IEC 61223-3-1:1999

(Main)Evaluation and routine testing in medical imaging departments - Part 3-1: Acceptance tests - Imaging performance of X-ray equipment for radiographic and radioscopic systems

Evaluation and routine testing in medical imaging departments - Part 3-1: Acceptance tests - Imaging performance of X-ray equipment for radiographic and radioscopic systems

Applies to those components of X-ray equipment which influence the image quality and patient dose of diagnostic X-ray systems using radiographic and radioscopic imaging systems. Defines: - the parameters which describe the performance of X-ray equipment with regard to imaging properties and patient dose; - methods of testing wether measured quantities related to those parameters comply with the specific tolerances. The aim is to verify compliance of the installation with specifications relating to the image quality and patient dose, and to detect malfunctions that are not in agreement with those specifications.

General Information

- Status

- Withdrawn

- Publication Date

- 23-Mar-1999

- Withdrawal Date

- 06-Oct-2010

- Technical Committee

- SC 62B - Medical imaging equipment, software, and systems

- Drafting Committee

- WG 23 - TC 62/SC 62B/WG 23

- Current Stage

- WPUB - Publication withdrawn

- Start Date

- 28-May-2010

- Completion Date

- 13-Feb-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

IEC 61223-3-1:1999 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Evaluation and routine testing in medical imaging departments - Part 3-1: Acceptance tests - Imaging performance of X-ray equipment for radiographic and radioscopic systems". This standard covers: Applies to those components of X-ray equipment which influence the image quality and patient dose of diagnostic X-ray systems using radiographic and radioscopic imaging systems. Defines: - the parameters which describe the performance of X-ray equipment with regard to imaging properties and patient dose; - methods of testing wether measured quantities related to those parameters comply with the specific tolerances. The aim is to verify compliance of the installation with specifications relating to the image quality and patient dose, and to detect malfunctions that are not in agreement with those specifications.

Applies to those components of X-ray equipment which influence the image quality and patient dose of diagnostic X-ray systems using radiographic and radioscopic imaging systems. Defines: - the parameters which describe the performance of X-ray equipment with regard to imaging properties and patient dose; - methods of testing wether measured quantities related to those parameters comply with the specific tolerances. The aim is to verify compliance of the installation with specifications relating to the image quality and patient dose, and to detect malfunctions that are not in agreement with those specifications.

IEC 61223-3-1:1999 is classified under the following ICS (International Classification for Standards) categories: 11.040.50 - Radiographic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61223-3-1:1999 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL IEC

STANDARD

61223-3-1

First edition

1999-03

Evaluation and routine testing

in medical imaging departments –

Part 3-1:

Acceptance tests –

Imaging performance of X-ray equipment

for radiographic and radioscopic systems

Essais d'évaluation et de routine

dans les services d'imagerie médicale –

Partie 3-1:

Essais d'acceptation –

Performance d'imagerie des appareils

à rayonnement X pour systèmes radiographiques

et radioscopiques

Reference number

Numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series.

Consolidated publications

Consolidated versions of some IEC publications including amendments are

available. For example, edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the

base publication, the base publication incorporating amendment 1 and the base

publication incorporating amendments 1 and 2.

Validity of this publication

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology.

Information relating to the date of the reconfirmation of the publication is available

in the IEC catalogue.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is to be found at the following IEC sources:

• IEC web site*

•

Catalogue of IEC publications

Published yearly with regular updates

(On-line catalogue)*

• IEC Bulletin

Available both at the IEC web site* and as a printed periodical

Terminology, graphical and letter symbols

For general terminology, readers are referred to IEC 60050: International

Electrotechnical Vocabulary (IEV).

For graphical symbols, and letter symbols and signs approved by the IEC for

general use, readers are referred to publications IEC 60027: Letter symbols to be

used in electrical technology, IEC 60417: Graphical symbols for use on equipment.

Index, survey and compilation of the single sheets and IEC 60617: Graphical symbols

for diagrams.

* See web site address on title page.

INTERNATIONAL IEC

STANDARD

61223-3-1

First edition

1999-03

Evaluation and routine testing

in medical imaging departments –

Part 3-1:

Acceptance tests –

Imaging performance of X-ray equipment

for radiographic and radioscopic systems

Essais d'évaluation et de routine

dans les services d'imagerie médicale –

Partie 3-1:

Essais d'acceptation –

Performance d'imagerie des appareils

à rayonnement X pour systèmes radiographiques

et radioscopiques

IEC 1999 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

Commission Electrotechnique Internationale

PRICE CODE

X

International Electrotechnical Commission

For price, see current catalogue

– 2 – 61223-3-1 © IEC:1999(E)

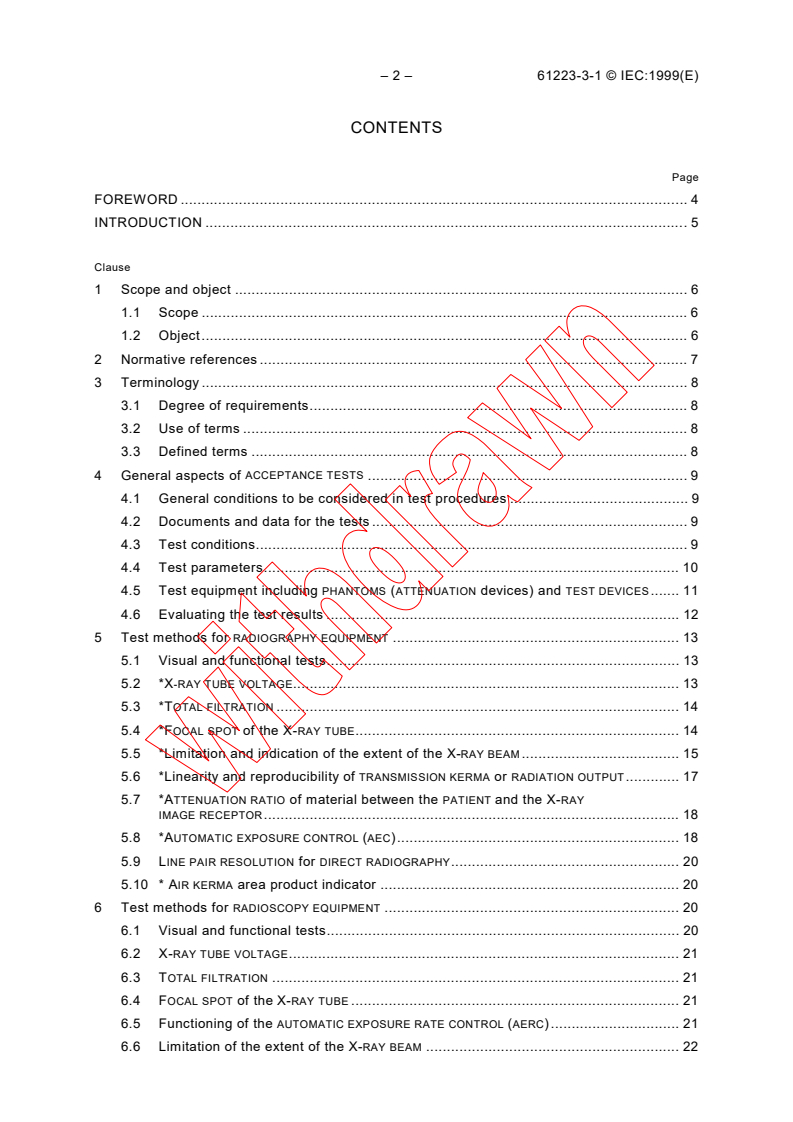

CONTENTS

Page

FOREWORD . 4

INTRODUCTION .5

Clause

1 Scope and object . 6

1.1 Scope.6

1.2 Object. 6

2 Normative references.7

3 Terminology.8

3.1 Degree of requirements. 8

3.2 Use of terms . 8

3.3 Defined terms.8

4 General aspects of ACCEPTANCE TESTS . 9

4.1 General conditions to be considered in test procedures . 9

4.2 Documents and data for the tests . 9

4.3 Test conditions.9

4.4 Test parameters.10

4.5 Test equipment including PHANTOMS (ATTENUATION devices) and TEST DEVICES. 11

4.6 Evaluating the test results . 12

5 Test methods for RADIOGRAPHY EQUIPMENT . 13

5.1 Visual and functional tests. 13

5.2 *X-RAY TUBE VOLTAGE. 13

5.3 *TOTAL FILTRATION . 14

5.4 *FOCAL SPOT of the X-RAY TUBE. 14

5.5 *Limitation and indication of the extent of the X-RAY BEAM. 15

5.6 *Linearity and reproducibility of TRANSMISSION KERMA or RADIATION OUTPUT. 17

5.7 *ATTENUATION RATIO of material between the PATIENT and the X-RAY

IMAGE RECEPTOR. 18

5.8 *AUTOMATIC EXPOSURE CONTROL (AEC). 18

5.9 LINE PAIR RESOLUTION for DIRECT RADIOGRAPHY. 20

5.10 * AIR KERMA area product indicator . 20

6 Test methods for RADIOSCOPY EQUIPMENT . 20

6.1 Visual and functional tests. 20

6.2 X-RAY TUBE VOLTAGE. 21

6.3 TOTAL FILTRATION . 21

6.4 FOCAL SPOT of the X-RAY TUBE . 21

6.5 Functioning of the AUTOMATIC EXPOSURE RATE CONTROL (AERC) . 21

6.6 Limitation of the extent of the X-RAY BEAM . 22

61223-3-1 © IEC:1999(E) – 3 –

Clause Page

6.7 ATTENUATION RATIO of material between the PATIENT and the X-RAY

IMAGE RECEPTOR. 23

6.8 *AIR KERMA RATE at the ENTRANCE PLANE of the X-RAY IMAGE INTENSIFIER

for RADIOSCOPY . 23

6.9 *Entrance AIR KERMA RATE for RADIOSCOPY with X-RAY IMAGE INTENSIFIER. 24

6.10 AIR KERMA at the ENTRANCE PLANE of the X-RAY IMAGE INTENSIFIER for

CINERADIOGRAPHY or other INDIRECT RADIOGRAPHY systems (excluding digital

systems) . 25

6.11 Entrance AIR KERMA for CINERADIOGRAPHY or other INDIRECT RADIOGRAPHY systems

(excluding digital systems) . 25

6.12 *LINE PAIR RESOLUTION for RADIOSCOPY with X-RAY IMAGE INTENSIFIER and for

CINERADIOGRAPHY or other INDIRECT RADIOGRAPHY systems (excluding digital

systems) . 26

6.13 *LOW CONTRAST RESOLUTION for RADIOSCOPY with X-RAY IMAGE INTENSIFIER and for

CINERADIOGRAPHY or other INDIRECT RADIOGRAPHY systems (excluding digital

systems) . 27

6.14 AIR KERMA area product indicator. 28

7 Additional tests required for TOMOGRAPHY EQUIPMENT. 28

7.1 *Requirements . 28

7.2 Test method . 29

8 Test report and statement of compliance . 29

Annex A (normative) Terminology – Index of defined terms . 36

Annex B (informative) Test parameters, symbols and units . 39

Annex C (informative) Examples of low contrast TEST DEVICES. 40

Annex D (informative) Examples of requirements (accuracy, tolerances, discrepancies)

according to actual IEC standards or state of the art. 42

Annex E (informative) Bibliography . 46

Tables

B.1 Test parameters, symbols and units. 39

D.1 Typical values of FOCAL SPOT dimensions for NOMINAL FOCAL SPOT VALUES . 42

D.2 Values for the discrepancy parameters X, Y and Z according to IEC 60601-1-3 . 43

D.3 Typical values for the TRANSMISSION KERMA index. 43

D.4 Typical values for the ATTENUATION RATIO of material between the PATIENT

and the X-RAY IMAGE RECEPTOR. 44

Figures

1 Measuring arrangement for RADIOGRAPHY and RADIOSCOPY EQUIPMENT for AIR KERMA

measurements. 31

2 Measuring arrangement for RADIOGRAPHY and RADIOSCOPY EQUIPMENT to test geometry

and resolutions. 32

3LINE PAIR RESOLUTION TEST DEVICE . 33

4TOMOGRAPHY LINE PAIR RESOLUTION TEST DEVICE. 34

5 Discrepancies in visual indication of the X-RAY FIELD . 35

6 Discrepancies in covering the IMAGE RECEPTION AREA . 35

– 4 – 61223-3-1 © IEC:1999(E)

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

EVALUATION AND ROUTINE TESTING

IN MEDICAL IMAGING DEPARTMENTS –

Part 3-1: Acceptance tests –

Imaging performance of X-ray equipment

for radiographic and radioscopic systems

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical reports or guides and they are accepted by the National Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61223-3-1 has been prepared by subcommittee 62B: Diagnostic

imaging equipment, of IEC technical committee 62: Electrical equipment in medical practice.

The text of this standard is based on the following documents:

FDIS Report on voting

62B/361/FDIS 62B/365/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

Annex A forms an integral part of this standard.

Annexes B, C, D and E are for information only.

In this standard, the following print types are used:

– requirements, compliance with which can be tested, and definitions: roman type;

– explanations, advice, notes, general statements, exceptions and references: smaller roman type;

– test specifications: italic type;

– TERMS DEFINED IN IEC 60788, IN IEC 60601-1 OR IN THE IEC 61223 SERIES: SMALL CAPITALS (SEE

ANNEX A).

A bilingual version of this standard may be issued at a later date.

61223-3-1 © IEC:1999(E) – 5 –

INTRODUCTION

This standard is part of a series of International Standards which give methods of acceptance

testing and constancy testing for subsystems and systems (for example diagnostic X-RAY

EQUIPMENT), including film processing, used in medical imaging departments.

Some provisions or statements in this standard require additional information. Such information

is presented in annex D. An asterisk in the left margin of a clause or subclause indicates the

presence of such additional information.

– 6 – 61223-3-1 © IEC:1999(E)

EVALUATION AND ROUTINE TESTING

IN MEDICAL IMAGING DEPARTMENTS –

Part 3-1: Acceptance tests –

Imaging performance of X-ray equipment

for radiographic and radioscopic systems

1 Scope and object

1.1 Scope

This part of IEC 61223 applies to those components of X-RAY EQUIPMENT which influence the

image quality and PATIENT dose of diagnostic X-ray systems using radiographic and radioscopic

imaging systems.

This standard applies to the performance of X-RAY EQUIPMENT in the ACCEPTANCE TEST on the

following medical diagnostic X-RAY EQUIPMENT and ASSOCIATED EQUIPMENT:

– radiography equipment, for example:

• stationary radiography EQUIPMENT;

• mobile radiography EQUIPMENT;

• skull radiography EQUIPMENT;

• lung radiography EQUIPMENT;

• TOMOGRAPHY EQUIPMENT – excluding COMPUTED TOMOGRAPHY;

• radiography devices (SPOTFILM DEVICES) in RADIOSCOPY EQUIPMENT;

• angiography EQUIPMENT (excluding DSA function);

• CINERADIOGRAPHY equipment;

– RADIOSCOPY EQUIPMENT, including:

• combined radiographic and radioscopic EQUIPMENT.

This standard applies to the generation of X-RADIATION and ACCESSORIES of digital systems. It

does not apply to any digital image acquisition or image processing parts of the above

mentioned diagnostic X-RAY EQUIPMENT.

NOTE – Since the characterization of digital detectors and image processing is still under development, this will be

included in a later edition of this standard.

This standard does not apply to mammographic X-RAY EQUIPMENT, RADIOTHERAPY simulators,

nor to dental X-RAY EQUIPMENT.

1.2 Object

This standard defines:

a) the parameters which describe the performance of X-RAY EQUIPMENT with regard to imaging

properties and PATIENT dose;

b) methods of testing whether measured quantities related to those parameters comply with

the specified tolerances.

61223-3-1 © IEC:1999(E) – 7 –

These methods rely mainly on non-invasive measurements, using appropriate test equipment,

performed during or after the installation is completed. Signed statements covering steps of

product testing at the MANUFACTURER's site or during the installation procedure can be used as

part of the acceptance testing.

The aim is to verify compliance of the installation with specifications relating to the image

quality and PATIENT dose, and to detect malfunctions that are not in agreement with those

specifications.

This standard does not specify tolerances for the parameters under investigation. Nor does it

consider:

c) aspects of mechanical and electrical safety,

d) aspects of mechanical, electrical and software performance unless they are essential to the

performance of the tests directly affecting image quality and PATIENT dose.

2 Normative references

The following normative documents contain provisions which, through reference in this

text, constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60336:1993, X-ray tube assemblies for medical diagnosis – Characteristics of focal spots

IEC 60417-1:1998, Graphical symbols for use on equipment – Part 1: Overview and application

IEC 60522:1976, Inherent filtration of an X-ray tube assembly

IEC 60580:1977, Area exposure product meter

IEC 60601-1:1988, Medical electrical equipment – Part 1: General requirements for safety

IEC 60601-1-3:1994, Medical electrical equipment – Part 1: General requirements for safety –

3. Collateral standard: General requirements for radiation protection in diagnostic X-ray

equipment

IEC 60601-2-7:1998, Medical electrical equipment – Part 2: Particular requirements for the

safety of high-voltage generators of diagnostic X-ray generators

IEC 60601-2-28:1993, Medical electrical equipment – Part 2: Particular requirements for the

safety of X-ray source assemblies and X-ray tube assemblies for medical diagnosis

IEC 60788:1984, Medical radiology – Terminology

IEC 60878:1988, Graphical symbols for electrical equipment in medical practice

IEC 61223-1:1993, Evaluation and routine testing in medical imaging departments – Part 1:

General aspects

IEC 61267:1994, Medical diagnostic X-ray equipment – Radiation conditions for use in the

determination of characteristics

ISO 2092:1981, Light metals and their alloys – Code of designation based on chemical symbols

– 8 – 61223-3-1 © IEC:1999(E)

3 Terminology

3.1 Degree of requirements

In this standard, certain terms which are not printed in SMALL CAPITALS have particular

meanings, as follows:

– "shall" indicates a requirement that is mandatory for compliance;

– "should" indicates a strong recommendation that is not mandatory for compliance;

– "may" indicates a permitted manner of complying with a requirement or of avoiding

the need to comply;

– "specific" is used to indicate definitive information stated in this standard or referenced

in other standards, usually concerning particular operating conditions, test

arrangements or values connected with compliance;

– "specified" is used to indicate definitive information stated by the MANUFACTURER in

ACCOMPANYING DOCUMENTS or in other documentation relating to the EQUIPMENT

under consideration, usually concerning its intended purposes, or the

parameters or conditions associated with its use or with testing to determine

compliance.

3.2 Use of terms

In this standard, terms printed in SMALL CAPITALS are used as defined in IEC 60601-1,

IEC 60788, IEC 61223-1 and in 3.3 of this standard (see annex A).

NOTE – Attention is drawn to the fact, that, in cases where the concept addressed is not strongly confined to the

definition given in one of the publications listed above, a corresponding term is printed in lower case letters.

3.3 Defined terms

3.3.1

ARTIFACT

apparent structure visible in the image which does not represent a structure within the object

and which cannot be explained by noise or the MODULATION TRANSFER FUNCTION of the system

3.3.2

LINE PAIR RESOLUTION

highest spatial frequency of the specified line-group test pattern imaged under specified

conditions which is distinguishable in the image. The unit is lp/mm

NOTE – LINE PAIR RESOLUTION is used here as a practical substitute for spatial resolution.

3.3.3

LOW CONTRAST RESOLUTION

lowest contrast detail object of a specified shape and area that can be resolved from an

uniform background

3.3.4

RADIATION OUTPUT

AIR KERMA per CURRENT TIME PRODUCT (mGy/mAs) at a given distance from the FOCAL SPOT in

the primary X-RAY BEAM

3.3.5

TRANSMISSION KERMA (TRANSMISSION KERMA RATE)

AIR KERMA (AIR KERMA RATE) in the central X-RAY BEAM behind the specified attenuating layer

61223-3-1 © IEC:1999(E) – 9 –

4 General aspects of ACCEPTANCE TESTS

4.1 General conditions to be considered in test procedures

The aim of an ACCEPTANCE TEST is to demonstrate that the specified characteristics of the

equipment lie within the specified tolerances. Some requirements are enforced by legislation.

Other requirements and specifications may be in the order contract, in the supplier's brochure

or in other standards, for example in the IEC 60601 series.

ACCEPTANCE TEST EQUIPMENT

Before any according to this standard is carried out, the has to be

installed and put into service according to the set-up procedure as given in the

MANUFACTURER's documentation.

An inventory of the EQUIPMENT under test, the ACCOMPANYING DOCUMENTS, and the test

protocols shall be compiled. Each item shall be identified by its MODEL OR TYPE REFERENCE

SERIAL NUMBER

(type number) and , and the entire inventory shall be compared with the order

contract.

RADIOGRAPHIC CASSETTES with INTENSIFYING SCREENS, RADIOGRAPHIC FILMS and film processing

are vital parts in the imaging chain. It is the responsibility of the USER to show that these

components perform in an acceptable way, based upon information given by MANUFACTURERs

RADIOGRAPHIC FILMS INTENSIFYING SCREENS

of and , for example with respect to sensitivity,

contrast and absence of ARTIFACTS.

Non-invasive measurements are preferred for ACCEPTANCE TESTS. Whenever invasive tests are

part of the programme, it shall be shown that the EQUIPMENT has been restored to its pre-test

condition after the test.

4.2 Documents and data for the tests

The following documentation is required:

– statements of compliance with applicable parts of IEC 60601;

– list of EQUIPMENT or EQUIPMENT parts ordered and the actual delivery list;

– performance specification as agreed upon between the purchaser and the supplier;

– results from tests performed at the MANUFACTURER's site or during installation covering

items of importance to quality, such as NOMINAL FOCAL SPOT VALUE;

– INSTRUCTIONS FOR USE, including guidance for the operation of the EQUIPMENT;

– details of the actual operating conditions under which the X-RAY EQUIPMENT is to be used in

medical practice and whether this results in a limitation of the scope of the tests or of the

functionality of the EQUIPMENT. If certain functions are disabled, only those used need to be

tested;

– guidance as to the extent and frequency of maintenance procedures;

– reports on previous tests where applicable;

– list of agreed technical modifications in the meantime between the order contract and the

ACCEPTANCE TEST.

4.3 Test conditions

Different categories of tests can be identified:

– visual inspection;

– functional tests;

– system performance;

– check of the uncertainty in the values of variables.

– 10 – 61223-3-1 © IEC:1999(E)

The measuring arrangements which may be used for performing tests are illustrated in

figures 1 and 2.

Figure 1 includes the measuring arrangement for the TRANSMISSION KERMA, K , or the

T

�

TRANSMISSION KERMA RATE, , and the X-RAY IMAGE RECEPTOR AIR KERMA, K , or the X-RAY

K

T

B

�

IMAGERECEPTOR AIR KERMA RATE, , and the test parameters derived from them.

K

B

Figure 2 includes the measuring arrangement to test geometry and resolutions.

The arrangements in figures 1 and 2 are indicative only. The test may be carried out in the

EQUIPMENT

vertical or the horizontal position according to the mode of operation of the . Not

every component in the figures is needed in every test.

The X-RAY FIELD size shall be the minimum size required for each measurement.

The distance between the additional attenuating layer and the detector of the KERMAMETER

(KERMA RATEMETER) shall be not less than 250 mm.

NOTE – For the effects of SCATTERED RADIATION, see 4.5.4.

The tests shall yield information reasonably necessary for a demonstration of performance over

the full range of OPERATOR accessible variables.

All relevant data, such as the identification of the X-RAY EQUIPMENT under test, identification of

the test equipment used, geometrical set-up, operating characteristics, correction factors and

test results of the ASSOCIATED EQUIPMENT (for example film, screen, processing) shall be

recorded with the test results. The record shall include the identification of the location, the

date and the names of the persons performing the tests.

4.4 Test parameters

The following items are subject to ACCEPTANCE TESTING:

– identification of EQUIPMENT;

– check of documents;

– visual and functional tests;

–X-RAY TUBE VOLTAGE;

– CURRENT TIME PRODUCT;

– LOADING TIME;

– limitation and indication of the extent of the X-RAY BEAM;

– FOCAL SPOT;

– TOTAL FILTRATION;

– RADIATION OUTPUT;

TRANSMISSION KERMA TRANSMISSION KERMA RATE

– ( );

– function of the AUTOMATIC EXPOSURE CONTROL;

– ATTENUATION RATIO;

– AIR KERMA (AIR KERMA RATE);

– AIR KERMA (AIR KERMA RATE) at the ENTRANCE PLANE of the X-RAY IMAGE INTENSIFIER;

– LINE PAIR RESOLUTION;

– LOW CONTRAST RESOLUTION;

– optical density (for AUTOMATIC EXPOSURE CONTROL test).

Annex B lists symbols and units for some of the above items.

61223-3-1 © IEC:1999(E) – 11 –

4.5 Test equipment including PHANTOMS (ATTENUATION devices) and TEST DEVICES

4.5.1 General

Measuring equipment used for ACCEPTANCE TESTS shall be certified (for example calibration

according to national or international regulations, if applicable).

The uncertainty of measuring instruments shall be less than one-third of the specified

tolerances for the quantities being measured.

4.5.2 High-voltage measuring instrument

The high-voltage measuring instrument shall measure the value of X-RAY TUBE VOLTAGES within

the specified range. Instruments based on either direct or indirect measurements may be used.

4.5.3 KERMAMETER

The KERMAMETER (KERMA RATEMETER) shall have a range sufficient to measure the AIR KERMA

(AIR KERMA RATE) within the required accuracy for the system under test and shall be calibrated

for the applied beam qualities.

If legal regulations require the use of other dosimetric quantities, they may be applied.

4.5.4 PHANTOMS (ATTENUATION devices) and TEST DEVICES

PHANTOMS and TEST DEVICES may consist of attenuating layers (PHANTOM part of the object)

and/or structural elements (TEST DEVICE part of the object) which can be arranged in

combination or separately.

The following requirements apply:

a) External dimensions

PHANTOM dimensions shall be at least large enough to intercept the entire RADIATION BEAM

for all test conditions applicable; see figures 1 and 2.

b) ATTENUATION and hardening

The attenuating layers of the PHANTOMS shall be in aluminium of at least 99,5 % purity

(Al 99,5 according to ISO 2092) and a material thickness of 25 mm ± 0,5 mm; see

IEC 61267.

Some, but not all, tests will need an additional homogeneous attenuating layer of about

1,5 mm copper.

A PHANTOM of low atomic number material (for example TISSUE EQUIVALENT MATERIAL) is

used to test the function of the AUTOMATIC EXPOSURE CONTROL, for example 10 cm, 15 cm or

20 cm of water.

For some tests lead layers (1 mm to 2 mm thick) are needed to make lead masks or for the

shielding of direct and indirect RADIATION.

c) Effects of SCATTERED RADIATION with various measuring arrangements

In all tests care shall be taken to reduce SCATTERED RADIATION to a minimum. If it is likely

that SCATTERED RADIATION will significantly affect the measurement, the correction factor

shall be determined and used in calculating the results.

d) Beam limiting TEST DEVICE

The beam limiting TEST DEVICE shall comprise structural elements for testing the centring,

RAY BEAM

limitation and indication of the extent of the X- as marking elements and a matrix

with intervals of 1 cm made of RADIATION absorbing material.

These structural elements should be of such material and arranged in such a way that the

function of the AUTOMATIC EXPOSURE CONTROL is unaffected.

– 12 – 61223-3-1 © IEC:1999(E)

e) LINE PAIR RESOLUTION TEST DEVICE

The TEST DEVICE shall comprise line-group test patterns with a lead thickness of 0,05 mm

and grid groups with local frequencies of 0,6 lp/mm to 5,0 lp/mm with a gradation of

less than or equal to 20 % from group to group. The outer dimensions are for example

55 mm × 65 mm; see figure 3.

f) LOW CONTRAST RESOLUTION TEST DEVICE

There are many devices available to measure the LOW CONTRAST RESOLUTION. If this

parameter is measured, the results should be recorded together with the description of the

TEST DEVICE used.

The detail diameters shall be such that their resolution is neither enhanced nor degraded by

the frequency response of the X-RAY IMAGE INTENSIFIER-television system (imaging system).

For examples, see annex C.

4.5.5 Lens

A magnifying lens shall be available. A 2 × to 6 × magnification is usually suitable.

4.5.6 Densitometer

The densitometer shall cover the optical density range 0 to 3,5.

4.5.7 Additional inspection and TEST DEVICES for TOMOGRAPHY X-RAY EQUIPMENT

The following TEST DEVICES are required:

–TEST DEVICE to test the layer height adjustment:

Holder for metallic slab with holes drilled at constant intervals (or the TEST DEVICE described

above with additional holes; see figure 4) with an inclination of the short axis of the test

pattern of 20° to 45° to the plane of the PATIENT SUPPORT. The holes in each row of the test

pattern shall be at such intervals as to give an interval of 1 mm in the direction of height;

– TOMOGRAPHY movement TEST DEVICE:

Pinhole DIAPHRAGM for displaying the tomographic movement;

– TOMOGRAPHY LINE PAIR RESOLUTION TEST DEVICE:

A line-group test pattern with a lead thickness of between 0,05 mm and 0,10 mm and grid

groups with local frequencies of 0,5 lp/mm to 4 lp/mm with a gradation of less than or equal

to 40 % from group to group. The outer dimensions are for example 42 mm × 110 mm; see

figure 4.

4.6 Evaluating the test results

Whenever specified limiting values or tolerances are not met, verify the results by making at

least two additional measurements.

In the evaluation of the results concerning limit values (upper or lower), the uncertainty in the

measurement shall be taken into consideration.

61223-3-1 © IEC:1999(E) – 13 –

5 Test methods for RADIOGRAPHY EQUIPMENT

5.1 Visual and functional tests

5.1.1 Requirements

The operation and functioning of the X-RAY EQUIPMENT shall comply with what is specified.

All OPERATOR accessible controls shall be labelled with a graphical symbol, for example

IEC 60417-1 or IEC 60878, and/or in plain language. The colour of indicator lamps shall comply

with applicable standards, for example IEC 60601-1. The marking on the X-RAY TUBE ASSEMBLY

shall comply with IEC 60601-2-28. The LIGHT FIELD shall be recognizable in the specified

ambient illumination.

The INSTRUCTIONS FOR USE shall describe comprehensively how the X-RAY EQUIPMENT under

test is to be operated. The function of each OPERATOR accessible control, indicator and display

shall be described and all symbols shall be illustrated with their significance. Reproductions in

the INSTRUCTIONS FOR USE shall be in agreement with the actual X-RAY EQUIPMENT, with respect

to position, labels and symbols. The INSTRUCTIONS FOR USE shall be written in the language that

is required locally or specified in the order contract.

5.1.2 Test methods

The tests are performed by visual inspection and functional check. They comprise:

– inventory of EQUIPMENT under test;

– check on the presence of all documents according to 4.2;

– functional test of the mechanical and electrical adjustment devices (including check of the

accuracy of FOCAL SPOT TO IMAGE RECEPTOR DISTANCE indicator and any detent positions,

where this parameter is variable);

– functional test and identification of the control elements;

– visual inspection of the labelling of control elements;

– visual inspection of the markings on the X-RAY SOURCE ASSEMBLY;

– visual inspection of the brightness of the LIGHT FIELD;

– visual inspection of the INSTRUCTIONS FOR USE (see IEC 60601-1).

5.2 *X-RAY TUBE VOLTAGE

5.2.1 Requirements

MEASURED VALUES RAY TUBE VOLTAGE

The of the X- shall agree with the values indicated at the

control panel within the specified tolerances.

5.2.2 Test methods

The measurements should be carried out using the arrangement in figure 1 without the

attenuating layer. The tests are preferably performed using a non-invasive method.

Place the detector of the high-voltage measuring instrument in the centre of the RADIATION

BEAM.

– 14 – 61223-3-1 © IEC:1999(E)

At least three standard X-RAY TUBE VOLTAGE measurements shall normally be performed, at

60 kV, 80 kV and 100 kV or at voltages close to these values, at 50 % or more of the highest

available X-RAY TUBE CURRENT and a LOADING TIME of approximately 0,1 s. At 80 kV, the

measurement shall be carried out also at the lowest and the highest available X-RAY TUBE

CURRENT settings.

NOTE 1 – The suggested LOADING FACTORS given above are a minimum recommendation. The choice of LOADING

FACTORS should be made considering the nature of the EQUIPMENT under test and its clinical application, so as to

explore enough of the X-RAY TUBE VOLTAGE/LOADING TIME/X-RAY TUBE CURRENT relationship to establish the

conformance of the EQUIPMENT to its specification and the needs of the USER.

NOTE 2 – At no time during testing should the maximum ratings of the X-RAY TUBE ASSEMBLY be exceeded.

Compare the MEASURED VALUES of the X-RAY TUBE VOLTAGE with the values indicated at the

control panel and the specified tolerances.

NOTE – The LOADING FACTORS should be recorded because the X-RAY TUBE VOLTAGE measured may vary with the

LOADING FACTOR.

5.3 *TOTAL FILTRATION

5.3.1 Requirements

The minimum TOTAL FILTRATION shall be as specified.

5.3.2 Test method

RAY

Compliance with the specification is checked by inspection of the markings on the X-

SOURCE ASSEMBLY and by examination of the ACCOMPANYING DOCUMENTS. The QUALITY

EQUIVALENT FILTRATION

may be determined according to clauses 3 and 4 of IEC 60522, if

necessary.

NOTE – This requires measuring the HALF-VALUE LAYER under NARROW BEAM CONDITIONS with the X-RAY EQUIPMENT

operating at appropriate values of X-RAY TUBE VOLTAGE and corresponding LOADING FACTORS, and to compare with

the HALF-VALUE LAYER from an X-RAY TUBE with the same TARGET material and TARGET ANGLE.

A simplified HALF-VALUE LAYER measurement may be carried out with the arrangement in

figure 1, without the attenuating layer. Measure the first HALF-VALUE LAYER with the X-RAY

EQUIPMENT operating at appropriate values of X-RAY TUBE VOLTAGE with suitable LOADING

FACTORS in the range of NORMAL USE. This test gives only an approximate estimate of the TOTAL

FILTRATION

because these test conditions do not fully comply with IEC 60522.

State either the compliance of the TOTAL FILTRATION with the specification, or the compliance of

HALF VALUE LAYER

the measured - with the requirements according to IEC 60601-1-3.

5.4 *FOCAL SPOT of the X-RAY TUBE

5.4.1 Requirements

The actual FOCAL SPOT dimensions for the stated NOMINAL FOCAL SPOT VALUES shall comply with

the dimensions specified in IEC 60336. Additional specifications, for example concerning

dimensions, direction of the REFERENCE AXIS or LOADING FACTORS, are subject to testing within

the scope of this standard only if these specifications also state the test method.

5.4.2 Test method

ACTUAL FOCAL SPOT NOMINAL FOCAL SPOT

The compliance of the dimensions for the stated

VALUES with IEC 60336 shall be confirmed by the MANUFACTURER.

NOTE – FOCAL SPOT measuring procedures by SLIT CAMERA, PINHOLE CAMERA, star pattern evaluation and

Fourier transform of images of TEST DEVICES all give different results concerning size and resolution. The standard

FOCAL SPOT measurement is specified according to IEC 60336 by SLIT CAMERA under specified projection conditions

and optical density.

61223-3-1 © IEC:1999(E) – 15 –

5.5 *Limitation and indication of the extent of the X-RAY BEAM

5.5.1 Accuracy of marked and written indications of the X-RAY FIELD size

5.5.1.1 Requirements

The actual size of the X-RAY FIELD shall comply with what is indicated on the EQUIPMENT within

the specified tolerances.

5.5.1.2 Test methods

Compliance is checked by inspection of the X-RAY EQUIPMENT and by examination of the

ACCOMPANYING DOCUMENTS. Where appropriate, measure the dimensions of the X-RAY FIELD

along its two major axes at selected indicated settings of the BEAM LIMITING SYSTEM, and the

FOCAL SPOT TO IMAGE RECEPTOR DISTANCE, as available for NORMAL USE and at the commonly

used X-RAY BEAM angulation.

Other test procedures than those described here may be used if they lead to comparable

results.

Use the FOCAL SPOT TO IMAGE RECEPTOR DISTANCE at the value indicated on the EQUIPMENT or

ACCOMPANYING DOCUMENTS

stated in the , for the setting used.

Make the measurements with a RADIOGRAPHIC CASSETTE arranged in the tray or on the top of

PATIENT SUPPORT RAY FIELD

the in the centre of the X- and using the arrangement in figure 2,

without the attenuating layer.

Produce RADIOGRAMS with two field sizes, for example 18 cm × 24 cm and 24 cm × 30 cm,

under these conditions, with LOADING FACTORS so as to give an optical density D in the range

0,5 to 2,0 on the RADIOGRAPHIC FILM.

Measure the X-RAY FIELD size on the processed RADIOGRAPHIC FILMS and note the

discrepancies with the displayed indication(s) on the X-RAY EQUIPMENT. If the RADIOGRAPHIC

CASSETTES had been exposed on the top of the PATIENT SUPPORT, this field size must be

corrected to correspond to that at the cassette tray.

Discrepancies between the measured X-RAY FIELD size and the displayed indications shall be

within the specified tolerances.

5.5.2 Accuracy of indication of the LIGHT FIELD-INDICATOR

5.5.2.1 Requirements

The discrepancies in the indication of the LIGHT FIELD and the X-RAY FIELD shall comply with the

tolerances specified.

5.5.2.2 Test methods

Site a RADIOGRAPHIC CASSETTE, for example 24 cm × 30 cm, on top of the PATIENT SUPPORT in

the centre of the X-RAY FIELD and manually set a LIGHT FIELD of for example 18 cm × 24 cm.

Mark the corners of the LIGHT FIELD with radio-opaque markers, for example metal wires.

Choose LOADING FACTORS so as to give an optical density D in the range 0,5 to 2,0 on the

RADIOGRAPHIC FILM.

Measure the X-RAY FIELD limits on the processed RADIOGRAPHIC FILM and the discrepancies

from the indicated LIGHT FIELD.

– 16 – 61223-3-1 © IEC:1999(E)

In figure 5, the measured discrepancies are represented by a and a on one axis, and by b

1 2 1

and b on the other. If the FOCAL SPOT to the plane of the LIGHT FIELD distance is r , then, for

2 L

compliance, the following relationships are true:

a + a ≤ X × r

1 2 L

b + b ≤ X × r

1 2 L

where

X is the tolerance specified.

5.5.3 Correspondence between the X-RAY FIELD and IMAGE RECEPTION AREA with

automatic adjustment of the RADIATION APERTURE

5.5.3.1 Requirements

The discrepancies between the edges of the X-RAY FIELD and the corresponding edges of the

IMAGE RECEPTION AREA shall comply with the tolerances specified.

5.5.3.2 Test methods

Compliance with the relevant requirements is checked by inspection of the EQUIPMENT, by

examination of the INSTRUCTIONS FOR USE and by measurement of the X-RAY FIELDS, where

appropriate.

Allow a period of at least 5 s for the automatic mechanism to complete any adjustment

occurring during the tests.

Use two cassette sizes for this test, for example 18 cm × 24 cm and 24 cm × 30 cm.

Use the arrangement of figure 2, without the attenuating layer. Put a non-screen RADIOGRAPHIC

CASSETTE RADIOGRAPHIC FILM PATIENT SUPPORT

or a in a light-proof envelope on the . Then

insert a loaded RADIOGRAPHIC CASSETTE into the cassette holder. The automatic BEAM LIMITING

DEVICE RAY FIELD RADIOGRAPHIC

will automatically adjust the X- size to the format of the

CASSETTE used. Choose LOADING FACTORS so as to give an optical density D in the range 0,5 to

RADIOGRAPHIC FILMS

2,0 on both .

Measure, on the processed RADIOGRAPHIC FILMS, the X-RAY FIELD limits and the discrepancies

IMAGE RECEPTION AREA

from the .

As shown in figure 6, the measured discrepancies in the IMAGE RECEPTOR PLANE are

represented by c and c on one axis, and by d and d on the other.

1 2 1 2

If the FOCAL SPOT TO IMAGE RECEPTOR DISTANCE is r , then for compliance, the following

B

relationships are true:

c + c ≤ Y × r

1 2 B

d + d ≤ Y × r

1 2 B

c + c + d + d ≤ Z × r

1 2 1 2 B

where

Y and Z are the tolerances specified.

NOTE – If the above requirements are fulfilled, the X-RAY EQUIPMENT complies with the X-RAY FIELD centring

requirements.

61223-3-1 © IEC:1999(E) – 17 –

5.6 *Linearity and reproducibility of TRANSMISSION KERMA or RADIATION OUTPUT

5.6.1 Requirements

The following requirements are applied alternatively (for TRANSMISSION KERMA or for RADIATION

OUTPUT) according to the regional requirements.

TRANSMISSION KERMA CURRENT TIME PRODUCT

The linearity of the with the and the reproducibility

shall comply with the tolerances or values specified.

The RADIATION OUTPUT and the TRANSMISSION KERMA per CURRENT TIME PRODUCT at a given

distance for a given setting of X-RAY

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...