IEC 60228:2023

(Main)Conductors of insulated cables

Conductors of insulated cables

IEC 60228:2023 specifies the nominal cross-sectional areas, in the range 0,5 mm2 to 3 500 mm2, for conductors in electric power cables and cords of a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid, stranded and Milliken, copper, aluminium and aluminium alloy conductors in cables for fixed installations and flexible copper conductors. This document does not apply to conductors for telecommunication purposes. The applicability of this document to a particular type of cable is as specified in the standard for the type of cable. Unless specified otherwise in a particular clause, IEC 60028 ED4 relates to the conductors in the finished cable and not to the conductor as made or supplied for inclusion into a cable. Conductors described in this document are specified in metric sizes. Informative annexes provide supplementary information covering temperature correction factors for resistance measurement (Annex B) and guidance on dimensional limits of circular conductors (Annex C). This document has the status of a horizontal publication in accordance with IEC Guide 108.

Ames des câbles isolés

L'IEC 60228:2023 spécifie les sections nominales, dans la plage de 0,5 mm2 à 3 500 mm2, des âmes d’un large éventail de types de câbles et de cordons électriques. Des exigences relatives au nombre et au diamètre des fils sont également spécifiées, ainsi que des valeurs de résistance. Les âmes concernées sont les âmes massives, câblées et segmentées, en cuivre, aluminium et alliage d’aluminium, destinées aux câbles pour installations fixes, ainsi que les âmes souples en cuivre. Le présent document ne s’applique pas aux âmes utilisées à des fins de télécommunication. L’applicabilité du présent document à un type de câble particulier est précisée dans la norme relative à ce type de câble. Sauf indication contraire dans un article particulier, le présent document porte sur les âmes des câbles terminés, et non sur les âmes seules ou fournies en vue d’une intégration dans un câble. Les âmes décrites dans le présent document sont spécifiées en tailles métriques. Des annexes informatives donnent des informations complémentaires sur les facteurs de correction de température à utiliser pour les mesures de résistance (Annexe B) et des recommandations sur les limites dimensionnelles des âmes circulaires (Annexe C).

General Information

- Status

- Published

- Publication Date

- 10-Dec-2023

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 19 - TC 20/WG 19

- Current Stage

- PPUB - Publication issued

- Start Date

- 11-Dec-2023

- Completion Date

- 17-Nov-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60228:2023 - "Conductors of insulated cables" - is the fourth edition (2023) International Electrotechnical Commission (IEC) standard that defines the nominal metric conductor sizes, construction classes and core requirements for conductors used in electric power cables and cords. The standard covers conductor cross-sectional areas from 0.5 mm² up to 3 500 mm², and addresses solid, stranded, Milliken and flexible conductor types in copper, aluminium and aluminium alloy. IEC 60228 is a horizontal reference intended for cable product standards, manufacturers, designers and testing laboratories.

Key topics and technical requirements

- Nominal cross-sectional areas: Standardized metric sizes for power and flexible conductors (0.5 mm² to 3 500 mm²).

- Conductor classes and constructions: Definitions and requirements for:

- Class 1 - solid conductors

- Class 2 - stranded conductors (including compacted and Milliken constructions)

- Classes 5 & 6 - flexible copper conductors

- Numbers and sizes of wires: Rules for wire counts and strand dimensions for different conductor classes.

- Electrical resistance values: Specified resistance limits and measurement methods for conductors; guidance on correction for temperature.

- Materials and mechanical properties: Requirements for copper, aluminium and aluminium alloy conductors, including tensile strength limits for solid and stranded aluminium conductors.

- Compliance and testing: Clauses and an informative annex structure to support verification - Annex A covers measurement of resistance (normative), Annex B provides temperature correction factors (informative) and Annex C offers guidance on dimensional limits of circular conductors (informative).

- Scope boundaries: Not applicable to telecommunication conductors; where relevant the cable‑type standard specifies applicability to particular cable constructions. The standard generally applies to conductors in the finished cable.

Applications and who uses IEC 60228

IEC 60228 is used by:

- Cable manufacturers for conductor specification, production and quality control.

- Electrical and power system designers when selecting conductor sizes and classes for fixed installations and flexible cords.

- Test laboratories and certification bodies for resistance measurement, dimensional checks and compliance testing.

- Procurement and standards committees drafting product standards and national regulations that reference conductor characteristics.

Practical applications include low- and medium-voltage power cables, industrial flexible cords, repair/maintenance specifications and cross-border procurement where harmonized conductor data is required.

Related standards

- IEC Guide 108 - horizontal publication status guidance.

- IECEE OD-5014 - instrument accuracy limits (referenced).

- Other IEC cable product standards from IEC TC 20, which reference IEC 60228 for conductor requirements.

Keywords: IEC 60228, conductors of insulated cables, conductor cross-sectional area, stranded conductors, Milliken conductor, copper conductor, aluminium conductor, resistance measurement, temperature correction factors.

Buy Documents

REDLINE IEC 60228:2023 CMV - Conductors of insulated cables Released:12/11/2023 Isbn:9782832280034

IEC 60228:2023 - Conductors of insulated cables Released:12/11/2023 Isbn:9782832278086

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60228:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Conductors of insulated cables". This standard covers: IEC 60228:2023 specifies the nominal cross-sectional areas, in the range 0,5 mm2 to 3 500 mm2, for conductors in electric power cables and cords of a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid, stranded and Milliken, copper, aluminium and aluminium alloy conductors in cables for fixed installations and flexible copper conductors. This document does not apply to conductors for telecommunication purposes. The applicability of this document to a particular type of cable is as specified in the standard for the type of cable. Unless specified otherwise in a particular clause, IEC 60028 ED4 relates to the conductors in the finished cable and not to the conductor as made or supplied for inclusion into a cable. Conductors described in this document are specified in metric sizes. Informative annexes provide supplementary information covering temperature correction factors for resistance measurement (Annex B) and guidance on dimensional limits of circular conductors (Annex C). This document has the status of a horizontal publication in accordance with IEC Guide 108.

IEC 60228:2023 specifies the nominal cross-sectional areas, in the range 0,5 mm2 to 3 500 mm2, for conductors in electric power cables and cords of a wide range of types. Requirements for numbers and sizes of wires and resistance values are also included. These conductors include solid, stranded and Milliken, copper, aluminium and aluminium alloy conductors in cables for fixed installations and flexible copper conductors. This document does not apply to conductors for telecommunication purposes. The applicability of this document to a particular type of cable is as specified in the standard for the type of cable. Unless specified otherwise in a particular clause, IEC 60028 ED4 relates to the conductors in the finished cable and not to the conductor as made or supplied for inclusion into a cable. Conductors described in this document are specified in metric sizes. Informative annexes provide supplementary information covering temperature correction factors for resistance measurement (Annex B) and guidance on dimensional limits of circular conductors (Annex C). This document has the status of a horizontal publication in accordance with IEC Guide 108.

IEC 60228:2023 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60228:2023 has the following relationships with other standards: It is inter standard links to IEC 60228:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60228:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60228 ®

Edition 4.0 2023-12

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Conductors of insulated cables

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a

Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60228 ®

Edition 4.0 2023-12

COMMENTED VERSION

INTERNATIONAL

STANDARD

colour

inside

Conductors of insulated cables

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.060.20 ISBN 978-2-8322-8003-4

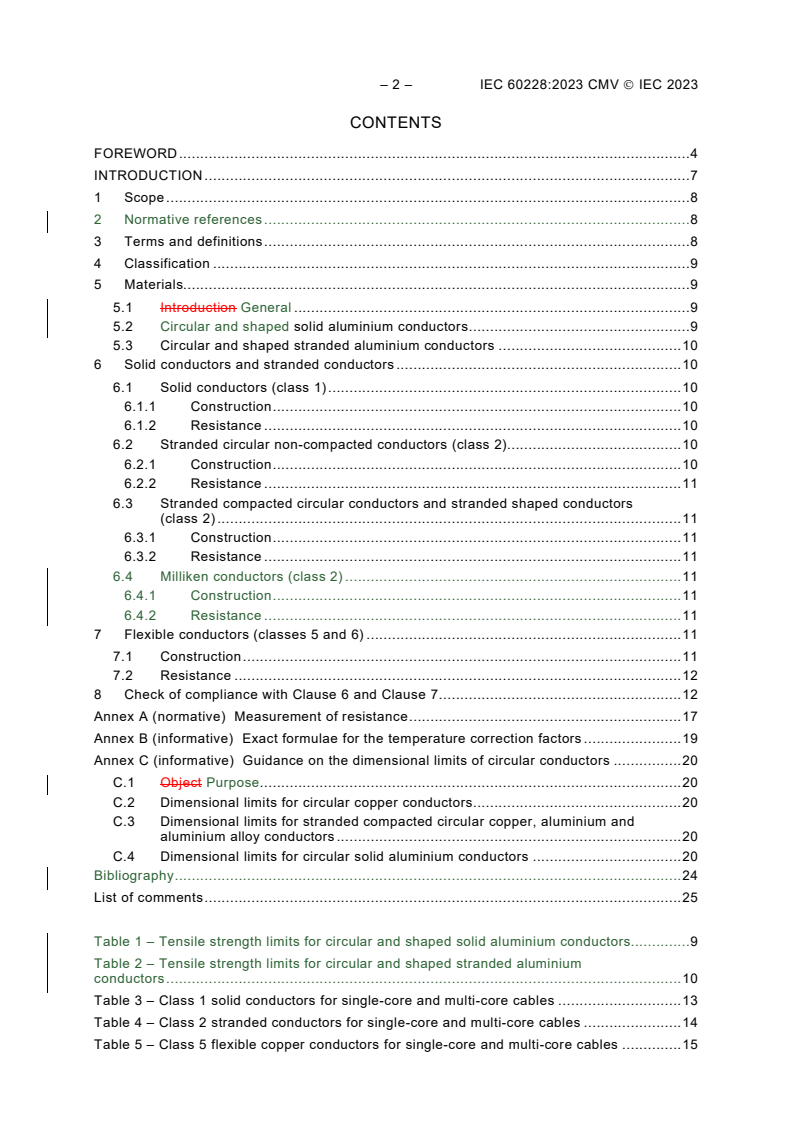

– 2 – IEC 60228:2023 CMV IEC 2023

CONTENTS

FOREWORD .4

INTRODUCTION .7

1 Scope .8

2 Normative references .8

3 Terms and definitions .8

4 Classification .9

5 Materials.9

5.1 Introduction General .9

5.2 Circular and shaped solid aluminium conductors .9

5.3 Circular and shaped stranded aluminium conductors . 10

6 Solid conductors and stranded conductors . 10

6.1 Solid conductors (class 1) . 10

6.1.1 Construction . 10

6.1.2 Resistance . 10

6.2 Stranded circular non-compacted conductors (class 2) . 10

6.2.1 Construction . 10

6.2.2 Resistance . 11

6.3 Stranded compacted circular conductors and stranded shaped conductors

(class 2) . 11

6.3.1 Construction . 11

6.3.2 Resistance . 11

6.4 Milliken conductors (class 2) . 11

6.4.1 Construction . 11

6.4.2 Resistance . 11

7 Flexible conductors (classes 5 and 6) . 11

7.1 Construction . 11

7.2 Resistance . 12

8 Check of compliance with Clause 6 and Clause 7 . 12

Annex A (normative) Measurement of resistance . 17

Annex B (informative) Exact formulae for the temperature correction factors . 19

Annex C (informative) Guidance on the dimensional limits of circular conductors . 20

C.1 Object Purpose . 20

C.2 Dimensional limits for circular copper conductors . 20

C.3 Dimensional limits for stranded compacted circular copper, aluminium and

aluminium alloy conductors . 20

C.4 Dimensional limits for circular solid aluminium conductors . 20

Bibliography . 24

List of comments . 25

Table 1 – Tensile strength limits for circular and shaped solid aluminium conductors.9

Table 2 – Tensile strength limits for circular and shaped stranded aluminium

conductors . 10

Table 3 – Class 1 solid conductors for single-core and multi-core cables . 13

Table 4 – Class 2 stranded conductors for single-core and multi-core cables . 14

Table 5 – Class 5 flexible copper conductors for single-core and multi-core cables . 15

Table 6 – Class 6 flexible copper conductors for single-core and multi-core cables . 16

Table A.1 – Temperature correction factors k for conductor resistance to correct the

t

measured resistance at t °C to 20 °C . 18

Table C.1 – Maximum diameters of solid, non-compacted stranded and flexible circular

copper conductors . 21

Table C.2 – Minimum and maximum diameters of stranded compacted circular copper,

aluminium and aluminium alloy conductors. 22

Table C.3 – Minimum and maximum diameters of solid circular aluminium conductors . 23

– 4 – IEC 60228:2023 CMV IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONDUCTORS OF INSULATED CABLES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

This commented version (CMV) of the official standard IEC 60228:2023 edition 4.0 allows

the user to identify the changes made to the previous IEC 60228:2004 edition 3.0.

Furthermore, comments from IEC TC 20 experts are provided to explain the reasons of

the most relevant changes, or to clarify any part of the content.

A vertical bar appears in the margin wherever a change has been made. Additions are in

green text, deletions are in strikethrough red text. Experts' comments are identified by a

blue-background number. Mouse over a number to display a pop-up note with the

comment.

This publication contains the CMV and the official standard. The full list of comments is

available at the end of the CMV.

IEC 60228 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This fourth edition cancels and replaces the third edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) a description of Milliken conductors has been added;

b) nominal cross-sectional areas above 2 500 mm have been added;

c) the old 2 500 mm aluminium resistance value has been corrected and a new value

introduced.

For legacy systems where the 2 500 mm aluminium conductor was designed taking into

account the value presented in previous editions and no longer tabulated, then the original

design can be maintained and still utilized.

The suppliers can furthermore utilize such superseded design of 2 500 mm aluminium

conductors either in systems already designed and qualified but not delivered or for example

to produce repair and additional spare lengths for delivered systems.

The choice of utilizing the original superseded design of 2 500 mm aluminium conductors

or a new one based on the new resistance tabulated value is a matter of agreement between

the supplier and final users.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/2125/FDIS 20/2131/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

– 6 – IEC 60228:2023 CMV IEC 2023

Conductors described in IEC 60228 are specified in metric sizes. Canada at present uses

conductor sizes and characteristics according to the American Wire Gauge (AWG) system and

kcmil for larger sizes as shown below. The use of these sizes is currently prescribed uniformly

across Canada for installations by sub-national regulations. IEC TC 20 cable product standards

do not prescribe cables with AWG/kcmil conductors. 1

AWG kcmil

Nominal Nominal Nominal Nominal

Conductor cross- Conductor cross- Conductor cross- Conductor cross-

size sectional size sectional size sectional size sectional

area area area area

2 2 2 2

mm mm mm mm

- - - - 250 127 750 380

- - - - 300 152 800 405

20 0,519 4 21,2 350 177 900 456

18 0,823 3 26,7 400 203 1000 507

16 1,31 2 33,6 450 228 1200 608

14 2,08 1 42,4 500 253 1250 633

12 3,31 1/0 53,5 550 279 1500 760

10 5,26 2/0 67,4 600 304 1750 887

8 8,37 3/0 85,0 650 329 2000 1010

6 13,3 4/0 107 700 355 - -

IMPORTANT – The "colour inside" logo on the cover page of this document indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this document using a colour printer.

INTRODUCTION

This document is intended as a fundamental reference standard for IEC technical committees

and National Committees in drafting standards for electric cables, and to the National

Committees in drafting specifications for use in their own countries. These committees should

select from the tables of this general standard the conductors appropriate to the particular

applications with which they are concerned relevant to them and either include the applicable

details in their cable specifications or make appropriate references to this document.

In preparing this edition the main objects have been to incorporate IEC 60228A into it and

maintain a simplified yet informative standard so far as is compatible with technical and

economic considerations.

– 8 – IEC 60228:2023 CMV IEC 2023

CONDUCTORS OF INSULATED CABLES

1 Scope

This document specifies the nominal cross-sectional areas, in the range 0,5 mm to 2 500 3

500 mm , for conductors in electric power cables and cords of a wide range of types.

Requirements for numbers and sizes of wires and resistance values are also included. These

conductors include solid, stranded and Milliken, copper, aluminium and aluminium alloy

conductors in cables for fixed installations and flexible copper conductors.

This document does not apply to conductors for telecommunication purposes.

The applicability of this document to a particular type of cable is as specified in the standard

for the type of cable.

Unless specified otherwise in a particular clause, this document relates to the conductors in

the finished cable and not to the conductor as made or supplied for inclusion into a cable.

Conductors described in this document are specified in metric sizes.

Informative annexes provide supplementary information covering temperature correction

factors for resistance measurement (Annex B) and guidance on dimensional limits of circular

conductors (Annex C).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IECEE OD-5014, Instrument Accuracy Limits

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

metal-coated

coated with a thin layer of suitable metal, such as tin or tin alloy

3.2

nominal cross-sectional area

value that identifies a particular size of conductor but is not subject to direct measurement

Note 1 to entry: Each particular size of conductor in this document is required to meet a maximum resistance value.

3.3

Milliken conductor

stranded conductor comprising an assembly of shaped conductors, lightly insulated from each

other 2

4 Classification

The conductors have been divided into four classes, 1, 2, 5 and 6. Those in classes 1 and 2

are intended for use in cables for fixed installations. Classes 5 and 6 are intended for use in

flexible cables and cords but may can also be used for fixed installations.

• class 1: solid conductors;

• class 2: stranded conductors;

• class 5: flexible conductors;

• class 6: flexible conductors which are more flexible made with smaller diameter wires than

class 5 for the same nominal conductor cross-section.

5 Materials

5.1 Introduction General

The wires of conductors shall consist of one of the following (except for the Milliken central

element):

• plain or metal-coated annealed copper;

• aluminium or aluminium alloy. 3 4

The wires of stranded conductors (for example Milliken conductors) can be oxidized or

enamelled.

5.2 Circular and shaped solid aluminium conductors

Circular and shaped solid aluminium conductors shall be made from aluminium such that the

tensile strength of the completed conductor is within the limits given in Table 1.

Table 1 – Tensile strength limits for circular

and shaped solid aluminium conductors

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

10 and 16 110 to 165

25 and 35 60 to 130

50 60 to 110

70 and above 60 to 90

NOTE The values given above are not applicable to aluminium alloy conductors.

There are no limits defined for the tensile strength of aluminium alloy solid conductors.

– 10 – IEC 60228:2023 CMV IEC 2023

5.3 Circular and shaped stranded aluminium conductors

Stranded aluminium conductors shall be made from aluminium such that the tensile strength of

the individual wires is within the limits given in Table 2:

Table 2 – Tensile strength limits for circular

and shaped stranded aluminium conductors

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

10 up to 200

16 and above 125 to 205

NOTE 1 The values given above are not applicable to aluminium alloy conductors.

There are no limits defined for the tensile strength of aluminium alloy stranded conductors.

NOTE 2 This data can only be checked on wires taken before stranding and not on wires taken

from a stranded conductor.

6 Solid conductors and stranded conductors

6.1 Solid conductors (class 1)

6.1.1 Construction

a) Solid conductors (class 1) or conductor wires shall consist of one of the materials specified

in Clause 5.

b) Solid copper conductors shall be of circular cross-section.

NOTE Solid copper conductors having nominal cross-sectional areas of 25 mm and above are for particular

types of cable, e.g. mineral insulated, and not for general purposes.

2 2

c) Solid aluminium and solid aluminium alloy conductors of sizes 10 mm to 35 mm shall be

of circular cross-section. Larger sizes shall be of circular cross-section for single-core

cables and may be of either circular or shaped cross-section for multi-core cables.

6.1.2 Resistance

The resistance of each conductor at 20 ºC, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 3.

NOTE For solid aluminium alloy conductors, having the same nominal cross-sectional area as

an aluminium conductor, the resistance value given in Table 3 should be multiplied by a factor

of 1,162 unless otherwise agreed between the manufacturer and the purchaser.

6.2 Stranded circular non-compacted conductors (class 2)

6.2.1 Construction

a) Stranded circular non-compacted conductors (class 2) shall consist of one of the materials

specified in Clause 5.

b) Stranded aluminium or aluminium alloy conductors shall have a cross-sectional area not

.

less than 10 mm

c) The wires in each conductor shall all have the same nominal diameter.

d) The number of wires in each conductor shall be not less than the appropriate minimum

number given in Table 4.

6.2.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 4.

6.3 Stranded compacted circular conductors and stranded shaped conductors

(class 2)

6.3.1 Construction

a) Stranded compacted circular conductors and stranded shaped conductors (class 2) shall

consist of one of the materials specified in Clause 5. Stranded compacted circular aluminium

or aluminium alloy conductors shall have a nominal cross-sectional area not less than

10 mm . Stranded compacted circular copper conductors shall have a nominal

cross-sectional area not less than 1,5 mm . Stranded shaped copper, aluminium or

aluminium alloy conductors shall have a nominal cross-sectional area of not less than

25 mm .

b) The ratio of the diameters of two different wires in the same conductor shall not exceed 2,

except for conductors made with pre-shaped wires.

c) The number of wires in each conductor shall be not less than the appropriate minimum

number given in Table 4, except for conductors made with pre-shaped wires. This

requirement applies to conductors made with wires of circular cross-section before

compaction.

NOTE This requirement applies to conductors made with wires of circular cross-section before compaction and not

to conductors made with pre-shaped wires.

6.3.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 4.

6.4 Milliken conductors (class 2)

6.4.1 Construction

a) Milliken conductors (class 2) shall consist of any of the materials specified in Clause 5.

Milliken conductors shall have a nominal cross-sectional area not less than 800 mm , and

the minimum number of wires for each cross section is not specified. 5

b) The ratio of the diameters of two different wires of any segment shall not exceed 2 (Milliken

central element excluded).

c) The Milliken central element can be empty, with a solid conductor, wires or with a plastic

filler.

d) This conductor may be constructed from 4, 5, or 6 equal segments. The number of wires in

each segment is defined by the manufacturer. In the case of a central element formed with

wires, it can be considered as an additional segment with a polygonal shape.

6.4.2 Resistance

The resistance of the whole conductor at 20 °C, for all different constructions described in 6.4.1,

when determined in accordance with Clause 8, shall not exceed the appropriate maximum value

given in Table 4.

7 Flexible conductors (classes 5 and 6)

7.1 Construction

a) Flexible conductors (classes 5 and 6) shall consist of plain or metal-coated annealed copper.

b) The wires in each conductor shall have the same nominal diameter.

– 12 – IEC 60228:2023 CMV IEC 2023

c) The diameter of the wires in each conductor shall not exceed the appropriate maximum

value given in Table 5 for class 5 or Table 6 for class 6 conductors.

7.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 5 or Table 6.

8 Check of compliance with Clause 6 and Clause 7

Compliance with the requirements for construction of 6.1.1, 6.2.1, 6.3.1, 6.4.1 and 7.1 shall be

checked on the completed cable by inspection and measurement where practicable.

Compliance with the requirements for resistance given in 6.1.2, 6.2.2, 6.3.2, 6.4.2, and 7.2 shall

be checked by measurement in accordance with Annex A and corrected for temperature by the

factors in Table A.1.

Table 3 – Class 1 solid conductors for single-core and multi-core cables

1 2 3 4

Nominal cross- Maximum resistance of conductor at 20 ºC

sectional area

Circular, annealed copper conductors Aluminium and

aluminium alloy

Plain Metal-coated

conductors, circular or

c

shaped

Ω/km Ω/km Ω/km

mm

0,5 36,0 36,7 -

0,75 24,5 24,8 -

1,0 18,1 18,2 -

1,5 12,1 12,2 -

2,5 7,41 7,56 -

4 4,61 4,70 -

6 3,08 3,11 -

a

10 1,83 1,84

3,08

a

16 1,15 1,16

1,91

b a

25 -

0,727 1,20

b a

35 -

0,524 0,868

b

50 - 0,641

0,387

b

70 - 0,443

0,268

b d

95 -

0,193 0,320

b d

120 -

0,153 0,253

b d

150 -

0,124 0,206

b d

185 -

0,101 0,164

b d

240 -

0,077 5 0,125

b d

300 -

0,062 0 0,100

b

400 - 0,077 8

0,046 5

500 - - 0,060 5

630 - - 0,046 9

800 - - 0,036 7

1 000 - - 0,029 1

1 200 - - 0,024 7

1 400 - - 0,021 2

1 600 - - 0,018 6

a 2 2

Aluminium conductors 10 mm to 35 mm circular only; see 6.1.1 c).

b

See note in 6.1.1 b).

c

See note in 6.1.2.

d

For single-core cables, four sectoral shaped conductors may be assembled into a single circular conductor.

The maximum resistance of the assembled conductor shall be 25 % of that of the individual component

conductors.

– 14 – IEC 60228:2023 CMV IEC 2023

Table 4 – Class 2 stranded conductors for single-core and multi-core cables 6

1 2 3 4 5 6 7 8 9 10

Minimum number of wires in the conductor Maximum resistance of conductor at 20 °C

Nominal

cross-

Circular Aluminium or

Circular Shaped Annealed copper conductor

sectional

compacted aluminium alloy

area

b

conductor

Cu Al Cu Al Cu Al Plain wires Metal-coated

wires

Ω/km Ω/km Ω/km

mm

0,5 7 - - - - - 36,0 36,7 -

0,75 7 - - - - - 24,5 24,8 -

1,0 7 - - - - - 18,1 18,2 -

1,5 7 - 6 - - - 12,1 12,2 -

2,5 7 - 6 - - - 7,41 7,56 -

4 7 - 6 - - - 4,61 4,70 -

6 7 - 6 - - - 3,08 3,11 -

10 7 7 6 6 - - 1,83 1,84 3,08

16 7 7 6 6 - - 1,15 1,16 1,91

25 7 7 6 6 6 6 0,727 0,734 1,20

35 7 7 6 6 6 6 0,524 0,529 0,868

50 19 19 6 6 6 6 0,387 0,391 0,641

70 19 19 12 12 12 12 0,268 0,270 0,443

95 19 19 15 15 15 15 0,193 0,195 0,320

120 37 37 18 15 18 15 0,153 0,154 0,253

150 37 37 18 15 18 15 0,124 0,126 0,206

185 37 37 30 30 30 30 0,099 1 0,100 0,164

240 37 37 34 30 34 30 0,075 4 0,076 2 0,125

300 61 61 34 30 34 30 0,060 1 0,060 7 0,100

400 61 61 53 53 53 53 0,047 0 0,047 5 0,077 8

500 61 61 53 53 53 53 0,036 6 0,036 9 0,060 5

630 91 91 53 53 53 53 0,028 3 0,028 6 0,046 9

800 91 91 53 53 - - 0,022 1 0,022 4 0,036 7

1 000 91 91 53 53 - - 0,017 6 0,017 7 0,029 1

b

1 200 0,0151 0,0151 0,0247

1 200 91 91 53 53 - - 0,015 1 0,015 1 0,024 7

a b

1 400 0,0129 0,0129 0,0212

a

91 91 53 53 - - 0,012 9 0,012 9 0,021 2

1 400

b

1 600 0,0113 0,0113 0,0186

1 600 91 91 53 53 - - 0,011 3 0,011 3 0,018 6

a b

- 0,010 1 0,010 1 0,016 5

1 800

b

2 000 - 0,009 0 0,009 0 0,014 9

b

2 500 - 0,007 2 0,007 2 0,01270,011 9

a

- 0,006 0 0,006 0 0,009 9

3 000

3 200 - 0,005 6 0,005 6 0,009 3

a

- 0,005 1 0,005 1 0,008 5

3 500

1 2 3 4 5 6 7 8 9 10

a

These sizes are non-preferred. Other non-preferred sizes are recognized for some specialized applications but

are not within the scope of this document. 7

b

The minimum number of wires for these sizes is not specified. These sizes may be constructed from 4, 5 or 6

equal segments (Milliken).

b

For stranded aluminium alloy conductors having the same nominal cross-sectional area as an aluminium

conductor the resistance value should be agreed between the manufacturer and the purchaser.

Table 5 – Class 5 flexible copper conductors for single-core and multi-core cables

1 2 3 4

Nominal cross- Maximum diameter of Maximum resistance of conductor at 20 °C

sectional area wires in conductor

Plain wires Metal-coated wires

mm Ω/km Ω/km

mm

0,5 0,21 39,0 40,1

0,75 0,21 26,0 26,7

1,0 0,21 19,5 20,0

1,5 0,26 13,3 13,7

2,5 0,26 7,98 8,21

4 0,31 4,95 5,09

6 0,31 3,30 3,39

10 0,41 1,91 1,95

16 0,41 1,21 1,24

25 0,41 0,780 0,795

35 0,41 0,554 0,565

50 0,41 0,386 0,393

70 0,51 0,272 0,277

95 0,51 0,206 0,210

120 0,51 0,161 0,164

150 0,51 0,129 0,132

185 0,51 0,106 0,108

240 0,51 0,080 1 0,081 7

300 0,51 0,064 1 0,065 4

400 0,51 0,048 6 0,049 5

500 0,61 0,038 4 0,039 1

630 0,61 0,028 7 0,029 2

– 16 – IEC 60228:2023 CMV IEC 2023

Table 6 – Class 6 flexible copper conductors for single-core and multi-core cables

1 2 3 4

Nominal cross- Maximum diameter of Maximum resistance of conductor at 20 °C

sectional area wires in conductor

Plain wires Metal-coated wires

mm Ω/km Ω/km

mm

0,5 0,16 39,0 40,1

0,75 0,16 26,0 26,7

1,0 0,16 19,5 20,0

1,5 0,16 13,3 13,7

2,5 0,16 7,98 8,21

4 0,16 4,95 5,09

6 0,21 3,30 3,39

10 0,21 1,91 1,95

16 0,21 1,21 1,24

25 0,21 0,780 0,795

35 0,21 0,554 0,565

50 0,31 0,386 0,393

70 0,31 0,272 0,277

95 0,31 0,206 0,210

120 0,31 0,161 0,164

150 0,31 0,129 0,132

185 0,41 0,106 0,108

240 0,41 0,080 1 0,081 7

300 0,41 0,064 1 0,065 4

Annex A

(normative)

Measurement of resistance

The cable shall be kept in the test area for a sufficient time to ensure that the conductor

temperature has reached a level which permits an accurate determination of resistance using

the correction factors provided.

Measure the DC resistance of the conductor(s), either on a complete length of cable or flexible

cord or on a sample of cable of flexible cord of at least 1 m in length, at room temperature and

record the temperature at which the measurement is made. Adjust the measured resistance by

means of the correction factors given in Table A.1.

Calculate the resistance per kilometre length of cable from the length of the complete cable and

not from the length of the individual core or wires.

If necessary, correction to 20 °C and 1 km length shall be made by applying the following

formula:

R = Rk××

20 t t

L

where

k is the temperature correction factor from Table A.1;

t

R is the conductor resistance at 20 °C, in Ω/km;

R is the measured conductor resistance, in Ω;

t

L is the length of the cable, in m.

The expanded measurement uncertainty (k = 2) for R shall be in accordance with

IECEE OD-5014.

– 18 – IEC 60228:2023 CMV IEC 2023

Table A.1 – Temperature correction factors k for conductor resistance

t

to correct the measured resistance at t °C to 20 °C

1 2 1 2

Temperature of Temperature of

Correction factor Correction factor

k k

t t

conductor at time of conductor at time of

measurement measurement

All conductors All conductors

t °C t °C

0 1,087 21 0,996

1 1,082 22 0,992

2 1,078 23 0,988

3 1,073 24 0,984

4 1,068 25 0,980

5 1,064 26 0,977

6 1,059 27 0,973

7 1,055 28 0,969

8 1,050 29 0,965

9 1,046 30 0,962

10 1,042 31 0,958

11 1,037 32 0,954

12 1,033 33 0,951

13 1,029 34 0,947

14 1,025 35 0,943

15 1,020 36 0,940

16 1,016 37 0,936

17 1,012 38 0,933

18 1,008 39 0,929

19 1,004 40 0,926

20 1,000

NOTE The values of correction factors are based on a resistance-temperature coefficient of 0,004 per Kelvin

k

t

at 20 °C.

The values of temperature correction factors specified in column 2 are approximate but give practical values well

within the accuracy that can normally be achieved in measurements of conductor temperature and length of cable

or flexible cords.

For more accurate values for the temperature correction factors for copper and aluminium, reference should be

made to Annex B. However, these should not be treated as a requirement for testing in compliance with this

document in the assessment of resistances.

Annex B

(informative)

Exact formulae for the temperature correction factors

a) Annealed copper conductors: plain or metal-coated

254,5 1

k

t,Cu

234,t5 ++1 0,00393()t − 20

b) Aluminium conductors

248 1

k

t,Al

228 ++t 1 0,t00403()− 20

NOTE For aluminium alloys, reference should be made to the manufacturer.

In all the above cases, t refers to the temperature of the conductor at the time of measurement

in degrees Celsius.

==

==

– 20 – IEC 60228:2023 CMV IEC 2023

Annex C

(informative)

Guidance on the dimensional limits of circular conductors

C.1 Object Purpose

This Annex C is intended as a guide for manufacturers of cables and cable connectors to assist

in ensuring that the conductors and connectors are dimensionally compatible. It gives guidance

on dimensional limits for the following types of conductor included in this document:

a) circular solid conductors, (class 1) of copper, aluminium and or aluminium alloy;

b) circular and compacted circular stranded conductors, (class 2) of copper, aluminium and or

aluminium alloy;

c) flexible conductors, (classes 5 and 6) of copper.

C.2 Dimensional limits for circular copper conductors

The diameters of circular copper conductors should not exceed the values given in Table C.1.

If minimum diameters for class 1 circular copper conductors are needed required, reference

can be made to the minimum diameters for solid circular aluminium or aluminium alloy

conductors indicated in Table C.3.

C.3 Dimensional limits for stranded compacted circular copper, aluminium

and aluminium alloy conductors

The diameters of stranded compacted circular copper, aluminium and aluminium alloy

conductors should not exceed the maximum values and should be not less than the minimum

values given in Table C.2.

In the exceptional case of uncompacted circular stranded aluminium or aluminium alloy

conductors, the maximum diameters should not exceed the corresponding values for copper

conductors given in column 3 of Table C.1.

C.4 Dimensional limits for circular solid aluminium conductors

The diameters of circular solid aluminium and aluminium alloy conductors should not exceed

the maximum values and should be not less than the minimum values given in Table C.3.

Table C.1 – Maximum diameters of solid, non-compacted

stranded and flexible circular copper conductors

1 2 3 4

Nominal Conductors in cables for fixed installations

cross-sectional area

Solid Stranded Flexible conductors

(Class 1) (Class 2) (Classes 5 and 6)

mm mm mm

mm

0,5 0,9 1,1 1,1

0,75 1,0 1,2 1,3

1,0 1,2 1,4 1,5

1,5 1,5 1,7 1,8

2,5 1,9 2,2 2,4

4 2,4 2,7 3,0

6 2,9 3,3 3,9

10 3,7 4,2 5,1

16 4,6 5,3 6,3

a

5,7 6,6 7,8

a

6,7 7,9 9,2

a

7,8 9,1 11,0

a

9,4 11,0 13,1

a

11,0 12,9 15,1

a

12,4 14,5 17,0

a

13,8 16,2 19,0

185 15,4 18,0 21,0

240 17,6 20,6 24,0

300 19,8 23,1 27,0

400 22,2 26,1 31,0

500 - 29,2 35,0

630 - 33,2 39,0

800 - 37,6 -

1 000 - 42,2 -

NOTE The values given for flexible conductors are intended to allow for both class 5 and class 6 conductors.

a

See 6.1.1 b).

– 22 – IEC 60228:2023 CMV IEC 2023

Table C.2 – Minimum and maximum diameters of stranded compacted

circular copper, aluminium and aluminium alloy conductors

1 2 3

Nominal cross-sectional Stranded compacted circular conductors (Class 2)

area

Minimum diameter Maximum diameter

mm mm

mm

10 3,6 4,0

16 4,6 5,2

25 5,6 6,5

35 6,6 7,5

50 7,7 8,6

70 9,3 10,2

95 11,0 12,0

120 12,3 13,5

150 13,7 15,0

185 15,3 16,8

240 17,6 19,2

300 19,7 21,6

400 22,3 24,6

500 25,3 27,6

630 28,7 32,5

NOTE 1 The dimensional limits of aluminium conductors with cross-sectional areas

above 630 mm are not given as the compaction technology is not generally

established.

NOTE 2 No values are given for compacted copper conductors in the size range

2 2

1,5 mm to 6 mm .

Table C.3 – Minimum and maximum diameters of solid circular aluminium conductors

1 2 3

Nominal cross- Solid conductors (Class 1)

sectional area

Minimum diameter Maximum diameter

mm mm

mm

10 3,4 3,7

16 4,1 4,6

25 5,2 5,7

35 6,1 6,7

50 7,2 7,8

70 8,7 9,4

95 10,3 11,0

120 11,6 12,4

150 12,9 13,8

185 14,5 15,4

240 16,7 17,6

300 18,8 19,8

400 21,2 22,2

500 24,0 25,1

630 27,3 28,4

800 30,9 32,1

1000 34,8 36,0

1200 37,8 39,0

– 24 – IEC 60228:2023 CMV IEC 2023

Bibliography

IEC Guide 108, Guidelines for ensuring the coherence of IEC publications – Horizontal

functions, horizontal publications and their application

List of comments

1 As IEC TC 20 do not prescribe cables with AWG/kcmil conductors it has been decided to

remove the below table and the paragraph.

See IEC TR 62602 to find AWG/kcmil information.

2 Segmented conductors without lightly insultation between them used for DC applications

are not considered Milliken.

3 Copper coated aluminium is not considered because of possible safety risks, including

possible corrosion of the metals which make them unsuitable for household use.

4 Conductors can be made of aluminium or copper, and only these materials are considered

in order to evaluate the resistance. Additional materials, i.e. lacquers, paint, tapes and

powders are allowed as part of the conductor design to improve characteristics but they

are not covered by this standard.

5 For cross-sections from 800 mm² to 1600 mm² the minimum number of wires indicated in

Table 4 is not applicable to Milliken conductors.

6 Milliken conductors from 800 mm² take the same DC resistance value than circular

conductors.

Circular conductors are considered up to 1600 mm².

7 Preferred sizes follow the Renard series of preferred numbers.

___________

IEC 60228 ®

Edition 4.0 2023-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Conductors of insulated cables

Ames des câbles isolés

– 2 – IEC 60228:2023 IEC 2023

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Classification . 8

5 Materials . 8

5.1 General . 8

5.2 Circular and shaped solid aluminium conductors . 8

5.3 Circular and shaped stranded aluminium conductors . 9

6 Solid conductors and stranded conductors . 9

6.1 Solid conductors (class 1) . 9

6.1.1 Construction . 9

6.1.2 Resistance . 9

6.2 Stranded circular non-compacted conductors (class 2) . 9

6.2.1 Construction .

...

IEC 60228 ®

Edition 4.0 2023-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Conductors of insulated cables

Ames des câbles isolés

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60228 ®

Edition 4.0 2023-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Conductors of insulated cables

Ames des câbles isolés

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.060.20 ISBN 978-2-8322-7808-6

– 2 – IEC 60228:2023 IEC 2023

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Classification . 8

5 Materials . 8

5.1 General . 8

5.2 Circular and shaped solid aluminium conductors . 8

5.3 Circular and shaped stranded aluminium conductors . 9

6 Solid conductors and stranded conductors . 9

6.1 Solid conductors (class 1) . 9

6.1.1 Construction . 9

6.1.2 Resistance . 9

6.2 Stranded circular non-compacted conductors (class 2) . 9

6.2.1 Construction . 9

6.2.2 Resistance . 10

6.3 Stranded compacted circular conductors and stranded shaped conductors

(class 2) . 10

6.3.1 Construction . 10

6.3.2 Resistance . 10

6.4 Milliken conductors (class 2) . 10

6.4.1 Construction . 10

6.4.2 Resistance . 10

7 Flexible conductors (classes 5 and 6) . 10

7.1 Construction . 10

7.2 Resistance . 11

8 Check of compliance with Clause 6 and Clause 7 . 11

Annex A (normative) Measurement of resistance . 16

Annex B (informative) Exact formulae for the temperature correction factors . 18

Annex C (informative) Guidance on the dimensional limits of circular conductors . 19

C.1 Purpose . 19

C.2 Dimensional limits for circular copper conductors . 19

C.3 Dimensional limits for stranded compacted circular copper, aluminium and

aluminium alloy conductors . 19

C.4 Dimensional limits for circular solid aluminium conductors . 19

Bibliography . 23

Table 1 – Tensile strength limits for circular and shaped solid aluminium conductors . 8

Table 2 – Tensile strength limits for circular and shaped stranded aluminium

conductors . 9

Table 3 – Class 1 solid conductors for single-core and multi-core cables . 12

Table 4 – Class 2 stranded conductors for single-core and multi-core cables . 13

Table 5 – Class 5 flexible copper conductors for single-core and multi-core cables . 14

Table 6 – Class 6 flexible copper conductors for single-core and multi-core cables . 15

Table A.1 – Temperature correction factors k for conductor resistance to correct the

t

measured resistance at t °C to 20 °C . 17

Table C.1 – Maximum diameters of solid, non-compacted stranded and flexible circular

copper conductors . 20

Table C.2 – Minimum and maximum diameters of stranded compacted circular copper,

aluminium and aluminium alloy conductors . 21

Table C.3 – Minimum and maximum diameters of solid circular aluminium conductors . 22

– 4 – IEC 60228:2023 IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

CONDUCTORS OF INSULATED CABLES

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 60228 has been prepared by IEC technical committee 20: Electric cables. It is an

International Standard.

This fourth edition cancels and replaces the third edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) a description of Milliken conductors has been added;

b) nominal cross-sectional areas above 2 500 mm have been added;

c) the old 2 500 mm aluminium resistance value has been corrected and a new value

introduced.

For legacy systems where the 2 500 mm aluminium conductor was designed taking into

account the value presented in previous editions and no longer tabulated, then the original

design can be maintained and still utilized.

The suppliers can furthermore utilize such superseded design of 2 500 mm aluminium

conductors either in systems already designed and qualified but not delivered or for example

to produce repair and additional spare lengths for delivered systems.

The choice of utilizing the original superseded design of 2 500 mm aluminium conductors

or a new one based on the new resistance tabulated value is a matter of agreement between

the supplier and final users.

The text of this International Standard is based on the following documents:

Draft Report on voting

20/2125/FDIS 20/2131/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

– 6 – IEC 60228:2023 IEC 2023

INTRODUCTION

This document is intended as a fundamental reference standard for IEC technical committees

and National Committees in drafting standards for electric cables, and to the National

Committees in drafting specifications for use in their own countries. These committees select

from the tables of this general standard the conductors appropriate to the particular applications

relevant to them and either include the applicable details in their cable specifications or make

appropriate references to this document.

CONDUCTORS OF INSULATED CABLES

1 Scope

2 2

This document specifies the nominal cross-sectional areas, in the range 0,5 mm to 3 500 mm ,

for conductors in electric power cables and cords of a wide range of types. Requirements for

numbers and sizes of wires and resistance values are also included. These conductors include

solid, stranded and Milliken, copper, aluminium and aluminium alloy conductors in cables for

fixed installations and flexible copper conductors.

This document does not apply to conductors for telecommunication purposes.

The applicability of this document to a particular type of cable is as specified in the standard

for the type of cable.

Unless specified otherwise in a particular clause, this document relates to the conductors in

the finished cable and not to the conductor as made or supplied for inclusion into a cable.

Conductors described in this document are specified in metric sizes.

Informative annexes provide supplementary information covering temperature correction

factors for resistance measurement (Annex B) and guidance on dimensional limits of circular

conductors (Annex C).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IECEE OD-5014, Instrument Accuracy Limits

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

metal-coated

coated with a thin layer of suitable metal, such as tin or tin alloy

3.2

nominal cross-sectional area

value that identifies a particular size of conductor but is not subject to direct measurement

Note 1 to entry: Each particular size of conductor in this document is required to meet a maximum resistance value.

– 8 – IEC 60228:2023 IEC 2023

3.3

Milliken conductor

stranded conductor comprising an assembly of shaped conductors, lightly insulated from each

other

4 Classification

The conductors have been divided into four classes, 1, 2, 5 and 6. Those in classes 1 and 2

are intended for use in cables for fixed installations. Classes 5 and 6 are intended for use in

flexible cables and cords but can also be used for fixed installations.

• class 1: solid conductors;

• class 2: stranded conductors;

• class 5: flexible conductors;

• class 6: flexible conductors made with smaller diameter wires than class 5 for the same

nominal conductor cross-section.

5 Materials

5.1 General

The wires of conductors shall consist of one of the following (except for the Milliken central

element):

• plain or metal-coated annealed copper;

• aluminium or aluminium alloy.

The wires of stranded conductors (for example Milliken conductors) can be oxidized or

enamelled.

5.2 Circular and shaped solid aluminium conductors

Circular and shaped solid aluminium conductors shall be made from aluminium such that the

tensile strength of the completed conductor is within the limits given in Table 1.

Table 1 – Tensile strength limits for circular

and shaped solid aluminium conductors

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

10 and 16 110 to 165

25 and 35 60 to 130

50 60 to 110

70 and above 60 to 90

There are no limits defined for the tensile strength of aluminium alloy solid conductors.

5.3 Circular and shaped stranded aluminium conductors

Stranded aluminium conductors shall be made from aluminium such that the tensile strength of

the individual wires is within the limits given in Table 2:

Table 2 – Tensile strength limits for circular

and shaped stranded aluminium conductors

Nominal cross-sectional area Tensile strength

2 2

mm N/mm

10 up to 200

16 and above 125 to 205

There are no limits defined for the tensile strength of aluminium alloy stranded conductors.

This data can only be checked on wires taken before stranding and not on wires taken from a

stranded conductor.

6 Solid conductors and stranded conductors

6.1 Solid conductors (class 1)

6.1.1 Construction

a) Solid conductors or conductor wires shall consist of one of the materials specified in

Clause 5.

b) Solid copper conductors shall be of circular cross-section.

NOTE Solid copper conductors having nominal cross-section areas of 25 mm and above are for particular

types of cable, e.g. mineral insulated, and not for general purposes.

2 2

c) Solid aluminium and solid aluminium alloy conductors of sizes 10 mm to 35 mm shall be

of circular cross-section. Larger sizes shall be of circular cross-section for single-core

cables and may be of either circular or shaped cross-section for multi-core cables.

6.1.2 Resistance

The resistance of each conductor at 20 ºC, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 3.

For solid aluminium alloy conductors, having the same nominal cross-sectional area as an

aluminium conductor, the resistance value given in Table 3 should be multiplied by a factor of

1,162 unless otherwise agreed between the manufacturer and the purchaser.

6.2 Stranded circular non-compacted conductors (class 2)

6.2.1 Construction

a) Stranded circular non-compacted conductors (class 2) shall consist of one of the materials

specified in Clause 5.

b) Stranded aluminium or aluminium alloy conductors shall have a cross-sectional area not

less than 10 mm .

c) The wires in each conductor shall all have the same nominal diameter.

d) The number of wires in each conductor shall be not less than the appropriate minimum

number given in Table 4.

– 10 – IEC 60228:2023 IEC 2023

6.2.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 4.

6.3 Stranded compacted circular conductors and stranded shaped conductors

(class 2)

6.3.1 Construction

a) Stranded compacted circular conductors and stranded shaped conductors (class 2) shall

consist of one of the materials specified in Clause 5. Stranded compacted circular aluminium

or aluminium alloy conductors shall have a nominal cross-sectional area not less than

10 mm . Stranded compacted circular copper conductors shall have a nominal

cross-sectional area not less than 1,5 mm . Stranded shaped copper, aluminium or

aluminium alloy conductors shall have a nominal cross-sectional area of not less than

25 mm .

b) The ratio of the diameters of two different wires in the same conductor shall not exceed 2,

except for conductors made with pre-shaped wires.

c) The number of wires in each conductor shall be not less than the appropriate minimum

number given in Table 4, except for conductors made with pre-shaped wires. This

requirement applies to conductors made with wires of circular cross-section before

compaction.

6.3.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 4.

6.4 Milliken conductors (class 2)

6.4.1 Construction

a) Milliken conductors (class 2) shall consist of any of the materials specified in Clause 5.

Milliken conductors shall have a nominal cross-sectional area not less than 800 mm , and

the minimum number of wires for each cross section is not specified.

b) The ratio of the diameters of two different wires of any segment shall not exceed 2 (Milliken

central element excluded).

c) The Milliken central element can be empty, with a solid conductor, wires or with a plastic

filler.

d) This conductor may be constructed from 4, 5, or 6 equal segments. The number of wires in

each segment is defined by the manufacturer. In the case of a central element formed with

wires, it can be considered as an additional segment with a polygonal shape.

6.4.2 Resistance

The resistance of the whole conductor at 20 °C, for all different constructions described in 6.4.1,

when determined in accordance with Clause 8, shall not exceed the appropriate maximum value

given in Table 4.

7 Flexible conductors (classes 5 and 6)

7.1 Construction

a) Flexible conductors (classes 5 and 6) shall consist of plain or metal-coated annealed copper.

b) The wires in each conductor shall have the same nominal diameter.

c) The diameter of the wires in each conductor shall not exceed the appropriate maximum

value given in Table 5 for class 5 or Table 6 for class 6 conductors.

7.2 Resistance

The resistance of each conductor at 20 °C, when determined in accordance with Clause 8, shall

not exceed the appropriate maximum value given in Table 5 or Table 6.

8 Check of compliance with Clause 6 and Clause 7

Compliance with the requirements for construction of 6.1.1, 6.2.1, 6.3.1, 6.4.1 and 7.1 shall be

checked on the completed cable by inspection and measurement where practicable.

Compliance with the requirements for resistance given in 6.1.2, 6.2.2, 6.3.2, 6.4.2, and 7.2 shall

be checked by measurement in accordance with Annex A and corrected for temperature by the

factors in Table A.1.

– 12 – IEC 60228:2023 IEC 2023

Table 3 – Class 1 solid conductors for single-core and multi-core cables

1 2 3 4

Nominal cross- Maximum resistance of conductor at 20 ºC

sectional area

Aluminium and

Circular, annealed copper conductors

aluminium alloy

Plain Metal-coated

conductors, circular or

c

shaped

Ω/km Ω/km Ω/km

mm

0,5 36,0 36,7 -

0,75 24,5 24,8 -

1,0 18,1 18,2 -

1,5 12,1 12,2 -

2,5 7,41 7,56 -

4 4,61 4,70 -

6 3,08 3,11 -

a

10 1,83 1,84

3,08

a

16 1,15 1,16

1,91

b a

25 -

0,727 1,20

b a

35 -

0,524 0,868

b

50 - 0,641

0,387

b

70 - 0,443

0,268

b d

95 -

0,193 0,320

b d

120 -

0,153 0,253

b d

150 -

0,124 0,206

b d

185 -

0,101 0,164

b d

240 -

0,077 5 0,125

b d

300 -

0,062 0 0,100

b

400 - 0,077 8

0,046 5

500 - - 0,060 5

630 - - 0,046 9

800 - - 0,036 7

1 000 - - 0,029 1

1 200 - - 0,024 7

1 400 - - 0,021 2

1 600 - - 0,018 6

a 2 2

Aluminium conductors 10 mm to 35 mm circular only; see 6.1.1 c).

b

See note in 6.1.1 b).

c

See note in 6.1.2.

d

For single-core cables, four sectoral shaped conductors may be assembled into a single circular conductor.

The maximum resistance of the assembled conductor shall be 25 % of that of the individual component

conductors.

Table 4 – Class 2 stranded conductors for single-core and multi-core cables

1 2 3 4 5 6 7 8 9 10

Minimum number of wires in the conductor Maximum resistance of conductor at 20 °C

Nominal

cross-

Circular Aluminium or

Circular Shaped Annealed copper conductor

sectional

compacted aluminium alloy

area

b

conductor

Cu Al Cu Al Cu Al Plain wires Metal-coated

wires

Ω/km Ω/km Ω/km

mm

0,5 7 - - - - - 36,0 36,7 -

0,75 7 - - - - - 24,5 24,8 -

1,0 7 - - - - - 18,1 18,2 -

1,5 7 - 6 - - - 12,1 12,2 -

2,5 7 - 6 - - - 7,41 7,56 -

4 7 - 6 - - - 4,61 4,70 -

6 7 - 6 - - - 3,08 3,11 -

10 7 7 6 6 - - 1,83 1,84 3,08

16 7 7 6 6 - - 1,15 1,16 1,91

25 7 7 6 6 6 6 0,727 0,734 1,20

35 7 7 6 6 6 6 0,524 0,529 0,868