IEC 60095-1:2018

(Main)Lead-acid starter batteries - Part 1: General requirements and methods of test

Lead-acid starter batteries - Part 1: General requirements and methods of test

CORRECTED VERSION 2026-02

IEC 60095-1:2018 is applicable to lead-acid batteries with a nominal voltage of 12 V, used primarily as a power source for the starting of internal combustion engines, lighting, and for auxiliary equipment of internal combustion engine vehicles. These batteries are commonly called "starter batteries".

This document is applicable to batteries for the following purposes:

• batteries for passenger cars;

• batteries for commercial and industrial vehicles.

IEC 60095-1:2018 is not applicable to batteries for other purposes, such as the starting of railcar internal combustion engines or for motorcycles and other power sport vehicles. IEC 60095-1:2018 defines many general properties of lead-acid batteries. Single sections can be referenced in other parts of the IEC 60095 series even if the application is excluded in the scope of this document. This document specifies the:

• general requirements;

• essential functional characteristics, relevant test methods and results required,

for several classes of starter batteries:

• according to the general type of application;

• according to the type of product.

IEC 60095-1:2018 cancels and replaces the seventh edition published in 2006. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) charge acceptance test;

b) cranking performance test;

c) charge retention test; and

d) endurance test added.

The content of the corrigendum 1 (2026-02) has been included in this copy.

General Information

- Status

- Published

- Publication Date

- 15-Nov-2018

- Technical Committee

- TC 21 - Secondary cells and batteries

- Drafting Committee

- WG 2 - TC 21/WG 2

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Nov-2018

- Completion Date

- 14-Dec-2018

Relations

- Effective Date

- 23-Jan-2026

- Revises

IEC 60095-1:2006 - Lead-acid starter batteries - Part 1: General requirements and methods of test - Effective Date

- 05-Sep-2023

Overview

IEC 60095-1:2018 - Lead‑acid starter batteries, Part 1 - defines the general requirements and methods of test for 12 V lead‑acid batteries used primarily to start internal combustion engines and supply lighting/auxiliary equipment in vehicles. Published as Edition 8.0 (2018), this technical revision replaces the 2006 edition and adds or updates key test methods including charge acceptance, cranking performance, charge retention, and an endurance test.

This standard applies to starter batteries for:

- Passenger cars

- Commercial and industrial vehicles

It does not apply to batteries for railcars, motorcycles or other power‑sport vehicles, although individual clauses may be referenced elsewhere in the IEC 60095 series.

Key Topics and Requirements

IEC 60095-1:2018 specifies general properties, functional characteristics and required test methods. Major technical topics covered include:

- Designation and marking: battery type, nominal voltage (12 V), capacity/reserve capacity, polarity, production date code, safety and recycling labels.

- Condition on delivery and definitions of dry‑charged or conserved‑charge batteries.

- Electrical and mechanical functional characteristics: capacity checks and cranking capability.

- Standardized test methods, including:

- 20 h capacity check (C) and reserve capacity (RC) checks

- Cranking performance test (standard −18 °C and very cold climate variants)

- High‑current discharge at low temperature

- Charge acceptance test and charge retention test

- Endurance and corrosion tests (including optional endurance cycle for passenger car batteries - max capacity 100 Ah)

- Water consumption, vibration resistance, and electrolyte retention tests

- Test conditions and equipment: sampling rules, charging methods to define a fully charged battery, measuring instruments, water bath and environmental chamber requirements.

- Normative and informative annexes: correlation between C and RC, temperature/duration conversions for water consumption, and safety labelling (ISO 7010 symbols).

Applications - Who Uses This Standard

IEC 60095-1 is used by:

- Battery manufacturers for product design, quality control and conformity testing

- Automotive OEMs and Tier‑1 suppliers to specify starter battery performance for vehicles

- Independent test labs and certification bodies performing standardized performance and safety tests

- Regulatory bodies and procurement teams for product acceptance criteria

- R&D and reliability engineers assessing charge acceptance, cranking performance and endurance

Related Standards

- IEC 60095-2 - Dimensions of batteries and terminals (related normative reference)

- IEC 60095-4 - Dimensions for heavy vehicle batteries

- IEC 60050-482 (electrotechnical vocabulary) and other parts of the IEC 60095 series provide complementary definitions and detailed application‑specific requirements.

Keywords: IEC 60095-1:2018, lead‑acid starter batteries, 12 V starter batteries, cranking performance test, charge acceptance test, charge retention, endurance test, battery test methods, automotive starter battery standard.

Buy Documents

IEC 60095-1:2018 - Lead-acid starter batteries - Part 1: General requirements and methods of test

IEC 60095-1:2018 RLV - Lead-acid starter batteries - Part 1: General requirements and methods of test

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

IEC 60095-1:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Lead-acid starter batteries - Part 1: General requirements and methods of test". This standard covers: CORRECTED VERSION 2026-02 IEC 60095-1:2018 is applicable to lead-acid batteries with a nominal voltage of 12 V, used primarily as a power source for the starting of internal combustion engines, lighting, and for auxiliary equipment of internal combustion engine vehicles. These batteries are commonly called "starter batteries". This document is applicable to batteries for the following purposes: • batteries for passenger cars; • batteries for commercial and industrial vehicles. IEC 60095-1:2018 is not applicable to batteries for other purposes, such as the starting of railcar internal combustion engines or for motorcycles and other power sport vehicles. IEC 60095-1:2018 defines many general properties of lead-acid batteries. Single sections can be referenced in other parts of the IEC 60095 series even if the application is excluded in the scope of this document. This document specifies the: • general requirements; • essential functional characteristics, relevant test methods and results required, for several classes of starter batteries: • according to the general type of application; • according to the type of product. IEC 60095-1:2018 cancels and replaces the seventh edition published in 2006. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) charge acceptance test; b) cranking performance test; c) charge retention test; and d) endurance test added. The content of the corrigendum 1 (2026-02) has been included in this copy.

CORRECTED VERSION 2026-02 IEC 60095-1:2018 is applicable to lead-acid batteries with a nominal voltage of 12 V, used primarily as a power source for the starting of internal combustion engines, lighting, and for auxiliary equipment of internal combustion engine vehicles. These batteries are commonly called "starter batteries". This document is applicable to batteries for the following purposes: • batteries for passenger cars; • batteries for commercial and industrial vehicles. IEC 60095-1:2018 is not applicable to batteries for other purposes, such as the starting of railcar internal combustion engines or for motorcycles and other power sport vehicles. IEC 60095-1:2018 defines many general properties of lead-acid batteries. Single sections can be referenced in other parts of the IEC 60095 series even if the application is excluded in the scope of this document. This document specifies the: • general requirements; • essential functional characteristics, relevant test methods and results required, for several classes of starter batteries: • according to the general type of application; • according to the type of product. IEC 60095-1:2018 cancels and replaces the seventh edition published in 2006. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) charge acceptance test; b) cranking performance test; c) charge retention test; and d) endurance test added. The content of the corrigendum 1 (2026-02) has been included in this copy.

IEC 60095-1:2018 is classified under the following ICS (International Classification for Standards) categories: 29.220.20 - Acid secondary cells and batteries; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60095-1:2018 has the following relationships with other standards: It is inter standard links to IEC 60095-1:2018/COR1:2026, IEC 60095-1:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60095-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60095-1 ®

Edition 8.0 2018-11

INTERNATIONAL

STANDARD

colour

inside

Lead-acid starter batteries –

Part 1: General requirements and methods of test

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60095-1 ®

Edition 8.0 2018-11

INTERNATIONAL

STANDARD

colour

inside

Lead-acid starter batteries –

Part 1: General requirements and methods of test

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.220.20; 43.040.10 ISBN 978-2-8322-6250-4

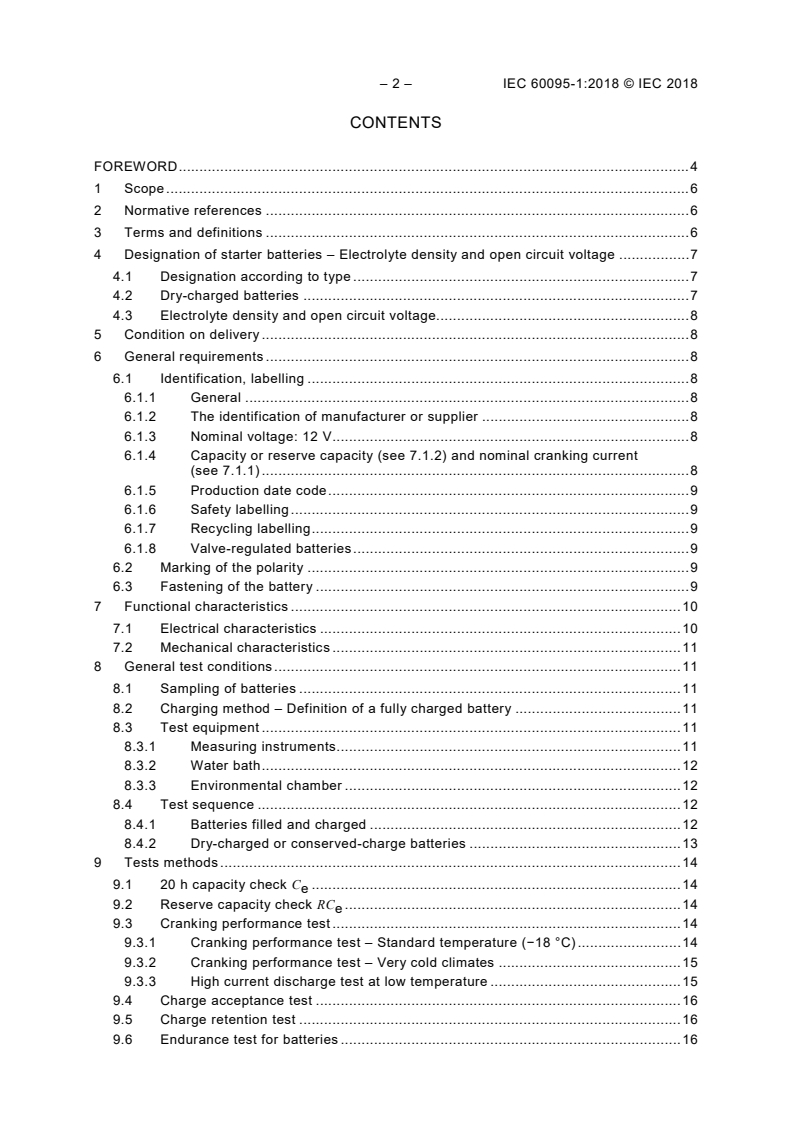

– 2 – IEC 60095-1:2018 © IEC 2018

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Designation of starter batteries – Electrolyte density and open circuit voltage . 7

4.1 Designation according to type . 7

4.2 Dry-charged batteries . 7

4.3 Electrolyte density and open circuit voltage. 8

5 Condition on delivery . 8

6 General requirements . 8

6.1 Identification, labelling . 8

6.1.1 General . 8

6.1.2 The identification of manufacturer or supplier . 8

6.1.3 Nominal voltage: 12 V . 8

6.1.4 Capacity or reserve capacity (see 7.1.2) and nominal cranking current

(see 7.1.1) . 8

6.1.5 Production date code . 9

6.1.6 Safety labelling . 9

6.1.7 Recycling labelling . 9

6.1.8 Valve-regulated batteries . 9

6.2 Marking of the polarity . 9

6.3 Fastening of the battery . 9

7 Functional characteristics . 10

7.1 Electrical characteristics . 10

7.2 Mechanical characteristics . 11

8 General test conditions . 11

8.1 Sampling of batteries . 11

8.2 Charging method – Definition of a fully charged battery . 11

8.3 Test equipment . 11

8.3.1 Measuring instruments. 11

8.3.2 Water bath . 12

8.3.3 Environmental chamber . 12

8.4 Test sequence . 12

8.4.1 Batteries filled and charged . 12

8.4.2 Dry-charged or conserved-charge batteries . 13

9 Tests methods . 14

9.1 20 h capacity check C . 14

e

9.2 Reserve capacity check RC . 14

e

9.3 Cranking performance test . 14

9.3.1 Cranking performance test – Standard temperature (−18 °C) . 14

9.3.2 Cranking performance test – Very cold climates . 15

9.3.3 High current discharge test at low temperature . 15

9.4 Charge acceptance test . 16

9.5 Charge retention test . 16

9.6 Endurance test for batteries . 16

9.6.1 Corrosion test . 16

9.6.2 Optional endurance cycle test for passenger car batteries – Maximum

capacity 100 Ah . 18

9.7 Water consumption test . 19

9.8 Vibration resistance test . 19

9.9 Electrolyte retention test . 20

9.10 Cranking performance for dry-charged (or conserved-charge) batteries after

activation . 20

10 Requirements . 20

Annex A (normative) Correlation between C and RC . 22

n n

Annex B (informative) Water consumption test – Conversion of test temperatures and

test durations . 23

B.1 General . 23

B.2 Conversion formula . 23

Annex C (informative) Safety labelling . 24

C.1 Definition of the six coloured symbols . 24

C.2 Safety labelling – Label for North America area . 24

Bibliography . 26

Figure C.1 – Symbol dimensions . 24

Figure C.2 – Safety labelling – Label for North America area, former version (still valid) . 25

Figure C.3 – Safety labelling – Label for North America area, new version . 25

Table 1 – Charging method . 11

Table 2 – Accuracy of test equipment . 12

Table 3 – Test sequence . 13

Table 4 – Parameters cycle test . 17

Table 5 – Vibration resistance – Levels V1 to V3 . 19

Table 6 – Summary of requirements . 21

Table C.1 – Definition of safety symbols according to ISO 7010 . 24

– 4 – IEC 60095-1:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LEAD-ACID STARTER BATTERIES –

Part 1: General requirements and methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60095-1 has been prepared by IEC technical committee 21:

Secondary cells and batteries.

This eighth edition cancels and replaces the seventh edition published in 2006. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) charge acceptance test;

b) cranking performance test;

c) charge retention test; and

d) endurance test added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

21/974/FDIS 21/987/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60095 series, published under the general title Lead-acid starter

batteries, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60095-1:2018 © IEC 2018

LEAD-ACID STARTER BATTERIES –

Part 1: General requirements and methods of test

1 Scope

This part of IEC 60095 is applicable to lead-acid batteries with a nominal voltage of 12 V,

used primarily as a power source for the starting of internal combustion engines, lighting, and

for auxiliary equipment of internal combustion engine vehicles. These batteries are commonly

called "starter batteries".

This document is applicable to batteries for the following purposes:

• batteries for passenger cars;

• batteries for commercial and industrial vehicles.

This document is not applicable to batteries for other purposes, such as the starting of railcar

internal combustion engines or for motorcycles and other power sport vehicles.

This document defines many general properties of lead-acid batteries. Single sections can be

referenced in other parts of the IEC 60095 series even if the application is excluded in the

scope of this document.

This document specifies the:

• general requirements;

• essential functional characteristics, relevant test methods and results required,

for several classes of starter batteries:

• according to the general type of application;

• according to the type of product.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-482, International Electrotechnical Vocabulary – Chapter 482: Primary and

secondary cells and batteries

IEC 60095-2, Lead-acid starter batteries – Part 2: Dimensions of batteries and dimensions

and marking of terminals

IEC 60095-4, Lead-acid starter batteries – Part 4: Dimensions of batteries for heavy vehicles

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

flooded battery

lead-acid battery having a cover provided with one or more openings through which gaseous

products may escape

3.2

enhanced flooded battery

EFB battery

flooded lead-acid battery with additional special design features to significantly improve the

cycling capability compared to standard flooded batteries

3.3

valve regulated lead-acid battery

VRLA battery

lead-acid battery which is closed under normal conditions but which has an arrangement that

allows the escape of gas if the internal pressure exceeds a predetermined value

Note 1 to entry: The VRLA battery cannot receive addition to the electrolyte and after activation of dry-charged

VRLA.

Note 2 to entry: In VRLA batteries the electrolyte is immobilized.

3.4

absorbent glass mat battery

AGM battery

VRLA battery in which the electrolyte is immobilized by absorption in a glass mat

3.5

gel battery

VRLA battery in which the electrolyte is immobilized by fixing as a gel

4 Designation of starter batteries – Electrolyte density and open circuit

voltage

4.1 Designation according to type

Batteries are designated according to their type, as follows:

• flooded batteries (vented);

• enhanced flooded batteries, EFB;

• valve regulated lead-acid batteries, VRLA;

– absorbent glass mat batteries, AGM;

– gel batteries.

4.2 Dry-charged batteries

Lead-acid batteries may be supplied in a dry-charged state. Dry-charged batteries can be

activated by filling with the defined electrolyte indicated by internal or external marks or

according to the manufacturer's activation instructions. After activation, these batteries are

ready to use.

– 8 – IEC 60095-1:2018 © IEC 2018

4.3 Electrolyte density and open circuit voltage

The density of the electrolyte in all fully charged vented batteries shall be in the range of

1,27 kg/l to 1,30 kg/l at 25 °C unless otherwise specified by the manufacturer.

NOTE For valve-regulated batteries, the electrolyte is not accessible and, therefore, its density cannot be

checked.

The open circuit voltage (OCV) at 25 °C, of fully charged batteries after a minimum 24 h stand

on open circuit, shall be in the range of 12,70 V to 12,90 V for vented types and 12,80 V to

13,10 V for valve regulated types unless otherwise specified by the manufacturer.

The manufacturer shall specify the value and tolerance of the electrolyte density or OCV. If

such information is not available, vented battery testing shall be carried out with a density of

1,28 kg/l ± 0,01 kg/l at 25 °C or an OCV of 12,76 V ± 0,06 V at 25 °C and valve regulated

battery testing shall be carried out with a minimum OCV of 12,80 V.

5 Condition on delivery

New vented batteries may be supplied either:

• in a state ready for use, or

• in a dry-charged (or charge-conserved) state not filled with electrolyte. The density of the

electrolyte to fill these batteries before use (unless otherwise recommended by the

manufacturer) shall be:

– 1,28 kg/l ± 0,01 kg/l at 25 °C;

Valve-regulated batteries are normally supplied in a state ready for use.

6 General requirements

6.1 Identification, labelling

6.1.1 General

Batteries complying with this document shall bear the following characteristics on at least the

top or one of their four sides.

6.1.2 The identification of manufacturer or supplier

The name of the manufacturer or supplier shall be indicated.

6.1.3 Nominal voltage: 12 V

The nominal voltage of 12 V shall be indicated.

6.1.4 Capacity or reserve capacity (see 7.1.2) and nominal cranking current (see

7.1.1)

Three options are possible for the identification and labelling of capacity (or reserve capacity)

and nominal cranking current:

Option 1:

• 20 h capacity C (Ah);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U ≥ 7,5 V and U ≥ 6,0 V (under I /0,6).

10s 90s cc

Option 2:

• reserve capacity RC (minutes);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U ≥ 7,20 V.

30 s

Option 3:

• 20 h capacity C (Ah);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U > 7,20 V.

30 s

NOTE These three options are in accordance with the present use in the different areas in the world.

The preferred version is Option 1.

6.1.5 Production date code

Batteries shall be marked with the date of production. This can be part of a more complex

code.

6.1.6 Safety labelling

If under national regulations, coloured safety symbols are required to be used, they should

follow the design as set out in Annex C, Clause C.1.

However, to be in compliance with some national regulations, additional wording or special

labelling can be used (for example, the safety label for North America area shown in Annex C,

Clause C.2).

6.1.7 Recycling labelling

Batteries shall be marked for separate collection and recycling, if required by local area

regulations.

6.1.8 Valve-regulated batteries

VRLA batteries shall be marked using the term "VRLA". In addition it is recommended that

VRLA batteries shall bear special indication that the battery shall not be opened.

EXAMPLE: "VRLA – Do not open"

6.2 Marking of the polarity

The terminals shall be identified according to the requirements of IEC 60095-2 or of

IEC 60095-4.

6.3 Fastening of the battery

Where batteries are fastened to the vehicle by means of integral parts (for example, bottom

ledges), these shall be in compliance with the requirements of IEC 60095-2 and of

IEC 60095-4.

– 10 – IEC 60095-1:2018 © IEC 2018

7 Functional characteristics

7.1 Electrical characteristics

7.1.1 The cranking performance is the discharge current I , as indicated by the

cc

manufacturer according to the option chosen (Option 1 or Option 2), which a battery can

supply according to 9.3.

7.1.2 The capacity of a starter battery is defined for a temperature of 25 °C ± 2 °C.

It may be indicated by the manufacturer as either:

• nominal 20 h capacity C , or

• nominal reserve capacity RC .

n

The nominal 20 h capacity C is the electric charge in ampere hours (Ah) that a battery can

n

supply with a current:

I C / 20 h (A)

n = n

until the terminal voltage falls to U = 10,50 V.

f

The effective 20 h capacity C shall be determined by discharging a battery with constant

e

current I to U = 10,50 V (see 9.1). The resultant discharge time, in hours, is used for the

n f

verification of C .

n

The nominal reserve capacity RC is the period of time (in minutes) for which a battery can

n

maintain a discharge current of 25 A to a cut-off voltage U = 10,50 V.

f

The effective reserve capacity RC shall be determined by discharging a battery with the

e

= 10,50 V (see 9.2). The resultant discharge time, in minutes,

constant current I = 25 A to U

f

is used for the verification of RC .

n

NOTE For the correlation (relationship) of C and RC , see Annex A.

n n

7.1.3 The charge acceptance is expressed as the current I which a partially discharged

ca

battery accepts at 0 °C and a constant charging voltage of 14,40 V.

7.1.4 The charge retention is rated by the cold cranking performance of the charged and

filled battery after storage on open circuit under defined conditions of temperature and time

(see 9.5).

7.1.5 The endurance test consists of two parts:

• the corrosion test represents the ability of a battery to perform repeated

overcharge/storage periods (see 9.6.1.1).

• the cycling test represents the ability of a battery to perform repeated discharge/recharge

cycles and long rest periods on open circuit. This ability shall be tested by a series of

cycles and rest periods under specified conditions after which the cold cranking or the

capacity performances shall be determined (see 9.6.1.2 or 9.6.2).

7.1.6 The water consumption test checks if the battery can keep its performance under

extended exposure to heat and overcharge condition

...

IEC 60095-1 ®

Edition 8.0 2018-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Lead-acid starter batteries –

Part 1: General requirements and methods of test

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60095-1 ®

Edition 8.0 2018-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Lead-acid starter batteries –

Part 1: General requirements and methods of test

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.220.20; 43.040.10 ISBN 978-2-8322-6285-6

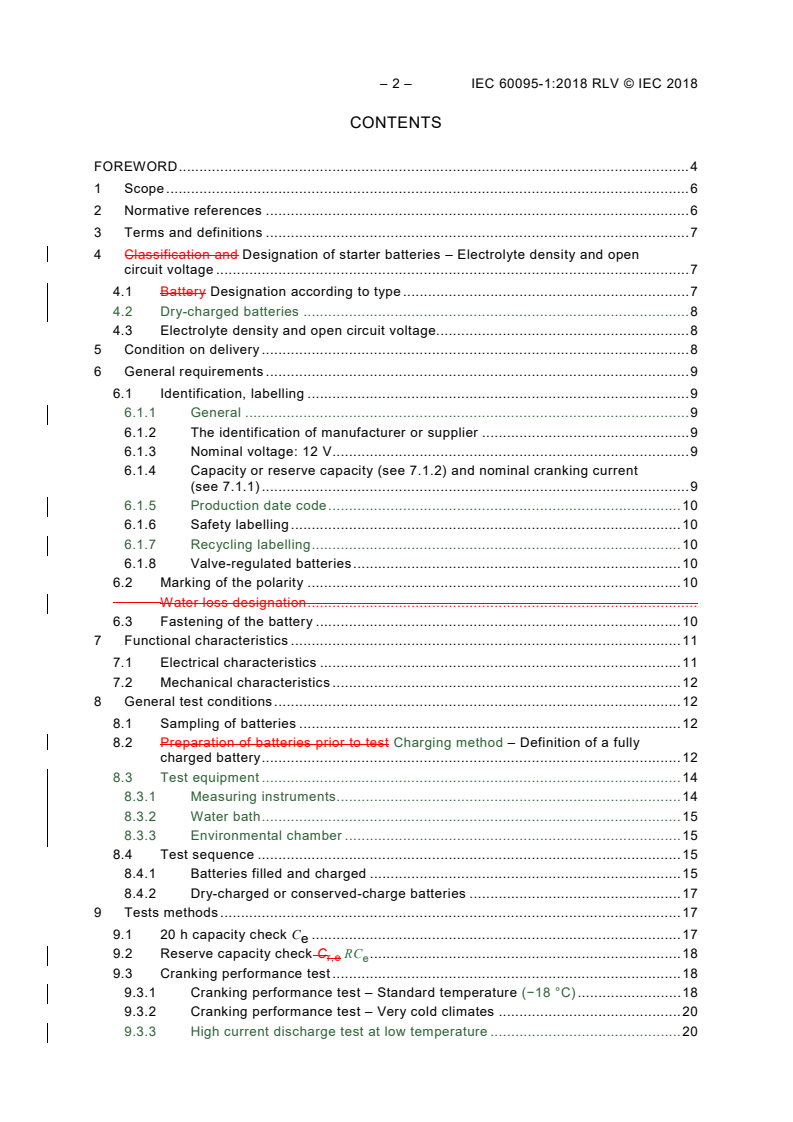

– 2 – IEC 60095-1:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Classification and Designation of starter batteries – Electrolyte density and open

circuit voltage . 7

4.1 Battery Designation according to type . 7

4.2 Dry-charged batteries . 8

4.3 Electrolyte density and open circuit voltage. 8

5 Condition on delivery . 8

6 General requirements . 9

6.1 Identification, labelling . 9

6.1.1 General . 9

6.1.2 The identification of manufacturer or supplier . 9

6.1.3 Nominal voltage: 12 V . 9

6.1.4 Capacity or reserve capacity (see 7.1.2) and nominal cranking current

(see 7.1.1) . 9

6.1.5 Production date code . 10

6.1.6 Safety labelling . 10

6.1.7 Recycling labelling . 10

6.1.8 Valve-regulated batteries . 10

6.2 Marking of the polarity . 10

Water loss designation .

6.3 Fastening of the battery . 10

7 Functional characteristics . 11

7.1 Electrical characteristics . 11

7.2 Mechanical characteristics . 12

8 General test conditions . 12

8.1 Sampling of batteries . 12

8.2 Preparation of batteries prior to test Charging method – Definition of a fully

charged battery . 12

8.3 Test equipment . 14

8.3.1 Measuring instruments. 14

8.3.2 Water bath . 15

8.3.3 Environmental chamber . 15

8.4 Test sequence . 15

8.4.1 Batteries filled and charged . 15

8.4.2 Dry-charged or conserved-charge batteries . 17

9 Tests methods . 17

9.1 20 h capacity check C . 17

e

9.2 Reserve capacity check C RC . 18

r,e

e

9.3 Cranking performance test . 18

9.3.1 Cranking performance test – Standard temperature (−18 °C) . 18

9.3.2 Cranking performance test – Very cold climates . 20

9.3.3 High current discharge test at low temperature . 20

9.4 Charge acceptance test . 20

9.5 Charge retention test . 21

9.6 Endurance test for batteries . 21

9.6.1 Corrosion test . 21

9.6.2 Optional endurance cycle test for passenger car batteries – Maximum

capacity 100 Ah . 28

9.7 Water consumption test . 28

9.8 Vibration resistance test . 29

9.9 Electrolyte retention test . 30

9.10 Cranking performance for dry-charged (or conserved-charge) batteries after

activation . 30

10 Requirements . 30

Annex A (normative) Correlation between C and C RC . 33

r,n

n n

Annex B (informative) Water consumption test – Conversion of test temperatures and

test durations . 34

B.1 General . 34

B.2 Conversion formula . 34

Annex C (normative informative) Safety labelling . 35

C.1 Definition of the six coloured symbols . 35

C.2 Safety labelling – Label for North America area . 36

Bibliography . 38

Figure – Symbols for safety labelling .

Figure C.1 – Symbol dimensions for symbols in safety labelling . 36

Figure C.2 – Safety labelling – Label for North America area,

former version (still valid) . 37

Figure C.3 – Safety labelling – Label for North America area, new version . 37

Table – Charging voltage .

Table – Discharge current and charge current .

Table – Endurance test sequence vented batteries .

Table – Endurance test sequence VRLA batteries.

Table – Values for vibration resistance test .

Table 1 – Charging method . 13

Table 2 – Accuracy of test equipment . 15

Table 3 – Test/Battery sequence . 16

Table 4 – Parameters cycle test . 27

Table 5 – Vibration resistance – Levels V1 to V3 . 29

Table 6 – Summary of requirements . 31

Table C.1 – Definition of safety symbols according to ISO 7010 . 35

– 4 – IEC 60095-1:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LEAD-ACID STARTER BATTERIES –

Part 1: General requirements and methods of test

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60095-1 has been prepared by IEC technical committee 21:

Secondary cells and batteries.

This eighth edition cancels and replaces the seventh edition published in 2006. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) charge acceptance test;

b) cranking performance test;

c) charge retention test; and

d) endurance test added.

The text of this International Standard is based on the following documents:

FDIS Report on voting

21/974/FDIS 21/987/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60095 series, published under the general title Lead-acid starter

batteries, can be found on the IEC website.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 60095-1:2018 RLV © IEC 2018

LEAD-ACID STARTER BATTERIES –

Part 1: General requirements and methods of test

1 Scope

This part of IEC 60095 is applicable to lead-acid batteries with a nominal voltage of 12 V,

used primarily as a power source for the starting of internal combustion engines, lighting, and

for auxiliary equipment of internal combustion engine vehicles. These batteries are commonly

called "starter batteries".

This document is applicable to batteries for the following purposes:

• batteries for passenger cars;

• batteries for commercial and industrial vehicles.

This document is not applicable to batteries for other purposes, such as the starting of railcar

internal combustion engines or for motorcycles and other power sport vehicles.

This document defines many general properties of lead-acid batteries. Single sections can be

referenced in other parts of the IEC 60095 series even if the application is excluded in the

scope of this document.

This document specifies the:

• general requirements;

• essential functional characteristics, relevant test methods and results required,

for several classes of starter batteries:

• according to the general type of application;

• according to the type of product.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60050-482, International Electrotechnical Vocabulary – Chapter 482: Primary and

secondary cells and batteries

IEC 60095-2, Lead-acid starter batteries – Part 2: Dimensions of batteries and dimensions

and marking of terminals

IEC 60095-4, Lead-acid starter batteries – Part 4: Dimensions of batteries for heavy trucks

vehicles

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

flooded battery

lead-acid battery having a cover provided with one or more openings through which gaseous

products may escape

3.2

enhanced flooded battery

EFB battery

flooded lead-acid battery with additional special design features to significantly improve the

cycling capability compared to standard flooded batteries

3.3

valve regulated lead-acid battery

VRLA battery

lead-acid battery which is closed under normal conditions but which has an arrangement that

allows the escape of gas if the internal pressure exceeds a predetermined value

Note 1 to entry: The VRLA battery cannot receive addition to the electrolyte and after activation of dry-charged

VRLA.

Note 2 to entry: In VRLA batteries the electrolyte is immobilized.

3.4

absorbent glass mat battery

AGM battery

VRLA battery in which the electrolyte is immobilized by absorption in a glass mat

3.5

gel battery

VRLA battery in which the electrolyte is immobilized by fixing as a gel

4 Classification and Designation of starter batteries – Electrolyte density and

open circuit voltage

4.1 Battery classification according to application

Three classes of batteries are defined according to their application, as follows:

– Class A: batteries for starter applications with usual cycling capability and normal

mechanical resistance;

– Class B: batteries for starter applications which have an important higher requirement in

cycling ability and /or mechanical resistance;

– Class C: batteries for starter applications and high temperature duty.

4.1 Battery Designation according to type

Batteries are designated according to their type, as follows:

– 8 – IEC 60095-1:2018 RLV © IEC 2018

– Vented (flooded) battery: a vented battery is a secondary battery having a cover provided

with one or more openings through which gaseous products may escape.

– Valve-regulated (with gas recombination) battery: a valve-regulated battery is a secondary

battery that is closed under normal conditions and has an arrangement that allows the

escape of gas if the internal pressure exceeds a predetermined value. The battery cannot

normally receive an addition of water or electrolyte. In this type of battery, the electrolyte

is immobilised.

• flooded batteries (vented);

• enhanced flooded batteries, EFB;

• valve regulated lead-acid batteries, VRLA;

– absorbent glass mat batteries, AGM;

– gel batteries.

4.2 Dry-charged batteries

Lead-acid batteries may be supplied in a dry-charged state. Dry-charged batteries can be

activated by filling with the defined electrolyte indicated by internal or external marks or

according to the manufacturer's activation instructions. After activation, these batteries are

ready to use.

4.3 Electrolyte density and open circuit voltage

The density of the electrolyte in all fully charged vented batteries shall be in the range of

1,27 kg/l to 1,30 kg/l at 25 °C unless otherwise specified by the manufacturer.

NOTE For valve-regulated batteries, the electrolyte is not accessible and, therefore, its density cannot be

checked.

The open circuit voltage (OCV) at 25 °C, of fully charged batteries after a minimum 24 h stand

on open circuit, shall be in the range of 12,70 V to 12,90 V for vented types and 12,80 V

minimum to 13,10 V for valve regulated types unless otherwise specified by the manufacturer.

The manufacturer shall specify the value and tolerance of the electrolyte density or OCV. If

such information is not available, vented battery testing shall be carried out with a density of

1,28 kg/l ± 0,01 kg/l at 25 °C or an OCV of 12,76 V ± 0,06 V at 25 °C and valve regulated

battery testing shall be carried out with a minimum OCV of 12,80 V.

5 Condition on delivery

New vented batteries may be supplied either:

• in a state ready for use, or

• in a dry-charged (or charge-conserved) state not filled with electrolyte. The density of the

electrolyte to fill these batteries before use (unless otherwise recommended by the

manufacturer) shall be:

– 1,28 kg/l ± 0,01 kg/l at 25 °C;

Valve-regulated batteries are normally supplied in a state ready for use.

6 General requirements

6.1 Identification, labelling

6.1.1 General

Batteries according to complying with this document shall bear the following characteristics on

at least the top or one of their four sides.

6.1.2 The identification of manufacturer or supplier

The name of the manufacturer or supplier shall be indicated.

6.1.2 Class of battery: (IEC) A, B or C (see 4.1)

NOTE In some countries, the class is indicated by the battery numbering system. In these cases, there is no need

to include the class on the label.

6.1.3 Nominal voltage: 12 V

The nominal voltage of 12 V shall be indicated.

6.1.4 Capacity: (see 7.1.2)

– either 20 hour capacity C (Ah),

n

– or reserve capacity C (min).

rn

NOTE In some countries, the capacity is indicated by the battery numbering system. In these cases, there is no

need to include the capacity on the label.

6.1.5 Nominal cranking current: I (A) (see 7.1.1)

cc

6.1.4 Capacity or reserve capacity (see 7.1.2) and nominal cranking current (see 7.1.1)

Three options are possible for the identification and labelling of capacity (or reserve capacity)

and nominal cranking current:

Option 1:

• 20 h capacity C (Ah);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U ≥ 7,5 V and U ≥ 6,0 V (under I /0,6).

10s 90s cc

Option 2:

• reserve capacity RC (minutes);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U ≥ 7,20 V.

30 s

Option 3:

• 20 h capacity C (Ah);

• with nominal cranking current I (A) (see 7.1.1 and 9.3.1) defined at −18 °C with

cc

U > 7,20 V.

30 s

NOTE These three options are in accordance with the present use in the different areas in the world.

The preferred version is Option 1.

– 10 – IEC 60095-1:2018 RLV © IEC 2018

6.1.5 Production date code

Batteries shall be marked with the date of production. This can be part of a more complex

code.

6.1.6 Safety labelling

Batteries shall be marked with the six coloured symbols as described in part 1 of Annex B.

If under national regulations, coloured safety symbols are required to be used, they should

follow the design as set out in Annex C, Clause C.1.

However, to be in compliance with some national regulations, additional wording or special

labelling can be used (for example, the safety label for North America area shown in Annex C,

Clause C.2).

6.1.7 Recycling labelling

Batteries shall be marked for separate collection and recycling, if required by local area

regulations.

6.1.8 Valve-regulated batteries

VRLA batteries shall be marked using the term "VRLA". In addition it is recommended that

Valve regulated VRLA batteries shall bear special indication mentioning that the battery shall

not be opened.

EXAMPLE: "VRLA – Do not open"

6.2 Marking of the polarity

The terminals shall be identified according to the requirements of IEC 60095-2 or of

IEC 60095-4.

6.3 Water loss designation

Vented starter batteries may be designated as "Low water loss” or “Very low water

loss“ according to IEC 60095-1, if they comply with the requirements of 9.5 and 9.7. If they do

not comply, they are designated as “Normal”.

This additional designation shall be indicated either on the battery label or in the catalogue.

NOTE Starter batteries are subject to a wide variety of operating conditions, for example temperature, overcharge

voltage, etc., that have an influence on the decomposition of water from the electrolyte, regardless of internal

design features. Thus, the terms "low water loss” or “very low water loss" in the sense of this standard are linked to

well-defined conditions in 9.7 that do not cover the complete range of practical operating conditions.

6.3 Fastening of the battery

Where batteries are fastened to the vehicle by means of integral parts (for example, bottom

ledges), these shall be in compliance with the requirements of IEC 60095-2 and of

IEC 60095-4.

7 Functional characteristics

7.1 Electrical characteristics

7.1.1 The cranking performance is the discharge current I , as indicated by the

cc

manufacturer according to the option chosen (Option 1 or Option 2), which a battery can

supply according to 9.3.

7.1.2 The capacity of a starter battery is defined for a temperature of 25 °C ± 2 °C.

It may be indicated by the manufacturer as either:

• nominal 20 h capacity C C , or

n 20

• nominal reserve capacity C RC .

r,n n

The nominal 20 h capacity C is the electric charge in ampere hours (Ah) that a battery can

n

supply with a current:

I C / 20 h (A)

n = n

until the terminal voltage falls to U = 10,50 V.

f

The effective 20 h capacity C shall be determined by discharging a battery with constant

e

current I to U = 10,50 V (see 9.1). The resultant discharge time, in hours, is used for the

n f

verification of C .

n

The nominal reserve capacity C RC is the period of time (in minutes) for which a battery

r,n n

can maintain a discharge current of 25 A to a cut-off voltage U = 10,50 V.

f

The effective reserve capacity C RC shall be determined by discharging a battery with the

r,e e

constant current I = 25 A to U = 10,50 V (see 9.2). The resultant discharge time, in minutes,

f

is used for the verification of C RC .

r,n n

NOTE For the correlation (relationship) of C and C RC , see Annex A.

r,n

n n

7.1.3 The charge acceptance is expressed as the current I which a partially discharged

ca

battery accepts at 0 °C and a constant charging voltage of 14,40 V.

7.1.4 The charge retention is defined as rated by the cold cranking performance of the

charged and filled battery after storage on open circuit under defined conditions of

temperature and time (see 9.5).

7.1.5 The endurance test consists of two parts:

7.1.5.1 • the corrosion test represents the ability of a battery to perform repeated

overcharge/storage periods (see 9.6.1.1).

7.1.5.2 • the cycling test represents the ability of a battery to perform repeated

discharge/recharge cycles and long rest periods on open circuit. This ability shall be

tested by a series of cycles and rest periods under specified conditions after which the

cold cranking or the capacity performances shall be determined (see 9.6.1.2 or 9.6.2).

7.1.6 Water consumption: maintenance-free service of a battery requires a low rate of water

decomposition through overcharge (see 9.7).

Valve regulated batteries have a very low water consumption and are not intended to receive

additional water.

– 12 – IEC 60095-1:2018 RLV © IEC 2018

The water consumption test checks if the battery can keep its performance under extended

exposure to heat and overcharge conditions. It is measured as loss of weight during

overcharge of a fully charged battery and is defined as g/Ah C (see 9.7).

e

7.1.7 Dry charged battery (or conserved charge battery): a new battery may be designated

as dry charged (or conserved charge) if it can be activated ready for service just by filling it

with the appropriate electrolyte and if it then conforms to the requirements of 9.10.

7.2 Mechanical characteristics

7.2.1 Vibration resistance represents the ability of a battery to maintain service under

periodic or irregular acceleration forces. Minimum requirements shall be verified by a test (see

9.8).

7.2.2 Electrolyte retention is the ability of a battery to retain the electrolyte under specified

physical conditions (see 9.9).

8 General test conditions

8.1 Sampling of batteries

All tests shall be carried out on new battery samples. Samples shall be considered as "new"

not later than:

– 30 days after shipment date of the manufacturer in the case of filled batteries;

– 60 days after shipment date of the manufacturer in the case of dry-charged or charge-

conserved batteries.

Samples shall be tested not later than:

• 45 days after the production date of the manufacturer in the case of filled batteries;

• 60 days after the production date of the manufacturer in the case of dry-charged batteries.

8.2 Preparation of batteries prior to test Charging method – Definition of a fully

charged battery

All tests, except that in 9.10, shall commence with fully-charged batteries.

Vented batteries shall be considered as fully-charged if they have undergone one of the two

charging procedures of 8.2.1 or 8.2.2 carried out at 25 °C ± 10 °C. If necessary, an

appropriate temperature control system, for example a water bath, shall be used.

Valve regulated batteries shall be considered as fully-charged if they have undergone one of

the two charging procedures of 8.2.3 or 8.2.4 carried out at 25 °C ± 10 °C. If necessary, an

appropriate temperature control system, for example a water bath, shall be used.

8.2.1 Charging of vented batteries at constant current

The battery shall be charged:

– at a constant current of 2 I (see 7.1.2), until voltage stabilisation is established when

n

three consecutive voltage or specific density measurements, corrected for the battery

temperature, taken at 15 min intervals, remain constant.

8.2.2 Charging of vented batteries at constant voltage and constant current (two step

method)

The battery shall be charged:

– at a constant voltage of U Volt for 20 h with the maximum current limited to 5 In (see 7.1.2)

where U is related to the battery water loss level (as for cycling tests):

Normal water loss U = 14,80 V ± 0,10 V

Low water loss U = 15,20 V ± 0,10 V

Very low water loss U = 16,00 V ± 0,10 V

– then with a constant current charge of In for 4 h.

In the case of recharging after a test for cranking performance (according to 9.3) the charging

time at constant voltage may be limited to 10 h.

NOTE If neither complete knowledge of the battery construction nor a specification from the manufacturer is

available, then charging according to the present subclause (8.2.2) with U = 14,8V is recommended.

8.2.3 Charging of valve regulated batteries at constant current (two step method)

The battery shall be charged:

– at a constant current of 2 I (see 7.1.2), until the voltage reaches 14,40 V;

n

– then at a constant current of I for 4h.

n

8.2.4 Charging of valve regulated batteries at constant voltage and constant current

(two step method)

The battery shall be charged:

– at a constant voltage of 14,40V ± 0,10 V for 20 h with the maximum current limited to 5 I

n

(see 7.1.2),

– then with a constant current of 0,5 I for 4 h.

n

NOTE If neither complete knowledge of the battery construction nor a specification from the manufacturer is

available, then charging according to the present subclause (8.2.4), is recommended.

Batteries shall be considered as fully charged if they have undergone the charging procedures.

Prior to the first capacity test, the battery charge shall be limited to 16 h.

If not specified differently by the battery manufacturer, the batteries that will be tested

according to this document shall be charged according to Table 1.

Table 1 – Charging method

Battery type Voltage U Current Time Remarks

c

a

Flooded batteries with size in 16,00 V ± 0,05 V 5 I 24 h (16 h)

n

accordance with IEC 60095-2

a

Flooded batteries with size in 16,00 V ± 0,05 V 5 I 20 h (16 h) Step 1

n

accordance with IEC 60095-4

no limitation I 4 h Step 2

n

a

Valve-regulated batteries VRLA 14,80 V ± 0,05 V 5 I 24 h (16 h)

n

a

A charging time of 16 h is sufficient after a cranking performance test and prior to the first capacity check.

All charges shall be performed with batteries in a water bath at 25 °C ± 2 °C.

– 14 – IEC 60095-1:2018 RLV © IEC 2018

8.3 Activation of dry-charged or charge-conserved batteries

Dry charged batteries shall be filled with the appropriate electrolyte (according to 4.3) to

the maximum level indicated by internal or external marks of the battery or according to the

manufacturer's instructions.

8.3 Test equipment

8.3.1 Measuring instruments

8.4.1 Electrical measuring instruments

The range of instruments used shall be appropriate for the magnitude of the voltage or current

to be measured.

– Voltage measurement:

The instruments used for measuring voltages shall be digital voltmeters having an

accuracy of ±0,04V or better.

– Current measurement:

The instruments used for current measurement shall be digital ammeters having an

accuracy of 1,0 % or better. The assembly of ammeter, shunt and leads shall have an

overall accuracy of 1,0 % or better.

8.4.2 Temperature measurement

The thermometers used for measuring temperature shall have an appropriate range, and the

value of each scale division shall not be greater than 1 K. The accuracy of the calibration of

the instruments shall be not less than 0,5 K.

8.4.3 Density measurement

The density of the electrolyte shall be measured with hydrometers having either graduated

scale or digital displays that are able to register increments of 0,005 kg/l.

8.4.4 Time measurement

The instruments used for measuring time shall be graduated in hours, minutes or seconds.

They shall have an accuracy within ±0,1 % in all cases with the exception of cranking

performance tests where the times measured in seconds shall have an accuracy within

±1,0 %.

The range of instruments used shall be appropriate for the magnitude of the parameters to be

measured. The minimum accuracy of test equipment is given in Table 2.

Table 2 – Accuracy of test equipment

Parameter Accuracy of test equipment

Current for cold cranking tests 0,5 %

Current for other tests 1 % full-scale with a minimum accuracy of ±30 mA

Voltage ± 0,04 V

Temperature ± 1 °C

Time ± 1 s

Density of electrolyte ≤ 0,005 kg/l

Weight of battery ± 1 g below 30 kg

± 5 g above 30 kg

The instruments used for measuring time shall be graduated in hours, minutes and seconds.

8.3.2 Water bath

If a test needs to be carried out in a water bath, the following conditions shall be fulfilled. The

terminal base of the battery shall be at least 15 mm but not more than 25 mm above the water

surface level. If several batteries are in the same water bath then the distance between them

and also the distance to the walls of the bath shall be at least 25 mm.

Minimum soak time for batteries in the water bath is 4 h.

If not stated differently in the individual test description, the tolerance for the temperature of

the water bath is ±2 °C.

It is recommended to cover the surface of the water with floating elements using testing

temperatures of 40 °C or more. This improves the thermal isolation against air and avoids

evaporation of water.

8.3.3 Environmental chamber

If a test needs to be carried out in an environmental chamber, the batteries are placed in an

air gaseous phase at the requested temperature and tolerance; the wind velocity near the

battery shall not be more than 2,0 m/s.

Minimum time for batteries in the environmental chamber before the test beginning is 8 h.

8.4 Test sequence

8.4.1 Batteries filled and charged

a) Initially, the batteries are subjected to the following series of tests:

– first C or C RC check;

e r,e e

– first cranking performance test;

– second C or C RC check;

e r,e e

– second cranking performance test;

– third C or C RC check;

e r,e e

– third cranking performance test.

For C or RC and the cranking performance, the specified values shall be met in at least

e e

one of the relevant discharges above.

It is not necessary to complete the sequence if the specified values are achieved on the

first or second test.

– 16 – IEC 60095-1:2018 RLV © IEC 2018

NOTE The choice between testing C or RC is the decision of the customer or user.

e e

b) The tests according to Table 3 shall be carried out only if batteries have complied with the

previous tests, and not later than one week after completion of the first part.

Table 3 – Test/Battery sequence

Test Battery

1 2 3 4 5 6

st

1 20 h capacity X X X

st

1 reserve capacity X X X

st

1 cranking

X X X X X X

performance

nd

2 20 h capacity X X X

nd

2 reserve capacity X X X

nd

2 cranking

X X X X X X

performance

rd

3 20 h capacity X X X

rd

3 reserve capacity X X X

rd

3 cranking

X X X X X X

performance

Corrosion test X

Endurance tests

(9.6)

Cycling test X

Charge retention

X

(9.5)

Charge acceptance

X

(9.4)

Electrolyte retention

X

(9.9)

Vibration resistance

X

(9.8)

Water consumption

X

(9.7)

NOTE The test for water consumption should be applied only to vented "low water loss" or

“very low water loss” batteries according to 6.3.

Step Test Battery

Reference

No. 1 No. 2 No. 3 No. 4 No. 5 No. 6

0 Cranking performance for dry charged 8.4.2 and 9.10

batteries

1 Initial charge prior to test 8.2

2 First 20 h capacity or 9.1 or 9.2 C

First reserve capacity

3 First cranking performance according to 9.3.1

Option 1 or Option 2

4 Second 20 h capacity 9.1 or 9.2 () () C () () ()

Second reserve capacity

5 Second cranking performance according to 9.3.1 () () () () () ()

Option 1 or Option 2

6 Third 20 h capacity 9.1 or 9.2 () () C () () ()

Third reserve capacity

7 Third cranking performance according to 9.3.1 () () () () () ()

Option 1 or Option 2

8 Cranking performance – very cold climate 9.3.2

9 Corrosion test 9.6.1.1

10 Endurance in cycle test 9.6.1.2 or

9.6.2

11 Charge retention 9.5

12 Charge acceptance 9.4

13 Electrolyte retention 9.9

14 Vibration resistance 9.8

15 Water consumption 9.7

Key

– : test to be fulfilled.

– (): test to be fulfilled only if the previous identical test carried out failed.

Battery no. 3 shall perform the full sequence of 3 tests with 20 h capacity before the charge acceptance test in

9.4.

8.4.2 Dry-charged or conserved-charge batteries

a) Initially, the batteries are subjected to:

– initial cranking performance after filling with electrolyte (see 9.10).

b) The tests according to Table 3 shall be carried out only if the batteries have complied with

the previous test mentioned in a) and no more than one weekafter the said test.

9 Tests methods

9.1 20 h capacity check C

e

9.1.1 Throughout the duration of the tests, the battery shall be placed in a water bath at a

temperature of 25 °C ± 2 °C, in accordance with 8.3.2. The terminal base of the battery shall

be at least 15 mm but no more than 25 mm above the level of the water. If several batteries

are in the same water bath then the distance between them and also the distance to the walls

of the bath shall be at least 25 mm.

--

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...