IEC 60364-5-52

Electrical installations of buildings - Part 5-52: Selection and erection of electrical equipment - Wiring systems

Electrical installations of buildings - Part 5-52: Selection and erection of electrical equipment - Wiring systems

Deals with the selection and erection of wiring systems.

Installations électriques des bâtiments - Partie 5-52: Choix et mise en oeuvre des matériels électriques - Canalisations

Traite du choix et de la mise en ouvre des canalisations.

Električne inštalacije zgradb - 5-52. del: Izbira in namestitev električne opreme - Inštalacijski sistemi

Del 5-52 dokumenta IEC 60364 obravnava izbiro in način namestitve inštalacijskih sistemov. OPOMBA: Ta standard velja na splošno tudi za zaščitne vodnike, medtem ko IEC 60364-5-54 navaja še druge zahteve za te vodnike. Upoštevati je treba temeljna načela IEC 60364-1, ki se uporabljajo za kable in vodnike, za njihovo priključevanje in/ali spajanje, način nameščanja, pritrjevanja ali obešanja in za njihove okrove ali metode zaščite pred zunanjimi vplivi.

General Information

- Status

- Not Published

- Technical Committee

- TC 64 - Electrical installations and protection against electric shock

- Current Stage

- PPUB - Publication issued

- Start Date

- 20-Aug-2001

Overview

IEC 60364-5-52 - "Electrical installations of buildings - Part 5-52: Selection and erection of electrical equipment - Wiring systems" is an international standard that specifies principles and requirements for the selection, installation and erection of wiring systems in buildings. Part of the IEC 60364 series, this standard addresses wiring system types, external influences, conductor sizing, current-carrying capacity, voltage drop, electrical connections, fire containment and maintainability. Annex A (normative) provides tabulated current‑carrying capacities and other annexes give informative calculation methods and guidance.

Key topics and technical requirements

- Types of wiring systems and recommended methods of installation for different environments.

- External influences affecting wiring selection, including ambient temperature, water, solid foreign bodies, corrosive substances, mechanical impact, vibration, fauna/flora, solar radiation, seismic effects and wind.

- Current‑carrying capacities and correction/reduction factors for different cable types and installation methods (detailed tables in Annex A).

- Conductor cross‑sectional area and minimum sizing principles to meet thermal and mechanical requirements.

- Voltage drop considerations for consumer installations and how to limit voltage drop through conductor selection and layout.

- Electrical connections: requirements for reliable joints and terminations.

- Fire safety and containment: selection and erection measures to minimise spread of fire, including sealing penetrations and precautions within fire‑segregated compartments.

- Proximity to other services: coordination with non‑electrical services to avoid interference or hazards.

- Maintainability and cleaning: installation practices that allow inspection, maintenance and cleaning access.

Practical applications

IEC 60364-5-52 is used to:

- Select cable types and insulation suitable for environmental and mechanical stresses.

- Determine appropriate conductor sizes using current‑carrying capacity tables and correction factors.

- Design wiring routes to limit voltage drop and reduce fire spread risk.

- Specify installation methods (in air, in ducts, buried, in conduit, trunking) that meet operational and safety requirements.

- Prepare installation and inspection checklists for contractors and electrical inspectors.

Keywords: IEC 60364-5-52, wiring systems, electrical installations, current-carrying capacity, conductor sizing, voltage drop, fire safety, cable selection.

Who should use this standard

- Electrical designers and consulting engineers

- Building services contractors and installation electricians

- Inspection bodies, authorities having jurisdiction and code writers

- Facility managers and maintenance teams

Related standards

Normative references in IEC 60364-5-52 include (among others): IEC 60228, IEC 60287, IEC 60332, IEC 60529, IEC 60614, IEC 60439-2, IEC 61200-52, and ISO 834. For protective conductor requirements see IEC 60364-5-54.

Frequently Asked Questions

IEC 60364-5-52 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electrical installations of buildings - Part 5-52: Selection and erection of electrical equipment - Wiring systems". This standard covers: Deals with the selection and erection of wiring systems.

Deals with the selection and erection of wiring systems.

IEC 60364-5-52 is classified under the following ICS (International Classification for Standards) categories: 13.260 - Protection against electric shock. Live working; 91.140.50 - Electricity supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60364-5-52 is associated with the following European legislation: EU Directives/Regulations: TRRTP129. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

IEC 60364-5-52 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI SIST IEC 60364-5-52:2006

STANDARD

september 2006

Električne inštalacije zgradb – 5-52. del: Izbira in namestitev električne

opreme – Inštalacijski sistemi

Electrical installations of buildings - Part 5-52: Selection and erection of electrical

equipment - Wiring systems

ICS 91.140.50 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

Edition 2.0 2001-08

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Electrical installations of buildings –

Part 5-52: Selection and erection of electrical equipment – Wiring systems

Installations électriques des bâtiments –

Partie 5-52: Choix et mise en œuvre des matériels électriques – Canalisations

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

XB

CODE PRIX

ICS 13.260; 91.140.50 ISBN 2-8318-5879-8

– 2 – 60364-5-52 © IEC:2001

CONTENTS

FOREWORD.5

520 Introduction.6

520.1 Scope.6

520.2 Normative references.6

520.3 General.13

521 Types of wiring systems .13

522 Selection and erection of wiring systems in relation to external influences .15

522.1 Ambient temperature (AA).15

522.2 External heat sources.15

522.3 Presence of water (AD) .15

522.4 Presence of solid foreign bodies (AE) .16

522.5 Presence of corrosive or polluting substances (AF).16

522.6 Impact (AG).16

522.7 Vibration (AH).16

522.8 Other mechanical stresses (AJ).16

522.9 Presence of flora and/or mould growth (AK) .17

522.10 Presence of fauna (AL) .17

522.11 Solar radiation (AN) .17

522.12 Seismic effects (AP).18

522.13 Wind (AS) .18

522.14 Nature of processed or stored materials (BE) .18

522.15 Building design (CB) .18

523 Current-carrying capacities.18

524 Cross-sectional areas of conductors.39

525 Voltage drop in consumers' installations.21

526 Electrical connections.21

527 Selection and erection of wiring systems to minimize the spread of fire.22

527.1 Precautions within a fire-segregated compartment .22

527.2 Sealing of wiring system penetrations .22

528 Proximity of wiring systems to other services .23

528.1 Proximity to electrical services .23

528.2 Proximity to non-electrical services .24

529 Selection and erection of wiring systems in relation to maintainability,

including cleaning .24

Annex A (normative) Current-carrying capacities .25

Annex B (informative) Example of a method of simplification of the tables of clause 523.51

Annex C (informative) Formulae to express current-carrying capacities .55

Annex D (informative) Effect of harmonic currents on balanced three-phase systems .58

Annex E (informative) IEC 60364 – Parts 1 to 6: Restructuring .60

Bibliography.64

60364-5-52 © IEC:2001 – 3 –

Table 52-1 (52F) – Selection of wiring systems.8

Table 52-2 (52G) – Erection of wiring systems.8

Table 52-3 (52H) – Examples of methods of installation providing instructions for obtaining

current-carrying capacity .9

Table 52-4 (52-A) – Maximum operating temperatures for types of insulation.18

Table 52-5 (52J) – Minimum cross-sectional area of conductors .21

Table A.52-1 (52-B1) – Schedule of reference methods of installation which form the basis

of the tabulated current-carrying capacities.30

Table A.52-2 (52-C1) – Current-carrying capacities in amperes for methods of installation

in table A.52-1 (52-B1) – PVC insulation/two loaded conductors/copper or aluminium –

Conductor temperature: 70 °C/Ambient temperature: 30 °C in air, 20 °C in ground .32

Table A.52-3 (52-C2) – Current-carrying capacities in amperes for methods of installation

in table A.52-1 (52-B1) – XLPE or EPR insulation/two loaded conductors/copper or

aluminium – Conductor temperature: 90 °C/Ambient temperature: 30 °C in air, 20 °C

in ground .33

Table A.52-4 (52-C3) – Current-carrying capacities in amperes for methods of installation

in table A.52-1 (52-B1) – PVC insulation/three loaded conductors/copper or aluminium –

Conductor temperature: 70 °C/Ambient temperature: 30 °C in air, 20 °C in ground .34

Table A.52-5 (52-C4) – Current-carrying capacities in amperes for methods of installation

in table A.52-1 (52-B1) – XLPE or EPR insulation/three loaded conductors/copper or

aluminium – Conductor temperature: 90 °C/Ambient temperature: 30 °C in air, 20 °C

in ground .35

Table A.52-6 (52-C5) – Current-carrying capacities in amperes for installation method C

of table A.52-1 (52-B1) – Mineral insulation/copper conductors and sheath – PVC covered

or bare exposed to touch (see note 2) Metallic sheath temperature: 70 °C/Reference

ambient temperature: 30 °C .36

Table A.52-7 (52-C6) – Current-carrying capacities in amperes for installation method C

of table A.52-1 (52-B1) – Mineral insulation/copper conductors and sheath – Bare cable

not exposed to touch and not in contact with combustible material Metallic sheath

temperature: 105 °C/Reference ambient temperature: 30 °C.37

Table A.52-8 (52-C7) – Current-carrying capacities in amperes for installation methods E,

F and G of table A.52-1 (52-B1) – Mineral insulation/Copper conductors and sheath/PVC

covered or bare exposed to touch (see note 2) Metallic sheath temperature:

70 °C/Reference ambient temperature: 30 °C .38

Table A.52-9 (52-C8) – Current-carrying capacities in amperes for installation methods E,

F and G of table A.52-1 (52-B1) – Mineral insulation/Copper conductors and sheath/ Bare

cable not exposed to touch (see note 2) Metallic sheath temperature: 105 °C/Reference

ambient temperature: 30 °C .39

Table A.52-10 (52-C9) – Current-carrying capacities in amperes for installation methods E,

F and G of table A.52-1 (52-B1) – PVC insulation/Copper conductors Conductor

temperature: 70 °C/Reference ambient temperature: 30 °C.40

Table A.52-11 (52-C10) – Current-carrying capacities in amperes for installation

methods E, F and G of table A.52-1 (52-B1) – PVC insulation/Aluminium conductors

Conductor temperature: 70 °C/Reference ambient temperature: 30 °C.41

Table A.52-12 (52-C11) – Current-carrying capacities in amperes for installation

methods E, F and G of table A.52-1 (52-B1) – XLPE or EPR insulation/Copper

conductors – Conductor temperature: 90 °C/Reference ambient temperature: 30 °C.42

Table A.52-13 (52-C12) – Current-carrying capacities in amperes for installation

methods E, F and G of table A.52-1 (52-B1) – XLPE or EPR insulation/Aluminium

conductors Conductor temperature: 90 °C/Reference ambient temperature: 30 °C.43

Table A.52-14 (52-D1) – Correction factor for ambient air temperatures other than 30 °C

to be applied to the current-carrying capacities for cables in the air .44

– 4 – 60364-5-52 © IEC:2001

Table A.52-15 (52-D2) – Correction factors for ambient ground temperatures other than

20 °C to be applied to the current-carrying capacities for cables in ducts in the ground.45

Table A.52-16 (52-D3) – Correction factors for cables in buried ducts for soil thermal

resistivities other than 2,5 K·m/W to be applied to the current-carrying capacities for

reference method D .45

Table A.52-17 (52-E1) – Reduction factors for groups of more than one circuit or of more

than one multi-core cable to be used with current carrying capacities of tables A.52-2

(52-C1) to A.52-13 (52-C12) .46

Table A.52-18 (52-E2) – Reduction factors for more than one circuit, cables laid directly

in the ground – Installation method D in tables A.52-2 (52-C1) to A.52-5 (52-C4) –

Single-core or multi-core cables.47

Table A.52-19 (52-E3) – Reduction factors for more than one circuit, cables laid in

ducts in the ground – Installation method D in tables A.52-2 (52-C1) to A.52-5 (52-C4) .48

Table A.52-20 (52-E4) – Reduction factors for group of more than one multi-core cable to

be applied to reference ratings for multi-core cables in free air – Method of installation E

in tables A.52-8 (52-C7) to A.52-13 (52-C12) .49

Table A.52-21 (52-E5) – Reduction factors for groups of more than one circuit of single-

core cables (note 2) to be applied to reference rating for one circuit of single-core cables

in free air – Method of installation F in tables A.52-8 (52-C7) to A.52-13) (52-C12).50

Table B.52-1 (A.52-1) – Current-carrying capacity in amperes .52

Table B.52-2 (A.52-2) – Current-carrying capacities (in amperes) .53

Table B.52-3 (A.52-3) – Reduction factors for groups of several circuits or of several

multi-core cables (to be used with current-carrying capacities of table B.52-1) (A.52-1) .54

Table C.52-1 (B.52-1) – Table of coefficients and exponents .56

Table D.52-1 (C.52-1) – Reduction factors for harmonic currents in four-core and

five-core cables .59

Table E.1 – Relationship between re-structured and original parts .60

Table E.2 – Relationship between new and old clause numbering.62

60364-5-52 © IEC:2001 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

–––––––––

ELECTRICAL INSTALLATIONS OF BUILDINGS –

Part 5-52: Selection and erection of electrical equipment –

Wiring systems

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60364-5-52 has been prepared by IEC technical committee 64:

Electrical installations and protection against electric shock.

The IEC 60364 series (parts 1 to 6), is currently being restructured, without any technical

changes, into a more simple form (see annex E).

According to a unanimous decision by the Committee of Action (CA/1720/RV (2000-03-21)),

the restructured parts of IEC 60364 have not been submitted to National Committees for

approval.

The text of this second edition of IEC 60364-5-52 is compiled from and replaces

– part 5-52, first edition (1993) and its amendment 1 (1997);

– part 5-523, second edition (1999).

This publication has been drafted, as close as possible, in accordance with the

ISO/IEC Directives, Part 3.

Annex A forms an integral part of this standard.

Annexes B, C, D and E are for information only.

The committee has decided that the contents of this publication will remain unchanged

until 2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 60364-5-52 © IEC:2001

ELECTRICAL INSTALLATIONS OF BUILDINGS –

Part 5-52: Selection and erection of electrical equipment –

Wiring systems

520 Introduction

520.1 Scope

Part 5-52 of IEC 60364 deals with the selection and erection of wiring systems.

NOTE This standard also applies in general to protective conductors, while IEC 60364-5-54 contains further

requirements for those conductors.

520.2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this part of IEC 60364. For dated references, subsequent amend-

ments to, or revisions of, any of these publications do not apply. However, parties to

agreements based on this part of IEC 60364 are encouraged to investigate the possibility of

applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of IEC

and ISO maintain registers of currently valid International Standards.

IEC 60228: 1978, Conductors of insulated cables

IEC 60287-1-1:1994, Electric cables – Calculation of the current rating – Part 1: Current rating

equations (100 % load factor) and calculation of losses – Section 1: General

IEC 60287-2-1:1994, Electric cables – Calculation of the current rating – Part 2: Thermal

resistance – Section 1: Calculation of thermal resistance

IEC 60287-3-1:1995, Electric cables – Calculation of the current rating – Part 3: Sections on

1)

operating conditions – Section 1: Reference operating conditions and selection of cable type

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60332-3-24:2000, Tests on electric cables under fire conditions – Part 3-24: Test for

vertical flame spread of vertically-mounted bunched wire or cables – Category C

IEC 60439-2:2000, Low-voltage switchgear and controlgear assemblies – Part 2: Particular

requirements for busbar trunking systems (busways)

2)

IEC 60529:1989, Degrees of protection provided by enclosures (IP Code)

IEC 60614 (all parts), Specification for conduits for electrical installations

IEC 61200-52:1993, Electrical installation guide – Part 52: Selection and erection of electrical

equipment – Wiring systems

ISO 834 (all parts) Fire-resistance tests – Elements of building construction

________

1)

A consoldated edition 1.1 exists (1999) that includes IEC 60287-3-1 (1995) and its amendment 1 (1999).

2)

A consoldated edition 2.1 exists (2001) that includes IEC 60529 (1989) and its amendment 1 (1999).

60364-5-52 © IEC:2001 – 7 –

520.3 General

Consideration shall be given to the application of the fundamental principles of IEC 60364-1

as it applies to cables and conductors, to their termination and/or jointing, to their associated

supports or suspensions and their enclosures or methods of protection against external

influences.

521 Types of wiring systems

521.1 The method of installation of a wiring system in relation to the type of conductor or

cable used shall be in accordance with table 52-1, provided the external influences are

covered by the requirements of the relevant product standards.

521.2 The method of installation of a wiring system in relation to the situation concerned

shall be in accordance with table 52-2.

521.3 Examples of wiring systems together with reference to the appropriate table of current-

carrying capacity are shown in table 52-3.

NOTE 1 Other types of wiring systems, not covered in this standard, may be used provided they comply with the

general rules of this standard.

NOTE 2 Table 52-3 gives the reference method of installation where it is considered that the same current-

carrying capacities can safely be used. It is not implied that all these items are necessarily recognized in national

rules of all countries.

521.4 Busbar trunking systems

Busbar trunking systems shall comply with IEC 60439-2 and shall be installed in accordance

with the manufacturer's instructions. The installation shall be in accordance with the

requirements of clauses 522 (with the exception of 522.1.1, 522.3.3, 522.8.7, 522.8.8

and 522.8.9), 525, 526, 527 and 528.

521.5 AC circuits

Conductors of a.c. circuits installed in ferromagnetic enclosures shall be arranged so that all

conductors of each circuit are contained in the same enclosure.

NOTE If this condition is not fulfilled, overheating and excessive voltage drop may occur due to inductive effects.

– 8 – 60364-5-52 © IEC:2001

Table 52-1 (52F) – Selection of wiring systems

Method of installation

Conductors and Cable

cables trunking

Cable ladder

(including

Without Clipped Cable Cable tray On in- Support

Conduit skirting

sulators wire

fixings direct ducting Cable

trunking,

brackets

flush floor

trunking)

Bare conductors – – – – – – + –

Insulated – – + + + – + –

conductors

Sheathed Multi- + + + + + + 0 +

cables core

(including

Single 0 + + + + + 0 +

armoured

-core

and

mineral

insulated)

+ Permitted.

– Not permitted.

0 Not applicable, or not normally used in practice.

Table 52-2 (52G) – Erection of wiring systems

Method of installation

Cable

trunking

Cable ladder,

Situations (including

Without With Cable On Support

Conduit skirting cable tray, cable

fixings fixings ducting insulators wire

trunking, brackets

flush floor

trunking)

Building voids 40, 46, 0 15,16, – 43 30, 31, 32, 33, 34 – –

15, 16 41,42

Cable channel 56 56 54, 55 0 44, 45 30, 31, 32, 33, 34 – –

Buried in 72, 73 0 70, 71 – 70, 71 0 – –

ground

Embedded in 57, 58 3 1, 2, 59, 50, 51, 52, 44, 45 0 – –

structure 60 53

Surface – 20, 21, 4, 5 6, 7, 8, 9, 6, 7, 8, 30, 31, 32, 33, 34 36 –

mounted 22, 23 12, 13, 14 9

Overhead – – 0 10, 11 – 30, 31, 32, 33, 34 36 35

Immersed 80 80 0 – 0 0 – –

The number in each box indicates the item number in table 52-3.

– Not permitted.

0 Not applicable or not normally used in practice.

60364-5-52 © IEC:2001 – 9 –

Table 52-3 (52H) – Examples of methods of installation providing instructions for obtaining

current-carrying capacity

NOTE The illustrations are not intended to depict actual product or installation practices but are indicative of the

method described.

Reference method of

installation to be used to

Item

Methods of installation Description obtain current-carrying

No.

capacity

(see annex A)

Insulated conductors or single-core

Room

Room

1 cables in conduit in a thermally A1

a

insulated wall

Room Multi-core cables in conduit in a

Room

2 A2

a

thermally insulated wall

Room

Room Multi-core cable direct in a thermally

3 A1

a

insulated wall

Insulated conductors or single-core

cables in conduit on a wooden, or

4 B1

masonry wall or spaced less than

0,3 × conduit diameter from it

Multi-core cable in conduit on a

wooden, or masonry wall or spaced

5 B2

less than 0,3 × conduit diameter

from it

Insulated conductors or single-core

cables in cable trunking on a

wooden wall

B1

b

– run horizontally

b, c

– run vertically

6 7

Multi-core cable in cable trunking on

a wooden wall

d

Under consideration

b

– run horizontally

b, c

– run vertically

8 9

a 2

The inner skin of the wall has a thermal conductance of not less than 10 W/m ·K.

b

Values given for installation methods B1 and B2 in annex A are for a single circuit. Where there is more than

one circuit in the trunking the group reduction factor given in table A.52-17 is applicable, irrespective of the

presence of an internal barrier or partition.

c

Care shall be taken where the cable runs vertically and ventilation is restricted. The ambient temperature at

the top of the vertical section can be increased considerably. The matter is under consideration.

d

Values for reference method B2 may be used.

– 10 – 60364-5-52 © IEC:2001

Table 52-3 (continued)

Reference method of

installation to be used to

Item

Methods of installation Description obtain current-carrying

No.

capacity

(see annex A)

Insulated conductors or single-core B1

a

cable in suspended cable trunking

Multi-core cable in suspended cable

11 B2

a

trunking

10 11

Insulated conductors or single-core

12 A1

b

cable run in mouldings

Insulated conductors or single-core

B1

cables in skirting trunking

TV TV

ISDN ISDN

Multi-core cable in skirting trunking B2

13 14

Insulated conductors in conduit or

15 single-core or multi-core cable in A1

c

architrave

Insulated conductors in conduit or

16 single-core or multi-core cable in A1

c

window frames

Single-core or multi-core cables:

20 C

– fixed on, or spaced less than 0,3 ×

cable diameter from a wooden wall

C, with item 3 of

21 – fixed directly under a wooden ceiling

table A.52-17

22 – spaced from a ceiling Under consideration

a

Values given for installation methods B1 and B2 in annex A are for a single circuit. Where there is more than

one circuit in the trunking the group reduction factor given in table A.52-17 is applicable, irrespective of the

presence of an internal barrier or partition.

b

The thermal resistivity of the enclosure is assumed to be poor because of the material of construction and

possible air spaces. Where the construction is thermally equivalent to methods of installation 6 or 7, reference

method B1 may be used.

c

The thermal resistivity of the enclosure is assumed to be poor because of the material of construction and

possible air spaces. Where the construction is thermally equivalent to methods of installation 6, 7, 8, or 9,

reference methods B1 or B2 may be used.

60364-5-52 © IEC:2001 – 11 –

Table 52-3 (continued)

Reference method of

Item Methods of installation Description installation to be used to

No. obtain current-carrying

capacity

(see annex A)

> < > 0,3 D

e

≥0,3 D

e

c

30 C with item 2

On unperforated tray

a

of table A.52-17

> < ≥0,3 D

> 0,3 D e

e

> < > 0,3 D

e

≥0,3 D

e

c

31 E or F with item 4

On perforated tray

a, b

of table A.52-17

≥0,3 D

> < > 0,3 D e

e

> 0,3 D

> <

e

≥0,3 D

e

c

32 E or F

On brackets or on a wire mesh

> 0,3 D

≥0,3 De

> < e

33 Spaced more than 0,3 times E or F

cable diameter from a wall with item 4 or 5

of table A.52-17

a, b

or method G

34 On ladder E or F

35 Single-core or multi-core cable E or F

suspended from or incorporating

a support wire

36 Bare or insulated conductors on G

insulators

a

For certain applications it may be more appropriate to use specific factors, for example tables A.52-20 and

A.52-21 (see A.52.4.2 of annex A).

b

Care shall be taken where the cable runs vertically and ventilation is restricted. The ambient temperature at the

top of the vertical section can be increased considerably. The matter is under consideration.

c

D = the external diameter of a multi-core cable:

e

– 2,2 x the cable diameter when three single core cables are bound in trefoil, or

– 3 x the cable diameter when three single core cables are laid in flat formation.

– 12 – 60364-5-52 © IEC:2001

Table 52-3 (continued)

Item No. Methods of installation Description Reference method of

installation to be used to

obtain current-carrying

capacity

(see annex A)

40 Single-core or multi-core cable in a

1,5 D ≤ V < 20 D

e e

a, 2

building void

B2

V

V

D

D e

e

V ≥ 20 D

e

B1

Single-core or multi-core cable in conduit

d

in a building void

Under consideration

Insulated conductors in cable ducting

1,5 D ≤ V < 20 D

e e

a, c, d

in a building void

24 V

V B2

D

e

D

e

V ≥ 20 D

e

B1

Single-core or multi-core cable in cable Under consideration

d

ducting in a building void

VV

D

e

D

e

Insulated conductors in cable ducting in 1,5 D ≤ V < 5 D

e e

masonry having a thermal resistivity not

B2

a, b, d

V

V greater than 2 K·m/W

5 D ≤ V < 50 D

e e

B1

Single-core or multi-core cable in cable Under consideration

ducting in masonry having a thermal

d

resistivity not greater than 2 K·m/W

Single-core or multi-core cable:

1,5 D ≤ V < 5 D

e e

– in a ceiling void

V

B2

V a, b

– in a suspended floor

D

D

ee

5 D ≤ V < 50 D

e e

B1

Insulated conductors or single-core

B1

50 cable in flush cable trunking in the floor

Multi-core cable in flush cable trunking B2

51 in the floor

a

V = the smaller dimension or diameter of a masonry duct or void, or the vertical depth of a rectangular duct,

floor or ceiling void.

b

D = the external diameter of a multi-core cable:

e

– 2,2 × the cable diameter when three single core cables are bound in trefoil, or

– 3 × the cable diameter when three single core cables are laid in flat formation.

c

D = external diameter of conduit or vertical depth of cable ducting.

e

d

Care shall be taken where the cable runs vertically and ventilation is restricted. The ambient temperature at the

top of the vertical section can be increased considerably. The matter is under consideration.

60364-5-52 © IEC:2001 – 13 –

Table 52-3 (continued)

Reference method of

installation to be used to

Item

Methods of installation Description obtain current-carrying

No.

capacity

(see annex A)

Insulated conductors or single-core

TV TV B1

cables in embedded trunking

ISDN ISDN

Multi-core cable in embedded trunking B2

52 53

1,5 D ≤ V < 20 D

e e

Insulated conductors or single-core

V

V

cables in conduit in an unventilated

B2

D

D e

e

cable channel run horizontally or

V ≥ 20 D

e

a, b

vertically

B1

Insulated conductors in conduit in

55 an open or ventilated cable channel B1

c, d

in the floor

Sheathed single-core or multi-core

56 cable in an open or ventilated cable B1

d

channel run horizontally or vertically

Single-core or multi-core cable direct in

masonry having a thermal resistivity

not greater than 2 K·m/W

57 C

Without added mechanical

e, f

protection

Single-core or multi-core cable direct in

masonry having a thermal resistivity

58 C

not greater than 2 K·m/W

e, f

With added mechanical protection

a

De = external diameter of conduit

V = internal depth of the channel

The depth of the channel is more important than the width.

b

Care shall be taken where the cable runs vertically and ventilation is restricted. The ambient temperature at the

top of the vertical section can be increased considerably. The matter is under consideration.

c

For multi-core cable installed in method 55, use ratings for reference method B2.

d

It is recommended that these methods of installation are used only in areas where access is restricted to

authorised persons so that the reduction in current carrying capacity and the fire hazard due to the accumulation

of debris can be prevented.

e 2

For cables having conductors not greater than 16 mm , the current-carrying capacity may be higher.

f

Thermal resistivity of masonry is not greater than 2 K·m/W.

– 14 – 60364-5-52 © IEC:2001

Table 52-3 (continued)

Reference method of

installation to be used to

Item

Methods of installation Description obtain current-carrying

No.

capacity

(see annex A)

Insulated conductors or single-core

59 B1

a

Cables in conduit in masonry

a

60 Multi-core cables in conduit in masonry B2

Multi-core cable in conduit or in cable

70 D

ducting in the ground

Single-core cable in conduit or in cable

71 D

ducting in the ground

Sheathed single-core or multi-core cables

D

direct in the ground

– without added mechanical protection

(see note)

Sheathed single-core or multi-core cables

73 D

direct in the ground

– with added mechanical protection

(see note)

Sheathed single-core or multi-core cables

80 Under consideration

immersed in water

NOTE The inclusion of directly buried cables in this item is satisfactory when the soil thermal resistivity is of

the order of 2,5 K·m/W. For lower soil resistivities, the current-carrying capacity for directly buried cables is

appreciably higher than for cables in ducts.

a

Thermal resistivity of masonry is not greater than 2 K·m/W.

60364-5-52 © IEC:2001 – 15 –

521.6 Conduits and trunking systems

Several circuits are allowed in the same conduit or trunking provided all conductors are

insulated for the highest nominal voltage present.

522 Selection and erection of wiring systems in relation to external influences

NOTE The external influences categorized in table 51A of IEC 60364-5-51 which are of significance to wiring

systems are included in this clause.

522.1 Ambient temperature (AA)

522.1.1 Wiring systems shall be selected and erected so as to be suitable for the highest

local ambient temperature and to ensure that the limiting temperature indicated in table 54-4

will not be exceeded.

522.1.2 Wiring system components including cables and wiring accessories shall only be

installed or handled at temperatures within the limits stated in the relevant product

specification or as given by the manufacturers.

522.2 External heat sources

522.2.1 In order to avoid the effects of heat from external sources, one of the following

methods or an equally effective method shall be used to protect wiring systems:

– shielding;

– placing sufficiently far from the source of heat;

– selecting a system with due regard for the additional temperature rise which may occur;

– local reinforcement or substitution of insulating material.

NOTE Heat from external sources may be radiated, convected or conducted, e.g.

– from hot water systems,

– from plant appliances and luminaires,

– from manufacturing process,

– through heat conducting materials,

– from solar gain of the wiring system or its surrounding medium.

522.3 Presence of water (AD)

522.3.1 Wiring systems shall be selected and erected so that no damage is caused by the

ingress of water. The completed wiring system shall comply with the IP degree of protection

relevant to the particular location.

NOTE In general, the sheaths and insulation of cables for fixed installations may be regarded, when intact, as

proof against penetration by moisture. Special considerations apply to cables liable to frequent splashing,

immersion or submersion.

522.3.2 Where water may collect or condensation may form in wiring systems, provision shall

be made for its escape.

522.3.3 Where wiring systems may be subjected to waves (AD6), protection against mecha-

nical damage shall be afforded by one or more of the methods of 522.6, 522.7 and 522.8.

– 16 – 60364-5-52 © IEC:2001

522.4 Presence of solid foreign bodies (AE)

522.4.1 Wiring systems shall be selected and erected so as to minimize the danger arising

from the ingress of solid foreign bodies. The completed wiring system shall comply with the IP

degree of protection relevant to the particular location.

522.4.2 In a location where dust in significant quantity is present (AE4), additional precautions

shall be taken to prevent the accumulation of dust or other substances in quantities which

could adversely affect the heat dissipation from the wiring system.

NOTE A wiring system which facilitates the removal of dust may be necessary (see clause 529).

522.5 Presence of corrosive or polluting substances (AF)

522.5.1 Where the presence of corrosive or polluting substances, including water, is likely to

give rise to corrosion or deterioration, parts of the wiring system likely to be affected shall be

suitably protected or manufactured from a material resistant to such substances.

NOTE Suitable protection for application during erection may include protective tapes, paints or grease.

522.5.2 Dissimilar metals liable to initiate electrolytic action shall not be placed in contact with

each other, unless special arrangements are made to avoid the consequences of such

contacts.

522.5.3 Materials liable to cause mutual or individual deterioration or hazardous degradation

shall not be placed in contact with each other.

522.6 Impact (AG)

522.6.1 Wiring systems shall be selected and erected so as to minimize the damage arising

from mechanical stress, e.g. by impact, penetration or compression.

522.6.2 In fixed installations where impacts of medium severity (AG2) or high severity (AG3)

can occur protection shall be afforded by:

– the mechanical characteristics of the wiring system; or

– the location selected; or

– the provision of additional local or general mechanical protection; or

– by any combination of the above.

522.7 Vibration (AH)

522.7.1 Wiring systems supported by or fixed to structures of equipment subject to vibration

of medium severity (AH2) or high severity (AH3) shall be suitable for such conditions,

particularly where cables and cable connections are concerned.

NOTE Special attention should be paid to connections to vibrating equipment. Local measures may be adopted

such as flexible wiring systems.

522.7.2 Fixed installation of suspended current-using equipment, e.g. luminaires, shall be

connected by cable with flexible core. Where no vibration nor movement can be expected,

cable with non-flexible core may be used

522.8 Other mechanical stresses (AJ)

522.8.1 Wiring systems shall be selected and erected so as to prevent during installation,

use or maintenance, damage to the sheath and insulation of cables and insulated conductors

and their terminations.

60364-5-52 © IEC:2001 – 17 –

522.8.2 (522.8.1.1) When buried in the structure, conduits or cable ducting systems shall be

completely erected for each circuit before any insulated conductor or cable is drawn in.

522.8.3 (522.8.1.2) The radius of every bend in a wiring system shall be such that

conductors or cables shall not suffer damage.

522.8.4 (522.8.1.3) Where the conductors or cables are not supported continuously due to

the method of the installation, they shall be supported by suitable means at appropriate

intervals in such a manner that the conductors or cables do not suffer damage by their own

weight.

522.8.5 (522.8.1.4) Where a permanent tensile stress is applied to the wiring system (e.g.

by its own weight in vertical runs) a suitable type of cable or conductor with appropriate cross-

sectional areas and method of mounting shall be selected in such a manner that the

conductors or cables do not suffer damage by their own weight.

522.8.6 (522.8.1.5) Wiring systems intended for the drawing in or out of conductors or

cables shall have adequate means of access to allow this operation.

522.8.7 (522.8.1.6) Wiring systems buried in floors shall be sufficiently protected to prevent

damage caused by the intended use of the floor.

522.8.8 (522.8.1.7) Wiring systems which are rigidly fixed and buried in the walls shall be

run horizontally or vertically or parallel to the room edges.

Wiring systems concealed in the structure but not fixed may follow the shortest practical

route.

522.8.9 (522.8.1.8) Flexible wiring systems shall be installed so that excessive tensile

stress to the conductors and connections is avoided.

522.9 Presence of flora and/or mould growth (AK)

522.9.1 Where the conditions experienced or expected constitute a hazard (AK2), the wiring

system shall be selected accordingly or special protective measures shall be adopted.

NOTE An installation method which facilitates the removal of such growths may be necessary (see clause 529).

522.10 Presence of fauna (AL)

522.10.1 Where conditions experienced or expected constitute a hazard (AL2) the wiring

system shall be selected accordingly or special protective measures shall be adopted,

for example, by:

– the mechanical characteristics of the wiring system; or

– the location selected; or

– the provision of additional local or general mechanical protection; or

– by any combination of the above.

522.11 Solar radiation (AN)

522.11.1 Where significant solar radiation (AN2) is experienced or expected, a wiring system

suitable for the conditions shall be selected and erected or adequate shielding shall be

provided.

NOTE See also 522.2.1 dealing with temperature rise.

– 18 – 60364-5-52 © IEC:2001

522.12 Seismic effects (AP)

522.12.1 The wiring system shall be selected and erected with due regard to the seismic

hazards of the location of the installation.

522.12.2 Where the seismic hazards experienced are low severity (AP2) or higher, particular

attention shall be paid to the following:

– the fixing of wiring systems to the building structure;

– the connections between the fixed wiring and all items of essential equipment, e.g. safety

services, shall be selected for their flexible quality.

522.13 Wind (AR)

522.13.1 See 522.7, Vibration (AH), and 522.8, Other mechanical stresses (AJ).

522.14 Nature of processed or stored materials (BE)

522.14.1 See 527, Selection and erection of wiring systems to minimize the spread of fire.

522.15 (522.14) Building design (CB)

522.15.1 (522.14.1) Where risks due to structural movement exist (CB3), the cable support

and protection system employed shall be capable of permitting relative movement so that

conductors and cables are not subjected to excessive mechanical stress.

522.15.2 (522.14.2) For flexible or unstable structures (CB4), flexible wiring systems shall

be used.

523 Current-carrying capacities

523.1 (523.1.3) The current to be carried by any conductor for sustained periods during

normal operation shall be such that the appropriate temperature limit specified in table 52-4 is

not exceeded. The value of current shall be selected in accordance with 523.2, or determined

in accordance with 523.3.

Table 52-4 (52-A) – Maximum operating temperatures for types of insulation

a

Type of insulation

Temperature limit

°C

Polyvinyl-chloride (PVC) 70 at the conductor

b

Cross-linked polyethylene (XLPE) and ethylene propylene rubber (EPR)

90 at the conductor

Mineral (PVC covered or bare exposed to touch) 70 at the sheath

b, c

Mineral (bare not exposed to touch and not in contact with combustible material)

105 at the sheath

a

The maximum permissible conductor temperatures given in table 52-4 on which the tabulated current-carrying

a

capacities given in annex A are based, have been taken from IEC 60502 (1983) and IEC 60702 (1981) and

are shown on these tables.

b

Where a conductor operates at a temperature exceeding 70 °C it shall be ascertained that the equipment

connected t

...

SLOVENSKI SIST IEC 60364-5-52

STANDARD

september 2006

Električne inštalacije zgradb – 5-52. del: Izbira in namestitev električne

opreme – Inštalacijski sistemi

Electrical installations of buildings – Part 5-52: Selection and erection of electrical

equipment – Wiring systems

Installation électriques des bâtiments – Partie 5-52: Choix et mise en œuvre des

matériels électriques – Canalisations

Referenčna oznaka

ICS 13.260; 91.140.50 SIST IEC 60364-5-52:2006 (sl)

Nadaljevanje na straneh od 2 do 70

© 2010–03: Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov standarda ni dovoljeno.

SIST IEC 60364-5-52 : 2006

NACIONALNI UVOD

Standard SIST IEC 60364-5-52 (sl), Električne inštalacije zgradb – 5-52. del: Izbira in namestitev

električne opreme – Inštalacijski sistemi, 2006, ima status slovenskega standarda in je istoveten

mednarodnemu standardu IEC 60364-5-52 (en), Electrical installations of building – Part 5-52:

Selection and erection of electrical equipment – Wiring systems, 2001.

NACIONALNI PREDGOVOR

Mednarodni standard IEC 60364-5-52:2001 je pripravil tehnični odbor Mednarodne elektrotehniške

komisije IEC/TC 64 Električne inštalacije in zaščita pred električnim udarom.

Slovenski standard SIST IEC 60364-5-52:2006 je prevod mednarodnega standarda IEC 60364-5-

52:2001. V primeru spora glede besedila slovenskega prevoda v tem standardu je odločilen izvirni

evropski standard v angleškem jeziku. Slovensko izdajo standarda je pripravil tehnični odbor SIST/TC

ELI Nizkonapetostne in komunikacijske električne inštalacije.

Odločitev za privzem tega standarda po metodi ponatisa je dne 2006-07-11 sprejel tehnični odbor

SIST/TC ELI. Hkrati je odbor tudi sklenil, da se pripravi prevod standarda.

OSNOVA ZA IZDAJO STANDARDA

Privzem standarda IEC 60364-5-52:2001.

ZVEZE S STANDARDI

S privzemom tega evropskega standarda veljajo za omenjeni namen referenčnih standardov vsi

standardi, navedeni v izvirniku, razen tistih, ki so že sprejeti v nacionalno standardizacijo:

SIST EN 60332-3-24:2010 Preskusi na električnih kablih in kablih iz optičnih vlaken v požarnih

razmerah – 3-24. del: Preskus navpičnega širjenja ognja po navpično

pritrjenih snopih žic ali kablov – Kategorija C (IEC 60332-3-24:2000 +

A1:2008)

Tests on electric cables under fire conditions – Part 3-24: Test for

vertical flame spread of vertically-mounted bunched wire or cables –

Category C

SIST EN 60439-2:2000 Sestavi nizkonapetostnih stikalnih in krmilnih naprav – 2. del: Posebne

zahteve za zbiralčne razdelilne sisteme (zbiralčna vodila)

(IEC 60439-2:2000)

Low-voltage switchgear and controlgear assemblies – Part 2:

Particular requirements for busbar trunking systems (busways)

SIST EN 60529:1997 Stopnje zaščite z okrovi (kode IP) (IEC 60529:1989)

2)

Degrees of protection provided by enclosures (IP Code)

SIST IEC/TR2 61200-52:2000 Vodilo za električne inštalacije – 52. del: Izbira in namestitev

električne opreme – Inštalacijski sistem (IEC 61200-52:1993)

Electrical installation guide – Part 52: Selection and erection of

electrical equipment – Wiring systems

OPOMBI

– Nacionalni uvod in nacionalni predgovor nista sestavni del standarda.

– Povsod, kjer se v besedilu standarda uporablja izraz “mednarodni standard”, v

SIST IEC 60364-5-52 : 2006

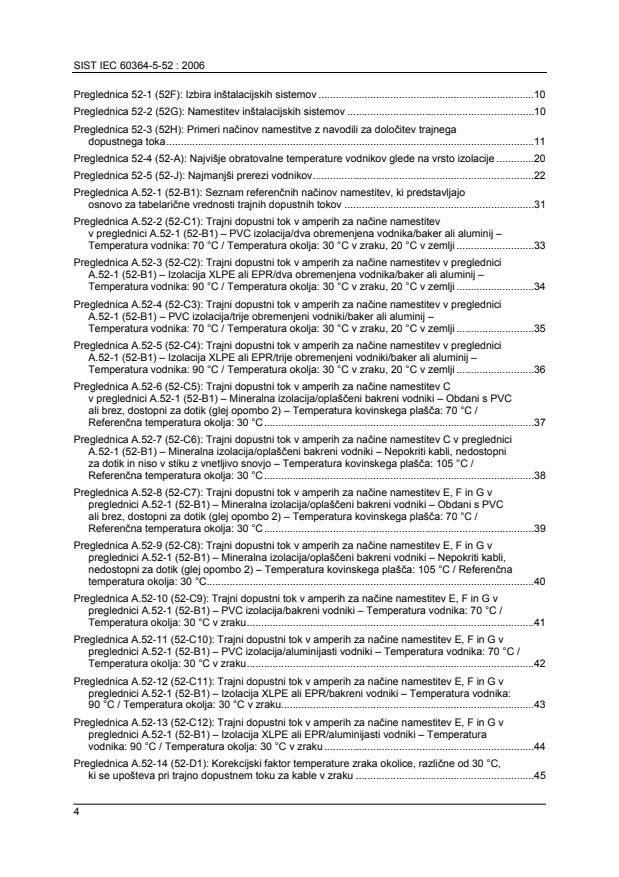

VSEBINA Stran

Predgovor .6

1 Uvod .8

520.1 Področje uporabe .8

520.2 Zveza s standardi .8

520.3 Splošno .9

521 Vrste inštalacijskih sistemov.9

522 Izbira in namestitev inštalacijskega sistema glede na zunanje vplive.17

522.1 Temperatura okolja (AA) .17

522.2 Zunanji viri toplote .17

522.3 Prisotnost vode (AD) .17

522.4 Prisotnost tujih trdnih teles (AE).17

522.5 Prisotnost snovi, ki povzročajo korozijo ali onesnaženje (AF) .18

522.6 Vpliv udarcev (AG) .18

522.7 Vibracije (AH) .18

522.8 Druge mehanske obremenitve (AJ).18

522.9 Prisotnost rastlinstva in/ali razvoj plesni (AK) .19

522.10 Prisotnost živali (AL).19

522.11 Sončno sevanje (AN) .19

522.12 Potresni učinki (AP).19

522.13 Gibanje zraka (AR).20

522.14 Lastnosti obdelovalnih ali skladiščenih materialov (BE).20

522.15 Načrtovanje stavb (CB) .20

523 Trajni dopustni tok .20

524 Prerezi vodnikov.22

525 Padec napetosti v uporabniških inštalacijah .23

526 Električni spoji.23

527 Izbira in izvedba inštalacijskega sistema za zmanjšanje širjenja požara.23

527.1 Previdnostni ukrepi v požarno ločenih območjih (v požarnem sektorju).23

527.2 Tesnjenje prebojev inštalacijskih sistemov .24

528 Približevanje inštalacijskega sistema drugim vodom .25

528.1 Približevanje električnim vodom.25

528.2 Približevanje neelektričnim vodom.25

529 Izbira in namestitev inštalacijskega sistema glede na vzdrževanje, vključno s čiščenjem .26

Dodatek A (normativni): Trajno dopustni tok.27

Dodatek B (informativni): Primer metode poenostavitev preglednic, podanih v točki 523.52

Dodatek C (informativni): Enačbe, ki izražajo trajni dopustni tok.56

Dodatek D (informativni): Vpliv harmonikov toka na uravnoteženost trifaznega sistema .60

Dodatek E (informativni): IEC 60364 – 1. do 6. del: Prestrukturiranje .62

Literatura.70

SIST IEC 60364-5-52 : 2006

Preglednica 52-1 (52F): Izbira inštalacijskih sistemov .10

Preglednica 52-2 (52G): Namestitev inštalacijskih sistemov .10

Preglednica 52-3 (52H): Primeri načinov namestitve z navodili za določitev trajnega

dopustnega toka.11

Preglednica 52-4 (52-A): Najvišje obratovalne temperature vodnikov glede na vrsto izolacije .20

Preglednica 52-5 (52-J): Najmanjši prerezi vodnikov.22

Preglednica A.52-1 (52-B1): Seznam referenčnih načinov namestitev, ki predstavljajo

osnovo za tabelarične vrednosti trajnih dopustnih tokov .31

Preglednica A.52-2 (52-C1): Trajni dopustni tok v amperih za načine namestitev

v preglednici A.52-1 (52-B1) – PVC izolacija/dva obremenjena vodnika/baker ali aluminij –

Temperatura vodnika: 70 °C / Temperatura okolja: 30 °C v zraku, 20 °C v zemlji .33

Preglednica A.52-3 (52-C2): Trajni dopustni tok v amperih za načine namestitev v preglednici

A.52-1 (52-B1) – Izolacija XLPE ali EPR/dva obremenjena vodnika/baker ali aluminij –

Temperatura vodnika: 90 °C / Temperatura okolja: 30 °C v zraku, 20 °C v zemlji .34

Preglednica A.52-4 (52-C3): Trajni dopustni tok v amperih za načine namestitev v preglednici

A.52-1 (52-B1) – PVC izolacija/trije obremenjeni vodniki/baker ali aluminij –

Temperatura vodnika: 70 °C / Temperatura okolja: 30 °C v zraku, 20 °C v zemlji .35

Preglednica A.52-5 (52-C4): Trajni dopustni tok v amperih za načine namestitev v preglednici

A.52-1 (52-B1) – Izolacija XLPE ali EPR/trije obremenjeni vodniki/baker ali aluminij –

Temperatura vodnika: 90 °C / Temperatura okolja: 30 °C v zraku, 20 °C v zemlji .36

Preglednica A.52-6 (52-C5): Trajni dopustni tok v amperih za načine namestitev C

v preglednici A.52-1 (52-B1) – Mineralna izolacija/oplaščeni bakreni vodniki – Obdani s PVC

ali brez, dostopni za dotik (glej opombo 2) – Temperatura kovinskega plašča: 70 °C /

Referenčna temperatura okolja: 30 °C.37

Preglednica A.52-7 (52-C6): Trajni dopustni tok v amperih za načine namestitev C v preglednici

A.52-1 (52-B1) – Mineralna izolacija/oplaščeni bakreni vodniki – Nepokriti kabli, nedostopni

za dotik in niso v stiku z vnetljivo snovjo – Temperatura kovinskega plašča: 105 °C /

Referenčna temperatura okolja: 30 °C.38

Preglednica A.52-8 (52-C7): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – Mineralna izolacija/oplaščeni bakreni vodniki – Obdani s PVC

ali brez, dostopni za dotik (glej opombo 2) – Temperatura kovinskega plašča: 70 °C /

Referenčna temperatura okolja: 30 °C.39

Preglednica A.52-9 (52-C8): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – Mineralna izolacija/oplaščeni bakreni vodniki – Nepokriti kabli,

nedostopni za dotik (glej opombo 2) – Temperatura kovinskega plašča: 105 °C / Referenčna

temperatura okolja: 30 °C.40

Preglednica A.52-10 (52-C9): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – PVC izolacija/bakreni vodniki – Temperatura vodnika: 70 °C /

Temperatura okolja: 30 °C v zraku.41

Preglednica A.52-11 (52-C10): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – PVC izolacija/aluminijasti vodniki – Temperatura vodnika: 70 °C /

Temperatura okolja: 30 °C v zraku.42

Preglednica A.52-12 (52-C11): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – Izolacija XLPE ali EPR/bakreni vodniki – Temperatura vodnika:

90 °C / Temperatura okolja: 30 °C v zraku.43

Preglednica A.52-13 (52-C12): Trajni dopustni tok v amperih za načine namestitev E, F in G v

preglednici A.52-1 (52-B1) – Izolacija XLPE ali EPR/aluminijasti vodniki – Temperatura

vodnika: 90 °C / Temperatura okolja: 30 °C v zraku .44

Preglednica A.52-14 (52-D1): Korekcijski faktor temperature zraka okolice, različne od 30 °C,

ki se upošteva pri trajno dopustnem toku za kable v zraku .45

SIST IEC 60364-5-52 : 2006

Preglednica A.52-15 (52-D2): Korekcijski faktorji za temperature okolne zemlje,

različne od 20 °C, ki se upošteva pri trajnem dopustnem toku za kable v kanalih v zemlji .46

Preglednica A.52-16 (52-D3): Korekcijski faktorji za kable v kanalih, zakopanih v zemljo,

s toplotno upornostjo, različno od 2,5 K·m/W, ki se upošteva pri trajnem dopustnem toku za

referenčni način namestitve D.46

Preglednica A.52-17 (52-E1): Redukcijski faktorji za skupine z več kot enim tokokrogom ali

več kot enim večžilnim kablom, ki se upošteva pri trajnem dopustnem toku v preglednicah

A.52-2 (52-C1) do A.52-13 (52-C12).47

Preglednica A.52-18 (52-E2): Redukcijski faktorji za več kot en tokokrog za kable, položene

neposredno v zemlji – Način namestitve D v preglednicah A.52-2 (52-C1) do A.52-13 (52-C4) –

Enožilni ali večžilni kabli.48

Preglednica A.52-19 (52-E3): Redukcijski faktorji za več kot en tokokrog za kable, položene

v kanalih v zemlji – Način namestitve D v preglednicah A.52-2 (52-C1) do A.52-5 (52-C4) .49

Preglednica A.52-20 (52-E4): Redukcijski faktorji za skupino z več kot enim večžilnim kablom,

ki se uporablja za večžilne kable, položene prosto v zraku – Način namestitve E v preglednicah

A.52-8 (52-C7) do A.52-13 (52-C12).50

Preglednica A.52-21 (52-E5): Redukcijski faktor za skupine z več kot enim tokokrogom enožilnih

kablov (opomba 2), ki se uporablja za enožilne kable z enim tokokrogom, položene prosto

v zraku – Način namestitve F v preglednicah A.52-8 (52-C7) do A.52-13 (52-C12) .51

Preglednica B.52-1 (A.52-1): Trajni dopustni tok (v amperih).53

Preglednica B.52-2 (A.52-2): Trajni dopustni tok (v amperih).54

Preglednica B.52-3 (A.52-3): Redukcijski faktorji za skupine z več tokokrogi ali z več

večžilnimi kabli (uporabiti skupaj s trajnim dopustnim tokom v preglednici B.52-1 (A.52-1)) .55

Preglednica C.52-1 (B.52-1): Preglednica koeficientov in eksponentov .57

Preglednica D.52-1 (C.52-1): Redukcijski faktorji za harmonike toka v štirižilnih in petžilnih

kablih .61

Preglednica E.1: Povezava med prestrukturiranimi in originalnimi deli .62

Preglednica E.2: Povezava med novim in starim številčenjem točk .66

SIST IEC 60364-5-52 : 2006

MEDNARODNA ELEKTROTEHNIŠKA KOMISIJA

ELEKTRIČNE INŠTALACIJE ZGRADB

5-52. del: Izbira in namestitev električne opreme – Inštalacijski sistemi

PREDGOVOR

1) IEC (Mednarodna elektrotehniška komisija) je svetovna organizacija za standardizacijo, ki združuje

vse nacionalne elektrotehnične komiteje (nacionalni komiteji IEC). Cilj IEC je pospeševati

mednarodno sodelovanje v vseh vprašanjih standardizacije s področja elektrotehnike in

elektronike. V ta namen poleg drugih aktivnosti izdaja mednarodne standarde. Za njihovo pripravo

so odgovorni tehnični odbori (TC). Vsak nacionalni komite IEC, ki ga zanima obravnavana tema,

lahko sodeluje v tem pripravljalnem delu. Prav tako lahko v pripravi sodelujejo mednarodne

organizacije ter vladne in nevladne ustanove, ki so povezane z IEC. IEC deluje v tesni povezavi z

mednarodno organizacijo za standardizacijo ISO skladno s pogoji, določenimi v soglasju med

obema organizacijama.

2) Uradne odločitve ali sporazumi IEC o tehničnih vprašanjih, pripravljeni v tehničnih odborih, kjer so

prisotni vsi nacionalni komiteji, ki jih tema zanima, izražajo, kolikor je mogoče, mednarodno

soglasje o obravnavani temi.

3) Publikacije IEC imajo obliko priporočil za mednarodno uporabo in se izdajajo kot standardi,

tehnične specifikacije, tehnična poročila ali vodila ter jih kot takšne sprejmejo nacionalni komiteji

IEC.

4) Da bi se pospeševalo mednarodno poenotenje, so nacionalni komiteji IEC v svojih nacionalnih in

regionalnih standardih dolžni čim pregledneje uporabljati mednarodne standarde. Vsako

odstopanje med standardom IEC in ustreznim nacionalnim ali regionalnim standardom je treba v

slednjem jasno označiti.

5) IEC ni določil nobenega postopka označevanja, ki bi kazal na njegovo potrditev in ne more biti

odgovoren za katero koli opremo, ki bi bila deklarirana kot skladna z eno od njegovih publikacij.

6) Opozarjamo na možnost, da bi lahko bil kateri od elementov tega mednarodnega standarda

predmet patentnih pravic. IEC ni odgovoren za identificiranje nobene od teh patentnih pravic.

Mednarodni standard IEC 60364-5-52 je pripravil tehnični odbor IEC/TC 64 Električne inštalacije in

zaščita pred električnim udarom.

Skupina standardov IEC 60364 (deli 1 do 6) je bila prestrukturirana brez tehničnih sprememb v

preprostejšo obliko (glej dodatek E).

Po soglasni odločitvi izvršnega odbora (CA/1720/RV (2000-03-21)) prestrukturirani deli IEC 60364

niso bili predloženi nacionalnim odborom v odobritev.

Sestavljeno besedilo te druge izdaje IEC 60364-5-52 nadomešča:

– 5.52. del, prvo izdajo (1993) in njegovo dopolnilo 1 (1997);

– 5-523. del, drugo izdajo (1999).

Ta publikacija je bila oblikovana kar najbolj v skladu z direktivo ISO/IEC, 3. del.

SIST IEC 60364-5-52 : 2006

Dodatek A je sestavni del tega standarda.

Dodatki B, C, D in E so le informativni.

Tehnični odbor je sklenil, da bo vsebina tega standarda ostala nespremenjena do leta 2005. Po tem

datumu bo publikacija:

– ponovno potrjena,

– razveljavljena,

– zamenjana z revidirano (popravljeno) izdajo ali

– dopolnjena.

SIST IEC 60364-5-52 : 2006

MEDNARODNA ELEKTROTEHNIŠKA KOMISIJA

ELEKTRIČNE INŠTALACIJE ZGRADB

5-52. del: Izbira in namestitev električne opreme – Inštalacijski sistemi

1 Uvod

520.1 Področje uporabe

Del 5-52 dokumenta IEC 60364 obravnava izbiro in način namestitve inštalacijskih sistemov.

OPOMBA: Ta standard velja na splošno tudi za zaščitne vodnike, medtem ko IEC 60364-5-54 navaja še druge zahteve za

te vodnike.

520.2 Zveza s standardi

Spodaj navedeni normativni dokumenti vsebujejo določila, ki s sklicevanjem v tem besedilu tvorijo

določila tega dela IEC 60364. Pri datiranih sklicevanjih se poznejša dopolnila ali spremembe katerekoli

od teh publikacij ne upoštevajo. Stranke naj v pogodbah, ki temeljijo na tem delu IEC 60364, uporabljajo

najnovejšo izdajo normativnih dokumentov, navedenih spodaj. Pri nedatiranih sklicevanjih se uporablja

zadnja izdaja normativnih dokumentov. Člani IEC in ISO vodijo sezname trenutno veljavnih mednarodnih

standardov.

IEC 60228:1978 Vodniki izoliranih kablov

Conductors of insulated cables

IEC 60287-1-1:1994 Electric cables – Calculation of the current rating – Part 1: Current rating

equations (100 % load factor) and calculation of losses – Section 1: General

IEC 60287-2-1:1994 Electric cables – Calculation of the current rating – Part 2: Thermal resistance –

Section 1: Calculation of thermal resistance

IEC 60287-3-1:1995 Electric cables – Calculation of the current rating – Part 3: Sections on

operating conditions – Section 1: Reference operating conditions and selection

1)

of cable type

IEC 60332-1:1993 Tests on electric cables under fire conditions – Part 1: Test on a single vertical

insulated wire or cable

IEC 60332-3-24:2000 Tests on electric cables under fire conditions – Part 3-24: Test for vertical flame

spread of vertically-mounted bunched wire or cables – Category C

IEC 60439-2:2000 Sestavi nizkonapetostnih stikalnih in krmilnih naprav – 2. del: Posebne zahteve

za zbiralčne razdelilne sisteme (zbiralčna vodila)

Low-voltage switchgear and controlgear assemblies – Part 2: Particular

requirements for busbar trunking systems (busways)

2)

IEC 60529:1989 Degrees of protection provided by enclosures (IP Code)

IEC 60614 (vsi deli) Specification for conduits for electrical installations

IEC 61200-52:1993 Vodilo za električne inštalacije – 52. del: Izbira in namestitev električne opreme

– Inštalacijski sistem

Electrical installation guide – Part 52: Selection and erection of electrical

equipment – Wiring systems

ISO 834 (vsi deli) Fire-resistance tests – Elements of building construction

1)

Konsolidirana izdaja 1.1 (1999), ki vključuje IEC 60287-3-1 (1995) in dopolnilo 1 (1999).

2)

Konsolidirana izdaja 2.1 (2001), ki vključuje IEC 60529 (1989) in dopolnilo 1 (1999).

SIST IEC 60364-5-52 : 2006

520.3 Splošno

Upoštevati je treba temeljna načela IEC 60364-1, ki se uporabljajo za kable in vodnike, za njihovo

priključevanje in/ali spajanje, način nameščanja, pritrjevanja ali obešanja in za njihove okrove ali

metode zaščite pred zunanjimi vplivi.

521 Vrste inštalacijskih sistemov

521.1 Način namestitve inštalacijskega sistema glede na vrsto vodnika ali kabla, ki se uporablja, mora

biti v skladu s preglednico 52-1, pod pogojem, da so zunanji vplivi zajeti v ustreznih standardih za

posamezne proizvode.

521.2 Način namestitve inštalacijskega sistema glede na okolico mora biti v skladu s preglednico

52-2.

521.3 Primeri načinov namestitev inštalacijskih sistemov skupaj z navedbo ter sklicevanjem na

ustrezne preglednice, po katerih se izbere trajni dopustni tok, so prikazani v preglednici 52-3.

OPOMBA 1: Druge vrste inštalacijskih sistemov, ki niso zajeti v tem standardu, se lahko uporabljajo, če so v skladu s

splošnimi pravili iz tega standarda.

OPOMBA 2: Preglednica 52-3 podaja referenčne načine namestitev inštalacijskih sistemov, pri katerih se trajni dopustni toki

lahko varno uporabljajo. Ni nujno, da so vse te vrste inštalacijskih sistemov dopustne v nacionalnih pravilih v

vseh državah.

521.4 Zbiralčni razdelilni sistemi

Zbiralčni razdelilni sistemi morajo biti v skladu z IEC 60439-2 in nameščeni skladno z navodili

proizvajalca. Namestitev mora biti v skladu z zahtevami iz točk 522 (razen 522.1.1, 522.3.3, 522.8.7,

522.8.8 in 522.8.9), 525, 526, 527 in 528.

521.5 Izmenični tokokrogi

Vodniki izmeničnih tokokrogov, nameščenih v feromagnetnih ohišjih, morajo biti položeni tako, da so

vsi vodniki vsakega tokokroga v istem ohišju.

OPOMBA: Če ta pogoj ni izpolnjen, se lahko zaradi induktivnosti pojavijo pregrevanja in prevelik padec napetosti.

SIST IEC 60364-5-52 : 2006

Preglednica 52-1 (52F): Izbira inštalacijskih sistemov

Način namestitve

Kabelska

Kabelske lestev,

Vodniki in kabli

Brez Neposredno kinete Kabelski kabelske Na Z nosilno

V ceveh

pritrjevanja pritrjevanje (na steni, kanali police, izolatorjih žico

v tleh) kabelski

nosilci

Goli vodniki – – – – – – + –

Izolirani vodniki – – + + + – + –

Oplaščeni

Večžilni + + + + + + 0 +

kabli

(vključno s

kovinskim

opletom in

Enožilni 0 + + + + + 0 +

mineralno

izolacijo)

+ Dovoljeno

– Ni dovoljeno

0 Se ne uporablja ali se v praksi ponavadi ne uporablja.

Preglednica 52-2 (52G): Namestitev inštalacijskih sistemov

Način namestitve

Kabelska

Kabelske lestev,

Namestitev

Brez Neposredno kinete Kabelski kabelske Na Z nosilno

V ceveh

pritrjevanja pritrjevanje (na steni, kanali police, izolatorjih žico

v tleh) kabelski

nosilci

40, 46, 15, 16, 30, 31, 32,

V prostorih v stavbah 0 – 43 – –

15, 16 41, 42 33, 34

30, 31, 32,

Kabelski kanal 56 56 54, 55 0 44, 45 – –

33, 34

Zakopan v zemlji 72, 73 0 70, 71 – 70, 71 0 – –

1, 2, 50, 51,

Pod omet 57, 58 3 44, 45 0 – –

59, 60 52, 53

20, 21, 6, 7, 8, 9, 6, 7, 30, 31, 32,

Nad omet – 4, 5 36 –

22, 23 12, 13, 14 8, 9 33, 34

30, 31, 32,

V zraku – – 0 10, 11 – 36 35

33, 34

Potopljen v vodi 80 80 0 – 0 0 – –

Številka v vsakem okencu označuje številko pozicije v preglednici 52-3.

– Ni dovoljeno.

0 Se ne uporablja ali se v praksi ponavadi ne uporablja.

SIST IEC 60364-5-52 : 2006

Preglednica 52-3 (52H): Primeri načinov namestitve z navodili za določitev

trajnega dopustnega toka

OPOMBA: Skice ne prikazujejo dejanskega načina namestitve v praksi, ampak služijo za opis načina namestitve.

Oznaka načina

namestitve za

Zap. št. Način namestitve Opis določitev trajnega

dopustnega toka

(glej dodatek A)

Izolirani vodniki ali enožilni kabli

1 Prostor A1

a

v cevi v toplotno izolirani steni

Večžilni kabel v cevi v toplotno

2 Prostor A2

a

izolirani steni

Večžilni kabel neposredno v

3 Prostor A1

a

toplotno izolirani steni

Izolirani vodniki ali enožilni kabli

v cevi na leseni steni ali steni z

4 B1

ometom ali odmikom od stene

manj kot 0,3-kratni premer cevi

Večžilni kabli v cevi na leseni

steni ali steni z ometom ali

5 B2

odmikom od stene manj kot

0,3-kratni premer cevi

Izolirani vodniki ali enožilni kabli

v kabelskem kanalu na leseni

steni B1

b

– vodoravno

b, c

– navpično

Večžilni kabel v kabelskem

kanalu na leseni steni d

V obravnavi

b

– vodoravno

b, c

– navpično

a 2

Toplotna prevodnost notranje plasti zidu ne sme biti manj kot 10 W/m · K.

b

Vrednosti za načina namestitve B1 in B2 v dodatku A veljajo za posamezen tokokrog. Kadar je več tokokrogov v isti

cevi, se uporablja redukcijski faktor skupine tokokrogov iz preglednice A.52-17 ne glede na prisotnost notranjih pregrad

ali sten.

c

Kjer kabli potekajo navpično in je prezračevanje omejeno, se lahko temperatura okolice na vrhu navpičnega odseka

znatno poveča. Zadeva je v obravnavi.

d

Uporabijo se lahko vrednosti za referenčni način namestitve B2.

SIST IEC 60364-5-52 : 2006

Preglednica 52-3 (nadaljevanje)

Oznaka načina

namestitve za

Zap. št. Način namestitve Opis določitev trajnega

dopustnega toka

(glej dodatek A)

Izolirani vodniki ali enožilni kabli v

10 B1

a

obešenem kabelskem kanalu

Večžilni kabel v obešenem

a

11 B2

kabelskem kanalu

10 11

Izolirani vodniki ali enožilni kabli

12 A1

b

v okrasnih letvah

Izolirani vodniki ali enožilni kabli

13 v večprekatnem kabelskem B1

kanalu

14 Večžilni kabel v večprekatnem B2

kabelskem kanalu

13 14

Izolirani vodniki v kovinskem

15 profilu ali enožilni ali večžilni A1

c

kabli v vratnem okvirju

Izolirani vodniki v kovinskem

16 profilu ali enožilni ali večžilni A1

c

kabli v okenskem okvirju

Enožilni ali večžilni kabli:

– pritrjeni na leseno steno ali

20 odmaknjeni od lesene stene C

manj kot 0,3-kratni premer

kabla

– pritrjeni neposredno na lesen C s točko 3 iz

strop preglednice A.52-17

– odmaknjeni od lesenega

22 V obravnavi

stropa

a

Vrednosti za načina namestitve B1 in B2 v dodatku A veljajo za posamezen tokokrog. Kadar obstaja več tokokrogov v

istem kanalu, se uporablja redukcijski faktor skupine tokokrogov iz preglednice A.52-17 ne glede na prisotnost notranjih

pregrad ali sten v kanalu.

b

Toplotna upornost okrasnih letev je zaradi zraka v njih ter zaradi materiala predvidoma slaba. Kjer je material toplotno

enakovreden načinu namestitve 6 ali 7, se lahko uporabi način namestitve B1.

c

Toplotna upornost okvirja je zaradi zraka v njem ter zaradi materiala predvidoma slaba. Kjer je material toplotno

enakovreden načinu namestitve 6, 7, 8 ali 9, se lahko uporabita načina namestitve B1 in B2.

SIST IEC 60364-5-52 : 2006

Preglednica 52-3 (nadaljevanje)

Oznaka načina

namestitve za

določitev trajnega

Zap. št. Način namestitve Opis

dopustnega toka

(glej dodatek A)

C s točko 2 iz

c

30 Na neperforirani kabelski polici

a

preglednice A.52-17

E ali F s točko 4 iz

c

31 Na perforirani kabelski polici a, b

preglednice A.52-17

Na konzolah ali mrežastih

32 E ali F

c

kabelskih policah

E ali F s točkama 4 ali 5

Odmaknjen od stene več kot

33 iz preglednice A.52-17

0,3-kratni premer kabla a, b

ali način G

34 Na kabelski lestvi E ali F

Enožilni ali večžilni kabli z

35 nosilno žico ali obešeni na E ali F

nosilni žici

Goli ali izolirani vodniki na

36 G

podpornih izolatorjih

a

Za nekatere vrste kabelskih polic je primerneje uporabljati specifične faktorje, kot na primer v preglednicah A.52-20 in

A.52.21 (glej A.52.4.2, dodatek A).

b

Kjer kabli potekajo navpično in je prezračevanje omejeno, se lahko temperatura okolice na vrhu navpičnega odseka

znatno poveča. Zadeva je v obravnavi.

c

D = zunanji premer večžilnega kabla:

e

– 2,2-kratni premer kabla, kadar so trije enožilni kabli položeni v trojček ali

– 3-kratni premer kabla, kadar so trije enožilni kabli položeni eden ob drugem.

SIST IEC 60364-5-52 : 2006

Preglednica 52-3 (nadaljevanje)

Oznaka načina

namestitve za

Zap. št. Način namestitve Opis določitev trajnega

dopustnega toka

(glej dodatek A)

1,5 D ≤ V < 20 D

e e

Enožilni ali večžilni kabli v B2

a, 2

medprostoru

V ≥ 20 D

e

B1

Enožilni ali večžilni kabli v cevi v

42 V obravnavi

d

medprostoru

1,5 D ≤ V < 20 D

e e

B2

Izolirani vodniki v kabelskem

a, c, d

kanalu v medprostoru

V ≥ 20 D

e

B1

Enožilni ali večžilni kabli v

43 kabelskem kanalu v V obravnavi

d

medprostoru

1,5 D ≤ V < 5 D

e e

Izolirani vodniki v kabelskem

B2

kanalu v zidu s toplotno

upornostjo, manjšo od

5 D ≤ V < 50 D

e e

a, b, d

2 K · m/W

B1

Enožilni ali večžilni kabli v

kabelskem kanalu v zidu s

45 V obravnavi

toplotno upornostjo, manjšo od

d

2 K · m/W

1,5 D ≤ V < 5 D

e e

Enožilni ali večžilni kabli:

B2

46 – v sekundarnem stropu

a, b

5 D ≤ V < 50 D

e e

– v dvojnem podu

B1

Izolirani vodniki ali enožilni kabli

50 B1

v kabelskem kanalu v tleh

Večžilni kabli v kabelskem

51 B2

kanalu v tleh

a

V = manjša dimenzija ali premer obzidanega kanala ali odprtine ali navpična globina pravokotnega kanala, dvojnega poda

ali sekundarnega stropa

b

D = zunanji premer večžilnega kabla:

e

– 2,2-kratni premer kabla, kadar so trije enožilni kabli položeni v trojček ali

– 3-kratni premer kabla, kadar so trije enožilni kabli položeni eden ob drugem

c

D = zunanji premer cevi ali navpična globina kabelskega kanala

e

d

Kjer kabli potekajo navpično in je prezračevanje omejeno, se lahko temperatura okolice na vrhu navpičnega odseka

znatno poveča. Zadeva je v obravnavi.

SIST IEC 60364-5-52 : 2006

Preglednica 52-3 (nadaljevanje)

Oznaka načina

namestitve za

Zap. št.

Način namestitve Opis določitev trajnega

dopustnega toka

(glej dodatek A)

Izolirani vodniki ali enožilni kabli B1

v parapetnem kanalu

Večžilni kabli v parapetnem B2

kanalu

52 53

1,5 D ≤ V < 20 D

e e

Izolirani vodniki ali enožilni kabli

v cevi v profilu ali

B2

54 neprezračevanem vodoravnem

V ≥ 20 D

ali navpičnem kabelskem

e

a, b

kanalu

B1

Izolirani vodniki v cevi v

55 odprtem ali prezračevanem B1

c, d

talnem kabelskem kanalu

Izolirani vodniki z opletom ali

večžilni kabli v odprtem ali

56 B1

prezračevanem vodoravnem ali

d

navpičnem kabelskem kanalu

Izolirani vodniki ali večžilni kabli

neposredno v ometu iz

57 materiala s toplotno upornostjo, C

manjšo od 2 K · m/W, brez

e, f

dodatne mehanske zaščite

Izolirani vodniki ali večžilni kabli

neposredno v ometu iz

58 materiala s toplotno upornostjo, C

manjšo od 2 K · m/W, z dodatno

e, f

mehansko zaščito

a

D = zunanji premer cevi