IEC 60079-26:2014

(Main)Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga

Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga

IEC 60079-26:2014 specifies alternative requirements for construction, test and marking for electrical equipment that provides Equipment Protection Level (EPL) Ga when single standardised Types of Protection (e.g. Ex "ia", Ex "ma", Ex "da") cannot be applied. This standard also applies to equipment mounted across a boundary where different Equipment Protection Levels may be required. This electrical equipment, within the operational parameters specified by the manufacturer, ensures a very high Level of Protection that includes rare malfunctions related to the equipment or two malfunctions occurring independently of each other. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard takes precedence. This third edition cancels and replaces the second edition published in 2006 and constitutes a technical revision. The numerous changes are identified in the Foreword of the document. Keywords: Equipment Protection Level (EPL) Ga

Atmosphères explosives - Partie 26: Matériel d'un niveau de protection du matériel (EPL) Ga

IEC 60079-26:2014 spécifie les exigences alternatives relatives à la construction, aux essais et au marquage du matériel électrique fournissant le niveau de protection du matériel (EPL, Equipment Protection Level) Ga lorsque des types normalisés uniques de Protection (comme par ex. Ex "ia", Ex "ma", Ex "da") ne peuvent pas être appliqués. La présente norme s'applique au matériel installé en chevauchement sur des emplacements pour lesquels différents niveaux de protection du matériel peuvent être exigés.Ce matériel électrique assure, dans les limites des paramètres de fonctionnement spécifiés par le constructeur, un très haut niveau de protection prenant en compte le cas de rares dysfonctionnements liés au matériel, ou d'apparition simultanée de deux dysfonctionnements indépendants l'un de l'autre. La présente norme complète et modifie les exigences générales de l'IEC 60079-0. Lorsqu'une exigence de la présente norme entre en contradiction avec une exigence de l'IEC 60079-0, l'exigence de la présente norme prévaut. Cette troisième édition annule et remplace la deuxième édition parue en 2006 et constitue une révision technique. Les nombreux changements sont identifiés dans l'avant-propos du document. Mots clés: protection du matériel (EPL) Ga

General Information

- Status

- Published

- Publication Date

- 27-Oct-2014

- Technical Committee

- TC 31 - Equipment for explosive atmospheres

- Drafting Committee

- MT 60079-26 - TC 31/MT 60079-26

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 25-Feb-2021

- Completion Date

- 14-Dec-2018

Relations

- Effective Date

- 10-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60079-26:2014 - Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga - specifies alternative construction, test and marking requirements for electrical equipment that must provide EPL Ga when a single standardized Type of Protection (for example Ex “ia”, Ex “ma”, Ex “da”) cannot be applied. EPL Ga corresponds to the very high level of protection required for Zone 0 (explosive gas atmosphere present continuously or for long periods). This third edition (2014) supplements and modifies IEC 60079-0 and takes precedence where the two standards conflict.

Key topics and technical requirements

- Scope and intent: Defines requirements for equipment that ensures protection against rare malfunctions and combinations of two independent malfunctions under manufacturer‑specified operational parameters. Applicable also where equipment is mounted across a boundary between zones (e.g., Zone 0 / Zone 1).

- Design and construction: Alternative measures where single standardized Types of Protection are infeasible. Topics include intrinsic safety, encapsulation, separation elements and construction rules for moving parts.

- Separation elements and process connections: Requirements and type tests for separation elements that prevent gas diffusion; process connections must provide sufficiently tight joints (IP66 added as an alternative to IP67 in this edition).

- Type tests and temperature evaluation: Defines tests to demonstrate compliance for separation elements and temperature assessment under specified conditions.

- Marking and instructions: Requirements for marking examples, EPL allocation and user information (including material specification for partition walls and guidance for separation elements and process connections).

- Relationship to IEC 60079-0: This part supplements/modifies general requirements; where conflicts exist, IEC 60079-26 takes precedence.

Practical applications

- Equipment that must operate inside Zone 0 but is mounted at a boundary with less-hazardous areas (e.g., sensors, transmitters, or actuators installed in vessel walls).

- Design of enclosures, feedthroughs and separation barriers where conventional single protection methods are not practical.

- Situations requiring documented type tests and marking to prove a very high level of protection for continuous explosive atmospheres.

Who should use this standard

- Electrical equipment designers and manufacturers targeting Zone 0 applications

- Certification and conformity assessment bodies

- Plant engineers, safety managers and procurement specialists in oil & gas, chemical and pharmaceutical industries

- Test laboratories and regulatory inspectors verifying EPL Ga claims

Related standards and keywords

- Related: IEC 60079-0 (general requirements for explosive atmospheres) and other parts of the IEC 60079 series (Types of Protection such as Ex “ia”, “ma”, “da”).

- Keywords: Equipment Protection Level Ga, EPL Ga, explosive atmospheres, Zone 0, separation element, process connection, intrinsic safety, encapsulation, IEC 60079-26:2014.

REDLINE IEC 60079-26:2014 - Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga Released:10/28/2014 Isbn:9782832219126

IEC 60079-26:2014 - Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60079-26:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Explosive atmospheres - Part 26: Equipment with Equipment Protection Level (EPL) Ga". This standard covers: IEC 60079-26:2014 specifies alternative requirements for construction, test and marking for electrical equipment that provides Equipment Protection Level (EPL) Ga when single standardised Types of Protection (e.g. Ex "ia", Ex "ma", Ex "da") cannot be applied. This standard also applies to equipment mounted across a boundary where different Equipment Protection Levels may be required. This electrical equipment, within the operational parameters specified by the manufacturer, ensures a very high Level of Protection that includes rare malfunctions related to the equipment or two malfunctions occurring independently of each other. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard takes precedence. This third edition cancels and replaces the second edition published in 2006 and constitutes a technical revision. The numerous changes are identified in the Foreword of the document. Keywords: Equipment Protection Level (EPL) Ga

IEC 60079-26:2014 specifies alternative requirements for construction, test and marking for electrical equipment that provides Equipment Protection Level (EPL) Ga when single standardised Types of Protection (e.g. Ex "ia", Ex "ma", Ex "da") cannot be applied. This standard also applies to equipment mounted across a boundary where different Equipment Protection Levels may be required. This electrical equipment, within the operational parameters specified by the manufacturer, ensures a very high Level of Protection that includes rare malfunctions related to the equipment or two malfunctions occurring independently of each other. This standard supplements and modifies the general requirements of IEC 60079-0. Where a requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of this standard takes precedence. This third edition cancels and replaces the second edition published in 2006 and constitutes a technical revision. The numerous changes are identified in the Foreword of the document. Keywords: Equipment Protection Level (EPL) Ga

IEC 60079-26:2014 is classified under the following ICS (International Classification for Standards) categories: 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60079-26:2014 has the following relationships with other standards: It is inter standard links to EN 61800-2:2015, EN ISO 20257-1:2020, EN ISO 16315:2016, IEC 60079-26:2006/COR1:2009, IEC 60079-26:2021, IEC 60079-26:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60079-26:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60079-26 ®

Edition 3.0 2014-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 26: Equipment with Equipment Protection Level (EPL) Ga

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60079-26 ®

Edition 3.0 2014-10

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Explosive atmospheres –

Part 26: Equipment with Equipment Protection Level (EPL) Ga

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.260.20 ISBN 978-2-8322-1912-6

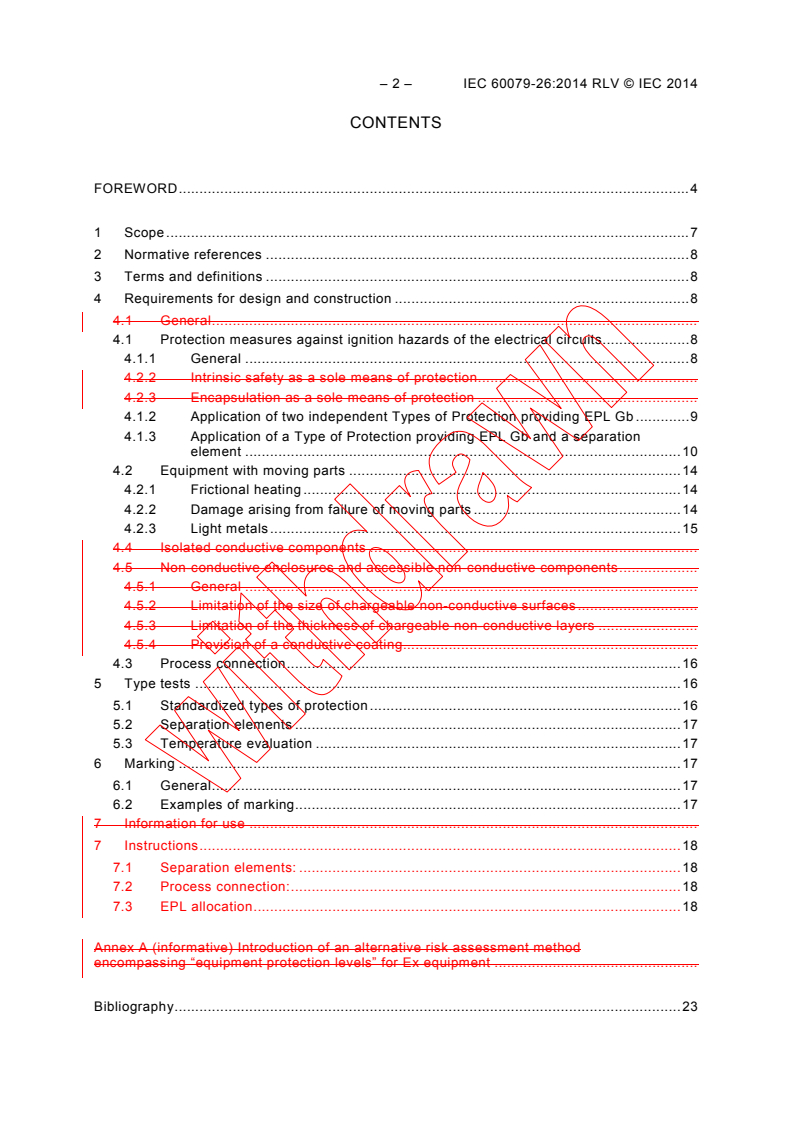

– 2 – IEC 60079-26:2014 RLV © IEC 2014

CONTENTS

FOREWORD . 4

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 8

4 Requirements for design and construction . 8

4.1 General .

4.1 Protection measures against ignition hazards of the electrical circuits. 8

4.1.1 General . 8

4.2.2 Intrinsic safety as a sole means of protection.

4.2.3 Encapsulation as a sole means of protection .

4.1.2 Application of two independent Types of Protection providing EPL Gb . 9

4.1.3 Application of a Type of Protection providing EPL Gb and a separation

element . 10

4.2 Equipment with moving parts . 14

4.2.1 Frictional heating . 14

4.2.2 Damage arising from failure of moving parts . 14

4.2.3 Light metals . 15

4.4 Isolated conductive components .

4.5 Non-conductive enclosures and accessible non-conductive components .

4.5.1 General .

4.5.2 Limitation of the size of chargeable non-conductive surfaces .

4.5.3 Limitation of the thickness of chargeable non-conductive layers .

4.5.4 Provision of a conductive coating.

4.3 Process connection . 16

5 Type tests . 16

5.1 Standardized types of protection . 16

5.2 Separation elements . 17

5.3 Temperature evaluation . 17

6 Marking . 17

6.1 General . 17

6.2 Examples of marking . 17

7 Information for use .

7 Instructions . 18

7.1 Separation elements: . 18

7.2 Process connection: . 18

7.3 EPL allocation . 18

Annex A (informative) Introduction of an alternative risk assessment method

encompassing “equipment protection levels” for Ex equipment .

Bibliography . 23

Figure 1 – Example of a partition wall with a conductor bushing considered as gas

diffusion tight . 11

Figure 2 – Example of a separation element with a cylindrical shaft joint and

naturalventilation . 14

Table 1 – Separation elements . 13

– 4 – IEC 60079-26:2014 RLV © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 26: Equipment with Equipment Protection Level

(EPL) Ga

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60079-26 has been prepared by IEC technical committee 31:

Equipment for explosive atmospheres.

This third edition cancels and replaces the second edition published in 2006 and constitutes a

technical revision.

This edition includes the following significant changes with respect to the previous edition:

Type

Changes Clause Minor and Extension Major

editorial technical

changes changes

Notes deleted 1 X

Reference to associated apparatus deleted 1 X

Additional normative references included 3 X

Requirements against mechanical and

electrostatic ignition hazards deleted (now 4.1 X

covered in IEC 60079-0)

Requirement for separation element detailed

4.1.3.2 X

regarding external influences

Intrinsic safety Ex ia as single type of protection

4.2.2

including associated apparatus deleted (now X

(ed.2)

covered by EPL)

Encapsulation Ex ma as single type of protection 4.2.3

X

deleted (now covered by EPL) (ed.2)

Conditions a) and b) linked with an “and” ,

therefore requirement of “flameproof joint” deleted

in following clause. Both requirements already 4.3 X

covered by separation elements and standardised

process connections.

Process connection requires a sufficiently tight

4.3 X

joint: IP66 added alternatively to IP67

Requirement for isolated conductive components 4.4

X

deleted (now covered in IEC 60079-0) (ed.2)

Requirements for non-conductive enclosures 4.5

X

deleted (now covered in IEC 60079-0) (ed.2)

Test of partition walls according to 4.1.3.2 b) is

5.2 C1

specified in more detail

Marking example for associated apparatus deleted 6.2 b) X

Note 3 with an additional example added 6.2 X

Specification of material of partition wall required

7 X

in instructions (also required in 4.1.3.2)

Alternative risk assessment method deleted (is AnnexA

X

now generally introduced) (ed.2)

NOTE The technical changes referred to include the significance of technical changes in the revised IEC

Standard, but they do not form an exhaustive list of all modifications from the previous version.

Explanation of the types of changes:

A) Definitions

1) Minor and editorial changes:

• Clarification

• Decrease of technical requirements

• Minor technical change

• Editorial corrections

– 6 – IEC 60079-26:2014 RLV © IEC 2014

These are changes which modify requirements in an editorial or a minor technical way.

They include changes of the wording to clarify technical requirements without any

technical change, or a reduction in level of existing requirement.

2) Extension: Addition of technical options

These are changes which add new or modify existing technical requirements, in a way

that new options are given, but without increasing requirements for equipment that was

fully compliant with the previous standard.Therefore, these will not have to be

considered for products in conformity with the preceding edition.

3) Major technical changes:

• addition of technical requirements

• increase of technical requirements

These are changes to technical requirements (addition, increase of the level or

removal) made in a way that a product in conformity with the preceding edition will not

always be able to fulfil the requirements given in the later edition. These changes have

to be considered for products in conformity with the preceding edition. For these

changes additional information is provided in Clause B below.

NOTE These changes represent current technological knowledge. However, these changes should not

normally have an influence on equipment already placed on the market.

B) Information about the background of ‘Major technical changes’

C1: Introduction of type tests for separation elements according to “4.1.3.2 b)”

The text of this standard is based on the following documents:

FDIS Report on voting

31/1146/FDIS 31/1155/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60079 series, published under the general title Explosive

atmospheres, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

EXPLOSIVE ATMOSPHERES –

Part 26: Equipment with Equipment Protection Level

(EPL) Ga

1 Scope

This part of IEC 60079 specifies the particular alternative requirements for construction, test

and marking for electrical equipment that provides Equipment Protection Level (EPL) Ga

when single standardised Types of Protection (e.g. Ex “ia” , Ex “ma”, Ex “da”) cannot be

applied. This standard also applies to equipment mounted across a boundary where different

Equipment Protection Levels may be required.

EXAMPLE: Equipment installed in the wall of a storage vessel containing Zone 0 (requiring EPL Ga) inside an

area defined as Zone 1 (requiring EPL Gb).

This electrical equipment, within the operational parameters specified by the manufacturer,

ensures a very high Level of Protection that includes rare faults malfunctions related to the

equipment or two faults malfunctions occurring independently of each other.

NOTE A malfunction may result from a failure of the component parts of the electrical equipment or from

anticipated externally applied influences. Two independent malfunctions which may occur more frequently and

which, separately, would not create an ignition hazard but which, in combination, could create a potential ignition

hazard, should be are regarded as occurring together to form a rare fault malfunction.

NOTE 2 This electrical equipment is intended for use in zone 0 hazardous areas, in which explosive gas

atmospheres caused by mixtures of air and gases, vapours or mists under normal atmospheric conditions are

present continuously, for long periods or frequently.

This standard also applies to equipment mounted across a boundary where different

protection levels may be required.

EXAMPLE: In the wall of a storage vessel containing zone 0 with an ambient defined as zone 1.

This standard also applies to equipment installed in an area requiring a lower protection level,

but electrically connected to equipment with equipment protection level (EPL) Ga (associated

apparatus).

This standard supplements and modifies the general requirements of IEC 60079-0. Where a

requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of

this standard takes precedence. and the requirements of the standardized types of protection,

in accordance with the IEC 60079 series, to adapt the level of safety provided by those

standards in order to provide EPL Ga.

NOTE 3 In designing equipment for operation in explosive gas atmospheres under conditions other than the

atmospheric conditions given in IEC 60079-0, this standard may be used as a guide. However, additional testing is

recommended related specifically to the intended conditions of use. This is particularly important when the types of

protection ‘Flameproof enclosures’ (IEC 60079-1) and ‘Intrinsic safety’ (IEC 60079-11) are applied.

NOTE 4 The classification of hazardous areas in zones is defined in IEC 60079-10.

NOTE 5 There may be other non-electrical sources of ignition (for example ultrasonic, optical or ionizing radiation)

that are not addressed by this standard; these should also be taken into consideration (see, for example, EN 1127-1).

NOTE 6 This concept provides equipment protection level (EPL) Ga. For further information, see Annex A.

– 8 – IEC 60079-26:2014 RLV © IEC 2014

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-0:2004, Explosive atmospheres − Part 0: Equipment − General requirements

IEC 60079-1, Explosive atmospheres − Part 1: Equipment protection by flameproof enclosures

"d"

IEC 60079-10, Electrical apparatus for explosive gas atmospheres – Part 10: Classification of

hazardous areas

IEC 60079-11, Explosive atmospheres − Part 11: Equipment protection by intrinsic safety "i"

IEC 60079-18, Electrical apparatus for explosive gas atmospheres – Part 18: Construction,

test and marking of type of protection encapsulation "m" electrical apparatus

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 60695-11-10, Fire hazard testing − Part 11-10: Test flames − 50 W horizontal and vertical

flame test methods

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60079-0 and the

following apply.

NOTE Additional definitions applicable to explosive atmospheres can be found in IEC 60050-426.

3.1

EPL

abbreviation of equipment protection level as defined in Annex A

3.1

separation element

mechanical element inside the equipment, which separates different parts of the equipment

with different EPLs

Note 1 to entry: A separation element consists of a mechanical partition wall, which may be combined with a

flameproof joint or a natural ventilation

4 Requirements for design and construction

4.1 General

The equipment shall comply with the requirements of 4.2 for the electrical circuits and with the

requirements of 4.3 to 4.6 for mechanical and electrostatic ignition hazards.

4.1 Protection measures against ignition hazards of the electrical circuits

4.1.1 General

The equipment shall comply with the requirements of either

a) 4.2.2 or 4.2.3 in the event of two faults occurring independently of each other in a single

equipment means of protection; or

b) 4.2.4 or 4.2.5 4.1.2 or 4.1.3 in the event of a failure of one equipment means of protection,

by the provision of a second independent means of protection.

NOTE 1 Types of Protection according to EPL Ga do not require a second independant means of protection, e.g.

Ex “ia” (IEC 60079-11), Ex “ma” (IEC 60079-18), Ex “da” (IEC 60079-1).

Electrical connections and permanently connected cables of the equipment sited within an

area requiring EPL Ga equipment shall comply with the same Level of Protection required by

this standard, for example an Ex “e” a cable suitable for EPL Gb containing non-Ex “ia”

circuits additionally protected by a flameproof conduit or an Ex “e” a cable suitable for EPL Gb

provided with earth leakage protection.

NOTE 2 Detailed cable and installation requirements for non Types of Protection accepted as achieving EPL Ga

beyond intrinsically safe circuits providing EPL Ga are under consideration in IEC 60079-14.

NOTE 3 Because of ignition hazards which can arise from faults and/or transient circulating currents in the

potential equalization system, galvanic isolation in the power and signal connections to the equipment according to

4.1.2 and 4.1.3 4.2.2, 4.2.3 and 4.2.4 is preferred. Consideration should also be given to minimize is commonly

applied along with minimizing the effect of transient fault currents in the potential equalization network by the use

of electrical protection equipment such as sensitive earth leakage monitors.

4.2.2 Intrinsic safety as a sole means of protection

Intrinsically safe electrical equipment providing EPL Ga and intrinsically safe electrical circuits

of associated apparatus entering an area requiring EPL Ga shall comply with the

requirements of IEC 60079-11, intrinsic safety “ia”.

NOTE Intrinsic safety “ib” in accordance with IEC 60079-11 may be considered as one of two independent means

of protection according to 4.2.4.

4.2.3 Encapsulation as a sole means of protection

Electrical equipment which is protected by encapsulation providing EPL Ga shall comply with

the requirements of IEC 60079-18, encapsulation “ma”.

NOTE Encapsulation “mb” in accordance with IEC 60079-18 may be considered as one of two independent means

of protection according to 4.2.4.

4.1.2 Application of two independent Types of Protection providing EPL Gb

Electrical equipment shall comply with the requirements of two independent Types of

Protection that provide EPL Gb. If one Type of Protection fails, the other Type of Protection

shall continue to function. The independent Types of Protection shall not have a common

mode of failure, except as specified in this clause. Combined types of protection providing

EPL Gb shall depend on different physical protection principles.

NOTE 1 An example of a common mode of failure is if an Ex “d” enclosure containing arcing contacts

components is used installed inside an Ex “e” enclosure. Should the Ex “d” enclosure be compromised, then

arcing inside the enclosure will it would also compromise the Ex “e” enclosure.

NOTE 2 Combined types of protection providing EPL Gb should depend on different physical protection principles.

For example The combination of Ex “d” and Ex “q” both depend on the avoidance of flame propagation (same

physical protection principle) and may not be useful in combination. In practice, some combinations may not be

useful, for example the combination of oil immersion “o” and powder filling “q”.

Where combined types of protection are used, it shall be possible for each Type of Protection

to be tested individually (see 5.1).

Both Types of Protection shall be assessed using the most arduous fault condition of the

other Type of Protection. When combining intrinsic safety, Type of Protection “ib”, with other

Types of Protection, the second Type of Protection shall be assessed, with the most arduous

– 10 – IEC 60079-26:2014 RLV © IEC 2014

fault condition applied to the intrinsically safe circuit. Thermal dissipation shall be considered

in case of a fault of one Type of protection.

When using two Types of Protection, which both rely on the same parameter (for example, the

creepage distance combining Ex “ib” with Ex “e”), the most stringent requirement of both

Types of Protection shall be applied.

If two Types of Protection are combined which both rely on the enclosure, one of the following

shall be met:

a) if two enclosures are used (one totally enclosed within the other), each enclosure shall

comply with the requirements of the respective Type of Protection; or

b) if only one enclosure is used, the enclosure and the cable glands shall meet the impact

test requirements of 26.4.2 of IEC 60079-0, using the Group I values.

Examples of relevant combinations of two independent Types of Protection are as follows:

– inductive transmitters (for example proximity switches, electrical position sensors) with

intrinsic safety “ib” enclosed by encapsulation “mb”. The connections to intrinsically safe

“ib” circuits can be protected by the increased safety “e”;

– a lamp with the bulb luminaire designed as increased safety “e”, the lamp circuit with the

switch as intrinsic safety “ib”. These components may be incorporated included in a

flameproof enclosure “d”;

– measuring transducers with intrinsic safety “ib” and a flameproof enclosure “d”;

– equipment with electrical circuits of intrinsic safety “ib”, additionally protected by powder

filling “q”;

– electromagnetic valves with encapsulation “mb”, enclosed by a flameproof enclosure “d”;

– increased safety “e”, with pressurized equipment “pxb”.

4.1.3 Application of a Type of Protection providing EPL Gb and a separation element

4.1.3.1 General

Equipment which is mounted through or forms part of the boundary wall to an area requiring

EPL Ga and contains electrical circuits which do not comply with protection level EPL Ga shall

comply with at least one of the Types of Protection providing EPL Gb. Additionally, it shall

contain a mechanical separation element as part of the equipment to seal off separate the

electrical circuits of the equipment from the area requiring EPL Ga.

If the Type of Protection fails, the separation element shall:

a) prevent flame propagation through the equipment into the area requiring EPL Ga,

b) maintain its safety characteristics,

c) not be heated above exceed the maximum surface temperature of the specified

temperature class of the equipment (see 5.3).

Separation elements consist of a partition wall, possibly combined with a flameproof joint or

an air gap with natural ventilation.

4.1.3.2 Partition walls

Partition walls shall be constructed of either:

a) corrosion-resistant metals, glass or ceramics, which are specified in the manufacturer’s

documentation; or

b) other materials which can be verified to provide the same level of safety. In this case, X-

marking or an advisory marking in accordance with 29.2 of IEC 60079-0 shall be applied

and the certificate shall clearly specify the material and its thermal and mechanical

properties to enable the user to confirm the suitability for the particular application the

certificate number shall include the "X" suffix in accordance with the marking requirements

of IEC 60079-0.

If the wall thickness is less than 1 mm, the equipment shall be marked with an “X” or an

advisory marking according to 29.2 of IEC 60079-0 with a special condition for safe use the

certificate number shall include the "X" suffix in accordance with the marking requirements of

IEC 60079-0 and the Specific Conditions of Use listed on the certificate shall indicate that the

material shall not be subject to environmental conditions which might adversely affect the

partition wall.

If the partition wall is under constant vibrational stress (for example vibrating membranes), the

minimum endurance limit at maximum amplitude shall be defined in the documentation (see

Clause 7). Due to specified process pressure, loads or temperature, the separation element

shall not impair the Type of Protection.

NOTE 1 A wall thickness less than 1 mm is only permitted in combination with intrinsic safety

“ib”, or a flameproof joint or natural ventilation (see 4.1.3.3).

NOTE 2 For glass or ceramics, a minimum thickness of 1/10 of the diameter/maximum

dimension but not less than 1 mm is recommended required.

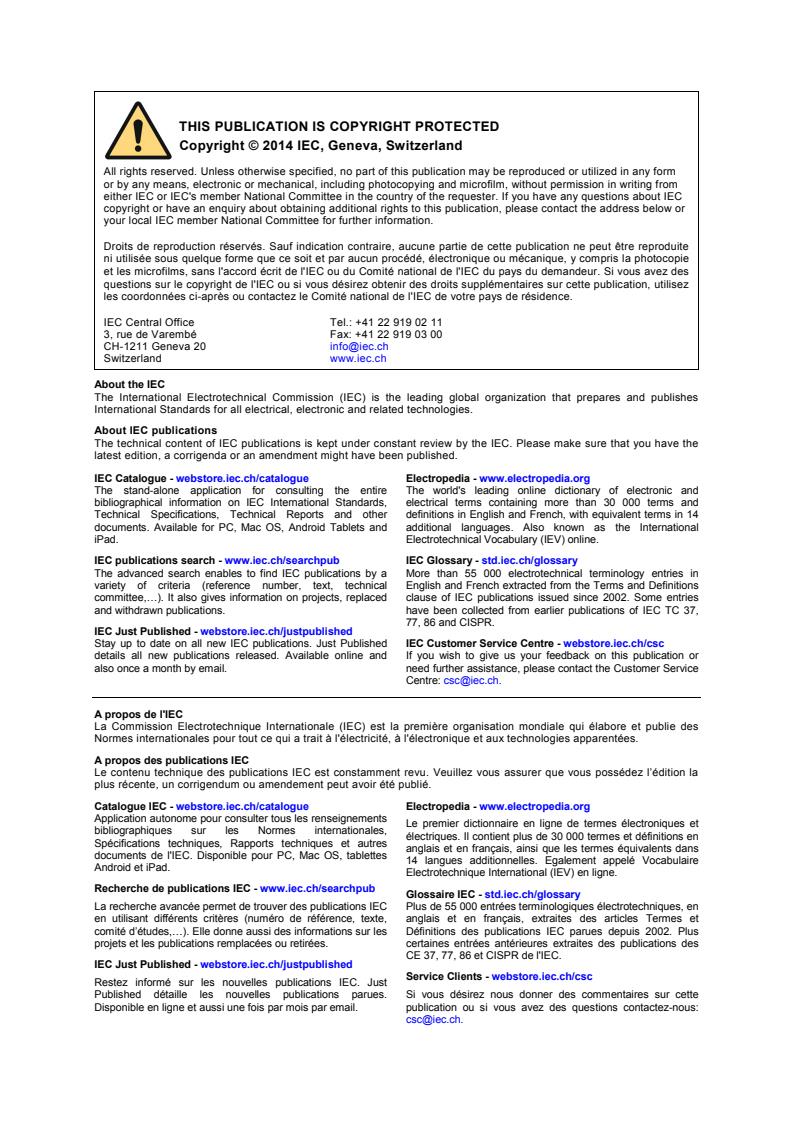

In addition to the requirements of 4.1.3.1 to 4.1.3.3, metallic partition walls with a thickness

≥ 1 mm may be provided with suitable conductor bushings (see Figure 1).

To avoid a critical concentration of explosive gas atmosphere diffusing from the area requiring

EPL Ga into the enclosure containing the electrical circuits, the leakage rate through the

bushing shall be low compared to the leakage rate from the enclosure into the free

atmosphere.

NOTE 3 For example this could be done using a standard enclosure with an IP67 rating

according to IEC 60529, a bushing with a leakage rate equivalent to a helium-leakage rate

-2 –4 5

less than 10 Pa×l/s (10 mbar × l/s) at a pressure difference of 10 Pa (1 bar) is sufficient.

This can be achieved, for example, by using a glass or ceramic bushing as shown in Figure 1.

Metallic sleeve, corrosion

resistant (wall thickness ≥ 1 mm)

Bushing insulator (e.g. melted

≥ 10 mm glass, brazed ceramics)

Less hazardous

area

“ia” circuit

Area

Ex “ia” circuit

requiring

Non-“ia”

EPL Ga

Non-“ia” supply circuit

circuit

(e.g. Ex “e”)

Partition wall

Welded

(t ≥1 mm)

(joint ≥ 1 mm)

Electrical equipment

IEC

Figure 1 – Example of a partition wall with a conductor bushing

considered as gas diffusion tight

– 12 – IEC 60079-26:2014 RLV © IEC 2014

4.1.3.3 Requirements depending on the thickness of the partition wall

The combinations of separation elements and additional protective measures depend on the

wall thickness, t, of the partition wall as described below and shown in Table 1:

i) For homogeneous partition walls with a thickness ≥3 mm, no additional protection

measures are required.

ii) For homogeneous partition walls with a thickness of 3 mm > t ≥ 1 mm, one EPL Gb type of

protection is required (see example a) of Table 1). A homogeneous part of the enclosure

of an equipment with a EPL Gb type of protection may form the partition wall, even for

types of protection which rely on the enclosure, provided the equipment does not contain

an ignition capable source, for example exposed contacts (see example a) of Table 1). If

the equipment contains a source of ignition in normal operation, either a flameproof joint

(example b) of Table 1) or a ventilated air gap (example c) of Table 1) is also required.

iii) Behind partition walls of 1 mm > t ≥ 0,2 mm, one of the following protective measures is

required:

– Type of Protection intrinsic safety “ib” according to IEC 60079-11 (example a) of Table

1); or

– one EPL Gb Type of Protection in combination with a flameproof joint (example b) of

Table 1); or

– one EPL Gb Type of Protection in combination with a ventilated air-gap and a

flameproof joint (example c) of Table 1).

iv) For a partition wall with t < 0.2 mm (for example membranes), a flameproof joint and one

EPL Gb Type of Protection are required (example b) of Table 1). If the equipment contains

a source of ignition in normal operation (for example by exposed contacts), a ventilated air

gap is also required (example type c) of Table 1).

NOTE In the context of this clause, ‘homogeneous’ means a membrane constructed of a single piece of material

without any insertions such as feed-throughs, bushings.

Table 1 – Separation elements

Requirements depending on the thickness, t, of the partition wall

i) t ≥ 3 mm: no additional requirements

ii) iii) iv)

Type of construction

3 mm > t ≥ 1 mm 1 mm > t ≥ 0.2 mm t < 0.2 mm

(“X” marking required) (“X” marking

required)

a) Partition wall

Less hazardous

area Area

requiring a

EPL Gb Type of

Area

lower EPL than

Protection

requiring

Ga

EPL Ga and

Type of Protection

Not permissible

intrinsic safety’ “ib”

no ignition source

Electrical

under normal operation

Partition

equipment

(for example no exposed

wall

contacts)

b) Partition wall + joint

Less hazardous

area Area

Area

requiring a

EPL Gb Type of

requiring

lower EPL than

Protection

EPL Ga

Ga

and

EPL Gb Type of Protection

Partition

Electrical

no ignition source

a

wall

equipment

under normal operation

(for example no

exposed contacts)

a

Joint

c) Partition wall + ventilation

Less hazardous

area Area

requiring a

Area lower EPL than

requiring Ga

EPL Gb Type of Protection

a

EPL Ga

(Joint )

EPL Gb Type of

and

Protection

Electrical

Partition

flameproof joint (dashed)

a

equipment

wall

Natural

ventilation

a

Flameproof joint and partition wall are exchangeable in sequence of order.

4.1.3.4 Partition wall combined with a flameproof joint

Joints supplementing partition walls shall comply with either:

a) the requirements in IEC 60079-1;

NOTE 1 to determine the joint characteristics, the free volume of the enclosure containing

the electrical circuits should shall be considered; or

b) a construction, where the same level of safety as for a) can be demonstrated.

– 14 – IEC 60079-26:2014 RLV © IEC 2014

NOTE For example, a cylindrical PTFE-bushing pressed form-fit into a metallic enclosure at a length

≥ 40 mm. A permanently compressed joint with a length of at least 17 mm is also suitable (for example using a

conical PTFE-bushing compressed by a spring).

Non-metallic components in separation elements shall meet the requirements of IEC 60695-

11-10, flammability category V-0 and have a chemical resistivity equivalent, for example to

that of glass, ceramics, non-regenerated PTFE or epoxy resin for petrol petrochemical

applications. The materials of the separation element and its mechanical and thermal stress

limits shall be clearly defined in the documentation to enable the user to confirm their

suitability for the particular application.

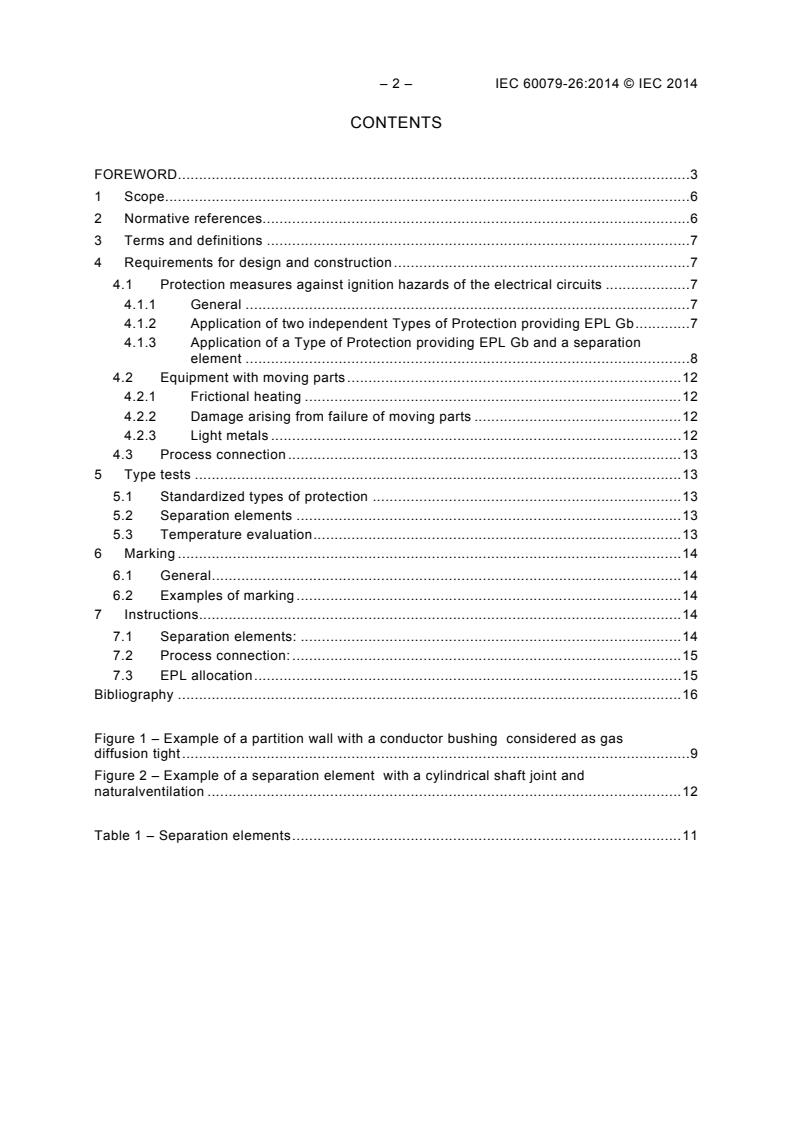

4.1.3.5 Partition wall combined with an airgap with natural ventilation

The ventilation shall ensure that under the most onerous arduous process conditions specified

by the manufacturer and the anticipated leakages, an accumulation of flammable materials in

the equipment is prevented. Under atmospheric process conditions, the ventilation is valid

sufficient for all gases, vapours and mists, if the length of the air-gap is ≥10 mm and the

effective perforation in the circumference is at least 50 %. In addition to the requirements of

4.1.3.1 to 4.1.3.3, metallic partition walls with a thickness ≥1 mm and a suitable air-gap may

be provided, for example with a cylindrical flameproof shaft joint according to IEC 60079-1

(see Figure 2). In this case, the ventilation air gap shall have a minimum length of 10 mm or a

length equal to the diameter of the shaft, whichever is greater.

a

≥ 10 mm

Perforation > 50 %

Less hazardous

area

Natural

ventilation

Shaft

Area e.g. electric motor

requiring

Ex “d”

Non-“ia” supply circuit

EPL Ga

Partition wall

(≥1 mm)

Cylindrical shaft joint flameproof

according to IEC 60079-1

IEC

a

Required for sufficient ventilation.

NOTE The cylindrical shaft joint inside the partition wall as shown in Figure 2 is not a supplementing joint as

referred to in 4.1.3.4.

NOTE 2 The electrical equipment should be selected in accordance with the appropriate gas group.

Figure 2 – Example of a separation element

with a cylindrical shaft joint and natural ventilation

4.2 Equipment with moving parts

4.2.1 Frictional heating

If the equipment contains moving parts, temperature rise due to frictional heating may occur

under normal operation or fault condition. It shall be taken into consideration when

determining the maximum surface temperature.

4.2.2 Damage arising from failure of moving parts

In case of a failure of moving parts, the Types of Protection shall not be adversely affected.

4.2.3 Light metals

Operational friction or impact between equipment parts made of light metals or their alloys

(with concentrations above the limits given in IEC 60079-0) with equipment parts made of

iron/steel is not permitted. Operational friction or impact between two light metals is

permitted.

NOTE Light metals include for example aluminium, magnesium, titanium or zirconium.

4.4 Isolated conductive components

Isolated conductive components on the surface of the equipment shall be bonded to ground,

except where they cannot be charged to an ignition capable level as demonstrated by the

charging test procedure of IEC 60079-0.

4.5 Non-conductive enclosures and accessible non-conductive components

4.5.1 General

Precautions shall be taken to ensure that the risk of ignition from electrostatic discharge is

reduced to a negligible level, particularly since equipment providing EPL Ga may be applied

directly in the process and non-conductive surfaces may be charged by the flow of non-

conductive media (for example in stirring vessels or pipes).

Therefore, the accessible chargeable surfaces of the equipment shall comply with the

requirements of 7.3 of IEC 60079-0 or one of the following:

a) limitation of the size of chargeable non-conductive surfaces – see 4.5.2;

b) limitation of the thickness of chargeable non-conductive layers – see 4.5.3;

c) provision of a conductive coating – see 4.5.4.

If none of these requirements can be complied with, X-marking or an advisory marking in

accordance with 29.2 of IEC 60079-0 shall be applied and the certificate shall contain special

conditions for safe use to enable the user to decide on the suitability of the equipment for the

particular application.

4.5.2 Limitation of the size of chargeable non-conductive surfaces

The projection of the chargeable non-conductive surface shall be limited to the values given in

in Table 4 of IEC 60079-0 for zone 0 (EPL Ga). In the case of long parts with non-conductive

surfaces, such as tubes, bars, cables or ropes, independent of their length, the diameters or

widths shall not exceed

a) 3 mm for equipment of groups IIA and IIB;

b) 1 mm for equipment of group IIC.

4.5.3 Limitation of the thickness of chargeable non-conductive layers

Where a non-conductive layer covers a bonded conductive surface, the thickness of that layer

shall not exceed

a) 2 mm for equipment of group IIA, IIB;

b) 0,2 mm for equipment of group IIC.

The bonded conductive surface may be formed by a wire mesh with a mesh area as defined

in IEC 60079-0, Table 4 for zone 0 (EPL Ga).

NOTE 1 Cables with a protective covering over a screen may comply.

NOTE 2 It should, however, be noted that in the presence of a very efficient charge generating mechanism

propagating brush discharges could occur.

– 16 – IEC 60079-26:2014 RLV © IEC 2014

4.5.4 Provision of a conductive coating

Non-conductive surfaces may be covered with a bonded durable conductive coating. The

resistance between coating and the point of bond shall not exceed 1 GΩ.

The resistance shall be measured in accordance with 26.13 of IEC 60079-0 using a 1 cm

electrode at the worst case position of the surface and the point of bond.

X-marking or an advisory marking in accordance with 29.2 of IEC 60079-0 shall be applied

and the certificate shall advise on the use of the bonding connection (if separately accessible

to the user and not an integral part of the equipment) and provide information to enable the

user to decide on the durability of the coating material with respect to the environmental

conditions (see Clause 7).

NOTE The requirements of 4.5 will be deleted after incorporation in IEC 60079-0.

4.3 Process connection

If the equipment is mounted across the boundary wall between an area requiring EPL Ga and

a less hazardous area, the construction shall ensure that either under normal operation

conditions:

a) explosive gas atmospheres cannot be released from an area requiring EPL Ga creating an

explosive atmosphere in the surrounding area; and

b) that in case of an ignition of an explosive gas atmosphere in the surrounding area there is

no flame propagation into the area requiring EPL Ga.

The equipment shall be designed to allow installation in a manner that will result in a

sufficiently tight joint (IP 66 or IP 67) or a flameproof joint according to IEC 60079-1 (joints

specified for a volume ≤ 100 cm )

...

IEC 60079-26 ®

Edition 3.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 26: Equipment with Equipment Protection Level (EPL) Ga

Atmosphères explosives –

Partie 26: Matériel d'un niveau de protection du matériel (EPL) Ga

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 60079-26 ®

Edition 3.0 2014-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Explosive atmospheres –

Part 26: Equipment with Equipment Protection Level (EPL) Ga

Atmosphères explosives –

Partie 26: Matériel d'un niveau de protection du matériel (EPL) Ga

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX Q

ICS 29.260.20 ISBN 978-2-8322-1903-4

– 2 – IEC 60079-26:2014 © IEC 2014

CONTENTS

FOREWORD . 3

1 Scope . 6

2 Normative references. 6

3 Terms and definitions . 7

4 Requirements for design and construction . 7

4.1 Protection measures against ignition hazards of the electrical circuits . 7

4.1.1 General . 7

4.1.2 Application of two independent Types of Protection providing EPL Gb . 7

4.1.3 Application of a Type of Protection providing EPL Gb and a separation

element . 8

4.2 Equipment with moving parts . 12

4.2.1 Frictional heating . 12

4.2.2 Damage arising from failure of moving parts . 12

4.2.3 Light metals . 12

4.3 Process connection . 13

5 Type tests . 13

5.1 Standardized types of protection . 13

5.2 Separation elements . 13

5.3 Temperature evaluation . 13

6 Marking . 14

6.1 General . 14

6.2 Examples of marking . 14

7 Instructions. 14

7.1 Separation elements: . 14

7.2 Process connection: . 15

7.3 EPL allocation . 15

Bibliography . 16

Figure 1 – Example of a partition wall with a conductor bushing considered as gas

diffusion tight . 9

Figure 2 – Example of a separation element with a cylindrical shaft joint and

naturalventilation . 12

Table 1 – Separation elements . 11

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

EXPLOSIVE ATMOSPHERES –

Part 26: Equipment with Equipment Protection Level

(EPL) Ga

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60079-26 has been prepared by IEC technical committee 31:

Equipment for explosive atmospheres.

This third edition cancels and replaces the second edition published in 2006 and constitutes a

technical revision.

– 4 – IEC 60079-26:2014 © IEC 2014

This edition includes the following significant changes with respect to the previous edition:

Type

Changes Clause Minor and Extension Major

editorial technical

changes changes

Notes deleted 1 X

Reference to associated apparatus deleted 1 X

Additional normative references included 3 X

Requirements against mechanical and

electrostatic ignition hazards deleted (now 4.1 X

covered in IEC 60079-0)

Requirement for separation element detailed

4.1.3.2 X

regarding external influences

Intrinsic safety Ex ia as single type of protection

4.2.2

including associated apparatus deleted (now X

(ed.2)

covered by EPL)

Encapsulation Ex ma as single type of protection 4.2.3

X

deleted (now covered by EPL) (ed.2)

Conditions a) and b) linked with an “and” ,

therefore requirement of “flameproof joint” deleted

in following clause. Both requirements already 4.3 X

covered by separation elements and standardised

process connections.

Process connection requires a sufficiently tight

4.3 X

joint: IP66 added alternatively to IP67

Requirement for isolated conductive components 4.4

X

deleted (now covered in IEC 60079-0) (ed.2)

Requirements for non-conductive enclosures 4.5

X

deleted (now covered in IEC 60079-0) (ed.2)

Test of partition walls according to 4.1.3.2 b) is

5.2 C1

specified in more detail

Marking example for associated apparatus deleted 6.2 b) X

Note 3 with an additional example added 6.2 X

Specification of material of partition wall required

7 X

in instructions (also required in 4.1.3.2)

Alternative risk assessment method deleted (is AnnexA

X

now generally introduced) (ed.2)

NOTE The technical changes referred to include the significance of technical changes in the revised IEC

Standard, but they do not form an exhaustive list of all modifications from the previous version.

Explanation of the types of changes:

A) Definitions

1) Minor and editorial changes:

• Clarification

• Decrease of technical requirements

• Minor technical change

• Editorial corrections

These are changes which modify requirements in an editorial or a minor technical way.

They include changes of the wording to clarify technical requirements without any

technical change, or a reduction in level of existing requirement.

2) Extension: Addition of technical options

These are changes which add new or modify existing technical requirements, in a way

that new options are given, but without increasing requirements for equipment that was

fully compliant with the previous standard.Therefore, these will not have to be

considered for products in conformity with the preceding edition.

3) Major technical changes:

• addition of technical requirements

• increase of technical requirements

These are changes to technical requirements (addition, increase of the level or

removal) made in a way that a product in conformity with the preceding edition will not

always be able to fulfil the requirements given in the later edition. These changes have

to be considered for products in conformity with the preceding edition. For these

changes additional information is provided in Clause B below.

NOTE These changes represent current technological knowledge. However, these changes should not

normally have an influence on equipment already placed on the market.

B) Information about the background of ‘Major technical changes’

C1: Introduction of type tests for separation elements according to “4.1.3.2 b)”

The text of this standard is based on the following documents:

FDIS Report on voting

31/1146/FDIS 31/1155/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 60079 series, published under the general title Explosive

atmospheres, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 60079-26:2014 © IEC 2014

EXPLOSIVE ATMOSPHERES –

Part 26: Equipment with Equipment Protection Level

(EPL) Ga

1 Scope

This part of IEC 60079 specifies alternative requirements for construction, test and marking

for electrical equipment that provides Equipment Protection Level (EPL) Ga when single

standardised Types of Protection (e.g. Ex “ia” , Ex “ma”, Ex “da”) cannot be applied. This

standard also applies to equipment mounted across a boundary where different Equipment

Protection Levels may be required.

EXAMPLE: Equipment installed in the wall of a storage vessel containing Zone 0 (requiring EPL Ga) inside an

area defined as Zone 1 (requiring EPL Gb).

This electrical equipment, within the operational parameters specified by the manufacturer,

ensures a very high Level of Protection that includes rare malfunctions related to the

equipment or two malfunctions occurring independently of each other.

NOTE A malfunction may result from a failure of the component parts of the electrical equipment or from

anticipated externally applied influences. Two independent malfunctions which may occur more frequently and

which, separately, would not create an ignition hazard but which, in combination, could create a potential ignition

hazard, are regarded as occurring together to form a rare malfunction.

This standard supplements and modifies the general requirements of IEC 60079-0. Where a

requirement of this standard conflicts with a requirement of IEC 60079-0, the requirement of

this standard takes precedence.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60079-0, Explosive atmospheres − Part 0: Equipment − General requirements

IEC 60079-1, Explosive atmospheres − Part 1: Equipment protection by flameproof enclosures

"d"

IEC 60079-11, Explosive atmospheres − Part 11: Equipment protection by intrinsic safety "i"

IEC 60695-11-10, Fire hazard testing − Part 11-10: Test flames − 50 W horizontal and vertical

flame test methods

IEC 60529, Degrees of protection provided by enclosures (IP Code)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60079-0 and the

following apply.

NOTE Additional definitions applicable to explosive atmospheres can be found in IEC 60050-426.

3.1

separation element

mechanical element inside the equipment, which separates different parts of the equipment

with different EPLs

Note 1 to entry: A separation element consists of a mechanical partition wall, which may be combined with a

flameproof joint or a natural ventilation

4 Requirements for design and construction

4.1 Protection measures against ignition hazards of the electrical circuits

4.1.1 General

The equipment shall comply with the requirements of 4.1.2 or 4.1.3 in the event of a failure of

one equipment means of protection, by the provision of a second independent means of

protection.

NOTE 1 Types of Protection according to EPL Ga do not require a second independant means of protection, e.g.

Ex “ia” (IEC 60079-11), Ex “ma” (IEC 60079-18), Ex “da” (IEC 60079-1).

Electrical connections and permanently connected cables of the equipment sited within an

area requiring EPL Ga equipment shall comply with the same Level of Protection required by

this standard, for example a cable suitable for EPL Gb containing non-Ex “ia” circuits

additionally protected by a flameproof conduit or a cable suitable for EPL Gb provided with

earth leakage protection.

NOTE 2 Detailed cable and installation requirements for Types of Protection accepted as achieving EPL Ga

beyond intrinsically safe circuits are under consideration in IEC 60079-14.

NOTE 3 Because of ignition hazards which can arise from faults and/or transient circulating currents in the

potential equalization system, galvanic isolation in the power and signal connections to the equipment according to

4.1.2 and 4.1.3 is commonly applied along with minimizing the effect of transient fault currents in the potential

equalization network by the use of electrical protection equipment such as sensitive earth leakage monitors.

4.1.2 Application of two independent Types of Protection providing EPL Gb

Electrical equipment shall comply with the requirements of two independent Types of

Protection that provide EPL Gb. If one Type of Protection fails, the other Type of Protection

shall continue to function. The independent Types of Protection shall not have a common

mode of failure, except as specified in this clause. Combined types of protection providing

EPL Gb shall depend on different physical protection principles.

NOTE 1 An example of a common mode of failure is if an Ex “d” enclosure containing arcing components is

installed inside an Ex “e” enclosure. Should the Ex “d” enclosure be compromised, it would also compromise the

Ex “e” enclosure.

NOTE 2 The combination of Ex “d” and Ex “q” both depend on the avoidance of flame propagation (same physical

protection principle) and may not be useful in combination. In practice, some combinations may not be useful, for

example the combination of oil immersion “o” and powder filling “q”.

Where combined types of protection are used, it shall be possible for each Type of Protection

to be tested individually (see 5.1).

Both Types of Protection shall be assessed using the most arduous fault condition of the

other Type of Protection. When combining intrinsic safety, Type of Protection “ib”, with other

– 8 – IEC 60079-26:2014 © IEC 2014

Types of Protection, the second Type of Protection shall be assessed, with the most arduous

fault condition applied to the intrinsically safe circuit. Thermal dissipation shall be considered

in case of a fault of one Type of protection.

When using two Types of Protection, which both rely on the same parameter (for example, the

creepage distance combining Ex “ib” with Ex “e”), the most stringent requirement of both

Types of Protection shall be applied.

If two Types of Protection are combined which both rely on the enclosure, one of the following

shall be met:

a) if two enclosures are used (one totally enclosed within the other), each enclosure shall

comply with the requirements of the respective Type of Protection; or

b) if only one enclosure is used, the enclosure and the cable glands shall meet the impact

test requirements of IEC 60079-0, using the Group I values.

Examples of relevant combinations of two independent Types of Protection are as follows:

– inductive transmitters (for example proximity switches, electrical position sensors) with

intrinsic safety “ib” enclosed by encapsulation “mb”. The connections to intrinsically safe

“ib” circuits can be protected by the increased safety “e”;

– a luminaire designed as increased safety “e”may be included in a flameproof enclosure

“d”:

– measuring transducers with intrinsic safety “ib” and a flameproof enclosure “d”;

– equipment with electrical circuits of intrinsic safety “ib”, additionally protected by powder

filling “q”;

– electromagnetic valves with encapsulation “mb”, enclosed by a flameproof enclosure “d”;

– increased safety “e”, with pressurized equipment “pxb”.

4.1.3 Application of a Type of Protection providing EPL Gb and a separation element

4.1.3.1 General

Equipment which is mounted through or forms part of the boundary wall to an area requiring

EPL Ga and contains electrical circuits which do not comply with EPL Ga shall comply with at

least one of the Types of Protection providing EPL Gb. Additionally, it shall contain a

mechanical separation element as part of the equipment to separate the electrical circuits of

the equipment from the area requiring EPL Ga.

If the Type of Protection fails, the separation element shall:

a) prevent flame propagation through the equipment into the area requiring EPL Ga,

b) maintain its safety characteristics,

c) not exceed the maximum surface temperature of the specified temperature class of the

equipment (see 5.3).

4.1.3.2 Partition walls

Partition walls shall be constructed of either:

a) corrosion-resistant metals, glass or ceramics,

b) other materials which can be verified to provide the same level of safety. In this case, the

certificate number shall include the "X" suffix in accordance with the marking requirements

of IEC 60079-0.

If the wall thickness is less than 1 mm, the certificate number shall include the "X" suffix in

accordance with the marking requirements of IEC 60079-0 and the Specific Conditions of Use

listed on the certificate shall indicate that the material shall not be subject to environmental

conditions which might adversely affect the partition wall.

If the partition wall is under constant vibrational stress (for example vibrating membranes), the

minimum endurance limit at maximum amplitude shall be defined in the documentation (see

Clause 7). Due to specified process pressure, loads or temperature, the separation element

shall not impair the Type of Protection.

A wall thickness less than 1 mm is only permitted in combination with intrinsic safety “ib”, or a

flameproof joint or natural ventilation (see 4.1.3.3). For glass or ceramics, a minimum

thickness of 1/10 of the diameter/maximum dimension but not less than 1 mm is required.

In addition to the requirements of 4.1.3.1 to 4.1.3.3, metallic partition walls with a thickness