IEC 60695-11-5:2016

(Main)Fire hazard testing - Part 11-5: Test flames - Needle-flame test method - Apparatus, confirmatory test arrangement and guidance

Fire hazard testing - Part 11-5: Test flames - Needle-flame test method - Apparatus, confirmatory test arrangement and guidance

IEC 60695-11-5:2016 specifies a needle-flame test to simulate the effect of a small flame which may result from fault conditions, in order to assess the fire hazard by a simulation technique. The results of this test may be used as elements of a fire hazard assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use. It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid electrical insulating materials or other combustible materials. This second edition cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

- The scope has been broadened to allow this test method to also simulate the effects of small flames from outside the equipment;

- Propane and butane gas are the specified fuel source with a minimum purity of 95 %;

- A new concept has been added which allows the burner to be moved during the test to avoid dripping material from falling onto the tip of the burner tube;

- The burner tube material is now a referenced source;

- The reference for the copper block material has changed - the ISO publication (ISO 1337) has been withdrawn with no replacement. A new callout is now used and Informative Annex C and a bibliography have been added. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

Essais relatifs aux risques du feu - Partie 11-5: Flammes d'essai - Méthode d'essai au brûleur-aiguille - Appareillage, dispositif d'essai de vérification et lignes directrices

L'IEC 60695-11-5:2016 spécifie un essai au brûleur-aiguille pour simuler l'effet d'une petite flamme qui peut provenir de conditions de défaut, afin d'évaluer le danger d'incendie par simulation. Les résultats de cet essai peuvent être utilisés comme éléments d'évaluation d'un danger d'incendie qui tient compte de tous les facteurs qui sont pertinents pour une évaluation de danger d'incendie dans une utilisation finale spécifique. Elle est applicable aux matériels électrotechniques, à leurs sous-ensembles et à leurs composants ainsi qu'aux matériaux isolants électriques solides ou à d'autres matériaux combustibles. Cette deuxième édition annule et remplace la première édition parue en 2004. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

- Le domaine d'application de la présente méthode d'essai a été élargi pour simuler les effets des petites flammes d'origine externe à l'équipement;

- Le gaz propane et le gaz butane sont les sources de combustible spécifiées avec une pureté minimale de 95 %;

- Un nouveau concept a été ajouté qui permet le déplacement du brûleur au cours de l'essai pour éviter que du matériau qui s'écoule tombe sur l'extrémité du tube du brûleur;

- Le matériau du tube du brûleur est maintenant une source référencée;

- La référence pour le matériau du bloc de cuivre a changé - la publication ISO (ISO 1337) a été supprimée sans remplacement et une nouvelle désignation est désormais utilisée. L'Annexe informative C et une bibliographie ont été ajoutées. La présente publication fondamentale de sécurité est destinée à être utilisée par les comités d'études dans le cadre de l'élaboration de normes conformément aux principes établis dans le IEC Guide 104 et le Guide ISO/IEC 51.

Mots clés: danger d'incendie, Flammes d'essai, Méthode d'essai au brûleur-aiguille

General Information

- Status

- Published

- Publication Date

- 05-Dec-2016

- Technical Committee

- TC 89 - Fire hazard testing

- Drafting Committee

- WG 12 - TC 89/WG 12

- Current Stage

- PPUB - Publication issued

- Start Date

- 06-Dec-2016

- Completion Date

- 15-Jan-2017

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

Overview - IEC 60695-11-5:2016 (Needle‑flame test)

IEC 60695-11-5:2016 is the IEC test method for the needle‑flame test used in fire hazard testing of electrotechnical equipment, sub‑assemblies, components and solid insulating or other combustible materials. The second edition (2016) replaces the 2004 edition and specifies the apparatus, confirmatory test arrangement and guidance for simulating the effect of a small flame that may result from fault conditions. The standard is intended as a simulation technique to provide input to a broader fire hazard assessment rather than as a full fire‑risk appraisal.

Key topics and technical requirements

- Scope and purpose: Simulation of small flames impinging on materials or parts inside or outside equipment to assess fire propagation potential.

- Apparatus specification: Detailed requirements for the needle burner, gas supply, control valve, flame profile, timing device, and laboratory fumehood/chamber.

- Fuel: Propane and butane are specified fuels with a minimum purity of 95% for reproducible flame characteristics.

- Test procedure: Specimen conditioning, specimen positioning, defined severities (flame application times), number of specimens and timing for repeatability.

- Confirmatory test: Annex A defines a confirmatory arrangement using a copper block and thermocouple(s) to verify flame characteristics and energy transfer.

- New/updated concepts (2016):

- Broadened scope to include small flames originating outside equipment.

- Burner movement option to prevent dripping materials from contacting the burner tip.

- Burner tube material referenced from an authoritative source.

- Changes to the copper block material reference (ISO 1337 withdrawn).

- Addition of Informative Annex C and bibliography.

- Observations & evaluation: Requirements for recording flame behaviour, ignition, flaming duration, dripping and damage; guidance on interpreting results as part of a comprehensive fire hazard assessment.

Applications and who uses it

- Product safety testing laboratories use IEC 60695-11-5 to evaluate material flammability and component susceptibility to small flame sources.

- Manufacturers and OEMs (electrical/electronic equipment, components, enclosures) apply the test when designing for fire safety or preparing technical dossiers.

- Standards/technical committees incorporate this basic safety publication into product standards and specifications.

- Compliance engineers, safety assessors and certification bodies use test results as elements of product conformity and risk assessments.

- Useful for risk mitigation in sectors such as consumer electronics, industrial control equipment, household appliances and lighting.

Related standards and guidance

- IEC 60695 series (Fire hazard testing) - related test methods and flame tests.

- IEC Guide 104 and ISO/IEC Guide 51 - principles for basic safety publications and risk assessment.

- Note: ISO 1337 (previous copper block reference) has been withdrawn; the 2016 edition provides updated callouts and informative annexes for reference.

Keywords: IEC 60695-11-5, needle‑flame test, fire hazard testing, electrotechnical equipment, propane butane fuel, confirmatory test, needle burner, fire safety standards.

REDLINE IEC 60695-11-5:2016 - Fire hazard testing - Part 11-5: Test flames - Needle-flame test method - Apparatus, confirmatory test arrangement and guidance Released:12/6/2016 Isbn:9782832236956

IEC 60695-11-5:2016 - Fire hazard testing - Part 11-5: Test flames - Needle-flame test method - Apparatus, confirmatory test arrangement and guidance

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60695-11-5:2016 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fire hazard testing - Part 11-5: Test flames - Needle-flame test method - Apparatus, confirmatory test arrangement and guidance". This standard covers: IEC 60695-11-5:2016 specifies a needle-flame test to simulate the effect of a small flame which may result from fault conditions, in order to assess the fire hazard by a simulation technique. The results of this test may be used as elements of a fire hazard assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use. It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid electrical insulating materials or other combustible materials. This second edition cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - The scope has been broadened to allow this test method to also simulate the effects of small flames from outside the equipment; - Propane and butane gas are the specified fuel source with a minimum purity of 95 %; - A new concept has been added which allows the burner to be moved during the test to avoid dripping material from falling onto the tip of the burner tube; - The burner tube material is now a referenced source; - The reference for the copper block material has changed - the ISO publication (ISO 1337) has been withdrawn with no replacement. A new callout is now used and Informative Annex C and a bibliography have been added. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

IEC 60695-11-5:2016 specifies a needle-flame test to simulate the effect of a small flame which may result from fault conditions, in order to assess the fire hazard by a simulation technique. The results of this test may be used as elements of a fire hazard assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use. It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid electrical insulating materials or other combustible materials. This second edition cancels and replaces the first edition published in 2004. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: - The scope has been broadened to allow this test method to also simulate the effects of small flames from outside the equipment; - Propane and butane gas are the specified fuel source with a minimum purity of 95 %; - A new concept has been added which allows the burner to be moved during the test to avoid dripping material from falling onto the tip of the burner tube; - The burner tube material is now a referenced source; - The reference for the copper block material has changed - the ISO publication (ISO 1337) has been withdrawn with no replacement. A new callout is now used and Informative Annex C and a bibliography have been added. This basic safety publication is intended for use by technical committees in the preparation of standards in accordance with the principles laid down in IEC Guide 104 and ISO/IEC Guide 51.

IEC 60695-11-5:2016 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60695-11-5:2016 has the following relationships with other standards: It is inter standard links to EN IEC 61084-2-3:2024/A11:2024, EN ISO 9773:2024, IEC 60695-11-5:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60695-11-5:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60695-11-5 ®

Edition 2.0 2016-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

BASIC SAFETY PUBLICATION

Fire hazard testing –

Part 11-5: Test flames – Needle-flame test method – Apparatus, confirmatory test

arrangement and guidance

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

IEC 60695-11-5 ®

Edition 2.0 2016-12

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

BASIC SAFETY PUBLICATION

Fire hazard testing –

Part 11-5: Test flames – Needle-flame test method – Apparatus, confirmatory

test arrangement and guidance

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.220.40; 29.020 ISBN 978-2-8322-3695-6

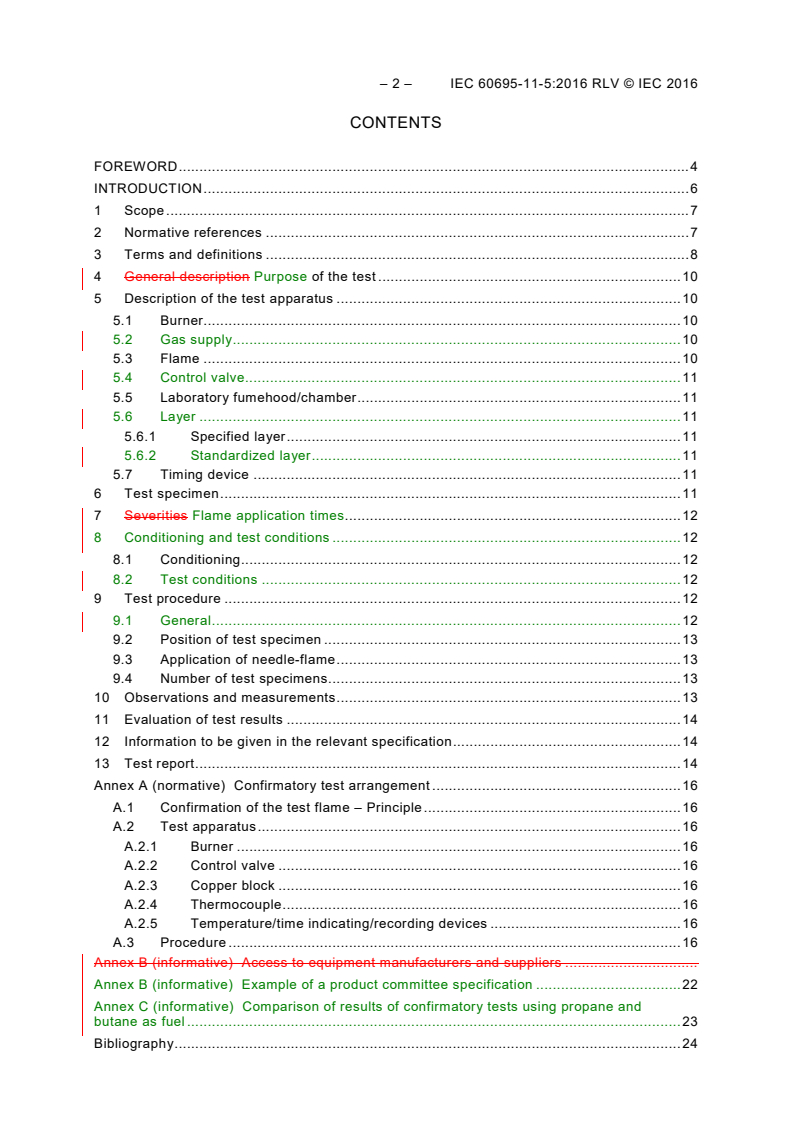

– 2 – IEC 60695-11-5:2016 RLV © IEC 2016

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General description Purpose of the test . 10

5 Description of the test apparatus . 10

5.1 Burner. 10

5.2 Gas supply . 10

5.3 Flame . 10

5.4 Control valve. 11

5.5 Laboratory fumehood/chamber . 11

5.6 Layer . 11

5.6.1 Specified layer . 11

5.6.2 Standardized layer . 11

5.7 Timing device . 11

6 Test specimen . 11

7 Severities Flame application times . 12

8 Conditioning and test conditions . 12

8.1 Conditioning . 12

8.2 Test conditions . 12

9 Test procedure . 12

9.1 General . 12

9.2 Position of test specimen . 13

9.3 Application of needle-flame . 13

9.4 Number of test specimens . 13

10 Observations and measurements . 13

11 Evaluation of test results . 14

12 Information to be given in the relevant specification . 14

13 Test report . 14

Annex A (normative) Confirmatory test arrangement . 16

A.1 Confirmation of the test flame – Principle . 16

A.2 Test apparatus . 16

A.2.1 Burner . 16

A.2.2 Control valve . 16

A.2.3 Copper block . 16

A.2.4 Thermocouple . 16

A.2.5 Temperature/time indicating/recording devices . 16

A.3 Procedure . 16

Annex B (informative) Access to equipment manufacturers and suppliers .

Annex B (informative) Example of a product committee specification . 22

Annex C (informative) Comparison of results of confirmatory tests using propane and

butane as fuel . 23

Bibliography . 24

Figure 1 – Needle Burner and flame. 15

Figure 2 – Test positions. 15

Figure A.1 – Copper block . 18

Figure A.2 – Confirmatory test arrangement . 19

Figure A.3 – Gauge to measure flame height and the distance between burner and

copper block (example) . 20

Table B.1 – Severities and requirements . 22

Table C.1 – Results of the confirmatory test using propane and butane as fuel . 23

– 4 – IEC 60695-11-5:2016 RLV © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 11-5: Test flames – Needle-flame test method –

Apparatus, confirmatory test arrangement and guidance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60695-11-5 has been prepared by IEC technical committee 89:

Fire hazard testing.

This second edition cancels and replaces the first edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) The scope has been broadened to allow this test method to also simulate the effects of

small flames from outside the equipment;

b) Propane and butane gas are the specified fuel source with a minimum purity of 95 %;

c) A new concept has been added which allows the burner to be moved during the test to

avoid dripping material from falling onto the tip of the burner tube;

d) The burner tube material is now a referenced source;

e) The reference for the copper block material has changed – the ISO publication (ISO 1337)

has been withdrawn with no replacement. A new callout is now used;

f) Informative Annex C and a bibliography have been added.

The text of this standard is based on the following documents:

FDIS Report on voting

89/1346/FDIS 89/1351/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a basic safety publication in accordance with IEC Guide 104 and

ISO/IEC Guide 51.

A list of all the parts in the IEC 60695 series, under the general title Fire hazard testing, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60695-11-5:2016 RLV © IEC 2016

INTRODUCTION

The best method for testing electrotechnical products with regard to fire hazard is to duplicate

exactly the conditions occurring in practice. In most instances this is not possible.

Accordingly, for practical reasons, the testing of electrotechnical products with regard to fire

hazard is best conducted by simulating as closely as possible the actual effects occurring in

practice.

Parts of electrotechnical equipment which might be exposed to excessive thermal stress due

to electric effects,. This can result in deterioration of that might impair the safety of the

equipment,. Such parts should not be unduly affected by heat and or by fire generated within

the equipment.

Parts of insulating material or of other combustible material which are liable to propagate

flames inside the equipment may be ignited by flames produced by a failing component.

Under certain conditions, for example a fault current flowing over a tracking path, overloading

of components or parts and bad connections, flames may also occur; such flames may

impinge upon combustible parts in the vicinity.

This part of IEC 60695 should is intended to be used to measure and describe the properties

of materials, products or assemblies in response to heat and flame under controlled

laboratory conditions and should is not intended to be used to describe or appraise the fire

hazard or fire risk of materials, products, or assemblies under actual fire conditions. This

standard may involve hazardous materials, operations and equipment.

It does not purport to address all of the safety problems associated with its use.

It is the responsibility of the user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to use.

FIRE HAZARD TESTING –

Part 11-5: Test flames – Needle-flame test method –

Apparatus, confirmatory test arrangement and guidance

1 Scope

This part of IEC 60695 specifies a needle-flame test to simulate the effect of a small flame

which may result from fault conditions, in order to assess the fire hazard by a simulation

technique. The results of this test may be used as elements of a fire hazard assessment

which takes into account all of the factors which are pertinent to an assessment of the fire

hazard of a particular end use.

It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid

electrical insulating materials or other combustible materials.

This basic safety publication is intended for use by technical committees in the preparation of

standards in accordance with the principles laid down in IEC Guide 104 and

ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications. The requirements, test methods

or test conditions of this basic safety publication will not apply unless specifically referred to

or included in the relevant publications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60695-4:2012, Fire hazard testing – Part 4: Terminology concerning fire tests for

electrotechnical products

IEC Guide 104:1997, The preparation of safety publications and the use of basic safety

publications and group safety publications

ISO/IEC Guide 51:1999, Safety aspects – Guidelines for their inclusion in standards

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 4046-4:2002 2016, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper

and board grades and converted products

ISO/IEC 13943:2000 2008, Fire safety – Vocabulary

ASTM-B187, Standard specification for copper, bus bar, rod, and shapes and general purpose

rod, bar, and shapes

– 8 – IEC 60695-11-5:2016 RLV © IEC 2016

3 Terms and definitions

For the purposes of this document, the terms and definitions of ISO/IEC 13943 given in

ISO 13943:2008, IEC 60695-4:2012 and ISO 4046:2002, as well as the following, apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

combustible, adj.

capable of being ignited and burned

[SOURCE: ISO 13943:2008, 4.43]

3.2

draught-free environment

space in which the results of experiments are not significantly affected by the local air speed

Note 1 to entry: A qualitative example is a space in which a wax candle flame remains essentially undisturbed.

-1 -1

Quantitative examples are small-scale fire tests in which a maximum air speed of 0,1 m × s or 0,2 m × s is

sometimes specified.

[SOURCE: ISO 13943:2008, 4.70]

3.3

fire

〈general〉 process of combustion characterized by the emission of heat and fire effluent and

usually accompanied by smoke, flame, glowing or a combination thereof

Note 1 to entry: In the English language the term “fire” is used to designate three concepts, two of which, fire

(3.4) and fire (3.5), relate to specific types of self-supporting combustion with different meanings and two of them

are designated using two different terms in both French and German.

[SOURCE: ISO 13943:2008, 4.96]

3.4

fire

〈controlled〉 self-supporting combustion that has been deliberately arranged to provide useful

effects and is limited in its extent in time and space

[SOURCE: ISO 13943:2008, 4.97]

3.5

fire

〈uncontrolled〉 self-supporting combustion that has not been deliberately arranged to provide

useful effects and is not limited in its extent in time and space

[SOURCE: ISO 13943:2008, 4.98]

3.6

fire hazard

physical object or condition with a potential for an undesirable consequence from fire (3.1)

[SOURCE: ISO 13943:2008, 4.112]

3.7

fire risk

probability of a fire (3.3) combined with a quantified measure of its consequence

Note 1 to entry: It is often calculated as the product of probability and consequence.

[SOURCE: ISO 13943:2008, 4.124]

3.8

flame, noun

rapid, self-sustaining, sub-sonic propagation of combustion in a gaseous medium, usually with

emission of light

[SOURCE: ISO 13943:2008, 4.133]

3.9

glowing, noun

luminosity caused by heat

cf. incandescence

[SOURCE: ISO 13943:2008, 4.168]

3.10

glowing combustion

combustion of a material in the solid phase without flame but with emission of light from the

combustion zone

cf. incandescence

[SOURCE: ISO 13943:2008, 4.169]

3.11

ignition

sustained ignition (deprecated)

〈general〉 initiation of combustion

[SOURCE: ISO 13943:2008, 4.187]

3.12

ignition

sustained ignition (deprecated)

〈flaming combustion〉 initiation of sustained flame

[SOURCE: ISO 13943:2008, 4.188]

3.13

wrapping tissue

soft and strong, lightweight wrapping paper of grammage generally between 12 g/m and

30 g/m , primarily intended for protective packaging of delicate articles and for gift wrapping

Note 1 to entry: In French, the word “mousseline” includes both white tissue and “bulle corde”, which is

unbleached or coloured tissue.

[SOURCE: ISO 4046-4:2016, 4.215]

– 10 – IEC 60695-11-5:2016 RLV © IEC 2016

4 General description Purpose of the test

Warning

Precautions shall be taken to safeguard the health of the personnel conducting tests against:

– the risks of explosion or fire;

– the inhalation of smoke and/or toxic products;

– toxic residues.

The test is performed to determine that, under defined conditions, the test flame either does

not cause ignition of parts or if it does, that a combustible parts ignited by the test flame has

have a limited duration of burning or a limited extent of burning, without spreading fire by

flames or burning or glowing particles falling from the test specimen.

This test determines the effects on the test specimen of a small flame such as may arise from

other ignited components and the relevant product specification shall specify the duration of

flame application and the criteria for acceptance.

The test flame, applied to the test specimen, imitates a flame that might arise from a

component that is close to the test specimen in the real application. Such a flame might have

occurred, for example, because of an electrical fault.

The relevant product specification shall specify, if applicable, the duration of the test flame

application and the acceptance criteria.

5 Description of the test apparatus

5.1 Burner

The burner to produce the test flame shall consist of a tube at least 35 mm long with a bore of

0,5 mm ± 0,1 mm and an outer diameter not exceeding 0,9 mm.

NOTE The tubing specified in ISO 9626:2016 [1] (0,8 mm normal walled or thin walled) meets these

requirements in this standard for an internal diameter of 0,5 mm ± 0,1 mm and an outside diameter no greater than

0,9 mm.

5.2 Gas supply

The burner is supplied with either propane or butane gas having a purity of at least not less

than 95 %.

5.3 Flame

With the axis of the burner in the vertical position, ignite the gas supply is and adjusted so

that the length the gas flow rate to ensure that the overall height of the flame is 12 mm ±

1 mm, when viewed in subdued light against a dark background (see Figure 1), and that the

flame is symmetrical. Wait for a period of at least 5 min to allow the burner conditions to reach

equilibrium. There shall be no air admitted to the burner tube.

The flame shall be confirmed using the apparatus and procedure detailed in Annex A. The

test time for the temperature to increase from 100 °C ± 5 °C to 700 °C ± 3 °C shall be 23,5 s ±

1,0 s.

___________

1 Numbers in square brackets refer to the bibliography.

5.4 Control valve

A control valve is required to set the gas flow rate to ensure that the overall height of the

flame is within the required tolerances.

5.5 Laboratory fumehood/chamber

The laboratory fumehood/chamber shall have an inside volume of at least 0,5 m . The

chamber shall provide a draught-free environment, whilst allowing normal thermal circulation

of air past the test specimen. The chamber shall permit observation of the test in progress.

The inside surfaces of the walls shall be of a dark colour. In case of dispute, the recorded

light level shall be less than 20 lx using a light meter, facing towards the rear of the chamber

and positioned in place of the test specimen.

For safety and convenience, it is desirable that this enclosure fumehood/chamber (which can

be completely closed) be fitted with an extraction device, such as an exhaust fan, to remove

products of combustion, which may be toxic. The extraction device, if used, shall be turned off

during the test and turned on immediately after the timing measurements have been made. A

positive closing damper may be needed.

NOTE Placing a mirror in the chamber, to provide a rear view of the test specimen, has been found to be useful.

5.6 Layer

5.6.1 Specified layer

To evaluate the possibility of spread of fire, for example by burning or glowing particles falling

from the test specimen, a layer of the material or components normally surrounding or

situated underneath the test specimen is shall be placed underneath the test specimen at a

distance equal to the distance between the test specimen and the surrounding material or

components when the test specimen is mounted as in normal use.

5.6.2 Standardized layer

If the test specimen is a sub-assembly or a component of the equipment and is tested

separately, such that surrounding materials and distances are unknown, a piece of flat smooth

wooden board, approximately 10 mm thick covered in close contact with a single layer of

wrapping tissue (3.13), is shall be positioned at a distance of 200 mm ± 5 mm below the place

where the needle-flame is applied to the test specimen, unless otherwise specified in the

relevant specification. Wrapping tissue as specified in 4.215 of ISO 4046-4 is a soft and

2 2

strong, lightweight wrapping tissue 12 g/m to 30 g/m .

If the test specimen is a complete free-standing equipment, it is shall be placed in its normal

position of use on the tissue covered wooden board, extending for a minimum of 100 mm

outside the base of the equipment in all directions.

If the test specimen is a complete wall-mounted equipment, it is shall be fixed in its normal

position of use 200 mm ± 5 mm above the tissue covered wooden board.

Means to fix the test specimen and the burner in position may be necessary.

5.7 Timing device

The timing device shall have a tolerance resolution of not more than 0,5 s.

6 Test specimen

If possible, the test specimen shall be a complete equipment, sub-assembly or component. If

it is necessary to take away parts of an enclosure or to cut off a suitable part to perform the

– 12 – IEC 60695-11-5:2016 RLV © IEC 2016

test, care shall be taken to ensure that the test conditions are not significantly different from

those occurring in normal use with regard to shape, ventilation conditions, effect of thermal

stresses and possible flames occurring, or burning or glowing particles falling in the vicinity of

the test specimen.

If the test specimen is a suitable part cut from a larger unit, care shall be taken to ensure that

in this particular case the test flame is not applied incorrectly, for example to an edge created

by cutting.

If it is not possible to conduct the test on a sub-assembly or component within the equipment,

the test is conducted on a test specimen removed from the equipment.

7 Severities Flame application times

Preferred values of the duration of application (t ) of the test flame are as follows:

a

5 s, 10 s, 15 s, 20 s, 30 s, 60 s, 120 s.

The tolerance for all values is s.

−1

NOTE The duration of application of the test flame should be chosen in relation to the

characteristics of the end product.

NOTE See Annex C for an example of a classification system for the needle-flame test.

8 Conditioning and test conditions

8.1 Conditioning

If not otherwise specified in the relevant specification, the test specimen, the wooden board

and the tissue paper -covered wooden board shall be conditioned for not less than 24 h in an

atmosphere having a temperature between 15 °C and 35 °C and a relative humidity between

45 % and 75 % before starting the test. Once removed from the conditioning atmosphere, the

test specimens shall be tested within 1 h (see ISO 291).

8.2 Test conditions

Unless otherwise specified, all test specimens shall be tested under standard atmospheric

conditions for testing as follows:

– temperature: 15 °C to 35 °C; and

– relative humidity: ≤ 75 %.

9 Test procedure

9.1 General

Warning

Precautions shall be taken to safeguard the health of the personnel conducting tests against:

– the risks of explosion or fire;

– the inhalation of smoke and/or toxic products; and

– toxic residues.

9.2 Position of test specimen

Unless otherwise specified in the relevant specification, the test specimen is shall be

arranged in a position of normal use such that ignition is most likely to occur during the test.

The means to fix the test specimen shall not influence the effect of the test flame or the

propagation of flames in a way other than that occurring under normal conditions of use.

9.3 Application of needle-flame

The test flame is shall be applied to that part of the surface of the test specimen which is most

likely to be affected by flames resulting from normal use or from fault conditions. Examples of

flame test positions are shown in Figures 2a and 2b.

The duration of application of the test flame shall be as specified in the relevant specification.

With the central axis of the burner tube vertical, place the burner remote from the test

specimen, set the burner (see 5.1) to produce a standardized 12 mm nominal test flame,

conforming to 5.3. Wait for a minimum of 5 min to allow the burner conditions to reach

equilibrium. Rotate the burner so that the burner tube is positioned at an angle of 45 ± 5°

from the vertical (see Figure 1) throughout the duration of the test.

The test flame is shall be positioned so that the tip of the flame is in contact with the surface

of the test specimen. The test flame is removed after the specified time.

If the test specimen drips molten or flaming material during the application of the flame, the

burner may be tilted up to 45 ° from the vertical to prevent material from dripping into the

burner tube while maintaining an 8 mm ± 1 mm spacing between the center of the top of the

burner and the remaining portion of the test specimen, ignoring any strings of molten material.

If the test specimen is located vertically above the test flame, a spacing of 8 mm ± 1 mm shall

be maintained between the center of the top of the burner and the remaining portion of the

test specimen during the test, ignoring any strings of molten material. If the test specimen is

located horizontally from the test flame, a spacing of 5 mm ± 1 mm shall be maintained

between the center of the top of the burner and the remaining portion of the test specimen

during the test (see Figure 1).

The test flame is removed after the specified flame application time (t ) (see Clause 7).

a

When required by the relevant specification, the test is applied at more than one point on the

same test specimen, in which case care shall be taken to ensure that any deterioration

caused by previous tests will not affect the result of the test to be conducted.

9.4 Number of test specimens

Unless otherwise specified in the relevant specification, the test is performed on three test

specimens.

10 Observations and measurements

In the case of ignition of the test specimen and/or the specified layer and/or the surrounding

parts, the duration of burning (t ) is measured and reported. Ignition of the specified layer

b

shall be observed and noted. The duration of burning denotes the time interval from the

moment the test flame is removed from the test specimen, until the last flames have

extinguished and the glowing combustion of the test specimen, the specified layer and/or the

surrounding parts is no longer visible.

– 14 – IEC 60695-11-5:2016 RLV © IEC 2016

11 Evaluation of test results

Unless otherwise prescribed in the relevant specification, The test specimen is considered to

have satisfactorily withstood the needle-flame test if one of the following situations criteria

applies:

a) There is no ignition of the specified layer or wrapping tissue and, after the removal of the

needle-flame, there is no flame and no glowing of the test specimen.

b) Flames or glowing of the test specimen and the surrounding parts extinguish within 30 s

after the removal of the needle-flame, that is t < 30 s. Also, the surrounding parts have

b

not burnt away completely and there has been no ignition of the specified layer or

wrapping tissue.

12 Information to be given in the relevant specification

The relevant specification shall indicate the following details:

a) any conditioning, if different from that specified in Clause 8;

b) the number of test specimens, if different from that specified in 9.4;

c) the position of the test specimen (see 9.2);

d) the surface to be tested and the point of application (see 9.3);

e) the specified layer to be used to evaluate the effect of burning or glowing particles falling

from the test specimen (see 5.6);

f) level of severity:

f) the duration of application of the test flame (t ) (see Clause 7);

a

g) the permissible duration and extent of burning, considering the design and arrangements

of the various parts, shields and barriers inside the equipment;

h) whether the criteria specified are sufficient to check compliance with the safety

requirements, or whether further criteria should be introduced;

i) any requirements if different from those given in Clauses 10 and 11.

13 Test report

The test report shall include the following information:

a) the type and description of the test specimen (see Clause 6);

b) the method of preparation (see Clause 6);

c) any conditioning of the test specimens (see Clause 8);

d) the number of test specimens (see 9.4);

e) level of severity:

e) the duration of application of the test flame (t ) (see Clauses 7 and 12);

a

f) the surface tested and the point of application of the needle-flame (see 9.3);

g) the specified layer used to evaluate the effect of burning or glowing particles falling from

the test specimen (see 5.6);

h) whether the test flame has been applied at more than one point on the same test

specimen, (see 9.3); and

i) the test results (see Clauses 10 and 11).

Dimensions in millimetres

Outside ø0,9 max.

Bore ø0,5 ± 0,1

Gas supply

IEC

Figure 1 – Needle Burner and flame

Dimensions in millimetres

Test specimen Test specimen

5 ± 1

45° 45°

IEC IEC

Figure 2a − Test position (horizontal example) Figure 2b − Test position (vertical example)

Figure 2 – Test positions

8 ± 1

12 ± 1

– 16 – IEC 60695-11-5:2016 RLV © IEC 2016

Annex A

(normative)

Confirmatory test arrangement

A.1 Confirmation of the test flame – Principle

The time for the temperature of the copper block, described in Figure A.1, to increase from

100 °C ± 5 °C to 700 °C ± 3 °C shall be 23,5 s ± 1,0 s, when the flame confirmatory test

arrangement of Figure A.2 is used.

The flame shall be confirmed in accordance with this Annex A every time the gas supply is

changed or replaced.

NOTE Detailed background information for the confirmation of a test flame can be found in IEC 60695-11-40 [2].

A.2 Test apparatus

A.2.1 Burner

The burner shall be in accordance with 5.1.

A.2.2 Control valve

One control valve is required to set the gas flow rate.

A.2.3 Copper block

The copper block material shall be specified as: Cu-ETP UNS C11000 (see ASTM-B187). The

diameter of the copper block shall be 4 mm ± 0,01 mm with a mass of 0,58 g ± 0,01 g in the

fully machined and polished but undrilled state, see Figure A.1.

A.2.4 Thermocouple

The thermocouple shall be a sheathed fine wire type K (NiCr/NiAl) with an outer sheath

diameter of 0,5 mm.

The preferred method of fastening the thermocouple to the copper block is by compressing

the copper around the thermocouple, after first ensuring that the thermocouple is inserted to

the full depth of the hole as shown in Figure A.2.

A.2.5 Temperature/time indicating/recording and timing devices

These devices shall be appropriate for the measurement of the time for the copper block to

heat up from 100 °C ± 5 °C to 700 °C ± 3 °C with a time uncertainty of 0,1 s. The timing

device shall have a tolerance of not more than 0,5 s.

A.3 Procedure

An example of a suitable gauge for the adjustment of flame height and the distance between

the burner and the copper block is given in Figure A.3. The fixture shall be constructed such

that it does not rest on the flame end of the burner tube nor disturb the root of the burner

flame.

– Set up the confirmatory test arrangement according to Figure A.2 in a draught-free

environment, ensuring leak-free gas connections.

– Temporarily remove the burner away from the copper block to ensure no influence of the

flame on the copper block during the preliminary adjustment of the gas flow rate.

– With the axis of the burner in the vertical position, ignite the gas supply and adjust the gas

flow rate to give a flame ensure that the overall height of the flame is 12 mm ± 1 mm,

when viewed in subdued light against a dark background, and that the flame is

symmetrical.

NOTE 1 In case of dispute, a light level of 20 lux should be used.

– Wait for a period of at least 5 min to allow the burner conditions to reach equilibrium and

then readjust measure the flame height, if necessary to determine that ensure that the

height is within the required limits.

– With the temperature/time indicating/recording devices operational, reposition the burner

under the copper block.

– Conduct three determinations of the time for the temperature of the copper block to

increase from 100 °C ± 5 °C to 700 °C ± 3 °C. Allow the copper block to cool naturally in

air to below 50 °C between determinations.

NOTE 2 At temperatures above 700 °C, the thermocouple can be easily damaged, therefore it is advisable to

remove the burner immediately after reaching 700 °C.

– If the copper block has not been used before, conduct a preliminary run to condition the

copper block surface. Discard the result.

– Calculate the mean time in seconds as the result.

– The flame is confirmed if the result is within the range 23,5 s ± 1,0 s.

– The flame shall be confirmed in accordance with this Annex A every time the gas supply is

changed or replaced.

– 18 – IEC 60695-11-5:2016 RLV © IEC 2016

Dimensions in millimetres

Hole drilled to be a close fit

on 0,5 mm thermocouple

45°

45°

Approximately 1 − machine

to give the correct mass

4,00 ± 0,01

IEC

Copper block polished all over

Tolerance: ± 0,1, ± 30 min (angular), unless otherwise stated

Material: high conductive electrolytic copper Cu-ETP UNS C 11000 (see ASTM-B187)

Weight Mass: 0,58 g ± 0,01 g before drilling

Figure A.1 – Copper block

1,00 ± 0,02

4,00 ± 0,05

6,00 ± 0,03

Dimensions in millimetres

Suspension point

Temperature/time

indicating/recording

devices

Burner tube

After first ensuring that the thermocouple

is inserted to the full depth of the hole, the

copper is compressed around thermocouple

to retain it without damage

IEC

The mode of suspension of the copper block shall be such that the block remains essentially stationary during the

test.

Figure A.2 – Confirmatory test arrangement

6,0 ± 0,5

≥ 40

– 20 – IEC 60695-11-5:2016 RLV © IEC 2016

Dimensions in millimetres

IEC

Figure A.3 – Gauge to measure flame height and the distance

between burner and copper block (example)

Annex B

(informative)

Access to equipment manufacturers and suppliers

An up-to-date list of equipment manufacturers and suppliers is maintained by the Secretary of

IEC technical committee 89. The address details can be found on the IEC website:

http://www.iec.ch

– 22 – IEC 60695-11-5:2016 RLV © IEC 2016

Annex B

(informative)

Example of a product committee specification

The IEC references the IEC 60695-11-5 Needle-flame test method in 4.38, Passive

flammability, of IEC 60384-1:2015, Fixed capacitors for use in electronic equipment – Part 1:

General specification [3]. The test procedure specifies in Table 7 of IEC 60384-1:2015 that

the test flame exposure time and the maximum burning time are dependent upon both the

volume of the part under test and the specified category of the capacitor. For example, a

capacitor with an assigned category of passive flammability of code C and a volume greater

than 1 750 mm wou

...

IEC 60695-11-5 ®

Edition 2.0 2016-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 11-5: Test flames – Needle-flame test method – Apparatus, confirmatory test

arrangement and guidance

Essais relatifs aux risques du feu –

Partie 11-5: Flammes d'essai – Méthode d'essai au brûleur-aiguille –

Appareillage, dispositif d'essai de vérification et lignes directrices

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 20 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 15 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 65 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient 20 000 termes et définitions en anglais

Spécifications techniques, Rapports techniques et autres

et en français, ainsi que les termes équivalents dans 15

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

65 000 entrées terminologiques électrotechniques, en anglais

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, et en français, extraites des articles Termes et Définitions des

comité d’études,…). Elle donne aussi des informations sur les publications IEC parues depuis 2002. Plus certaines entrées

projets et les publications remplacées ou retirées. antérieures extraites des publications des CE 37, 77, 86 et

CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60695-11-5 ®

Edition 2.0 2016-12

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

BASIC SAFETY PUBLICATION

PUBLICATION FONDAMENTALE DE SÉCURITÉ

Fire hazard testing –

Part 11-5: Test flames – Needle-flame test method – Apparatus, confirmatory test

arrangement and guidance

Essais relatifs aux risques du feu –

Partie 11-5: Flammes d'essai – Méthode d'essai au brûleur-aiguille –

Appareillage, dispositif d'essai de vérification et lignes directrices

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.220.40; 29.020 ISBN 978-2-8322-3792-2

– 2 – IEC 60695-11-5:2016 © IEC 2016

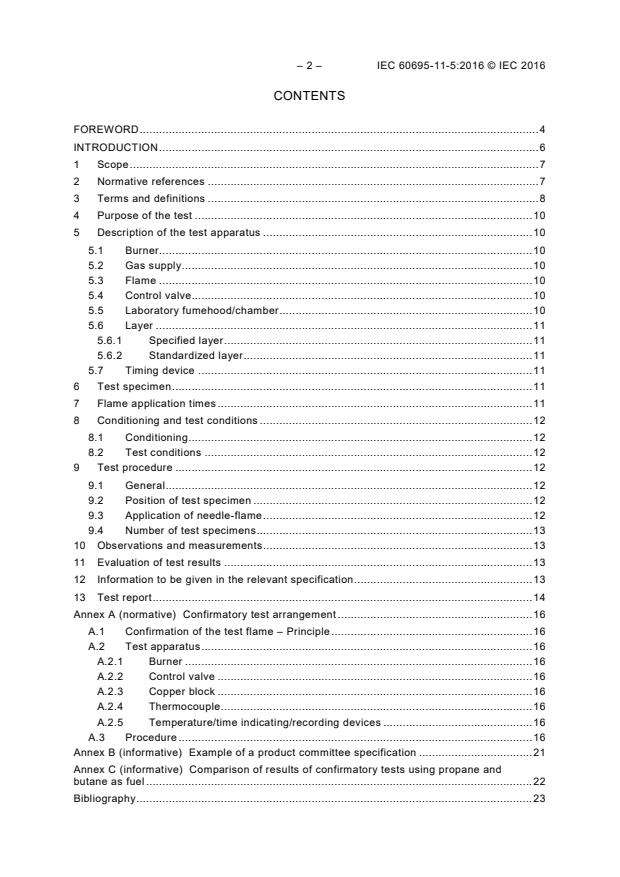

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Purpose of the test . 10

5 Description of the test apparatus . 10

5.1 Burner. 10

5.2 Gas supply . 10

5.3 Flame . 10

5.4 Control valve. 10

5.5 Laboratory fumehood/chamber . 10

5.6 Layer . 11

5.6.1 Specified layer . 11

5.6.2 Standardized layer . 11

5.7 Timing device . 11

6 Test specimen . 11

7 Flame application times . 11

8 Conditioning and test conditions . 12

8.1 Conditioning . 12

8.2 Test conditions . 12

9 Test procedure . 12

9.1 General . 12

9.2 Position of test specimen . 12

9.3 Application of needle-flame . 12

9.4 Number of test specimens . 13

10 Observations and measurements . 13

11 Evaluation of test results . 13

12 Information to be given in the relevant specification . 13

13 Test report . 14

Annex A (normative) Confirmatory test arrangement . 16

A.1 Confirmation of the test flame – Principle . 16

A.2 Test apparatus . 16

A.2.1 Burner . 16

A.2.2 Control valve . 16

A.2.3 Copper block . 16

A.2.4 Thermocouple . 16

A.2.5 Temperature/time indicating/recording devices . 16

A.3 Procedure . 16

Annex B (informative) Example of a product committee specification . 21

Annex C (informative) Comparison of results of confirmatory tests using propane and

butane as fuel . 22

Bibliography . 23

Figure 1 – Burner and flame . 14

Figure 2 – Test positions. 15

Figure A.1 – Copper block . 18

Figure A.2 – Confirmatory test arrangement . 19

Figure A.3 – Gauge to measure flame height and the distance between burner and

copper block (example) . 20

Table B.1 – Severities and requirements . 21

Table C.1 – Results of the confirmatory test using propane and butane as fuel . 22

– 4 – IEC 60695-11-5:2016 © IEC 2016

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FIRE HAZARD TESTING –

Part 11-5: Test flames – Needle-flame test method –

Apparatus, confirmatory test arrangement and guidance

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60695-11-5 has been prepared by IEC technical committee 89:

Fire hazard testing.

This second edition cancels and replaces the first edition published in 2004. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) The scope has been broadened to allow this test method to also simulate the effects of

small flames from outside the equipment;

b) Propane and butane gas are the specified fuel source with a minimum purity of 95 %;

c) A new concept has been added which allows the burner to be moved during the test to

avoid dripping material from falling onto the tip of the burner tube;

d) The burner tube material is now a referenced source;

e) The reference for the copper block material has changed – the ISO publication (ISO 1337)

has been withdrawn with no replacement. A new callout is now used;

f) Informative Annex C and a bibliography have been added.

The text of this standard is based on the following documents:

FDIS Report on voting

89/1346/FDIS 89/1351/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a basic safety publication in accordance with IEC Guide 104 and

ISO/IEC Guide 51.

A list of all the parts in the IEC 60695 series, under the general title Fire hazard testing, can

be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60695-11-5:2016 © IEC 2016

INTRODUCTION

The best method for testing electrotechnical products with regard to fire hazard is to duplicate

exactly the conditions occurring in practice. In most instances this is not possible.

Accordingly, for practical reasons, the testing of electrotechnical products with regard to fire

hazard is best conducted by simulating as closely as possible the actual effects occurring in

practice.

Parts of electrotechnical equipment might be exposed to excessive thermal stress due to

electric effects. This can result in deterioration that might impair the safety of the equipment.

Such parts should not be unduly affected by heat or by fire generated within the equipment.

Parts of insulating material or of other combustible material which are liable to propagate

flames inside the equipment may be ignited by flames produced by a failing component.

Under certain conditions, for example a fault current flowing over a tracking path, overloading

of components or parts and bad connections, flames may also occur; such flames may

impinge upon combustible parts in the vicinity.

This part of IEC 60695 is intended to be used to measure and describe the properties of

materials, products or assemblies in response to heat and flame under controlled laboratory

conditions and is not intended to be used to describe or appraise the fire hazard or fire risk of

materials, products, or assemblies under actual fire conditions. This standard may involve

hazardous materials, operations and equipment.

It does not purport to address all of the safety problems associated with its use.

It is the responsibility of the user of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limitations prior to use.

FIRE HAZARD TESTING –

Part 11-5: Test flames – Needle-flame test method –

Apparatus, confirmatory test arrangement and guidance

1 Scope

This part of IEC 60695 specifies a needle-flame test to simulate the effect of a small flame

which may result from fault conditions, in order to assess the fire hazard by a simulation

technique. The results of this test may be used as elements of a fire hazard assessment

which takes into account all of the factors which are pertinent to an assessment of the fire

hazard of a particular end use.

It is applicable to electrotechnical equipment, its sub-assemblies and components and to solid

electrical insulating materials or other combustible materials.

This basic safety publication is intended for use by technical committees in the preparation of

standards in accordance with the principles laid down in IEC Guide 104 and

ISO/IEC Guide 51.

One of the responsibilities of a technical committee is, wherever applicable, to make use of

basic safety publications in the preparation of its publications. The requirements, test methods

or test conditions of this basic safety publication will not apply unless specifically referred to

or included in the relevant publications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60695-4:2012, Fire hazard testing – Part 4: Terminology concerning fire tests for

electrotechnical products

IEC Guide 104, The preparation of safety publications and the use of basic safety publications

and group safety publications

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

ISO 291, Plastics – Standard atmospheres for conditioning and testing

ISO 4046-4:2016, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper and

board grades and converted products

ISO 13943:2008, Fire safety – Vocabulary

ASTM-B187, Standard specification for copper, bus bar, rod, and shapes and general purpose

rod, bar, and shapes

– 8 – IEC 60695-11-5:2016 © IEC 2016

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943:2008,

IEC 60695-4:2012 and ISO 4046:2002, as well as the following, apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

combustible, adj.

capable of being ignited and burned

[SOURCE: ISO 13943:2008, 4.43]

3.2

draught-free environment

space in which the results of experiments are not significantly affected by the local air speed

Note 1 to entry: A qualitative example is a space in which a wax candle flame remains essentially undisturbed.

-1 -1

Quantitative examples are small-scale fire tests in which a maximum air speed of 0,1 m × s or 0,2 m × s is

sometimes specified.

[SOURCE: ISO 13943:2008, 4.70]

3.3

fire

〈general〉 process of combustion characterized by the emission of heat and fire effluent and

usually accompanied by smoke, flame, glowing or a combination thereof

Note 1 to entry: In the English language the term “fire” is used to designate three concepts, two of which, fire

(3.4) and fire (3.5), relate to specific types of self-supporting combustion with different meanings and two of them

are designated using two different terms in both French and German.

[SOURCE: ISO 13943:2008, 4.96]

3.4

fire

〈controlled〉 self-supporting combustion that has been deliberately arranged to provide useful

effects and is limited in its extent in time and space

[SOURCE: ISO 13943:2008, 4.97]

3.5

fire

〈uncontrolled〉 self-supporting combustion that has not been deliberately arranged to provide

useful effects and is not limited in its extent in time and space

[SOURCE: ISO 13943:2008, 4.98]

3.6

fire hazard

physical object or condition with a potential for an undesirable consequence from fire (3.1)

[SOURCE: ISO 13943:2008, 4.112]

3.7

fire risk

probability of a fire (3.3) combined with a quantified measure of its consequence

Note 1 to entry: It is often calculated as the product of probability and consequence.

[SOURCE: ISO 13943:2008, 4.124]

3.8

flame, noun

rapid, self-sustaining, sub-sonic propagation of combustion in a gaseous medium, usually with

emission of light

[SOURCE: ISO 13943:2008, 4.133]

3.9

glowing, noun

luminosity caused by heat

cf. incandescence

[SOURCE: ISO 13943:2008, 4.168]

3.10

glowing combustion

combustion of a material in the solid phase without flame but with emission of light from the

combustion zone

cf. incandescence

[SOURCE: ISO 13943:2008, 4.169]

3.11

ignition

sustained ignition (deprecated)

〈general〉 initiation of combustion

[SOURCE: ISO 13943:2008, 4.187]

3.12

ignition

sustained ignition (deprecated)

〈flaming combustion〉 initiation of sustained flame

[SOURCE: ISO 13943:2008, 4.188]

3.13

wrapping tissue

soft and strong, lightweight wrapping paper of grammage generally between 12 g/m and

30 g/m , primarily intended for protective packaging of delicate articles and for gift wrapping

Note 1 to entry: In French, the word “mousseline” includes both white tissue and “bulle corde”, which is

unbleached or coloured tissue.

[SOURCE: ISO 4046-4:2016, 4.215]

– 10 – IEC 60695-11-5:2016 © IEC 2016

4 Purpose of the test

The test is performed to determine that, under defined conditions, the test flame either does

not cause ignition of parts or if it does, combustible parts ignited by the test flame have a

limited duration of burning or a limited extent of burning, without spreading fire by flames or

burning or glowing particles falling from the test specimen.

The test flame, applied to the test specimen, imitates a flame that might arise from a

component that is close to the test specimen in the real application.Such a flame might have

occurred, for example, because of an electrical fault.

The relevant product specification shall specify, if applicable, the duration of the test flame

application and the acceptance criteria.

5 Description of the test apparatus

5.1 Burner

The burner to produce the test flame shall consist of a tube at least 35 mm long with a bore of

0,5 mm ± 0,1 mm and an outer diameter not exceeding 0,9 mm.

NOTE The tubing specified in ISO 9626:2016 [1] (0,8 mm normal walled or thin walled) meets these

requirements.

5.2 Gas supply

The burner is supplied with either propane or butane gas having a purity not less than 95 %.

5.3 Flame

With the axis of the burner in the vertical position, ignite the gas supply and adjust the gas

flow rate to ensure that the overall height of the flame is 12 mm ± 1 mm, when viewed in

subdued light against a dark background (see Figure 1), and that the flame is symmetrical.

Wait for a period of at least 5 min to allow the burner conditions to reach equilibrium. There

shall be no air admitted to the burner tube.

The flame shall be confirmed using the apparatus and procedure detailed in Annex A.

5.4 Control valve

A control valve is required to set the gas flow rate to ensure that the overall height of the

flame is within the required tolerances.

5.5 Laboratory fumehood/chamber

. The

The laboratory fumehood/chamber shall have an inside volume of at least 0,5 m

chamber shall provide a draught-free environment, whilst allowing normal thermal circulation

of air past the test specimen. The chamber shall permit observation of the test in progress.

The inside surfaces of the walls shall be of a dark colour. In case of dispute, the recorded

light level shall be less than 20 lx using a light meter, facing towards the rear of the chamber

and positioned in place of the test specimen.