of the terminal impedance and its suitability for the type of cable under test

should be demonstrated using the procedure described in 5.6. This check should be carried

out when the test circuit is set up and also when any changes are made to the circuit.

5.2.3 Determination of superposition of travelling waves

If a terminal impedance is not used, it is necessary to determine the properties of the test

circuit with respect to superposition of travelling waves. A double pulse generator is

connected according to Figure 10 and a double pulse diagram is plotted (see 5.5 and

Figures 11, 12 and 13). This check should be carried out when the test circuit is set up and

also when any changes are made to the circuit.

5.2.4 Reflection suppressor

The purpose of using a reflection suppressor is to obtain a double pulse diagram of Type 1

corresponding to Figure 11. Using the arrangement shown in Figure 14, the efficiency of the

reflection suppressor should be checked by plotting a double pulse diagram (see 5.5 and

Figures 11, 12 and 13), when the test circuit is set up and also when any changes are made

to the circuit.

5.2.5 Calibration of the measuring system in the complete test circuit

Calibration of the measuring system in the complete test circuit shall be carried out in

accordance with Clause 5 of IEC 60270:2000. The calibrator used shall comply with

IEC 60270. For long lengths of cable (> 100 m) there is an additional requirement that the

calibrating capacitance shall be not greater than 150 pF.

5.2.6 Sensitivity

The sensitivity of the measuring system is defined as the minimum detectable discharge

pulse, q (in picocoulombs – pC) that can be observed in the presence of background noise.

min

Value of q shall be determined by evaluation of the background noise level and shall be no

min

more than twice the apparent noise level, h (h is the noise reading on the measuring

n n

instrument).

Therefore:

q = x × k × h

min n

where k is the scale factor and x is the ratio of the minimum detectable discharge to the

background noise. The maximum allowed value of x is 2. Typically values of x of between 1,25

and 1,5 should be achievable.

The maximum values of sensitivity shall be determined according to 5.4.

5.3 Measurement procedures

5.3.1 General

The selection of the test circuit depends on whether the cable sample may be considered as a

short length (see 5.3.2) or a long length (see 5.3.3, 5.3.4 and 5.3.5). The test circuit shall be

discharge free in order to achieve the required sensitivity (see 5.2.6). Calibration does not