IEC 60404-8-4:2022

(Main)Magnetic materials - Part 8-4: Specifications for individual materials - Cold-rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state

Magnetic materials - Part 8-4: Specifications for individual materials - Cold-rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state

IEC 60404-8-4:2022 defines the grades of cold-rolled non-oriented electrical steel strip and sheet in nominal thicknesses of 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00 mm. In particular, it gives general requirements, magnetic properties, geometric characteristics, tolerances and technological characteristics, as well as inspection procedure. The nominal thickness 0,47 mm applies to the grades for use at 60 Hz only. This document applies to cold-rolled non-oriented electrical steel strip and sheet supplied in the fully-processed state, i.e. the final annealed condition, in coils or sheets, and intended for the construction of magnetic circuits. This document does not apply to materials supplied in the semi-processed state. This edition includes the following significant technical changes with respect to the previous edition:

- modification of terms and technical requirements concerning geometrical characteristics to be consistent with IEC 60404-9:2018;

- insertion of Table 3 - Tolerances on nominal thickness;

- change of the length of test specimen for determination of geometrical characteristics from 2 m to 1 m.

Matériaux magnétiques - Partie 8-4: Spécifications pour matériaux particuliers - Bandes et tôles magnétiques en acier à grains non orientés, laminées à froid et livrées à l'état fini

L'IEC 60404-8-4:2022 définit les qualités des bandes et tôles magnétiques en acier à grains non orientés, laminées à froid, d'épaisseurs nominales 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm et 1,00 mm. Elle définit notamment les exigences générales, les caractéristiques magnétiques, les caractéristiques géométriques, les tolérances et les caractéristiques technologiques, ainsi que les procédures de contrôle applicables. L'épaisseur nominale 0,47 mm s'applique aux qualités pour utilisation à 60 Hz seulement. Le présent document s'applique aux bandes et tôles magnétiques en acier à grains non orientés, laminées à froid, livrées à l'état fini, c'est-à-dire à l'état de recuit final, en bobines ou en tôles et destinées à la construction de circuits magnétiques. Le présent document ne s'applique pas aux matériaux livrés à l'état semi-fini. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- modification des termes et des exigences techniques concernant les caractéristiques géométriques dans un souci de cohérence avec l'IEC 60404-9:2018;

- insertion du Tableau 3 - Tolérances sur l'épaisseur nominale;

- modification de la longueur de l'éprouvette pour la détermination des caractéristiques géométriques de 2 m à 1 m.

General Information

- Status

- Published

- Publication Date

- 20-Sep-2022

- Technical Committee

- TC 68 - Magnetic alloys and steels

- Drafting Committee

- WG 1 - TC 68/WG 1

- Current Stage

- PPUB - Publication issued

- Start Date

- 21-Sep-2022

- Completion Date

- 24-Oct-2022

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60404-8-4:2022 specifies grades and delivery requirements for cold-rolled non-oriented electrical steel strip and sheet supplied in the fully-processed (final annealed) state. The standard covers nominal thicknesses of 0.35 mm, 0.47 mm, 0.50 mm, 0.65 mm and 1.00 mm (the 0.47 mm grade is specified for use at 60 Hz only). It defines general requirements, magnetic properties, geometric characteristics, tolerances, technological characteristics and inspection procedures for materials intended for magnetic circuits. This part applies to coils or sheets in the fully-processed state and does not cover semi-processed materials (see IEC 60404-8-3).

Key topics and technical requirements

- Magnetic properties: Defined grades and measured using standardized methods (Epstein method referenced to IEC 60404-2). Tables provide magnetic polarization, specific total loss and anisotropy of loss where applicable.

- Geometrical characteristics & tolerances: Nominal thickness tolerances (Table 3), width and length tolerances, edge wave (wave factor), residual curvature, edge camber and related measurement methods. Test specimen length for geometric testing revised to 1 m (was 2 m).

- Technological characteristics: Density, stacking factor, number of bends, deviation from shearing line (internal stress) and other manufacturability criteria relevant to assembly and lamination.

- Inspection & testing procedures: Sampling, specimen preparation, test methods, retests, plus marking, labelling, packaging and complaint handling requirements.

- Classification: Grades correspond to Class C.21 of IEC 60404-1.

- Consistency updates: Terminology and geometric requirements aligned with IEC 60404-9:2018.

Practical applications and who uses this standard

IEC 60404-8-4 is essential for:

- Motor and generator designers selecting lamination steel for magnetic circuits.

- Transformer and electrical equipment manufacturers specifying sheet or strip for core construction.

- Material suppliers and steel producers setting product grades and certificates.

- Quality assurance and testing laboratories performing magnetic and geometric tests.

- Procurement and purchasing teams creating compliant specifications and contracts.

Practical value:

- Ensures consistent magnetic performance and mechanical tolerances across suppliers.

- Reduces risk in core assembly (stacking factor, flatness, edge condition).

- Facilitates compliance with international testing methods (Epstein test) and interoperability with related IEC 60404 parts.

Related standards

- IEC 60404-1 (classification)

- IEC 60404-2 (Epstein method for magnetic loss and properties)

- IEC 60404-8-3 (semi-processed cold-rolled non-oriented steel)

- IEC 60404-9:2018 (geometrical characteristics terminology)

Keywords: IEC 60404-8-4, cold-rolled non-oriented electrical steel, non-oriented electrical steel strip and sheet, magnetic materials, fully-processed state, Epstein method, Class C.21, tolerances, annealed.

Buy Documents

IEC 60404-8-4:2022 RLV - Magnetic materials - Part 8-4: Specifications for individual materials - Cold-rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state Released:9/21/2022 Isbn:9782832257357

IEC 60404-8-4:2022 - Magnetic materials - Part 8-4: Specifications for individual materials - Cold-rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state Released:9/21/2022 Isbn:9782832257081

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60404-8-4:2022 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Magnetic materials - Part 8-4: Specifications for individual materials - Cold-rolled non-oriented electrical steel strip and sheet delivered in the fully-processed state". This standard covers: IEC 60404-8-4:2022 defines the grades of cold-rolled non-oriented electrical steel strip and sheet in nominal thicknesses of 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00 mm. In particular, it gives general requirements, magnetic properties, geometric characteristics, tolerances and technological characteristics, as well as inspection procedure. The nominal thickness 0,47 mm applies to the grades for use at 60 Hz only. This document applies to cold-rolled non-oriented electrical steel strip and sheet supplied in the fully-processed state, i.e. the final annealed condition, in coils or sheets, and intended for the construction of magnetic circuits. This document does not apply to materials supplied in the semi-processed state. This edition includes the following significant technical changes with respect to the previous edition: - modification of terms and technical requirements concerning geometrical characteristics to be consistent with IEC 60404-9:2018; - insertion of Table 3 - Tolerances on nominal thickness; - change of the length of test specimen for determination of geometrical characteristics from 2 m to 1 m.

IEC 60404-8-4:2022 defines the grades of cold-rolled non-oriented electrical steel strip and sheet in nominal thicknesses of 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00 mm. In particular, it gives general requirements, magnetic properties, geometric characteristics, tolerances and technological characteristics, as well as inspection procedure. The nominal thickness 0,47 mm applies to the grades for use at 60 Hz only. This document applies to cold-rolled non-oriented electrical steel strip and sheet supplied in the fully-processed state, i.e. the final annealed condition, in coils or sheets, and intended for the construction of magnetic circuits. This document does not apply to materials supplied in the semi-processed state. This edition includes the following significant technical changes with respect to the previous edition: - modification of terms and technical requirements concerning geometrical characteristics to be consistent with IEC 60404-9:2018; - insertion of Table 3 - Tolerances on nominal thickness; - change of the length of test specimen for determination of geometrical characteristics from 2 m to 1 m.

IEC 60404-8-4:2022 is classified under the following ICS (International Classification for Standards) categories: 17.220.20 - Measurement of electrical and magnetic quantities; 29.030 - Magnetic materials. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60404-8-4:2022 has the following relationships with other standards: It is inter standard links to IEC 60404-8-4:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60404-8-4:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60404-8-4 ®

Edition 4.0 2022-09

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Magnetic materials –

Part 8-4: Specifications for individual materials – Cold-rolled non-oriented

electrical steel strip and sheet delivered in the fully-processed state

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always

committee, …). It also gives information on projects, replaced have access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and

and French, with equivalent terms in 19 additional languages.

once a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60404-8-4 ®

Edition 4.0 2022-09

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Magnetic materials –

Part 8-4: Specifications for individual materials – Cold-rolled non-oriented

electrical steel strip and sheet delivered in the fully-processed state

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 17.220.20; 29.030 ISBN 978-2-8322-5735-7

– 2 – IEC 60404-8-4:2022 RLV © IEC 2022

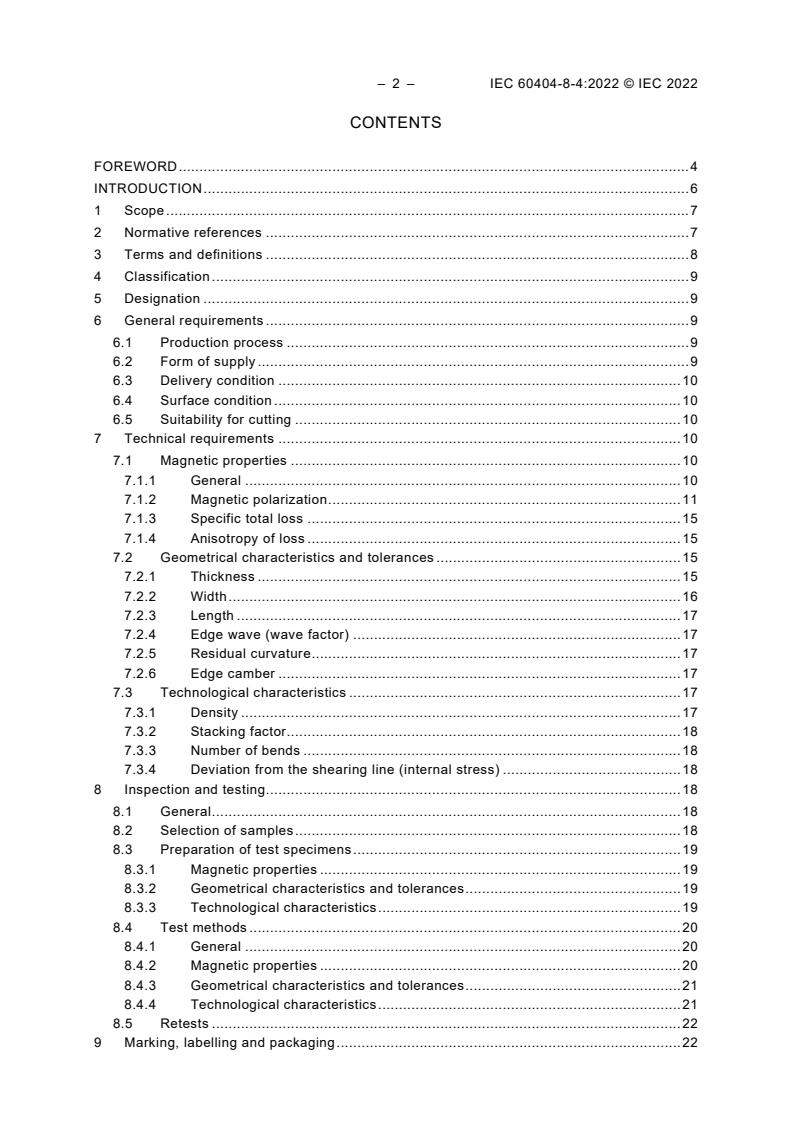

CONTENTS

FOREWORD . 4

INTRODUCTION . 2

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Classification . 8

5 Designation . 9

6 General requirements . 10

6.1 Production process . 10

6.2 Form of supply . 10

6.3 Delivery condition . 10

6.4 Surface condition . 10

6.5 Suitability for cutting . 11

7 Technical requirements . 11

7.1 Magnetic properties . 11

7.1.1 General . 11

7.1.2 Magnetic polarization . 11

7.1.3 Specific total loss . 15

7.1.4 Anisotropy of loss . 15

7.2 Geometrical characteristics and tolerances . 15

7.2.1 Thickness . 15

7.2.2 Width . 16

7.2.3 Length . 17

7.2.4 Edge wave (wave factor) . 17

7.2.5 Flatness (wave factor) .

7.2.5 Residual curvature . 18

7.2.6 Edge camber . 18

7.3 Technological characteristics . 18

7.3.1 Density . 18

7.3.2 Stacking factor. 18

7.3.3 Number of bends . 19

7.3.4 Deviation from the shearing line (internal stress) . 19

8 Inspection and testing . 19

8.1 General . 19

8.2 Selection of samples . 19

8.3 Preparation of test specimens . 20

8.3.1 Magnetic properties . 20

8.3.2 Geometrical characteristics and tolerances . 20

8.3.3 Technological characteristics . 21

8.4 Test methods . 21

8.4.1 General . 21

8.4.2 Magnetic properties . 21

8.4.3 Geometrical characteristics and tolerances . 22

8.4.4 Technological characteristics . 22

8.5 Retests . 23

9 Marking, labelling and packaging . 23

10 Complaints . 23

11 Information to be supplied by the purchaser . 23

Annex A (informative) Non-specified magnetic properties . 25

Annex B (informative) European steel numbers .

Annex B (informative) Calculation of density values Calculated density of non-oriented

electrical steel . 27

Bibliography . 28

Table 1 – Technological properties and magnetic properties (magnetic properties are

measured by using the Epstein method according to IEC 60404-2) . 12

Table 2 – Technological properties and magnetic properties measured by the Epstein

method for strip and sheet of nominal thickness 0,47 mm for use at 60 Hz only

(magnetic properties are measured using the Epstein method according to

IEC 60404-2) . 14

Table 3 – Tolerances on nominal thickness . 16

Table 4 – Tolerances on nominal width . 17

Table A.1 – Non-specified magnetic properties . 25

– 4 – IEC 60404-8-4:2022 RLV © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 8-4: Specifications for individual materials –

Cold-rolled non-oriented electrical steel strip and sheet

delivered in the fully-processed state

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes made to

the previous edition IEC 60404-8-4:2013. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

IEC 60404-8-4 has been prepared by IEC technical committee 68: Magnetic alloys and steels.

It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2013. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modification of terms and technical requirements concerning geometrical characteristics to

be consistent with IEC 60404-9:2018;

b) insertion of Table 3 – Tolerances on nominal thickness;

c) change of the length of test specimen for determination of geometrical characteristics from

2 m to 1 m.

The text of this International Standard is based on the following documents:

Draft Report on voting

68/700/CDV 68/713/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 60404 series, published under the general title Magnetic materials,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 60404-8-4:2022 RLV © IEC 2022

INTRODUCTION

This revision of International Standard IEC 60404-8-4 has been prepared by the experts of the

Working Group 1 of the IEC Technical Committee 68: Magnetic alloys and steels.

The third edition of IEC 60404-8-4 was issued in 2013. After that, other IEC 60404 standards

were revised and IEC TC 68 decided in 2019 at their meeting in Düsseldorf to revise this

document to maintain consistency for user's convenience. The revision is made mainly on

technical amendments regarding testing and definitions of geometrical characteristics in

accordance with IEC 60404-9. The length of test specimen for determination of geometrical

characteristics is changed from 2 m to 1 m. The term of “flatness” is divided into “edge wave

(wave factor)” and “residual curvature” and the horizontal method is introduced for verification

of residual curvature. This revision also includes corrections in order to improve consistency

with other standards of the IEC 60404-8 series.

MAGNETIC MATERIALS –

Part 8-4: Specifications for individual materials –

Cold-rolled non-oriented electrical steel strip and sheet

delivered in the fully-processed state

1 Scope

This part of IEC 60404 defines the grades of cold-rolled non-oriented electrical steel strip and

sheet in nominal thicknesses of 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00 mm. In

particular, it specifies gives general requirements, magnetic properties, geometric

characteristics, tolerances and technological characteristics, as well as inspection procedure.

The nominal thickness 0,47 mm applies to the grades for use at 60 Hz only.

This standard gives in Table 2 the magnetic properties of cold-rolled non-oriented electrical

steel strip and sheet of nominal thickness 0,47 mm for use at 60 Hz only.

This standard applies to materials supplied in the fully annealed condition intended for the

construction of magnetic circuits. It does not apply to semi-processed material.

These magnetic materials correspond to class C.21 of IEC 60404-1.

This document applies to cold-rolled non-oriented electrical steel strip and sheet supplied in the

fully-processed state, i.e. the final annealed condition, in coils or sheets, and intended for the

construction of magnetic circuits. This document does not apply to materials supplied in the

semi-processed state.

NOTE The cold-rolled non-oriented electrical steel strip and sheet supplied in the semi-processed state is specified

in IEC 60404-8-3.

The grades defined in this document correspond to Class C21 of IEC 60404-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050 (all parts), International Electrotechnical Vocabulary (available at

)

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60404-1, Magnetic materials – Part 1: Classification

IEC 60404-2, Magnetic materials – Part 2: Methods of measurement of the magnetic properties

of electrical steel strip and sheet and strip by means of an Epstein frame

– 8 – IEC 60404-8-4:2022 RLV © IEC 2022

IEC 60404-3, Magnetic materials – Part 3: Methods of measurement of the magnetic properties

of electrical steel strip and sheet by means of a single sheet tester

IEC 60404-9, Magnetic materials – Part 9: Methods of determination of the geometrical

characteristics of magnetic electrical steel strip and sheet and strip

IEC 60404-13, Magnetic materials – Part 13: Methods of measurement of density, resistivity,

density and stacking factor of electrical steel strip and sheet and strip

ISO 404, Steel and steel products – General technical delivery requirements

ISO 7799, Metallic materials – Sheet and strip 3 mm thick or less – Reverse bend test

ISO 10474, Steel and steel products – Inspection documents

3 Terms and definitions

For the purposes of this document, the terms and definitions relating to magnetic properties

given in IEC 60050-121, IEC 60050-221 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

edge wave

wave factor

variations of flatness of a length of strip or a sheet taking a form of waves at the slit edge of the

product

Note 1 to entry: The edge wave is characterized by the wave factor which is the relation of the height of the wave

to its length, expressed as a percentage.

[SOURCE: IEC 60404-9:2018, 3.1]

3.2

residual curvature

variations of flatness of a length of strip or a sheet taking a permanent curvature in the direction

of rolling of the product

[SOURCE: IEC 60404-9:2018, 3.2]

3.3

edge camber

greatest distance between a longitudinal edge of a length of strip or a sheet and the line joining

the two extremities of the measured length of this edge

[SOURCE: IEC 60404-9:2018, 3.3]

3.2

flatness

property of a sheet or a length of strip which is characterized by the wave factor, i.e. by the

relation of the height of the wave to its length

3.4

deviation from the shearing line

internal stress

deviation from the shearing line due to internal stresses

greatest distance between corresponding points on the two sheared edges of a length of strip

or a sheet sheared in the middle of the width, in parallel to the direction of rolling of the product,

which characterizes the internal stress of the materials

[SOURCE: IEC 60404-9:2018, 3.4]

3.5

number of bends

number of alternate bends possible before the appearance in the base metal of the first crack

visible to the naked eye

Note 1 to entry: The number of bends constitutes an indication of the ductility of the material.

counts of alternate bending in the reverse bend test prior to the appearance of the first crack in

the base metal of the specimen visible to the naked eye or sudden failure occurs by fracture

[SOURCE: IEC TR 63114:2018, 3.2]

4 Classification

The grades covered by this document are classified according to the specified value of

maximum specific total loss in watts per kilogram at 1,5 T and according to the nominal

thickness of the material (0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00mm) the product .

The products of the nominal thicknesses 0,35 mm, 0,50 mm, 0,65 mm and 1,00 mm are

classified according to the specified values tested at a magnetic polarization of 1,5 T and 50

Hz, in watts per kilogram. The product of the nominal thickness 0,47 mm is classified according

to the specified value tested at a magnetic polarization of 1,5 T and 60 Hz, in watts per kilogram.

5 Designation

The steel name comprises the following in the order given:

a) a letter “M” for electrical steel;

b) one hundred times the specified value of maximum specific total loss at a magnetic

polarization of 1,5 T and 50 Hz, in watts per kilogram, at 1,5 T and 50 Hz for the materials

given in Table 1 and at 1,5 T and 60 Hz for the materials given in Table 2 and corresponding

to the nominal product thickness for the products of the nominal thicknesses 0,35 mm, 0,50

mm, 0,65 mm and 1,00 mm, or at a magnetic polarization of 1,5 T and 60 Hz, in watts per

kilogram, for the products of the nominal thickness 0,47 mm;

c) one hundred times the nominal thickness of the material product, in millimeters;

d) the characteristic letter “A” for the grades of cold-rolled non-oriented electrical steel strip or

sheet supplied in the fully-processed state;

e) one tenth of the frequency at which the maximum specific total loss is specified, i.e. 5 or 6.

EXAMPLE M250-35A5 for cold-rolled non-oriented electrical steel strip or sheet with a maximum specific total loss

of 2,50 W/kg at a magnetic polarization of 1,5 T and 50 Hz, and a nominal thickness of 0,35 mm, supplied in the

fully-processed state.

NOTE The corresponding steel numbers used in the European standard are given in Annex B.

___________

1 In the rest of the document, the word “product” is used to mean “strip and sheet”.

– 10 – IEC 60404-8-4:2022 RLV © IEC 2022

6 General requirements

6.1 Production process

The production process of the steel and its chemical composition are left to the discretion of

the manufacturer.

6.2 Form of supply

The material product is supplied in coils in the case of strip and in bundles in the case of sheets.

The mass of coils or bundles of sheets shall be agreed between the manufacturer and the

purchaser at the time of ordering enquiry and order.

The recommended value for the internal diameter of coils is approximately 508 mm or

approximately 610 mm.

Strip shall be of constant width and wound in such a manner that the edges are superimposed

in a regular manner and the side faces of the coil are substantially flat.

Coils shall be sufficiently tightly wound in order that they do not collapse under their own weight.

Strip can occasionally may exhibit welds or interleaves resulting from the removal of defective

zones, subject to prior agreement if agreed between the parties manufacturer and the purchaser

at the time of enquiry and order. If necessary, the marking of welds or interleaves may be

agreed between the manufacturer and the purchaser at the time of ordering enquiry and order.

For coils containing welds or interleaves, each part of the strip shall be of the same grade.

The edges of parts welded together shall not be so much out of alignment as to affect the further

processing of the material product.

Sheets which make up each bundle shall be stacked so that the side faces of the bundle are

substantially flat and approximately perpendicular to the top face.

6.3 Delivery condition

The material products may be are usually supplied either without insulation coating or with

insulation coating on one or both sides. If the material product is supplied with insulation coating,

the nature of the insulation coating, its properties, the stacking factor and their verification shall

be agreed are subject to agreement between the manufacturer and the purchaser at the time

of ordering enquiry and order.

NOTE Further information on the classification of surface insulation coatings can be found in IEC 60404-1-1.

6.4 Surface condition

The surfaces shall be smooth and clean, free from grease and rust . Dispersed defects such

as scratches, blisters, cracks, etc. are only permitted if they are within the limits of tolerances

on thickness tolerances, and if they are not detrimental to the correct use of the supplied

material product.

When an insulation coating is present on the surface of the material, it For products supplied

with insulation coating, the coating shall be sufficiently adherent so that it does not become

detached during cutting manufacturing operations. During the alternating reverse bend test (see

8.4.4.2), the coating shall not become detached after a bend of 90°. If the coating becomes

___________

2 This should not be confused with some coloration of the insulation coating inherent to the manufacturing process.

detached during the test, the piece sample of the product from which the sample test specimen

was taken shall be subjected to a shearing test. During this test, it shall not be admissible for

large pieces of the coating to become detached. By shearing the sample with well sharpened

tools, a detachment of large pieces of the coating shall not be admissible. However, some slight

chipping of the coating at the sheared edges shall be tolerated.

6.5 Suitability for cutting

The material product shall be able to be cut or punched without causing premature wear of tools;

it shall be able to be cut at any point and into the usual shapes, thus ensuring accurate working

with the correct cutting tools. If there are special requirements with regard to a suitability test

for cutting or punching, these shall be established by agreement between the manufacturer and

the purchaser. The product shall be suitable for cutting or punching accurately into the usual

shapes at any point when appropriate cutting or punching tools and technologies are used.

A special requirement concerning suitability for cutting or punching of the product may be

subject to agreement between the manufacturer and the purchaser at the time of enquiry and

order.

7 Technical requirements

7.1 Magnetic properties

7.1.1 General

The properties defined in 7.1.2 to 7.1.4 are applicable shall apply to products in the delivery

conditions defined in 6.3.

For coated products supplied with insulation coating, the mass of the insulation coating shall

be taken into account to determine the magnetic properties.

7.1.2 Magnetic polarization

The minimum specified values of magnetic polarization for magnetic field strengths H of

2 500 A/m, 5 000 A/m and 10 000 A/m (expressed as a peak value) shall be as given in Table 1.

The magnetic polarization shall be determined in an alternating magnetic field at 50 Hz or 60

Hz.

The specified values of minimum magnetic polarization, expressed as a peak value, at AC

magnetic field strengths H of 2 500 A/m, 5 000 A/m and 10 000 A/m, expressed as a peak value,

shall be as given in Table 1 at 50 Hz or Table 2 at 60 Hz.

– 12 – IEC 60404-8-4:2022 RLV © IEC 2022

Table 1 – Technological properties and magnetic properties

(magnetic properties are measured by using the Epstein method according to IEC 60404-2)

a

Minimum magnetic polarization

Maximum specific total loss Maximum Minimum Minimum

Steel Nominal Conventional

in an alternating magnetic field

at 1,5 T anisotropy stacking number of

c

name thickness

for at an AC magnetic field strength density

W/kg of loss factor bends

T

b 3

mm at 50 Hz at 60 Hz 2 500 A/m 5 000 A/m 10 000 A/m % kg/dm

M210-35A5 2,10 2,65 1,49 1,60 1,70 ±17 2 7,60

M230-35A5 2,30 2,90 1,49 1,60 1,70 ±17 2 7,60

M235-35A5 2,35 2,97 1,49 1,60 1,70 ±17 2 7,60

M250-35A5 2,50 3,14 1,49 1,60 1,70 ±17 2 7,60

0,35

M270-35A5 2,70 3,36 1,49 1,60 1,70 ±17 0,95 2 7,65

M300-35A5 3,00 3,74 1,49 1,60 1,70 ±17 3 7,65

M330-35A5 3,30 4,12 1,49 1,60 1,70 ±17 3 7,65

M360-35A5 3,60 4,55 1,49 1,60 1,70 ±17 3 7,65

M230-50A5 2,30 2,95 1,49 1,60 1,70 ±17 2 7,60

M250-50A5 2,50 3,21 1,49 1,60 1,70 ±17 2 7,60

M270-50A5 2,70 3,47 1,49 1,60 1,70 ±17 2 7,60

M290-50A5 2,90 3,71 1,49 1,60 1,70 ±17 2 7,60

M310-50A5 3,10 3,95 1,49 1,60 1,70 ±14 3 7,65

M330-50A5 3,30 4,20 1,49 1,60 1,70 ±14 3 7,65

M350-50A5 3,50 4,45 1,50 1,60 1,70 ±12 5 7,65

M400-50A5 0,50 4,00 5,10 1,53 1,63 1,73 ±12 0,96 5 7,70

M470-50A5 4,70 5,90 1,54 1,64 1,74 ±10 10 7,70

M530-50A5 5,30 6,66 1,56 1,65 1,75 ±10 10 7,70

M600-50A5 6,00 7,53 1,57 1,66 1,76 ±10 10 7,75

M700-50A5 7,00 8,79 1,60 1,69 1,77 ±10 10 7,80

M800-50A5 8,00 10,06 1,60 1,70 1,78 ±10 10 7,80

M940-50A5 9,40 11,84 1,62 1,72 1,81 ±8 10 7,85

M1000-50A5 10,00 12,60 1,62 1,72 1,81 ±8 10 7,85

a

Minimum magnetic polarization

Maximum specific total loss Maximum Minimum Minimum

Conventional

Steel Nominal

in an alternating magnetic field

at 1,5 T anisotropy stacking number of

c

name thickness

for at an AC magnetic field strength density

W/kg of loss factor bends

T

b 3

mm at 50 Hz at 60 Hz 2 500 A/m 5 000 A/m 10 000 A/m % kg/dm

M310-65A5 3,10 4,08 1,49 1,60 1,70 ±15 2 7,60

M330-65A5 3,30 4,30 1,49 1,60 1,70 ±15 2 7,60

M350-65A5 3,50 4,57 1,49 1,60 1,70 ±14 2 7,60

M400-65A5 4,00 5,20 1,52 1,62 1,72 ±14 2 7,65

M470-65A5 4,70 6,13 1,53 1,63 1,73 ±12 0,97 5 7,65

0,65

M530-65A5 5,30 6,84 1,54 1,64 1,74 ±12 5 7,70

M600-65A5 6,00 7,71 1,56 1,66 1,76 ±10 10 7,75

M700-65A5 7,00 8,98 1,57 1,67 1,76 ±10 10 7,75

M800-65A5 8,00 10,26 1,60 1,70 1,78 ±10 10 7,80

M1000-65A5 10,00 12,77 1,61 1,71 1,80 ±10 10 7,80

M600-100A5 6,00 8,14 1,53 1,63 1,72 ±10 2 7,60

M700-100A5 7,00 9,38 1,54 1,64 1,73 ±8 3 7,65

M800-100A5 1,00 8,00 10,70 1,56 1,66 1,75 ±6 0,98 5 7,70

M1000-100A5 10,00 13,39 1,58 1,68 1,76 ±6 10 7,80

M1300-100A5 13,00 17,34 1,60 1,70 1,78 ±6 10 7,80

a

It has been common practice for many years to give values of magnetic flux density. In fact, the Epstein frame is used to determine magnetic polarization (intrinsic flux density)

which is defined as follows in accordance with IEC 60050-121:

J = B – µ H

where

J is the magnetic polarization;

B is the magnetic flux density;

–7 –1

µ is the magnetic constant: 4π × 10 H m ;

H is the magnetic field strength.

b

Only for information.

c

Other values may be agreed between the manufacturer and the purchaser at the time of enquiry and order, see Annex B.

– 14 – IEC 60404-8-4:2022 RLV © IEC 2022

Table 2 – Technological properties and magnetic properties measured by the Epstein method

for strip and sheet of nominal thickness 0,47 mm for use at 60 Hz only

(magnetic properties are measured using the Epstein method according to IEC 60404-2)

a

Steel Nominal Maximum specific total loss Maximum Minimum Minimum Conventional

Minimum magnetic polarization

c

name thickness at 1,5 T anisotropy stacking number of

in an alternating magnetic field density

of loss factor bends

for at an AC magnetic field strength

W/kg

T

b 3

mm at 60 Hz 2 500 A/m 5 000 A/m 10 000 A/m %

at 50 Hz kg/dm

M370-47A6 2,92 3,70 1,49 1,60 1,70 ±18 2 7,65

M380-47A6 3,00 3,80 1,49 1,60 1,70 ±14 3 7,65

M408-47A6 3,22 4,08 1,49 1,60 1,70 ±14 3 7,65

M419-47A6 3,31 4,19 1,49 1,60 1,70 ±14 3 7,70

M452-47A6 0,47 3,57 4,52 1,50 1,60 1,70 ±14 0,96 5 7,70

M507-47A6 4,01 5,07 1,51 1,61 1,71 ±14 5 7,70

M638-47A6 5,04 6,38 1,54 1,64 1,74 ±12 10 7,75

M836-47A6 6,60 8,36 1,58 1,68 1,77 ±12 10 7,80

M990-47A6 7,82 9,90 1,58 1,68 1,77 ±12 10 7,80

a

It has been common practice for many years to give values of magnetic flux density. In fact the Epstein frame is used to determine magnetic polarization (intrinsic flux density)

which is defined as follows in accordance with IEC 60050-121:

J = B – µ H

where

J is the magnetic polarization;

B is the magnetic flux density;

–7 –1

µ is the magnetic constant: 4π × 10 H m ;

H is the magnetic field strength.

b

Only for information.

c

Other values may be agreed between the manufacturer and the purchaser at the time of enquiry and order, see Annex B.

7.1.3 Specific total loss

The specified values of maximum specific total loss at 50 Hz shall be as given in Table 1. They

apply:

– for the nominal thicknesses 0,35 mm, 0,50 mm and 0,65 mm to aged or non-aged test

pieces (see 8.3.1);

– for the nominal thickness 1,00 mm to non-aged test pieces.

Table 2 gives the specified values of maximum specific total loss at 60 Hz for products of

0,47 mm nominal thickness.

In certain cases, the specified value of maximum specific total loss can be made the subject of

agreement for longitudinal test pieces only or for transverse test pieces only.

The values of the specific total loss are specified for a magnetic polarization of 1,5 T.

The test shall be made in an alternating magnetic field at 50 Hz or at 60 Hz.

The specified values of maximum specific total loss at a magnetic polarization of 1,5 T and

50 Hz shall be as given in Table 1 for products of the nominal thicknesses 0,35 mm, 0,50 mm,

0,65 mm and 1,00 mm. They apply to:

– aged or non-aged test strips (see 8.3.1), for products of the nominal thicknesses 0,35 mm,

0,50 mm and 0,65 mm;

– non-aged test strips, for products of the nominal thickness 1,00 mm.

The specified values of maximum specific total loss at a magnetic polarization of 1,5 T and

60 Hz shall be as given in Table 2, for products of the nominal thickness 0,47 mm.

A special requirement concerning the value of maximum specific total loss measured using test

strips cut parallel to the direction of rolling only or test strips cut perpendicular to the direction

of rolling only may be subject to agreement between the manufacturer and the purchaser at the

time of enquiry and order.

NOTE Annex A gives non-specified values of maximum specific total loss at a magnetic polarization of 1,0 T and

50 Hz.

7.1.4 Anisotropy of loss

The maximum permitted values of maximum anisotropy of loss at a magnetic polarization of 1,5

T shall be as specified given in Table 1 and Table 2.

A special requirement concerning the declaration of the measured value of anisotropy of loss

may be specified by subject to agreement when ordering between the manufacturer and the

purchaser at the time of enquiry and order.

7.2 Geometrical characteristics and tolerances

7.2.1 Thickness

The nominal thicknesses of the material product are 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and

1,00 mm.

The nominal thickness 0,47 mm applies only to the grades for use at 60 Hz only is also given

in Table 2.

For thickness tolerance, a distinction is made between

– 16 – IEC 60404-8-4:2022 RLV © IEC 2022

– the allowable tolerance on the nominal thickness within the same acceptance unit;

– the deviation from the nominal thickness within an acceptance unit;

– the difference in thickness in a sheet or in a length of strip in a direction parallel to the

direction of rolling in a length of strip or sheet;

– the difference in thickness in a direction perpendicular to the direction of rolling. This

tolerance applies only to materials products supplied with a width greater than 150 mm.

The allowable tolerance on the nominal thickness within the same acceptance unit shall be ± 8 %

of the nominal value for the nominal thicknesses 0,35 mm, 0,47 mm and 0,50 mm, and ± 6 %

of the nominal value for the nominal thicknesses 0,65 mm and 1,00 mm. The additional

thickness due to welds, with respect to the measured thickness of the steel strip or sheet, shall

not exceed 0,10 mm.

The difference in thickness in a sheet or in a length of strip (see 8.3.2) in a direction parallel to

the direction of rolling shall not exceed 8 % for nominal thicknesses 0,35 mm, 0,47 mm and

0,50 mm, and 6 % for nominal thicknesses 0,65 mm and 1,00 mm.

The difference in thickness in a direction perpendicular to the direction of rolling shall not

exceed 0,020 mm for nominal thicknesses of 0,35 mm, 0,47 mm and 0,50 mm, and 0,030 mm

for the nominal thicknesses of 0,65 mm and 1,00 mm, the measurements being made at least

30 mm from the edges (see 8.4.3.1). These tolerances apply only to materials with a width

greater than 150 mm. For narrow strips, other agreements may be reached.

At any point, the deviation from the nominal thickness within an acceptance unit shall not

exceed the tolerance of Table 3.

The additional thickness due to welds with respect to the measured thickness of the product

shall not exceed 0,10 mm.

The difference in thickness in a direction parallel to the direction of rolling in a 1 m length of the

product shall not exceed

– 0,030 mm, 0,038 mm and 0,040 mm for products of the nominal thicknesses 0,35 mm,

0,47 mm and 0,50 mm respectively;

– 0,045 mm and 0,060 mm for products of the nominal thicknesses 0,65 mm and 1,00 mm

respectively.

Table 3 – Tolerances on nominal thickness

Nominal thickness Tolerance

mm mm

0,35 ±0,030

0,47 ±0,038

0,50 ±0,040

0,65 ±0,045

1,00 ±0,060

For products supplied with a width greater than 150 mm, the difference in thickness in a

direction perpendicular to the direction of rolling shall not exceed

– 0,020 mm for products of the nominal thicknesses 0,35 mm, 0,47 mm and 0,50 mm;

– 0,030 mm for products of the nominal thicknesses 0,65 mm and 1,00 mm.

The measurements shall be made at any point located at least 20 mm from the edges (see

8.4.3.1). For narrow strips, other agreements may be needed.

7.2.2 Width

The commonly available nominal widths are less than or equal to 1 250 mm.

For the tolerances on width, a distinction is made between material products supplied with slit

edges in the as-rolled condition and material delivered with trimmed edges and products

supplied with as-rolled edges.

For materials products supplied with trimmed slit edges, the tolerances of Table 4 shall apply.

Table 4 – Tolerances on nominal width

a

Tolerance

Nominal width l

mm mm

+02,

l ≤ 150

+03,

150 < l ≤ 300

+0,5

300 < l ≤ 600

+1,0

600 < l ≤ 1 000

+1,5

b

1 000 < l ≤ 1 250

a

By agreement when ordering between the manufacturer and the purchaser at the

time of enquiry and order, the tolerances on nominal width can be all minus values

tolerances.

b

Nominal widths greater than 1 250 mm may be delivered. In this case, the

tolerance should be agreed between the manufacturer and the purchaser at the

time of enquiry and order.

For materials products supplied with as-rolled edges, the tolerances on nominal width should

geometric characteristics shall be subject to agreement when ordering between the

manufacturer and the purchaser at the time of enquiry and order.

7.2.3 Length

The verification of length does not apply to the products supplied in coils.

For products supplied in sheets, the tolerance on the length of sheets in relation to the length

+0,5

ordered shall be %, but with a maximum of +6 mm.

7.2.4 Edge wave (wave factor)

The verification of edge wave applies only to products supplied with a width greater than

100 mm. The wave factor (see 8.4.3.3), shall not exceed 2 %.

7.2.5 Flatness (wave factor)

The verification of flatness does not apply to material of width less than or equal to 100 mm.

The wave factor (see 8.4.3.4), expressed as a percentage, shall not exceed 2.

– 18 – IEC 60404-8-4:2022 RLV © IEC 2022

7.2.5 Residual curvature

The verification of residual curvature does not apply to material of width less than or equal to

applies only to products supplied with a width greater than 100 mm.

A requirement concerning residual curvature can be specified by agreement when ordering; in

this case, the distance between the bottom edge of the test specimen and the supporting plate

shall not exceed 35 mm for the products of nominal thicknesses 0,35 mm, 0,47 mm, 0,50 mm

and 0,65 mm. For the nominal thickness 1,00 mm, this distance shall be subject to an

agreement between the manufacturer and the purchaser.

A requirement concerning residual curvature may be subject to agreement between the

manufacturer and the purchaser at the time of enquiry and order.

Two methods for the determination of the residual curvature in the direction of rolling of the

product are described in IEC 60404-9: a horizontal method and a vertical method. The

horizontal method is recommended from the aspect of worker’s safety and consistency with

ISO standards.

• Horizontal method:

In this method, the maximum dis

...

IEC 60404-8-4 ®

Edition 4.0 2022-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 8-4: Specifications for individual materials – Cold-rolled non-oriented

electrical steel strip and sheet delivered in the fully-processed state

Matériaux magnétiques –

Partie 8-4: Spécifications pour matériaux particuliers – Bandes et tôles

magnétiques en acier à grains non orientés, laminées à froid et livrées à l'état

fini

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 60404-8-4 ®

Edition 4.0 2022-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Magnetic materials –

Part 8-4: Specifications for individual materials – Cold-rolled non-oriented

electrical steel strip and sheet delivered in the fully-processed state

Matériaux magnétiques –

Partie 8-4: Spécifications pour matériaux particuliers – Bandes et tôles

magnétiques en acier à grains non orientés, laminées à froid et livrées à l'état

fini

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 17.220.20; 29.030 ISBN 978-2-8322-5708-1

– 2 – IEC 60404-8-4:2022 © IEC 2022

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Classification . 9

5 Designation . 9

6 General requirements . 9

6.1 Production process . 9

6.2 Form of supply . 9

6.3 Delivery condition . 10

6.4 Surface condition . 10

6.5 Suitability for cutting . 10

7 Technical requirements . 10

7.1 Magnetic properties . 10

7.1.1 General . 10

7.1.2 Magnetic polarization . 11

7.1.3 Specific total loss . 15

7.1.4 Anisotropy of loss . 15

7.2 Geometrical characteristics and tolerances . 15

7.2.1 Thickness . 15

7.2.2 Width . 16

7.2.3 Length . 17

7.2.4 Edge wave (wave factor) . 17

7.2.5 Residual curvature . 17

7.2.6 Edge camber . 17

7.3 Technological characteristics . 17

7.3.1 Density . 17

7.3.2 Stacking factor. 18

7.3.3 Number of bends . 18

7.3.4 Deviation from the shearing line (internal stress) . 18

8 Inspection and testing . 18

8.1 General . 18

8.2 Selection of samples . 18

8.3 Preparation of test specimens . 19

8.3.1 Magnetic properties . 19

8.3.2 Geometrical characteristics and tolerances . 19

8.3.3 Technological characteristics . 19

8.4 Test methods . 20

8.4.1 General . 20

8.4.2 Magnetic properties . 20

8.4.3 Geometrical characteristics and tolerances . 21

8.4.4 Technological characteristics . 21

8.5 Retests . 22

9 Marking, labelling and packaging . 22

10 Complaints . 22

11 Information to be supplied by the purchaser . 22

Annex A (informative) Non-specified magnetic properties . 24

Annex B (informative) Calculated density of non-oriented electrical steel . 25

Bibliography . 26

Table 1 – Technological properties and magnetic properties (magnetic properties are

measured using the Epstein method according to IEC 60404-2) . 12

Table 2 – Technological properties and magnetic properties for strip and sheet of

nominal thickness 0,47 mm for use at 60 Hz only (magnetic properties are measured

using the Epstein method according to IEC 60404-2) . 14

Table 3 – Tolerances on nominal thickness . 16

Table 4 – Tolerances on nominal width . 16

Table A.1 – Non-specified magnetic properties . 24

– 4 – IEC 60404-8-4:2022 © IEC 2022

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

MAGNETIC MATERIALS –

Part 8-4: Specifications for individual materials –

Cold-rolled non-oriented electrical steel strip and sheet

delivered in the fully-processed state

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 60404-8-4 has been prepared by IEC technical committee 68: Magnetic alloys and steels.

It is an International Standard.

This fourth edition cancels and replaces the third edition published in 2013. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modification of terms and technical requirements concerning geometrical characteristics to

be consistent with IEC 60404-9:2018;

b) insertion of Table 3 – Tolerances on nominal thickness;

c) change of the length of test specimen for determination of geometrical characteristics from

2 m to 1 m.

The text of this International Standard is based on the following documents:

Draft Report on voting

68/700/CDV 68/713/RVC

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 60404 series, published under the general title Magnetic materials,

can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60404-8-4:2022 © IEC 2022

INTRODUCTION

This revision of International Standard IEC 60404-8-4 has been prepared by the experts of the

Working Group 1 of the IEC Technical Committee 68: Magnetic alloys and steels.

The third edition of IEC 60404-8-4 was issued in 2013. After that, other IEC 60404 standards

were revised and IEC TC 68 decided in 2019 at their meeting in Düsseldorf to revise this

document to maintain consistency for user's convenience. The revision is made mainly on

technical amendments regarding testing and definitions of geometrical characteristics in

accordance with IEC 60404-9. The length of test specimen for determination of geometrical

characteristics is changed from 2 m to 1 m. The term of “flatness” is divided into “edge wave

(wave factor)” and “residual curvature” and the horizontal method is introduced for verification

of residual curvature. This revision also includes corrections in order to improve consistency

with other standards of the IEC 60404-8 series.

MAGNETIC MATERIALS –

Part 8-4: Specifications for individual materials –

Cold-rolled non-oriented electrical steel strip and sheet

delivered in the fully-processed state

1 Scope

This part of IEC 60404 defines the grades of cold-rolled non-oriented electrical steel strip and

sheet in nominal thicknesses of 0,35 mm, 0,47 mm, 0,50 mm, 0,65 mm and 1,00 mm. In

particular, it gives general requirements, magnetic properties, geometric characteristics,

tolerances and technological characteristics, as well as inspection procedure. The nominal

thickness 0,47 mm applies to the grades for use at 60 Hz only.

This document applies to cold-rolled non-oriented electrical steel strip and sheet supplied in the

fully-processed state, i.e. the final annealed condition, in coils or sheets, and intended for the

construction of magnetic circuits. This document does not apply to materials supplied in the

semi-processed state.

NOTE The cold-rolled non-oriented electrical steel strip and sheet supplied in the semi-processed state is specified

in IEC 60404-8-3.

The grades defined in this document correspond to Class C21 of IEC 60404-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-121, International Electrotechnical Vocabulary – Part 121: Electromagnetism

IEC 60050-221, International Electrotechnical Vocabulary – Chapter 221: Magnetic materials

and components

IEC 60404-1, Magnetic materials – Part 1: Classification

IEC 60404-2, Magnetic materials – Part 2: Methods of measurement of the magnetic properties

of electrical steel strip and sheet by means of an Epstein frame

IEC 60404-3, Magnetic materials – Part 3: Methods of measurement of the magnetic properties

of electrical steel strip and sheet by means of a single sheet tester

IEC 60404-9, Magnetic materials – Part 9: Methods of determination of the geometrical

characteristics of electrical steel strip and sheet

IEC 60404-13, Magnetic materials – Part 13: Methods of measurement of resistivity, density

and stacking factor of electrical steel strip and sheet

ISO 404, Steel and steel products – General technical delivery requirements

ISO 7799, Metallic materials – Sheet and strip 3 mm thick or less – Reverse bend test

– 8 – IEC 60404-8-4:2022 © IEC 2022

ISO 10474, Steel and steel products – Inspection documents

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-121,

IEC 60050-221 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

edge wave

wave factor

variations of flatness of a length of strip or a sheet taking a form of waves at the slit edge of the

product

Note 1 to entry: The edge wave is characterized by the wave factor which is the relation of the height of the wave

to its length, expressed as a percentage.

[SOURCE: IEC 60404-9:2018, 3.1]

3.2

residual curvature

variations of flatness of a length of strip or a sheet taking a permanent curvature in the direction

of rolling of the product

[SOURCE: IEC 60404-9:2018, 3.2]

3.3

edge camber

greatest distance between a longitudinal edge of a length of strip or a sheet and the line joining

the two extremities of the measured length of this edge

[SOURCE: IEC 60404-9:2018, 3.3]

3.4

deviation from the shearing line

internal stress

greatest distance between corresponding points on the two sheared edges of a length of strip

or a sheet sheared in the middle of the width, in parallel to the direction of rolling of the product,

which characterizes the internal stress of the materials

[SOURCE: IEC 60404-9:2018, 3.4]

3.5

number of bends

counts of alternate bending in the reverse bend test prior to the appearance of the first crack in

the base metal of the specimen visible to the naked eye or sudden failure occurs by fracture

[SOURCE: IEC TR 63114:2018, 3.2]

4 Classification

The grades covered by this document are classified according to the specified value of

maximum specific total loss and according to the nominal thickness of the product .The

products of the nominal thicknesses 0,35 mm, 0,50 mm, 0,65 mm and 1,00 mm are classified

according to the specified values tested at a magnetic polarization of 1,5 T and 50 Hz, in watts

per kilogram. The product of the nominal thickness 0,47 mm is classified according to the

specified value tested at a magnetic polarization of 1,5 T and 60 Hz, in watts per kilogram.

5 Designation

The steel name comprises the following in the order given:

a) a letter “M” for electrical steel;

b) one hundred times the specified value of maximum specific total loss at a magnetic

polarization of 1,5 T and 50 Hz, in watts per kilogram, for the products of the nominal

thicknesses 0,35 mm, 0,50 mm, 0,65 mm and 1,00 mm, or at a magnetic polarization of

1,5 T and 60 Hz, in watts per kilogram, for the products of the nominal thickness 0,47 mm;

c) one hundred times the nominal thickness of the product, in millimeters;

d) the characteristic letter “A” for the grades of cold-rolled non-oriented electrical steel strip or

sheet supplied in the fully-processed state;

e) one tenth of the frequency at which the maximum specific total loss is specified, i.e. 5 or 6.

EXAMPLE M250-35A5 for cold-rolled non-oriented electrical steel strip or sheet with a maximum specific total loss

of 2,50 W/kg at a magnetic polarization of 1,5 T and 50 Hz, and a nominal thickness of 0,35 mm, supplied in the

fully-processed state.

6 General requirements

6.1 Production process

The production process of the steel and its chemical composition are left to the discretion of

the manufacturer.

6.2 Form of supply

The product is supplied in coils in the case of strip and in bundles in the case of sheets.

The mass of coils or bundles of sheets shall be agreed between the manufacturer and the

purchaser at the time of enquiry and order.

The recommended value for the internal diameter of coils is approximately 508 mm or

approximately 610 mm.

Strip shall be of constant width and wound in such a manner that the edges are superimposed

in a regular manner and the side faces of the coil are substantially flat.

Coils shall be sufficiently tightly wound in order that they do not collapse under their own weight.

Strip may exhibit welds or interleaves resulting from the removal of defective zones if agreed

between the manufacturer and the purchaser at the time of enquiry and order. If necessary, the

marking of welds or interleaves may be agreed between the manufacturer and the purchaser at

the time of enquiry and order.

___________

1 In the rest of the document, the word “product” is used to mean “strip and sheet”.

– 10 – IEC 60404-8-4:2022 © IEC 2022

For coils containing welds or interleaves, each part of the strip shall be of the same grade.

The edges of parts welded together shall not be so much out of alignment as to affect the further

processing of the product.

Sheets which make up each bundle shall be stacked so that the side faces of the bundle are

substantially flat and approximately perpendicular to the top face.

6.3 Delivery condition

The products are usually supplied either without insulation coating or with insulation coating on

one or both sides. If the product is supplied with insulation coating, the nature of the coating,

its properties, the stacking factor and their verification are subject to agreement between the

manufacturer and the purchaser at the time of enquiry and order.

NOTE Further information on the classification of surface insulation coatings can be found in IEC 60404-1-1.

6.4 Surface condition

The surfaces shall be smooth and clean, free from grease and rust . Dispersed defects such

as scratches, blisters, cracks, etc. are only permitted if they are within the tolerances on

thickness and if they are not detrimental to the correct use of the supplied product.

For products supplied with insulation coating, the coating shall be sufficiently adherent so that

it does not become detached during manufacturing operations. During the reverse bend test

(see 8.4.4.2), the coating shall not become detached after a bend of 90°. If the coating becomes

detached during the test, the sample of the product from which the test specimen was taken

shall be subjected to a shearing test. By shearing the sample with well sharpened tools, a

detachment of large pieces of the coating shall not be admissible. However, some slight

chipping of the coating at the sheared edges shall be tolerated.

6.5 Suitability for cutting

The product shall be able to be cut or punched without causing premature wear of tools. The

product shall be suitable for cutting or punching accurately into the usual shapes at any point

when appropriate cutting or punching tools and technologies are used.

A special requirement concerning suitability for cutting or punching of the product may be

subject to agreement between the manufacturer and the purchaser at the time of enquiry and

order.

7 Technical requirements

7.1 Magnetic properties

7.1.1 General

The properties defined in 7.1.2 to 7.1.4 shall apply to products in the delivery conditions defined

in 6.3.

For products supplied with insulation coating, the mass of the coating shall be taken into

account to determine the magnetic properties.

___________

2 This should not be confused with some coloration of the insulation coating inherent to the manufacturing process.

7.1.2 Magnetic polarization

The specified values of minimum magnetic polarization, expressed as a peak value, at AC

magnetic field strengths H of 2 500 A/m, 5 000 A/m and 10 000 A/m, expressed as a peak value,

shall be as given in Table 1 at 50 Hz or Table 2 at 60 Hz.

– 12 – IEC 60404-8-4:2022 © IEC 2022

Table 1 – Technological properties and magnetic properties

(magnetic properties are measured using the Epstein method according to IEC 60404-2)

a

Maximum specific total loss Maximum Minimum Minimum

Minimum magnetic polarization

Conventional

Steel Nominal

at 1,5 T anisotropy stacking number of

at an AC magnetic field strength

c

name thickness

density

W/kg T of loss factor bends

b 3

mm at 50 Hz at 60 Hz 2 500 A/m 5 000 A/m 10 000 A/m % kg/dm

M210-35A5 2,10 2,65 1,49 1,60 1,70 ±17 2 7,60

M230-35A5 2,30 2,90 1,49 1,60 1,70 ±17 2 7,60

M235-35A5 2,35 2,97 1,49 1,60 1,70 ±17 2 7,60

M250-35A5 2,50 3,14 1,49 1,60 1,70 ±17 2 7,60

0,35

M270-35A5 2,70 3,36 1,49 1,60 1,70 ±17 0,95 2 7,65

M300-35A5 3,00 3,74 1,49 1,60 1,70 ±17 3 7,65

M330-35A5 3,30 4,12 1,49 1,60 1,70 ±17 3 7,65

M360-35A5 3,60 4,55 1,49 1,60 1,70 ±17 3 7,65

M230-50A5 2,30 2,95 1,49 1,60 1,70 ±17 2 7,60

M250-50A5 2,50 3,21 1,49 1,60 1,70 ±17 2 7,60

M270-50A5 2,70 3,47 1,49 1,60 1,70 ±17 2 7,60

M290-50A5 2,90 3,71 1,49 1,60 1,70 ±17 2 7,60

M310-50A5 3,10 3,95 1,49 1,60 1,70 ±14 3 7,65

M330-50A5 3,30 4,20 1,49 1,60 1,70 ±14 3 7,65

M350-50A5 3,50 4,45 1,50 1,60 1,70 ±12 5 7,65

M400-50A5 0,50 4,00 5,10 1,53 1,63 1,73 ±12 0,96 5 7,70

M470-50A5 4,70 5,90 1,54 1,64 1,74 ±10 10 7,70

M530-50A5 5,30 6,66 1,56 1,65 1,75 ±10 10 7,70

M600-50A5 6,00 7,53 1,57 1,66 1,76 ±10 10 7,75