IEC 60601-1-6:2006

(Main)Medical electrical equipment - Part 1-6: General requirements for basic safety and essential performance - Collateral standard: Usability

Medical electrical equipment - Part 1-6: General requirements for basic safety and essential performance - Collateral standard: Usability

Specifies requirements for a process to analyse, design, verify and validate the usability, as it relates to basic safety and essential performance of medical electrical equipment. This collateral standard addresses normal use and use errors but excludes abnormal use. The object of this collateral standard is to specify general requirements that are in addition to those of the general standard IEC 60601-1 and to serve as the basis for particular standards.

Appareils électromédicaux - Partie 1-6: Exigences générales pour la sécurité de base et les performances essentielles - Norme collatérale: Aptitude à l'utilisation

Spécifie les exigences d'un processus destiné à analyser, concevoir, vérifier et valider l'aptitude à l'utilisation ayant trait à la sécurité de base et les performances essentielles des appareils électromédicaux. La présente norme collatérale traite de l'utilisation normale et des erreurs d'utilisation mais exclut l'utilisation anormale. La présente norme collatérale est destinée à spécifier des exigences générales qui viennent compléter celles de la norme générale CEI 60601-1 et à servir de base pour les normes particulières.

General Information

- Status

- Published

- Publication Date

- 07-Dec-2006

- Technical Committee

- SC 62A - Common aspects of medical equipment, software, and systems

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jan-2010

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60601-1-6:2006 - "Medical electrical equipment - Part 1-6: Collateral standard: Usability" specifies requirements for a usability engineering process applied to medical electrical equipment (ME equipment). It defines how manufacturers must analyse, design, verify and validate usability as it relates to basic safety and essential performance. The standard focuses on normal use and use errors (excluding abnormal use) and serves as a collateral complement to IEC 60601-1 and as a basis for particular standards.

Key topics and requirements

- Usability engineering process: Establish a lifecycle process to identify user needs, user profiles, and usability requirements; design the operator‑equipment interface; and plan verification and validation activities.

- Integration with risk management: Usability is an element of the overall risk management process (per IEC 60601-1 and ISO 14971), intended to reduce use‑related risks and minimize use errors.

- Operator‑equipment interface: Define and control the means by which operators interact with devices, including hardware, software, and accompanying documents (manuals, labelling).

- Addressing use errors: Identify probable use errors, assess their impact on basic safety and essential performance, and implement mitigations (design, instructions, training).

- Verification and validation: Demonstrate through objective and subjective testing that usability goals are met and that user tasks can be performed safely and effectively.

- Documentation and training: Provide required supporting materials and training strategies as part of the device’s accompanying documentation.

- Scope limits: Covers normal use and reasonably foreseeable misuse; abnormal use (beyond manufacturer’s reasonable control) is excluded.

Applications and who uses this standard

IEC 60601-1-6 is used by:

- Medical device manufacturers to design safer, more effective ME equipment and to prepare usability specifications, test plans and validation reports.

- Human factors and usability engineers to implement a structured usability engineering process aligned with regulatory expectations.

- Regulatory affairs and quality teams to support conformity assessments and technical files.

- Clinical engineers, hospital procurement, and risk managers to evaluate device usability and likely use errors.

- Standards committees and developers of particular standards to incorporate usability requirements specific to device families (e.g., monitors, infusion pumps).

Practical uses include designing operator interfaces, preparing usability testing protocols, improving labelling and training materials, and reducing patient/operator risk from use errors.

Related standards

- IEC 60601-1 (general standard for basic safety and essential performance)

- ISO 14971 (application of risk management to medical devices)

- IEC 60601-1-8 (alarm systems)

Annexes in IEC 60601-1-6 provide detailed guidance: rationale, taxonomy of operator actions, examples of use errors and design flaws, usability engineering guidance, a sample usability specification, and reference documents - useful resources for implementation.

IEC 60601-1-6:2006 - Medical electrical equipment - Part 1-6: General requirements for basic safety and essential performance - Collateral standard: Usability Released:12/8/2006

IEC 60601-1-6:2006 - Appareils électromédicaux - Partie 1-6: Exigences générales pour la sécurité de base et les performances essentielles - Norme collatérale: Aptitude à l'utilisation Released:12/8/2006

IEC 60601-1-6:2006 - Medical electrical equipment - Part 1-6: General requirements for basic safety and essential performance - Collateral standard: Usability Released:12/8/2006 Isbn:2831889332

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 60601-1-6:2006 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Medical electrical equipment - Part 1-6: General requirements for basic safety and essential performance - Collateral standard: Usability". This standard covers: Specifies requirements for a process to analyse, design, verify and validate the usability, as it relates to basic safety and essential performance of medical electrical equipment. This collateral standard addresses normal use and use errors but excludes abnormal use. The object of this collateral standard is to specify general requirements that are in addition to those of the general standard IEC 60601-1 and to serve as the basis for particular standards.

Specifies requirements for a process to analyse, design, verify and validate the usability, as it relates to basic safety and essential performance of medical electrical equipment. This collateral standard addresses normal use and use errors but excludes abnormal use. The object of this collateral standard is to specify general requirements that are in addition to those of the general standard IEC 60601-1 and to serve as the basis for particular standards.

IEC 60601-1-6:2006 is classified under the following ICS (International Classification for Standards) categories: 11.040.01 - Medical equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60601-1-6:2006 has the following relationships with other standards: It is inter standard links to IEC 60601-1-6:2010, IEC 60601-1-6:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60601-1-6:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD 60601-1-6

Second edition

2006-12

Medical electrical equipment –

Part 1-6:

General requirements for basic safety

and essential performance –

Collateral standard: Usability

This English-language version is derived from the original

bilingual publication by leaving out all French-language

pages. Missing page numbers correspond to the French-

language pages.

Reference number

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

INTERNATIONAL IEC

STANDARD 60601-1-6

Second edition

2006-12

Medical electrical equipment –

Part 1-6:

General requirements for basic safety

and essential performance –

Collateral standard: Usability

© IEC 2006 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or mechanical,

including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale XB

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

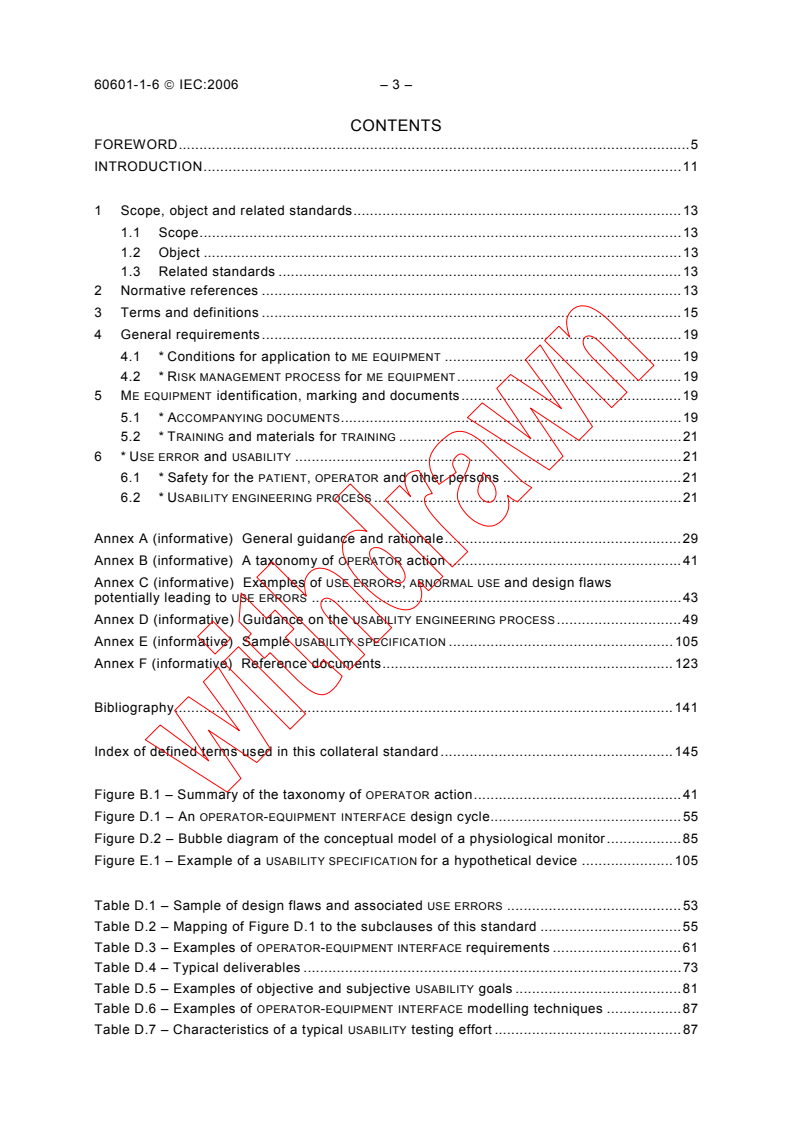

60601-1-6 © IEC:2006 – 3 –

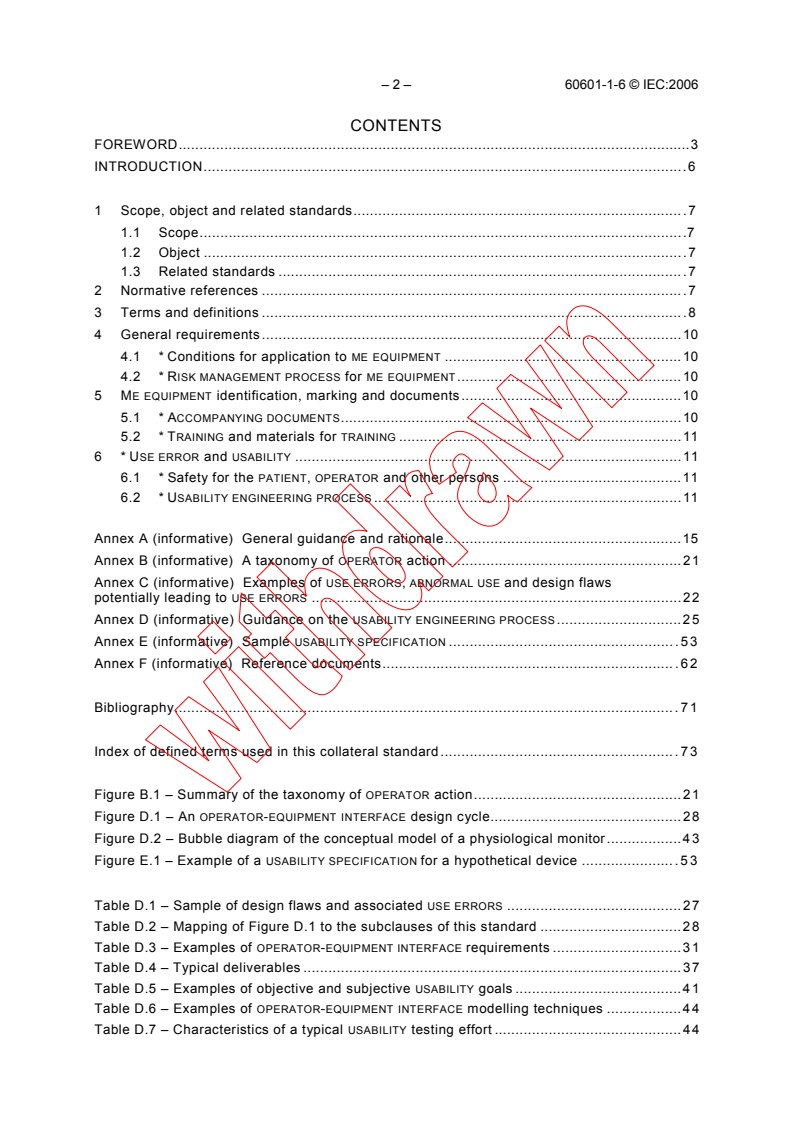

CONTENTS

FOREWORD.5

INTRODUCTION.11

1 Scope, object and related standards.13

1.1 Scope.13

1.2 Object .13

1.3 Related standards .13

2 Normative references .13

3 Terms and definitions .15

4 General requirements .19

4.1 * Conditions for application to ME EQUIPMENT .19

4.2 * RISK MANAGEMENT PROCESS for ME EQUIPMENT.19

5 ME EQUIPMENT identification, marking and documents.19

5.1 * ACCOMPANYING DOCUMENTS.19

5.2 * TRAINING and materials for TRAINING .21

6 * USE ERROR and USABILITY .21

6.1 * Safety for the PATIENT, OPERATOR and other persons .21

6.2 * USABILITY ENGINEERING PROCESS .21

Annex A (informative) General guidance and rationale.29

Annex B (informative) A taxonomy of OPERATOR action .41

Annex C (informative) Examples of USE ERRORS, ABNORMAL USE and design flaws

potentially leading to USE ERRORS .43

Annex D (informative) Guidance on the USABILITY ENGINEERING PROCESS.49

Annex E (informative) Sample USABILITY SPECIFICATION .105

Annex F (informative) Reference documents.123

Bibliography.141

Index of defined terms used in this collateral standard.145

Figure B.1 – Summary of the taxonomy of OPERATOR action.41

Figure D.1 – An OPERATOR-EQUIPMENT INTERFACE design cycle.55

Figure D.2 – Bubble diagram of the conceptual model of a physiological monitor.85

Figure E.1 – Example of a USABILITY SPECIFICATION for a hypothetical device .105

Table D.1 – Sample of design flaws and associated USE ERRORS .53

Table D.2 – Mapping of Figure D.1 to the subclauses of this standard .55

Table D.3 – Examples of OPERATOR-EQUIPMENT INTERFACE requirements .61

Table D.4 – Typical deliverables .73

Table D.5 – Examples of objective and subjective USABILITY goals .81

Table D.6 – Examples of OPERATOR-EQUIPMENT INTERFACE modelling techniques .87

Table D.7 – Characteristics of a typical USABILITY testing effort .87

60601-1-6 © IEC:2006 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MEDICAL ELECTRICAL EQUIPMENT –

Part 1-6: General requirements for basic safety

and essential performance –

Collateral Standard: Usability

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International standard IEC 60601-1-6 has been prepared by IEC subcommittee 62A: Common

aspects of electrical equipment used in medical practice of IEC technical committee 62:

Electrical equipment in medical practice.

This second edition constitutes a collateral standard to IEC 60601-1: Medical electrical

equipment – Part 1: General requirements for safety and essential performance hereafter

referred to as the general standard.

This document cancels and replaces the first edition of IEC 60601-1-6.

60601-1-6 © IEC:2006 – 7 –

This edition of IEC 60601-1-6 was revised to structurally align it with the 2005 edition of IEC

60601-1 and to implement the decision of IEC Subcommittee 62A that the clause numbering

structure of collateral standards written to IEC 60601-1:2005 would adhere to the form

specified in ISO/IEC Directives, Part 2:2004. The principle technical changes are in Clause 4,

which now recognizes that there is a general requirement for a risk management process in

IEC 60601-1:2005.

The text of this collateral standard is based on the following documents:

FDIS Report on voting

62A/550/FDIS 62A/557/RVD

Full information on the voting for the approval of this collateral standard can be found in the

report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

In the IEC 60601 series of publications, collateral standards specify general requirements for

safety applicable to:

– a subgroup of MEDICAL ELECTRICAL EQUIPMENT (e.g. radiological equipment); or

– a specific characteristic of all MEDICAL ELECTRICAL EQUIPMENT, not fully addressed in the

general standard (e.g. alarm systems).

In this collateral standard, the following print types are used:

– Requirements and definitions: roman type.

– Test specifications: italic type.

– Informative material appearing outside of tables, such as notes, examples and references: in smaller type.

Normative text of tables is also in a smaller type.

– TERMS DEFINED IN CLAUSE 3 OF THE GENERAL STANDARD, IN THIS COLLATERAL STANDARD OR AS

NOTED: SMALL CAPITALS.

In referring to the structure of this standard, the term

– “clause” means one of the seventeen numbered divisions within the table of contents,

inclusive of all subdivisions (e.g. Clause 6 includes subclauses 6.1, 6.2, etc.);

– “subclause” means a numbered subdivision of a clause (e.g. 6.1, 6.2 and 6.2.1 are all

subclauses of Clause 6).

References to clauses within this standard are preceded by the term “Clause” followed by the

clause number. References to subclauses within this standard are by number only.

In this standard, the conjunctive “or” is used as an “inclusive or” so a statement is true if any

combination of the conditions is true.

The verbal forms used in this standard conform to usage described in Annex H of the ISO/IEC

Directives, Part 2. For the purposes of this standard, the auxiliary verb:

− “shall” means that compliance with a requirement or a test is mandatory for compliance

with this standard;

− “should” means that compliance with a requirement or a test is recommended but is not

mandatory for compliance with this standard;

60601-1-6 © IEC:2006 – 9 –

− “may” is used to describe a permissible way to achieve compliance with a requirement or

test.

Clauses, subclauses and definitions for which a rationale is provided in informative Annex A

are marked with an asterisk (*).

A list of all parts of the IEC 60601 series, under the general title: Medical electrical

equipment, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

60601-1-6 © IEC:2006 – 11 –

INTRODUCTION

Medical practice is increasingly using MEDICAL ELECTRICAL EQUIPMENT for observation and

treatment of PATIENTS. USE ERRORS caused by inadequate MEDICAL ELECTRICAL EQUIPMENT

USABILITY have become an increasing cause for concern. The USABILITY ENGINEERING PROCESS

is intended to achieve reasonable USABILITY, which in turn is intended to minimise USE ERRORS

and to minimise use associated RISKS. Some, but not all, forms of incorrect use are amenable

to control by the MANUFACTURER. The USABILITY ENGINEERING PROCESS is an element of the

RISK MANAGEMENT PROCESS.

This collateral standard describes a USABILITY ENGINEERING PROCESS, and provides guidance

on how to implement and execute the PROCESS to provide BASIC SAFETY and ESSENTIAL

PERFORMANCE as it relates to USABILITY of MEDICAL ELECTRICAL EQUIPMENT. It is intended to be

useful not only for MANUFACTURERS of MEDICAL ELECTRICAL EQUIPMENT, but also for technical

committees responsible for the preparation of particular standards.

60601-1-6 © IEC:2006 – 13 –

MEDICAL ELECTRICAL EQUIPMENT –

Part 1-6: General requirements for basic safety

and essential performance –

Collateral Standard: Usability

1 Scope, object and related standards

1.1 Scope

This International Standard specifies requirements for a PROCESS to analyse, design, verify

and validate the USABILITY, as it relates to BASIC SAFETY and ESSENTIAL PERFORMANCE of

MEDICAL ELECTRICAL EQUIPMENT, hereafter referred to as ME EQUIPMENT. This collateral

standard addresses NORMAL USE and USE ERRORS but excludes ABNORMAL USE.

1.2 Object

The object of this collateral standard is to specify general requirements that are in addition to

those of the general standard and to serve as the basis for particular standards.

1.3 Related standards

1.3.1 IEC 60601-1

For ME EQUIPMENT, this collateral standard complements IEC 60601-1.

When referring to IEC 60601-1 or to this collateral standard, either individually or in

combination, the following conventions are used:

• "the general standard" designates IEC 60601-1 alone;

• "this collateral standard" designates IEC 60601-1-6 alone;

• "this standard" designates the combination of the general standard and this collateral

standard.

1.3.2 Particular standards

A requirement in a particular standard takes priority over the corresponding requirement in

this collateral standard.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60601-1:2005, Medical electrical equipment – Part 1: General requirements for basic

safety and essential performance

IEC 60601-1-8:2006, Medical electrical equipment – Part 1-8: General requirements for basic

safety and essential performance – Collateral Standard: General requirements, tests and

guidance for alarm systems in medical electrical equipment and medical electrical systems

60601-1-6 © IEC:2006 – 15 –

ISO 14971:2000, Medical devices – Application of risk management to medical devices

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60601-1:2005,

IEC 60601-1-8:2006 and the following definitions apply.

NOTE An index of defined terms is found beginning on page 145.

3.1

ABNORMAL USE

intended act or intended omission of an act by the RESPONSIBLE ORGANIZATION or OPERATOR of

ME EQUIPMENT as a result of conduct that is beyond any reasonable means of RISK CONTROL by

the MANUFACTURER

NOTE 1 See also Annex B. Examples are given in Annex C.

NOTE 2 It is possible for the PATIENT to be the OPERATOR, e.g. when ME EQUIPMENT is used in the PATIENT’S home.

NOTE 3 ABNORMAL USE is not considered REASONABLY FORESEABLE MISUSE.

3.2

EFFECTIVENESS

accuracy and completeness with which OPERATORS achieve specified goals

[ISO 9241-11:1998, definition 3.2, modified]

3.3

EFFICIENCY

resources expended in relation to the accuracy and completeness with which OPERATORS

achieve goals

[ISO 9241-11:1998, definition 3.3 modified]

3.4

OPERATOR-EQUIPMENT INTERFACE

*

means by which the OPERATOR and the ME EQUIPMENT communicate

[ANSI/AAMI/HE 74:2001, definition 3.24 modified]

NOTE The ACCOMPANYING DOCUMENTS are considered part of the ME EQUIPMENT and the OPERATOR-EQUIPMENT

INTERFACE.

3.5

OPERATOR PROFILE

summary of the mental, physical and demographic traits of the intended OPERATOR population,

as well as any special characteristics that can have a bearing on design decisions, such as

occupational skills and job requirements

3.6

* PRIMARY OPERATING FUNCTION

function that involves OPERATOR interaction that is either frequently used or related to the

BASIC SAFETY or ESSENTIAL PERFORMANCE of the ME EQUIPMENT in NORMAL USE

3.7

* REASONABLY FORESEEABLE MISUSE

use by the OPERATOR in a way not intended by the MANUFACTURER but which can result from

readily predictable human behaviour

[ISO/IEC Guide 51:1999, definition 3.14, modified]

60601-1-6 © IEC:2006 – 17 –

NOTE 1 REASONABLY FORESEEABLE MISUSE is an intended action.

NOTE 2 Use refers to a product, PROCESS or service.

NOTE 3 Slips, lapses, mistakes and ABNORMAL USE can also be reasonably foreseeable, but are not considered

REASONABLY FORESEEABLE MISUSE.

NOTE 4 See also Annex B.

3.8

TRAINING

application-specific OPERATOR-oriented instruction or exercises required for the safe and

effective use of the ME EQUIPMENT

3.9

USE ERROR

act or omission of an act that has a different ME EQUIPMENT response than intended by the

MANUFACTURER or expected by the OPERATOR

NOTE 1 USE ERROR includes slips, lapses, mistakes, and REASONABLY FORESEEABLE MISUSE.

NOTE 2 See also Annex B and D.1.3.

NOTE 3 The physiological response of the PATIENT is not considered part of USE ERROR.

3.10

USE SCENARIO

sequence of events and tasks used to specify and test the USABILITY of the ME EQUIPMENT

3.11

* USABILITY

characteristic that establishes EFFECTIVENESS, EFFICIENCY and OPERATOR learnability and

satisfaction

3.12

USABILITY ENGINEERING

application of knowledge about human behaviour, abilities, limitations, and other

characteristics to the design of tools, machines, ME EQUIPMENT, devices, systems, tasks, jobs,

and environments to achieve adequate USABILITY

3.13

* USABILITY ENGINEERING FILE

set of RECORDS and other documents that are produced by USABILITY ENGINEERING activities

3.14

USABILITY SPECIFICATION

documentation defining the OPERATOR-EQUIPMENT INTERFACE requirements related to USABILITY

3.15

VALIDATION

confirmation, through the provision of objective evidence, that the requirements for a specific

intended use or application have been fulfilled

NOTE 1 The term “validated” is used to designate the corresponding status.

NOTE 2 The use conditions for VALIDATION can be real or simulated.

[ISO 9000:2000, definition 3.8.5]

60601-1-6 © IEC:2006 – 19 –

4 General requirements

4.1 * Conditions for application to ME EQUIPMENT

The ME EQUIPMENT shall provide adequate USABILITY such that the RISKS resulting from NORMAL

and USE ERROR are acceptable. See also 7.1.1 and 12.2 of the general standard.

USE

Compliance with this subclause is considered to exist when compliance with the other clauses

and subclauses of this collateral standard is demonstrated.

4.2 * RISK MANAGEMENT PROCESS for ME EQUIPMENT

When performing the RISK ANALYSIS step of the RISK MANAGEMENT PROCESS required by 4.2 of

the general standard, the analysis shall consider the following:

– application specification (see 6.2.2.1);

– OPERATOR PROFILE;

– predictable USE ERRORS (see ANNEX C for a list of predictable USE ERRORS);

– * task related requirements;

– * context of use;

– information on HAZARDS known for existing OPERATOR-EQUIPMENT INTERFACES for

ME EQUIPMENT of a similar type, if available;

– results of the review of the OPERATOR-EQUIPMENT INTERFACE (see D.2.2 in this document

and D.7 of ISO 14971:2000).

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

5 ME EQUIPMENT identification, marking and documents

5.1 * ACCOMPANYING DOCUMENTS

A brief description of the ME EQUIPMENT, its physical operating principles and significant

physical and performance characteristics relevant to its USABILITY, shall be included in the

instructions for use. The same information shall also be included in the technical description,

if this is provided as a separate document.

ACCOMPANYING DOCUMENTS for ME EQUIPMENT may be provided electronically, e.g. by

electronic file format or CD-ROM. If the ACCOMPANYING DOCUMENTS are provided

electronically, the USABILITY ENGINEERING PROCESS shall include consideration of which

information also needs to be provided as hard copy or as markings on the ME EQUIPMENT, e.g.

to cover emergency operation.

The ACCOMPANYING DOCUMENTS shall include a description of the OPERATOR PROFILE. The

ACCOMPANYING DOCUMENTS shall be written at a level consistent with the intended OPERATOR

PROFILE.

Compliance is checked by inspecting the ACCOMPANYING DOCUMENTS and the USABILITY

ENGINEERING FILE.

60601-1-6 © IEC:2006 – 21 –

5.2 * TRAINING and materials for TRAINING

If ME EQUIPMENT specific TRAINING is required for the PRIMARY OPERATING FUNCTIONS of the

ME EQUIPMENT, the MANUFACTURER shall:

– provide the necessary materials for TRAINING;

– ensure that these materials are available; or

– provide the TRAINING.

NOTE 1 ME EQUIPMENT-specific TRAINING provides the knowledge and skills required for safe and effective use of

ME EQUIPMENT in addition to the OPERATOR PROFILE.

The INTENDED USE shall be the basis for TRAINING and TRAINING material. The instructions for

use shall indicate whether specific TRAINING for this ME EQUIPMENT is required and shall

indicate the available TRAINING options.

1)

NOTE 2 See IEC 61258 [1].

6 * USE ERROR and USABILITY

6.1 * Safety for the PATIENT, OPERATOR and other persons

A USABILITY ENGINEERING PROCESS shall be conducted to provide safety for the PATIENT,

OPERATOR and other persons related to USABILITY of the OPERATOR-EQUIPMENT INTERFACE.

NOTE 1 To guide the application of USABILITY ENGINEERING principles, the HAZARDS to PATIENTS, OPERATORS and

other persons as listed in ISO 14971 should be considered.

NOTE 2 The following are examples of HAZARDS for the PATIENT:

– unintentional setting of the diagnostic or therapeutic ME EQUIPMENT, e.g. inappropriate X-ray exposure setting

requiring an additional exposure;

– unintentional interruption of delivery of therapy;

– misinterpretation of displayed values followed by an inappropriate treatment;

– confusing data presentation contributing to mental fatigue resulting in increased USE ERROR.

NOTE 3 The following are examples of HAZARDS for the OPERATOR:

– poor anthropometric design leading to musculoskeletal injury;

– repetitive-motion resulting in nerve/tendon injuries;

– poor display contrast resulting in eye fatigue;

– loud noise emanating from the ME EQUIPMENT resulting in hearing impairment.

Compliance with this subclause is considered to exist when compliance with the other clauses

and subclauses of this collateral standard is demonstrated.

6.2 * USABILITY ENGINEERING PROCESS

6.2.1 General

The results of the USABILITY ENGINEERING PROCESS shall be recorded in the USABILITY

ENGINEERING FILE. The USABILITY ENGINEERING PROCESS may vary in form and extent based on

the nature of the ME EQUIPMENT, its intended OPERATOR and its INTENDED USE (see D.3.2). The

records and other documents that make up the USABILITY ENGINEERING FILE may form part of

other documents and files, e.g. a MANUFACTURER’S product file or RISK MANAGEMENT FILE.

—————————

1)

Figures in square brackets refer to the Bibliography.

60601-1-6 © IEC:2006 – 23 –

In the case of the modification of existing ME EQUIPMENT design, the USABILITY ENGINEERING

PROCESS may be scaled based on the significance of the modification depending on the

results of the RISK ANALYSIS (see D.3.2.2).

NOTE 1 The MANUFACTURER should conduct iterative design and development. USABILITY ENGINEERING should

begin early and continue through the ME EQUIPMENT design and development life cycle.

NOTE 2 Due to the iterative nature of the USABILITY ENGINEERING PROCESS, the activities described in the following

subclauses may be carried out in any convenient order (see D.2).

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

USABILITY ENGINEERING PROCESS

6.2.2 Input for the

6.2.2.1 * ME EQUIPMENT application specification

The MANUFACTURER shall specify the application of the ME EQUIPMENT in the USABILITY

ENGINEERING FILE.

This specification shall include:

– medical purpose (e.g. conditions(s) or disease(s) to be screened, monitored, treated, or

diagnosed);

– PATIENT population (e.g. age, weight, region of body, health, condition);

– part of the body or type of tissue applied to or interacted with;

– * intended OPERATOR PROFILE; and

– application (e.g. environment, frequency of use, location, mobility).

NOTE This specification contains elements of the INTENDED USE.

A summary of the ME EQUIPMENT application specification shall be included in the instructions

for use.

Compliance is checked by inspecting the USABILITY ENGINEERING FILE and the instructions for

use.

6.2.2.2 PRIMARY OPERATING FUNCTIONS

The MANUFACTURER shall determine the PRIMARY OPERATING FUNCTIONS and record them in the

USABILITY ENGINEERING FILE.

NOTE 1 See also D.5.3, D.5.5, D.5.9, D.5.10 and D.5.14 for a discussion of methods that might be useful in

determining PRIMARY OPERATING FUNCTIONS.

NOTE 2 PRIMARY OPERATING FUNCTIONS should be easily recognizable and self-explanatory to the OPERATOR.

NOTE 3 See element 1.2 of Figure E.1 for an example of PRIMARY OPERATING FUNCTIONS for a hypothetical

ME EQUIPMENT.

Compliance is checked by inspection of the USABILITY ENGINEERING FILE.

6.2.2.3 * Information for safety as a RISK CONTROL

For RISK CONTROL related to USABILITY, the MANUFACTURER shall decide what information is

required for BASIC SAFETY or ESSENTIAL PERFORMANCE, e.g. warnings or limitation of use in the

ACCOMPANYING DOCUMENTS, marking, etc. Any such information shall be subject to the

USABILITY ENGINEERING PROCESS. Disregarding this information shall be considered ABNORMAL

USE. See also Annex B.

60601-1-6 © IEC:2006 – 25 –

NOTE 1 RISK CONTROL consists of an integrated approach in which the MANUFACTURER uses one or more of the

following in the priority listed:

a) inherent SAFETY by design;

b) protective measures in the ME EQUIPMENT itself or in the manufacturing PROCESS, e.g. ALARM SYSTEMS;

c) information for safety, e.g. warnings in the instructions for use, display of a monitored variable.

The results of the RISK ANALYSIS or a reference to the location of the results of the RISK

ANALYSIS shall be recorded in the USABILITY ENGINEERING FILE.

NOTE 2 The RISK ANALYSIS for the ME EQUIPMENT or for the corresponding generic device type is an input for the

USABILITY SPECIFICATION as required for the USABILITY ENGINEERING PROCESS. Any RESIDUAL RISK evaluation should

consider the results of the USABILITY VALIDATION.

NOTE 3 The evaluation of post-production information (post-market surveillance) should include USABILITY (see

ISO 14971:2000, Clause 9).

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

6.2.3 * USABILITY SPECIFICATION

As part of the USABILITY ENGINEERING PROCESS, the MANUFACTURER shall develop a USABILITY

SPECIFICATION. The USABILITY SPECIFICATION shall be recorded in USABILITY ENGINEERING FILE.

The USABILITY SPECIFICATION may be integrated into other specifications.

The USABILITY SPECIFICATION shall be based on the following:

– application specification (see 6.2.2.1);

– HAZARDS related to the use of the ME EQUIPMENT (results from RISK ANALYSIS as described

in 4.2); and

– predictable USE ERRORS associated with the ME EQUIPMENT.

The USABILITY SPECIFICATION shall describe at least:

– * USE SCENARIOS for the ME EQUIPMENT;

– OPERATOR actions related to the PRIMARY OPERATING FUNCTIONS;

– OPERATOR-EQUIPMENT INTERFACE requirements for the PRIMARY OPERATING FUNCTIONS; and

– requirements for determining whether PRIMARY OPERATING FUNCTIONS are easily

recognizable by the OPERATOR.

NOTE 1 The USABILITY SPECIFICATION should include references to context of use (see the rationale for Subclause

4.2 and D.4.1.2.4).

NOTE 2 For guidance, see D.2.6.

NOTE 3 See Annex E for an example of a USABILITY SPECIFICATION for hypothetical ME EQUIPMENT.

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

6.2.4 * USABILITY VERIFICATION

As part of the ME EQUIPMENT design VERIFICATION PROCESS, the MANUFACTURER shall verify the

OPERATOR-EQUIPMENT interface design according to the USABILITY SPECIFICATION. The results of

the VERIFICATION shall be recorded in USABILITY ENGINEERING FILE.

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

60601-1-6 © IEC:2006 – 27 –

6.2.5 Usability validation plan

The MANUFACTURER shall develop and maintain a USABILITY VALIDATION plan. The USABILITY

VALIDATION plan shall specify:

– any method used for VALIDATION of the USABILITY of the PRIMARY OPERATING FUNCTIONS;

– the criteria for determining successful VALIDATION of the USABILITY of the PRIMARY

OPERATING FUNCTIONS (see Table D.5); and

– the involvement of representative intended OPERATORS (see D.4.3.2).

USABILITY VALIDATION methods may be quantitative or qualitative. USABILITY VALIDATION may be

performed in a laboratory setting, in a simulated use environment or in the actual use

environment.

NOTE 1 The MANUFACTURER should apply one or more methods for the USABILITY VALIDATION of PRIMARY OPERATING

FUNCTIONS of the ME EQUIPMENT depending on the INTENDED USE. Examples of these methods are found in Clause

D.5.

NOTE 2 Findings based on any single method can be insufficient, e.g. in a clinical evaluation it might not be

possible to explore some high-RISK situations.

The USABILITY VALIDATION plan shall address:

– worst case USE SCENARIOS derived from:

• the application specification (see 6.2.2.1),

• predictable USE ERRORS, and

• the results of the RISK ANALYSIS; and

– USE SCENARIOS representing frequent application situations identified in the USABILITY

SPECIFICATION.

The USABILITY VALIDATION plan shall be recorded in the USABILITY ENGINEERING FILE.

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

6.2.6 * USABILITY VALIDATION

The MANUFACTURER shall validate OPERATOR-EQUIPMENT INTERFACE design according to the

USABILITY VALIDATION plan. The results shall be recorded, including any required design

modification needed to satisfy the criteria as defined in the USABILITY VALIDATION plan.

NOTE 1 The ACCOMPANYING DOCUMENTS are part of the ME EQUIPMENT and are also subject to activities for

validating USABILITY.

NOTE 2 Individuals that were not directly involved in the OPERATOR-EQUIPMENT INTERFACE design should be

involved in the USABILITY VALIDATION.

Compliance is checked by inspecting the USABILITY ENGINEERING FILE.

60601-1-6 © IEC:2006 – 29 –

Annex A

(informative)

General guidance and rationale

A.1 General guidance

This annex provides a concise rationale for the important requirements of this collateral

standard. Its purpose is to promote effective application of the collateral standard by

explaining the reasons for the requirements and provide additional guidance where

appropriate.

A.2 Rationale for particular clauses and subclauses

The following are rationales for specific clauses and subclauses in this collateral standard,

with clause and subclause numbers parallel to those in the body of the document.

Definition 3.4 – OPERATOR-EQUIPMENT INTERFACE

The OPERATOR-EQUIPMENT INTERFACE includes all means of communication between the

ME EQUIPMENT to the OPERATOR and the OPERATOR to the ME EQUIPMENT. These means include,

but are not limited to:

– markings and ACCOMPANYING DOCUMENTS;

– lights;

– video displays;

– push buttons;

– touch screens;

– auditory and visual INFORMATION SIGNALS;

– ALARM SIGNALS;

– vibratory signals;

– keyboard and mouse; and

– haptic controls.

Definition 3.6 – PRIMARY OPERATING FUNCTION

For the purposes of this collateral standard, a PRIMARY OPERATING FUNCTION is a function that

is directly related to the BASIC SAFETY or ESSENTIAL PERFORMANCE of the ME EQUIPMENT in

NORMAL USE or a function that is frequently used. Examples of PRIMARY OPERATING FUNCTION

that directly relate to BASIC SAFETY or ESSENTIAL PERFORMANCE include:

– inactivating an ALARM SIGNAL (temporarily or indefinitely);

– setting ALARM LIMITS;

– setting X-ray exposure parameters (e.g. kV , mA);

p

– setting infusion parameters (e.g. flow rate);

– setting gas flow rates and anaesthetic vaporizer concentration.

60601-1-6 © IEC:2006 – 31 –

Frequently used functions are included in the PRIMARY OPERATING FUNCTIONS because

inadequate USABILITY of the frequently used functions adds to OPERATORS’ workloads and can

increase the probability of USE ERRORS affecting safety-related functions. A collection of

relatively minor shortcomings in the design of OPERATOR-EQUIPMENT INTERFACES can raise the

probability of USE ERRORS and their consequences, particularly when they involve frequently

used functions. Examples of such shortcomings include poor labelling, ambiguous control-

display relationships, difficult to read indicators, connectors that lack the proper shape coding,

inconsistent software navigation methods, etc. At a minimum, these shortcomings can

increase the time required to learn to use the ME EQUIPMENT and increase the time required to

perform frequent tasks due to an overall increase in mental and physical workload. At worse,

these shortcomings can induce USE ERROR because OPERATORS have to focus more attention

on operational mechanics, taking attention away from higher-level considerations directly

related to PATIENT safety. As workload increases, there is generally an increased chance of

errors of various types. There is less time to check one's work, less time to consider all

variables and a greater chance of imprecision and blundering due to rushing. Accordingly, it

makes sense to review all functions, particularly the most frequent ones, and determine if

there could be a problem due to the cumulative effect of USABILITY ENGINEERING deficiencies

that could have a negative impact on BASIC SAFETY or ESSENTIAL PERFORMANCE.

Definition 3.7 – REASONABLY FORESEEABLE MISUSE

There is often a thin line between ABNORMAL USE and REASONABLY FORESEEABLE MISUSE. What

might look to be a case of ABNORMAL USE can later turn out to be REASONABLY FORESEEABLE

MISUSE after investigation and closer examination by experts trained in the USABILITY

ENGINEERING PROCESS and the science of human error. The RISK MANAGEMENT PROCESS of

ME EQUIPMENT defines within the context of that particular ME EQUIPMENT what is REASONABLY

FORESEEABLE MISUSE and what is ABNORMAL USE, and documents what RISK CONTROL measures

have been taken to mitigate the REASONABLY FORESEEABLE MISUSE.

A MANUFACTURER needs to exercise judgement in selecting the appropriate RISK CONTROL

measure to avoid unnecessarily limiting the practice of medicine. ME EQUIPMENT should not

arbitrarily prevent off-label use that does not present a HAZARD, e.g. preventing the use of

ME EQUIPMENT for a PATIENT population because efficacy data does not exist. In such a case,

using a protective measure in the ME EQUIPMENT is more appropriate, e.g. a warning message

or pop-up window on the display.

The USABILITY ENGINEERING PROCESS helps discover which actions are “readily predictable.”

Definition 3.11 – USABILITY

The time needed to become acquainted with the ME EQUIPMENT and its operation is called

“learnability” (ISO 9241-11:1998, Table B.2 [5]). Freedom from discomfort, and positive

attitude towards the use of the ME EQUIPMENT is called “satisfaction” (ISO 9241-11:1998,

definition 3.4 [5]).

NOTE HOW easy it is to remember the operational details of ME EQUIPMENT can be thought of as

“memorizability” [10].

USABILITY is a measure of the EFFECTIVENESS, EFFICIENCY, and satisfaction with which

specified OPERATORS achieve specified goals in particular environments, within the scope of

the INTENDED USE of the ME EQUIPMENT. Many of these factors can influence safety to various

extents.

60601-1-6 © IEC:2006 – 33 –

To gauge if ME EQUIPMENT exhibits adequate USABILITY, specifications for the following

influencing factors are required:

– OPERATOR;

– task/goals; and

– conditions and setting in which the OPERATOR interacts with the ME EQUIPMENT.

This is because a change in a single factor could change the USABILITY significantly.

EXAMPLE An AC/battery-powered ECG monitor that works perfectly well in the relatively protected environment

of an ICU ward could exhibit severe drawbacks in USABILITY if it were to be used outside at night. This is a change

in the conditions and setting. In the new location of use, the influencing factors vary for:

– power up/pre-check needs;

– ambient light (night, bright sunlight), reflections; or

– requirements for handling, transportation, weight.

Some OPERATOR-EQUIPMENT INTERFACES contribute to USE ERROR because they employ non-

intuitive or counter-intuitive displays or controls. The consequences of such design flaws

often only become apparent when the OPERATOR is using the ME EQUIPMENT in an emergency

or stressful situation, is fatigued, or uses the ME EQUIPMENT only rarely.

Definition 3.13 – uSABILITY ENGINEERING FILE

The USABILITY ENGINEERING FILE can be part of the RISK MANAGEMENT FILE. There is no

requirement for the USABILITY ENGINEERING FILE to be independently stored from the RISK

MANAGEMENT FILE. The USABILITY ENGINEERING FILE need not physically contain all the records

and other documents produced by USABILITY ENGINEERING activities. However, it should

contain at least references or pointers to all required documentation.

Subclause 4.1 – Conditions for application to ME EQUIPMENT

RISKS associated with

This collateral standard specifies requirements addressing particular

USABILITY. When these requirements are complied with, the RESIDUAL RISKS associated with

USABILITY are presumed to be acceptable unless there is objective evidence to the contrary.

This follows from 4.2 of the General Standard, which states “Where this standard or any of its

collateral or particular standards specify verifiable requirements addressing particular RISKS,

and these requirements are complied with, the RESIDUAL RISKS addressed by these

OBJECTIVE EVIDENCE to the

requirements shall be presumed to be acceptable unless there is

contrary.”

The criteria for judging RISK acceptability are established by the USABILITY VALIDATION plan,

which specifies the criteria for determining successful VALIDATION of the USABILITY of the

PRIMARY OPERATING FUNCTIONS.

Subclause 4.2 – RISK MANAGEMENT PROCESS for ME EQUIPMENT

Task related requirements:

Task related requirements are derived from the task analysis (see D.5.14) and are typically

USABILITY SPECIFICATION (see element 1.3.4 in Figure E.1).

identified as an input to the

Examples of task related requirements are:

– exterior surface shall facilitate ease of cleaning;

– markings shall be readable under low lighting conditions;

– ME EQUIPMENT shall be transportable with one hand only.

60601-1-6 © IEC:2006 – 35 –

Context of use:

The context of use can have a significant impact on USABILITY of ME EQUIPMENT. For safety

reasons the context of use needs to be analyzed and considered by the MANUFACTURER. When

ME EQUIPMENT is used as part of a MEDICAL ELECTRICAL SYSTEM, context of use needs to

consider the attributes of the other elements of the system.

Examples of different contextual factors that need to be addressed are:

– spatial context:

• architecture: in-house, in town, types of building, e.g.: hospital (ward, OT, ICU),

theatre, cinema, home;

• outside;

• technological settings (airplane, ship, ambulance, car);

• smoothness and inclination of floor;

• emergency location;

– social context:

• organization;

• shift work (requirement to receive/forward inputs/outputs for ME EQUIPMENT);

• presence of: unattended children; untrained and/or curious adults;

...

NORME CEI

INTERNATIONALE 60601-1-6

Deuxième édition

2006-12

Appareils électromédicaux –

Partie 1-6:

Exigences générales pour la sécurité

de base et les performances essentielles –

Norme collatérale: Aptitude à l’utilisation

Cette version française découle de la publication d’origine

bilingue dont les pages anglaises ont été supprimées.

Les numéros de page manquants sont ceux des pages

supprimées.

Numéro de référence

CEI 60601-1-6:2006(F)

Numérotation des publications

Depuis le 1er janvier 1997, les publications de la CEI sont numérotées à partir de

60000. Ainsi, la CEI 34-1 devient la CEI 60034-1.

Editions consolidées

Les versions consolidées de certaines publications de la CEI incorporant les

amendements sont disponibles. Par exemple, les numéros d’édition 1.0, 1.1 et 1.2

indiquent respectivement la publication de base, la publication de base incorporant

l’amendement 1, et la publication de base incorporant les amendements 1 et 2

Informations supplémentaires sur les publications de la CEI

Le contenu technique des publications de la CEI est constamment revu par la CEI

afin qu'il reflète l'état actuel de la technique. Des renseignements relatifs à cette

publication, y compris sa validité, sont disponibles dans le Catalogue des

publications de la CEI (voir ci-dessous) en plus des nouvelles éditions, amende-

ments et corrigenda. Des informations sur les sujets à l’étude et l’avancement des

travaux entrepris par le comité d’études qui a élaboré cette publication, ainsi que la

liste des publications parues, sont également disponibles par l’intermédiaire de:

• Site web de la CEI (www.iec.ch)

• Catalogue des publications de la CEI

Le catalogue en ligne sur le site web de la CEI (www.iec.ch/searchpub) vous permet

de faire des recherches en utilisant de nombreux critères, comprenant des

recherches textuelles, par comité d’études ou date de publication. Des informations

en ligne sont également disponibles sur les nouvelles publications, les publications

remplacées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

Ce résumé des dernières publications parues (www.iec.ch/online_news/justpub)

est aussi disponible par courrier électronique. Veuillez prendre contact avec le

Service client (voir ci-dessous) pour plus d’informations.

• Service clients

Si vous avez des questions au sujet de cette publication ou avez besoin de

renseignements supplémentaires, prenez contact avec le Service clients:

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Fax: +41 22 919 03 00

NORME CEI

INTERNATIONALE 60601-1-6

Deuxième édition

2006-12

Appareils électromédicaux –

Partie 1-6:

Exigences générales pour la sécurité

de base et les performances essentielles –

Norme collatérale: Aptitude à l’utilisation

© IEC 2006 Droits de reproduction réservés

Aucune partie de cette publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun

procédé, électronique ou mécanique, y compris la photocopie et les microfilms, sans l'accord écrit de l'éditeur.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale XB

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

– 2 – 60601-1-6 © CEI:2006

SOMMAIRE

AVANT-PROPOS.4

INTRODUCTION.10

1 Domaine d'application, objet et normes connexes .12

1.1 Domaine d’application .12

1.2 Objet .12

1.3 Normes connexes.12

2 Références normatives.12

3 Termes et définitions .14

4 Exigences générales .18

4.1 * Conditions d’application aux APPAREILS EM .18

4.2 * PROCESSUS DE GESTION DES RISQUES pour les APPAREILS EM.18

5 Identification, marquage et documentation des APPAREILS EM.18

5.1 * DOCUMENTS D'ACCOMPAGNEMENT.18

5.2 * FORMATION et supports de FORMATION .20

6 * ERREUR D'UTILISATION et APTITUDE À L'UTILISATION.20

6.1 * SÉCURITÉ du PATIENT, de L'OPÉRATEUR et des tiers .20

6.2 * PROCESSUS D'INGÉNIERIE DE L’APTITUDE À L'UTILISATION .20

Annexe A (informative) Guide général et justifications .28

Annexe B (informative) Taxinomie des actions de l’OPÉRATEUR .40

Annexe C (informative) Exemples d'ERREURS D'UTILISATION, d'UTILISATIONS ANORMALES

et de défauts de conception conduisant potentiellement à des ERREURS D'UTILISATION.42

Annexe D (informative) Guide pour le PROCESSUS D’INGÉNIERIE D’APTITUDE À

L’UTILISATION .48

Annexe E (informative) Exemple de SPÉCIFICATION DE L’APTITUDE À L’UTILISATION .104

Annexe F (informative) Documents de référence.122

Bibliographie.140

Index des termes définis dans la présente norme collatérale .144

Figure B.1 – Résumé de la taxinomie des actions de L'OPÉRATEUR.40

Figure D.1 – Cycle de conception d'une INTERFACE OPÉRATEUR-APPAREIL .54

Figure D.2 – Schéma à bulles du modèle conceptuel d'un moniteur physiologique.84

Figure E.1 – Exemple de SPÉCIFICATION DE L'APTITUDE À L'UTILISATION pour un dispositif

hypothétique .104

Tableau D.1 – Echantillon de défauts de conception et d'ERREURS D'UTILISATION

associées .52

Tableau D.2 – Correspondance entre la Figure D.1 et les paragraphes de la présente

norme .54

Tableau D.3 – Exemples d'exigences d'INTERFACE OPÉRATEUR-APPAREIL.60

Tableau D.4 – Réalisations types.72

Tableau D.5 – Exemples d'objectifs de l’APTITUDE À L'UTILISATION objectifs et subjectifs .80

Tableau D.6 – Exemples de techniques de modélisation d'INTERFACE OPÉRATEUR-

APPAREIL. .86

Tableau D.7 – Caractéristiques d'un effort d'essai type d'APTITUDE À L'UTILISATION .86

– 4 – 60601-1-6 © CEI:2006

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

APPAREILS ÉLECTROMÉDICAUX –

Partie 1-6: Exigences générales pour la sécurité de base

et les performances essentielles –

Norme collatérale: Aptitude à l'utilisation

AVANT-PROPOS

1) La Commission Electrotechnique Internationale (CEI) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI – entre autres activités – publie des Normes

internationales, des Spécifications techniques, des Rapports techniques, des Spécifications accessibles au

public (PAS) et des Guides (ci-après dénommés "Publication(s) de la CEI"). Leur préparation est confiée aux

comités d'études; il est permis à tout Comité national intéressé par le sujet traité de participer à ces travaux

préparatoires. Les organisations internationales, gouvernementales et non gouvernementales qui assurent la

liaison avec la CEI participent également à cette préparation. La CEI collabore étroitement avec l'Organisation

Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux de la CEI

intéressés sont représentés dans chaque comité d’études.

3) Les Publications de la CEI se présentent sous la forme de recommandations internationales et sont agréées

comme telles par les Comités nationaux de la CEI. Tous les efforts raisonnables sont entrepris afin que la CEI

s'assure de l'exactitude du contenu technique de ses publications; la CEI ne peut pas être tenue responsable

de l'éventuelle mauvaise utilisation ou interprétation qui en est faite par un quelconque utilisateur final.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les normes internationales de la CEI dans leurs normes

nationales et régionales. Toutes divergences entre toutes Publications de la CEI et toutes publications

nationales ou régionales correspondantes doivent être indiquées en termes clairs dans ces dernières.

5) La CEI n’a prévu aucune procédure de marquage valant indication d’approbation et n'engage pas sa

responsabilité pour les équipements déclarés conformes à une de ses Publications.

6) Tous les utilisateurs doivent s'assurer qu'ils sont en possession de la dernière édition de cette publication.

7) Aucune responsabilité ne doit être imputée à la CEI, à ses administrateurs, employés, auxiliaires ou

mandataires, y compris ses experts particuliers et les membres de ses comités d'études et des Comités

nationaux de la CEI, pour tout préjudice causé en cas de dommages corporels et matériels, ou de tout autre

dommage de quelque nature que ce soit, directe ou indirecte, ou pour supporter les coûts (y compris les frais

de justice) et les dépenses découlant de la publication ou de l'utilisation de cette Publication de la CEI ou de

toute autre Publication de la CEI, ou au crédit qui lui est accordé.

8) L'attention est attirée sur les références normatives citées dans cette publication. L'utilisation de publications

référencées est obligatoire pour une application correcte de la présente publication.

9) L’attention est attirée sur le fait que certains des éléments de la présente Publication de la CEI peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60601-1-6 a été établie par le sous–comité 62A: Aspects

généraux des équipements utilisés en pratique médicale, du comité d’études 62 de la CEI:

Equipements électriques dans la pratique médicale.

Cette deuxième édition constitue une norme collatérale de la CEI 60601-1: Appareils

électromédicaux – Partie 1: Exigences générales de sécurité de base et les performances

essentielles, appelée norme générale dans la suite du texte.

Ce document annule et remplace la première édition de la CEI 60601-1-6.

– 6 – 60601-1-6 © CEI:2006

Cette édition de la CEI 60601-1-6 a été révisée pour s’aligner structurellement avec l’édition

2005 de la CEI 60601-1 et pour mettre en place la décision du Sous-comité 62 A de la CEI,

stipulant que la structure de la numérotation des articles des normes collatérales écrites avec

la CEI 60601-1:2005 adhérerait à la forme spécifiée dans les Directives ISO/CEI,

Partie 2:2004. Les principaux changements techniques se trouvent à l’Article 4, qui reconnaît

maintenant qu’il existe une exigence générale de processus de gestion du risque dans la

CEI 60601-1:2005.

Le texte de la présente norme collatérale est issu des documents suivants:

FDIS Rapport de vote

62A/550/FDIS 62A/557/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme collatérale.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Dans la série des publications CEI 60601, les normes collatérales spécifient les exigences

générales de sécurité applicables:

– à un sous-groupe d'APPAREILS ÉLECTROMÉDICAUX (par exemple les appareils de radiologie);

ou

– à une caractéristique particulière de tous les APPAREILS ÉLECTROMÉDICAUX, qui n'est pas

complètement traitée dans la norme générale (par exemple les systèmes d'alarme).

Dans la présente norme collatérale, les caractères d’imprimerie suivants sont utilisés:

– Exigences et définitions: caractères romains.

– Modalités d’essais: caractères italiques.

– Les indications de nature informative apparaissant hors des tableaux, comme les notes, les exemples et les

références: petits caractères. Le texte normatif à l’intérieur des tableaux est également en petits caractères.

– LES TERMES DÉFINIS A L’ARTICLE 3 DE LA NORME GÉNÉRALE, DE LA PRÉSENTE NORME

COLLATERALE OU COMME NOTES: PETITES MAJUSCULES.

Concernant la structure de la présente norme, le terme:

– “article” désigne l’une des six articles numérotés dans la table des matières, avec toutes

ses subdivisions (par exemple, l’Article 6 inclut les paragraphes 6.1, 6.2, etc.);

– “paragraphe” désigne une subdivision numérotée d’un article (par exemple 6.1, 6.2 et

6.2.1 sont tous des paragraphes appartenant à l’Article 6).

Dans la présente norme, les références à des articles sont précédées du mot “Article” suivi du

numéro de l’article concerné. Dans la présente norme, les références aux paragraphes

utilisent uniquement le numéro du paragraphe concerné.

Dans la présente norme, la conjonction "ou" est utilisée avec la valeur d'un "ou inclusif", ainsi

un énoncé est vrai si une combinaison des conditions, quelle qu'elle soit, est vraie.

Les formes verbales utilisées dans la présente norme sont conformes à l’usage donné à

l’Annexe H des Directives ISO/CEI, Partie 2. Pour les besoins de la présente norme:

– “devoir” mis au présent de l’indicatif signifie que la satisfaction à une exigence ou à un

essai est obligatoire pour la conformité à la présente norme;

– “il convient/il est recommandé” signifie que la satisfaction à une exigence ou à un essai

est recommandée mais n’est pas obligatoire pour la conformité à la présente norme;

– 8 – 60601-1-6 © CEI:2006

– “pouvoir” mis au présent de l’indicatif est utilisé pour décrire un moyen admissible pour

satisfaire à une exigence ou à un essai.

Les articles, les paragraphes et les définitions pour lesquels une justification est donnée dans

l'Annexe informative A sont repérés par un astérisque (*).

Une liste de toutes les parties de la CEI 60601, sous le titre général: Appareils

électromédicaux, est disponible sur le site web de la CEI.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant la date de

maintenance indiquée sur le site web de la CEI sous «http://webstore.iec.ch» dans les

données relatives à la publication recherchée. A cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

– 10 – 60601-1-6 © CEI:2006

INTRODUCTION

Les APPAREILS ÉLECTROMÉDICAUX sont de plus en plus utilisés en pratique médicale pour

l'observation et le traitement des PATIENTS. Les ERREURS D'UTILISATION dues à une APTITUDE À

L'UTILISATION inadéquate des APAPREILS ÉLECTROMÉDICAUX sont devenues une préoccupation

majeure. Le PROCESSUS D'INGÉNIERIE de l’APTITUDE À L'UTILISATION est destiné à obtenir une

APTITUDE À L'UTILISATION raisonnable qui, à son tour, est destinée à minimiser les ERREURS

D'UTILISATION et à minimiser les RISQUES associés à l'utilisation. Certaines formes d'utilisation

incorrecte, mais pas toutes, sont maîtrisables par le FABRICANT. Le PROCESSUS D'INGÉNIERIE de

l'APTITUDE À L'UTILISATION est un des éléments du PROCESSUS de GESTION DES RISQUES.

La présente norme collatérale décrit un PROCESSUS D'INGÉNIERIE de l'APTITUDE À L'UTILISATION

et fournit des lignes directrices pour la mise en œuvre et l'exécution de ce PROCESSUS pour

contribuer à la SÉCURITÉ DE BASE et les PERFORMANCES ESSENTIELLES ayant trait à l'APTITUDE À

L'UTILISATION des APPAREILS ÉLECTROMÉDICAUX. Elle est destinée à aider non seulement les

FABRICANTS d'APPAREILS ÉLECTROMÉDICAUX, mais aussi les comités responsables de la

préparation des normes particulières.

– 12 – 60601-1-6 © CEI:2006

APPAREILS ÉLECTROMÉDICAUX –

Partie 1-6: Exigences générales pour la sécurité de base

et les performances essentielles –

Norme collatérale: Aptitude à l'utilisation

1 Domaine d'application, objet et normes connexes

1.1 Domaine d’application

La présente Norme internationale spécifie les exigences d'un PROCESSUS destiné à analyser,

concevoir, vérifier et valider l'APTITUDE À L'UTILISATION ayant trait à la SÉCURITÉ DE BASE et les

PERFORMANCES ESSENTIELLES des APPAREILS ÉLECTROMÉDICAUX, désignés ci-après sous le

terme d'APPAREILS EM. La présente norme collatérale traite de l'UTILISATION NORMALE et des

ERREURS D'UTILISATION mais exclut l'UTILISATION ANORMALE.

1.2 Objet

La présente norme collatérale est destinée à spécifier des exigences générales qui viennent

compléter celles de la norme générale et à servir de base pour les normes particulières.

1.3 Normes connexes

1.3.1 CEI 60601-1

Pour les APPAREILS EM, la présente norme collatérale complète la CEI 60601-1.

Lorsqu'il est fait référence à la CEI 60601-1 ou à la présente norme collatérale, soit

individuellement soit combinées, les conventions suivantes sont utilisées:

• "la norme générale" désigne la CEI 60601-1 seule;

• "la présente norme collatérale" désigne la CEI 60601-1-6 seule;

• "la présente norme" désigne la combinaison de la norme générale et de la présente norme

collatérale.

1.3.2 Normes particulières

Une exigence donnée dans une norme particulière prévaut sur l'exigence correspondante

contenue dans la présente norme collatérale.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60601-1:2005, Appareils électromédicaux – Partie 1: Exigences générales pour la

sécurité de base et les performances essentielles

CEI 60601-1-8:2006, Appareils électromédicaux – Partie 1-8: Exigences générales pour la

sécurité de base et les performances essentielles – Norme collatérale: Exigences générales,

essais et guide pour les systèmes d'alarme des appareils et des systèmes électromédicaux

– 14 – 60601-1-6 © CEI:2006

ISO 14971:2000, Dispositifs médicaux – Application de la gestion des risques aux dispositifs

médicaux

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions donnés dans la

CEI 60601-1:2005, la CEI 60601-1-8:2006, ainsi que les définitions suivantes s’appliquent.

NOTE Un index des termes définis est donné à partir de la page 144.

3.1

UTILISATION ANORMALE

acte volontaire ou omission volontaire d'un acte de la part de l'ORGANISME RESPONSABLE ou de

l'OPÉRATEUR d'un APAPREIL EM qui découle d'un comportement qui échappe à tout moyen

raisonnable de MAÎTRISE DU RISQUE par le FABRICANT

NOTE 1 Voir aussi l’Annexe B. Des exemples sont donnés à l’Annexe C.

NOTE 2 Il est possible que le PATIENT soit l'OPÉRATEUR, par exemple lorsque l’APPAREIL EM est utilisé au domicile

du PATIENT.

NOTE 3 L'UTILISATION ANORMALE n'est pas considérée comme un MAUVAIS USAGE RAISONNABLEMENT PRÉVISIBLE.

3.2

EFFICACITÉ

précision et degré d'achèvement atteints par les OPÉRATEURS pour des objectifs spécifiés

[ISO 9241-11:1998, définition 3.2, modifiée]

3.3

RENDEMENT

ressources mises en œuvre par rapport à la précision et au degré d'achèvement atteints par

les OPÉRATEURS pour des objectifs spécifiés

[ISO 9241-11:1998, définition 3.3, modifiée]

3.4

* INTERFACE OPÉRATEUR-APPAREIL

moyens par lesquels l'OPÉRATEUR et l'APPAREIL EM communiquent

[ANSI/AAMI/HE 74:2001, définition 3.24, modifiée]

NOTE Les DOCUMENTS D'ACCOMPAGNEMENT sont considérés comme faisant partie de l'APPAREIL EM et de

l’INTERFACE OPÉRATEUR-APPAREIL.

3.5

PROFIL DE L'OPÉRATEUR

synthèse des caractères mentaux, physiques et démographiques de la population

d'OPÉRATEURS prévue, ainsi que toute caractéristique particulière qui peut avoir une influence

sur les décisions de conception, comme les aptitudes professionnelles et les exigences de

travail

3.6

* FONCTION PRINCIPALE DE SERVICE

fonction qui implique une interaction avec L'OPÉRATEUR qui est soit fréquemment utilisée soit

liée à la SÉCURITÉ DE BASE ou les PERFORMANCES ESSENTIELLES de l'APPAREIL EM en UTILISATION

NORMALE

3.7

* MAUVAIS USAGE RAISONNABLEMENT PRÉVISIBLE

utilisation par l'OPÉRATEUR d'une manière qui n'est pas prévue par le FABRICANT mais qui peut

résulter d'un comportement humain envisageable

[Guide ISO/CEI 51:1999, définition 3.14, modifiée]

– 16 – 60601-1-6 © CEI:2006

NOTE 1 Un MAUVAIS USAGE RAISONABLEMENT PRÉVISIBLE est une action volontaire.

NOTE 2 Utilisation fait référence à un produit, un PROCESSUS ou un service.

NOTE 3 Les fautes d'inattention, les défaillances, les fautes et l'UTILISATION ANORMALE peuvent également être

raisonnablement prévisibles mais elles ne sont pas considérées comme des cas de MAUVAIS USAGE

RAISONNABLEMENT PRÉVISIBLE.

NOTE 4 Voir aussi l’Annexe B.

3.8

FORMATION

instruction prenant en compte les besoins de l'OPÉRATEUR et qui est spécifique à une

application ou exercices nécessaires à l'utilisation efficace et en toute sécurité de l'APPAREIL

EM

3.9

ERREUR D'UTILISATION

APPAREIL EM différente de celle

acte ou omission d'un acte qui conduit à une réponse de l'

prévue par le FABRICANT ou attendue par l'OPÉRATEUR

NOTE 1 L'ERREUR D'UTILISATION englobe les fautes d'inattention, les défaillances, les fautes et le MAUVAIS USAGE

RAISONNABLEMENT PRÉVISIBLE.

NOTE 2 Voir aussi l’Annexe B et D.1.3.

NOTE 3 La réponse physiologique du PATIENT n'est pas considérée comme faisant partie de l'ERREUR

D'UTILISATION.

3.10

SCÉNARIO D'UTILISATION

séquence des événements et des tâches utilisée pour spécifier et soumettre aux essais

l’APTITUDE À L'UTILISATION des APPAREILS EM

3.11

* APTITUDE À L'UTILISATION

EFFICACITÉ, le RENDEMENT et la simplicité d'apprentissage et la

caractéristique qui établit l'

satisfaction pour L'OPÉRATEUR

3.12

INGÉNIERIE DE L'APTITUDE À L'UTILISATION

application des connaissances concernant le comportement, les capacités, les limitations des

personnes et d'autres caractéristiques à la conception des outils, des machines, des

APPAREILS EM, des dispositifs, des systèmes, des tâches, des emplois et des environnements

pour obtenir une APTITUDE À L'UTILISATION adéquate

3.13

* DOSSIER INGÉNIERIE DE L'APTITUDE À L'UTILISATION

ensemble des ENREGISTREMENTS et autres documents qui sont générés par les activités

D'INGÉNIERIE DE L'APTITUDE À L'UTILISATION

3.14

SPÉCIFICATION DE L'APTITUDE À L'UTILISATION

documentation définissant les exigences de l'INTERFACE OPÉRATEUR-APPAREIL liées à

l'APTITUDE À L'UTILISATION

3.15

VALIDATION

confirmation, par la fourniture de preuves objectives, que les exigences concernant une

utilisation ou une application prévues spécifiques sont satisfaites

NOTE 1 Le terme “validé” est utilisé pour désigner le statut correspondant.

NOTE 2 Les conditions d'utilisation pour la VALIDATION peuvent être réelles ou simulées.

[ISO 9000:2000, définition 3.8.5]

– 18 – 60601-1-6 © CEI:2006

4 Exigences générales

4.1 * Conditions d’application aux APPAREILS EM

L'APPAREIL EM doit offrir une APTITUDE À L'UTILISATION adéquate telle que les RISQUES résultant

d’une UTILISATION NORMALE et des ERREURS D'UTILISATION soient acceptables. Voir aussi 7.1.1

et 12.2 de la norme générale.

La conformité avec le présent paragraphe est réputée exister lorsque la conformité aux autres

articles et paragraphes de la présente norme collatérale est démontrée.

4.2 * PROCESSUS DE GESTION DES RISQUES pour les APPAREILS EM

Au moment de l’étape d’ANALYSE DE RISQUE du PROCESSUS DE GESTION DES RISQUES exigé en

4.2 de la norme générale, l’analyse doit prendre en compte les éléments suivants:

– spécification d’application (voir 6.2.2.1);

– PROFIL DE L'OPÉRATEUR;

– ERREURS D'UTILISATION prévisibles (voir l'Annexe C qui donne une liste des ERREURS

D'UTILISATION prévisibles);

– * les contraintes liées aux tâches;

– * le contexte d'utilisation;

– les informations sur les DANGERS connus pour les INTERFACES OPÉRATEUR-APPAREIL

existantes pour les APPAREILS EM d'un type similaire, si disponibles;

– les résultats de la revue de l'INTERFACE OPÉRATEUR-APPAREIL (voir D.2.2 dans ce document

et D.7 dans l'ISO 14971:2000).

La conformité est vérifiée par examen du DOSSIER D’INGÉNIERIE D’APTITUDE À L’UTILISATION.

5 Identification, marquage et documentation des APPAREILS EM

5.1 * DOCUMENTS D'ACCOMPAGNEMENT

Une brève description de l'APPAREIL EM, de ses principes de fonctionnement physiques et de

ses principales caractéristiques physiques et de performances touchant l'APTITUDE À

L'UTILISATION doit être incluse dans les instructions d'utilisation. Les mêmes informations

doivent également être incluses dans la description technique si celle-ci est fournie comme

document séparé.

Les DOCUMENTS D'ACCOMPAGNEMENT des APPAREILS EM peuvent être fournis sur support

électronique, par exemple sur fichier électronique ou CD-ROM. Si les DOCUMENTS

D'ACCOMPAGNEMENT sont fournis de manière électronique, le PROCESSUS D'INGÉNIERIE DE

’APTITUDE À L'UTILISATION doit prendre en compte quelles informations doivent également être

L

fournies sur papier ou sous forme de marquages sur les APPAREILS EM, par exemple pour le

fonctionnement d'urgence.

Les DOCUMENTS D'ACCOMPAGNEMENT doivent inclure une description du PROFIL DE

L'OPÉRATEUR. Les DOCUMENTS D'ACCOMPAGNEMENT doivent être rédigés de manière à ce que

leur niveau soit cohérent avec le PROFIL DE L'OPÉRATEUR prévu.

DOCUMENTS D’ACCOMPAGNEMENT et du DOSSIER

La conformité est vérifiée par examen des