IEC 60229:2007

(Main)Electric cables - Tests on extruded oversheaths with a special protective function

Electric cables - Tests on extruded oversheaths with a special protective function

Provides a range of tests which may be required for electric cables which have an extruded oversheath and where that oversheath performs a special protective function. The standard covers cables for use in insulated systems and in uninsulated systems. The tests are categorized for use as routine tests, type tests and tests after installation. These tests comprise of electrical routine tests on cable oversheath used in insulated or uninsulated systems, abrasion and corrosion spread type tests, electrical test on cable oversheath after installation. Routine tests and tests after installation, as specified in the relevant cable standards, are applicable for all situations. Type tests depend upon the nature of the system and the construction of the cable and do not have to be carried out for normal conditions of use. The significant technical changes with respect to the previous edition are as follows: - The text has been modified in order to consider the function of the oversheath, irrespective of the way the metallic sheath or screen of the cable is earthed because, in some cases, the oversheath is designed to act not only as a protection against corrosion, but also to reduce the risk of degradation of the cable insulation system. This requirement may be independent of the nature of the insulation and independent of the rated voltage of the cable. - More precise wording has been introduced regarding the application of some tests (if the sheaths or foils are bonded to the oversheath or not). - The test requirements have been revised in order to be in line with the standards published after the second edition. - The pressure test at high temperature has been deleted as the requirement is specified in the relevant cable standards. - A "Guidance on tests after installation" (Annex B) has been included.

Câbles électriques - Essais sur les gaines extérieures extrudées avec fonction spéciale de protection

Fournit une gamme d'essais que l'on peut demander pour les câbles électriques qui comportent une gaine extrudée, quand cette gaine remplit une fonction spéciale de protection. Cette norme s'applique aux câbles destinés aux réseaux à écran isolé et aux réseaux à écran non isolé. Les essais sont classés en tant qu'essais individuels, essais de type et essais après pose. Ces essais comprennent: - des essais diélectriques individuels pour les gaines des câbles utilisés dans les réseaux à écran isolé ou non isolé, - des essais de type d'abrasion, et de diffusion de la corrosion, - un essai diélectrique de gaine après pose. Les essais individuels et les essais après pose, tels que spécifiés dans les normes particulières de câbles, sont applicables en toute circonstance. Les essais de type dépendent de la nature du réseau et de la structure du câble et n'ont pas à être effectués pour des conditions normales d'utilisation. Les modifications techniques majeures, par rapport à la précédente édition, sont les suivantes: - Le texte a été modifié pour prendre en compte la fonction de la gaine extérieure, indépendamment du type de mise à la terre de la gaine ou l'écran métallique du câble, parce que, dans certains cas, la gaine extérieure est conçue non seulement pour assurer une protection contre la corrosion, mais aussi pour réduire le risque de dégradation de l'isolation du câble. Cette exigence peut être indépendante de la nature de l'enveloppe isolante et indépendante de la tension assignée du câble. - La rédaction concernant la pertinence de certains essais a été précisée (selon que les gaines ou feuilles sont contrecollées ou non à la gaine extérieure). - Les exigences d'essai ont été revues pour être en accord avec les spécifications publiées postérieurement à la deuxième édition. - L'essai de pression à température élevée a été supprimé, car cette exigence est spécifiée dans les spécifications particulières des câbles. - Des " Recommandations pour les essais après pose " (Annexe B) ont été introduites.

General Information

- Status

- Published

- Publication Date

- 09-Oct-2007

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- PPUB - Publication issued

- Start Date

- 10-Oct-2007

- Completion Date

- 15-Nov-2007

Overview

IEC 60229:2007 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the testing requirements for electric cables featuring extruded oversheaths with special protective functions. This standard outlines a comprehensive set of tests designed to verify the integrity and performance of the cable oversheath, which serves critical roles such as corrosion protection and insulation degradation prevention across insulated and uninsulated cable systems.

This third edition revises earlier versions by refining test applications, removing redundant pressure tests, and adding guidance on post-installation testing. The standard is essential for manufacturers, installers, and testing laboratories aiming to ensure the durability, electrical safety, and protective functionality of extruded oversheaths in electric cable installations.

Key Topics

Scope and Application: Applies to electric cables with extruded oversheaths that serve special protective functions, regardless of insulation type or rated voltage. Covers both insulated and uninsulated cable systems.

Test Categories:

- Routine Tests: Include electrical checks such as d.c. voltage and spark tests to assess oversheath integrity.

- Type Tests: Include abrasion resistance and corrosion spread evaluations, applied based on system and cable construction specifics.

- Tests After Installation: Electrical post-installation tests ensure oversheath functionality in situ.

Electrical Routine Tests:

- D.C. Voltage Test: Application of up to 25 kV d.c. voltage for one minute to test for dielectric breakdown.

- Spark Test: High voltage a.c. or d.c. spark tests to locate defects in the oversheath.

Type Tests:

- Abrasion Test: Simulates mechanical wear during cable laying by repeatedly sliding a weighted steel angle over the cable surface. Electrical tests follow to verify no damage.

- Corrosion Spread Test: Specific to cables with aluminium metallic screens, this test measures resistance to corrosion spread under defined conditions.

Guidance on Post-Installation Tests: Included in Annex B to assist in verifying oversheath condition after deployment.

Technical Updates: Clarifies that oversheath functions are evaluated independently of metallic sheath earthing; updates test applications with precise terminology; removes the high-temperature pressure test now covered in relevant cable standards.

Applications

Cable Manufacturing: Provides a framework for quality assurance regarding the physical and electrical protection performance of extruded oversheaths.

Installation and Maintenance: Enables contractors and utilities to perform routine and post-installation tests ensuring cable oversheath integrity and preventing premature degradation in various environments.

Safety and Reliability Assurance: Supports compliance with international safety standards, reducing cable failures due to abrasion, corrosion, and electrical faults.

System Design and Specification: Essential reference for specifying cables in systems where oversheaths play critical protective roles beyond conventional insulation functions.

Related Standards

IEC 60230: Impulse tests on cables and accessories-provides methodologies referenced for impulse voltage testing in IEC 60229.

IEC 62230: Electric cables – Spark test method-defines the spark testing procedures detailed in routine test requirements.

Relevant Cable Standards: Pressure tests and other testing practices applicable in conjunction with IEC 60229 to ensure full compliance with cable design and operating requirements.

Keywords: IEC 60229, extruded oversheath tests, electric cable standards, abrasion test, corrosion protection, electrical routine test, spark test, d.c. voltage test, cable installation testing, cable oversheath functionality.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60229:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electric cables - Tests on extruded oversheaths with a special protective function". This standard covers: Provides a range of tests which may be required for electric cables which have an extruded oversheath and where that oversheath performs a special protective function. The standard covers cables for use in insulated systems and in uninsulated systems. The tests are categorized for use as routine tests, type tests and tests after installation. These tests comprise of electrical routine tests on cable oversheath used in insulated or uninsulated systems, abrasion and corrosion spread type tests, electrical test on cable oversheath after installation. Routine tests and tests after installation, as specified in the relevant cable standards, are applicable for all situations. Type tests depend upon the nature of the system and the construction of the cable and do not have to be carried out for normal conditions of use. The significant technical changes with respect to the previous edition are as follows: - The text has been modified in order to consider the function of the oversheath, irrespective of the way the metallic sheath or screen of the cable is earthed because, in some cases, the oversheath is designed to act not only as a protection against corrosion, but also to reduce the risk of degradation of the cable insulation system. This requirement may be independent of the nature of the insulation and independent of the rated voltage of the cable. - More precise wording has been introduced regarding the application of some tests (if the sheaths or foils are bonded to the oversheath or not). - The test requirements have been revised in order to be in line with the standards published after the second edition. - The pressure test at high temperature has been deleted as the requirement is specified in the relevant cable standards. - A "Guidance on tests after installation" (Annex B) has been included.

Provides a range of tests which may be required for electric cables which have an extruded oversheath and where that oversheath performs a special protective function. The standard covers cables for use in insulated systems and in uninsulated systems. The tests are categorized for use as routine tests, type tests and tests after installation. These tests comprise of electrical routine tests on cable oversheath used in insulated or uninsulated systems, abrasion and corrosion spread type tests, electrical test on cable oversheath after installation. Routine tests and tests after installation, as specified in the relevant cable standards, are applicable for all situations. Type tests depend upon the nature of the system and the construction of the cable and do not have to be carried out for normal conditions of use. The significant technical changes with respect to the previous edition are as follows: - The text has been modified in order to consider the function of the oversheath, irrespective of the way the metallic sheath or screen of the cable is earthed because, in some cases, the oversheath is designed to act not only as a protection against corrosion, but also to reduce the risk of degradation of the cable insulation system. This requirement may be independent of the nature of the insulation and independent of the rated voltage of the cable. - More precise wording has been introduced regarding the application of some tests (if the sheaths or foils are bonded to the oversheath or not). - The test requirements have been revised in order to be in line with the standards published after the second edition. - The pressure test at high temperature has been deleted as the requirement is specified in the relevant cable standards. - A "Guidance on tests after installation" (Annex B) has been included.

IEC 60229:2007 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60229:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60229

Edition 3.0 2007-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric cables – Tests on extruded oversheaths with a special protective

function

Câbles électriques – Essais sur les gaines extérieures extrudées avec fonction

spéciale de protection

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60229

Edition 3.0 2007-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electric cables – Tests on extruded oversheaths with a special protective

function

Câbles électriques – Essais sur les gaines extérieures extrudées avec fonction

spéciale de protection

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

L

CODE PRIX

ICS 29.060.20 ISBN 2-8318-9338-0

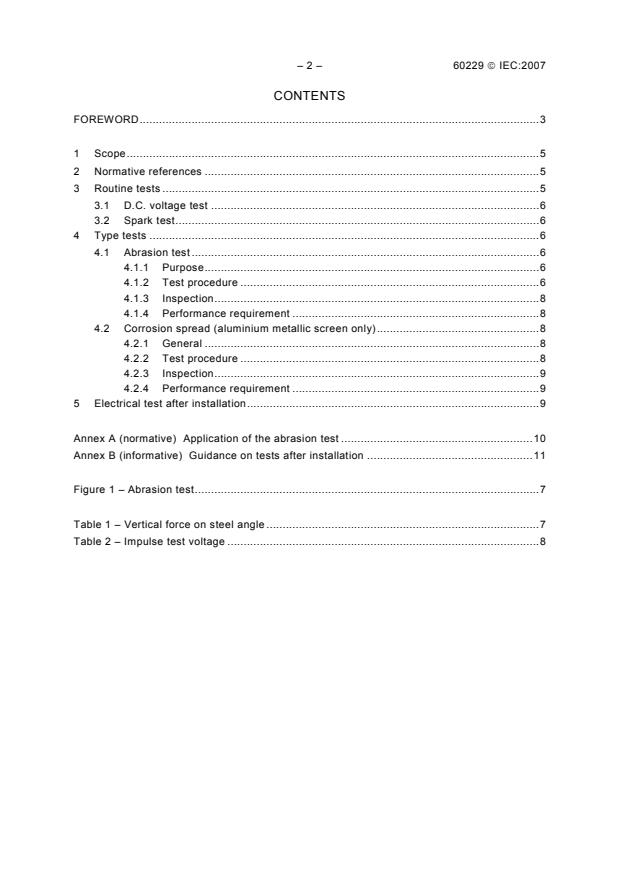

– 2 – 60229 © IEC:2007

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 Routine tests .5

3.1 D.C. voltage test .6

3.2 Spark test.6

4 Type tests .6

4.1 Abrasion test .6

4.1.1 Purpose.6

4.1.2 Test procedure .6

4.1.3 Inspection.8

4.1.4 Performance requirement .8

4.2 Corrosion spread (aluminium metallic screen only).8

4.2.1 General .8

4.2.2 Test procedure .8

4.2.3 Inspection.9

4.2.4 Performance requirement .9

5 Electrical test after installation.9

Annex A (normative) Application of the abrasion test .10

Annex B (informative) Guidance on tests after installation .11

Figure 1 – Abrasion test.7

Table 1 – Vertical force on steel angle .7

Table 2 – Impulse test voltage .8

60229 © IEC:2007 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRIC CABLES –

TESTS ON EXTRUDED OVERSHEATHS

WITH A SPECIAL PROTECTIVE FUNCTION

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60229 has been prepared by IEC technical committee 20: Electric

cables.

This third edition cancels and replaces the second edition published in 1982 and constitutes a

technical revision.

The significant technical changes with respect to the previous edition are as follows:

– The text has been modified in order to consider the function of the oversheath,

irrespective of the way the metallic sheath or screen of the cable is earthed because, in

some cases, the oversheath is designed to act not only as a protection against corrosion,

but also to reduce the risk of degradation of the cable insulation system. This requirement

may be independent of the nature of the insulation and independent of the rated voltage of

the cable.

– More precise wording has been introduced regarding the application of some tests (if the

sheaths or foils are bonded to the oversheath or not).

– The test requirements have been revised in order to be in line with the standards

published after the second edition.

– 4 – 60229 © IEC:2007

– The pressure test at high temperature has been deleted as the requirement is specified in

the relevant cable standards.

– A “Guidance on tests after installation” (Annex B) has been included.

The text of this standard is based on the following documents:

FDIS Report on voting

20/901/FDIS 20/908/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60229 © IEC:2007 – 5 –

ELECTRIC CABLES –

TESTS ON EXTRUDED OVERSHEATHS

WITH A SPECIAL PROTECTIVE FUNCTION

1 Scope

This International Standard provides a range of tests which may be required for electric

cables which have an extruded oversheath and where that oversheath performs a special

protective function.

NOTE 1 The need for the special functions may be independent of the nature of the insulation type or

independent of the rated voltage of the cable.

The standard covers cables for use in insulated systems and in uninsulated systems.

The tests are categorized for use as

a) routine tests,

b) type tests,

c) tests after installation.

These tests comprise:

− electrical routine tests on cable oversheath used in insulated or uninsulated systems,

− abrasion and corrosion spread type tests,

− electrical test on cable oversheath after installation.

Routine tests and tests after installation, as specified in the relevant cable standards, are

applicable for all situations.

Type tests depend upon the nature of the system and the construction of the cable and do not

have to be carried out for normal conditions of use.

The application of the abrasion test is given in Annex A.

NOTE 2 Guidance on tests after installation is given in Annex B.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60230, Impulse tests on cables and their accessories

IEC 62230, Electric cables – Spark test method

3 Routine tests

The electrical integrity of the oversheath shall be tested using either a d.c. voltage test (3.1)

or a spark test (3.2).

– 6 – 60229 © IEC:2007

NOTE The spark test method is not applicable when a conducting layer is already applied to the oversheath. In

such cases only the test according to 3.1 may be used.

Testing is applicable in all cases.

3.1 D.C. voltage test

A d.c. voltage of 8 kV per millimetre of the specified nominal thickness of the extruded

oversheath shall be applied for 1 min between the underlying metal layer at negative polarity

and the outer conducting layer, subject to a maximum voltage of 25 kV.

No breakdown of the oversheath shall occur during the test.

NOTE The outer conducting layer may consist of a conductive layer applied to the extruded oversheath or

obtained by immersion in water for the duration of the test.

3.2 Spark test

A spark test according to the method given in IEC 62230 shall be carried out by earthing the

underlying metallic layer for an a.c. test or connecting it to the negative pole in the case of a

d.c. supply. The voltages shall be 6 kV a.c. per millimetre or 9 kV d.c. per millimetre of the

specified nominal thickness of the extruded oversheath, subject to maximum values of 15 kV

a.c. and 25 kV d.c., respectively.

The dwell time of the cable in the region of test shall be of sufficient duration to detect any

defect.

No faults shall be detected during the test.

4 Type tests

4.1 Abrasion test

4.1.1 Purpose

The purpose of this test is to demonstrate that the extruded oversheath will withstand

abrasion during the laying operation.

The abrasion test shall be carried out if the oversheath material is not of type ST1, ST2, ST3

or ST7 compound and if the thickness does not comply with the particular IEC cable standard.

4.1.2 Test procedure

A sample of the cable, of sufficient length, shall be submitted to the bending operation given

in the bending test, as specified in the particular IEC cable standard.

After bending, the procedure specified in 4.1.2.1 shall be carried out at a temperature of (20 ±

5) °C for cases a) and b), as described in Annex A. This shall be followed by the electrical

test in 4.1.2.2 for case a) only.

4.1.2.1 Abrasion

The sample of cable shall be laid out straight and horizontal on a firm base, with the plane of

the previous bending operation in the horizontal plane. In the middle of the sample and

perpendicular to it, a length of mild steel angle shall be placed horizontally, at right angles to

the cable, with its angle edge resting on the cable and with its arms symmetrical about the

vertical plane through the longitudinal axis of the cable. The outer radius of curvature of the

angle edge shall be not less than 1 mm and not greater than 2 mm (see Figure 1).

60229 © IEC:2007 – 7 –

Dimensions in millimetres

B

A

600 min.

IEC 2007/07

Key

1 force (see Table 1) A start/finish position

2 mild steel angle B finish/start position

3 plane of bending A-B test path length (minimum)

Figure 1 – Abrasion test

The steel angle shall be vertically loaded, above the point of contact, with a force in

accordance with Table 1.

The steel angle shall be dragged horizontally along the cable for a distance not less than

600 mm at a speed of between 150 mm/s and 300 mm/s. The direction of movement shall be

reversed at the end of each pass to give 50 passes, 25 in each direction over the 600 mm test

path.

Table 1 – Vertical force on steel angle

Overall measured diameter of cable

mm

Force

Above and including Up to N

30 40 65

40 50 105

50 60 155

60 70 210

70 80 270

80 90 340

90 100 420

100 110 500

110 and above 550

– 8 – 60229 © IEC:2007

4.1.2.2 Electrical test

The middle of the cable sample, conditioned as above, shall be submerged at ambient

temperature in a 0,5 % by weight solution of sodium chloride in water containing

approximately 0,1 % by weight of a suitable non-ionic surface active agent.

After at least 24 h of constant immersion, a d.c. voltage of 20 kV shall be applied for a period

of 1 min between the saline solution and the underlying metal layer which shall be at negative

polarity.

With the middle of the cable still submerged at ambient temperature in the sodium chloride

solution, apply 10 positive, followed by 10 negative impulse voltages, in accordance with

IEC 60230, and Table 2:

Table 2 – Impulse test voltage

Rated lightning impulse withstand Impulse test

voltage of main insulation voltage voltage

(peak) (peak)

kV kV

V ≤ 325

37,5

325 < V ≤ 750

47,5

750 < V < 1 175

62,5

1 175 ≤ V < 1 550

72,5

V ≥ 1 550

4.1.3 Inspection

The cable sample shall be taken (from the solution if test following 4.1.2.2 is performed) and a

1 m length, which includes the abraded area of the extruded oversheath, shall be removed,

employing two longitudinal cuts which do not pass through the conditioned area. The test

sample shall be cleaned of foreign material.

4.1.4 Performance requirement

The oversheaths shall be deemed satisfactory provided that

a) the electrical test has been passed, where required, and

b) an examination of the sample with normal or corrected vision without magnification reveals

no cracks or splits in the internal and external surfaces.

4.2 Corrosion spread (aluminium metallic screen only)

4.2.1 General

The corrosion spread test is relevant in the case of aluminium wires, aluminium sheaths and

aluminium foils when not bonded to the oversheath. It is not applicable in the case of

aluminium sheaths or foils bonded to the oversheath.

The purpose is to demonstrate that, in the event of local damage to an oversheath, any

consequential corrosion of the outer surface of the aluminium screen will remain virtually

confined to the damaged area of covering.

4.2.2 Test procedure

a) Bending operation

A sample of cable shall be submitted to the bending procedure of the bending test, as

specified in the particular IEC cable standard.

60229 © IEC:2007 – 9 –

b) Local damage

The oversheath shall be punctured down to the aluminium sheath or wires, in four places,

by means of a core drill of 10 mm diameter. These four holes shall be arranged spirally

about the mid-portion of the cable sample, at longitudinal intervals of about 100 mm and

circumferential spacings of 90°. All material shall be removed from each hole to expose

the 10 mm diameter of bare aluminium.

c) Corrosion procedure

The sample shall be formed into a U-shape with the curved portion having a radius of

curvature not greater than specified in the bending operation above. The curved portion

shall be submerged in a 1 % solution of sodium sulphate in water at ambient temperature,

with the cable ends in the air. All four holes shall be submerged to a depth of at least

500 mm in the solution. With a d.c. voltage applied between the metallic screen and the

solution and with metallic screen at negative polarity, a current of 10 mA shall flow for a

total period of (100 ± 2) h. This value of current shall be maintained substantially constant.

This may be achieved by the inclusion of a series resistor, resistance value of about

10 kΩ, in the electrical circuit. If two or more samples are electrically tested

simultaneously, each sample shall be independently controlled (for example by being

connected through its own series resistor).

4.2.3 Inspection

The cable sample shall be taken from the solution and the oversheath removed for a length of

about 500 mm, extending to at least 100 mm beyond each of the outer holes. All other

material in this region shall be removed from the metallic screen to expose bare aluminium.

4.2.4 Performance requirement

The oversheath shall be deemed satisfactory provided that, by examination with normal or

corrected vision without magnification, there are no signs of corrosion extending more than

10 mm beyond the rim of any hole at any point.

5 Electrical test after installation

Where an ‘after installation’ test of the oversheath is performed, a d.c. voltage of 4 kV per

millimetre of specified thickness of extruded oversheath shall be applied with a maximum of

10 kV d.c. between the underlying metallic layers and the outer electrode, for a period of

1 min. All metallic layers under the oversheath shall be connected together.

This test requires that the oversheath has an outer “electrode” which may be moist backfill or

a conductive layer.

No breakdown of the oversheath shall occur during the test.

– 10 – 60229 © IEC:2007

Annex A

(normative)

Application of the abrasion test

A.1 Case a) where the oversheath is to act as an insulation:

i) where special metallic screen bonding is employed to reduce metallic sheath or screen

losses, resulting in an applied voltage to the oversheath under load and fault conditions;

ii) where the underlying metallic layer can be isolated from earth to permit a voltage to be

applied to the oversheath to check its integrity.

A.2 Case b) where the oversheath is to act as an improved protection against

corrosion:

i) where protection of the metallic layer is of significant importance;

ii) where the combination of the particular metal and the cable environment would give rise to

a serious risk of corrosion;

iii) where corrosion, plus the ingress of water, could result in degradation of the cable

insulation system.

60229 © IEC:2007 – 11 –

Annex B

(informative)

Guidance on tests after installation

Both before and after installation, testing of cable sheaths which have a conductive coating is

being per

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...