IEC 61207-1:2010

(Main)Expression of performance of gas analyzers - Part 1: General

Expression of performance of gas analyzers - Part 1: General

IEC 61207-1:2010 specifies the terminology, definitions, requirements for statements by manufacturers and tests that are common to all gas analyzers. It is applicable to analyzers specified for permanent installation in any location (indoors or outdoors) and to such analyzers utilizing either a sample handling system or an in situ measurement technique. It is applicable to the complete analyzer when supplied by one manufacturer as an integral unit, comprised of all mechanical, electrical and electronic portions. It also applies to sensor units alone and electronic units alone when supplied separately or by different manufacturers. This second edition cancels and replaces the first edition published in 1994 and constitutes a technical revision. The significant technical changes with respect to the first edition are the following:

- all references (normative and informative) have been updated, deleted or added, as appropriate;

- all the terms and definitions relating to this International Standard have been updated;

- all references to "errors" have been replaced by "uncertainties" and appropriate updated definitions applied.

Where only one value is quoted for a performance specification, such as intrinsic uncertainty, linearity uncertainty or repeatability throughout a measurement range, this has now been defined as the maximum value, rather than an average or "representative" value. This was previously undefined. Where zero and 100 % span calibration gases are used, there is now a defined requirement that the analyser must be able to respond within its standard performance specifications beyond its normal measurement range, to allow for any under or over response of the instrument to be recorded. A new Annex A has been added giving recommended standard values of influence.

Expression des performances des analyseurs de gaz - Partie 1: Généralités

La CEI 61207-1:2010 comprend la terminologie, les définitions, les exigences de déclarations des fabricants ainsi que les essais communs à tous les analyseurs de gaz. Elle s'applique aux analyseurs spécifiés pour installation permanente en tout emplacement (à l'intérieur comme à l'extérieur) et aux analyseurs tels que ceux utilisant soit un système de manipulation des échantillons soit une technique de mesure sur site. Elle s'applique à l'analyseur complet lorsque celui-ci est fourni par un seul fabricant en une unité intégrée comprenant toutes les parties mécaniques, électriques et électroniques. Elle s'applique également aux unités de capteur seules et unités électroniques seules lorsqu'elles sont fournies séparément ou par des fabricants différents. Cette deuxième édition annule et remplace la première édition, parue en 1994, et constitue une révision technique. Cette édition inclut les modification techniques majeures suivantes:

- toutes les références (normatives et informatives) ont été mises à jour, retirées ou ajoutées comme il convient;

- tous les termes et définitions en rapport avec la présente Norme internationale ont été mis à jour;

- toutes les références aux erreurs ont été remplacées par "incertitude" et les définitions ont été mises à jour comme il convient.

Lorsqu'une seule valeur est appelée pour une spécification de performance, telle que l'incertitude intrinsèque, l'incertitude de linéarité ou de répétabilité, sur une étendue de mesure, cette valeur est maintenant définie comme valeur maximale plutôt qu'une moyenne ou une valeur représentative. Auparavant, ceci était indéfini. Lorsque les gaz d'étalonnage pour le zéro et le 100 % sont utilisés, il y a maintenant une exigence définie à savoir il faut que l'analyseur soit capable de répondre dans ses performances normalisées au delà de son étendue normale de mesure, afin de permettre l'enregistrement des réponses en deçà ou au-delà. Une nouvelle Annexe A a été ajouté pour donner les valeurs d'influence normalisées recommandées.

General Information

- Status

- Published

- Publication Date

- 30-May-2010

- Technical Committee

- SC 65B - Measurement and control devices

- Drafting Committee

- WG 14 - TC 65/SC 65B/WG 14

- Current Stage

- PPUB - Publication issued

- Start Date

- 31-May-2010

- Completion Date

- 15-Jun-2010

IEC 61207-1:2010 – Expression of Performance of Gas Analyzers – Part 1: General

Overview

IEC 61207-1:2010 is a key international standard published by the International Electrotechnical Commission (IEC) that defines the general principles for expressing the performance of gas analyzers. This standard sets out terminology, definitions, manufacturer requirements, and test procedures relevant to all types of gas analyzers used in measuring constituents within gaseous mixtures. It applies to analyzers intended for permanent installation, both indoors and outdoors, whether using sample handling systems or in situ measurement techniques.

Crucially, IEC 61207-1:2010 covers integrated analyzer units provided by a single manufacturer, as well as sensor or electronic units supplied separately or by different manufacturers. It represents a technical revision of the first edition from 1994 and introduces important updates to terminology-replacing "errors" with "uncertainties"-and clarifies performance specification methodologies.

Key Topics

Terminology and Definitions: Provides standardized terminology related to gas analyzers, ensuring clear and consistent communication across industries and manufacturers.

Performance Specification: Defines how manufacturers should state and specify values such as intrinsic uncertainty, linearity, and repeatability. It clarifies that performance values quoted must be maximum values within a measurement range rather than averages or representative figures.

Testing Procedures: Details the compliance tests required for verifying gas analyzer performance, including methods for measuring intrinsic uncertainty, linearity uncertainty, repeatability, output fluctuations, drift, response times, and interference uncertainties.

Measurement Conditions: Specifies operational, storage, and transport conditions impacting analyzer performance and requires analyzers to respond accurately beyond their calibrated measurement ranges (using zero and 100% span calibration gases).

Scope of Application: Applicable to permanently installed gas analyzers using either sample handling systems or direct in situ measurements. Includes complete analyzers, sensor units, and electronic units irrespective of whether supplied by one or multiple manufacturers.

Influence Quantities: Introduces recommended standard values of influence-environmental and operational factors affecting analyzer accuracy-and provides guidance to account for them in performance expression.

Annexes and References: Contains informative annexes such as Annex A recommending standard values of influence and a bibliography for extended reference to related standards.

Applications

IEC 61207-1:2010 is essential for manufacturers, users, and certifiers of gas analyzers across various industries including:

Industrial Process Control: Ensuring accurate gas measurement in manufacturing plants, chemical processing, and power generation.

Environmental Monitoring: Measuring pollutant gas concentrations reliably in indoor and outdoor air quality monitoring stations.

Safety Systems: Accurate measurement of flammable or hazardous gases, ensuring operation within safe concentration limits.

Instrumentation Suppliers: Providing a benchmark for the design, testing, and documentation of gas analyzers and sensor units.

By following IEC 61207-1, manufacturers can demonstrate compliance with internationally accepted performance standards, facilitating global market access. End users benefit from reliable, standardized performance data to select instruments optimized for their specific measurement needs.

Related Standards

IEC 61207 Series: Includes other parts addressing specific analyzer technologies, such as IEC 61207-2 which focuses on analyzers utilizing high-temperature electrochemical sensors.

IEC 60359: General principles for expressing uncertainty and performance in measuring instruments.

IEC 60770: Procedures for evaluation of measurement uncertainty.

IEC 60381-1 and IEC 60382: Standards for analogue and pneumatic signals used in process control.

IEC 60654: Specifies values for testing influence quantities affecting equipment performance.

IEC 61187: Requirements for documentation accompanying analyzers.

IEC 61010-1: Safety requirements for electrical equipment, applicable to gas analyzers.

ISO 1000 and ISO 31-0: Standards covering quantities, units, and symbols used in measurements.

Keywords: IEC 61207-1, gas analyzers, performance expression, intrinsic uncertainty, linearity, repeatability, measurement standards, gas analysis, compliance testing, sensor units, in situ measurement, industrial process control, environmental monitoring, international standards.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Sponsored listings

Frequently Asked Questions

IEC 61207-1:2010 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Expression of performance of gas analyzers - Part 1: General". This standard covers: IEC 61207-1:2010 specifies the terminology, definitions, requirements for statements by manufacturers and tests that are common to all gas analyzers. It is applicable to analyzers specified for permanent installation in any location (indoors or outdoors) and to such analyzers utilizing either a sample handling system or an in situ measurement technique. It is applicable to the complete analyzer when supplied by one manufacturer as an integral unit, comprised of all mechanical, electrical and electronic portions. It also applies to sensor units alone and electronic units alone when supplied separately or by different manufacturers. This second edition cancels and replaces the first edition published in 1994 and constitutes a technical revision. The significant technical changes with respect to the first edition are the following: - all references (normative and informative) have been updated, deleted or added, as appropriate; - all the terms and definitions relating to this International Standard have been updated; - all references to "errors" have been replaced by "uncertainties" and appropriate updated definitions applied. Where only one value is quoted for a performance specification, such as intrinsic uncertainty, linearity uncertainty or repeatability throughout a measurement range, this has now been defined as the maximum value, rather than an average or "representative" value. This was previously undefined. Where zero and 100 % span calibration gases are used, there is now a defined requirement that the analyser must be able to respond within its standard performance specifications beyond its normal measurement range, to allow for any under or over response of the instrument to be recorded. A new Annex A has been added giving recommended standard values of influence.

IEC 61207-1:2010 specifies the terminology, definitions, requirements for statements by manufacturers and tests that are common to all gas analyzers. It is applicable to analyzers specified for permanent installation in any location (indoors or outdoors) and to such analyzers utilizing either a sample handling system or an in situ measurement technique. It is applicable to the complete analyzer when supplied by one manufacturer as an integral unit, comprised of all mechanical, electrical and electronic portions. It also applies to sensor units alone and electronic units alone when supplied separately or by different manufacturers. This second edition cancels and replaces the first edition published in 1994 and constitutes a technical revision. The significant technical changes with respect to the first edition are the following: - all references (normative and informative) have been updated, deleted or added, as appropriate; - all the terms and definitions relating to this International Standard have been updated; - all references to "errors" have been replaced by "uncertainties" and appropriate updated definitions applied. Where only one value is quoted for a performance specification, such as intrinsic uncertainty, linearity uncertainty or repeatability throughout a measurement range, this has now been defined as the maximum value, rather than an average or "representative" value. This was previously undefined. Where zero and 100 % span calibration gases are used, there is now a defined requirement that the analyser must be able to respond within its standard performance specifications beyond its normal measurement range, to allow for any under or over response of the instrument to be recorded. A new Annex A has been added giving recommended standard values of influence.

IEC 61207-1:2010 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing; 71.040.40 - Chemical analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61207-1:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61207-1 ®

Edition 2.0 2010-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Expression of performance of gas analyzers –

Part 1: General

Expression des performances des analyseurs de gaz –

Partie 1: Généralités

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 61207-1 ®

Edition 2.0 2010-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Expression of performance of gas analyzers –

Part 1: General

Expression des performances des analyseurs de gaz –

Partie 1: Généralités

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

W

CODE PRIX

ICS 19.080; 71.040.40 ISBN 978-2-88910-947-0

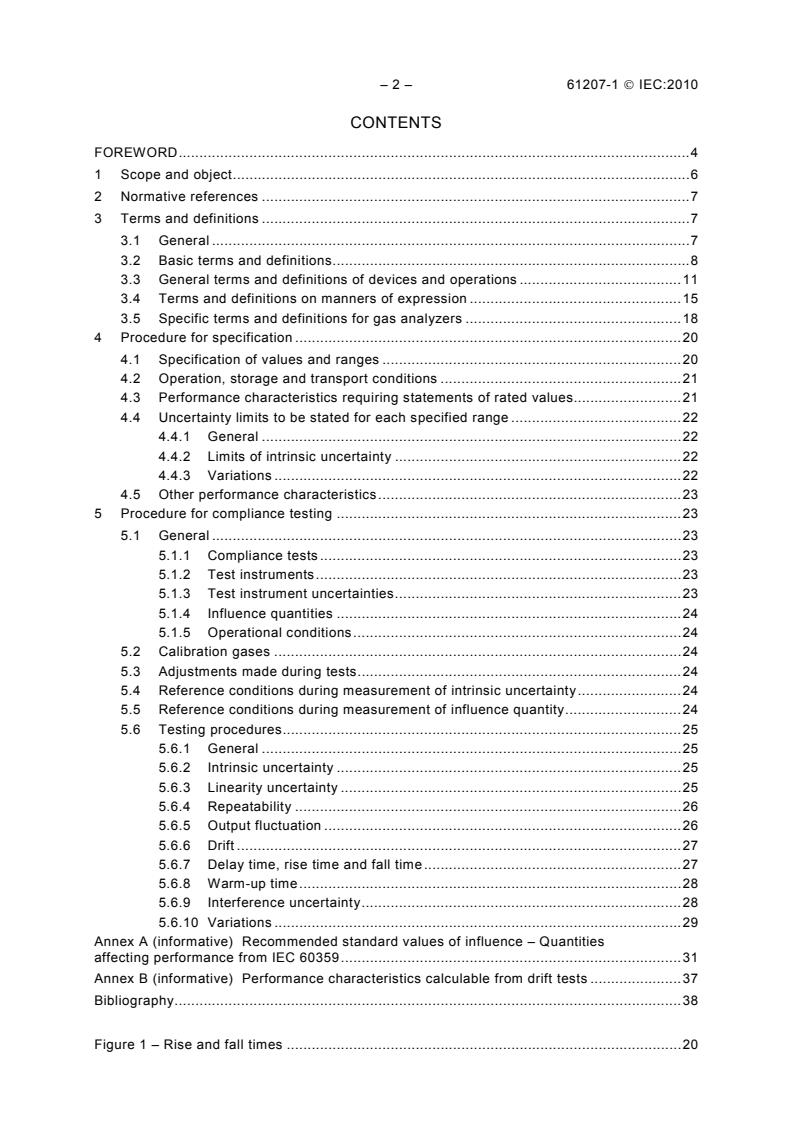

– 2 – 61207-1 © IEC:2010

CONTENTS

FOREWORD.4

1 Scope and object.6

2 Normative references .7

3 Terms and definitions .7

3.1 General .7

3.2 Basic terms and definitions.8

3.3 General terms and definitions of devices and operations .11

3.4 Terms and definitions on manners of expression .15

3.5 Specific terms and definitions for gas analyzers .18

4 Procedure for specification .20

4.1 Specification of values and ranges .20

4.2 Operation, storage and transport conditions .21

4.3 Performance characteristics requiring statements of rated values.21

4.4 Uncertainty limits to be stated for each specified range .22

4.4.1 General .22

4.4.2 Limits of intrinsic uncertainty .22

4.4.3 Variations .22

4.5 Other performance characteristics.23

5 Procedure for compliance testing .23

5.1 General .23

5.1.1 Compliance tests .23

5.1.2 Test instruments.23

5.1.3 Test instrument uncertainties.23

5.1.4 Influence quantities .24

5.1.5 Operational conditions.24

5.2 Calibration gases .24

5.3 Adjustments made during tests.24

5.4 Reference conditions during measurement of intrinsic uncertainty.24

5.5 Reference conditions during measurement of influence quantity.24

5.6 Testing procedures.25

5.6.1 General .25

5.6.2 Intrinsic uncertainty .25

5.6.3 Linearity uncertainty .25

5.6.4 Repeatability .26

5.6.5 Output fluctuation .26

5.6.6 Drift .27

5.6.7 Delay time, rise time and fall time.27

5.6.8 Warm-up time.28

5.6.9 Interference uncertainty.28

5.6.10 Variations .29

Annex A (informative) Recommended standard values of influence – Quantities

affecting performance from IEC 60359.31

Annex B (informative) Performance characteristics calculable from drift tests .37

Bibliography.38

Figure 1 – Rise and fall times .20

61207-1 © IEC:2010 – 3 –

Figure 2 – Output fluctuations .26

Table A.1 – Mains supply voltage .35

Table A.2 – Mains supply frequency .35

Table A.3 – Ripple of d.c. supply .36

Table B.1 – Data: applied concentration 1 000 units .37

– 4 – 61207-1 © IEC:2010

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPRESSION OF PERFORMANCE OF GAS ANALYZERS –

Part 1: General

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61207-1 has been prepared by subcommittee 65B: Devices and

process analysis, of IEC technical committee 65: Industrial-process measurement, control and

automation.

This second edition cancels and replaces the first edition published in 1994 and constitutes a

technical revision.

The significant technical changes with respect to the first edition are the following:

a) All references (normative and informative) have been updated, deleted or added, as

appropriate.

b) All the terms and definitions relating to this International Standard have been updated.

c) All references to “errors” have been replaced by “uncertainties” and appropriate updated

definitions applied.

d) Where only one value is quoted for a performance specification, such as intrinsic

uncertainty, linearity uncertainty or repeatability throughout a measurement range, this

61207-1 © IEC:2010 – 5 –

has now been defined as the maximum value, rather than an average or “representative”

value. This was previously undefined.

e) Where zero and 100 % span calibration gases are used, there is now a defined

requirement that the analyser must be able to respond within its standard performance

specifications beyond its normal measurement range, to allow for any under or over

response of the instrument to be recorded.

f) A new Annex A has been added giving recommended standard values of influence.

The text of this standard is based on the following documents:

FDIS Report on voting

65B/741/FDIS 65B/752/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61207 series, under the general title Expression of performance of

gas analyzers, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 61207-1 © IEC:2010

EXPRESSION OF PERFORMANCE OF GAS ANALYZERS –

Part 1: General

1 Scope and object

This part of IEC 61207 is applicable to gas analyzers used for the determination of certain

constituents in gaseous mixtures.

This part of IEC 61207 specifies the terminology, definitions, requirements for statements by

manufacturers and tests that are common to all gas analyzers. Other international standards

in this series, for example IEC 61207-2, describe those aspects that are specific to certain

types (utilizing high-temperature electrochemical sensors).

This part IEC 61207 is in accordance with the general principles set out in IEC 60359 and

IEC 60770.

This standard is applicable to analyzers specified for permanent installation in any location

(indoors or outdoors) and to such analyzers utilizing either a sample handling system or an in

situ measurement technique.

This standard is applicable to the complete analyzer when supplied by one manufacturer as

an integral unit, comprised of all mechanical, electrical and electronic portions. It also applies

to sensor units alone and electronic units alone when supplied separately or by different

manufacturers.

For the purposes of this standard, any regulator for mains-supplied power or any non-mains

power supply, provided with the analyzer or specified by the manufacturer, is considered part

of the analyzer whether it is integral with the analyzer or housed separately.

Safety requirements are dealt with in IEC 61010-1.

If one or more components in the sample is flammable, and air or another gas mixture

containing oxygen or other oxidizing component is present, then the concentration range of

the reactive components are limited to levels which are not within flammability limits.

Standard range of analogue d.c. current and pneumatic signals used in process control

systems are dealt with in IEC 60381-1 and IEC 60382.

Specifications for values for the testing of influence quantities can be found in IEC 60654.

Requirements for documentation to be supplied with instruments are dealt with in IEC 61187.

Requirements for general principles concerning quantities, units and symbols are dealt with in

ISO 1000. See also ISO 31-0.

This part of IEC 61207 does not apply to:

– accessories such as recorders, analogue-to-digital converters or data acquisition systems

used in conjunction with the analyzer, except that when two or more such analyzers are

combined and sold as a subsystem and a single electronic unit is supplied to provide

continuous measurement of several properties, that read-out unit is considered to be part

of the analyzer. Similarly, e.m.f-to-current or e.m.f-to-pressure converters which are an

integral part of the analyzer are included.

61207-1 © IEC:2010 – 7 –

The object of this part of IEC 61207 is:

– to specify the general aspects in the terminology and definitions related to the

performance of gas analyzers used for the continuous measurement of gas composition;

– to unify methods used in making and verifying statements on the functional performance of

such analyzers;

– to specify which tests should be performed in order to determine the functional

performance and how such tests should be carried out;

– to provide basic documents to support the application of standards of quality assurance

within ISO 9001.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60068 (all parts), Environmental testing

IEC 60359:2001, Electrical and electronic measurement equipment – Expression of

performance

IEC 60381-1, Analogue signals for process control systems – Part 1: Direct current signals

IEC 60382, Analogue pneumatic signal for process control systems

IEC 60654 (all parts), Industrial-process measurement and control equipment – Operating

conditions

IEC 60654-1, Industrial-process measurement and control equipment – Operating conditions –

Part 1: Climatic conditions

IEC 60770 (all parts), Transmitters for use in industrial-process control systems

IEC 60770-1, Transmitters for use in industrial-process control systems – Part 1: Methods for

performance evaluation

IEC 61010-1, Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

IEC 61187, Electrical and electronic measurement equipment – Documentation

ISO 31-0, Quantities and units – General principles

ISO 1000, SI units and recommendations for the use of their multiples and of certain other

units

3 Terms and definitions

3.1 General

For the purposes of this document, the following terms and definitions apply. The definitions

in 3.2 (excepting 3.2.17), 3.3 and 3.4 are taken from IEC 60359.

– 8 – 61207-1 © IEC:2010

3.2 Basic terms and definitions

3.2.1

measurand

quantity subjected to measurement, evaluated in the state assumed by the measured system

during the measurement itself

NOTE 1 The value assumed by a quantity subjected to measurement when it is not interacting with the measuring

instrument may be called unperturbed value of the quantity.

NOTE 2 The unperturbed value and its associated uncertainty can only be computed through a model of the

measured system and of the measurement interaction with the knowledge of the appropriate metrological

characteristics of the instrument that may be called instrumental load.

3.2.2

(result of a) measurement

set of values attributed to a measurand, including a value, the corresponding uncertainty and

the unit of measurement

[IEC 60050-311, 311-01-01, modified]

NOTE 1 The mid-value of the interval is called the value (see 3.2.3) of the measurand and its half-width the

uncertainty (see 3.2.4).

NOTE 2 The measurement is related to the indication (see 3.2.5) given by the instrument and to the values of

correction obtained by calibration.

NOTE 3 The interval can be considered as representing the measurand provided that it is compatible with all

other measurements of the same measurand.

NOTE 4 The width of the interval, and hence the uncertainty, can only be given with a stated level of confidence

(see 3.2.4, NOTE 1).

3.2.3

(measure-) value

mid element of the set assigned to represent the measurand

NOTE The measure-value is no more representative of the measurand than any other element of the set. It is

singled out merely for the convenience of expressing the set in the format V ± U, where V is the mid element and U

the half-width of the set, rather than by its extremes. The qualifier "measure-" is used when deemed necessary to

avoid confusion with the reading-value or the indicated value.

3.2.4

uncertainty (of measurement)

parameter, associated with the result of a measurement, that characterizes the dispersion of

the values that could reasonably be attributed to the measurand

NOTE 1 The parameter can be, for example, a standard deviation (or a given multiple of it), or a half-width of an

interval having a stated level of confidence.

NOTE 2 Uncertainty of measurement comprises, in general, many components. Some of these components can

be evaluated from the statistical distribution of the results of a series of measurements and can be characterized

by experimental standard deviations. The other components, which can also be characterized by standard

deviations, are evaluated from the assumed probability distributions based on experience or other information.

[IEC 60050-311, 311-01-02, ISO/IEC Guide 99, 2.26 modified]

NOTE 3 It is understood that the result of the measurement is the best estimate of the value of the measurand,

and that all components of uncertainty, including those arising from systematic effects, such as components

associated with corrections and reference standards, contribute to the dispersion.

NOTE 4 The definition and notes 1 and 2 are from GUM, Clause B.2.18. The option used in this standard is to

express the uncertainty as the half-width of an interval with the GUM procedures with a coverage factor of 2. This

choice corresponds to the practice now adopted by many national standards laboratories. With the normal

distribution a coverage factor of 2 corresponds to a level of confidence of 95 %. Otherwise statistical elaborations

are necessary to establish the correspondence between the coverage factor and the level of confidence. As the

data for such elaborations are not always available, it is deemed preferable to state the coverage factor. This

interval can be "reasonably" assigned to describe the measurand, in the sense of the GUM definition, as in most

61207-1 © IEC:2010 – 9 –

usual cases it ensures compatibility with all other results of measurements of the same measurand assigned in the

same way at a sufficiently high confidence level.

NOTE 5 Following CIPM document INC-1 and ISO/IEC Guide 98-3, the components of uncertainty that are

evaluated by statistical methods are referred to as components of category A, and those evaluated with the help of

other methods as components of category B.

3.2.5

indication or reading-value

output signal of the instrument

[IEC 60050-311, 311-01-01, modified]

NOTE 1 The indicated value can be derived from the indication by means of the calibration curve.

NOTE 2 For a material measure, the indication is its nominal or stated value.

NOTE 3 The indication depends on the output format of the instrument:

– for analogue outputs it is a number tied to the appropriate unit of the display;

– for digital outputs it is the displayed digitized number;

– for code outputs it is the identification of the code pattern.

NOTE 4 For analogue outputs meant to be read by a human observer (as in the index-on-scale instruments) the

unit of output is the unit of scale numbering; for analogue outputs meant to be read by another instrument (as in

calibrated transducers) the unit of output is the unit of measurement of the quantity supporting the output signal.

3.2.6

calibration

set of operations which establishes the relationship which exists, under specified conditions,

between the indication and the result of a measurement

[IEC 60050-311, 311-01-09]

NOTE 1 The relationship between the indications and the results of measurement can be expressed, in principle,

by a calibration diagram.

NOTE 2 The calibration must be performed under well-defined operating conditions for the instrument. The

calibration diagram representing its result is not valid if the instrument is operated under conditions outside the

range used for the calibration.

NOTE 3 Quite often,e specially for instruments whose metrological characteristics are sufficiently known from

past experience, it is convenient to predefine a simplified calibration diagram and perform only a verification of

calibration (see 3.3.12) to check whether the response of the instrument stays within its limits. The simplified

diagram is, of course, wider than the diagram that would be defined by the full calibration of the instrument, and

the uncertainty assigned to the results of measurements is consequently larger.

3.2.7

calibration diagram

portion of the co-ordinate plane, defined by the axis of indication and the axis of results of

measurement, which represents the response of the instrument to differing values of the

measurand

[IEC 60050-311, 311-01-10]

3.2.8

calibration curve

curve which gives the relationship between the indication and the value of the measurand

NOTE 1 When the calibration curve is a straight line passing through zero, it is convenient to refer to the slope

which is known as the instrument constant.

[IEC 60050-311, 311-01-11]

NOTE 2 The calibration curve is the curve bisecting the width of the calibration diagram parallel to the axis of

results of measurement, thus joining the points representing the values of the measurand.

– 10 – 61207-1 © IEC:2010

3.2.9

indicated value

value given by an indicating instrument on the basis of its calibration curve

[IEC 60050-311, 311-01-08]

NOTE The indicated value is the measure-value of the measurand when the instrument is used in a direct

measurement (see 3.3.7) under all the operating conditions for which the calibration diagram is valid.

3.2.10

(measurement) compatibility

property satisfied by all the results of measurement of the same measurand, characterized by

an adequate overlap of their intervals

[IEC 60050-311, 311-01-14]

NOTE 1 The compatibility of any result of a measurement with all the other ones that represent the same

measurand can be asserted only at some level of confidence, as it depends on statistical inference, a level that

should be indicated, at least by implicit convention or through a coverage factor.

NOTE 2 The compatibility of the results of measurements obtained with different instruments and methods is

ensured by the traceability (see 3.2.16) to a common primary standard (see 3.3.6) of the standards used for the

calibration of the several instruments (and of course by the correctness of the calibration and operation

procedures).

NOTE 3 When two results of a measurement are not compatible it must be decided by independent means

whether one or both results are wrong (perhaps because the uncertainty is too narrow), or whether the measurand

is not the same.

NOTE 4 Measurements carried out with wider uncertainty yield results which are compatible on a wider range,

because they discriminate less among different measurands allowing to classify them with simpler models; with

narrower uncertainties the compatibility calls for more detailed models of the measured systems.

3.2.11

intrinsic uncertainty of the measurand

minimum uncertainty that can be assigned in the description of a measured quantity

NOTE 1 No quantity can be measured with narrower and narrower uncertainty, in as much as any given quantity

is defined or identified at a given level of detail. If one tries to measure a given quantity with uncertainty lower than

its own intrinsic uncertainty one is compelled to redefine it with higher detail, so that one is actually measuring

another quantity. See also GUM D.1.1.

NOTE 2 The result of a measurement carried out with the intrinsic uncertainty of the measurand may be called the

best measurement of the quantity in question.

3.2.12

(absolute) instrumental uncertainty

uncertainty of the result of a direct measurement of a measurand having negligible intrinsic

uncertainty

NOTE 1 Unless explicitly stated otherwise, the instrumental uncertainty is expressed as an interval with coverage

factor 2.

NOTE 2 In single-reading direct measurements of measurands having intrinsic uncertainty small with respect to

the instrumental uncertainty, the uncertainty of the measurement coincides, by definition, with the instrumental

uncertainty. Otherwise the instrumental uncertainty is to be treated as a component of category B in evaluating the

uncertainty of the measurement on the basis of the model connecting the several direct measurements involved.

NOTE 3 The instrumental uncertainty automatically includes, by definition, the effects due to the quantization of

the reading-values (minimum evaluable fraction of the scale interval in analogic outputs, unit of the last stable digit

in digital outputs).

NOTE 4 For material measures the instrumental uncertainty is the uncertainty that should be associated to the

value of the quantity reproduced by the material measure in order to ensure the compatibility of the results of its

measurements.

NOTE 5 When possible and convenient the uncertainty may be expressed in the relative form (see 3.4.3) or in the

fiducial form (see 3.4.4). The relative uncertainty is the ratio U/V of the absolute uncertainty U to the measure

61207-1 © IEC:2010 – 11 –

value V, and the fiducial uncertainty the ratio U/V of the absolute uncertainty U to a conventionally chosen value

f

V .

f

3.2.13

conventional value measure

value of a standard used in a calibration operation and known with uncertainty negligible with

respect to the uncertainty of the instrument to be calibrated

NOTE This definition is adapted to the object of this standard from the definition of "conventional true value (of a

quantity)": value attributed to a particular quantity and accepted, sometimes by convention, as having an

uncertainty appropriate for a given purpose (see IEC 60050-311, 311-01-06, ISO/IEC Guide 99, 2.13 modified).

3.2.14

influence quantity

quantity which is not the subject of the measurement and whose change affects the

relationship between the indication and the result of the measurement

NOTE 1 Influence quantities can originate from the measured system, the measuring equipment or the

environment.

NOTE 2 As the calibration diagram depends on the influence quantities, in order to assign the result of a

measurement it is necessary to know whether the relevant influence quantities lie within the specified range.

[IEC 60050-311, 311-06-01]

NOTE 3 An influence quantity is said to lie within a range C’ to C" when the results of its measurement satisfy the

relationship: C' ≤ V – U < V + U ≤ C".

3.2.15

steady-state conditions

operating conditions of a measuring device in which the variation of the measurand with the

time is such that the relation between the input and output signals of the instruments does not

suffer a significant change with respect to the relation obtaining when the measurand is

constant in time

3.2.16

traceability

property of the result of a measurement or of the value of a standard such that it can be

related to stated references, usually national or international standards, through an unbroken

chain of comparisons all having stated uncertainties

[IEC 60050-311, 311-01-15, ISO/IEC Guide 99, 2.41 modified]

NOTE 1 The concept is often expressed by the adjective traceable.

NOTE 2 The unbroken chain of comparisons is called a traceability chain.

NOTE 3 The traceability implies that a metrological organization be established with a hierarchy of standards

(instruments and material measures) of increasing intrinsic uncertainty. The chain of comparisons from the primary

standard to the calibrated device adds indeed new uncertainty at each step.

NOTE 4 Traceability is ensured only within a given uncertainty that should be specified.

3.2.17

mean

summation of the individual values divided by the total number of values for a set of values

3.3 General terms and definitions of devices and operations

3.3.1

(measuring) instrument

device intended to be used to make measurements, alone or in conjunction with

supplementary devices

[IEC 60050-311, 311-03-01, ISO/IEC Guide 99, 3.1 modified]

– 12 – 61207-1 © IEC:2010

NOTE The term "(measuring) instruments" includes both the indicating instruments and the material measures.

3.3.2

indicating (measuring) instrument

measuring instrument which displays an indication

NOTE 1 The display can be analogue (continuous or discontinuous), digital or coded [IEV].

NOTE 2 Values of more than one quantity can be displayed simultaneously [IEV].

NOTE 3 A displaying measuring instrument can also provide a record [IEV].

NOTE 4 The display can consist of an output signal not directly readable by a human observer, but able to be

interpreted by suitable devices [IEV].

[IEC 60050-311, 311-03-02, ISO/IEC Guide 99, 3.3 modified]

NOTE 5 An indicating instrument may consist of a chain of transducers with the possible addition of other process

devices, or it may consist of one transducer.

NOTE 6 The interaction between the indicating instrument, the measured system and the environment generates

a signal in the first stage of the instrument (called sensor). This signal is elaborated inside the instrument into an

output signal which carries the information on the measurand. The description of the output signal in a suitable

output format is the indication supplied by the instrument.

NOTE 7 A chain of instruments is treated as a single indicating instrument when a single calibration diagram is

available that connects the measurand to the output of the last element of the chain. In this case the influence

quantities must be defined for the whole chain.

3.3.3

material measure

device intended to reproduce or supply, in a permanent manner during its use, one or more

known values of a given quantity

NOTE 1 The quantity concerned may be called the supplied quantity [IEV].

[IEC 60050-311, 311-03-03, ISO/IEC Guide 99, 3.6 modified]

NOTE 2 The definition covers also the devices, such as signal generators and standard voltage or current

generators, often referred to as supply instruments.

NOTE 3 The identification of the value and uncertainty of the supplied quantity is given by a number tied to a unit

of measurement or a code term, called nominal value or marked value of the material measure.

3.3.4

electrical measuring instrument

measuring instrument intended to measure an electrical or non-electrical quantity using

electrical or electronic means

[IEC 60050-311, 311-03-04]

3.3.5

transducer

technical device which performs a given elaboration on an input signal, transforming it into an

output signal

NOTE All indicating instruments contain transducers and they may consist of one transducer. When the signals

are elaborated by a chain of transducers, the input and output signals of each transducer are not always directly

and univocally accessible.

3.3.6

primary standard

standard that is designated or widely acknowledged as having the highest metrological

qualities and whose value is accepted without reference to other standards of the same

quantity

NOTE 1 The concept of a primary standard is equally valid for base quantities and derived quantities.

61207-1 © IEC:2010 – 13 –

NOTE 2 A primary standard is never used directly for measurement other than for comparison with other primary

standards or reference standards.

[IEC 60050-311, 311-04-02, ISO/IEC Guide 99, 5.4 modified]

3.3.7

direct (method of) measurement

method of measurement in which the value of a measurand is obtained directly, without the

necessity for supplementary calculations based on a functional relationship between the

measurand and other quantities actually measured

NOTE 1 The value of the measurand is considered to be obtained directly even when the scale of a measuring

instrument has values which are linked to corresponding values of the measurand by means of a table or a graph

[IEV].

NOTE 2 The method of measurement remains direct even if it is necessary to make supplementary measurements

to determine the values of influence quantities in order to make corrections [IEV].

[IEC 60050-311, 311-02-01]

NOTE 3 The definitions of the metrological characteristics of the instruments refer implicitly to their use in direct

measurements.

3.3.8

indirect (method of) measurement

method of measurement in which the value of a quantity is obtained from measurements

made by direct methods of measurement of other quantities linked to the measurand by a

known relationship

[IEC 60050-311, 311-02-02]

NOTE 1 In order to apply an indirect method of measurement a model is needed which is able to supply the

relationship, and which is fully explicit, between the measurand and the parameters that are measured by direct

measurement.

NOTE 2 The computations must be carried out on both values and uncertainties, and therefore require accepted

rules for the propagation of the uncertainty as provided by GUM.

3.3.9

(method of) measurement by repeated observations

method of measurement by which the result of the measurement is assigned on the basis of a

statistical analysis on the distribution of the data obtained by several observations repeated

under nominally equal conditions

NOTE 1 One should resort to a statistical analysis when the instrumental uncertainty is too small to ensure the

measurement compatibility. This may happen in two quite different sets of circumstances:

a) when the measurand is a quantity subjected to intrinsic statistical fluctuations (e.g. in measurements involving

nuclear decay). In this case the actual measurand is the statistical distribution of the states of the measured

quantity, to be described by its statistical parameters (mean and standard deviation). The statistical analysis is

carried out on a population of results of measurement, each with its own value and uncertainty, as each

observation correctly describes one particular state of the measured quantity. The situation may be considered

a particular case of indirect measurement.

b) when the noise associated with the transmission of signals affects the reading-value more than in the

operating conditions used for the calibration, contributing to the uncertainty of the measurement to an extent

comparable with the instrumental uncertainty or higher (e.g. in the field use of surveyor instruments). In this

case, the statistical analysis is carried out on a population of reading-values with the purpose of separating the

information on the measurand from the noise. The situation may be considered as a new calibration of the

instrument for a set of operating conditions outside their rated range.

NOTE 2 One cannot presume to obtain by means of repeated observation an uncertainty lower than the

instrumental uncertainty assigned by the calibration or the class of precision of the instrument. Indeed, if the

results of the repeated measurements are compatible with each other within the instrumental uncertainty, the latter

is the valid datum for the uncertainty of the measurement and several observations do not bring more information

than one. In the other hand, if they are not compatible within the instrumental uncertainty, the final result of the

measurement should be expressed with a larger uncertainty in order to make all results compatible as they should

be by definition.

– 14 – 61207-1 © IEC:2010

NOTE 3 For instruments that exhibit non-negligible hysteresis a straightforward statistical analysis of repeated

observations is misleading. Appropriate test procedures for such instruments should be expounded in their

particular standards.

3.3.10

intrinsic (instrumental) uncertainty

uncertainty of a measuring instrument when used under reference conditions

[IEC 60050-311, 311-03-09, modified]

3.3.11

operating instrumental uncertainty

instrumental uncertainty under the rated operating conditions

NOTE The operating instrumental uncertainty, like the intrinsic one, is not evaluated by the user of the

instrument, but is stated by its manufacturer or calibrator. The statement may be expressed by means of an

algebraic relation involving the intrinsic instrumental uncertainty and the values of one or several influence

quantities, but such a relation is just a convenient means of expressing a set of operating instrumental

uncertainties under different operating conditions, not a functional relation to be used for evaluating the

propagation of uncertainty inside the instrument.

3.3.12

verification (of calibration)

set of operations which is used to check whether the indications, under specified conditio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...