IEC 60754-1:2011

(Main)Test on gases evolved during combustion of materials from cables - Part 1: Determination of the halogen acid gas content

Test on gases evolved during combustion of materials from cables - Part 1: Determination of the halogen acid gas content

IEC 60754-1:2011 specifies the apparatus and procedure for the determination of the amount of halogen acid gas, other than hydrofluoric acid, evolved during the combustion of compounds based on halogenated polymers and compounds containing halogenated additives taken from electric or optical fibre cable constructions. The method specified in this standard is intended for the testing of individual components used in a cable construction. The use of this method will enable the verification of requirements which are stated in the appropriate cable specification for individual components of a cable construction. The significant technical changes with respect to the previous edition are as follows:

- improved definition of safety requirements relating to capture of gases and use of reagents;

- introduction of guidance on preparation of test specimens for a more even combustion;

- improvements to the procedure for establishing the heating regime;

- improved expression of tolerances and precision;

- definition of the procedure for the blank test;

- introduction of an informative annex giving details of a methodology for the determination of the halogen acid gas content of a sample representative of a cable construction.

The contents of the corrigendum of November 2013 have been included in this copy.

Essai sur les gaz émis lors de la combustion des matériaux des câbles - Partie 1: Détermination de la quantité de gaz acide halogéné

La CEI 60754-1:2011 décrit l'appareillage et la procédure d'essai pour la détermination de la quantité de gaz acide halogéné, autre que l'acide fluorhydrique, émis au cours de la combustion de mélanges à base de polymères halogénés et de mélanges contenant des additifs halogénés prélevés sur un câble électrique ou à fibre optique. La présente méthode décrite dans cette norme est destinée à être utilisée pour l'analyse des composants individuels utilisés dans la construction d'un câble. L'emploi de cette méthode d'essai permettra de vérifier les exigences qui sont établies dans la spécification du câble pour les composants individuels du câble. Les modifications techniques importantes par rapport aux publications antérieures sont les suivantes:

- amélioration définition des exigences de sécurité relatives au piégeage des gaz et à l'utilisation des réactifs;

- introduction de recommandations pour la préparation des éprouvettes d'essai pour une meilleure combustion;

- améliorations du mode opératoire pour établir le régime de chauffage;

- amélioration de l'expression des tolérances et précisions;

- définition de la procédure d'un essai à blanc;

- introduction d'une annexe informative donnant des détails sur la méthodologie pour la détermination de la quantité de gaz acides halogénés contenus dans un échantillon représentatif de la construction du câble.

Le contenu du corrigendum de novembre 2013 a été pris en considération dans cet exemplaire.

General Information

- Status

- Published

- Publication Date

- 16-Nov-2011

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 18 - TC 20/WG 18

- Current Stage

- PPUB - Publication issued

- Start Date

- 17-Nov-2011

- Completion Date

- 31-Oct-2011

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60754-1:2011 is an international standard published by the International Electrotechnical Commission (IEC) that specifies the test method for determining the amount of halogen acid gases evolved during the combustion of materials sourced from electrical and optical fibre cables. Specifically, this standard covers halogen acid gases except hydrofluoric acid, which are released when halogenated polymer-based compounds or those containing halogenated additives within cable constructions burn.

The significance of IEC 60754-1 lies in its focus on safety and performance evaluation of cable components. It provides a reliable and repeatable procedure for manufacturers and testing laboratories to verify compliance with halogen acid gas emission limits stated in cable specifications, ensuring minimal corrosive damage to adjacent electrical and electronic equipment during fire incidents.

Key Topics

- Test Methodology: IEC 60754-1 describes a detailed apparatus setup including tube furnaces, quartz glass tubes, combustion boats, gas bubbling devices, and air supply systems necessary to simulate controlled combustion conditions for cable materials.

- Specimen Preparation: Guidance is provided on conditioning and preparing test specimens to ensure even combustion and accurate results.

- Heating Regime: The standard includes procedures for determining and applying the proper heating regime for sample combustion to generate representative gas outputs.

- Halogen Acid Gas Measurement: The evolved gases are absorbed and chemically analyzed to quantify halogen acid gas content, while excluding hydrofluoric acid.

- Safety Requirements: Emphasis on safe capture of evolved gases and careful handling of reagents is detailed to protect testing personnel and prevent environmental contamination.

- Blank Test Procedure: Inclusion of a blank test to establish baseline measurements and ensure accuracy.

- Result Evaluation: Methods for calculating halogen acid content and interpreting the test results are standardized.

- Informative Annex: An annex describes techniques for assessing halogen acid gas emissions from a sample representative of an entire cable construction.

Applications

IEC 60754-1 has practical applications across the electrical and electronics industries:

- Cable Manufacturing Quality Control: Ensures that cable components comply with safety specifications regarding halogen acid gas emissions during combustion, facilitating the production of safer cables.

- Fire Safety Assessment: Enables fire safety engineers and regulatory bodies to evaluate the potential corrosive hazards posed by cable materials in fire scenarios.

- Material Research and Development: Assists R&D teams in selecting or formulating cable insulation and sheathing materials with reduced harmful gas emissions.

- Compliance and Certification Testing: Provides an internationally recognized method for certification laboratories to perform accredited testing on cable materials.

- Incident Investigation: Supports forensic analyses of cable fires by quantifying acid gases that may have contributed to equipment damage.

- Standards Harmonization: Helps harmonize international cable safety standards by offering a unified testing approach.

Related Standards

IEC 60754-1 is part of a series focused on gases evolved during cable combustion:

- IEC 60754-2: Determination of acidity by pH measurement and conductivity of gases evolved during cable combustion.

- IEC 60754-3: Measurement of low levels of halogen content using ion chromatography techniques.

These complementary parts collectively address different aspects of gas emission testing to provide a comprehensive safety profile of cable materials under fire conditions.

IEC 60754-1:2011 is essential for stakeholders requiring high standards in cable safety and environmental considerations. By adopting this standard, manufacturers and testing bodies can mitigate risks related to halogen acid gases, protecting equipment, infrastructure, and human health in the event of cable fires.

IEC 60754-1:2011 - Test on gases evolved during combustion of materials from cables - Part 1: Determination of the halogen acid gas content

IEC 60754-1:2011+AMD1:2019 CSV - Test on gases evolved during combustion of materials from cables - Part 1: Determination of the halogen acid gas content Released:11/25/2019 Isbn:9782832276587

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

IEC 60754-1:2011 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Test on gases evolved during combustion of materials from cables - Part 1: Determination of the halogen acid gas content". This standard covers: IEC 60754-1:2011 specifies the apparatus and procedure for the determination of the amount of halogen acid gas, other than hydrofluoric acid, evolved during the combustion of compounds based on halogenated polymers and compounds containing halogenated additives taken from electric or optical fibre cable constructions. The method specified in this standard is intended for the testing of individual components used in a cable construction. The use of this method will enable the verification of requirements which are stated in the appropriate cable specification for individual components of a cable construction. The significant technical changes with respect to the previous edition are as follows: - improved definition of safety requirements relating to capture of gases and use of reagents; - introduction of guidance on preparation of test specimens for a more even combustion; - improvements to the procedure for establishing the heating regime; - improved expression of tolerances and precision; - definition of the procedure for the blank test; - introduction of an informative annex giving details of a methodology for the determination of the halogen acid gas content of a sample representative of a cable construction. The contents of the corrigendum of November 2013 have been included in this copy.

IEC 60754-1:2011 specifies the apparatus and procedure for the determination of the amount of halogen acid gas, other than hydrofluoric acid, evolved during the combustion of compounds based on halogenated polymers and compounds containing halogenated additives taken from electric or optical fibre cable constructions. The method specified in this standard is intended for the testing of individual components used in a cable construction. The use of this method will enable the verification of requirements which are stated in the appropriate cable specification for individual components of a cable construction. The significant technical changes with respect to the previous edition are as follows: - improved definition of safety requirements relating to capture of gases and use of reagents; - introduction of guidance on preparation of test specimens for a more even combustion; - improvements to the procedure for establishing the heating regime; - improved expression of tolerances and precision; - definition of the procedure for the blank test; - introduction of an informative annex giving details of a methodology for the determination of the halogen acid gas content of a sample representative of a cable construction. The contents of the corrigendum of November 2013 have been included in this copy.

IEC 60754-1:2011 is classified under the following ICS (International Classification for Standards) categories: 13.220.40 - Ignitability and burning behaviour of materials and products; 29.020 - Electrical engineering in general; 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60754-1:2011 has the following relationships with other standards: It is inter standard links to IEC 60754-1:2011/AMD1:2019, IEC 60754-1:2011/COR1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60754-1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 60754-1 ®

Edition 3.0 2011-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the halogen acid gas content

Essai sur les gaz émis lors de la combustion des matériaux prélevés sur câbles

– Partie 1: Détermination de la quantité de gaz acide halogéné

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60754-1 ®

Edition 3.0 2011-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the halogen acid gas content

Essai sur les gaz émis lors de la combustion des matériaux prélevés sur câbles

– Partie 1: Détermination de la quantité de gaz acide halogéné

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX S

ICS 13.220.40; 29.020; 29.060.20 ISBN 978-2-88912-715-3

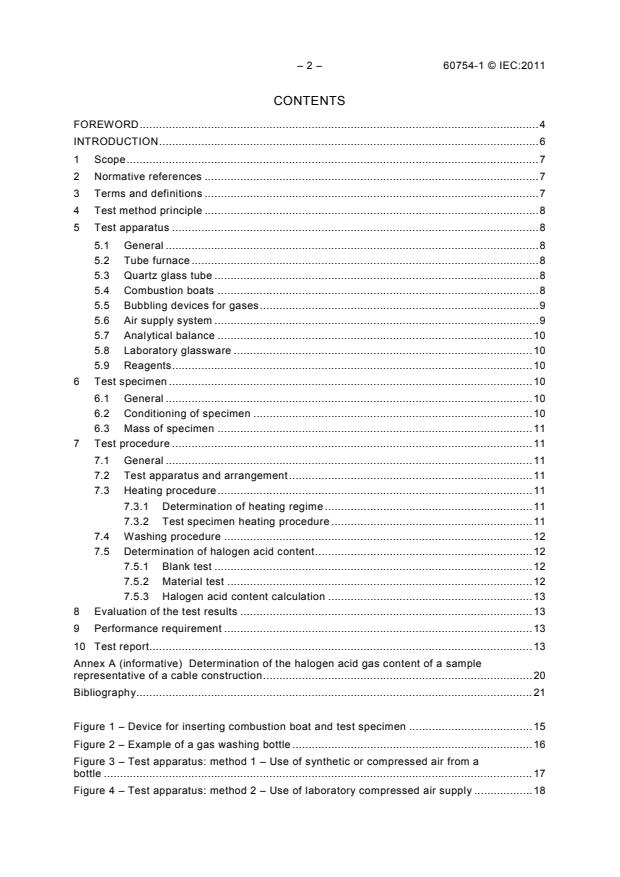

– 2 – 60754-1 © IEC:2011

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Test method principle . 8

5 Test apparatus . 8

5.1 General . 8

5.2 Tube furnace . 8

5.3 Quartz glass tube . 8

5.4 Combustion boats . 8

5.5 Bubbling devices for gases . 9

5.6 Air supply system . 9

5.7 Analytical balance . 10

5.8 Laboratory glassware . 10

5.9 Reagents . 10

6 Test specimen . 10

6.1 General . 10

6.2 Conditioning of specimen . 10

6.3 Mass of specimen . 11

7 Test procedure . 11

7.1 General . 11

7.2 Test apparatus and arrangement . 11

7.3 Heating procedure . 11

7.3.1 Determination of heating regime . 11

7.3.2 Test specimen heating procedure . 11

7.4 Washing procedure . 12

7.5 Determination of halogen acid content . 12

7.5.1 Blank test . 12

7.5.2 Material test . 12

7.5.3 Halogen acid content calculation . 13

8 Evaluation of the test results . 13

9 Performance requirement . 13

10 Test report. 13

Annex A (informative) Determination of the halogen acid gas content of a sample

representative of a cable construction . 20

Bibliography . 21

Figure 1 – Device for inserting combustion boat and test specimen . 15

Figure 2 – Example of a gas washing bottle . 16

Figure 3 – Test apparatus: method 1 – Use of synthetic or compressed air from a

bottle . 17

Figure 4 – Test apparatus: method 2 – Use of laboratory compressed air supply . 18

60754-1 © IEC:2011 – 3 –

Figure 5 – Test apparatus: method 3 – Use of ambient air sucked by means of a

suction pump . 19

– 4 – 60754-1 © IEC:2011

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST ON GASES EVOLVED DURING

COMBUSTION OF MATERIALS FROM CABLES –

Part 1: Determination of the halogen acid gas content

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60754-1 has been prepared by IEC technical committee 20:

Electric cables.

It has the status of a group safety publication in accordance with IEC Guide 104.

This third edition cancels and replaces the second edition, published in 1994, and constitutes

a technical revision.

The significant technical changes with respect to the previous edition are as follows:

– improved definition of safety requirements relating to capture of gases and use of

reagents;

– introduction of guidance on preparation of test specimens for a more even combustion;

– improvements to the procedure for establishing the heating regime;

– improved expression of tolerances and precision;

60754-1 © IEC:2011 – 5 –

– definition of the procedure for the blank test;

– introduction of an informative annex giving details of a methodology for the determination

of the halogen acid gas content of a sample representative of a cable construction.

The text of this standard is based on the following documents:

FDIS Report on voting

20/1266/FDIS 20/1276/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60754 series, published under the general title Test on gases

evolved during combustion of materials from cables, can be found on the IEC website.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

The contents of the corrigendum of November 2013 have been included in this copy.

– 6 – 60754-1 © IEC:2011

INTRODUCTION

IEC 60754 consists of the following parts, under the general title Test on gases evolved

during combustion of materials from cables:

– Part 1: Determination of the halogen acid gas content

– Part 2: Determination of acidity (by pH measurement) and conductivity

IEC 60754-1 was developed due to concerns expressed by cable users over the amount of

acid gas which is evolved when some cable insulating, sheathing and other materials are

burned, as this acid can cause extensive damage to electrical and electronic equipment not

involved in the fire itself.

This standard provides a method for determining the amount of acid gases evolved by burning

cable components so that limits can be agreed for cable specifications. As the test is not

carried out on a complete cable test piece, for a hazard assessment the actual material

volumes of the cable components should be taken into consideration.

60754-1 © IEC:2011 – 7 –

TEST ON GASES EVOLVED DURING

COMBUSTION OF MATERIALS FROM CABLES –

Part 1: Determination of the halogen acid gas content

1 Scope

This part of IEC 60754 specifies the apparatus and procedure for the determination of the

amount of halogen acid gas, other than hydrofluoric acid, evolved during the combustion of

compounds based on halogenated polymers and compounds containing halogenated

additives taken from electric or optical fibre cable constructions.

NOTE 1 This test method is not able to determine hydrofluoric acid. A suitable method may be found in

IEC 60684-2.

NOTE 2 This test method may be used to test materials to be used in cable manufacture, but a declaration of

cable performance should not be made based on such a test.

NOTE 3 The relevant cable standard should indicate which components of the cable should be tested.

NOTE 4 For the purposes of this standard, the term “electric cable” covers all insulated metallic conductor cables

used for the conveyance of energy or signals.

The method specified in this standard is intended for the testing of individual components

used in a cable construction. The use of this method will enable the verification of

requirements which are stated in the appropriate cable specification for individual components

of a cable construction.

NOTE 5 By agreement between the producer and purchaser, the methodology given in this standard may be used

to test combinations of materials representing a cable construction, but a declaration of cable performance to this

standard should not be made based on such a test. Information on such a method is given in Annex A.

For reasons of precision this method is not recommended for reporting values of halogen acid

evolved less than 5 mg/g of the sample taken.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

ISO 385, Laboratory glassware – Burettes

ISO 1042, Laboratory glassware – One-mark volumetric flasks

ISO 3696, Water for analytical laboratory use – Specification and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

halogen acid gas content

amount of halogen acid gas evolved, except hydrofluoric acid, expressed as milligrams of

hydrochloric acid per gram of total test specimen

– 8 – 60754-1 © IEC:2011

4 Test method principle

The material under test shall be heated in a stream of dry air and the gases shall be absorbed

in 0,1 M sodium hydroxide solution contained in wash bottles. The amount of halogen acid

shall then be determined by acidifying the solution with nitric acid, adding a measured volume

of 0,1 M silver nitrate solution and back titrating the excess with 0,1 M ammonium

thiocyanate, using ferric ammonium sulphate as the indicator.

NOTE 1 Other analytical methods having at least the same precision may be used, but in case of dispute the

method given in this standard is the one to use.

NOTE 2 Although both hydrogen chloride and hydrogen bromide are detected by this analytical method, the

halogen acid content is reported as if all the halogen acid is hydrogen chloride.

5 Test apparatus

5.1 General

The apparatus is shown in Figures 1 to 5.

The assembly of the components which constitute the test apparatus shall be leak-tight. The

connecting distances between the quartz glass tube and the first bottle and between

subsequent bottles shall be as short as possible. Glass or silicone rubber tubing shall be used

for these connections.

NOTE 1 At the exit side of the quartz glass tube, as close to the end as possible, it is permitted to place a plug of

silica wool to aid collection of condensates.

NOTE 2 A third empty bottle, of the same size as the gas washing bottles, placed before the gas washing bottles,

may be used to improve safety, i.e. to prevent suck back of water into the quartz glass tube.

5.2 Tube furnace

The length of the heating zone of the furnace shall be within the range 480 mm to 620 mm,

and its inside diameter shall be within the range 38 mm to 62 mm. It shall be equipped with an

adjustable electrical heating system.

5.3 Quartz glass tube

For the test, a quartz glass tube shall be introduced into the tube furnace. The tube shall be

approximately concentric to the furnace. It shall be resistant to the action of corrosive gases.

The inside diameter of the tube shall be within the range 30 mm to 46 mm. The tube shall

protrude on the entrance side of the furnace by a length of between 60 mm to 200 mm, and

on the exit side by between 60 mm to 100 mm. The initial clearance shall allow for thermal

expansion. For the purposes of measurement of the protrusion distances, the tube shall be

regarded as that part of essentially constant diameter.

NOTE The outer diameter of the tube should be chosen with due regard to the inside diameter of the tube

furnace.

Prior to each test, the tube shall be cleaned throughout its length by being calcined at

approximately 950 °C.

5.4 Combustion boats

The combustion boat shall be made of porcelain, fused quartz or soapstone and shall have

the following dimensions:

– external length: within the range 45 mm to 100 mm;

60754-1 © IEC:2011 – 9 –

– external width: within the range 12 mm to 30 mm;

– internal depth: within the range 5 mm to 10 mm.

NOTE The dimensions of the boat should be chosen with due regard to the inside diameter of the quartz tube.

The preferred method for insertion of the combustion boat into the quartz glass tube is shown

in Figure 1.

Prior to each test, the combustion boat shall be washed and calcined in a muffle furnace at

approximately 950 °C for 4 h after which it shall be introduced into a desiccator and cooled to

ambient temperature. The combustion boat shall then be weighed to an accuracy of 0,1 mg.

shall be recorded.

This weight m

5.5 Bubbling devices for gases

At the exit of the quartz glass tube, the evolved gases shall be passed through two wash

bottles (see Figure 2), each containing at least 220 ml of 0,1 M sodium hydroxide solution.

A magnetic stirrer shall be introduced in the first gas washing bottle to get a good swirling

motion and an effective absorption of the combustion gases. The tubes into the wash bottles

shall have a maximum internal diameter at their tip of 5 mm, in order to aid absorption.

The height of the liquid above the end of the tube shall be (110 ±10) mm in each bottle.

NOTE Use of a standard laboratory glass bottle of approximately 50 mm internal diameter will enable this

requirement to be met.

5.6 Air supply system

The gas used for combustion shall be air.

The flow rate of air introduced into the quartz glass tube shall be adjusted according to the

actual internal cross-sectional area of the tube, such that the speed of air flowing across the

sample is approximately 20 ml/mm /h.

The speed of air shall be regulated by reference to the flow rate of air. The flow rate of air

shall be (0,0157 × D ) l/h with a tolerance of ±10 %.

NOTE The derivation of the flow rate of air from the speed of air is:

π D

ρ = V ×

where

D is the internal diameter of the tube (mm);

ρ is the flow rate of air (ml/h);

V is the speed of air (ml/mm /h).

The air supply shall be adjusted and controlled by a needle valve, and the flow rate

monitored by a flowmeter of the appropriate range.

The air supplied shall be selected from one of the following methods:

Method 1

This method uses synthetic air or compressed air from a bottle. The air shall be introduced

on the inlet side of the quartz glass tube (see Figure 3).

– 10 – 60754-1 © IEC:2011

Method 2

This method uses a laboratory compressed air supply. The air shall be introduced on the

inlet side of the quartz glass tube and shall be be filtered and dried (see Figure 4).

Method 3

This method uses the ambient air of the laboratory. The air shall be filtered and dried. In

this case, the mixture of air and combustion gas shall be sucked by a pump. (See

Figure 5.)

5.7 Analytical balance

The balance shall have a precision of ±0,1 mg.

5.8 Laboratory glassware

For the titration, the following laboratory glassware shall be available:

– 20 ml pipette;

– 100 ml pipette;

– one mark volumetric flask in accordance with ISO 1042 with 1 000 ml capacity;

– conical flask with 250 ml to 500 ml capacity;

– burette in accordance with ISO 385-1.

5.9 Reagents

For the analysis, the following reagents of a recognized analytical quality shall be used.

Demineralized or distilled water shall be of a purity at least Grade 3 in accordance with

ISO 3696.

a) concentrated nitric acid: about 65 %, with a specific gravity ρ of approximately 1,40 g/ml;

b) nitric acid, approximately 6 M;

c) 0,1 M silver nitrate;

d) nitrobenzene, toluene or iso-amyl alcohol;

e) an approximately 40% weight/volume solution of ferric ammonium sulphate;

f) 0,1 M ammonium thiocyanate solution.

WARNING Nitrobenzene is regarded as highly toxic. Toluene or iso-amyl alcohol are safer alternatives.

6 Test specimen

6.1 General

Two test specimens, each consisting of (750 ± 250) mg of the material to be tested, shall be

prepared. Each test specimen shall be taken from a sample representative of the material.

Each test specimen shall be cut into a number of smaller pieces.

NOTE Pieces with a maximum dimension of 3 mm have been found to be suitable.

6.2 Conditioning of specimen

The prepared test specimens shall be conditioned for at least 16 h at a temperature of

(23 ±2) °C and a relative humidity of (50 ± 5) %.

60754-1 © IEC:2011 – 11 –

6.3 Mass of specimen

Weigh the combustion boat ( m ) to an accuracy of 0,1 mg (see 5.4). After conditioning, the

test specimen shall be put into the combustion boat and evenly distributed on the bottom of

the boat, which shall be weighed to an accuracy of 0,1 mg, The weight ( m ) shall be

recorded.

The mass m of the test specimen shall be calculated as follows:

m = m − m

2 1

where

m is the mass of the test specimen in grams;

is the mass of the combustion boat in grams;

m

m is the mass of the combustion boat with the test specimen, in grams.

NOTE Modern weighing equipment with suitable automatic zeroing could allow direct measurement of m.

7 Test procedure

7.1 General

The test procedure and determination shall be carried out on each test specimen.

7.2 Test apparatus and arrangement

The test procedure defined in this clause shall be carried out using the apparatus detailed

in Clause 5.

7.3 Heating procedure

7.3.1 Determination of heating regime

The empty combustion boat shall be inserted into the quartz glass tube and placed

approximately in the centre of the tube furnace.

The flow rate of air shall be adjusted by means of a needle valve to the value specified in 5.6

and shall be kept constant during the determination.

Position a thermocouple, or other suitable temperature measuring device (suitably protected

against corrosion), at the test specimen point in the empty combustion boat. The combustion

boat shall be heated at an approximately uniform heating rate over a period of (40 ± 5) min

in order to raise the temperature recorded by the thermocouple to (800 ± 10) °C, after

which it shall be maintained at that temperature for (20 ± 1) min.

Determine from this procedure a heating regime which will ensure that the required test

specimen heating rate and temperature is achieved.

7.3.2 Test specimen heating procedure

The combustion boat containing the test specimen shall be inserted into the quartz glass tube

and placed approximately in the centre of the tube furnace.

– 12 – 60754-1 © IEC:2011

The flow rate of air shall be adjusted by means of a needle valve to the value specified in 5.6

and shall be kept constant during the test.

The test specimen shall be heated using the heating regime determined in 7.3.1.

WARNING The operator should take precautions, e.g. the wearing of eye protection and suitable protective

clothing, because certain materials ignite quickly, and can cause "blow back" of hot gases. Care should also be

taken to avoid over-pressurization of the system, and to allow for venting of exhaust gases. Guidance on the

avoidance of “blow back” is given in NOTE 2 of 5.1.

7.4 Washing procedure

Following the heating procedure, all the bottles used shall be disconnected, and the contents

washed into a 1 000 ml volumetric flask. Using distilled or demineralized water, the bottles,

the connecting links and, after cooling, the end of the quartz glass tube including the silica

wool (if used) shall also be washed into the flask, and the contents made up to 1 000 ml.

7.5 Determination of halogen acid content

7.5.1 Blank test

Prior to conducting a test on a test specimen, a blank test shall be carried out using the test

procedure given in 7.3.2 but without a test specimen in the combustion boat.

After cooling to ambient temperature, 200 ml of the solution shall be measured into a conical

flask using a suitable pipette, and the following reagents introduced successively:

a) approximately 4 ml of concentrated nitric acid;

b) 20 ml of 0,1 M silver nitrate, measured with a pipette;

c) approximately 3 ml of either nitrobenzene, toluene or iso-amyl alcohol.

The contents shall be well shaken to achieve conglomeration and coating of the silver halide

that is formed by the reaction.

1 ml of a 40 % (weight/volume) aqueous solution of ferric ammonium sulphate containing a

few drops of 6 M nitric acid shall then be added and the whole mixed together. The solution

shall then be titrated with 0,1 M ammonium thiocyanate solution using a burette and the whole

shaken or stirred vigorously. The end-point shall be the red end-point for the titration.

The volume, B, of 0,1 M ammonium thiocyanate solution shall be recorded.

NOTE It is recommended that the blank test be carried out prior to each testing campaign and whenever a new

batch of sodium hydroxide solution, silver nitrate solution, ammonium thiocyanate solution or distilled or

demineralized water is started.

7.5.2 Material test

The test procedure given in 7.3.2 shall be carried out with a test specimen in the combustion

boat.

After cooling to ambient temperature, 200 ml of the solution shall be measured into a conical

flask using a suitable pipette and the following reagents introduced successively:

a) approximately 4 ml of concentrated nitric acid;

b) 20 ml of 0,1 M silver nitrate, measured with a pipette;

c) approximately 3 ml of either nitrobenzene, toluene or iso-amyl alcohol.

The contents shall be well shaken to achieve conglomeration and coating of the silver halide

that is formed by the reaction.

60754-1 © IEC:2011 – 13 –

1 ml of a 40 % (weight/volume) aqueous solution of ferric ammonium sulphate containing a

few drops of 6 M nitric acid shall then be added and the whole mixed together. The solution

shall then be titrated with 0,1 M ammonium thiocyanate solution using a burette and the whole

shaken or stirred vigorously. The end-point shall be the red end-point for the titration.

The volume, A, of 0,1 M ammonium thiocyanate solution shall be recorded.

7.5.3 Halogen acid content calculation

The amount of halogen acid, expressed as milligrams of hydrochloric acid per gram of test

specimen taken, shall be determined according to the formula:

1 000

36,5 (B − A) M ×

C =

m

where

A is the volume in ml of 0,1 M ammonium thiocyanate solution used in the test specimen

determination;

B is the volume in ml of 0,1 M ammonium thiocyanate solution used in the blank test

determination;

C is the amount of halogen acid expressed in milligrams of hydrochloric acid per gram of

the test specimen;

m is the mass of test specimen taken in grams;

M is the molarity of ammonium thiocyanate solution;

36,5 is the molar mass of hydrogen chloride.

8 Evaluation of the test results

The halogen acid gas content of the material, C , shall be taken as the mean of the

m

determination of the two test specimens.

The individual values shall not vary from the mean by more than ±10 % where the halogen

acid gas content is ≥ 5 mg/g.

Record C = 5 when the amount of halogen acid is less than 5 mg/g.

9 Performance requirement

No requirements for conformity are included in this standard.

10 Test report

The test report shall include the following information:

a) a full description of the material tested;

b) the number of this standard;

c) the halogen acid gas content of the material (C );

m

d) the analytical method used for the determination of the halogen acid gas content (if not as

given in this standard);

e) the supplier’s reference used for reagents 3) and 6) (as per 5.9) shall be reported;

– 14 – 60754-1 © IEC:2011

f) the type of test apparatus used (method 1, method 2 or method 3).

60754-1 © IEC:2011 – 15 –

2 5

7 9

IEC 2235/11

Key

1 Synthetic air or compressed air, filtered and dried 6 Bar magnets

2 Glass tube 7 Platinum wire

3 Thermocouple 8 Combustion boat

4 Quartz glass tube 9 Standard ground joint, size in correlation to the diameter of the quartz glass tube

5 Test specimen 10 Furnace

Figure 1 – Device for inserting combustion boat and test specimen

– 16 – 60754-1 © IEC:2011

IEC 2236/11

Key

1 Magnetic stirring bar h 100 mm to 120 mm

Figure 2 – Example of a gas washing bottle

h

60754-1 © IEC:2011 – 17 –

10 12

IEC 2237/11

Key

1 Pressure reducing valve 7 Gas washing bottles

2 Flow meter 8 Synthetic air

3 Quartz glass tube 9 Device for inserting combustion boat containing test specimen

4 Furnace 10 Combustion boat containing test specimen

5 Needle valve 11 Magnetic stirrer

6 Thermocouple 12 Magnetic stirring bar

Figure 3 – Test apparatus: method 1 – Use of synthetic or compressed air from a bottle

– 18 – 60754-1 © IEC:2011

3 4

7 8

11 12

IEC 2238/11

Key

1 Pressure reducing valve 7 Activated charcoal 13 Device for inserting combustion boat containing test specimen

2 Flow meter 8 Silica gel 14 Combustion boat containing test specimen

3 Quartz glass tube 9 Thermocouple 15 Magnetic stirring bar

4 Furnace 10 Gas washing bottles 16 Magnetic stirrer

5 Compressed air 11 Air filtering

6 Needle valve 12 Air drying

Figure 4 – Test apparatus: method 2 – Use of laboratory compressed air supply

60754-1 © IEC:2011 – 19 –

6 7

11 12

IEC 2239/11

Key

1 Flow meter 7 Silica gel 13 Device for inserting combustion boat containing test specimen

2 Furnace 8 Thermocouple 14 Combustion boat containing test specimen

3 Ambient air 9 Gas washing bottles 15 Magnetic stirring bar

4 Quartz glass tube 10 Suction pump 16 Magnetic stirrer

5 Needle valve 11 Air filtering

6 Activated charcoal 12 Air drying

Figure 5 – Test apparatus: method 3 – Use of ambient air sucked by means of a suction pump

– 20 – 60754-1 © IEC:2011

Annex A

(informative)

Determination of the halogen acid gas content

of a sample representative of a cable construction

If agreed between the cable producer and the customer, a representative sample of all the

non-metallic components of the cable construction may be used as the test specimen.

The representative sample should be prepared by the following method:

A sample of approximate length 15 mm to 25 mm of the complete cable should be cut into

small pieces after all metal elements have been removed. The sample should be of sufficient

length to give the required weight of test specimen according to 6.1. A sharp knife or a razor

blade should be used to cut the cable components into smaller pieces complying with the

requirements of 6.1.

The pieces should be well mixed and the required number of test specimens in accordance

with 6.1 should be taken from the mixture.

60754-1 © IEC:2011 – 21 –

Bibliography

IEC 60684-2, Flexible insulating sleeving – Part 2: Methods of test

IEC Guide 104, The preparation of safety publications and the use of basic safety publications

and group safety publications

_____________

– 22 – 60754-1 © CEI:2011

SOMMAIRE

AVANT-PROPOS . 24

INTRODUCTION . 26

1 Domaine d'application . 27

2 Références normatives . 27

3 Termes et définitions . 27

4 Principe de la méthode d’essai . 28

5 Appareillage d’essai . 28

5.1 Généralités. 28

5.2 Four tubulaire . 28

5.3 Tube en quartz . 28

5.4 Nacelles de combustion . 29

5.5 Dispositif de barbotage des gaz . 29

5.6 Dispositif d'entraînement . 29

5.7 Balance analytique . 30

5.8 Verrerie de laboratoire . 30

5.9 Réactifs . 30

6 Éprouvette d'essai . 31

6.1 Généralité . 31

6.2 Conditionnement des éprouvettes d'essai . 31

6.3 Masse de l’éprouvette . 31

7 Mode opératoire . 31

7.1 Généralité . 31

7.2 Appareillage d’essai et matériel . 31

7.3 Procédure de chauffage . 31

7.3.1 Détermination du régime de chauffage . 31

7.3.2 Procédure de chauffage de l’éprouvette d’essai . 32

7.4 Procédure de lavage . 32

7.5 Détermination de la quantité d'acide halogéné . 32

7.5.1 Dosage à blanc . 32

7.5.2 Essai du matériau . 33

7.5.3 Calcul de la concentration en acide halogéné . 33

8 Évaluation des résultats . 33

9 Exigence (d’exécution) . 34

10 Rapport d’essai . 34

Annexe A (informative) Détermination de la quantité d’acide halogéné contenu dans

un échantillon représentatif de la construction d’un câble . 40

Bibliographie . 41

Figure 1 – Système pour introduire la nacelle de combustion et l’éprouvette d’essai . 35

Figure 2 – Exemple de flacon barboteur . 36

Figure 3 – Appareillage d’essai: méthode 1 – Utilisation de l’air synthétique ou

comprimé provenant d’une bouteille . 37

Figure 4 – Appareillage d’essai: méthode 2 – Utilisation de l’air comprimé provenant du

laboratoire . 38

60754-1 © CEI:2011 – 23 –

Figure 5 – Appareillage d’essai: méthode 3 – Utilisation de l’air aspiré au moyen d’une

pompe . 39

– 24 – 60754-1 © CEI:2011

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

_____________

ESSAI SUR LES GAZ ÉMIS LORS DE LA COMBUSTION

DES MATÉRIAUX PRÉLEVÉS SUR CÂBLES –

Partie 1: Détermination de la quantité de gaz acide halogéné

AVANT-PROPOS

1) La Commission Electrotechnique International

...

IEC 60754-1 ®

Edition 3.1 2019-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the halogen acid gas content

Essai sur les gaz émis lors de la combustion des matériaux prélevés sur câbles –

Partie 1: Détermination de la quantité de gaz acide halogéné

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 60754-1 ®

Edition 3.1 2019-11

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the halogen acid gas content

Essai sur les gaz émis lors de la combustion des matériaux prélevés sur câbles –

Partie 1: Détermination de la quantité de gaz acide halogéné

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.220.40; 29.020; 29.060.20 ISBN 978-2-8322-7658-7

IEC 60754-1 ®

Edition 3.1 2019-11

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Test on gases evolved during combustion of materials from cables –

Part 1: Determination of the halogen acid gas content

Essai sur les gaz émis lors de la combustion des matériaux prélevés sur câbles –

Partie 1: Détermination de la quantité de gaz acide halogéné

– 2 – IEC 60754-1:2011+AMD1:2019 CSV

© IEC 2019

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Test method principle . 7

5 Test apparatus . 7

5.1 General . 7

5.2 Tube furnace . 7

5.3 Quartz glass tube . 7

5.4 Combustion boats . 7

5.5 Bubbling devices for gases . 8

5.6 Air supply system . 8

5.7 Analytical balance . 9

5.8 Laboratory glassware . 9

5.9 Reagents . 9

6 Test specimen . 10

6.1 General . 10

6.2 Conditioning of specimen . 10

6.3 Mass of specimen . 10

7 Test procedure . 10

7.1 General . 10

7.2 Test apparatus and arrangement . 10

7.3 Heating procedure . 11

7.3.1 Determination of heating regime . 11

7.3.2 Test specimen heating procedure . 11

7.4 Washing procedure . 11

7.5 Determination of halogen acid content . 11

7.5.1 Blank test . 11

7.5.2 Material test . 12

7.5.3 Halogen acid content calculation . 12

8 Evaluation of the test results . 13

9 Performance requirement . 13

10 Test report. 13

Annex A (informative) Determination of the halogen acid gas content of a sample

representative of a cable construction . 22

Bibliography . 23

Figure 1 – Device for inserting combustion boat and test specimen . 14

Figure 2 – Example of a gas washing bottle . 15

Figure 3 – Test apparatus: method 1 – Use of synthetic or compressed air

from a bottle . 17

Figure 4 – Test apparatus: method 2 – Use of laboratory compressed air supply . 19

Figure 5 – Test apparatus: method 3 – Use of ambient air sucked by means of a

suction pump . 21

© IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

TEST ON GASES EVOLVED DURING

COMBUSTION OF MATERIALS FROM CABLES –

Part 1: Determination of the halogen acid gas content

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 60754-1 edition 3.1 contains the third edition (2011-11) [documents 20/1266/

FDIS and 20/1276/RVD] and its corrigendum (2013-11), and its amendment 1

(2019-11) [documents 20/1882/FDIS and 20/1891/RVD].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

– 4 – IEC 60754-1:2011+AMD1:2019 CSV

© IEC 2019

International Standard IEC 60754-1 has been prepared by IEC technical committee 20:

Electric cables.

It has the status of a group safety publication in accordance with IEC Guide 104.

This third edition constitutes a technical revision.

The significant technical changes with respect to the previous edition are as follows:

– improved definition of safety requirements relating to capture of gases and use of

reagents;

– introduction of guidance on preparation of test specimens for a more even combustion;

– improvements to the procedure for establishing the heating regime;

– improved expression of tolerances and precision;

– definition of the procedure for the blank test;

– introduction of an informative annex giving details of a methodology for the determination

of the halogen acid gas content of a sample representative of a cable construction.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all the parts in the IEC 60754 series, published under the general title Test on gases

evolved during combustion of materials from cables, can be found on the IEC website.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

© IEC 2019

INTRODUCTION

IEC 60754 consists of the following parts, under the general title Test on gases evolved

during combustion of materials from cables:

– Part 1: Determination of the halogen acid gas content

– Part 2: Determination of acidity (by pH measurement) and conductivity

– Part 3: Measurement of low level of halogen content by ion chromatography

IEC 60754-1 was developed due to concerns expressed by cable users over the amount of

acid gas which is evolved when some cable insulating, sheathing and other materials are

burned, as this acid can cause extensive damage to electrical and electronic equipment not

involved in the fire itself.

This standard provides a method for determining the amount of acid gases evolved by burning

cable components so that limits can be agreed for cable specifications. As the test is not

carried out on a complete cable test piece, for a hazard assessment the actual material

volumes of the cable components should be taken into consideration.

– 6 – IEC 60754-1:2011+AMD1:2019 CSV

© IEC 2019

TEST ON GASES EVOLVED DURING

COMBUSTION OF MATERIALS FROM CABLES –

Part 1: Determination of the halogen acid gas content

1 Scope

This part of IEC 60754 specifies the apparatus and procedure for the determination of the

amount of halogen acid gas, other than hydrofluoric acid, evolved during the combustion of

compounds based on halogenated polymers and compounds containing halogenated

additives taken from electric or optical fibre cable constructions.

NOTE 1 This test method is not able to determine hydrofluoric acid. A suitable method may be found in

IEC 60684-2.

NOTE 2 This test method may be used to test materials to be used in cable manufacture, but a declaration of

cable performance should not be made based on such a test.

NOTE 3 The relevant cable standard should indicate which components of the cable should be tested.

NOTE 4 For the purposes of this standard, the term “electric cable” covers all insulated metallic conductor cables

used for the conveyance of energy or signals.

The method specified in this standard is intended for the testing of individual components

used in a cable construction. The use of this method will enable the verification of

requirements which are stated in the appropriate cable specification for individual components

of a cable construction.

NOTE 5 By agreement between the producer and purchaser, the methodology given in this standard may be used

to test combinations of materials representing a cable construction, but a declaration of cable performance to this

standard should not be made based on such a test. Information on such a method is given in Annex A.

For reasons of precision this method is not recommended for reporting values of halogen acid

evolved less than 5 mg/g of the sample taken.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

ISO 385, Laboratory glassware – Burettes

ISO 1042, Laboratory glassware – One-mark volumetric flasks

ISO 3696, Water for analytical laboratory use – Specification and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

halogen acid gas content

amount of halogen acid gas evolved, except hydrofluoric acid, expressed as milligrams of

hydrochloric acid per gram of total test specimen

© IEC 2019

4 Test method principle

The material under test shall be heated in a stream of dry air and the gases shall be absorbed

in 0,1 M sodium hydroxide solution contained in wash bottles. The amount of halogen acid

shall then be determined by acidifying the solution with nitric acid, adding a measured volume

of 0,1 M silver nitrate solution and back titrating the excess with 0,1 M ammonium

thiocyanate, using ferric ammonium sulphate as the indicator.

NOTE 1 Other analytical methods having at least the same precision may be used, but in case of dispute the

method given in this standard is the one to use.

NOTE 2 Although both hydrogen chloride and hydrogen bromide are detected by this analytical method, the

halogen acid content is reported as if all the halogen acid is hydrogen chloride.

5 Test apparatus

5.1 General

The apparatus is shown in Figures 1 to 5.

The assembly of the components which constitute the test apparatus shall be leak-tight. The

connecting distances between the quartz glass tube and the first bottle and between

subsequent bottles shall be as short as possible. Glass or silicone rubber tubing shall be used

for these connections.

NOTE 1 At the exit side of the quartz glass tube, as close to the end as possible, it is permitted to place a plug of

silica wool to aid collection of condensates.

NOTE 2 A third empty bottle, of the same size as the gas washing bottles, placed before the gas washing bottles,

may be used to improve safety, i.e. to prevent suck back of water into the quartz glass tube.

5.2 Tube furnace

The length of the heating zone of the furnace shall be within the range 480 mm to 620 mm,

and its inside diameter shall be within the range 38 mm to 62 mm. It shall be equipped with an

adjustable electrical heating system.

5.3 Quartz glass tube

For the test, a quartz glass tube shall be introduced into the tube furnace. The tube shall be

approximately concentric to the furnace. It shall be resistant to the action of corrosive gases.

The inside diameter of the tube shall be within the range 30 mm to 46 mm. The tube shall

protrude on the entrance side of the furnace by a length of between 60 mm to 200 mm, and

on the exit side by between 60 mm to 100 mm. The initial clearance shall allow for thermal

expansion. For the purposes of measurement of the protrusion distances, the tube shall be

regarded as that part of essentially constant diameter.

NOTE The outer diameter of the tube should be chosen with due regard to the inside diameter of the tube

furnace.

Prior to each test, the tube shall be cleaned throughout its length by being calcined at

approximately 950 °C.

5.4 Combustion boats

The combustion boat shall be made of porcelain, fused quartz or soapstone and shall have

the following dimensions:

– external length: within the range 45 mm to 100 mm;

– 8 – IEC 60754-1:2011+AMD1:2019 CSV

© IEC 2019

– external width: within the range 12 mm to 30 mm;

– internal depth: within the range 5 mm to 10 mm.

NOTE The dimensions of the boat should be chosen with due regard to the inside diameter of the quartz tube.

The preferred method for insertion of the combustion boat into the quartz glass tube is shown

in Figure 1.

Prior to each test, the combustion boat shall be washed and calcined in a muffle furnace at

approximately 950 °C for 4 h after which it shall be introduced into a desiccator and cooled to

ambient temperature. The combustion boat shall then be weighed to an accuracy of 0,1 mg

with an analytical balance in mg, rounded to one decimal figure, with an accuracy as

described in 5.7. This weight m shall be recorded.

5.5 Bubbling devices for gases

At the exit of the quartz glass tube, the evolved gases shall be passed through two wash

bottles (see Figure 2), each containing at least 220 ml of 0,1 M sodium hydroxide solution.

A magnetic stirrer shall be introduced in the first gas washing bottle to get a good swirling

motion and an effective absorption of the combustion gases. The tubes into the wash bottles

shall have a maximum internal diameter at their tip of 5 mm, in order to aid absorption.

The height of the liquid above the end of the tube shall be (110 ±10) mm in each bottle.

NOTE Use of a standard laboratory glass bottle of approximately 50 mm internal diameter will enable this

requirement to be met.

5.6 Air supply system

The gas used for combustion shall be air.

The flow rate of air introduced into the quartz glass tube shall be adjusted according to the

actual internal cross-sectional area of the tube, such that the speed of air flowing across the

sample is approximately 20 ml/mm /h.

The speed of air shall be regulated by reference to the flow rate of air. The flow rate of air

shall be (0,0157 × D ) l/h with a tolerance of ±10 %.

NOTE The derivation of the flow rate of air from the speed of air is:

π D

ρ =V ×

where

D is the internal diameter of the tube (mm);

ρ is the flow rate of air (ml/h);

V is the speed of air (ml/mm /h).

2 -3

The flow rate of air, ρ, shall be 20 m/h × (π/4) x D x 10 with a tolerance of ±10 %, where D

is the internal diameter of the quartz tube.

EXAMPLE

2 -3

If D = 30 mm, 20 m/h × (π/4) × D x 10 = 14,1 l/h, and the flow rate can be in the range 12,7 l/h to 15,5 l/h.

2 -3

If D = 46 mm, 20 m/h × (π/4) × D x 10 = 33,2 l/h, and the flow rate can be in the range 29,9 l/h to 36,5 l/h.

NOTE The flow rate of air, ρ, is related to the velocity, v, according to the formula

© IEC 2019

π D²

−3

ρ=v ××10

where

D is the internal diameter of the tube (mm);

ρ is the flow rate of air (l/h);

v is the speed of air (m/h).

2 -3

If v = 20 m/h, this becomes, ρ = 15,7 m/h × D x 10 .

The air supply shall be adjusted and controlled by a needle valve, and the flow rate

monitored by a flowmeter of the appropriate range.

The air supplied shall be selected from one of the following methods:

Method 1

This method uses synthetic air or compressed air from a bottle. The air shall be introduced

on the inlet side of the quartz glass tube (see Figure 3).

Method 2

This method uses a laboratory compressed air supply.

The air shall be filtered and dried and shall be introduced on the inlet side of the quartz

glass tube shall be be filtered and dried (see Figure 4).

Method 3

This method uses the ambient air of the laboratory. The air shall be filtered and dried. In

this case, the mixture of air and combustion gas shall be sucked by a pump. (See

Figure 5.)

5.7 Analytical balance

The balance shall have a precision resolution and an accuracy of ±0,1 mg or better.

5.8 Laboratory glassware

For the titration, the following laboratory glassware shall be available:

– 20 ml pipette;

– 100 ml pipette;

– one mark volumetric flask in accordance with ISO 1042 Class B with 1 000 ml capacity;

– conical flask with 250 ml to 500 ml capacity;

– burette in accordance with ISO 385-1.

5.9 Reagents

For the analysis, the following reagents of a recognized analytical quality shall be used.

Demineralized or distilled water shall be of a purity at least Grade 3 in accordance with

ISO 3696.

a) concentrated nitric acid: about 65 %, with a specific gravity ρ of approximately 1,40 g/ml;

b) nitric acid, approximately 6 M;

c) 0,1 M silver nitrate;

– 10 – IEC 60754-1:2011+AMD1:2019 CSV

© IEC 2019

d) nitrobenzene, toluene or iso-amyl alcohol;

e) an approximately 40% weight/volume solution of ferric ammonium sulphate;

f) 0,1 M ammonium thiocyanate solution.

WARNING Nitrobenzene is regarded as highly toxic. Toluene or iso-amyl alcohol are safer alternatives.

6 Test specimen

6.1 General

Two test specimens, each consisting of (750 ± 250) mg of the material to be tested, shall be

prepared. Each test specimen shall be taken from a sample representative of the material.

Each test specimen shall be cut into a number of smaller pieces.

NOTE Pieces with a maximum dimension of 3 mm have been found to be suitable.

6.2 Conditioning of specimen

The prepared test specimens shall be conditioned for at least 16 h at a temperature of

(23 ±2) °C and a relative humidity of (50 ± 5) %.

6.3 Mass of specimen

Weigh the combustion boat (m ) to an accuracy of 0,1 mg (see as defined in 5.4). After

conditioning, the test specimen shall be put into the combustion boat and evenly distributed

on the bottom of the boat, which shall be weighed to an accuracy of 0,1 mg, as defined in

5.4. The weight ( ) shall be recorded.

m

The mass m of the test specimen shall be calculated as follows:

m =m −m

2 1

where

m is the mass of the test specimen in grams;

m is the mass of the combustion boat in grams;

m is the mass of the combustion boat with the test specimen, in grams.

NOTE Modern weighing equipment with suitable automatic zeroing could allow direct measurement of m.

7 Test procedure

7.1 General

The test procedure and determination shall be carried out on each test specimen.

7.2 Test apparatus and arrangement

The test procedure defined in this clause shall be carried out using the apparatus detailed

in Clause 5.

© IEC 2019

7.3 Heating procedure

7.3.1 Determination of heating regime

The empty combustion boat shall be inserted into the quartz glass tube and placed

approximately in the centre of the tube furnace.

The flow rate of air shall be adjusted by means of a needle valve to the value specified in 5.6