IEC TS 62282-7-1:2010

(Main)Fuel cell technologies - Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)

Fuel cell technologies - Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)

IEC/TS 62282-7-1:2010(E) covers cell assemblies, test apparatus, measuring instruments and measuring methods, performance test methods, and test reports for PEFC single cells. This Technical Specification is used for evaluating:

- the performance of membrane electrode assemblies (MEAs) for PEFCs;

- materials or structures of other components of PEFCs;

- or the influence of impurities in fuel and/or in air on the fuel cell performance.

General Information

- Status

- Published

- Publication Date

- 09-Jun-2010

- Technical Committee

- TC 105 - Fuel cell technologies

- Drafting Committee

- MT 103 - TC 105/MT 103

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 27-Jan-2017

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC TS 62282-7-1:2010 - "Fuel cell technologies – Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)" is a Technical Specification from the International Electrotechnical Commission (IEC). It defines standardized test methods, required equipment and reporting practices for laboratory single‑cell testing of polymer electrolyte fuel cells (PEFCs). The specification is intended to ensure reproducible evaluation of membrane electrode assemblies (MEAs), cell components and the effect of fuel/air impurities on single‑cell performance.

Key topics and requirements

This Technical Specification covers the full test chain for PEFC single‑cell evaluation, including:

- Cell components and sizing - guidance on MEA dimensions, gas diffusion layers (GDLs), gaskets, flow plates, current collectors and clamping hardware.

- Cell assembly and leak checks - assembly procedures, orientation, gas connections and verification of gas tightness.

- Test station setup - minimum equipment requirements, schematic test station layout and control limits for fuel cell test rigs.

- Measurement principles - instrument uncertainty, measuring methods, units and data quality practices.

- Gas composition - fuel and oxidant composition considerations for controlled testing and impurity tests.

- Test preparation - standard test conditions, conditioning, ambient control, repeatability and reproducibility.

- Performance tests - steady‑state I–V (polarization) tests, IR (internal resistance) measurement, limiting current, stoichiometry, temperature/pressure/humidity effect tests, overload, long‑term operation, start/stop and load cycling.

- Impurity influence tests - procedures to evaluate the effect of contaminants in fuel and air on PEFC performance.

- Reporting - required test report items, data description and sample test input/output tables.

- Informative annexes - examples of flow plate designs, alignment, conditioning, leak tests, cycling profiles and test report templates.

Practical applications

IEC TS 62282-7-1:2010 is used to produce comparable, repeatable laboratory data for:

- MEA development and characterization (catalysts, membranes, coatings)

- Material and component evaluation (GDLs, flow-field designs, seals)

- Performance benchmarking across research groups and suppliers

- Contamination/impurity screening for fuel and air quality requirements

- Durability and cycling protocols for R&D and pre‑qualification

Who should use this standard

- Fuel cell researchers and laboratories

- MEA and component manufacturers

- Test‑house and certification bodies conducting PEFC lab evaluations

- Product developers and quality engineers defining acceptance testing

Related standards

- Other parts of the IEC 62282 series on fuel cell technologies and system‑level testing (refer to IEC/TC 105 publications)

Keywords: IEC TS 62282-7-1:2010, PEFC, polymer electrolyte fuel cell, single cell test methods, MEA testing, fuel cell performance, I‑V characteristics, fuel cell impurities.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC TS 62282-7-1:2010 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Fuel cell technologies - Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)". This standard covers: IEC/TS 62282-7-1:2010(E) covers cell assemblies, test apparatus, measuring instruments and measuring methods, performance test methods, and test reports for PEFC single cells. This Technical Specification is used for evaluating: - the performance of membrane electrode assemblies (MEAs) for PEFCs; - materials or structures of other components of PEFCs; - or the influence of impurities in fuel and/or in air on the fuel cell performance.

IEC/TS 62282-7-1:2010(E) covers cell assemblies, test apparatus, measuring instruments and measuring methods, performance test methods, and test reports for PEFC single cells. This Technical Specification is used for evaluating: - the performance of membrane electrode assemblies (MEAs) for PEFCs; - materials or structures of other components of PEFCs; - or the influence of impurities in fuel and/or in air on the fuel cell performance.

IEC TS 62282-7-1:2010 is classified under the following ICS (International Classification for Standards) categories: 27.070 - Fuel cells. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC TS 62282-7-1:2010 has the following relationships with other standards: It is inter standard links to IEC TS 62282-7-1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC TS 62282-7-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC/TS 62282-7-1 ®

Edition 1.0 2010-06

TECHNICAL

SPECIFICATION

Fuel cell technologies –

Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)

IEC/TS 62282-7-1:2010(E)

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC/TS 62282-7-1 ®

Edition 1.0 2010-06

TECHNICAL

SPECIFICATION

Fuel cell technologies –

Part 7-1: Single cell test methods for polymer electrolyte fuel cell (PEFC)

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

PRICE CODE

X

ICS 27.070 ISBN 978-2-88910-984-5

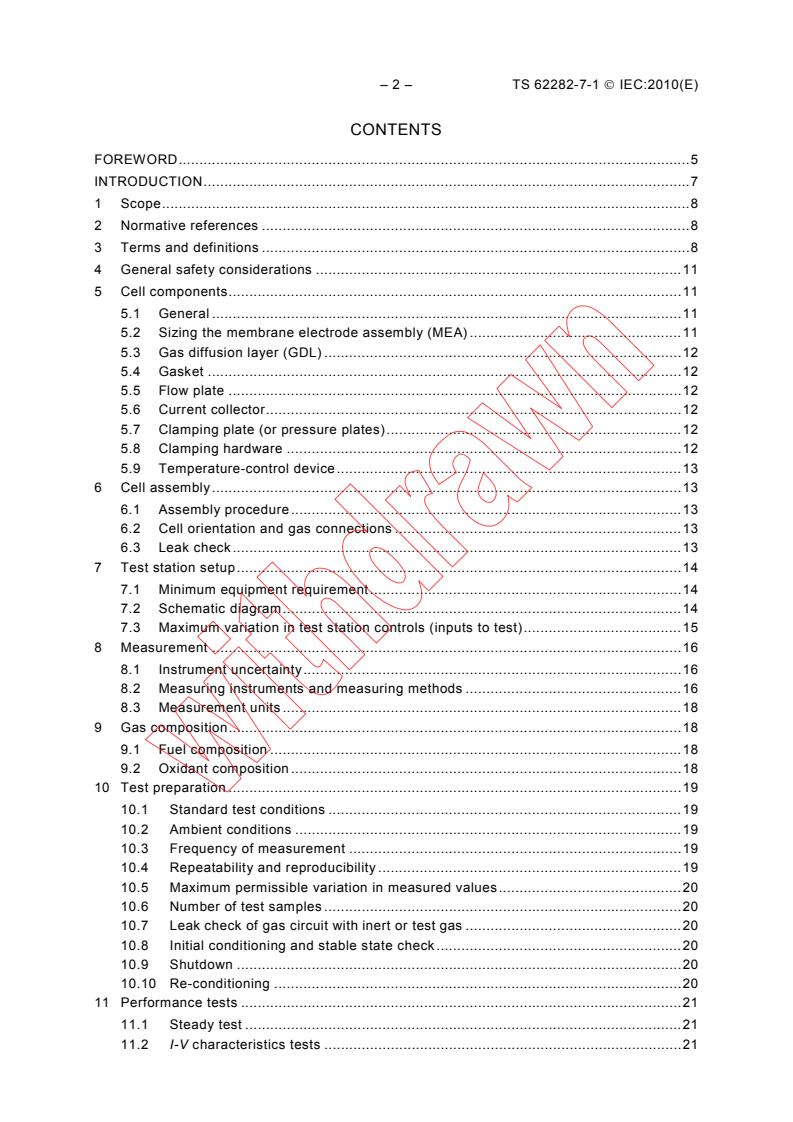

– 2 – TS 62282-7-1 © IEC:2010(E)

CONTENTS

FOREWORD.5

INTRODUCTION.7

1 Scope.8

2 Normative references .8

3 Terms and definitions .8

4 General safety considerations .11

5 Cell components.11

5.1 General .11

5.2 Sizing the membrane electrode assembly (MEA) .11

5.3 Gas diffusion layer (GDL) .12

5.4 Gasket .12

5.5 Flow plate .12

5.6 Current collector.12

5.7 Clamping plate (or pressure plates).12

5.8 Clamping hardware .12

5.9 Temperature-control device.13

6 Cell assembly.13

6.1 Assembly procedure.13

6.2 Cell orientation and gas connections .13

6.3 Leak check.13

7 Test station setup.14

7.1 Minimum equipment requirement.14

7.2 Schematic diagram.14

7.3 Maximum variation in test station controls (inputs to test).15

8 Measurement .16

8.1 Instrument uncertainty.16

8.2 Measuring instruments and measuring methods .16

8.3 Measurement units .18

9 Gas composition.18

9.1 Fuel composition .18

9.2 Oxidant composition.18

10 Test preparation .19

10.1 Standard test conditions .19

10.2 Ambient conditions .19

10.3 Frequency of measurement .19

10.4 Repeatability and reproducibility .19

10.5 Maximum permissible variation in measured values.20

10.6 Number of test samples .20

10.7 Leak check of gas circuit with inert or test gas .20

10.8 Initial conditioning and stable state check.20

10.9 Shutdown .20

10.10 Re-conditioning .20

11 Performance tests .21

11.1 Steady test .21

11.2 I-V characteristics tests .21

TS 62282-7-1 © IEC:2010(E) – 3 –

11.3 IR measurement .22

11.4 Limiting current test .22

11.5 Gain tests .23

11.6 Gas stoichiometry tests .24

11.7 Temperature effect test.24

11.8 Pressure effect test .25

11.9 Humidity effect tests .25

11.10 Fuel composition test.26

11.11 Overload test .26

11.12 Long-term operation test.26

11.13 Start/stop cycling test .27

11.14 Load cycling test.27

11.15 Impurity influence tests.28

12 Test report.29

12.1 General .29

12.2 Report items.30

12.3 Test data description.30

12.4 Measurement condition description .30

12.5 Test cell data description.30

Annex A (informative) Flow plate .31

Annex B (informative) Cell component alignment .33

Annex C (informative) Leak test.34

Annex D (informative) Initial conditioning .35

Annex E (informative) Shutdown .36

Annex F (informative) Reconditioning .37

Annex G (informative) I-V characteristic test .38

Annex H (informative) Start/stop cycling test.40

Annex I (informative) Load cycling test .41

Annex J (informative) Test report.43

Bibliography.48

Figure 1 – Test station schematic diagram for single cell testing.15

Figure 2 – Typical testing flowchart.19

Figure A.1 – Design for flow plate (single serpentine flow channel) .32

Figure A.2 – Design for flow plate (triple serpentine flow channel) .32

Figure B.1 – Single cell assembly using typical components .33

Figure I.1 – First load cycling profile .41

Figure I.2 – Second load cycling profile .42

Table 1 – Parameters and units .18

Table G.1 – Current density increments if maximum current density is known.38

Table G.2 – Current density increments if maximum current density is unknown .39

Table J.1– Test input parameters.45

Table J.2 – Test output parameters.46

– 4 – TS 62282-7-1 © IEC:2010(E)

Table J.3 – Functional performance before the measurement step (start up and

conditioning) .46

Table J.4 – Functional performance during the polarization step .47

TS 62282-7-1 © IEC:2010(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

FUEL CELL TECHNOLOGIES –

Part 7-1: Single cell test methods

for polymer electrolyte fuel cell (PEFC)

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

The main task of IEC technical committees is to prepare International Standards. In

exceptional circumstances, a technical committee may propose the publication of a technical

specification when

• the required support cannot be obtained for the publication of an International Standard,

despite repeated efforts, or

• the subject is still under technical development or where, for any other reason, there is the

future but no immediate possibility of an agreement on an International Standard.

Technical specifications are subject to review within three years of publication to decide

whether they can be transformed into International Standards.

IEC 62282-7-1, which is a technical specification, has been prepared by IEC technical

committee 105: Fuel cell technologies.

– 6 – TS 62282-7-1 © IEC:2010(E)

The text of this technical specification is based on the following documents:

Enquiry draft Report on voting

105/241/DTS 105/253A/RVC

Full information on the voting for the approval of this technical specification can be found in

the report on voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 62282 series, under the general title: Fuel cell technologies, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be be

• transformed into an International standard,

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

TS 62282-7-1 © IEC:2010(E) – 7 –

INTRODUCTION

This Technical Specification describes standard single-cell test methods for polymer

electrolyte fuel cells (PEFCs); it provides consistent and repeatable methods to test the

performance of single cells. This Technical Specification is to be used by component

manufacturers or stack manufacturers who assemble components in order to evaluate the

performance of cell components, including membrane-electrode assemblies (MEAs) and flow

plates. This Technical Specification is also available for fuel suppliers to determine the

maximum allowable impurities in fuels.

Users of this Technical Specification may selectively execute test items suitable for their

purposes from those described in this technical specification. This document is not intended

to exclude any other methods.

– 8 – TS 62282-7-1 © IEC:2010(E)

FUEL CELL TECHNOLOGIES –

Part 7-1: Single cell test methods

for polymer electrolyte fuel cell (PEFC)

1 Scope

This part of IEC 62282 covers cell assemblies, test apparatus, measuring instruments and

measuring methods, performance test methods, and test reports for PEFC single cells.

This Technical Specification is used for evaluating:

a) the performance of membrane electrode assemblies (MEAs) for PEFCs,

b) materials or structures of other components of PEFCs, or

c) the influence of impurities in fuel and/or in air on the fuel cell performance.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC/TS 62282-1:2010, Fuel cell technologies – Part 1: Terminology

ISO/TS 14687-2:2008, Hydrogen fuel – Product specification – Part 2: Proton exchange

membrane (PEM) fuel cell applications for road vehicles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1

anode

the electrode at which fuel oxidation takes place by the removal of electrons from the fuel to

+

the external electric load, concurrent with the release of protons (H ) to the polymer

electrolyte

3.2

catalyst

substance that accelerates (increases the rate of) a reaction without being consumed itself

The catalyst lowers the activation energy of the reaction, allowing for an increase in the

reaction rate. This is also referred to as an electrocatalyst, as defined in IEC/TS 62282-1.

3.3

catalyst-coated membrane

CCM

term used to describe a membrane (in a PEFC) whose surfaces are coated with a layer of

catalyst to form the reaction zone of the electrode

TS 62282-7-1 © IEC:2010(E) – 9 –

3.4

cathode

the electrode at which oxidant reduction takes place, facilitated by the donation of electrons

+

from the external circuit and protons (H ) from the polymer electrolyte, followed by the release

of reduced oxidant products (water)

3.5

clamping plate (or pressure plate)

frame used to compress the cell components together to maintain electrical conductivity and

sealing

3.6

current collector

conductive material, which can consist of metals, graphite or composite materials, that

collects electrons from an anode or disburses electrons to a cathode

3.7

electrode

catalytic layer that facilitates either an oxidation or reduction reaction, and has both electronic

and ionic conduction.

3.8

flow plate

conductive plate made of metals, a material such as graphite, or a conductive polymer that

may be a carbon-filled composite, which is incorporated with flow channels for fuel or oxidant

gas feed and has electrical contact with an electrode

3.9

fuel

hydrogen or hydrogen-containing gas that reacts at the anode

3.10

fuel cell

electrochemical device that converts the chemical energy of a fuel and an oxidant to electrical

energy (DC power), heat and reaction products

The fuel and oxidant are typically stored outside of the fuel cell and transferred into the fuel

cell as the reactants are consumed.

3.11

gas diffusion electrode

GDE

component on the anode or cathode side comprising all electronic conductive elements of the

electrode, i.e. gas diffusion layer and catalyst layer

3.12

gas diffusion layer

GDL

porous conductive component placed between an electrode and a flow plate, to serve as

electric contact and allow access of reactants to the electrode and the removal of reaction

products

3.13

gasket

sealing component which prevents the reaction gas from leaking out of a cell

– 10 – TS 62282-7-1 © IEC:2010(E)

3.14

limiting current density

the current density where the cell voltage sharply decreases to near zero

3.15

maximum current density

the highest current density specified by the manufacturer allowed for a short time

3.16

membrane electrode assembly

MEA

component of a fuel cell (3.10) consisting of an electrolyte membrane with gas diffusion

electrodes (3.11) on either side

3.17

minimum cell voltage

the lowest cell voltage specified by the manufacturer

3.18

open circuit voltage

OCV

the cell voltage at zero current density with the cell under operating conditions

3.19

oxidant

oxygen or oxygen-containing gas (e.g., air) that reacts at the cathode

3.20

polymer electrolyte

polymer resin membrane having proton exchange capability in which current is carried by the

movement of such ions from an anode to a cathode

3.21

polymer electrolyte fuel cell

PEFC

fuel cell that employs a polymer electrolyte membrane as an electrolyte, which is also called a

proton exchange membrane fuel cell (PEMFC)

3.22

power

measure calculated from the voltage multiplied by the current at a steady state (P = V × I)

3.23

power density

measure calculated by dividing the power by the geometric, electrode area

3.24

rated current density

maximum current density specified by the manufacturer of the MEA or single cell for

continuous operation

3.25

rated power density

maximum power density specified by the manufacturer of the MEA or single cell for

continuous operation

TS 62282-7-1 © IEC:2010(E) – 11 –

3.26

rated voltage

minimum cell voltage specified by the manufacturer of the MEA or single cell for continuous

operation

3.27

single cell

cell typically consisting of an anode flow plate, MEA, cathode flow plate and sealing gaskets

(see Annex B for additional information)

3.28

single cell test

test of the fuel cell performance based on a single cell

3.29

stoichiometry

molar ratio of the fuel (or oxidant) gases supplied to the cell to that required by the chemical

reaction, as calculated from the current

4 General safety considerations

An operating fuel cell uses oxidizing and reducing gases. Typically, these gases are stored in

high-pressure containers. The fuel cell itself may or may not be operated at pressures greater

than atmospheric pressure.

Those who carry out single cell testing shall be trained and experienced in the operation of

single cell test systems and specifically in safety procedures involving electrical equipment

and reactive, compressed gases. Safely operating a single cell test station requires

appropriate technical training and experience as well as safe facilities and equipment, all of

which are outside the scope of this technical specification.

5 Cell components

5.1 General

A single cell of a PEFC shall be composed of all or some of the following components:

a) an MEA,

b) gaskets,

c) an anode-side flow plate and a cathode-side flow plate,

d) an anode-side current collector and a cathode-side current collector,

e) an anode-side clamping plate and a cathode-side clamping plate,

f) electrically insulating sheets,

g) clamping or axial load hardware which may include bolts, washers, springs, etc.,

h) temperature-control devices,

i) other miscellaneous parts.

5.2 Sizing the membrane electrode assembly (MEA)

The electrode area shall be as large as needed to measure desired parameters. A suggested

electrode size should be approximately 25 cm , though larger cells having larger electrodes

may give more relevant data for practical applications. The active electrode area shall be

reported and shall be the smaller of the two electrode active areas. The approximate

uncertainty in the area measurement shall be reported also.

– 12 – TS 62282-7-1 © IEC:2010(E)

5.3 Gas diffusion layer (GDL)

A gas diffusion layer shall be made of highly gas-diffusible, electrically conductive and

corrosion-resistant materials.

5.4 Gasket

The gasket material shall be compatible with fuel cell reactants, components and reaction

products, and cell operating temperature. It shall prevent gas leakage.

5.5 Flow plate

Flow plates shall be made of materials that have negligible gas permeability, but high electric

conductivity. Resin-impregnated, high-density, synthetic graphite, polymer/carbon composites,

or corrosion-resistant metal, such as titanium or stainless steel, is recommended. If metal is

used, the plate surface may be coated/plated (e.g., with gold) in order to reduce contact

resistance. The flow plate should be corrosion-resistant and should provide a suitable seal.

A serpentine flow channel is suggested. Further information about a suggest design is given

in Annex A. The flow field configuration shall be documented in the test report.

The flow plates for testing shall allow the accurate measurement of cell operating temperature.

For example, flow plates may have a small hole on an edgewise face in order to

accommodate a temperature sensor. In this case, the hole shall reach the centre of the flow

plate.

NOTE If the objective of testing is to evaluate the design of a particular flow channel, it is not necessary to use

the suggested flow plate design.

5.6 Current collector

Current collectors shall be made of materials that have high electric conductivity, such as

metal. Metal collectors may be plated with contact-resistance-reducing materials, such as

gold or silver; however care must be taken in choosing the coating material. It must be

compatible with the cell components and reactants and products.

They should be thick enough to minimize voltage drop over their surface area. They should

provide an output terminal for wire connection.

If metal flow plates act as current collectors, independent current collectors are not required.

5.7 Clamping plate (or pressure plates)

Clamping plates (or pressure plates) shall be flat and smooth-surfaced, with their mechanical

properties strong enough to withstand the bending force being applied when clamped with

bolts.

If the clamping plates are conductive, they shall be insulated from the current collectors in

order to prevent short-circuiting.

5.8 Clamping hardware

Clamping hardware shall have high mechanical strength in order to withstand the stresses

generated during installation and operation. Washers and springs may be used to maintain

constant, uniform pressure on the single cell. A torque wrench or other measuring device shall

be used to set exact pressure on the cell.

It is recommended to electrically insulate the clamping hardware.

TS 62282-7-1 © IEC:2010(E) – 13 –

5.9 Temperature-control device

The single cell shall be provided with a temperature-control device (for heating/cooling) in

order to maintain it at a constant temperature and with a uniform temperature profile along the

flow plate and across the cell. The temperature-control device may be programmable to follow

a fixed temperature profile. The temperature-control device shall have means to prevent over-

temperature.

There are multiple ways of achieving this requirement.

One simple way is to convectively cool and electrically heat the clamping (pressure) plates.

The heating can be achieved by attaching a skin resistance heater to the external surface of

the plate. An alternate method is to insert a cartridge heater into a hole in the plate.

In either case, care is required to maintain isolation for electrical safety.

6 Cell assembly

6.1 Assembly procedure

Cell assembly procedures have large impact on the repeatability of fuel cell data. Specific

procedures shall be documented for the following assembly operations:

a) membrane alignment, including identification of anode and cathode sides,

b) diffusion media (i.e., GDL) alignment, including identification of anode and cathode parts,

as well as the sides to be placed facing the membrane and flowfield,

c) gasket/seal placement,

d) alignment fixtures or jigs to be used, if any,

e) compression procedures and specifications, such as diffusion media compression values,

bolt tightening order, compression springs, and final torque specifications.

NOTE Pressure may be checked by pressure-sensitive paper/film.

Typical alignment of cell component is shown in Annex B.

After assembling, the isolation between the clamping plates and current collectors shall be

checked.

6.2 Cell orientation and gas connections

A cell shall be operated in an orientation which facilitates product water removal. The cell

orientation shall be documented.

Many flow patterns can be used; the flow pattern shall be documented. Examples are given in

Annex A.

6.3 Leak check

The differential pressure on the membrane is the most critical. The maximum differential

pressure specified by the manufacturer should not be exceeded.

The cell must have minimal external and internal leakage. Examples leak-check procedures

are given in Annex C. In principle, the leak-check procedure consists of injecting an inert or

test gas into both the anode and cathode sides. By using a suitable pressure difference, the

nature and direction of the leak can be ascertained. The maximum pressures, the nature of

the test gas and leakage rates shall be documented. If a leak is detected, other tests, such as

bubble test, may be performed to further delineate type and nature of leak.

– 14 – TS 62282-7-1 © IEC:2010(E)

7 Test station setup

7.1 Minimum equipment requirement

A fuel cell test station is required to conduct the testing of the single cell. The minimum test

equipment functionality in order to meet the intention of the single cell test procedure includes

the following test parameters:

a) reactant gas flow rate control – to meter the flow rate of fuel and oxidant gases to the fuel

cell at the desired stoichiometric ratio;

b) reactant gas humidification control – to humidify the reactant gases to a specified dew

point prior to delivery to the fuel cell. The recommended water resistivity is at least

–4 –1

1 MΩ⋅cm (or at most a conductivity of 10 S m ).

NOTE The gas transfer lines between the humidifiers and the cell should be heated, at minimum, 5 °C to 10 °C

above the dew point temperature to minimize condensation. The lines should be insulated to minimize heat loss.

c) reactant gas pressure control – to regulate the reactant gas pressure within the fuel cell;

d) load control – load bank to draw a specified current from the cell. It should be capable of

operating in either constant current or constant voltage mode;

e) cell heating/cooling control – to heat or cool the single cell to the desired operating

temperature;

f) cell voltage monitoring and data acquisition – instrumentation to measure and record the

cell voltage throughout the test;

g) test station control – test station must be capable of controlling the above parameters;

h) safety systems – a safety system is needed that is capable of automatically (or manually

with audible alarms) shutting down the test in the event of a failure. A nitrogen purge

capability is recommended for the anode and cathode circuits. Interlocks triggered by

high/low cell voltage, pressure and temperature and gas leaks are also recommended.

Adequate ventilation should also be provided.

7.2 Schematic diagram

Figure 1 is a schematic block representation of the major sub-systems required in a test

station to conduct fuel cell testing.

TS 62282-7-1 © IEC:2010(E) – 15 –

TTest staest stattion ion

controlcontrol

Load Load Fuel cell Fuel cell

controlcontrol temperature temperature

controlcontrol

TTest staest stattion ion

controlcontrol

OxOxidant idant

OxOxidant idant HHeated eated

eexxhausthaust

inletinlet CCathode athode pipepipe

CCathode athode

LoaLoad d CCathode athode

flofloww

humidificationgas

ccontontoorr

pressure pressure

Fuel cell Fuel cell

control

humidification

ll

control contrcontrolol

under under

testtest

Fuel Fuel

inletinlet

AAnode node AAnode node

AAnode node

pressure pressure

humidificationgas

flofloww

contrcontrolol

humidification

control

control

HHeated eated

Fuel Fuel

pipepipe

eexxhausthaust

CCeell ll

vvoltage oltage

monitormonitor

IEC 1239/10

Figure 1 – Test station schematic diagram for single cell testing

Materials used for all components which will be in contact with humidified gas or humidifier

water shall be compatible with the gas or water to prevent the extraction of impurities from the

material. Example materials include stainless steel and fluoro-plastics.

The gas humidification system shall be designed to avoid removing the test impurities from

the gas stream prior to the gas entering the cell.

NOTE Impurities are given in ISO/TS 14687-2:2008, Hydrogen fuel – Product specification – Part 2: Proton

exchange membrane (PEM) fuel cell applications for road vehicles.

If this test is not to be executed, a bubbler saturator can be used for fuel humidification.

Variations to this configuration are acceptable providing that the functional requirements of

this document are met.

7.3 Maximum variation in test station controls (inputs to test)

The fuel cell test station shall have the following recommended maximum variation in its

controls:

a) current control ±1 % relative to set point;

b) voltage control ±1 % relative to set point;

c) cell temperature control ±1 °C at set point (at steady state);

d) humidity dew point control ±2 °C at set point (at steady state);

e) flow rate control ±5 % relative to set point;

f) pressure control ±3 % relative to set point.

– 16 – TS 62282-7-1 © IEC:2010(E)

8 Measurement

8.1 Instrument uncertainty

The maximum instrument uncertainty for the measurements (test outputs) in the tests shall be

as follows:

a) current ±1 % of maximum expected value;

b) voltage ±0,5 % of maximum expected value;

c) temperature ±1 °C;

d) dew point ±2 °C;

e) flow rate ±2 % of maximum expected value;

f) pressure ±3 % of maximum expected value.

NOTE At low current, voltage and flow rates, the uncertainties may be very large with respect to the measured

values.

8.2 Measuring instruments and measuring methods

8.2.1 General

Measuring instruments shall be selected in accordance with the range of values to be

measured. The instruments shall be calibrated regularly in order to maintain the level of

accuracy described in 10.1. All measuring devices must be calibrated to traceable standards.

8.2.2 Voltage

A voltage meter shall be connected to the anode and cathode flow plates or current collectors,

minimizing the influence of electrical contact resistances. The electrical contact resistances

between the connections of the voltage meter, either anode and cathode flow plates or output

terminals of anode and cathode current collectors, shall be measured and reported, if not

negligible.

8.2.3 Current

A current measuring device shall be located in the current-carrying circuit of the cell. The

current-measuring device may consist of a low-impedance ammeter or a calibrated shunt

resistor, which develops a precisely known voltage reflecting the current flowing. The current

may also be measured using the features of an electronic load.

8.2.4 Internal resistance (IR)

Recommended IR measuring methods are a current-interrupt method and an electrochemical

impedance spectroscopy (EIS) method. An AC resistance method using AC milliohm meter is

also acceptable. Although the frequency of the milliohm meter is typically 1 kHz, the value of

the measurement frequency should be reported.

Plus/minus sense leads of these measuring instruments shall be connected to the output

terminals of cathode and anode current collectors, respectively.

8.2.5 Fuel and oxidant flow rates

Fuel and oxidant flow rates shall be measured by means of a volumetric meter, a mass flow

meter, or a turbine-type flow meter. If such a method is not practical, flow measurement by a

nozzle, orifices, or venturi meter is recommended. The location of a flow meter shall be

upstream of the humidifier.

TS 62282-7-1 © IEC:2010(E) – 17 –

If the flow meter requires pressure compensation, a static pressure measuring port shall be

located immediately upstream of the flow meter to be corrected.

8.2.6 Fuel and oxidant temperature

The recommended sensor for direct temperature measurement is a thermocouple, resistance

thermometer with a transducer or a thermister.

The temperature sensor shall be located immediately downstream of the single cell. It is

recommended to position another sensor immediately upstream of the single cell.

If the fuel and/or oxidant flow meter require temperature compensation, the sensor for such

correction shall be located immediately upstream of the flow meter.

8.2.7 Cell temperature

The recommended sensor for direct temperature measurement is a thermocouple, resistance

thermometer with a transducer or a thermister.

The temperature sensor should be located as close as possible to the center of the cathode

active area. Ideally, it should be at the center of both anode and cathode flow plates. (See 5.5

and Annex A for more details.)

8.2.8 Fuel and oxidant pressures

For measuring fuel and oxidant pressures, calibrated pressure transducers are the preferred

method. Other acceptable methods include calibrated manometers, dead-weight gauges,

bourdon tubes or other elastic type gauges.

A static pressure measuring port shall be located immediately upstream of the single cell. If

necessary, another pressure-measuring port shall be also placed immediately downstream of

the single cell.

Connecting piping shall be checked to verify that it is leak-free under working conditions in

advance of the performance tests. Liquid water in the piping must be avoided.

If pressure fluctuations occur, a suitable means of damping shall be installed in an effective

position.

Pressures shall be measured as static pressures with the effect of velocity considered and

eliminated.

8.2.9 Fuel and oxidant humidity

For measuring fuel and oxidant humidity, a chilled mirror, aluminum oxide, bulk polymer

resistive or capacitance type hygrometer can be used to obtain humidity values, depending on

the fuel and oxidant temperatures.

Humidity shall be expressed as a dew-point temperature.

A humidity measuring port shall be located upstream of the single cell, or the humidity sensor

can be in the reactant gas before testing commences. In the case of using ambient or

synthetic air as oxidant, the dew point shall be measured and reported.

8.2.10 Ambient conditions

It is recommended that the ambient temperature, pressure and humidity shall be measured

and recorded.

– 18 – TS 62282-7-1 © IEC:2010(E)

For the direct measurement of ambient temperature, thermocouples with transducer or a

resistance thermometer with transducer is recommended.

For the direct measurement of ambient pressure, a mercury barometer is recommended.

For direct measurement of ambient humidity, a hygrometer is recommended.

8.3 Measurement units

Table 1 identifies the parameters and their measurement units for the tests.

Table 1 – Parameters and units

Parameter Unit

Temperature °C

c

Fuel and oxidant pressures kPa

Dew points of fuel and oxidant °C

a

3 –1 3 –1

Fuel and oxidant flow rates (NTP) cm min , cm s

Fuel and oxidant stoichiometries

Current A

–2

Current density A cm

Voltage V

Output power W

–2

Power density W cm

Area-specific cell resistance

Ωcm

b

–1

Fuel composition (mol) mol

b

–1

Oxidant composition (mol) mol

a

NTP = normal temperature and pressure: 0 °C and 101,325 kPa (absolute). Unless otherwise noted, NTP is

used for the flow rate.

b

–1

Impurities shall be listed as (μmol) mol .

c

ISO recommends using absolute pressure (kPa), if possible. If gauge pressure is used, it should be noted as

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...