IEC 62282-6-106:2024

(Main)Fuel cell technologies - Part 6-106: Micro fuel cell power systems - Safety - Indirect Class 8 (corrosive) compounds

Fuel cell technologies - Part 6-106: Micro fuel cell power systems - Safety - Indirect Class 8 (corrosive) compounds

IEC 62282-6-106:2024 covers micro fuel cell power systems, micro fuel cell power units and fuel cartridges using hydrogen produced from UN Class 8 (corrosive) borohydride formulations as fuel. These systems and units use proton exchange membrane (PEM) fuel cell technologies. The designs include fuel processing subsystems to derive hydrogen gas from the corrosive fuel formulation.

This first edition, together with the other parts of the IEC 62282-6-1XX series, cancels and replaces IEC 62282-6-100:2010 and IEC 62282-6-100:2010/AMD1:2012.This edition includes the following significant technical changes with respect to IEC 62282‑6‑100:2010 and IEC 62282-6-100:2010/AMD1:2012:

a) A new structure has been set up: IEC 62282-6-101 covers the general safety requirements common to all fuel types whereas IEC 62282-6-102 and subsequent parts of the IEC 62282-6-1XX series cover particular requirements for individual fuel types.

Technologies des piles à combustible - Partie 6-106: Systèmes à micropiles à combustible - Sécurité - Composés (corrosifs) indirects de classe 8

IEC 62282-6-106:2024 raite des systèmes à micropiles à combustible, des blocs d’alimentation électrique des micropiles à combustible et des cartouches de combustible qui utilisent comme combustible l’hydrogène produit à partir de formulations de borohydrure de classe 8 des Nations Unies (corrosifs). Ces systèmes et blocs d’alimentation utilisent des technologies de piles à combustible à membrane à échange de protons (PEM, Proton Exchange Membrane). Les conceptions incluent des sous-systèmes de traitement de combustibles pour obtenir un gaz hydrogène à partir de la formulation corrosive d’un combustible.

Cette première édition, ainsi que les autres parties de la série IEC 62282-6-1XX, annulent et remplacent l'IEC 62282-6-100:2010 et l'IEC 62282-6-100:2010/AMD1:2012. Cette édition inclut les modifications techniques majeures suivantes par rapport à l’IEC 62282‑6‑100:2010 et l’IEC 62282-6-100:2010/AMD1:2012:

a) une nouvelle structure a été établie: l’IEC 62282-6-101 couvre les exigences générales de sécurité communes à tous les types de combustibles, tandis que l’IEC 62282-6-102 et les parties suivantes de la série IEC 62282-6-1XX couvrent les exigences particulières pour les différents types de combustibles.

General Information

- Status

- Published

- Publication Date

- 15-Feb-2024

- Technical Committee

- TC 105 - Fuel cell technologies

- Drafting Committee

- WG 402 - TC 105/WG 402

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Feb-2024

- Completion Date

- 23-Feb-2024

Relations

- Replaces

IEC 62282-6-100:2010 - Fuel cell technologies - Part 6-100: Micro fuel cell power systems - Safety - Effective Date

- 05-Sep-2023

Overview

IEC 62282-6-106:2024 is an international standard published by the International Electrotechnical Commission (IEC) that addresses safety requirements for micro fuel cell power systems utilizing indirect Class 8 (corrosive) compounds. Specifically, this standard applies to micro fuel cell power units and fuel cartridges that use hydrogen generated from UN Class 8 corrosive borohydride fuel formulations. The systems covered incorporate proton exchange membrane (PEM) fuel cell technology and include fuel processing subsystems designed to extract hydrogen gas from corrosive fuel.

This first edition replaces and updates earlier standards IEC 62282-6-100:2010 and its amendment. It introduces a new structural framework within the IEC 62282-6-1XX series, where IEC 62282-6-101 outlines general safety requirements applicable to all fuel types, and IEC 62282-6-106 delivers specific provisions for indirect Class 8 corrosive compounds.

Key Topics

Scope and Applicability

IEC 62282-6-106 focuses on safety aspects specific to micro fuel cell power systems using borohydride-based corrosive fuel formulations to produce hydrogen indirectly. These fuels may include activators or inhibitors to control hydrogen production.Safety Principles and Requirements

The standard mandates comprehensive safety principles including:- Chemical safety related to handling and containment of corrosive borohydride compounds

- Material selection for compatibility with corrosive fuels

- Mechanical design to ensure structural integrity under normal and fault conditions

- Electrical safety including functional safety mechanisms

- Hazard analysis and risk assessment to evaluate potential operational and fault scenarios

Testing Protocols

IEC 62282-6-106 specifies rigorous type test requirements aimed at validating safety under diverse conditions:- Leakage and gas loss tests to detect hazardous emissions

- Pressure differential, vibration, temperature cycling, high-temperature exposure, drop, and compressive loading tests

- Electrical tests including external short-circuit scenarios

- Long-term storage and connection cycling tests

Instruction and Labeling Requirements

The standard emphasizes the importance of providing clear warnings, operational instructions, and safety information for users and operators of micro fuel cell power systems and fuel cartridges.

Applications

IEC 62282-6-106:2024 is essential for manufacturers, designers, and safety engineers involved in the production and certification of small-scale hydrogen fuel cell systems employing corrosive borohydride fuels. Typical applications include:

- Portable and micro-scale power systems powered by PEM fuel cells

- Fuel cartridges designed for safe storage and controlled release of hydrogen from corrosive compounds

- Fuel processing subsystems that facilitate environmentally safe and efficient hydrogen generation

This standard supports the safe commercialization and deployment of micro fuel cell technologies in industries such as:

- Portable electronics requiring clean, lightweight power supplies

- Backup power and emergency energy systems

- Specialized chemical or industrial equipment where indirect hydrogen generation is advantageous

Related Standards

IEC 62282-6-106 functions as a part of the broader IEC 62282 series on fuel cell technologies, alongside:

- IEC 62282-6-101:2024 - General safety requirements applicable to all micro fuel cell power systems regardless of fuel type

- IEC 62282-6-102 and subsequent parts - Specific provisions for other fuel types beyond indirect Class 8 corrosive compounds

Users of IEC 62282-6-106 should reference IEC 62282-6-101 to ensure compliance with baseline safety principles, as 62282-6-106 provides additional, specialized requirements for corrosive fuels meant to complement the general requirements.

Keywords: IEC 62282-6-106:2024, micro fuel cell power systems, PEM fuel cell technology, Class 8 corrosive compounds, borohydride fuel, hydrogen generation, fuel cartridge safety, fuel processing subsystem, chemical safety, micro power systems, fuel cell safety standards.

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC 62282-6-106:2024 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Fuel cell technologies - Part 6-106: Micro fuel cell power systems - Safety - Indirect Class 8 (corrosive) compounds". This standard covers: IEC 62282-6-106:2024 covers micro fuel cell power systems, micro fuel cell power units and fuel cartridges using hydrogen produced from UN Class 8 (corrosive) borohydride formulations as fuel. These systems and units use proton exchange membrane (PEM) fuel cell technologies. The designs include fuel processing subsystems to derive hydrogen gas from the corrosive fuel formulation. This first edition, together with the other parts of the IEC 62282-6-1XX series, cancels and replaces IEC 62282-6-100:2010 and IEC 62282-6-100:2010/AMD1:2012.This edition includes the following significant technical changes with respect to IEC 62282‑6‑100:2010 and IEC 62282-6-100:2010/AMD1:2012: a) A new structure has been set up: IEC 62282-6-101 covers the general safety requirements common to all fuel types whereas IEC 62282-6-102 and subsequent parts of the IEC 62282-6-1XX series cover particular requirements for individual fuel types.

IEC 62282-6-106:2024 covers micro fuel cell power systems, micro fuel cell power units and fuel cartridges using hydrogen produced from UN Class 8 (corrosive) borohydride formulations as fuel. These systems and units use proton exchange membrane (PEM) fuel cell technologies. The designs include fuel processing subsystems to derive hydrogen gas from the corrosive fuel formulation. This first edition, together with the other parts of the IEC 62282-6-1XX series, cancels and replaces IEC 62282-6-100:2010 and IEC 62282-6-100:2010/AMD1:2012.This edition includes the following significant technical changes with respect to IEC 62282‑6‑100:2010 and IEC 62282-6-100:2010/AMD1:2012: a) A new structure has been set up: IEC 62282-6-101 covers the general safety requirements common to all fuel types whereas IEC 62282-6-102 and subsequent parts of the IEC 62282-6-1XX series cover particular requirements for individual fuel types.

IEC 62282-6-106:2024 is classified under the following ICS (International Classification for Standards) categories: 27.070 - Fuel cells. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62282-6-106:2024 has the following relationships with other standards: It is inter standard links to IEC 62282-6-100:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62282-6-106:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62282-6-106 ®

Edition 1.0 2024-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fuel cell technologies –

Part 6-106: Micro fuel cell power systems – Safety – Indirect Class 8 (corrosive)

compounds

Technologies des piles à combustible –

Partie 6-106: Systèmes à micropiles à combustible – Sécurité – Composés

(corrosifs) indirects de classe 8

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications, symboles

en utilisant différents critères (numéro de référence, texte, graphiques et le glossaire. Avec un abonnement, vous aurez

comité d’études, …). Elle donne aussi des informations sur les toujours accès à un contenu à jour adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 500 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 25 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62282-6-106 ®

Edition 1.0 2024-02

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Fuel cell technologies –

Part 6-106: Micro fuel cell power systems – Safety – Indirect Class 8 (corrosive)

compounds

Technologies des piles à combustible –

Partie 6-106: Systèmes à micropiles à combustible – Sécurité – Composés

(corrosifs) indirects de classe 8

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 27.070 ISBN 978-2-8322-8161-1

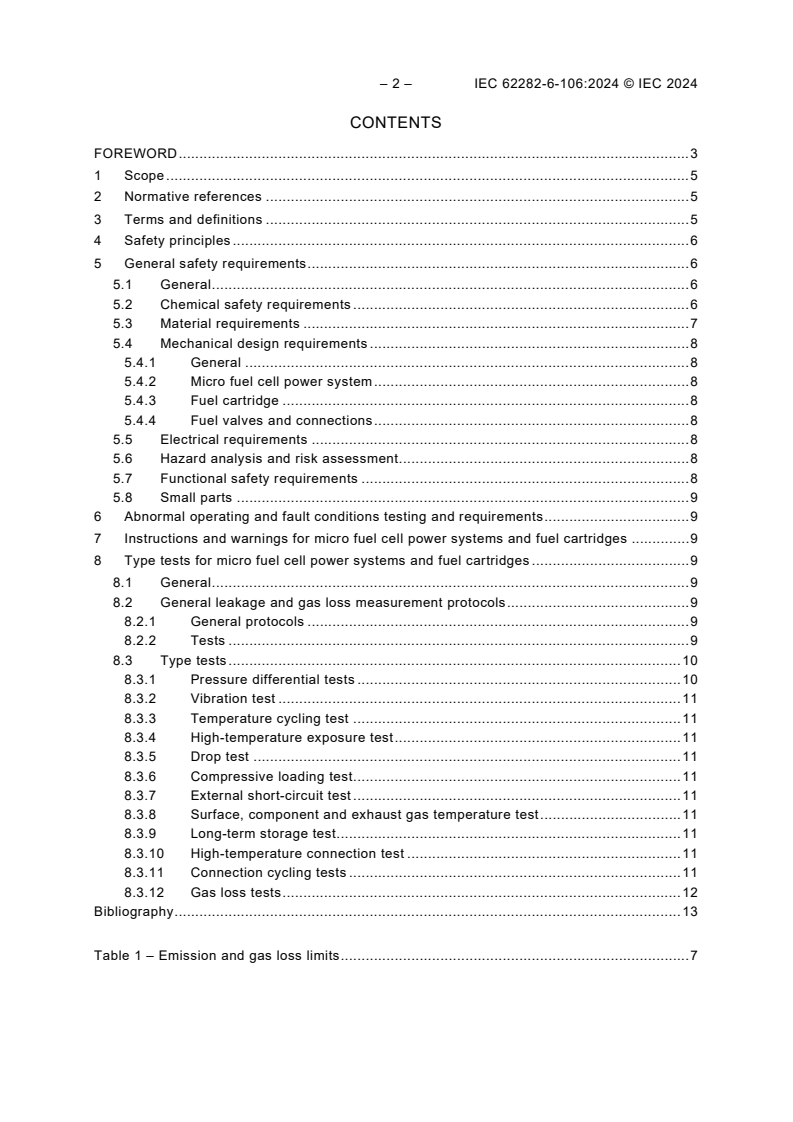

– 2 – IEC 62282-6-106:2024 © IEC 2024

CONTENTS

FOREWORD . 3

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Safety principles . 6

5 General safety requirements . 6

5.1 General . 6

5.2 Chemical safety requirements . 6

5.3 Material requirements . 7

5.4 Mechanical design requirements . 8

5.4.1 General . 8

5.4.2 Micro fuel cell power system . 8

5.4.3 Fuel cartridge . 8

5.4.4 Fuel valves and connections . 8

5.5 Electrical requirements . 8

5.6 Hazard analysis and risk assessment. 8

5.7 Functional safety requirements . 8

5.8 Small parts . 9

6 Abnormal operating and fault conditions testing and requirements . 9

7 Instructions and warnings for micro fuel cell power systems and fuel cartridges . 9

8 Type tests for micro fuel cell power systems and fuel cartridges . 9

8.1 General . 9

8.2 General leakage and gas loss measurement protocols . 9

8.2.1 General protocols . 9

8.2.2 Tests . 9

8.3 Type tests . 10

8.3.1 Pressure differential tests . 10

8.3.2 Vibration test . 11

8.3.3 Temperature cycling test . 11

8.3.4 High-temperature exposure test . 11

8.3.5 Drop test . 11

8.3.6 Compressive loading test . 11

8.3.7 External short-circuit test . 11

8.3.8 Surface, component and exhaust gas temperature test . 11

8.3.9 Long-term storage test . 11

8.3.10 High-temperature connection test . 11

8.3.11 Connection cycling tests . 11

8.3.12 Gas loss tests . 12

Bibliography . 13

Table 1 – Emission and gas loss limits . 7

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUEL CELL TECHNOLOGIES –

Part 6-106: Micro fuel cell power systems – Safety –

Indirect Class 8 (corrosive) compounds

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s), which

may be required to implement this document. However, implementers are cautioned that this may not represent

the latest information, which may be obtained from the patent database available at https://patents.iec.ch. IEC

shall not be held responsible for identifying any or all such patent rights.

IEC 62282-6-106 has been prepared by IEC technical committee 105: Fuel cell technologies. It

is an International Standard.

This first edition, together with the other parts of the IEC 62282-6-1XX series, cancels and

replaces IEC 62282-6-100:2010 and IEC 62282-6-100:2010/AMD1:2012.

This edition constitutes a technical revision.

This edition includes the following significant technical changes with respect to

IEC 62282-6-100:2010 and IEC 62282-6-100:2010/AMD1:2012:

a) A new structure has been set up: IEC 62282-6-101 covers the general safety requirements

common to all fuel types whereas IEC 62282-6-102 and subsequent parts of the IEC 62282-

6-1XX series cover particular requirements for individual fuel types.

– 4 – IEC 62282-6-106:2024 © IEC 2024

The text of this International Standard is based on the following documents:

Draft Report on voting

105/1017/FDIS 105/1025/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

A list of all parts in the IEC 62282 series, published under the general title Fuel cell

technologies, can be found on the IEC website.

This document is to be used in conjunction with IEC 62282-6-101:2024 and is not to be used

as a stand-alone document. This document provides additional requirements specific to

corrosive fuel formulations, which apply in addition to the general requirements specified in

IEC 62282-6-101:2024. The (sub)clause numbers in this document are aligned with those of

IEC 62282-6-101:2024 and are intended to provide additional information and refined

requirements, as appropriate.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

NOTE The attention of National Committees is drawn to the fact that equipment manufacturers and testing

organizations may need a transitional period following publication of a new, amended or revised IEC publication in

which to make products in accordance with the new requirements and to equip themselves for conducting new or

revised tests.

It is the recommendation of the committee that the content of this publication be adopted for implementation nationally

not earlier than 12 months from the date of publication.

FUEL CELL TECHNOLOGIES –

Part 6-106: Micro fuel cell power systems – Safety –

Indirect Class 8 (corrosive) compounds

1 Scope

This part of IEC 62282 covers micro fuel cell power systems, micro fuel cell power units and

fuel cartridges using hydrogen produced from UN Class 8 (corrosive) borohydride formulations

as fuel. These systems and units use proton exchange membrane (PEM) fuel cell technologies.

The designs include fuel processing subsystems to derive hydrogen gas from the corrosive fuel

formulation.

IEC 62282-6-101:2024, Figure 1 is applicable.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62282-6-101:2024, Fuel cell technologies – Part 6-101: Micro fuel cell power systems –

Safety – General requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62282-6-101 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following

addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

fuel

corrosive (UN Class 8) formulation of borohydride compounds used as fuel for an indirect PEM

micro fuel cell power system

Note 1 to entry: The formulation may contain a non-hazardous activator to facilitate the production of hydrogen, or

an inhibitor, such as an alkali metal hydroxide, to modulate or inhibit the production of hydrogen from the corrosive

fuel formulation or both. The formulation may be solid or liquid, or may include both solid and liquid components that

are combined during fuel processing.

Note 2 to entry: This document only applies to corrosive (UN Class 8) compounds which can be processed to evolve

hydrogen gas (e.g. through contact with water, non-hazardous or corrosive aqueous solutions, or an activator, or

both).

Note 3 to entry: Guidance on the classification of materials, including mixtures, can be found in the current edition

of the United Nations Recommendations on the Transport of Dangerous Goods, Model Regulations.

– 6 – IEC 62282-6-106:2024 © IEC 2024

3.2

borohydride compound

sodium or potassium borohydride, or a mixture thereof

3.3

liquid fuel component

Class 8 (corrosive), or non-hazardous, water solutions used to produce hydrogen within the fuel

processing subsystem

3.4

fuel by-product

Class 8 (corrosive), or non-hazardous, compound produced after hydrogen or electricity, or

both, is produced from fuel

3.5

activator

substance that facilitates the production of hydrogen from fuel, such as a catalyst

4 Safety principles

The safety principles included in IEC 62282-6-101:2024, Clause 4 apply in their entirety to

technologies included in this document.

5 General safety requirements

5.1 General

The general safety requirements of IEC 62282-6-101:2024, 5.1 shall apply as written with the

following addition.

NOTE The limited quantity exception for cargo transport of fuel cell cartridges containing corrosive fuel is 1 kg of

solid fuel or 1 l of liquid fuel according to the UN Model Regulations. For passenger carriage in the aircraft cabin or

in checked baggage the maximum quantity of corrosive fuel permitted inside the cartridge is 200 g of solid fuel or

200 g of liquid fuel according to the 2013 edition of the International Civil Aviation Organization (ICAO) Technical

Instructions.

5.2 Chemical safety requirements

Consistent with IEC 62282-6-101:2024, Table 4, the following limits given in Table 1 shall apply

for the emission and gas loss measurements for micro fuel cell power systems and fuel

cartridges tested in accordance with this document.

Table 1 – Emission and gas loss limits

a b c

Constituent

Concentration limit Gas loss rate limit Gas loss rate limit

(Operating devices) (Operating devices) (Non-operating devices)

Non-hazardous aqueous Unlimited for pH between Unlimited for pH between Unlimited for pH between

solutions 3,5 and 10,5 3,5 and 10,5 3,5 and 10,5

0,8 g/h total 0,003 2 g/h total

0,8 g/m

(impermissible H gas loss)

Hydrogen

0,016 g/h from single point

d

leak

e g 3

0,000 6 g/h 0,000 6 g/h

Formaldehyde 0,000 1 g/m

g 3

0,290 g/h 0,290 g/h

CO 0,029 g/m

g 3

f f

CO 9 g/m

60 g/h 60 g/h

g 3

2,45 g/h 0,4 g/h

Methyl formate 0,245 g/m

a

The concentration limit for chemical compounds of interest shall be based on internationally recommended

values. All toxicity based limits listed in this Table 1 are based on long-term, time-averaged limits, for instance

TWA for ICSC’s occupational limit. The gas loss rate limit shall be obtained using similar computation as used

in this Table 1 to ensure that overall gas loss rates do not exceed time-averaged limits for the constituent of

interest. For such constituents, short-term increases in gas loss rate may be permissible, provided that the

transient rate does not exceed the short-term exposure limit (STEL) for that constituent and the overall gas loss

rate does not exceed the time-averaged rate specified in this Table 1.

b 3

The "operating" emission rate limit was based on 10 m ACH, selected as the product of the reference volume

times the air changes per hour (ACH) because it covers the reasonably foreseeable environments where micro

fuel cell power systems will be used. The interior space in a small car and the minimum volume per person on a

commercial aircraft is at 1 m . The minimum ACH used on a passenger aircraft is 10 and the lowest ventilation

setting in cars is 10 ACH. Homes and offices may have ACH levels as low as 0,5 but the per-person volume is

over 20 m , so a product of 10 is conservative.

c

The non-operating limits have been chosen based on a scenario of devices in an enclosed space with no

ventilation. The space chosen has a volume of 0,28 m , or approximately 10 cubic feet. The criterion has been

specified so that a concentration of greater than 25 % of the lower flammability limit (LFL) is not permitted to

develop over a twenty-four hour (24 h) period, if three devices are in the enclosed space. For example, this

criterion is applied for the determination of a maximum gas-loss rate based on the emission of flammable

constituents from non-operating micro fuel cell power systems. Note that the control volume for non-operating

systems should not be applied using toxicity limits, as the core principle of this enclosed space is that of a

storage space, not one that a person can spend time in. For the determination of non-operating limits for

constituents with both flammable and toxic properties, the lower of the flammability based limit for the "non-

operating" control volume and the toxicity based limit for the "operating" control volume shall apply.

d

0,016 g/h reflects an emission rate lower than the limit reported by Swain, et al, (Proceedings of the 2001 DOE

Program Review; NREL/CP-570-30535; M.R. Swain and M.N. Swain, Codes and Standards Analysis, 2001

(USA); available at: http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/30535bc.pdf) wherein "no hole was

able to support a hydrogen flame at less than 3.5 cc/min." (3.5 cc/min ≈ 0,018 g/h). This value was chosen in

conformance with the guidelines in IEC 62282-6-101:2024, Table 3.

e 3 3

The WHO guideline limit is 0,000 1 g/m . Background levels are 0,000 03 g/m . The emission limit cannot push

the background level above the guideline limit

f

A seated human adult has a CO emission rate of 30 g/h. The fuel cell plus human adult emission rates are

limited such that the CO concentration does not reach the WHO eight-hour concentration limit of 9 g/m . In an

environment with 10 m ACH, this limits the contribution from the fuel cell to 60 g/h.

g

Testing for the presence of these constituents may be omitted for micro fuel cell power systems and fuel

cartridges that do not contain, or have the potential to evolve, carbon-based compounds. In such cases, the

rationale for such omission shall be documented in the hazard analysis and risk assessment.

5.3 Material requirements

The requirements of IEC 62282-6-101:2024, 5.3 shall apply as written.

– 8 – IEC 62282-6-106:2024 © IEC 2024

5.4 Mechanical design requirements

5.4.1 General

The requirements of IEC 62282-6-101:2024, 5.4.1 shall apply as written, with the following

additions.

5.4.1.1 Structural integrity

The general requirements of IEC 62282-6-101:2024, 5.4.1.1 shall apply as written with the

following addition:

In addition, fuel cartridges intended to contain or evolve hydrogen at greater than atmospheric

pressure shall also be capable of withstanding fire testing in accordance with 8.3.1 through

8.3.12.

5.4.2 Micro fuel cell power system

The general requirements of IEC 62282-6-101:2024, 5.4.2.1 and 5.4.2.2 shall apply as written.

5.4.3 Fuel cartridge

The general requirements of IEC 62282-6-101:2024, 5.4.3 shall apply as written with the

following additions.

In addition, the following fuel specific requirements shall apply:

• In cases where materials (either solid or liquid) are present and are incompatible with either

the borohydride fuel or liquid fuel component, the design of the fuel cartridge and micro fuel

cell power system shall provide a means for preventing inadvertent or uncontrolled mixing

of these materials.

• Two independent means for preventing inadvertent or uncontrolled mixing of these materials

shall be provided during transportation and storage prior to use. Illustrative examples of

these means include but are not limited to: positive activation by the control system; physical

removal of an impermeable barrier preventing contact; opening of a normally closed

manually controlled valve preventing contact. For at least one of these means for preventing

uncontrolled mixing, it shall be necessary for the user to take positive action to remove or

deactivate it prior to use.

• At least one means for preventing uncontrolled mixing of these materials shall be provided

during use and storage after use. This means may include active control by system

electronics, subject to the hazard analysis and risk assessment of 5.6.

5.4.4 Fuel valves and connections

The general requirements of IEC 62282-6-101:2024, 5.4.4.1 and 5.4.4.2 shall apply as written.

5.5 Electrical requirements

The general requirements of IEC 62282-6-101:2024, 5.5 shall apply as written.

5.6 Hazard analysis and risk assessment

The general requirements of IEC 62282-6-101:2024, 5.6 shall apply as written.

5.7 Functional safety requirements

The general requirements of IEC 62282-6-101:2024, 5.7 shall apply as written.

5.8 Small parts

The general requirements of IEC 62282-6-101:2024, 5.8 shall apply as written.

6 Abnormal operating and fault conditions testing and requirements

The general requirements of IEC 62282-6-101:2024, Clause 6 shall apply as written.

7 Instructions and warnings for micro fuel cell power systems and fuel

cartridges

The general requirements of IEC 62282-6-101:2024, Clause 7 shall apply as written with the

following addition.

In addition, both fuel cartridges and micro fuel cell power systems shall also include the

following marking:

"MAY CONTAIN FLAMMABLE GAS."

8 Type tests for micro fuel cell power systems and fuel cartridges

8.1 General

The general requirements of IEC 62282-6-101:2024, 8.1 shall apply as written.

8.2 General leakage and gas loss measurement protocols

8.2.1 General protocols

The general requirements and principles of IEC 62282-6-101:2024, 8.2 shall be applied as

appropriate for each of the type tests required in IEC 62282-6-101:2024, 8.3 with the following

additional requirements.

For fuel cartridges and micro fuel cell power systems tested in accordance with this document,

in general, concentration-based measurements are recommended over mass-based

measurements. It is possible that mass-based measurements will not be appropriate for fuel

cartridges containing water-reactive fuel, as leakage can be indicated by an increase in overall

mass (e.g. absorption of water) rather than mass loss. If mass-based measurements are utilized

for any type test, the test method shall be verified and validated prior to use for assessing

compliance.

8.2.2 Tests

8.2.2.1 General

Following each type test, all test samples shall be checked for leakage and gas loss in

accordance with the following procedures.

8.2.2.2 Leakage and gas loss test procedures for fuel cartridges

1) Perform a visual inspection of all possible leak locations as follows:

a) The method for the detection of accessible hazardous liquids given in IEC 62282-6-

101:2024, 8.2.8, or an equivalent method, shall be used to detect any hazardous liquid

leakage.

b) Accessible fuel, fuel by-products, electrolyte or liquid fuel component, or crystals on the

exterior of the fuel cartridge are indications of leakage. If fuel, fuel by-products,

– 10 – IEC 62282-6-106:2024 © IEC 2024

electrolyte or liquid fuel component, or crystals are visible on the exterior, the fuel

cartridge fails the leakage test.

2) Check for hydrogen gas loss using a liquid leak detector on possible leak locations of fuel

cartridges using the protocol described in IEC 62282-6-101:2024, 8.2.5, or an equivalent

method.

If the fuel cartridge is of the type that is refillable by the manufacturer (automated or by

trained technicians), it shall be filled to its rated capacity prior to testing. If the fuel cartridge

is not refillable, it shall be tested in the condition in which it completed the type test in

question. The fuel cartridge shall be tested for leaks at laboratory temperature. There shall

be no leakage or gas loss from any point on the fuel cartridge.

8.2.2.3 Leakage and gas loss test procedures for micro fuel cell power systems

1) Perform a visual inspection of all possible leak locations for leakage as follows:

a) The method for the detection of accessible hazardous liquids given in IEC 62282-6-

101:2024, 8.2.8, or an equivalent method, shall be used to detect any hazardous liquid

leakage.

b) Accessible fuel, fuel by-products, electrolyte or liquid fuel component, or crystals on the

exterior of the fuel cartridge are indications of leakage. If fuel, fuel by-products,

electrolyte or liquid fuel component, or crystals are visible on the exterior, the micro fuel

cell power system fails the leakage test.

2) If the micro fuel cell power system includes a fuel management system or an internal

reservoir that contains hydrogen gas above ambient pressure or both, a check for hydrogen

gas loss shall be done following each type test using a liquid leak detector (bubble forming)

solution as described in IEC 62282-6-101:2024, 8.2.5 or other equivalent means on all

possible leak locations of the fuel management system. The fuel management system and

internal reservoir shall be tested for leaks at laboratory temperature. There shall be no gas

loss from any point on the fuel management system or internal reservoir. If checking for gas

loss from the fuel management system or an internal reservoir or both, requires the

disassembly of the micro fuel cell power system, this check may be performed following all

other gas loss testing.

3) Perform gas loss testing in accordance with the protocol for performing concentration-based

measurements in IEC 62282-6-101:2024, 8.2.3 with the micro fuel cell power system or unit

turned off ("DEVICE – OFF") to check for hydrogen gas loss. Hydrogen gas loss shall be

less than the gas loss rate limit for non-operating devices specified in 5.2 of this document

(< 0,003 2 g/h). If transient gas loss rates greater than 0,016 g/h are observed during

hydrogen gas loss testing, hydrogen point-source gas loss detection testing in accordance

with IEC 62282-6-101:2024, 8.2.4, or an equivalent test for ensuring compliance with the

safety principles expressed in IEC 62282-6-101:2024, 4.2, shall be performed.

4) Turn the micro fuel cell power system "on" and operate for 10 min ± 30 s. Check whether

fire or explosion occurs.

5) Perform gas loss testing in accordance with the protocol for performing concentration-based

measurements in IEC 62282-6-101:2024, 8.2.3 to check for hydrogen gas loss, with the

micro fuel cell power system turned on ("DEVICE – ON"), regardless of whether or not the

micro fuel cell power system is operational. Hydrogen gas loss shall be less than the

applicable gas loss rate limits specified in 5.2 of this document. If the device is not

operational, the gas loss rate limit for non-operating devices shall be met. If transient gas

loss rates greater than 0,016 g/h are observed during hydrogen gas loss testing, hydrogen

point-source gas loss detection testing in accordance with IEC 62282-6-101:2024, 8.2.4, or

an equivalent test for ensuring compliance with the safety principles expressed in

IEC 62282-6-101:2024, 4.2, shall be performed.

8.3 Type tests

8.3.1 Pressure differential tests

The pressure differential tests of IEC 62282-6-101:2024, 8.3.1 shall be performed as written

with the following addition.

Class 8 (corrosive) borohydride fuel will chemically react with water; therefore, water or water-

containing substances shall not be used as the fluid test medium. Class 8 (corrosive)

borohydride fuels have the potential to react with substances other than water, therefore, the

chemical reactivity and stability of the particular Class 8 (corrosive) borohydride fuel being

tested shall be used to guide the selection of a suitable liquid test medium.

8.3.2 Vibration test

The vibration test of IEC 62282-6-101:2024, 8.3.2 shall be performed as written.

8.3.3 Temperature cycling test

The temperature cycling test of IEC 62282-6-101:2024, 8.3.3 shall be performed as written.

8.3.4 High-temperature exposure test

The high temperature exposure test of IEC 62282-6-101:2024, 8.3.4 shall be performed as

written.

8.3.5 Drop test

The drop test of IEC 62282-6-101:2024, 8.3.5 shall be performed as written.

8.3.6 Compressive loading test

The compressive loading test of IEC 62282-6-101:2024, 8.3.6 shall be performed as written.

8.3.7 External short-circuit test

The external short-circuit test of IEC 62282-6-101:2024, 8.3.7 shall be performed as written.

8.3.8 Surface, component and exhaust gas temperature test

The surface, component and exhaust gas temperature test of IEC 62282-6-101:2024, 8.3.8

shall be performed as written.

8.3.9 Long-term storage test

The long-term storage test of IEC 62282-6-101:2024, 8.3.9 shall be performed as written.

8.3.10 High-temperature connection test

The high-temperature connection test of IEC 62282-6-101:2024, 8.3.10 shall be performed as

written.

8.3.11 Connection cycling tests

The connection cycling tests of IEC 62282-6-101:2024, 8.3.11 shall be performed as written.

– 12 – IEC 62282-6-106:2024 © IEC 2024

8.3.12 Gas loss tests

8.3.12.1 General gas loss test

The general gas loss test of IEC 62282-6-101:2024, 8.3.12.1 shall be performed as written to

check for gas loss from operating systems for the constituents listed in 5.2 of this document,

with the following passing criteria:

a) Passing criteria:

During gas loss testing, hydrogen gas loss shall be less than the applicable gas loss rate

limits specified in 5.2 of this document. If the device is not operational, the gas loss rate

limit for non-operating devices shall be met. If transient gas loss rates greater than 0,016 g/h

are observed during hydrogen gas loss testing, hydrogen point-source gas loss detection

testing in accordance with IEC 62282-6-101:2024, 8.2.4, or an equivalent test for ensuring

compliance with the safety principles expressed in IEC 62282-6-101:2024, 4.2, shall be

performed.

Gas loss rates from all other measured constituents shall not exceed the gas loss rate limits

as specified in 5.2 of this document, or shall meet an equivalent level of safety to the

principles expressed in IEC 62282-6-101:2024, 4.2.

8.3.12.2 Gas loss test for devices to be used in close proximity to consumer’s mouth

or nose

The gas loss test of IEC 62282-6-101:2024, 8.3.12.2 shall be performed only if the hazard

analysis and risk assessment indicates that constituents with toxicity hazards can be emitted

from the micro fuel cell power system during operation and the device is intended to be used in

close proximity to a consumer’s mouth or nose. This test is only required for micro fuel cell

power systems that are intended to be used in close proximity (10 cm or less) to a consumer’s

mouth or nose. In such cases, the gas loss test shall be performed as written.

Bibliography

The bibliographical references listed in the Bibliography of IEC 62282-6-101 apply.

___________

– 14 – IEC 62282-6-106:2024 © IEC 2024

SOMMAIRE

AVANT-PROPOS . 15

1 Domaine d’application . 17

2 Références normatives . 17

3 Termes et définitions . 17

4 Principes de sécurité . 18

5 Exigences générales de sécurité . 18

5.1 Généralités . 18

5.2 Exigences de sécurité chimique . 18

5.3 Exigences relatives aux matières et matériaux . 20

5.4 Exigences de conception mécanique . 20

5.4.1 Généralités . 20

5.4.2 Système à micropile à combustible . 20

5.4.3 Cartouche de combustible . 20

5.4.4 Vannes de combustible et connexions . 20

5.5 Exigences électriques . 20

5.6 Analyse des dangers et appréciation du risque . 21

5.7 Exigences de sécurité électrique . 21

5.8 Petites pièces . 21

6 Essais et exigences des conditions anormales de fonctionnement et de défaut . 21

7 Instructions et avertissements pour les systèmes à micropiles à combustible et les

cartouches de combustible . 21

8 Essais de type pour les systèmes à micropiles à combustible et les cartouches de

combustible . 21

8.1 Généralités . 21

8.2 Protocoles généraux de mesurage des fuites et des pertes de gaz . 21

8.2.1 Protocoles généraux . 21

8.2.2 Essais . 22

8.3 Essais de type . 23

8.3.1 Essais de pression différentielle . 23

8.3.2 Essai de vibrations . 23

8.3.3 Essai de cycles de températures . 23

8.3.4 Essai d’exposition à température élevée . 23

8.3.5 Essai de chute . 23

8.3.6 Essai de charge de compression . 24

8.3.7 Essai de court-circuit externe . 24

8.3.8 Essai de température de surface, de composant et de gaz

d’échappement . 24

8.3.9 Essai de stockage de longue durée . 24

8.3.10 Essai de connexion à température élevée . 24

8.3.11 Essais de cycles de connexion . 24

8.3.12 Essais de perte de gaz . 24

Bibliographie . 26

Tableau 1 – Limites d'émission et de pertes de gaz . 19

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...