IEC 60432-3:2012

(Main)Incandescent lamps - Safety specifications - Part 3: Tungsten halogen lamps (non-vehicle)

Incandescent lamps - Safety specifications - Part 3: Tungsten halogen lamps (non-vehicle)

IEC 60432-3:2012 specifies the safety requirements for single-capped and double-capped tungsten halogen lamps, having rated voltages of up to 250 V, used for the following applications:

- projection (including cinematograph and still projection),

- photographic (including studio),

- floodlighting,

- special purpose,

- general purpose,

- stage lighting.

This second edition of IEC 60432-3 cancels and replaces the first edition published in 2002, Amendment 1 (2005) and Amendment 2 (2008). The main changes with respect to the previous edition are as follows:

- adapting the cold fill pressure requirements and tests for self-shielded lamps to the state of the technology,

- introduction of requirements to fully cover photobiological safety according to IEC 62471.

Lampes à incandescence - Prescriptions de sécurité - Partie 3: Lampes tungstène-halogène (véhicules exceptés)

La CEI 60432-3:2012 fournit les exigences de sécurité relatives aux lampes tungstène-halogène à culot unique et à celles à deux culots, ayant des tensions assignées jusqu'à 250 V, utilisées pour les applications suivantes:

- projection (y compris cinéma et projection statique),

- photographie (y compris prise de vues),

- illumination,

- usage special,

- usage general,

- éclairage de scène.

Cette deuxième édition de la 60432-3 annule et remplace la première édition parue en 2002, l'Amendement 1 (2005) et l'Amendement 2 (2008). Par rapport à l'édition précédente, les changements principaux sont les suivants:

- la mise à jour des exigences et essais concernant la pression à froid pour les lampes à écran intégré conformément à l'état de l'art de la technologie,

- l'introduction des exigences pour couvrir intégralement la sécurité photobiologique en conformité avec la CEI 62471.

General Information

- Status

- Published

- Publication Date

- 03-Jul-2012

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 6 - TC 34/SC 34A/WG 6

- Current Stage

- PPUB - Publication issued

- Start Date

- 04-Jul-2012

- Completion Date

- 31-Jul-2012

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60432-3:2012 is an international standard established by the International Electrotechnical Commission (IEC) that specifies safety requirements for tungsten halogen incandescent lamps intended for non-vehicle applications. This second edition updates previous editions to align safety specifications with the current technology state, especially concerning cold fill pressure requirements and photobiological safety in accordance with IEC 62471.

The standard applies to single-capped and double-capped tungsten halogen lamps with rated voltages up to 250 V. It covers multiple application sectors including projection, photographic, floodlighting, special purpose, general, and stage lighting. Notably, this standard excludes general purpose single-capped tungsten halogen lamps used as replacements for conventional tungsten filament lamps, as these are covered by IEC 60432-2.

Key Topics

Scope and Application

Covers tungsten halogen lamps used in projection (cinematograph and still), photographic studios, floodlighting, stage lighting, and special-purpose lighting, supporting voltages up to 250 V.Safety Requirements

Defines comprehensive safety specifications including lamp marking, lamp caps or bases dimensional standards, creepage distances, and photobiological safety to protect users and equipment.Photobiological Safety

Integrates requirements from IEC 62471 to ensure lamps do not pose photobiological risks. Lamps categorized as floodlight, general purpose capsule, or reflector lamps in this standard do not require risk group marking due to low risk levels.Testing and Assessment

Provides methodologies for assessing compliance during production, including sampling procedures, acceptance quality levels (AQLs), and batch testing to maintain consistent quality and safety.Technical Definitions

Clarifies terms such as single-capped and double-capped tungsten halogen lamps, extra low voltage (ELV) and self-shielded lamps to ensure uniform understanding across manufacturers and users.

Applications

IEC 60432-3:2012 is essential for manufacturers, designers, and safety compliance officers involved in the specification, production, and distribution of tungsten halogen lamps intended for:

- Projection Lighting: Includes both cinematograph and still image projection systems requiring high-quality illumination standards and safety.

- Photographic and Studio Lighting: Ensures safety in photographic setups by addressing electrical, thermal, and photobiological hazards.

- Floodlighting: Used for broad-area illumination such as stages, outdoor events, and architectural lighting where safety under varying environmental conditions is critical.

- Special-Purpose and Stage Lighting: Provides safety standards for theatrical, entertainment, and specialized lighting instruments where lamp performance and user safety are paramount.

- General Lighting: Although certain general purpose lamps are excluded, many specialized general lighting lamps fall within this scope, ensuring they meet international safety norms.

By following IEC 60432-3, manufacturers ensure their tungsten halogen products meet high safety standards that protect against hazards such as electrical shock, thermal damage, and photobiological exposure, thereby building trust and compliance in global markets.

Related Standards

- IEC 60432-2: Incandescent lamps – Safety specifications – Part 2, focuses on general purpose single-capped tungsten halogen lamps.

- IEC 60357: Performance specifications for tungsten halogen lamps (non-vehicle), complementing safety with performance criteria.

- IEC 62471: Photobiological safety of lamps and lamp systems, providing assessment methods relevant for the safe use of light-emitting products.

- IEC 60061 series: Standards governing lamp caps and holders, ensuring interchangeability and safety of lamp fittings.

- IEC 60050-845: International Electrotechnical Vocabulary related to lighting, offering standardized terminology important for consistency in application.

By integrating requirements from these IEC standards, IEC 60432-3:2012 supports a holistic approach to illumination safety and performance, making it a critical reference for the tungsten halogen lamp industry covering a wide range of non-vehicle applications.

For professionals seeking to comply with global safety regulations for tungsten halogen lamps, IEC 60432-3:2012 delivers a robust framework focused on both electrical safety and photobiological protection, ensuring products meet modern technological and health standards while supporting diverse lighting applications worldwide.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60432-3:2012 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Incandescent lamps - Safety specifications - Part 3: Tungsten halogen lamps (non-vehicle)". This standard covers: IEC 60432-3:2012 specifies the safety requirements for single-capped and double-capped tungsten halogen lamps, having rated voltages of up to 250 V, used for the following applications: - projection (including cinematograph and still projection), - photographic (including studio), - floodlighting, - special purpose, - general purpose, - stage lighting. This second edition of IEC 60432-3 cancels and replaces the first edition published in 2002, Amendment 1 (2005) and Amendment 2 (2008). The main changes with respect to the previous edition are as follows: - adapting the cold fill pressure requirements and tests for self-shielded lamps to the state of the technology, - introduction of requirements to fully cover photobiological safety according to IEC 62471.

IEC 60432-3:2012 specifies the safety requirements for single-capped and double-capped tungsten halogen lamps, having rated voltages of up to 250 V, used for the following applications: - projection (including cinematograph and still projection), - photographic (including studio), - floodlighting, - special purpose, - general purpose, - stage lighting. This second edition of IEC 60432-3 cancels and replaces the first edition published in 2002, Amendment 1 (2005) and Amendment 2 (2008). The main changes with respect to the previous edition are as follows: - adapting the cold fill pressure requirements and tests for self-shielded lamps to the state of the technology, - introduction of requirements to fully cover photobiological safety according to IEC 62471.

IEC 60432-3:2012 is classified under the following ICS (International Classification for Standards) categories: 29.140.20 - Incandescent lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60432-3:2012 has the following relationships with other standards: It is inter standard links to IEC 60432-3:2002/AMD1:2005, IEC 60432-3:2002, IEC 60432-3:2002/AMD2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60432-3:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60432-3 ®

Edition 2.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Incandescent lamps – Safety specifications –

Part 3: Tungsten halogen lamps (non-vehicle)

Lampes à incandescence – Prescriptions de sécurité –

Partie 3: Lampes tungstène-halogène (véhicules exceptés)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 60432-3 ®

Edition 2.0 2012-07

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Incandescent lamps – Safety specifications –

Part 3: Tungsten halogen lamps (non-vehicle)

Lampes à incandescence – Prescriptions de sécurité –

Partie 3: Lampes tungstène-halogène (véhicules exceptés)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX V

ICS 29.140.20 ISBN 978-2-83220-197-8

– 2 – 60432-3 © IEC:2012

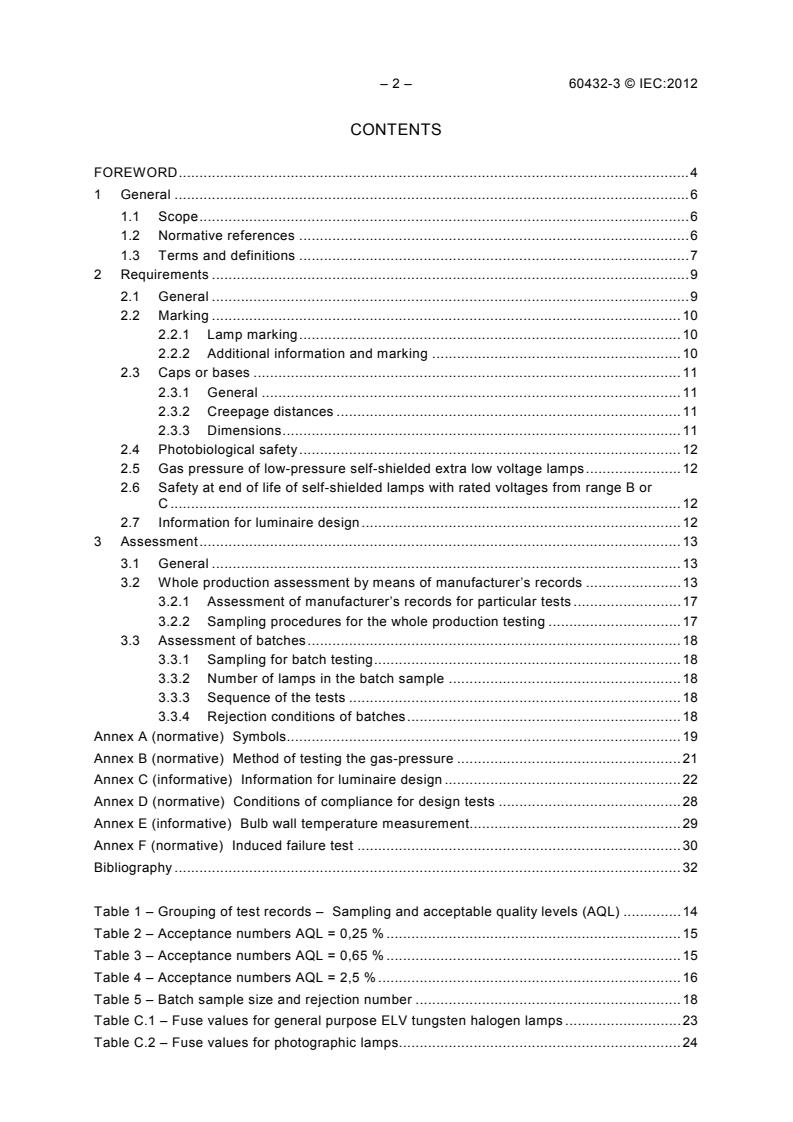

CONTENTS

FOREWORD . 4

1 General . 6

1.1 Scope . 6

1.2 Normative references . 6

1.3 Terms and definitions . 7

2 Requirements . 9

2.1 General . 9

2.2 Marking . 10

2.2.1 Lamp marking . 10

2.2.2 Additional information and marking . 10

2.3 Caps or bases . 11

2.3.1 General . 11

2.3.2 Creepage distances . 11

2.3.3 Dimensions . 11

2.4 Photobiological safety . 12

2.5 Gas pressure of low-pressure self-shielded extra low voltage lamps . 12

2.6 Safety at end of life of self-shielded lamps with rated voltages from range B or

C . 12

2.7 Information for luminaire design . 12

3 Assessment . 13

3.1 General . 13

3.2 Whole production assessment by means of manufacturer’s records . 13

3.2.1 Assessment of manufacturer’s records for particular tests . 17

3.2.2 Sampling procedures for the whole production testing . 17

3.3 Assessment of batches . 18

3.3.1 Sampling for batch testing . 18

3.3.2 Number of lamps in the batch sample . 18

3.3.3 Sequence of the tests . 18

3.3.4 Rejection conditions of batches . 18

Annex A (normative) Symbols. 19

Annex B (normative) Method of testing the gas-pressure . 21

Annex C (informative) Information for luminaire design . 22

Annex D (normative) Conditions of compliance for design tests . 28

Annex E (informative) Bulb wall temperature measurement. 29

Annex F (normative) Induced failure test . 30

Bibliography . 32

Table 1 – Grouping of test records – Sampling and acceptable quality levels (AQL) . 14

Table 2 – Acceptance numbers AQL = 0,25 % . 15

Table 3 – Acceptance numbers AQL = 0,65 % . 15

Table 4 – Acceptance numbers AQL = 2,5 % . 16

Table 5 – Batch sample size and rejection number . 18

Table C.1 – Fuse values for general purpose ELV tungsten halogen lamps . 23

Table C.2 – Fuse values for photographic lamps. 24

60432-3 © IEC:2012 – 3 –

Table C.3 – List of maximum bulb temperatures . 24

Table C.4 – Maximum base-pin temperatures . 25

Table C.5 – Maximum contact temperatures . 26

Table C.6 – Maximum reflector-rim temperatures . 26

– 4 – 60432-3 © IEC:2012

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

INCANDESCENT LAMPS –

SAFETY SPECIFICATIONS –

Part 3: Tungsten halogen lamps (non-vehicle)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60432-3 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This second edition of IEC 60432-3 cancels and replaces the first edition published in 2002,

Amendment 1 (2005) and Amendment 2 (2008). The document 34A/1567/FDIS, circulated to

the National Committees as Amendment 3, led to the publication of this new edition.

The main changes with respect to the previous edition are as follows:

– adapting the cold fill pressure requirements and tests for self-shielded lamps to the state of

the technology,

– introduction of requirements to fully cover photobiological safety according to IEC 62471.

60432-3 © IEC:2012 – 5 –

The text of this standard is based on the first edition, its Amendments 1 and 2, and the

following documents:

FDIS Report on voting

34A/1567/FDIS 34A/1585/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60432 series, published under the general title Incandescent

lamps – Safety specifications can be found on the IEC website.

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 60432-3 © IEC:2012

INCANDESCENT LAMPS –

SAFETY SPECIFICATIONS –

Part 3: Tungsten halogen lamps (non-vehicle)

1 General

1.1 Scope

This part of IEC 60432 specifies the safety requirements for single-capped and double-capped

tungsten halogen lamps, having rated voltages of up to 250 V, used for the following

applications:

• projection (including cinematograph and still projection),

• photographic (including studio),

• floodlighting,

• special purpose,

• general purpose,

• stage lighting,

This International Standard does not apply to general purpose single-capped tungsten halogen

lamps, covered by IEC 60432-2, that are used as replacement for conventional tungsten

filament lamps.

This part of IEC 60432 covers photobiological safety according to IEC 62471 and

IEC/TR 62471-2. Lamps covered by this part of IEC 60432 do not reach risk levels that require

risk group marking if they are

a) floodlight lamps,

b) general purpose capsule lamps, or

c) general purpose reflector lamps.

1.2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

IEC 60050-845, International Electrotechnical Vocabulary – Part 845: Lighting

Available from: http://www.electropedia.org/

IEC 60061-1, Lamp caps and holders together with gauges for the control of interchangeability

and safety – Part 1: Lamp caps

IEC 60061-3, Lamp caps and holders together with gauges for the control of interchangeability

and safety – Part 3: Gauges

IEC 60061-4, Lamp caps and holders together with gauges for the control of interchangeability

and safety – Part 4: Guidelines and general information

IEC 60357, Tungsten halogen lamps (non-vehicle) – Performance specifications

60432-3 © IEC:2012 – 7 –

IEC 60432-1:1999, Incandescent lamps – Safety specifications – Part 1: Tungsten filament

lamps for domestic and similar general lighting purposes

IEC 62471, Photobiological safety of lamps and lamp systems

IEC/TR 62471-2, Photobiological safety of lamps and lamp systems – Part 2: Guidance on

manufacturing requirements relating to non-laser optical radiation safety

1.3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-845 as well as

the following apply.

1.3.1

tungsten halogen lamp

gas-filled lamp containing halogens or halogen compounds, the filament being of tungsten

1.3.2

single-capped tungsten halogen lamp

tungsten halogen lamp having a single cap or base

1.3.3

double-capped tungsten halogen lamp

tungsten halogen lamp having a cap or base on each end of the lamp

1.3.4

extra low voltage tungsten halogen lamp

tungsten halogen lamp with a rated voltage lower than 50 V

Note 1 to entry: Abbreviated: ELV tungsten halogen lamp.

1.3.5

extra low voltage low-pressure tungsten halogen lamp

tungsten halogen lamp with a gas pressure below a certain value and a rated voltage less than

or equal to 12 V

1.3.6

self-shielded tungsten halogen lamp

tungsten halogen lamp for which the luminaire needs no protective shield

Note 1 to entry: Abbreviated: self-shielded lamp.

Examples of self-shielded tungsten halogen lamps are:

ELV tungsten halogen lamps with integral outer envelope;

ELV low-pressure tungsten halogen lamps;

mains voltage tungsten halogen lamps which conform to IEC 60432-2;

mains voltage tungsten halogen lamps which conform to the relevant clauses of this standard.

1.3.7

outer envelope

transparent or translucent enclosure containing a tungsten halogen light source

Note 1 to entry: The enclosure can also consist of a reflector with integral front cover.

– 8 – 60432-3 © IEC:2012

1.3.8

rated voltage

voltage or voltage range specified in this standard or assigned by the manufacturer or

responsible vendor

Note 1 to entry: If lamps are marked with a voltage range, they are appropriate for use on any supply voltage

within that range.

1.3.9

test voltage

rated voltage unless otherwise specified

Note 1 to entry: If lamps are marked with a voltage range, the test voltage is the mean of the voltage range,

unless otherwise specified.

1.3.10

rated wattage

wattage specified in this standard or assigned by the manufacturer or responsible vendor

1.3.11

rated current

current specified in this standard or assigned by the manufacturer or responsible vendor

1.3.12

test current

rated current unless otherwise specified

1.3.13

specific effective radiant UV power

effective power of the UV radiation of a lamp related to its luminous flux

Note 1 to entry: The specific effective radiant UV power is expressed in: mW/klm.

For a reflector lamp, this is the effective irradiance of the UV radiation related to the

illuminance.

Note 2 to entry: The effective irradiance of the UV radiation related to the illuminance is expressed in

mW/(m ·klx).

Note 3 to entry: The effective power (or irradiance) of the UV radiation is obtained by weighting the spectral power

distribution of the lamp with the action spectrum published by the American Conference of Governmental Industrial

Hygienists (ACGIH), which is endorsed by the World Health Organization (WHO) and recommended by the

International Radiation Protection Association (IRPA). For references, see Bibliography.

1.3.14

maximum pinch temperature

maximum temperature which the components in the pinch/seal of a lamp are designed to

withstand over the expected life of the lamp

1.3.15

maximum lamp cap-contact, base-pin or base-post temperature

maximum temperature of the lamp cap-contact, base-pin or base-post, which should be

observed to safeguard electrical contact over the expected life of the lamp

1.3.16

maximum cap temperature

maximum temperature for which the components in the cap area of a lamp are designed

to withstand over the expected life of the lamp

60432-3 © IEC:2012 – 9 –

1.3.17

maximum reflector-rim temperature

maximum temperature for which the connection between front cover and reflector is designed

to withstand over the expected life of the lamp

1.3.18

group

lamps for the same application as defined by the scope of this standard

1.3.19

type

lamps of the same group having the same nominal wattage, bulb shape and cap

1.3.20

family

grouping of lamps characterized by common features such as materials, components and/or

method of processing

1.3.21

design test

test made on a sample for the purpose of checking compliance of the design of a family, group

or a number of groups with the requirements of the relevant clause

1.3.22

periodic test

test, or series of tests, repeated at intervals in order to check that a product does not deviate in

certain respects from the given design

1.3.23

running test

test repeated at frequent intervals to provide data for assessment

1.3.24

batch

all lamps in one family and/or group and identified as such and put forward at one time for

checking compliance

1.3.25

whole production

production during a period of twelve months of all types of lamps within the scope of this

standard and nominated in a list of the manufacturer for inclusion in the certificate

1.3.26

breakdown

plasma discharge between two points inside the bulb of the lamp with maximum difference of

electrical potential

Note 1 to entry: For the purposes of this standard, it is assumed that breakdown has occurred if the current

exceeds the rated current by a factor of 5 (under consideration).

2 Requirements

2.1 General

Tungsten halogen lamps shall be so designed and constructed that in normal use they present

no danger to the user or surroundings.

– 10 – 60432-3 © IEC:2012

In general, compliance is checked by carrying out all the relevant tests specified in this

standard. For the purposes of this standard, the voltage designations shown in IEC 60357

apply.

2.2 Marking

2.2.1 Lamp marking

The following information shall be legibly and durably marked on the lamps:

– mark of origin (this may take the form of a trademark, the manufacturer's name, the brand

name or the name of the responsible vendor);

– rated wattage (marked “W” or “watts”);

– rated voltage or rated voltage range (marked “V” or “volts”), or for airfield lamps the rated

current (marked “A”).

The rated voltage marking for lamps intended for use on United Kingdom supply voltages may

be “240 volts” or “240 V”.

NOTE The United Kingdom implementation of 230 V (European harmonization process) allows supply voltages to

remain at 240 V.

Compliance is checked on unused lamps as follows:

– presence and legibility by visual inspection;

– durability by applying the following test.

The area of the marking on the lamp shall be rubbed by hand with a smooth cloth, moistened

with water, for a period of 15 s.

After this test, the marking shall still be legible.

2.2.2 Additional information and marking

If applicable, the following information shall be given.

a) Lamps shall be supplied with an appropriate cautionary notice indicating the need of a

protective shield to be fitted to the luminaire. Alternatively the immediate lamp wrapping or

container may be marked with the corresponding symbol as shown in Clause A.1.

NOTE In North America, a suitable cautionary notice is required. Use of the symbol is optional.

b) For self-shielded lamps (not needing luminaire shielding), the immediate lamp wrapping or

container shall be marked with the symbol as shown in Clause A.2.

NOTE 1 This does not apply to lamps covered by IEC 60432-2.

NOTE 2 In North America, a written notice may be used in place of this symbol.

c) For dichroic-coated reflector lamps, the immediate lamp wrapping or container shall be

marked with the symbol as shown in Clause A.3.

NOTE This symbol is not required in North America.

d) Double-capped lamps, with rated voltages 50 V – 250 V, shall be supplied with a cautionary

notice or symbol as shown in Clause A.4 indicating that the luminaire shall be disconnected

from the power supply before insertion or withdrawal of the lamp.

NOTE 1 In the USA, special package marking is required regarding the use of 500 W double-capped halogen

lamps in residential indoor luminaires.

NOTE 2 In North America, a suitable cautionary notice is required. Use of the symbol is optional.

60432-3 © IEC:2012 – 11 –

e) Projection lamps, photographic lamps, special purpose and stage lighting lamps shall be

marked with the following symbol on the packaging or accompanying information.

f) Projection lamps, photographic lamps, special purpose and stage lighting lamps shall be

marked with the following symbol on the packaging or accompanying information.

Information shall be given on the manufacturer's homepage, catalogue or similar means of

information on how to address IR hazards properly.

Compliance is checked by visual inspection.

2.3 Caps or bases

2.3.1 General

Caps or bases originally developed for single-capped ELV lamps shall not be used for general

purpose tungsten halogen lamps with rated voltages higher than 50 V.

NOTE Examples of such ELV fits are: G4, GU4, GY4, GX5.3, GU5.3, G6.35, GY6.35, GU7 and G53.

The GU10 base shall be used for aluminised reflector lamps only. The G9, GU10 or GZ10 base

shall be used for self-shielded lamps only.

Compliance is checked by inspection.

2.3.2 Creepage distances

The minimum creepage distance between contacts or between contacts and the metal shell of

the cap, if any, shall be in accordance with the recommendations in IEC 60061-4.

Compliance is checked by measurement.

2.3.3 Dimensions

If tungsten halogen lamps use standardized caps/bases they shall be in accordance with the

requirements of IEC 60061-1.

Compliance is checked on finished lamps by using the gauges of IEC 60061-3.

– 12 – 60432-3 © IEC:2012

Non standardized caps/bases shall be in accordance with the manufacturer's specification.

Compliance is checked by inspection.

2.4 Photobiological safety

The specific effective radiant UV power of self-shielded tungsten halogen lamps shall not

exceed:

– 2 mW/klm or,

– for reflector lamps 2 mW/(m ·klx).

Compliance is checked by measurement of the spectral power distribution.

NOTE Blue light and infrared hazards are covered by marking requirements.

2.5 Gas pressure of low-pressure self-shielded extra low voltage lamps

During operation, the gas pressure of single-capped low-pressure self-shielded ELV tungsten

halogen lamps shall be limited. This shall be achieved by restricting:

a) the cold fill pressure to less than 1 × 10 Pa (1 bar) for rated wattages above 50 W and up

to 100 W, and

b) the cold fill pressure to less than 4 × 10 Pa (4 bar) for rated wattages up to 50 W, and

c) the lamp volume to 1 cm maximum.

Compliance is checked by inspection and by means of the test specified in Annex B.

2.6 Safety at end of life of self-shielded lamps with rated voltages from range B or C

When tested under the specified conditions, lamp failure shall not be accompanied by

breakage of the bulb nor its ejection from the cap.

For bayonet capped lamps, it is also required that there shall not be an internal short-circuit to

the cap shell after the test.

The test conditions are:

– an induced-failure test in accordance with Annex F, or

– an operation-to-failure test.

The operation-to-failure test shall be carried out under the conditions specified for the life test

procedure in Annex A of IEC 60357:2002. The test rack circuit characteristics shall be in line

with Table E.1 of IEC 60432-1:1999. The test is continued until end of life.

NOTE 1 In the event of dispute the reference test method is the induced failure test.

NOTE 2 Some lamp designs are not suitable for testing with the induced failure test because a breakdown cannot

reliably be achieved. Such lamps, provided they are of voltage range B or C, will be submitted to an operation-to-

failure test as described above.

2.7 Information for luminaire design

Refer to Annex C.

60432-3 © IEC:2012 – 13 –

3 Assessment

3.1 General

This clause specifies the method a manufacturer should use to show that his product conforms

to this standard on the basis of whole production assessment, in association with his test

records on finished products. This method can also be applied for certification purposes.

Subclause 3.2 gives details of assessment by means of the manufacturer’s records.

Details of a batch test procedure which can be used to make limited assessment of batches

are given in 3.3. Requirements for batch testing are included in order to enable the assessment

of batches presumed to contain unsafe lamps. As some safety requirements cannot be

checked by batch testing, and as there may be no previous knowledge of the manufacturer’s

quality, batch testing cannot be used for certification purposes nor in any way for an approval

of the batch. Where a batch is found to be acceptable, a testing agency may only conclude that

there is no reason to reject the batch on safety grounds.

3.2 Whole production assessment by means of manufacturer’s records

The manufacturer shall show evidence that his products comply with the particular

requirements of 3.2.1. To this end, the manufacturer shall make available all the results of his

product testing pertinent to the requirements of this standard.

The test results may be drawn from working records and, as such, may not be immediately

available in collated form.

The assessment shall be based in general on individual factories, each meeting the

acceptance criteria of 3.2.1. However, a number of factories may be grouped together,

providing they are under the same quality management. For certification purposes, one

certificate may be issued to cover a nominated group of factories, but the certification authority

shall have the right to visit each plant to examine the local relevant records and quality control

procedures.

For certification purposes, the manufacturer shall declare a list of marks of origin and

corresponding lamp families, groups and/or types which are within the scope of this standard

and manufactured in a nominated group of factories. The certificate shall be taken to include

all lamps so listed made by the manufacturer. Notification of additions or deletions may be

made at any time.

In presenting the test results, the manufacturer may combine the results of different lamp

families, groups and/or types according to column 4 of Table 1.

The whole production assessment requires that the quality control procedures of a

manufacturer shall satisfy recognized quality system requirements for final inspection. Within

the framework of a quality assurance system based also on in-process inspection and testing,

the manufacturer may show compliance with some of the requirements of this standard by

means of in-process inspection instead of finished product testing.

The manufacturer shall provide sufficient test records with respect to each clause and

subclause as indicated in column 5 of Table 1.

– 14 – 60432-3 © IEC:2012

Table 1 – Grouping of test records –

Sampling and acceptable quality levels (AQL)

1 2 3 4 5 6

Minimum annual sample per

accumulation

a

AQL

Sub- Type of Permitted accumulation

Test

For lamps For lamps

clause test of test records

%

made most of made

the year infrequently

2.2.1 Marking – legibility Running All families with the 200 32 2,5

same method of marking

2.2.1 Marking – durability Periodic All families with the 50 20 2,5

same method of marking

2.2.2 Additional Running By group and type 200 32 2,5

information and

marking

2.3.2 Caps or bases – Design All families with same Use Clause D.1 –

creepage distances cap or base

2.3.3 Caps or bases – Periodic All families with same 32 2,5

dimensions cap or base

2.4 UV radiation Design Use Clause D.2 –

2.5 Gas pressure Periodic By group and type 125 80 0,65

2.6 Safety at end of life

– Induced failure Use Clause D.3 –

or Design

– Operation to

b –

failure Use Clause D.4

All lamps of all families

– Induced failure

or Periodic 315 0,25

– Operation to

b

failure

a

For the use of this term, see IEC 60410.

b

The operation to failure test is allowed in those cases where no reliable breakdown can be achieved. See also

Note 2 to Subclause 2.6.

The number of non-conformities in the manufacturer’s records shall not exceed the limits

shown in Tables 2, 3 or 4 relevant to the acceptable quality level (AQL) values shown in

column 6 of Table 1.

60432-3 © IEC:2012 – 15 –

Table 2 – Acceptance numbers AQL = 0,25 %

Number of lamps in Acceptance Number of lamps in Qualifying limit for

manufacturer's records number manufacturer's records acceptance as percentage

of lamps in records

%

315 2 2 001 0,485

316 to 500 3 2 200 0,48

501 to 635 4 2 600 0,46

636 to 800 5 3 300 0,44

801 to 1 040 6 4 200 0,42

1 041 to 1 250 7 5 400 0,40

1 251 to 1 500 8 7 200 0,38

1 501 to 1 750 9 10 000 0,36

1 751 to 2 000 10

Table 3 – Acceptance numbers AQL = 0,65 %

Number of lamps in Acceptance Number of lamps in Qualifying limit for

manufacturer's records number manufacturer's records acceptance as percentage

of lamps in records

%

80 1 2 001 1,03

81 to 125 2 2 100 1,02

126 to 200 3 2 400 1,00

201 to 260 4 2 750 0,98

261 to 315 5 3 150 0,96

316 to 400 6 3 550 0,94

401 to 500 7 4 100 0,92

501 to 600 8 4 800 0,90

601 to 700 9 5 700 0,88

701 to 800 10 6 800 0,86

801 to 920 11 8 200 0,84

921 to 1 040 12 10 000 0,82

1 041 to 1 140 13 13 000 0,80

1 141 to 1 250 14 17 500 0,78

1 251 to 1 360 15 24 500 0,76

1 361 to 1 460 16 39 000 0,74

1 461 to 1 570 17 69 000 0,72

1 571 to 1 680 18 145 000 0,70

1 681 to 1 780 19 305 000 0,68

1 781 to 1 890 20 1 000 000 0,67

1 891 to 2 000 21

– 16 – 60432-3 © IEC:2012

Table 4 – Acceptance numbers AQL = 2,5 %

Number of lamps in Acceptance Number of lamps in Qualifying limit for

manufacturer's records number manufacturer's records acceptance as percentage

of lamps in records

%

20 1 1 001 3,65

21 to 32 2 1 075 3,60

33 to 50 3 1 150 3,55

51 to 65 4 1 250 3,50

66 to 80 5 1 350 3,45

81 to 100 6 1 525 3,40

101 to 125 7 1 700 3,35

126 to 145 8 1 925 3,30

146 to 170 9 2 200 3,25

171 to 200 10 2 515 3,20

201 to 225 11 2 950 3,15

226 to 255 12 3 600 3,10

256 to 285 13 4 250 3,05

286 to 315 14 5 250 3,00

316 to 335 15 6 400 2,95

336 to 360 16 8 200 2,90

361 to 390 17 11 000 2,85

391 to 420 18 15 500 2,80

421 to 445 19 22 000 2,75

446 to 475 20 34 000 2,70

476 to 500 21 60 000 2,65

501 to 535 22 110 000 2,60

536 to 560 23 500 000 2,55

561 to 590 24 1 000 000 2,54

591 to 620 25

621 to 650 26

651 to 680 27

681 to 710 28

711 to 745 29

746 to 775 30

776 to 805 31

806 to 845 32

846 to 880 33

881 to 915 34

916 to 955 35

956 to 1 000 36

60432-3 © IEC:2012 – 17 –

The period of review for assessment purposes need not be limited to a predetermined year, but

may consist of 12 consecutive calendar months immediately preceding the date of review.

A manufacturer who has met, but no longer meets the specified criteria, shall not be

disqualified from claiming compliance with this standard providing he can show that:

a) action has been taken to remedy the situation as soon as the trend was reasonably

confirmed from his test records;

b) the specified acceptance level was re-established within a period of:

1) six months for Subclause 2.6;

2) one month for the other clauses and subclauses.

When compliance is assessed after corrective action has been taken in accordance with items

a) and b), the test records of these lamp families, groups and/or types which do not comply

shall be excluded from the 12-month summation for their period of non-compliance. The test

results relating to the period of corrective action shall be retained in the records.

A manufacturer who has failed to meet the requirements of a clause or subclause where

grouping of the test results is permitted shall not be disqualified for the whole of the lamp

families, groups and/or types so grouped if he can show by additional testing that the problem

is present only in certain families, groups and/or types so grouped. In this case, either these

families, groups and/or types are dealt with in accordance with a) and b) as above or they are

deleted from the list of families, groups and/or types which the manufacturer may claim are in

conformity with the standard.

In the case of a family, group and/or type which has been deleted from the list, it may be

reinstated if satisfactory results are obtained from tests on a number of lamps equivalent to the

minimum annual sample specified in Table 1, required by the clause or subclause where non-

compliance occurred. This sample may be collected over a short period of time.

In the case of new products, there may be features which are common to existing lamp

families, groups and/or types, and these can be taken as being in compliance if the new

product is taken into the sampling scheme as soon as manufacture is started. Any feature not

so covered shall be tested before production starts.

3.2.1 Assessment of manufacturer’s records for particular tests

Table 1 specifies the type of test and other information which applies to the method of

assessing compliance to the requirements of various clauses and subclauses.

A design test need be repeated only when a substantial change is made in the physical or

mechanical construction, materials, or manufacturing process used to manufacture the relevant

product. Tests are required for only those properties affected by the change.

3.2.2 Sampling procedures for the whole production testing

The conditions of Table 1 apply.

The whole production running tests shall be applied at least once per production day. They may

also be based on in-process inspection and testing.

The frequency of application of the various tests may be different, providing the conditions of

Table 1 are met.

Whole production tests shall be made on samples randomly selected at a rate not less than

that indicated in column 5 of Table 1. Lamps selected for one test need not be used for other

tests.

– 18 – 60432-3 © IEC:2012

In relation to the safety at end of life (see 2.6), the manufacturer shall have a sampling plan

which does not deliberately exclude any of the types in his nominated list.

3.3 Assessment of batches

3.3.1 Sampling for batch testing

The lamps for testing shall be selected in accordance with a mutually agreed method so as to

ensure proper representation. Selection shall be randomly made as nearly as possible from

one-third of the total number of containers in the batch, with a minimum of ten containers.

In order to cover the risk of accidental breakage, a certain number of lamps in addition to the

test quantity shall be selected. These lamps shall only be substituted for lamps of the test

quantities if necessary to make up the required quantities of lamps for the tests.

It is not necessary to replace an accidentally broken lamp if the results of the test are not

affected by its replacement, provided the required quantity of lamps for the following test is

available. If replaced, such a broken lamp shall be neglected in calculating results.

Lamps having broken bulbs when removed from the packaging after transit shall not be

included in the test.

3.3.2 Number of lamps in the batch sample

There shall be at least 500 lamps (see Table 5).

3.3.3 Sequence of the tests

The testing shall be carried out in the order of the subclause numbers listed in Table 5, up to

and including Subclause 2.4. Subsequent tests may involve damage to the lamp and each test

sample shall be taken separately from the original sample.

3.3.4 Rejection conditions of batches

Rejection is established if any rejection number in Table 5, with due regard to Annex D is

reached, irrespective of the quantity tested. A batch shall be rejected as soon as the rejection

number for a particular test is reached

Table 5 – Batch sample size and rejection number

Sub- Test Number of Rejection

clause lamps tested number

2.2.1 Marking – legibility 200 11

2.2.1 Marking – durability 50 4

2.2.2 Additional information and 200 11

marking

2.3.2 Caps and bases – creepage Use Clause D.1

distances

2.3.3 Caps and bases – dimensions 32 3

2.4 UV radiation Use Clause D.2

2.5 Gas pressure 125 3

2.6 Safety at end of life – Induced Use Clause D.3

failure

60432-3 © IEC:2012 – 19 –

Annex A

(normative)

Symbols

This concerns symbols as referred to in 2.2.2.

The height of graphical symbols shall not be less than 5 mm, and for letters, not less than

2 mm.

A.1 Symbol indicating that the lamp shall be operated only in a luminaire with

a protective shield

A.2 Self-shielded lamp symbol indicating that the lamp can be operated in a

luminaire without a protective shield

A.3 Symbol for dichroic-coated reflector lamp

COOL

BEAM

The bulb shape may be varied to show the shape of the lamp.

– 20 – 60432-3 © IEC:2012

A.4 Symbol indicating that the luminaire shall be disconnected from

the power supply before insertion or withdrawal of the lamp

60432-3 © IEC:2012 – 21 –

Annex B

(normative)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...