IEC 60404-1:2016

(Main)Magnetic materials - Part 1: Classification

Magnetic materials - Part 1: Classification

IEC 60404-1:2016 is intended to classify commercially available magnetic materials. The term "magnetic materials" denotes substances where the application requires the existence of ferromagnetic or ferrimagnetic properties. The classification of magnetic materials is based upon the generally recognized existence of two main groups of products:

- soft magnetic materials (coercivity less than or equal to 1 000 A/m);

- hard magnetic materials (coercivity greater than 1 000 A/m). This edition includes the following significant technical changes with respect to the previous edition:

a) Removal of all tables and values describing typical properties of the material to be consistent with the aim of the document to be a classification and not a specification.

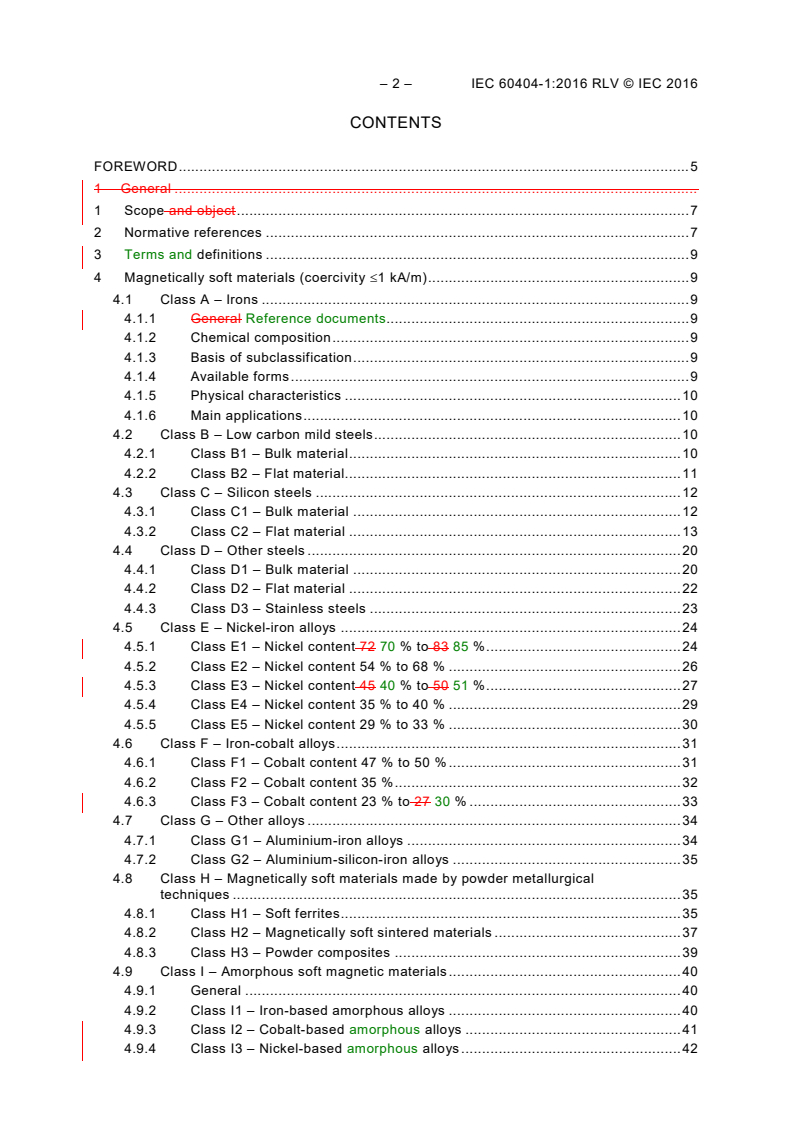

b) Enlargement of the Ni content for the classes E1 and E3.

c) Enlargement of the Co content for the classes F3.

d) Addition of a new class: U5 bonded rare earth-iron-nitrogen magnets.

Matériaux magnétiques - Partie 1: Classification

L'IEC 60404-1:2016 a pour objet la classification des matériaux magnétiques disponibles commercialement.

Le terme "matériaux magnétiques" décrit les substances dont l'application exige l'existence de propriétés ferromagnétiques ou ferrimagnétiques.

Dans le présent document, la classification des matériaux magnétiques est basée sur l'existence généralement reconnue de deux groupes principaux de produits:

- les matériaux magnétiques doux (coercitivité ≤ 1 000 A/m);

- les matériaux magnétiques durs (coercitivité >1 000 A/m).

Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) Suppression de l'ensemble des tableaux et valeurs décrivant les propriétés types du matériau dans un souci de cohérence avec l'objectif du document visant à établir une classification et non une spécification.

b) Augmentation de la teneur en Ni pour les classes E1 et E3.

c) Augmentation de la teneur en Co pour les classes F3.

d) Ajout d'une nouvelle classe: classe U5 - aimants agglomérés terres rares-fer-azote.

General Information

- Status

- Published

- Publication Date

- 23-Oct-2016

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 1 - TC 68/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 24-Oct-2016

- Completion Date

- 31-Dec-2016

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60404-1:2016 - "Magnetic materials - Part 1: Classification" is an International Electrotechnical Commission (IEC) standard that defines a harmonized classification system for commercially available magnetic materials. The standard applies to materials used where ferromagnetic or ferrimagnetic properties are required and separates products into two principal groups based on coercivity:

- Soft magnetic materials (coercivity ≤ 1 000 A/m)

- Hard magnetic materials (coercivity > 1 000 A/m)

This 2016 edition emphasizes classification (what a material is) rather than specification (how it performs). Notable changes in this edition include removal of tables/values that described typical material properties to keep the document strictly a classification, adjustments to allowable compositional ranges for certain nickel- and cobalt-based classes, and the addition of a new bonded magnet class (bonded rare earth‑iron‑nitrogen, U5).

Key topics

- Classification scheme: Detailed class structure covering soft magnetic classes (A–J) and hard magnetic classes (Q–U), e.g., irons, low‑carbon steels, silicon steels, nickel‑iron and iron‑cobalt alloys, amorphous and nanocrystalline materials, hard ferrites, RE‑Fe‑B, AlNiCo and bonded magnet families.

- Coercivity threshold: The primary criterion separating soft and hard materials (1 kA/m).

- Chemical classing and subclassification: Materials are grouped by chemistry and processing route (bulk, flat, sintered, bonded).

- Forms and production methods: Identification of available product forms (strip, bulk, sintered, bonded) and relevant manufacturing routes (powder metallurgy, amorphous ribbon, nanocrystalline processing).

- Scope-focused content: The edition is focused on identification and class definitions rather than providing performance tables or specification limits.

Applications and users

IEC 60404-1 is useful to:

- Material manufacturers and suppliers for class labeling and product catalogs

- Design engineers specifying magnetic materials for transformers, inductors, motors, generators, sensors and actuators

- Procurement and standards teams to harmonize material terminology across contracts

- Test laboratories and certification bodies for material identification and reference

- R&D groups comparing material families (e.g., amorphous vs. nanocrystalline vs. ferrite vs. rare-earth magnets)

By using the standard, stakeholders ensure consistent naming and class-based selection of magnetic materials during design, purchasing and regulatory processes.

Related standards

IEC 60404-1 is the classification part of the IEC 60404 family. Other parts of the IEC 60404 series and related IEC documents address measurement methods, specifications, testing and application guidelines for magnetic materials and magnetic components. Use IEC 60404-1 for consistent terminology and class identification before consulting subsequent parts for test methods and performance specifications.

Keywords: IEC 60404-1, magnetic materials, classification, soft magnetic materials, hard magnetic materials, coercivity, bonded magnets, nickel‑iron, iron‑cobalt, rare‑earth magnets.

Buy Documents

IEC 60404-1:2016+AMD1:2025 CSV - Magnetic materials - Part 1: Classification Released:7/25/2025 Isbn:9782832706213

IEC 60404-1:2016 - Magnetic materials - Part 1: Classification Released:10/24/2016 Isbn:9782832236710

IEC 60404-1:2016 RLV - Magnetic materials - Part 1: Classification Released:10/24/2016 Isbn:9782832237144

IEC 60404-1:2016 - Magnetic materials - Part 1: Classification Released:10/24/2016 Isbn:9782832251577

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60404-1:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Magnetic materials - Part 1: Classification". This standard covers: IEC 60404-1:2016 is intended to classify commercially available magnetic materials. The term "magnetic materials" denotes substances where the application requires the existence of ferromagnetic or ferrimagnetic properties. The classification of magnetic materials is based upon the generally recognized existence of two main groups of products: - soft magnetic materials (coercivity less than or equal to 1 000 A/m); - hard magnetic materials (coercivity greater than 1 000 A/m). This edition includes the following significant technical changes with respect to the previous edition: a) Removal of all tables and values describing typical properties of the material to be consistent with the aim of the document to be a classification and not a specification. b) Enlargement of the Ni content for the classes E1 and E3. c) Enlargement of the Co content for the classes F3. d) Addition of a new class: U5 bonded rare earth-iron-nitrogen magnets.

IEC 60404-1:2016 is intended to classify commercially available magnetic materials. The term "magnetic materials" denotes substances where the application requires the existence of ferromagnetic or ferrimagnetic properties. The classification of magnetic materials is based upon the generally recognized existence of two main groups of products: - soft magnetic materials (coercivity less than or equal to 1 000 A/m); - hard magnetic materials (coercivity greater than 1 000 A/m). This edition includes the following significant technical changes with respect to the previous edition: a) Removal of all tables and values describing typical properties of the material to be consistent with the aim of the document to be a classification and not a specification. b) Enlargement of the Ni content for the classes E1 and E3. c) Enlargement of the Co content for the classes F3. d) Addition of a new class: U5 bonded rare earth-iron-nitrogen magnets.

IEC 60404-1:2016 is classified under the following ICS (International Classification for Standards) categories: 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60404-1:2016 has the following relationships with other standards: It is inter standard links to IEC 60404-1:2016/AMD1:2025, IEC 60404-1:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60404-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60404-1 ®

Edition 3.1 2025-07

INTERNATIONAL

STANDARD

CONSOLIDATED VERSION

Magnetic materials -

Part 1: Classification

ICS 29.030 ISBN 978-2-8327-0621-3

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Discover our powerful search engine and read freely all the

The advanced search enables to find IEC publications by publications previews, graphical symbols and the glossary.

a variety of criteria (reference number, text, technical With a subscription you will always have access to up to

committee, …). It also gives information on projects, date content tailored to your needs.

replaced and withdrawn publications.

Electropedia - www.electropedia.org

The world's leading online dictionary on electrotechnology,

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just containing more than 22 500 terminological entries in

Published details all new publications released. Available English and French, with equivalent terms in 25 additional

online and once a month by email. languages. Also known as the International Electrotechnical

Vocabulary (IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer

Service Centre: sales@iec.ch.

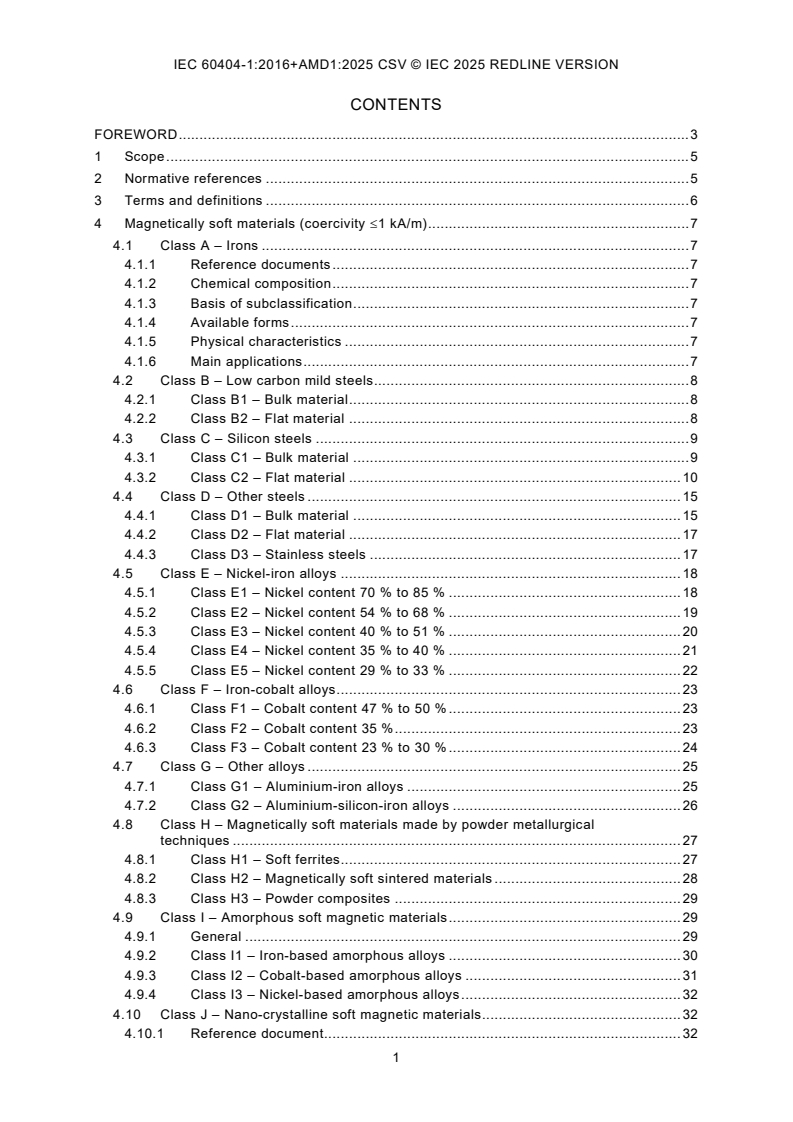

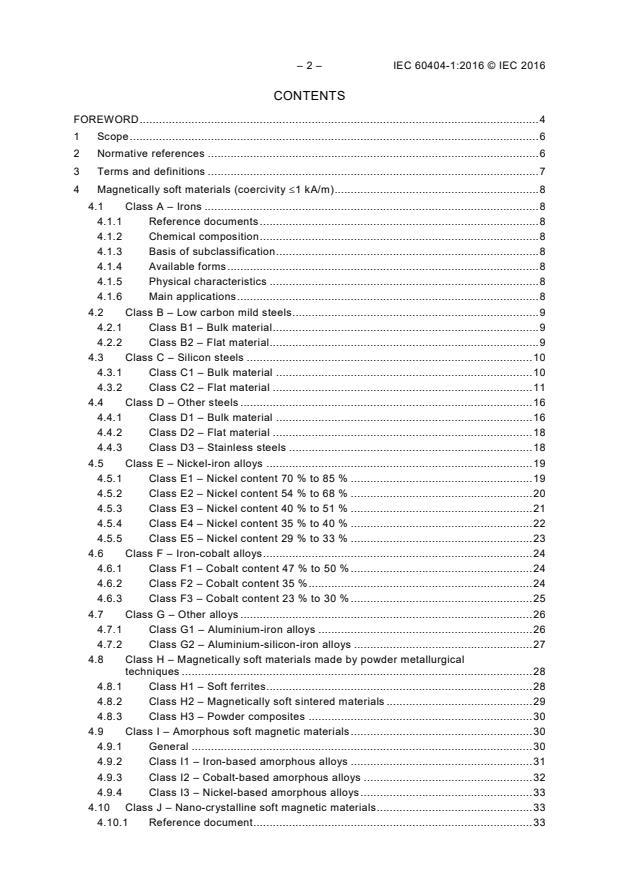

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Magnetically soft materials (coercivity ≤1 kA/m) . 7

4.1 Class A – Irons . 7

4.1.1 Reference documents . 7

4.1.2 Chemical composition . 7

4.1.3 Basis of subclassification . 7

4.1.4 Available forms . 7

4.1.5 Physical characteristics . 7

4.1.6 Main applications . 7

4.2 Class B – Low carbon mild steels . 8

4.2.1 Class B1 – Bulk material . 8

4.2.2 Class B2 – Flat material . 8

4.3 Class C – Silicon steels . 9

4.3.1 Class C1 – Bulk material . 9

4.3.2 Class C2 – Flat material . 10

4.4 Class D – Other steels . 15

4.4.1 Class D1 – Bulk material . 15

4.4.2 Class D2 – Flat material . 17

4.4.3 Class D3 – Stainless steels . 17

4.5 Class E – Nickel-iron alloys . 18

4.5.1 Class E1 – Nickel content 70 % to 85 % . 18

4.5.2 Class E2 – Nickel content 54 % to 68 % . 19

4.5.3 Class E3 – Nickel content 40 % to 51 % . 20

4.5.4 Class E4 – Nickel content 35 % to 40 % . 21

4.5.5 Class E5 – Nickel content 29 % to 33 % . 22

4.6 Class F – Iron-cobalt alloys . 23

4.6.1 Class F1 – Cobalt content 47 % to 50 % . 23

4.6.2 Class F2 – Cobalt content 35 % . 23

4.6.3 Class F3 – Cobalt content 23 % to 30 % . 24

4.7 Class G – Other alloys . 25

4.7.1 Class G1 – Aluminium-iron alloys . 25

4.7.2 Class G2 – Aluminium-silicon-iron alloys . 26

4.8 Class H – Magnetically soft materials made by powder metallurgical

techniques . 27

4.8.1 Class H1 – Soft ferrites . 27

4.8.2 Class H2 – Magnetically soft sintered materials . 28

4.8.3 Class H3 – Powder composites . 29

4.9 Class I – Amorphous soft magnetic materials . 29

4.9.1 General . 29

4.9.2 Class I1 – Iron-based amorphous alloys . 30

4.9.3 Class I2 – Cobalt-based amorphous alloys . 31

4.9.4 Class I3 – Nickel-based amorphous alloys . 32

4.10 Class J – Nano-crystalline soft magnetic materials . 32

4.10.1 Reference document. 32

4.10.2 Production process . 32

4.10.3 Chemical composition . 33

4.10.4 Basis of subclassification . 33

4.10.5 Available forms . 33

4.10.6 Physical characteristics . 33

4.10.7 Main applications . 33

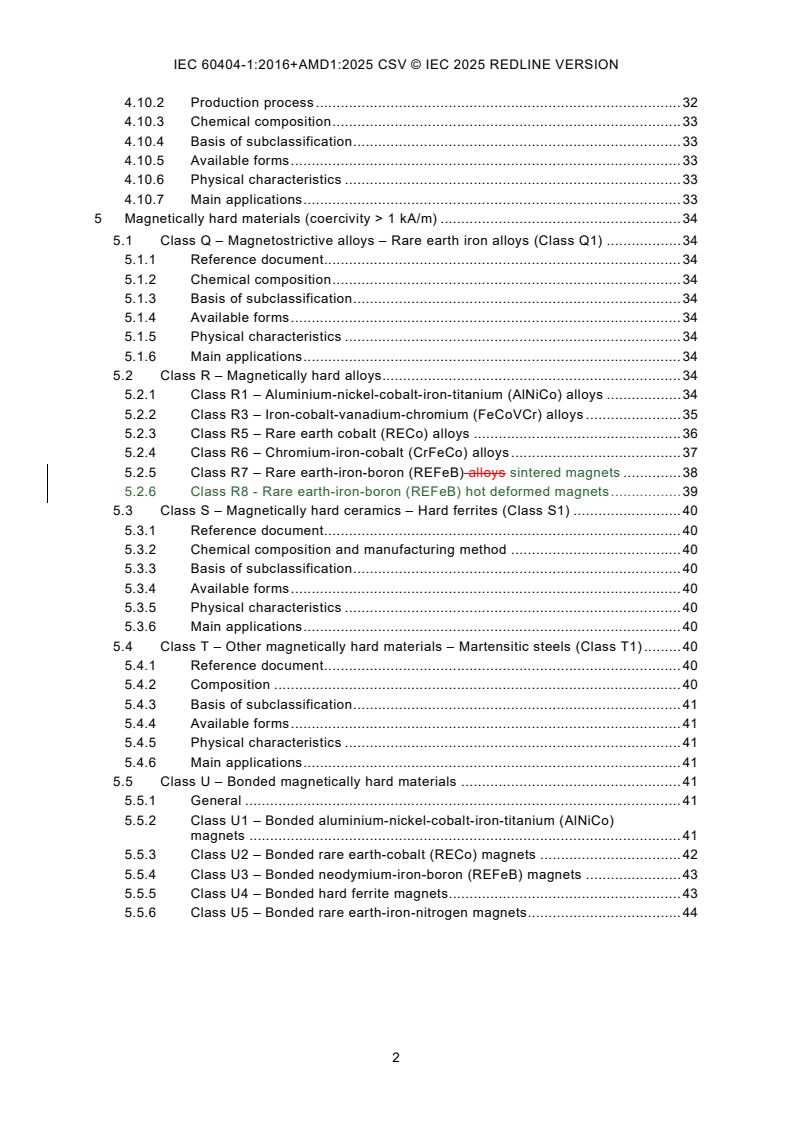

5 Magnetically hard materials (coercivity > 1 kA/m) . 34

5.1 Class Q – Magnetostrictive alloys – Rare earth iron alloys (Class Q1) . 34

5.1.1 Reference document. 34

5.1.2 Chemical composition . 34

5.1.3 Basis of subclassification . 34

5.1.4 Available forms . 34

5.1.5 Physical characteristics . 34

5.1.6 Main applications . 34

5.2 Class R – Magnetically hard alloys. 34

5.2.1 Class R1 – Aluminium-nickel-cobalt-iron-titanium (AlNiCo) alloys . 34

5.2.2 Class R3 – Iron-cobalt-vanadium-chromium (FeCoVCr) alloys . 35

5.2.3 Class R5 – Rare earth cobalt (RECo) alloys . 36

5.2.4 Class R6 – Chromium-iron-cobalt (CrFeCo) alloys . 37

5.2.5 Class R7 – Rare earth-iron-boron (REFeB) alloys sintered magnets . 38

5.2.6 Class R8 - Rare earth-iron-boron (REFeB) hot deformed magnets . 39

5.3 Class S – Magnetically hard ceramics – Hard ferrites (Class S1) . 40

5.3.1 Reference document. 40

5.3.2 Chemical composition and manufacturing method . 40

5.3.3 Basis of subclassification . 40

5.3.4 Available forms . 40

5.3.5 Physical characteristics . 40

5.3.6 Main applications . 40

5.4 Class T – Other magnetically hard materials – Martensitic steels (Class T1) . 40

5.4.1 Reference document. 40

5.4.2 Composition . 40

5.4.3 Basis of subclassification . 41

5.4.4 Available forms . 41

5.4.5 Physical characteristics . 41

5.4.6 Main applications . 41

5.5 Class U – Bonded magnetically hard materials . 41

5.5.1 General . 41

5.5.2 Class U1 – Bonded aluminium-nickel-cobalt-iron-titanium (AlNiCo)

magnets . 41

5.5.3 Class U2 – Bonded rare earth-cobalt (RECo) magnets . 42

5.5.4 Class U3 – Bonded neodymium-iron-boron (REFeB) magnets . 43

5.5.5 Class U4 – Bonded hard ferrite magnets. 43

5.5.6 Class U5 – Bonded rare earth-iron-nitrogen magnets . 44

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

Magnetic materials -

Part 1: Classification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s),

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 60404-1 edition 3.1 contains the third edition (2016-10) [documents 68/533/CDV and

68/555/RVC] and its amendment 1 (2025-07) [documents 68/780/CDV and 68/791A/RVC].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text.

A separate Final version with all changes accepted is available in this publication.

International Standard IEC 60404-1 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

This bilingual version (2017-12) corresponds to the monolingual English version, published in

2016-10.

This third edition cancels and replaces the second edition published in 2000 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Removal of all tables and values describing typical properties of the material to be

consistent with the aim of the document to be a classification and not a specification.

b) Enlargement of the Ni content for the classes E1 and E3.

c) Enlargement of the Co content for the classes F3.

d) Addition of a new class: U5 bonded rare earth-iron-nitrogen magnets.

The text of this standard is based on the following documents:

CDV Report on voting

68/533/CDV 68/555/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

The French version of this standard has not been voted upon.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60404 series, published under the general title Magnetic

materials, can be found on the IEC website.

The committee has decided that the contents of this document and its amendment will remain

unchanged until the stability date indicated on the IEC website under webstore.iec.ch in the

data related to the specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

1 Scope

This part of IEC 60404 is intended to classify commercially available magnetic materials.

The term "magnetic materials" denotes substances where the application requires the

existence of ferromagnetic or ferrimagnetic properties.

In this document, the classification of magnetic materials is based upon the generally

recognized existence of two main groups of products:

• soft magnetic materials (coercivity ≤1 000 A/m);

• hard magnetic materials (coercivity >1 000 A/m).

Within these main groups, the classification when appropriate recognizes the following

characteristics:

• the main alloying element and the metallurgical state and physical properties of the

material;

• when possible and convenient, the relationship between these characteristics is identified.

A classification by specific areas of application cannot be applied to all materials because

different materials can very often be used for the same application depending on the

characteristics required.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-151, International Electrotechnical Vocabulary – Part 151: Electrical and magnetic

devices

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60401-3, Terms and nomenclature for cores made of magnetically soft ferrites – Part 3:

Guidelines on the format of data appearing in manufacturers catalogues of transformer and

inductor cores

IEC 60404-2, Magnetic materials – Part 2: Methods of measurement of the magnetic

properties of electrical steel sheet and strip by means of an Epstein frame

IEC 60404-3, Magnetic materials – Part 3: Methods of measurement of the magnetic

properties of magnetic sheet and strip by means of a single sheet tester

IEC 60404-4, Magnetic materials – Part 4: Methods of measurement of d.c. magnetic

properties of iron and steel

IEC 60404-6, Magnetic materials – Part 6: Methods of measurement of the magnetic

properties of magnetically soft metallic and powder materials at frequencies in the range

20 Hz to 200 kHz by the use of ring specimens

IEC 60404-7, Magnetic materials – Part 7: Method of measurement of the coercivity of

magnetic materials in an open magnetic circuit

IEC 60404-8-1, Magnetic materials – Part 8-1: Specifications for individual materials –

Magnetically hard materials

IEC 60404-8-3, Magnetic materials – Part 8-3: Specifications for individual materials – Cold-

rolled electrical non-alloyed and alloyed steel sheet and strip delivered in the semi-processed

state

IEC 60404-8-4, Magnetic materials – Part 8-4: Specifications for individual materials – Cold-

rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state

IEC 60404-8-5, Magnetic materials – Part 8: Specifications for individual materials –

Section Five: Specification for steel sheet and strip with specified mechanical properties and

magnetic permeability

IEC 60404-8-6, Magnetic materials – Part 8-6: Specifications for individual materials – Soft

magnetic metallic materials

IEC 60404-8-7, Magnetic materials – Part 8-7: Specifications for individual materials –Cold-

rolled grain-oriented electrical steel strip and sheet delivered in the fully processed state

IEC 60404-8-8, Magnetic materials – Part 8: Specifications for individual materials –

Section 8: Specification for thin magnetic steel strip for use at medium frequencies

IEC 60404-8-9, Magnetic materials – Part 8: Specifications for individual materials –

Section 9: Standard specification for sintered soft magnetic materials

IEC 60404-8-10, Magnetic materials – Part 8-10: Specifications for individual materials –

Magnetic materials (iron and steel) for use in relays

IEC 60404-8-11, Magnetic materials - Part 8-11: Specifications for individual materials - Fe-

based amorphous strip delivered in the semi-processed state

IEC 60404-10, Magnetic materials – Part 10: Methods of measurement of magnetic properties

of magnetic sheet and strip at medium frequencies

ISO 4948-1, Steels – Classification – Part 1: Classification of steels into unalloyed and alloy

steels based on chemical composition

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-121,

IEC 60050-151, IEC 60050-221 and in the product standards of the IEC 60404-8 series apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

4 Magnetically soft materials (coercivity ≤1 kA/m)

4.1 Class A – Irons

4.1.1 Reference documents

These materials are covered by IEC 60404-8-6 and IEC 60404-8-10.

4.1.2 Chemical composition

The basic constituent of these materials is pure iron, and they are often referred to as

"commercially pure" or "magnetically soft" irons. The material also contains unavoidable

impurities that may affect magnetic properties. The amount of impurities that adversely affect

the remanence, coercivity, saturation, magnetic polarization and stability of the magnetic

properties are limited to produce the required magnetic properties for the proposed

application. For information the most significant impurities when they are present in these

materials are carbon (up to 0,03 %), silicon (up to 0,1 %), manganese (up to 0,2 %),

phosphorus (up to 0,015 %), sulphur (up to 0,03 %), aluminium (up to 0,08 %), titanium (up to

0,1 %) and vanadium (up to 0,1 %).

NOTE For improved free machining capability, the amount of phosphorus and sulphur can be higher than

indicated above.

4.1.3 Basis of subclassification

The recommended subclassification is based on coercivity values.

4.1.4 Available forms

These materials are available in a wide variety of forms. They may be supplied as slabs,

billets, ingots or forgings; as hot-rolled bar in rectangular and square cross-sections; as hot-

rolled wire rod in round, hexagonal and octagonal cross-sections; in cold-rolled and drawn

forms as bar and wire; as hot- or cold-rolled sheet and strip.

4.1.5 Physical characteristics

In addition to the values of coercivity, a more complete definition of these materials can be

based on the following characteristics:

saturation magnetic polarization, magnetic polarization at various

• magnetic:

values of magnetic field strength (from which permeability can be

derived), stability of characteristics with time;

• mechanical: hardness, suitability for punching operations, free machining

capability, deep drawing properties, tensile strength;

• metallurgical state: hot- or cold-worked, forged, deep drawn, fully processed state, i.e.

final annealed.

NOTE For material not delivered in the fully processed state, subclassification is based on the coercivity

measured after heat treatment according to the requirements of the product standard or the recommendations of

the manufacturer.

Ranges of specified values for the above-mentioned magnetic characteristics in the fully

processed state are given in the corresponding product specifications.

4.1.6 Main applications

The main applications are in DC relays, loudspeakers, electromagnets, magnetic clutches,

brakes, parts for magnetic circuits in instruments and control apparatus, as well as for pole

pieces and other DC parts for generators and motors.

4.2 Class B – Low carbon mild steels

4.2.1 Class B1 – Bulk material

4.2.1.1 Reference document

Some of these materials are covered by IEC 60404-8-10.

4.2.1.2 Chemical composition

The basic constituent of these materials is iron containing unavoidable impurities, together

with a low level of other elements which may arise from additions necessitated during the

manufacturing process. The amount of alloying elements is limited to that of a non-alloy steel

as defined in ISO 4948-1, in particular silicon is less than 0,5 %.

4.2.1.3 Basis of subclassification

The recommended subclassification is based on the coercivity.

4.2.1.4 Available forms

These materials are normally supplied in the form of castings or forgings in a final heat-

treated condition or partially machined to drawings supplied by the user or as bar, wire rod or

wire in the hot-rolled, cold-rolled or cold-drawn condition.

4.2.1.5 Physical characteristics

In addition to the coercivity a more complete definition of these materials can be based on the

following properties:

• magnetic: magnetic polarization at various values of magnetic field strength;

yield strength (or 0,2 % proof stress) elongation (L = 5 d ),

• mechanical:

o o

freedom from defects;

hot- or cold-worked, annealed to produce required magnetic

• metallurgical state:

characteristics.

Mechanical and non-destructive tests are made in accordance with the appropriate

ISO standards. Coercivity shall be measured in accordance with IEC 60404-7, other magnetic

properties in accordance with IEC 60404-4.

Ranges of typical values of magnetic and mechanical properties are given in the

corresponding product specification.

4.2.1.6 Main applications

The materials are used for large DC magnets where no mechanical strength is required, for

example, in deflection magnets in elementary particle physics and for relay applications.

4.2.2 Class B2 – Flat material

4.2.2.1 Reference documents

These materials are covered by IEC 60404-8-3, IEC 60404-8-4 and IEC 60404-8-10.

4.2.2.2 Chemical composition

The basic constituent of these materials is iron containing unavoidable impurities, together

with a low level of other elements which may arise from additions necessitated during the

manufacturing process. The amount of alloying elements is limited to that of non-alloy steel as

defined in ISO 4948-1, in particular silicon is less than 0,5 %. These materials can have an

annealing treatment after punching to enhance their magnetic properties.

4.2.2.3 Basis of subclassification

The recommended subclassification is based either on the specific total loss which is a

function of thickness and is normally measured at a magnetic polarization value of 1,5 T and

at normal industrial power frequencies or (for relay application) on the coercivity.

4.2.2.4 Available forms

These materials are supplied in the form of cold-rolled coils or sheets or (for relay application)

in the form of hot-rolled strip, sheet or plate.

4.2.2.5 Physical characteristics

In addition to specific total loss, a more complete definition of these materials can be based

on the following properties:

magnetic polarization at various values of magnetic field strength;

• magnetic:

suitability for punching operations, surface condition, stacking

• mechanical:

factor;

hot-rolled; hard state – i.e. cold-rolled; semi-processed state – i.e.

• metallurgical state:

annealed and finally cold-rolled;

fully processed state – i.e. final annealed.

NOTE For material delivered in the hard or semi-processed state, subclassification is based on the total specific

loss or coercivity measured after heat treatment according to the requirements of the product standard or

recommendations of the manufacturer.

thickness, width and (as required) length.

• dimensions:

Recommended nominal thicknesses for the cold-rolled materials are given in the

corresponding product specifications.

Magnetic measurements are made in accordance with IEC 60404-2, IEC 60404-3 or

IEC 60404-7.

Ranges of specified values of maximum specific total loss, after annealing, for the commonly

used thicknesses are also shown in the corresponding product specifications.

The specified maximum value of coercivity for relay material ranges from 40 A/m to 240 A/m.

4.2.2.6 Main applications

The materials are used in the manufacture of laminated cores for electrical apparatus and

especially small machines and for relay applications.

4.3 Class C – Silicon steels

4.3.1 Class C1 – Bulk material

4.3.1.1 Reference documents

Some of these materials are covered by IEC 60404-8-6 and IEC 60404-8-10.

4.3.1.2 Chemical composition

The basic constituent of these materials is iron in which the main alloying element is silicon

with a content of up to approximately 5 %.

4.3.1.3 Basis of subclassification

The recommended subclassification is based on coercivity values or on electrical resistivity

which is a function of silicon content.

4.3.1.4 Available forms

These materials are available as hot-rolled and cold-drawn bar, wire, ground bar and forging

billets and require heat treatment after mechanical working to achieve the required magnetic

properties.

4.3.1.5 Physical characteristics

In addition to the coercivity and the electrical resistivity, a more complete definition of these

materials can be based on the following characteristics:

• magnetic: saturation magnetic polarization, magnetic polarization at various

values of magnetic field strength, remanent magnetic polarization;

machinability, ductility, hardness;

• mechanical:

hot- or cold-worked, annealed to produce required magnetic

• metallurgical state:

characteristics.

4.3.1.6 Main applications

The main applications are for the magnetic circuits of relays, magnetic clutches, magnetic

pole pieces, stepping motors and gyro housings.

4.3.2 Class C2 – Flat material

4.3.2.1 Class C21 – Isotropic (non-oriented) steels for use at power frequencies

4.3.2.1.1 Reference documents

These materials are covered by IEC 60404-8-3, IEC 60404-8-4, IEC 60404-8-6 and

IEC 60404-8-10.

4.3.2.1.2 Chemical composition

The basic constituent of these materials is iron. The main alloying element is silicon, whose

content may be up to approximately 5 %. Other alloying elements, for example aluminium,

may also be present. The material also contains unavoidable impurities, together with a low

level of other elements which may arise from additions necessitated during the manufacturing

process.

4.3.2.1.3 Basis of subclassification

The recommended subclassification is based on the specific total loss which is a function of

thickness and normally measured at a magnetic polarization value of 1,5 T and at power

frequencies.

When the application demands it (for example relays), it may be more appropriate for the

subclassification to be based on coercivity or permeability.

___________

This describes a material which is substantially isotropic and deliberately processed to be so.

4.3.2.1.4 Available forms

These materials are normally supplied in the form of cold-rolled coils or sheets.

4.3.2.1.5 Physical characteristics

In addition to the values of specific total loss, a more complete definition of these materials

can be based on the following characteristics:

magnetic polarization at various values of magnetic field strength,

• magnetic:

specific apparent power for different values of magnetic polarization

anisotropy of loss;

type of surface insulation and its resistance, resistivity;

• electrical:

suitability for punching operations, ductility, tensile strength,

• mechanical:

hardness, surface condition and finish, stacking factor, flatness,

edge camber;

hard state, i.e. as cold rolled semi-processed state, i.e. annealed or

• metallurgical state:

annealed and temper rolled; fully-processed state, i.e. final

annealed;

NOTE For material delivered in the hard or semi-processed state, the subclassification is based on the specific

total losses measured after heat treatment according to the requirements of the product standard or the

recommendations of the manufacturer.

• dimensions: thickness, width and (as required) length.

The values of nominal thickness are given in the corresponding product specifications.

Magnetic measurements are made in accordance with IEC 60404-2 or IEC 60404-3. The

density values to be used for magnetic measurements should be as defined in the relevant

product standard. In other cases, the density values should be the subject of agreement.

Ranges of specified values of specific total loss, after final annealing, for four commonly used

thicknesses are shown in the corresponding product specifications.

4.3.2.1.6 Main application

These materials are used mainly in the magnetic circuits of electrical apparatus, particularly in

the parts of rotating machines in which the flux is not unidirectional. They may also be used

in electromagnetic relays, small transformers, chokes for fluorescent tubes, electrical meters,

shielding and magnetic poles of electron and proton synchrotrons.

4.3.2.2 Class C22 – Anisotropic (oriented) steels for use at power frequencies

4.3.2.2.1 Reference documents

These materials are covered by IEC 60404-8-6, IEC 60404-8-7 and IEC 60404-8-8.

4.3.2.2.2 Chemical composition

The basic constituent of these materials is iron and the main alloying element is silicon

(approximately 3 %), together with unavoidable impurities and low levels of other elements

which may arise from additions necessitated during the manufacturing process. This type of

magnetic material possesses anisotropic properties (orientation) such that the direction

parallel to the axis of rolling shows the lowest values of specific total losses and the highest

permeability. These properties are sensitive to mechanical treatment, and stress relief

annealing may be used to optimize the inherent properties.

___________

This describes a material which is substantially anisotropic and deliberately processed to be so.

4.3.2.2.3 Basis of subclassification

The recommended subclassification is based on the perfection of crystal orientation

expressed by the magnetic polarization for a magnetic field strength of 800 A/m and on the

specific total loss, which is a function of thickness and of the orientation, and is normally

measured at magnetic polarization values of 1,5 T or 1,7 T and at power frequencies.

With the revision of IEC 60404-8-7 in 2020, an additional subclassification has been

introduced in order to distinguish between high-permeability grades with and without magnetic

domain refinement.

4.3.2.2.4 Available forms

These materials are normally supplied in the form of cold-rolled coils or sheets having an

inorganic insulating coating.

4.3.2.2.5 Physical characteristics

In addition to the perfection of crystal orientation and to the values of specific total loss, a

more complete definition of these materials can be based on the following characteristics:

magnetic polarization at various values of magnetic field strength;

• magnetic:

whether or not the material has been treated with a technology for

• Domain Refined

(DR) state: magnetic domain refinement;

• electrical: type of surface insulation and its resistance, resistivity;

ductility, surface condition and finish, stacking factor, flatness, edge

• mechanical:

camber;

annealed and fully recrystallized;

• metallurgical state:

thickness, width and (if required) length.

• dimensions:

The values of nominal thickness normally used are given in the corresponding product

specifications.

Magnetic measurements are made in accordance with IEC 60404-2 or IEC 60404-3. The

density used for calculations is normally 7,65 kg/dm³ and test pieces are taken parallel to the

axis of rolling and, before measurement, undergo stress relief annealing in accordance with

the recommendations of the manufacturer.

Ranges of specified values of maximum specific total loss, after stress relief annealing, for the

normally used thicknesses are also shown in the corresponding product specifications.

NOTE According to IEC 60404-8-7, the magnetic properties of non-heatproof magnetic domain refined

high-permeability grades are determined according to IEC 60404-3 without applying a supplementary heat

treatment, and in the case of heatproof magnetic domain refinement grades, these properties are determined in

accordance with IEC 60404-2 after the required heat treatment.

In addition, materials which are not yet specified in IEC 60404-8-7 are available.

4.3.2.2.6 Main applications

These materials are used mainly for the manufacture of magnetic cores in which the magnetic

flux paths are substantially parallel to the direction of cold-rolling, as for example in

transformer cores.

4.3.2.3 Class C23 – Thin silicon steels

4.3.2.3.1 Reference document

These materials are covered by IEC 60404-8-8.

4.3.2.3.2 Chemical composition

The basic constituent of these materials is iron. The main alloying element is silicon, whose

content may be between 2 % and 4 %. Other alloying elements, namely aluminium, may also

be present. The material also contains unavoidable impurities, together with a low level of

other elements which may arise from additions necessitated during the manufacturing

process.

4.3.2.3.3 Basis of subclassification

The recommended subclassification is based on the magnetic anisotropy and the specific total

loss which is a function of thickness, magnetic polarization value and test frequency.

4.3.2.3.4 Available forms

These materials are normally supplied in the form of cold-rolled coils or sheets.

4.3.2.3.5 Physical characteristics

In addition to the values of specific total loss, a more complete definition of these materials

can be based on the following characteristics:

magnetic polarization at various values of magnetic field strength;

• magnetic:

type of surface insulation and its resistance, resistivity;

• electrical:

ductility, stacking factor, flatness, edge camber;

• mechanical:

annealed and fully recrystallized;

• metallurgical state:

thickness, width and (if required) length.

• dimensions:

The specified values of maximum specific total loss for the commonly used thicknesses are

shown in the corresponding product specification.

The magnetic properties are determined in accordance with IEC 60404-10 and the test

specimens are prepared as described in the specification.

4.3.2.3.6 Main applications

These materials are mainly used in magnetic circuits of transformers and rotating machines

operating at frequencies above 100 Hz.

4.3.2.4 Class C24 – Steels with specified mechanical properties and specific total

loss

4.3.2.4.1 Reference document

These materials are not covered by an IEC publication.

4.3.2.4.2 Chemical composition

The basic constituent of these materials is iron. The main alloying element is silicon whose

content may be between 2 % and 5 %. Other alloying elements, such as aluminium,

manganese, may be added to increase strength and improve magnetic properties. The

material also contains unavoidable impurities, together with a low level of other elements

which may arise from additions necessitated during the manufacturing process.

4.3.2.4.3 Basis of subclassification

The recommended subclassification is based on the yield strength.

4.3.2.4.4 Available forms

These materials are normally supplied in the form of cold-rolled and final annealed coils or

sheet.

4.3.2.4.5 Physical characteristics

In addition to the yield strength, a more complete definition of these materials can be based

on the following characteristics:

specific total loss, magnetic polarization at various values of

• magnetic:

magnetic field strength;

surface insulation and its resistance, resistivity;

• electrical:

tensile strength, elongation, hardness, stacking factor;

• mechanical:

fully processed, i.e. final annealed;

• metallurgical state:

thickness, width and (if required) length.

• dimensions:

4.3.2.4.6 Main applications

These materials are generally used under conditions of alternating flux for the stressed parts

of magnetic circuits such as rotors of high-speed rotating electric machines.

4.3.2.5 Class C25 – 6,5 % silicon steels

4.3.2.5.1 Reference document

These materials are not covered by an IEC publication.

4.3.2.5.2 Chemical composition

The basic constituent of these materials is iron. The main alloying element is silicon whose

content may be between 6 % and 7 %. Other alloying elements may also be present. The

material also contains unavoidable impu

...

IEC 60404-1 ®

Edition 3.0 2016-10

INTERNATIONAL

STANDARD

Magnetic materials –

Part 1: Classification

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60404-1 ®

Edition 3.0 2016-10

INTERNATIONAL

STANDARD

Magnetic materials –

Part 1: Classification

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.030 ISBN 978-2-8322-3671-0

– 2 – IEC 60404-1:2016 © IEC 2016

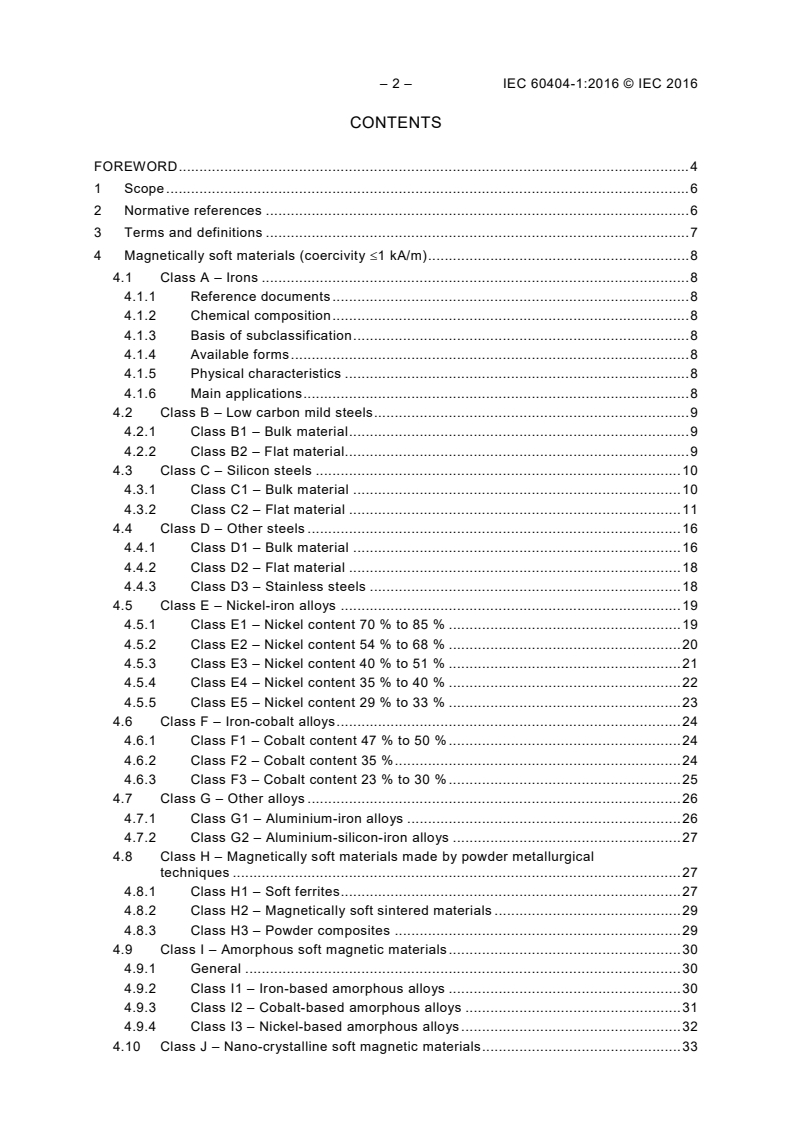

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Magnetically soft materials (coercivity ≤1 kA/m) . 8

4.1 Class A – Irons . 8

4.1.1 Reference documents . 8

4.1.2 Chemical composition . 8

4.1.3 Basis of subclassification . 8

4.1.4 Available forms . 8

4.1.5 Physical characteristics . 8

4.1.6 Main applications . 8

4.2 Class B – Low carbon mild steels . 9

4.2.1 Class B1 – Bulk material . 9

4.2.2 Class B2 – Flat material. 9

4.3 Class C – Silicon steels . 10

4.3.1 Class C1 – Bulk material . 10

4.3.2 Class C2 – Flat material . 11

4.4 Class D – Other steels . 16

4.4.1 Class D1 – Bulk material . 16

4.4.2 Class D2 – Flat material . 18

4.4.3 Class D3 – Stainless steels . 18

4.5 Class E – Nickel-iron alloys . 19

4.5.1 Class E1 – Nickel content 70 % to 85 % . 19

4.5.2 Class E2 – Nickel content 54 % to 68 % . 20

4.5.3 Class E3 – Nickel content 40 % to 51 % . 21

4.5.4 Class E4 – Nickel content 35 % to 40 % . 22

4.5.5 Class E5 – Nickel content 29 % to 33 % . 23

4.6 Class F – Iron-cobalt alloys . 24

4.6.1 Class F1 – Cobalt content 47 % to 50 % . 24

4.6.2 Class F2 – Cobalt content 35 % . 24

4.6.3 Class F3 – Cobalt content 23 % to 30 % . 25

4.7 Class G – Other alloys . 26

4.7.1 Class G1 – Aluminium-iron alloys . 26

4.7.2 Class G2 – Aluminium-silicon-iron alloys . 27

4.8 Class H – Magnetically soft materials made by powder metallurgical

techniques . 27

4.8.1 Class H1 – Soft ferrites . 27

4.8.2 Class H2 – Magnetically soft sintered materials . 29

4.8.3 Class H3 – Powder composites . 29

4.9 Class I – Amorphous soft magnetic materials . 30

4.9.1 General . 30

4.9.2 Class I1 – Iron-based amorphous alloys . 30

4.9.3 Class I2 – Cobalt-based amorphous alloys . 31

4.9.4 Class I3 – Nickel-based amorphous alloys . 32

4.10 Class J – Nano-crystalline soft magnetic materials . 33

4.10.1 Reference document . 33

4.10.2 Production process . 33

4.10.3 Chemical composition . 33

4.10.4 Basis of subclassification . 33

4.10.5 Available forms . 33

4.10.6 Physical characteristics . 33

4.10.7 Main applications . 34

5 Magnetically hard materials (coercivity > 1 kA/m) . 34

5.1 Class Q – Magnetostrictive alloys – Rare earth iron alloys (Class Q1) . 34

5.1.1 Reference document . 34

5.1.2 Chemical composition . 34

5.1.3 Basis of subclassification . 34

5.1.4 Available forms . 34

5.1.5 Physical characteristics . 34

5.1.6 Main applications . 35

5.2 Class R – Magnetically hard alloys . 35

5.2.1 Class R1 – Aluminium-nickel-cobalt-iron-titanium (AlNiCo) alloys . 35

5.2.2 Class R3 – Iron-cobalt-vanadium-chromium (FeCoVCr) alloys . 36

5.2.3 Class R5 – Rare earth cobalt (RECo) alloys . 36

5.2.4 Class R6 – Chromium-iron-cobalt (CrFeCo) alloys . 37

5.2.5 Class R7 – Rare earth-iron-boron (REFeB) alloys . 38

5.3 Class S – Magnetically hard ceramics – Hard ferrites (Class S1) . 39

5.3.1 Reference document . 39

5.3.2 Chemical composition and manufacturing method . 39

5.3.3 Basis of subclassification . 39

5.3.4 Available forms . 39

5.3.5 Physical characteristics . 40

5.3.6 Main applications . 40

5.4 Class T – Other magnetically hard materials – Martensitic steels (Class T1) . 40

5.4.1 Reference document . 40

5.4.2 Composition . 40

5.4.3 Basis of subclassification . 40

5.4.4 Available forms . 40

5.4.5 Physical characteristics . 40

5.4.6 Main applications . 41

5.5 Class U – Bonded magnetically hard materials. 41

5.5.1 General . 41

5.5.2 Class U1 – Bonded aluminium-nickel-cobalt-iron-titanium (AlNiCo)

magnets . 41

5.5.3 Class U2 – Bonded rare earth-cobalt (RECo) magnets . 42

5.5.4 Class U3 – Bonded neodymium-iron-boron (REFeB) magnets . 42

5.5.5 Class U4 – Bonded hard ferrite magnets . 43

5.5.6 Class U5 – Bonded rare earth-iron-nitrogen magnets . 44

– 4 – IEC 60404-1:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 1: Classification

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60404-1 has been prepared by IEC technical committee 68:

Magnetic alloys and steels.

This third edition cancels and replaces the second edition published in 2000 and constitutes a

technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) Removal of all tables and values describing typical properties of the material to be

consistent with the aim of the document to be a classification and not a specification.

b) Enlargement of the Ni content for the classes E1 and E3.

c) Enlargement of the Co content for the classes F3.

d) Addition of a new class: U5 bonded rare earth-iron-nitrogen magnets.

The text of this standard is based on the following documents:

CDV Report on voting

68/533/CDV 68/555/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60404 series, published under the general title Magnetic

materials, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 60404-1:2016 © IEC 2016

MAGNETIC MATERIALS –

Part 1: Classification

1 Scope

This part of IEC 60404 is intended to classify commercially available magnetic materials.

The term "magnetic materials" denotes substances where the application requires the

existence of ferromagnetic or ferrimagnetic properties.

In this document, the classification of magnetic materials is based upon the generally

recognized existence of two main groups of products:

• soft magnetic materials (coercivity ≤1 000 A/m);

• hard magnetic materials (coercivity >1 000 A/m).

Within these main groups, the classification when appropriate recognizes the following

characteristics:

• the main alloying element and the metallurgical state and physical properties of the

material;

• when possible and convenient, the relationship between these characteristics is identified.

A classification by specific areas of application cannot be applied to all materials because

different materials can very often be used for the same application depending on the

characteristics required.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-151, International Electrotechnical Vocabulary – Part 151: Electrical and magnetic

devices

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60401-3, Terms and nomenclature for cores made of magnetically soft ferrites – Part 3:

Guidelines on the format of data appearing in manufacturers catalogues of transformer and

inductor cores

IEC 60404-2, Magnetic materials – Part 2: Methods of measurement of the magnetic

properties of electrical steel sheet and strip by means of an Epstein frame

IEC 60404-3, Magnetic materials – Part 3: Methods of measurement of the magnetic

properties of magnetic sheet and strip by means of a single sheet tester

IEC 60404-4, Magnetic materials – Part 4: Methods of measurement of d.c. magnetic

properties of iron and steel

IEC 60404-6, Magnetic materials – Part 6: Methods of measurement of the magnetic

properties of magnetically soft metallic and powder materials at frequencies in the range

20 Hz to 200 kHz by the use of ring specimens

IEC 60404-7, Magnetic materials – Part 7: Method of measurement of the coercivity of

magnetic materials in an open magnetic circuit

IEC 60404-8-1, Magnetic materials – Part 8-1: Specifications for individual materials –

Magnetically hard materials

IEC 60404-8-3, Magnetic materials – Part 8-3: Specifications for individual materials – Cold-

rolled electrical non-alloyed and alloyed steel sheet and strip delivered in the semi-processed

state

IEC 60404-8-4, Magnetic materials – Part 8-4: Specifications for individual materials – Cold-

rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state

IEC 60404-8-5, Magnetic materials – Part 8: Specifications for individual materials –

Section Five: Specification for steel sheet and strip with specified mechanical properties and

magnetic permeability

IEC 60404-8-6, Magnetic materials – Part 8-6: Specifications for individual materials – Soft

magnetic metallic materials

IEC 60404-8-7, Magnetic materials – Part 8-7: Specifications for individual materials –Cold-

rolled grain-oriented electrical steel strip and sheet delivered in the fully processed state

IEC 60404-8-8, Magnetic materials – Part 8: Specifications for individual materials –

Section 8: Specification for thin magnetic steel strip for use at medium frequencies

IEC 60404-8-9, Magnetic materials – Part 8: Specifications for individual materials –

Section 9: Standard specification for sintered soft magnetic materials

IEC 60404-8-10, Magnetic materials – Part 8-10: Specifications for individual materials –

Magnetic materials (iron and steel) for use in relays

IEC 60404-10, Magnetic materials. Part 10: Methods of measurement of magnetic properties

of magnetic sheet and strip at medium frequencies

ISO 4948-1, Steels – Classification – Part 1: Classification of steels into unalloyed and alloy

steels based on chemical composition

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-121,

IEC 60050-151, IEC 60050-221 and in the product standards of the IEC 60404-8 series apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

– 8 – IEC 60404-1:2016 © IEC 2016

4 Magnetically soft materials (coercivity ≤1 kA/m)

4.1 Class A – Irons

4.1.1 Reference documents

These materials are covered by IEC 60404-8-6 and IEC 60404-8-10.

4.1.2 Chemical composition

The basic constituent of these materials is pure iron, and they are often referred to as

"commercially pure" or "magnetically soft" irons. The material also contains unavoidable

impurities that may affect magnetic properties. The amount of impurities that adversely affect

the remanence, coercivity, saturation, magnetic polarization and stability of the magnetic

properties are limited to produce the required magnetic properties for the proposed

application. For information the most significant impurities when they are present in these

materials are carbon (up to 0,03 %), silicon (up to 0,1 %), manganese (up to 0,2 %),

phosphorus (up to 0,015 %), sulphur (up to 0,03 %), aluminium (up to 0,08 %), titanium (up to

0,1 %) and vanadium (up to 0,1 %).

NOTE For improved free machining capability, the amount of phosphorus and sulphur can be higher than

indicated above.

4.1.3 Basis of subclassification

The recommended subclassification is based on coercivity values.

4.1.4 Available forms

These materials are available in a wide variety of forms. They may be supplied as slabs,

billets, ingots or forgings; as hot-rolled bar in rectangular and square cross-sections; as hot-

rolled wire rod in round, hexagonal and octagonal cross-sections; in cold-rolled and drawn

forms as bar and wire; as hot- or cold-rolled sheet and strip.

4.1.5 Physical characteristics

In addition to the values of coercivity, a more complete definition of these materials can be

based on the following characteristics:

saturation magnetic polarization, magnetic polarization at various

• magnetic:

values of magnetic field strength (from which permeability can be

derived), stability of characteristics with time;

• mechanical: hardness, suitability for punching operations, free machining

capability, deep drawing properties, tensile strength;

• metallurgical state: hot- or cold-worked, forged, deep drawn, fully processed state, i.e.

final annealed.

NOTE For material not delivered in the fully processed state, subclassification is based on the coercivity

measured after heat treatment according to the requirements of the product standard or the recommendations of

the manufacturer.

Ranges of specified values for the above-mentioned magnetic characteristics in the fully

processed state are given in the corresponding product specifications.

4.1.6 Main applications

The main applications are in DC relays, loudspeakers, electromagnets, magnetic clutches,

brakes, parts for magnetic circuits in instruments and control apparatus, as well as for pole

pieces and other DC parts for generators and motors.

4.2 Class B – Low carbon mild steels

4.2.1 Class B1 – Bulk material

4.2.1.1 Reference document

Some of these materials are covered by IEC 60404-8-10.

4.2.1.2 Chemical composition

The basic constituent of these materials is iron containing unavoidable impurities, together

with a low level of other elements which may arise from additions necessitated during the

manufacturing process. The amount of alloying elements is limited to that of a non-alloy steel

as defined in ISO 4948-1, in particular silicon is less than 0,5 %.

4.2.1.3 Basis of subclassification

The recommended subclassification is based on the coercivity.

4.2.1.4 Available forms

These materials are normally supplied in the form of castings or forgings in a final heat-

treated condition or partially machined to drawings supplied by the user or as bar, wire rod or

wire in the hot-rolled, cold-rolled or cold-drawn condition.

4.2.1.5 Physical characteristics

In addition to the coercivity a more complete definition of these materials can be based on the

following properties:

magnetic polarization at various values of magnetic field strength;

• magnetic:

yield strength (or 0,2 % proof stress) elongation (L = 5 d ),

• mechanical:

o o

freedom from defects;

hot- or cold-worked, annealed to produce required magnetic

• metallurgical state:

characteristics.

Mechanical and non-destructive tests are made in accordance with the appropriate

ISO standards. Coercivity shall be measured in accordance with IEC 60404-7, other magnetic

properties in accordance with IEC 60404-4.

Ranges of typical values of magnetic and mechanical properties are given in the

corresponding product specification.

4.2.1.6 Main applications

The materials are used for large DC magnets where no mechanical strength is required, for

example, in deflection magnets in elementary particle physics and for relay applications.

4.2.2 Class B2 – Flat material

4.2.2.1 Reference documents

These materials are covered by IEC 60404-8-3, IEC 60404-8-4 and IEC 60404-8-10.

4.2.2.2 Chemical composition

The basic constituent of these materials is iron containing unavoidable impurities, together

with a low level of other elements which may arise from additions necessitated during the

manufacturing process. The amount of alloying elements is limited to that of non-alloy steel as

– 10 – IEC 60404-1:2016 © IEC 2016

defined in ISO 4948-1, in particular silicon is less than 0,5 %. These materials can have an

annealing treatment after punching to enhance their magnetic properties.

4.2.2.3 Basis of subclassification

The recommended subclassification is based either on the specific total loss which is a

function of thickness and is normally measured at a magnetic polarization value of 1,5 T and

at normal industrial power frequencies or (for relay application) on the coercivity.

4.2.2.4 Available forms

These materials are supplied in the form of cold-rolled coils or sheets or (for relay application)

in the form of hot-rolled strip, sheet or plate.

4.2.2.5 Physical characteristics

In addition to specific total loss, a more complete definition of these materials can be based

on the following properties:

magnetic polarization at various values of magnetic field strength;

• magnetic:

suitability for punching operations, surface condition, stacking

• mechanical:

factor;

hot-rolled; hard state – i.e. cold-rolled; semi-processed state – i.e.

• metallurgical state:

annealed and finally cold-rolled;

fully processed state – i.e. final annealed.

NOTE For material delivered in the hard or semi-processed state, subclassification is based on the total specific

loss or coercivity measured after heat treatment according to the requirements of the product standard or

recommendations of the manufacturer.

thickness, width and (as required) length.

• dimensions:

Recommended nominal thicknesses for the cold-rolled materials are given in the

corresponding product specifications.

Magnetic measurements are made in accordance with IEC 60404-2, IEC 60404-3 or

IEC 60404-7.

Ranges of specified values of maximum specific total loss, after annealing, for the commonly

used thicknesses are also shown in the corresponding product specifications.

The specified maximum value of coercivity for relay material ranges from 40 A/m to 240 A/m.

4.2.2.6 Main applications

The materials are used in the manufacture of laminated cores for electrical apparatus and

especially small machines and for relay applications.

4.3 Class C – Silicon steels

4.3.1 Class C1 – Bulk material

4.3.1.1 Reference documents

Some of these materials are covered by IEC 60404-8-6 and IEC 60404-8-10.

4.3.1.2 Chemical composition

The basic constituent of these materials is iron in which the main alloying element is silicon

with a content of up to approximately 5 %.

4.3.1.3 Basis of subclassification

The recommended subclassification is based on coercivity values or on electrical resistivity

which is a function of silicon content.

4.3.1.4 Available forms

These materials are available as hot-rolled and cold-drawn bar, wire, ground bar and forging

billets and require heat treatment after mechanical working to achieve the required magnetic

properties.

4.3.1.5 Physical characteristics

In addition to the coercivity and the electrical resistivity, a more complete definition of these

materials can be based on the following characteristics:

saturation magnetic polarization, magnetic polarization at various

• magnetic:

values of magnetic field strength, remanent magnetic polarization;

machinability, ductility, hardness;

• mechanical:

hot- or cold-worked, annealed to produce required magnetic

• metallurgical state:

characteristics.

4.3.1.6 Main applications

The main applications are for the magnetic circuits of relays, magnetic clutches, magnetic

pole pieces, stepping motors and gyro housings.

4.3.2 Class C2 – Flat material

4.3.2.1 Class C21 – Isotropic (non-oriented) steels for use at power frequencies

4.3.2.1.1 Reference documents

These materials are covered by IEC 60404-8-3, IEC 60404-8-4, IEC 60404-8-6 and

IEC 60404-8-10.

4.3.2.1.2 Chemical composition

The basic constituent of these materials is iron. The main alloying element is silicon, whose

content may be up to approximately 5 %. Other alloying elements, for example aluminium,

may also be present. The material also contains unavoidable impurities, together with a low

level of other elements which may arise from additions necessitated during the manufacturing

process.

4.3.2.1.3 Basis of subclassification

The recommended subclassification is based on the specific total loss which is a function of

thickness and normally measured at a magnetic polarization value of 1,5 T and at power

frequencies.

When the application demands it (for example relays), it may be more appropriate for the

subclassification to be based on coercivity or permeability.

____________

This describes a material which is substantially isotropic and deliberately processed to be so.

– 12 – IEC 60404-1:2016 © IEC 2016

4.3.2.1.4 Available forms

These materials are normally supplied in the form of cold-rolled coils or sheets.

4.3.2.1.5 Physical characteristics

In addition to the values of specific total loss, a more complete definition of these materials

can be based on the following characteristics:

magnetic polarization at various values of magnetic field strength,

• magnetic:

specific apparent power for different values of magnetic polarization

anisotropy of loss;

type of surface insulation and its resistance, resistivity;

• electrical:

suitability for punching operations, ductility, tensile strength,

• mechanical:

hardness, surface condition and finish, stacking factor, flatness,

edge camber;

hard state, i.e. as cold rolled semi-processed state, i.e. annealed or

• metallurgical state:

annealed and temper rolled; fully-processed state, i.e. final

annealed;

NOTE For material delivered in the hard or semi-processed state, the subclassification is based on the specific

total losses measured after heat treatment according to the requirements of the product standard or the

recommendations of the manufacturer.

• dimensions: thickness, width and (as required) length.

The values of nominal thickness are given in the corresponding product specifications.

Magnetic measurements are made in accordance with IEC 60404-2 or IEC 60404-3. The