IEC 60331-2:2018

(Main)Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

IEC 60331-2:2018 specifies the test method for cables which are required to maintain circuit integrity when subject to fire and mechanical shock under specified conditions.

This document is applicable to cables of rated voltage not exceeding 600 V/1 000 V, including those of rated voltage below 80 V, metallic data and telecom cables and optical fibre cables.

It is intended for use when testing cables of not greater than 20 mm overall diameter.

Cables of larger diameter are intended to be tested using the apparatus, procedure and requirements of IEC 60331-1.

This document includes details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to electric power and control cables with rated voltage up to and including 600 V/1000 V. Details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallic data and telecom cables and optical fibre cables are not given by IEC 60331-2.

Although the scope is restricted to cables with rated voltage up to and including 0,6/1,0 kV, the procedure can be used, with the agreement of the manufacturer and the purchaser, for cables with rated voltage up to and including 1,8/3 (3,3) kV, provided that suitable fuses are used.

Annex A provides the method of verification of the burner and control system used for the test.

Requirements are stated for an identification that may optionally be marked on the cable to signify compliance with this standard.

This second edition cancels and replaces the first edition published in 2009. It constitutes a technical revision.

The significant technical changes with respect to the previous edition are as follows:

– extension of the scope with metallic data and telecom cables and optical fibre cables, although details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallicdata and telecom cables and optical fibre cables are not given by IEC 60331-2;

– improved description of the test environment;

– mandatory use of mass flow meters/controllers as the means of controlling accurately the input flow rates of fuel and air to the burner;

– improved figure illustrating method of mounting of the sample regarding bending radius;

– improved description of the information to be included in the test report.

Essais pour câbles électriques soumis au feu – Intégrité des circuits – Partie 2: Méthode d’essai au feu avec chocs pour les câbles de tension assignée au plus égale à 0,6/1,0 kV et de diamètre externe inférieur ou égal à 20 mm, à une température d’au moins 830 °C

L'IEC 60331-2:2018 spécifie la méthode d'essai pour les câbles nécessaires afin de conserver l'intégrité du circuit quand ils sont soumis à un feu et à des chocs mécaniques dans des conditions spécifiées.

Le présent document s'applique aux câbles de tension assignée au plus égale à 600 V/1000 V, y compris ceux dont la tension assignée est inférieure à 80 V, aux câbles métalliques de données et de télécommunications ainsi qu'aux câbles à fibres optiques.

Elle est destinée à être utilisée pour soumettre à l'essai des câbles de diamètre externe inférieur ou égal à 20 mm.

Pour les câbles de diamètre plus grand, l'appareillage, la procédure et les exigences de l'IEC 60331-1 sont utilisés.

Le présent document inclut des informations concernant le point spécifique de défaillance, le dispositif de contrôle de la continuité, l'échantillon d'essai, la procédure d'essai et le rapport d'essai pertinents pour les câbles électriques de puissance et de commande de tension assignée au plus égale à 600 V/1000 V. Les informations concernant le point spécifique de défaillance, le dispositif de contrôle de la continuité, l'échantillon d'essai, la procédure d'essai et le rapport d'essai pertinents pour les câbles métalliques de données et de télécommunications et les câbles à fibres optiques ne sont pas données dans l'IEC 60331-2.

Bien que le domaine d'application soit limité aux câbles de tension assignée au plus égale à 0,6/1,0 kV, cette procédure peut être utilisée, après accord entre le fabricant et l'acheteur, pour les câbles de tension assignée au plus égale à 1,8/3 (3,3) kV, à condition d'utiliser des fusibles appropriés.

L'Annexe A donne la méthode de vérification du brûleur et le système de contrôle utilisé pour l'essai.

Des exigences sont indiquées pour une identification pouvant être éventuellement apposée par marquage sur le câble pour signifier sa conformité à la présente norme.

Cette deuxième édition annule et remplace la première édition parue en 2009. Elle constitue une révision technique;

Les modifications techniques majeures par rapport à l'édition précédente sont les suivantes:

– extension du domaine d'application aux câbles métalliques de données et de télécommunications et aux câbles à fibres optiques, bien que les informations concernant le point spécifique de défaillance, le dispositif de contrôle de la continuité, l'échantillon d'essai, la procédure d'essai et le rapport d'essai pour les câbles métalliques de données et de télécommunications et pour les câbles à fibres optiques ne soient pas données dans l'IEC 60331-2;

– amélioration de la description de l'environnement d'essai;

– utilisation obligatoire de débitmètres massiques/régulateurs comme moyens précis de contrôle des débits d'entrée de combustible et d'air au brûleur;

– amélioration de la figure représentant la méthode de montage de l'échantillon au niveau du rayon de courbure;

– amélioration de la description des informations à inclure dans le rapport d'essai.

General Information

- Status

- Published

- Publication Date

- 27-Mar-2018

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 18 - TC 20/WG 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 28-Mar-2018

- Completion Date

- 20-Apr-2018

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 60331-2:2018 is an International Electrotechnical Commission standard that defines a test method for circuit integrity of electric cables under fire with mechanical shock. The method applies to cables with an overall diameter not exceeding 20 mm and rated voltage up to and including 0,6/1,0 kV (600 V/1 000 V). The test simulates a fire environment at a temperature of at least 830 °C combined with a shock event to verify that cables can maintain electrical continuity under extreme fire conditions.

Keywords: IEC 60331-2, circuit integrity, fire with shock, electric cables, 830 °C, 0.6/1.0 kV

Key Topics and Requirements

- Scope and applicability

- Intended for electric power and control cables (≤ 600 V/1 000 V) and can be used, by agreement, for higher voltages up to 1,8/3 (3,3) kV with suitable fusing.

- Extended to include metallic data/telecom and optical fibre cables; however, specific continuity-checking and reporting details for those cable types are not provided in this part.

- Test environment and apparatus

- Fire source producing at least 830 °C, mounted relative to a standard test wall and specimen mounting arrangement.

- Mandatory use of mass flow meters/controllers for accurate control of fuel and air delivery to the burner.

- Annex A specifies verification procedures for the burner and control system.

- Specimen preparation and mounting

- Limits on overall diameter (≤ 20 mm) and defined methods for mounting and bending radius of samples to ensure repeatable results.

- Continuity checking and failure criteria

- Detailed continuity checking arrangements, specific point of failure definition and electrical connections are given for power/control cables up to 600 V/1 000 V.

- Test procedure, reporting & marking

- Requirements for the test sequence, shock application, test report content and optional cable identification marking to indicate compliance.

Keywords: burner verification, mass flow controllers, continuity checking, test report, cable marking

Practical Applications and Who Uses This Standard

- Cable manufacturers use IEC 60331-2 to design and validate fire-resistant cables and to support product claims of circuit integrity under fire with shock.

- Independent test laboratories adopt the method to perform standardized cable fire/shock tests and issue test reports for certification and procurement.

- Specifiers, procurement and safety engineers (buildings, tunnels, transport systems, industrial plants) reference the standard to select cables for emergency circuits, fire detection, alarm and safety-critical power/control systems.

- Certification bodies and compliance teams use the documented procedure and reporting requirements to assess conformity and to allow optional marking on compliant cable products.

Keywords: cable testing, fire-resistant cables, emergency circuits, safety-critical cables

Related Standards

- IEC 60331 series (other parts): Part 1 (larger diameter cables), Part 3 (metal enclosure tests), and associated parts (11, 21, 23, 25) that address alternative apparatus and procedures for different cable types and test conditions.

Buy Documents

IEC 60331-2:2018 - Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm Released:3/28/2018

IEC 60331-2:2018 RLV - Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830°C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20mm Released:3/28/2018

IEC 60331-2:2018 - Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm Released:11/8/2018

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60331-2:2018 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Tests for electric cables under fire conditions - Circuit integrity - Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm". This standard covers: IEC 60331-2:2018 specifies the test method for cables which are required to maintain circuit integrity when subject to fire and mechanical shock under specified conditions. This document is applicable to cables of rated voltage not exceeding 600 V/1 000 V, including those of rated voltage below 80 V, metallic data and telecom cables and optical fibre cables. It is intended for use when testing cables of not greater than 20 mm overall diameter. Cables of larger diameter are intended to be tested using the apparatus, procedure and requirements of IEC 60331-1. This document includes details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to electric power and control cables with rated voltage up to and including 600 V/1000 V. Details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallic data and telecom cables and optical fibre cables are not given by IEC 60331-2. Although the scope is restricted to cables with rated voltage up to and including 0,6/1,0 kV, the procedure can be used, with the agreement of the manufacturer and the purchaser, for cables with rated voltage up to and including 1,8/3 (3,3) kV, provided that suitable fuses are used. Annex A provides the method of verification of the burner and control system used for the test. Requirements are stated for an identification that may optionally be marked on the cable to signify compliance with this standard. This second edition cancels and replaces the first edition published in 2009. It constitutes a technical revision. The significant technical changes with respect to the previous edition are as follows: – extension of the scope with metallic data and telecom cables and optical fibre cables, although details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallicdata and telecom cables and optical fibre cables are not given by IEC 60331-2; – improved description of the test environment; – mandatory use of mass flow meters/controllers as the means of controlling accurately the input flow rates of fuel and air to the burner; – improved figure illustrating method of mounting of the sample regarding bending radius; – improved description of the information to be included in the test report.

IEC 60331-2:2018 specifies the test method for cables which are required to maintain circuit integrity when subject to fire and mechanical shock under specified conditions. This document is applicable to cables of rated voltage not exceeding 600 V/1 000 V, including those of rated voltage below 80 V, metallic data and telecom cables and optical fibre cables. It is intended for use when testing cables of not greater than 20 mm overall diameter. Cables of larger diameter are intended to be tested using the apparatus, procedure and requirements of IEC 60331-1. This document includes details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to electric power and control cables with rated voltage up to and including 600 V/1000 V. Details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallic data and telecom cables and optical fibre cables are not given by IEC 60331-2. Although the scope is restricted to cables with rated voltage up to and including 0,6/1,0 kV, the procedure can be used, with the agreement of the manufacturer and the purchaser, for cables with rated voltage up to and including 1,8/3 (3,3) kV, provided that suitable fuses are used. Annex A provides the method of verification of the burner and control system used for the test. Requirements are stated for an identification that may optionally be marked on the cable to signify compliance with this standard. This second edition cancels and replaces the first edition published in 2009. It constitutes a technical revision. The significant technical changes with respect to the previous edition are as follows: – extension of the scope with metallic data and telecom cables and optical fibre cables, although details for the specific point of failure, continuity checking arrangement, test sample, test procedure and test report relevant to metallicdata and telecom cables and optical fibre cables are not given by IEC 60331-2; – improved description of the test environment; – mandatory use of mass flow meters/controllers as the means of controlling accurately the input flow rates of fuel and air to the burner; – improved figure illustrating method of mounting of the sample regarding bending radius; – improved description of the information to be included in the test report.

IEC 60331-2:2018 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.020 - Electrical engineering in general; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60331-2:2018 has the following relationships with other standards: It is inter standard links to IEC 60331-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60331-2:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60331-2 ®

Edition 2.0 2018-03

INTERNATIONAL

STANDARD

GROUP SAFETY PUBLICATION

Tests for electric cables under fire conditions – Circuit integrity –

Part 2: Test method for fire with shock at a temperature of at least 830 °C for

cables of rated voltage up to and including 0,6/1,0 kV and with an overall

diameter not exceeding 20 mm

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60331-2 ®

Edition 2.0 2018-03

INTERNATIONAL

STANDARD

GROUP SAFETY PUBLICATION

Tests for electric cables under fire conditions – Circuit integrity –

Part 2: Test method for fire with shock at a temperature of at least 830 °C for

cables of rated voltage up to and including 0,6/1,0 kV and with an overall

diameter not exceeding 20 mm

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.220.40; 29.020; 29.060.20 ISBN 978-2-8322-5490-5

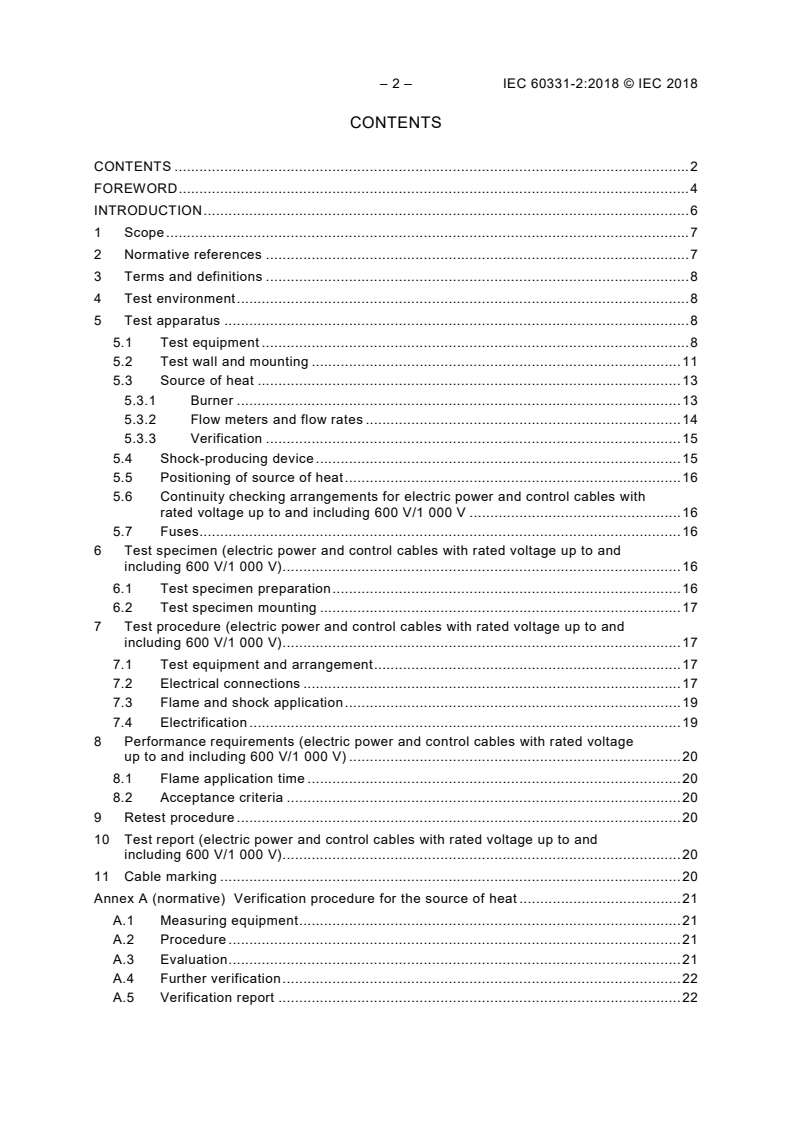

– 2 – IEC 60331-2:2018 © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Test environment . 8

5 Test apparatus . 8

5.1 Test equipment . 8

5.2 Test wall and mounting . 12

5.3 Source of heat . 14

5.3.1 Burner . 14

5.3.2 Flow meters and flow rates . 15

5.3.3 Verification . 16

5.4 Shock-producing device . 16

5.5 Positioning of source of heat . 17

5.6 Continuity checking arrangements for electric power and control cables with

rated voltage up to and including 600 V/1 000 V . 17

5.7 Fuses. 17

6 Test specimen (electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 17

6.1 Test specimen preparation . 17

6.2 Test specimen mounting . 18

7 Test procedure (electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 18

7.1 Test equipment and arrangement . 18

7.2 Electrical connections . 18

7.3 Flame and shock application . 20

7.4 Electrification . 20

8 Performance requirements (electric power and control cables with rated voltage

up to and including 600 V/1 000 V) . 21

8.1 Flame application time . 21

8.2 Acceptance criteria . 21

9 Retest procedure . 21

10 Test report (electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 21

11 Cable marking . 21

Annex A (normative) Verification procedure for the source of heat . 22

A.1 Measuring equipment . 22

A.2 Procedure . 22

A.3 Evaluation . 22

A.4 Further verification . 23

A.5 Verification report . 23

Annex B (informative) Guidance on the choice of recommended test apparatus . 24

B.1 Burner and venturi . 24

B.2 Test wall material . 24

Bibliography . 25

Figure 1 – Schematic diagram of test configuration . 10

Figure 2 – Plan view of fire test equipment . 11

Figure 3 – End elevation of fire test equipment (not to scale) . 12

Figure 4 – Typical rubber bush (hardness: 50-60 shore A) for fastening wall . 14

Figure 5 – Burner face . 15

Figure 6 – Schematic diagram of an example of a burner control system . 16

Figure 7 – Example of method of mounting a sample for test . 18

Figure 8 – Basic circuit diagram – Electric power and control cables with rated voltage

up to 600 V/1 000 V . 20

Figure A.1 – Temperature measuring arrangement . 22

– 4 – IEC 60331-2:2018 © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TESTS FOR ELECTRIC CABLES UNDER FIRE CONDITIONS –

CIRCUIT INTEGRITY –

Part 2: Test method for fire with shock at a temperature of at least 830 °C

for cables of rated voltage up to and including 0,6/1,0 kV and with

an overall diameter not exceeding 20 mm

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60331-2 has been prepared by IEC technical committee 20:

Electric cables.

This second edition cancels and replaces the first edition published in 2009. It constitutes a

technical revision.

The significant technical changes with respect to the previous edition are as follows:

– extension of the scope with metallic data and telecom cables and optical fibre cables,

although details for the specific point of failure, continuity checking arrangement, test

sample, test procedure and test report relevant to metallicdata and telecom cables and

optical fibre cables are not given by IEC 60331-2;

– improved description of the test environment;

– mandatory use of mass flow meters/controllers as the means of controlling accurately the

input flow rates of fuel and air to the burner;

– improved figure illustrating method of mounting of the sample regarding bending radius;

– improved description of the information to be included in the test report.

The text of this International Standard is based on the following documents:

FDIS Report on voting

20/1783A/FDIS 20/1793/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a group safety publication in accordance with IEC Guide 104.

A list of all parts of the IEC 60331 series, published under the title: Tests for electric cables

under fire conditions – Circuit integrity, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

A bilingual version of this publication may be issued at a later date.

– 6 – IEC 60331-2:2018 © IEC 2018

INTRODUCTION

IEC 60331 consists of the following parts under the general title: Tests for Electric cables

under fire conditions – Circuit integrity:

Part 1: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

Part 3: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV tested in a metal enclosure

Part 11: Apparatus – Fire alone at a flame temperature of at least 750 °C

Part 21: Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

Part 23: Procedures and requirements – Electric data cables

Part 25: Procedures and requirements – Optical fibre cables

NOTE 1 Parts 21, 23 and 25 relate to fire-only conditions at a flame temperature of at least 750 °C.

NOTE 2 Parts 11, 21, 23 and 25 are no longer subject to maintenance. IEC 60331 Parts 1 and 2 are the

recommended test procedures

Since its first edition (1970), IEC 60331 has been extended and has introduced a range of test

apparatus in order that a test may be carried out on large and small power, control, data and

optical fibre cables.

Successful tests carried out in accordance with this standard will enable an identification to be

marked on the product.

TESTS FOR ELECTRIC CABLES UNDER FIRE CONDITIONS –

CIRCUIT INTEGRITY –

Part 2: Test method for fire with shock at a temperature of at least 830 °C

for cables of rated voltage up to and including 0,6/1,0 kV and with

an overall diameter not exceeding 20 mm

1 Scope

This part of IEC 60331 specifies the test method for cables which are required to maintain

circuit integrity when subject to fire and mechanical shock under specified conditions.

This document is applicable to cables of rated voltage not exceeding 600 V/1 000 V, including

those of rated voltage below 80 V, metallic data and telecom cables and optical fibre cables.

It is intended for use when testing cables of not greater than 20 mm overall diameter.

Cables of larger diameter are intended to be tested using the apparatus, procedure and

requirements of IEC 60331-1.

This document includes details for the specific point of failure, continuity checking

arrangement, test sample, test procedure and test report relevant to electric power and

control cables with rated voltage up to and including 600 V/1000 V. Details for the specific

point of failure, continuity checking arrangement, test sample, test procedure and test report

relevant to metallic data and telecom cables and optical fibre cables are not given by

IEC 60331-2.

Although the scope is restricted to cables with rated voltage up to and including 0,6/1,0 kV,

the procedure can be used, with the agreement of the manufacturer and the purchaser, for

cables with rated voltage up to and including 1,8/3 (3,3) kV, provided that suitable fuses are

used.

Annex A provides the method of verification of the burner and control system used for the

test.

Requirements are stated for an identification that may optionally be marked on the cable to

signify compliance with this standard.

CAUTION – The test given in this standard may involve the use of dangerous voltages

and temperatures. Suitable precautions should be taken against the risk of shock,

burning, fire and explosion that may be involved, and against any noxious fumes that

may be produced.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60584-1, Thermocouples – Part 1: EMF specifications and tolerances

– 8 – IEC 60331-2:2018 © IEC 2018

IEC 60269-3, Low-voltage fuses – Part 3: Supplementary requirements for fuses for use by

unskilled persons (fuses mainly for household and similar applications) – Examples of

standardized systems of fuses A to F

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

circuit integrity

ability of an electric cable to continue to operate in the designated manner whilst subjected to

a specified flame source for a specified period of time under specified conditions

3.2

draught-free environment

space in which the results of tests are not significantly affected by the local air speed

4 Test environment

The test shall be carried out in a draught-free environment within a suitable chamber, of

minimum volume 20 m , with facilities for disposing of any noxious gases resulting from the

burning. Sufficient ventilation shall be available to sustain the flame for the duration of the

test. Air inlets and the exhaust chimney should be located in such a way that the burner flame

remains stable during the verification procedure and test. If necessary, the burner shall be

shielded from any draughts by the use of draught shields. Windows may be installed in the

walls of the chamber in order to observe the behaviour of the cable during the test. Fume

exhaust should be achieved by means of natural draught through a chimney located at least

1 m from the burner. A damper may be used for adjustment of ventilation conditions.

NOTE Experience has shown a chamber similar to the "3 m cube" specified in IEC 61034-1 to be suitable.

The chamber and test apparatus shall be at a temperature of between 10 °C and 40 °C at the

start of each test.

The same ventilation and shielding conditions shall be used in the chamber during both the

verification and cable test procedures.

5 Test apparatus

5.1 Test equipment

The test equipment shall consist of the following:

a) a test wall onto which the cable is mounted, comprising a board manufactured from

heat-resistant, non-combustible material suitable for the temperatures involved fastened to

steel supports and mounted on a rigid support as described in 5.2;

b) a source of heat comprising a horizontally mounted ribbon burner as described in 5.3;

c) a shock-producing device as described in 5.4;

d) a test wall equipped with thermocouples for verification of the source of heat as described

in Annex A;

...

IEC 60331-2 ®

Edition 2.0 2018-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Tests for electric cables under fire conditions – Circuit integrity –

Part 2: Test method for fire with shock at a temperature of at least 830 °C for

cables of rated voltage up to and including 0,6/1,0 kV and with an overall

diameter not exceeding 20 mm

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing 21 000 terms and definitions in

Technical Specifications, Technical Reports and other English and French, with equivalent terms in 16 additional

documents. Available for PC, Mac OS, Android Tablets and languages. Also known as the International Electrotechnical

iPad. Vocabulary (IEV) online.

IEC publications search - webstore.iec.ch/advsearchform IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a 67 000 electrotechnical terminology entries in English and

variety of criteria (reference number, text, technical French extracted from the Terms and Definitions clause of

committee,…). It also gives information on projects, replaced IEC publications issued since 2002. Some entries have been

and withdrawn publications. collected from earlier publications of IEC TC 37, 77, 86 and

CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 60331-2 ®

Edition 2.0 2018-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Tests for electric cables under fire conditions – Circuit integrity –

Part 2: Test method for fire with shock at a temperature of at least 830 °C for

cables of rated voltage up to and including 0,6/1,0 kV and with an overall

diameter not exceeding 20 mm

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 13.220.40; 29.020; 29.060.20 ISBN 978-2-8322-5550-6

– 2 – IEC 60331-2:2018 RLV © IEC 2018

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 8

4 Test conditions – Test environment . 8

5 Test apparatus . 9

5.1 Test equipment . 9

5.2 Test wall and mounting . 12

5.3 Source of heat . 14

5.3.1 Burner . 14

5.3.2 Flow meters and flow rates . 14

5.3.3 Verification . 16

5.4 Shock-producing device . 16

5.5 Positioning of source of heat . 16

5.6 Continuity checking arrangements for electric power and control cables with

rated voltage up to and including 600 V/1 000 V . 16

5.7 Fuses. 16

6 Test specimen(electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 17

6.1 Test specimen preparation . 17

6.2 Test specimen mounting . 17

7 Test procedure(electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 18

7.1 Test equipment and arrangement . 18

7.2 Electrical connections . 18

7.3 Flame and shock application . 19

7.4 Electrification . 19

8 Performance requirements(electric power and control cables with rated voltage up

to and including 600 V/1 000 V) . 20

8.1 Flame application time . 20

8.2 Acceptance criteria . 20

9 Retest procedure . 20

10 Test report (electric power and control cables with rated voltage up to and

including 600 V/1 000 V) . 20

11 Cable marking . 21

Annex A (normative) Verification procedure for the source of heat . 22

A.1 Measuring equipment . 22

A.2 Procedure . 22

A.3 Evaluation . 22

A.4 Further verification . 23

A.5 Verification report . 23

Annex B (informative) Guidance on the choice of recommended test apparatus . 24

B.1 Burner and venturi . 24

B.2 Test wall material . 24

Influence of draughts in the test chamber .

Guidance on provision of a suitable test chamber .

Bibliography . 26

Figure 1 – Schematic diagram of test configuration . 10

Figure 2 – Plan view of fire test equipment . 11

Figure 3 – End elevation of fire test equipment (not to scale) . 12

Figure 4 – Typical rubber bush (hardness: 50-60 shore A) for fastening wall . 13

Figure 5 – Burner face . 14

Figure 6 – Schematic diagram of an example of a burner control system using

rotameters . 15

Figure 7 – Example of method of mounting a sample for test . 17

Figure 8 – Basic circuit diagram – Electric power and control cables with rated voltage

up to 600 V/1 000 V . 19

Figure A.1 – Temperature measuring arrangement . 22

– 4 – IEC 60331-2:2018 RLV © IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TESTS FOR ELECTRIC CABLES UNDER FIRE CONDITIONS –

CIRCUIT INTEGRITY –

Part 2: Test method for fire with shock at a temperature of at least 830 °C

for cables of rated voltage up to and including 0,6/1,0 kV and with

an overall diameter not exceeding 20 mm

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 60331-2 has been prepared by IEC technical committee 20:

Electric cables.

This second edition cancels and replaces the first edition published in 2009. It constitutes a

technical revision.

The significant technical changes with respect to the previous edition are as follows:

– extension of the scope with metallic data and telecom cables and optical fibre cables,

although details for the specific point of failure, continuity checking arrangement, test

sample, test procedure and test report relevant to metallicdata and telecom cables and

optical fibre cables are not given by IEC 60331-2;

– improved description of the test environment;

– mandatory use of mass flow meters/controllers as the means of controlling accurately the

input flow rates of fuel and air to the burner;

– improved figure illustrating method of mounting of the sample regarding bending radius;

– improved description of the information to be included in the test report.

The text of this International Standard is based on the following documents:

FDIS Report on voting

20/1783A/FDIS 20/1793/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

It has the status of a group safety publication in accordance with IEC Guide 104.

A list of all parts of the IEC 60331 series, published under the title: Tests for electric cables

under fire conditions – Circuit integrity, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in

the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The “colour inside” logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct understanding

of its contents. Users should therefore print this publication using a colour printer.

– 6 – IEC 60331-2:2018 RLV © IEC 2018

INTRODUCTION

IEC 60331 consists of the following parts under the general title: Tests for Electric cables

under fire conditions – Circuit integrity:

Part 1: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV and with an overall diameter exceeding 20 mm

Part 2: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV and with an overall diameter not exceeding 20 mm

Part 3: Test method for fire with shock at a temperature of at least 830 °C for cables of rated

voltage up to and including 0,6/1,0 kV tested in a metal enclosure

Part 11: Apparatus – Fire alone at a flame temperature of at least 750 °C

Part 21: Procedures and requirements – Cables of rated voltage up to and including 0,6/1,0 kV

Part 23: Procedures and requirements – Electric data cables

Part 25: Procedures and requirements – Optical fibre cables

NOTE 1 Parts 21, 23 and 25 relate to fire-only conditions at a flame temperature of at least 750 °C.

NOTE 2 Parts 11, 21, 23 and 25 are no longer subject to maintenance. IEC 60331 Parts 1 and 2 are the

recommended test procedures

Since its first edition (1970), IEC 60331 has been extended and has introduced a range of test

apparatus in order that a test may be carried out on large and small power, control, data and

optical fibre cables.

Successful tests carried out in accordance with this standard will enable an identification to be

marked on the product.

TESTS FOR ELECTRIC CABLES UNDER FIRE CONDITIONS –

CIRCUIT INTEGRITY –

Part 2: Test method for fire with shock at a temperature of at least 830 °C

for cables of rated voltage up to and including 0,6/1,0 kV and with

an overall diameter not exceeding 20 mm

1 Scope

This part of IEC 60331 specifies the test apparatus and procedure and gives the performance

requirements, including recommended flame application times, for low-voltage power cables

of rated voltage up to and including 0,6/1,0 kV and control cables with a rated voltage which

are required to maintain circuit integrity when subject to fire and mechanical shock under

specified conditions. It is intended for use when testing cables not greater than 20 mm overall

diameter.

This part of IEC 60331 specifies the test method for cables which are required to maintain

circuit integrity when subject to fire and mechanical shock under specified conditions.

This document is applicable to cables of rated voltage not exceeding 600 V/1 000 V, including

those of rated voltage below 80 V, metallic data and telecom cables and optical fibre cables.

It is intended for use when testing cables of not greater than 20 mm overall diameter.

NOTE Cables of larger diameter should are intended to be tested using the apparatus,

procedure and requirements of IEC 60331-1.

This standard describes the means of test specimen preparation, the continuity checking

arrangements, the electrical testing procedure, the method of burning the cables and the

method of shock production, and gives requirements for evaluating test results

This document includes details for the specific point of failure, continuity checking

arrangement, test sample, test procedure and test report relevant to electric power and

control cables with rated voltage up to and including 600 V/1000 V. Details for the specific

point of failure, continuity checking arrangement, test sample, test procedure and test report

relevant to metallic data and telecom cables and optical fibre cables are not given by

IEC 60331-2.

Although the scope is restricted to cables with rated voltage up to and including 0,6/1,0 kV,

the procedure can be used, with the agreement of the manufacturer and the purchaser, for

cables with rated voltage up to and including 1,8/3 (3,3) kV, provided that suitable fuses are

used.

Annex A provides the method of verification of the burner and control system used for the

test.

Requirements are stated for an identification that may optionally be marked on the cable to

signify compliance with this standard.

CAUTION – The test given in this standard may involve the use of dangerous voltages

and temperatures. Suitable precautions should be taken against the risk of shock,

burning, fire and explosion that may be involved, and against any noxious fumes that

may be produced.

– 8 – IEC 60331-2:2018 RLV © IEC 2018

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60584-1, Thermocouples – Part 1: Reference tables EMF specifications and tolerances

IEC 60269-3, Low-voltage fuses – Part 3: Supplementary requirements for fuses for use by

unskilled persons (fuses mainly for household and similar applications) – Examples of

standardized systems of fuses A to F

IEC Guide 104, The preparation of safety publications and the use of basic safety publications

and group safety publications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

circuit integrity

ability of an electric cable to continue to operate in the designated manner whilst subjected to

a specified flame source for a specified period of time under specified conditions

3.2

draught-free environment

space in which the results of tests are not significantly affected by the local air speed

4 Test conditions – Test environment

The test shall be carried out in a draught-free environment within a suitable chamber, of

minimum volume 10 20 m , with facilities for disposing of any noxious gases resulting from

the burning. Sufficient ventilation shall be available to sustain the flame for the duration of the

test. Air inlets and the exhaust chimney should be located in such a way that the burner flame

remains stable during the verification procedure and test. If necessary, the burner shall be

shielded from any draughts by the use of draught shields. Windows may be installed in the

walls of the chamber in order to observe the behaviour of the cable during the test. Fume

exhaust should be achieved by means of natural draught through a chimney located at least

1 m from the burner. A damper may be used for adjustment of ventilation conditions.

NOTE Guidance on the choice of suitable chambers is given in Annex B.

NOTE Experience has shown a chamber similar to the "3 m cube" specified in IEC 61034-1 to be suitable.

The chamber and test apparatus shall be at a temperature of between 10 °C and 40 °C at the

start of each test.

The same ventilation and shielding conditions shall be used in the chamber during both the

verification and cable test procedures.

NOTE The test given in this standard may involve the use of dangerous voltages and temperatures. Suitable

precautions should be taken against the risk of shock, burning, fire and explosion that may be involved, and

against any noxious fumes that may be produced.

5 Test apparatus

5.1 Test equipment

The test equipment shall consist of the following:

a) a test wall onto which the cable is mounted, comprising a board manufactured from

heat-resistant, non-combustible material with suitable for the temperatures involved

fastened to steel supports and mounted on a rigid support as described in 5.2;

b) a source of heat comprising a horizontally mounted ribbon burner as described in 5.3;

c) a shock-producing device as described in 5.4;

d) a test wall equipped with thermocouples for verification of the source of heat as described

in Annex A;

e) a continuity checking arrangement as described in 5.6;

f) fuses as described in 5.7.

A general arrangement of the test equipment is shown in Figure 1, Figure 2 and Figure 3.

– 10 – IEC 60331-2:2018 RLV © IEC 2018

Dimensions in millimetres

10 ±2

900 ±100

EC

Key

1 shock-producing device 4 ribbon gas burner

2 steel support 5 air inlet pipe

3 rubber bush 6 propane inlet pipe

Figure 1 – Schematic diagram of test configuration

300 ±50

Dimensions in millimetres

IEC

Key

1 entry for air 4 support framework

2 board 5 horizontal steel support for board

3 rubber bush 6 entry for propane gas

Figure 2 – Plan view of fire test equipment

900 ±100

– 12 – IEC 60331-2:2018 RLV © IEC 2018

Dimensions in millimetres

+5

60° 0

2 200 ±5

400 ±5

600 ±5

40 ±2

IEC

Key

1 shock-producing device 4 centre line of burner face

2 board 5 support framework

3 gas burner 6 test sample

V Vertical distance from centre line of burner to

the centre of the test specimen

Figure 3 – End elevation of fire test equipment

(not to scale)

5.2 Test wall and mounting

The test wall shall consist of a board of heat-resistant, non-combustible and non-metallic

material fastened rigidly to two horizontal steel supports, one at the top of the board and the

other at the bottom, as shown in Figure 1. Vertical supports may also be used. The board

shall be (900 ± 100) mm long, (300 ± 50) mm high and (10 ± 2) mm thick and the total mass of

the test wall (i.e. board and steel supports) shall be (10,0 ± 0,5) kg. Ballast, if required, shall

be placed on the steel supports.

25,0 ±0,1

V ±2

300 ±50

In case of dispute, a new board should be used for each test.

NOTE 1 Supports made from square section steel tube approximately 25 mm x 25 mm and approximately 1 m

long have been found to be suitable.

NOTE The top support should be fastened to the board so that its upper face is slightly above

the upper edge of the board, so that the shock-producing device impacts on the support and

not the board.

Each horizontal support shall have a mounting hole at each end, not more than 100 mm from

the edge of the board, the exact position and diameter being determined by the particular

supporting bush and supporting framework used. The test wall shall be fastened to a rigid

support by four bonded rubber bushes of hardness 50–60 Shore A fitted between the

horizontal steel supports of the wall and the support framework, as shown in Figure 1 and

Figure 2 so as to allow movement under impact.

NOTE 2 A typical rubber bush, which has been found to be suitable, is shown in Figure 4.

In order to check the mounting of the wall, the static deflection following application of a mass

to the centre of the upper support of the wall shall periodically be measured.

The values of mass and deflection shall comply with the following:

Mass Deflection

kg mm

25,0 ± 0,2 1,5 ± 0,3

Dimensions in millimetres

30-40

IEC

Figure 4 – Typical rubber bush (hardness: 50-60 shore A) for fastening wall

20-30

– 14 – IEC 60331-2:2018 RLV © IEC 2018

5.3 Source of heat

5.3.1 Burner

The source of heat shall be a ribbon type propane gas burner with a nominal burner face

length of 500 mm (outer distance between outer holes) with a venturi mixer. The nominal

burner face width shall be 10 mm. The face of the burner shall have three staggered rows of

drilled holes, nominally 1,32 mm in diameter and drilled at centres 3,2 mm from one another,

as shown in Figure 5.

A centre-feed burner is recommended.

Additionally, A row of small holes milled on each side of the burner plate, to serve as pilot

holes for keeping the flame burning, is permitted.

Guidance on the choice of a recommended burner system is given in Annex B.

Dimensions in millimetres

(Dimensions are approximate)

3,2

IEC

NOTE Round holes, 1,32 mm in diameter, on centres 3,2 mm from one another, staggered in three rows and

centred on the face of the burner. Nominal burner face length 500 mm.

Figure 5 – Burner face

5.3.2 Flow meters and flow rates

Mass flow meters/controllers should shall be used as the means of controlling accurately the

input flow rates of fuel and air to the burner.

NOTE Rotameter type flow meters may be used as an alternative, but are not recommended. Guidance on their

use, and the application of appropriate correction factors is given in IEC 60331-11:1999, Annex C.

NOTE Figure 6 shows an example of a rotameter type system.

For the purpose of this test, the air shall have a dew point not higher than 0 °C.

The mass flow rates used for the test shall be as follows:

– air: (80 ± 4) l/min at reference conditions (1 bar and 20 °C) or (1600 ± 80) mg/s;

– propane: (5,0 ± 0,2) l/min at reference conditions (1 bar and 20 °C) or (160 ± 6) mg/s.

Propane: (160 ± 6) mg/s

NOTE 1 This is approximately equivalent to a volume flow rate of (5,0 ± 0,2) litres/min at reference conditions

(1 bar and 20 °C).

3,2

4,5

NOTE The purity of the propane is not defined. Industrial grades that contain impurities are

allowed provided that the calibration requirements are achieved.

Air: (1 600 ± 80) mg/s

NOTE 2 This is approximately equivalent to a volume flow rate of (80 ± 4) litres/min at reference conditions

(1 bar and 20 °C).

A schematic diagram of an example of a burner control system is given in Figure 6.

6A

IEC

Key

1 regulator 9 mass flow meters

2 piezoelectric igniter 10 venturi mixer

3 flame failure device 11 burner

4 control thermocouples 12 ball valve

5 propane cylinder 13 air flow

6 screw valve (6A = alternative position) 14 compressed air cylinder

7 pilot feed 15 screw valve on pilot feed

8 gas flow

Figure 6 – Schematic diagram of an example of a burner control

system using rotameters

– 16 – IEC 60331-2:2018 RLV © IEC 2018

5.3.3 Verification

The burner and control system shall be subject to verification following the procedure given in

Annex A.

5.4 Shock-producing device

The shock producing device shall be a mild steel round bar (25,0 ± 0,1) mm in diameter and

(600 ± 5) mm long. The bar shall be freely pivoted about an axis parallel to the test wall,

which shall be in the same horizontal plane as, and (200 ± 5) mm away from, the upper edge

of the wall. The axis shall divide the bar into two unequal lengths, the longer length being

(400 ± 5) mm which shall impact the wall. The bar shall drop under its own weight from an

+5

angle of (60 ) ° to the horizontal to strike the upper steel support of the wall at its midpoint

as shown in Figure 1 and Figure 3.

5.5 Positioning of source of heat

The burner face shall be positioned in the test chamber so that it is at least 200 mm above the

floor of the chamber, or any solid mounting block, and at least 500 mm from any chamber

wall.

By reference to the centre point of the cable to be tested, the burner shall be positioned

centrally at a horizontal distance of (40 ± 2) mm from the burner face to the test wall and at a

vertical distance of (V ± 2) mm from the burner horizontal central plane to the central

horizontal plane of the test specimen, as shown in Figure 3 and Figure A.1.

The exact burner location to be used during cable testing shall be determined using the

verification procedure given in Annex A, where the value of V to be used shall be determined.

NOTE The burner should be rigidly fixed to the framework during testing so as to prevent

movement relative to the test sample specimen.

5.6 Continuity checking arrangements for electric power and control cables with rated

voltage up to and including 600 V/1 000 V

During the test, a current for continuity checking shall be passed through all conductors of the

test specimen. This shall be provided by a three-phase star-connected or single-phase

transformer(s) of sufficient capacity to maintain the test voltage up to the maximum leakage

current allowable.

NOTE 1 Due Note should be taken of the fuse characteristics when determining the power rating of the

transformer.

This current shall be achieved by connecting, at the other end of the test specimen, a suitable

load and an indicating device (e.g. lamp) to each conductor, or group of conductors.

NOTE 2 A current of 0,25 A at the test voltage, through each conductor or group of conductors, has been found to

be suitable.

5.7 Fuses

Fuses used in the test procedure in Clause 7 shall be of type DII, complying with IEC 60269-3

Fuse System A-D Type DII, 2A. Alternatively, a circuit-breaker with equivalent characteristics

may be used.

Where a circuit-breaker is used, its equivalent characteristics shall be demonstrated by

reference to the characteristic curve shown in IEC 60269-3.

The test method using fuses shall be the reference method in the case of dispute.

6 Test specimen (electric power and control cables with rated voltage up to

and including 600 V/1 000 V)

6.1 Test specimen preparation

A cable sample at least 4,5 3,6 m long shall be available from the cable length for test. Each

individual test specimen to be tested shall be a piece of cable, taken from the cable sample,

not less than 1 200 mm long with approximately 100 mm of sheath or outer covering removed

at each end.

At each end of the test specimen, each conductor shall be suitably prepared for electrical

connections, and, if there is more than one conductor, the exposed conductors shall be

spread apart to avoid contact with each other.

6.2 Test specimen mounting

The test specimen shall be bent to form an approximate “U” shape. The internal radius of

each bend shall be the manufacturer’s declared minimum bending radius in normal use and

the overall distance between the vertical portions of the cable shall be (475 ± 10) mm as

shown in Figure 7.

The test specimen shall be mounted centrally on the wall using metal clips which shall be

earthed. The lower edge of the cable shall be (200 ± 10) mm below the top of the test wall.

P-clips made of metal strip (10 ± 1) mm wide shall support the test specimen at either both

ends of the radiused section and in the centre as shown in Figure 7. The P-clips shall be

formed so as to have approximately the same diameter as the cable under test.

Dimensions in millimetres

900 ±100

R

475 ±10

IEC

Key

1 metal clips

R minimum bending radius of cables in normal use

Figure 7 – Example of method of mounting a sample for test

300 ±50

200 ±10

– 18 – IEC 60331-2:2018 RLV © IEC 2018

7 Test procedure (electric power and control cables with rated voltage up to

and including 600 V/1 000 V)

7.1 Test equipment and arrangement

The test procedure defined in this clause shall be carried out using the apparatus detailed in

Clause 5.

Mount the test specimen on the test wall and adjust the burner to the correct position relative

to the specimen in accordance with 5.5.

7.2 Electrical connections

At the transformer end of the test specimen, earth the neutral conductor, if present, and any

protective conductors. Any metal screens, drain wire or metallic layer shall be interconnected

and earthed. Connect the transformer(s) to the conductors, excluding any conductor which is

specifically identified as intended for use as a neutral or a protective conductor, as shown in

the circuit diagram in Figure 8. Where a metallic sheath, armour or screen acts as a neutral or

protective conductor, it shall be connected, as shown in the circuit diagram in Figure 8, as for

a neutral or protective conductor.

For single-, twin- or three-phase conductor cables, connect each phase conductor to a

separate phase of the transformer(s) output with a 2 A fuse or circuit-breaker with equivalent

characteristics in each phase.

For multicore cables that have four or more conductors (excluding any neutral or protective

conductors), the conductors shall be divided into three roughly equal groups, ensuring that

adjacent conductors are, as far as possible, in different groups.

For multipair cables, the conductors shall be divided into two equal groups, ensuring that the

a-core of each pair is connected to one phase and the b-core of each pair is connected to

another phase (L1 and L2 in Figure 8). Quads shall be treated as two pairs.

For multi-triple cables, the conductors shall be divided into three equal groups, ensuring that

the a-core of each triple is connected to one phase, the b-core of each triple to another phase

and the c-core of each triple to the third phase of the transformer (L1, L2 and L3 in Figure 8).

Connect the conductors of each group in series and connect each group to a separate phase

of the transformer output with a 2 A fuse or circuit-breaker with equivalent characteristics in

each phase.

NOTE The above test procedure connects the neutral conductor to earth. This may not be

appropriate if the cable is designed for use on a system where neutral is not earthed. If

required by the cable standard it is permissible for the neutral conductor to be tested as if it

were a phase conductor. Where a metallic sheath, armour or screen acts as a neutral

conductor, it shall always be connected to earth. Any such variations in methodology should

be included in the test report.

NOTE For cable constructions not specifically identified above, the test voltage should be

applied, as far as is practicable, to ensure that adjacent conductors are connected to different

phases.

NOTE In certain cases, for example when testing a control cable using a three-phase

transformer, it may not be possible to apply a test voltage between conductors and from

conductor to earth equal to the rated voltage simultaneously. In such cases, either the test

voltage between conductors, or the test voltage from conductor to earth shall be equal to the

rated voltage, such that both the test voltage between conductors and the test voltage from

conductor to earth is equal to or higher than the rated voltage.

At the end of the test specimen remote from the transformer:

– connect each phase conductor, or group of conductors, to one terminal of the load and

indicating device (as described in 5.6), the other terminal being earthed;

– connect the neutral conductor and any protective conductor to one terminal of the load

and indicating device (as described in 5.6), the other terminal being connected to L1 (or

L2 or L3) at the transformer end (see Figure 8).

3 6

2 5

L3 L3

L2 L2

L1

L1

N

PE

N

IECI

Key

L1, L2, L3 phase conductors (L2, L3 if present)

N neutral conductor (if present)

PE protective earth (if present)

1 Transformer 5 test conductor or group

2 fuse (2 A) 6 load and indicating device (e.g. lamp)

3 connection to phase L1 (or L2 or L3) 7 test specimen

4 metal clips 8 metal screen (if present)

Figure 8 – Basic circuit diagram – Electric power and control cables

with rated voltage up to 600 V/1 000 V

7.3 Flame and shock application

Ignite the burner and adjust the propane and air flow rates to those obtained during the

verification procedure (see Annex A).

Immediately after igniting the burner, activate the shock-producing device and start the test

duration timer. The shock-producing device shall impact the wall after 5 min ± 10 s from

activation and subsequently at 5 min ± 10 s intervals. After each impact, the impacting bar

shall be raised from the test wall no more than 20 s after the impact.

7.4 Electrification

Immediately after starting the test duration timer, switch on the electricity supply and adjust

the voltage to the rated voltage of the cable (subject to a minimum voltage of 100 V AC),

i.e. the test voltage between conductors shall equal the rated voltage between conductors,

and the test voltage from conductor to earth shall equal the rated voltage from conductor to

earth.

– 20 – IEC 60331-2:2018 RLV © IEC 2018

The test shall continue for the flame application time given in 8.1, after which the flame shall

be extinguished.

8 Performance requirements (electric power and control cables with rated

voltage up to and including 600 V/1 000 V)

8.1 Flame application time

The flame application time shall be as specified in the relevant cable standard. In the absence

of such a standard, a flame and impact application of 30 min, 60 min, 90 min or 120 min shall

be chosen.

8.2 Acceptance criteria

With reference to the test procedure given in Clause 7, the cable possesses the

characteristics for providing circuit integrity so long as during the course of the test

– the voltage is maintained, i.e. no fuse fails or circuit-breaker is interrupted,

– a conductor does not rupture, i.e. the lamp is not extinguished.

Failure by either one of the criteria listed shall be sufficient to show a failure for that cable.

9 Retest procedure

In the event of a failure, as judged by the requirements of the relevant standard, two further

test specimens, taken from the same cable sample, shall be tested. If both comply, the test

shall be deemed successful.

10 Test report (electric power and control cables with rated voltage up to and

including 600 V/1 000 V)

The test report shall include the following information:

a) the number of this standard;

b) a full description of the cable tested;

c) the manufacturer of the cable tested;

d) the test voltage and actual applied electrical connections, in accordance with Paragraphs

7 to 9 of 7.2;

e) any option used in the test procedure (i.e. type of test wall, failure detection method);

f) the type and disposition of clips supporting cable sample;

g) the actual cable bending radius used for the test;

h) the method used for temperature monitoring during the verification procedure;

i) the point of failure mechanism (i.e. voltage not maintained or conductor rupture);

j) the actual performance requirement applied (by reference to Clause 8);

k) the flame application time;

l) the chamber volume and temperature at the start of the test.

11 Cable marking

If a cable is required to be marked to signify compliance with this standard, it shall be marked

with the number of this standard and the duration of flame a

...

IEC 60331-2 ®

Edition 2.0 2018-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Tests for electric cables under fire conditions – circuit integrity –

Part 2: Test method for fire with shock at a temperature of at least 830 °C for

cables of rated voltage up to and including 0,6/1,0 kV and with an overall

diameter not exceeding 20 mm

Essais pour câbles électriques soumis au feu – intégrité des circuits –

Partie 2: Méthode d'essai au feu avec chocs pour les câbles de tension assignée

au plus égale à 0,6/1,0 kV et de diamètre externe inférieur ou égal à 20 mm, à une

température d'au moins 830 °C

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des