IEC 60810:2003

(Main)Lamps for road vehicles - Performance requirements

Lamps for road vehicles - Performance requirements

One of a series of IEC standards for incandescent lamps to be used in headlamps, fog-lamps and signalling lamps of road vehicles.

Lampes pour véhicules routiers - Prescriptions de performances

Fait partie d'une série de normes de la CEI relatives aux lampes à filament à être utilisées dans les projecteurs avant; feux de brouillard et feux de signalisation des véhicules routiers.

General Information

- Status

- Published

- Publication Date

- 13-Feb-2013

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 6 - TC 34/SC 34A/WG 6

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 16-Dec-2014

- Completion Date

- 14-Feb-2026

Relations

- Amended By

IEC 60810:2003/AMD2:2013 - Amendment 2 - Lamps for road vehicles - Performance requirements - Effective Date

- 05-Sep-2023

- Amended By

IEC 60810:2003/AMD1:2008 - Amendment 1 - Lamps for road vehicles - Performance requirements - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 60810:2003 is an international standard developed by the International Electrotechnical Commission (IEC) that defines performance requirements for lamps used in road vehicles. This standard applies to incandescent filament lamps, discharge lamps, and LED light sources designed for integration in headlamps, fog-lamps, and signalling lamps. It is part of a series of IEC standards focusing on lamp performance specifically for automotive applications.

The primary goal of IEC 60810 is to provide standardized test methods and performance benchmarks related to lamp life, durability, lumen maintenance, mechanical strength, and environmental resistance. It complements the basic requirements laid out in IEC 60809, offering manufacturers, designers, and certification bodies a reliable framework to ensure high-quality road vehicle lighting products.

Key Topics

IEC 60810 encompasses a range of critical performance aspects for automotive lamps:

Lamp Life and Lumen Maintenance

Specifies characteristic life values and lumen output retention over time for filament, discharge, and LED lamps to guarantee consistent illumination performance.Mechanical Strength

Includes tests for torsion strength, glass bulb strength, and resistance to vibration and shock, ensuring lamps withstand road conditions, mechanical impacts, and vibrations.Electrical and Thermal Conditions

Provides guidelines on maximum tolerable voltage surges and temperature operating limits to protect lamp integrity and ensure safety.Interchangeability and Basic Function

Addresses design parameters for consistent fit and performance across different vehicle models and lighting systems.Electromagnetic Compatibility (for LED Light Sources)

Ensures LED lamps meet EMC requirements to prevent interference with vehicular electronic systems.Test Conditions and Methods

Detailed normative annexes define testing procedures for life expectancy, vibration, glass strength, lumen maintenance, and thermal cycling.

Applications

IEC 60810 is essential in the design, manufacture, and quality assurance of lighting components for road vehicles, including:

- Headlamps – ensuring long-lasting, reliable, and safe illumination for driver visibility.

- Fog lamps – maintaining performance under harsh environmental conditions such as moisture and vibration.

- Signalling lamps – guaranteeing visibility and compliance for indicator, brake, and tail lighting.

- Automotive lighting equipment design – guiding engineers on mechanical and electrical limits including bulb size, power surges, and heat dissipation.

- Quality Control and Certification – providing test methods and performance criteria for regulatory approvals and market acceptance.

- LED Light Source Development – addressing the evolving use of LEDs with performance metrics including lumen and color maintenance, thermal cycling, and EMC.

By adhering to IEC 60810, manufacturers can assure that automotive lamps meet international safety and performance standards critical for road safety.

Related Standards

IEC 60810 is part of a broader family of IEC standards aimed at automotive lighting and lamp performance:

- IEC 60809 – Basic specification for incandescent lamps used in road vehicles, focusing on lamp dimensions and electrical characteristics.

- IEC 60068 Series – Environmental testing standards referenced for vibration and thermal cycling tests.

- ISO 303 – Standard related to photometric and colorimetric methods for vehicle lighting.

- IEC 62471 – Photobiological safety of lamps, addressing UV radiation considerations relevant to LED sources.

These complementary standards collectively support robust quality control, enhance interoperability, and promote standardized vehicle lighting solutions worldwide.

Keywords: IEC 60810, automotive lamps, road vehicle lighting, filament lamps, LED light sources, discharge lamps, lamp performance, vehicle headlamps, fog lamps, signaling lamps, lamp durability, vibration resistance, lumen maintenance, mechanical strength, electrical surges, automotive lighting standards.

Buy Documents

IEC 60810:2003 - Lamps for road vehicles - Performance requirements Released:5/21/2003

IEC 60810:2003+AMD1:2008 CSV - Lamps for road vehicles - Performance requirements Released:10/15/2008

IEC 60810:2003+AMD1:2008+AMD2:2013 CSV - Lamps for road vehicles - Performance requirements Released:2/14/2013

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 60810:2003 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Lamps for road vehicles - Performance requirements". This standard covers: One of a series of IEC standards for incandescent lamps to be used in headlamps, fog-lamps and signalling lamps of road vehicles.

One of a series of IEC standards for incandescent lamps to be used in headlamps, fog-lamps and signalling lamps of road vehicles.

IEC 60810:2003 is classified under the following ICS (International Classification for Standards) categories: 29.140.99 - Other standards related to lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 60810:2003 has the following relationships with other standards: It is inter standard links to IEC 60810:2003/AMD2:2013, IEC 60810:2003/AMD1:2008, IEC 60810:2014, IEC 60810:1993/AMD2:2001, IEC 60810:1993. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 60810:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2003-05

Lampes pour véhicules routiers –

Prescriptions de performances

Lamps for road vehicles –

Performance requirements

Numéro de référence

Reference number

CEI/IEC 60810:2003

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(http://www.iec.ch/searchpub/cur_fut.htm) vous permet (http://www.iec.ch/searchpub/cur_fut.htm) enables

de faire des recherches en utilisant de nombreux you to search by a variety of criteria including text

critères, comprenant des recherches textuelles, par searches, technical committees and date of

comité d’études ou date de publication. Des publication. On-line information is also available

informations en ligne sont également disponibles sur on recently issued publications, withdrawn and

les nouvelles publications, les publications rempla- replaced publications, as well as corrigenda.

cées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published • IEC Just Published

Ce résumé des dernières publications parues This summary of recently issued publications

(http://www.iec.ch/online_news/justpub/jp_entry.htm) (http://www.iec.ch/online_news/justpub/jp_entry.htm)

est aussi disponible par courrier électronique. is also available by email. Please contact the

Veuillez prendre contact avec le Service client Customer Service Centre (see below) for further

(voir ci-dessous) pour plus d’informations. information.

• Service clients • Customer Service Centre

Si vous avez des questions au sujet de cette If you have any questions regarding this

publication ou avez besoin de renseignements publication or need further assistance, please

supplémentaires, prenez contact avec le Service contact the Customer Service Centre:

clients:

Email: custserv@iec.ch Email: custserv@iec.ch

Tél: +41 22 919 02 11 Tel: +41 22 919 02 11

Fax: +41 22 919 03 00 Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Troisième édition

STANDARD

Third edition

2003-05

Lampes pour véhicules routiers –

Prescriptions de performances

Lamps for road vehicles –

Performance requirements

IEC 2003 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in any

utilisée sous quelque forme que ce soit et par aucun procédé, form or by any means, electronic or mechanical, including

électronique ou mécanique, y compris la photocopie et les photocopying and microfilm, without permission in writing from

microfilms, sans l'accord écrit de l'éditeur. the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

CODE PRIX

V

Commission Electrotechnique Internationale PRICE CODE

International Electrotechnical Commission

Международная Электротехническая Комиссия

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 60810 CEI:2003

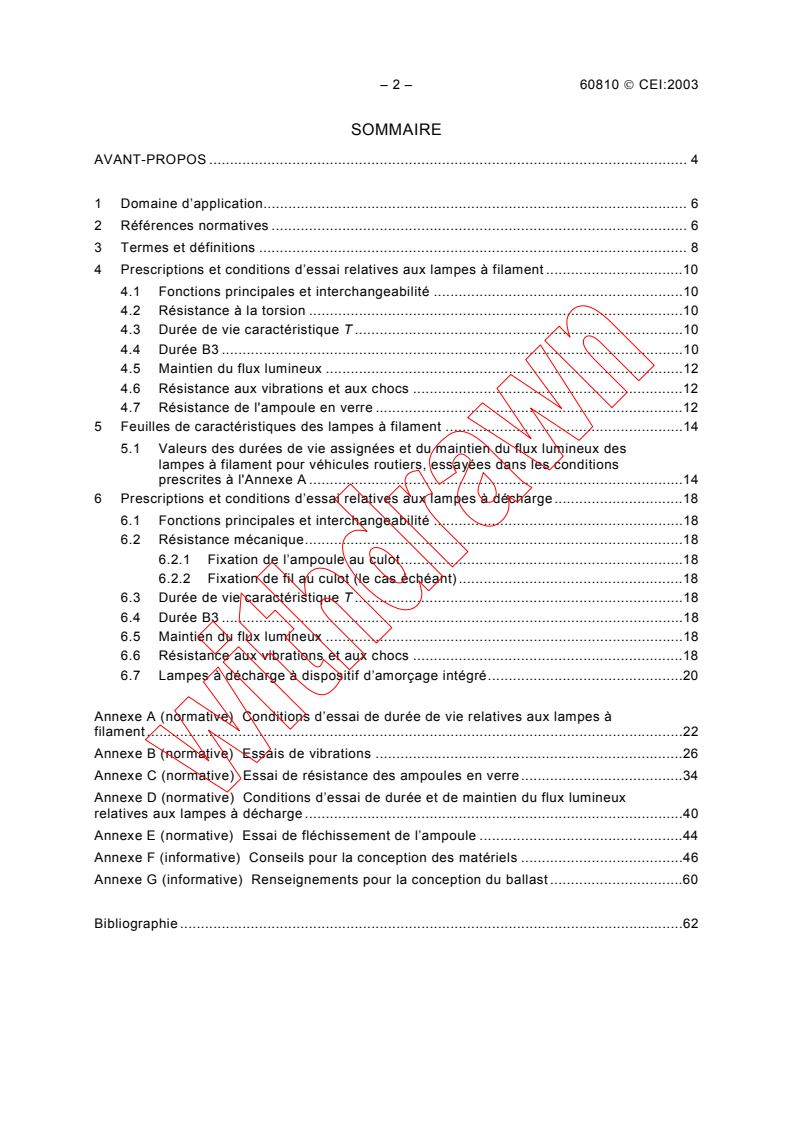

SOMMAIRE

AVANT-PROPOS . 4

1 Domaine d’application. 6

2 Références normatives . 6

3 Termes et définitions . 8

4 Prescriptions et conditions d’essai relatives aux lampes à filament .10

4.1 Fonctions principales et interchangeabilité .10

4.2 Résistance à la torsion .10

4.3 Durée de vie caractéristique T .10

4.4 Durée B3 .10

4.5 Maintien du flux lumineux .12

4.6 Résistance aux vibrations et aux chocs .12

4.7 Résistance de l'ampoule en verre .12

5 Feuilles de caractéristiques des lampes à filament .14

5.1 Valeurs des durées de vie assignées et du maintien du flux lumineux des

lampes à filament pour véhicules routiers, essayées dans les conditions

prescrites à l'Annexe A .14

6 Prescriptions et conditions d’essai relatives aux lampes à décharge.18

6.1 Fonctions principales et interchangeabilité .18

6.2 Résistance mécanique.18

6.2.1 Fixation de l’ampoule au culot.18

6.2.2 Fixation de fil au culot (le cas échéant) .18

6.3 Durée de vie caractéristique T .18

6.4 Durée B3 .18

6.5 Maintien du flux lumineux .18

6.6 Résistance aux vibrations et aux chocs .18

6.7 Lampes à décharge à dispositif d’amorçage intégré.20

Annexe A (normative) Conditions d’essai de durée de vie relatives aux lampes à

filament.22

Annexe B (normative) Essais de vibrations .26

Annexe C (normative) Essai de résistance des ampoules en verre.34

Annexe D (normative) Conditions d’essai de durée et de maintien du flux lumineux

relatives aux lampes à décharge .40

Annexe E (normative) Essai de fléchissement de l’ampoule .44

Annexe F (informative) Conseils pour la conception des matériels .46

Annexe G (informative) Renseignements pour la conception du ballast .60

Bibliographie .62

60810 IEC:2003 – 3 –

CONTENTS

FOREWORD . 3

1 Scope . 7

2 Normative references. 7

3 Terms and definitions . 9

4 Requirements and test conditions for filament lamps .11

4.1 Basic function and interchangeability.11

4.2 Torsion strength .11

4.3 Characteristic life T.11

4.4 Life B3.11

4.5 Lumen maintenance .13

4.6 Resistance to vibration and shock .13

4.7 Glass-bulb strength .13

5 Filament lamp data .15

5.1 Rated life and lumen-maintenance values for road vehicle filament lamps

tested under conditions as prescribed in Annex A.15

6 Requirements and test conditions for discharge lamps.19

6.1 Basic function and interchangeability.19

6.2 Mechanical strength.19

6.3 Characteristic life T.19

6.4 Life B3.19

6.5 Lumen maintenance .19

6.6 Resistance to vibration and shock .19

6.7 Discharge lamps with integrated starting device .21

Annex A (normative) Life test conditions for filament lamps.23

Annex B (normative) Vibration tests .27

Annex C (normative) Glass-bulb strength test .35

Annex D (normative) Life and lumen maintenance test conditions for discharge lamps.41

Annex E (normative) Bulb deflection test.45

Annex F (informative) Guidance for equipment design.47

Annex G (informative) Information for ballast design .61

Bibliography.63

– 4 – 60810 CEI:2003

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

LAMPES POUR VÉHICULES ROUTIERS –

PRESCRIPTIONS DE PERFORMANCES

AVANT-PROPOS

1) La CEI (Commission Electrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les

deux organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible, un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 60810 a été établie par le sous-comité 34A: Lampes, du comité

d'études 34 de la CEI: Lampes et équipements associés.

Cette troisième édition annule et remplace la deuxième édition parue en 1993, ainsi que ses

amendements 1(1994) et 2(2001). Elle constitue une révision technique.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

34A/1031/FDIS 34A/1034/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote

ayant abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 2.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2005. A

cette date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

60810 IEC:2003 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LAMPS FOR ROAD VEHICLES –

PERFORMANCE REQUIREMENTS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International

Organization for Standardization (ISO) in accordance with conditions determined by agreement between the

two organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60810 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This third edition cancels and replaces the second edition published in 1993 and its

amendment 1 (1994) and amendment 2 (2001).It constitutes a technical revision.

The text of this standard is based on the following documents:

FDIS Report on voting

34A/1031/FDIS 34A/1034/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 6 – 60810 CEI:2003

LAMPES POUR VÉHICULES ROUTIERS –

PRESCRIPTIONS DE PERFORMANCES

1 Domaine d’application

La présente Norme internationale est applicable aux lampes remplaçables (lampes à filament

et lampes à décharge) destinées à être utilisées dans les projecteurs avant, feux de brouillard

et feux de signalisation des véhicules routiers. Elle s’applique particulièrement aux lampes

figurant dans la CEI 60809. Cependant, elle peut aussi être utilisée pour d’autres lampes

relevant de son domaine d’application, ainsi que pour des réalisations futures, par exemple

dans le cas où la lumière est produite par des diodes électroluminescentes (DEL).

Elle précise les prescriptions et les méthodes de vérification des caractéristiques de

performance telles que la durée de la lampe, le maintien du flux lumineux, la résistance à la

torsion, la résistance de l’ampoule de verre et la résistance aux vibrations et aux chocs. En

outre, des renseignements sont donnés sur les limites de température, les encombrements

maximaux et les surtensions maximales admissibles, en vue de guider la conception des

équipements électriques et d’éclairage.

Pour certaines des prescriptions de la présente norme, le texte renvoie à des données

figurant dans des tableaux. Pour les lampes qui n’apparaissent pas dans ces tableaux, les

données correspondantes sont fournies par le fabricant ou le vendeur responsable.

Les prescriptions de performance sont un complément aux prescriptions principales

spécifiées dans la CEI 60809. Elles ne sont cependant pas destinées à être utilisées par les

administrations pour les homologations légales de type.

NOTE Dans les divers vocabulaires et normes, différents termes sont utilisés pour désigner une «lampe à

incandescence» (VEI 845-07-04) et une «lampe à décharge» (VEI 845-07-17). La présente norme utilise les

termes «lampe à filament» et «lampe à décharge». Cependant, lorsque le terme «lampe» apparaît seul, ce terme

désigne les deux types, à moins que le contexte n’indique clairement qu’il ne s’applique qu’à l’un des types.

2 Références normatives

Les documents de référence suivants sont indispensables pour l'application du présent

document. Pour les références datées, seule l'édition citée s'applique. Pour les références

non datées, la dernière édition du document de référence s'applique (y compris les éventuels

amendements).

CEI 60050(845):1987, Vocabulaire Électrotechnique International (VEI) – Chapitre 845: Éclairage

CEI 60068-2-6:1995, Essais d'environnement – Partie 2: Essais – Essai Fc: Vibrations

(sinusoïdales) – Publication fondamentale de sécurité

CEI 60068-2-47:1999, Essais d'environnement – Partie 2-47: Méthodes d’essai – Fixation de

composants, matériels et autres articles pour essais dynamiques de vibrations, d’impacts et

autres essais similaires

CEI 60410:1973, Plans et règles d'échantillonnage pour les contrôles par attributs

CEI 60809, Lampes pour véhicules routiers – Prescriptions dimensionnelles, électriques, et

lumineuses

ISO 5344:1980, Moyens d’essais électrodynamiques utilisés pour la génération de vibrations

– Méthodes de description des caractéristiques

60810 IEC:2003 – 7 –

LAMPS FOR ROAD VEHICLES –

PERFORMANCE REQUIREMENTS

1 Scope

This International Standard is applicable to replaceable lamps (filament lamps and discharge

lamps) to be used in headlamps, fog-lamps and signalling lamps for road vehicles. It is

especially applicable to those lamps which are listed in IEC 60809. However, the standard

may also be used for other lamps falling under the scope of this standard, as well as for future

developments, e.g. such where the light is produced by light emitting diodes (LED).

It specifies requirements and test methods for the measurement of performance charac-

teristics such as lamp life, lumen maintenance, torsion strength, glass bulb strength and

resistance to vibration and shock. Moreover, information on temperature limits, maximum

lamp outlines and maximum tolerable voltage surges is given for the guidance of lighting and

electrical equipment design.

For some of the requirements given in this standard, reference is made to data given in

tables. For lamps not listed in such tables, the relevant data are supplied by the lamp

manufacturer or responsible vendor.

The performance requirements are additional to the basic requirements specified in

IEC 60809. They are, however, not intended to be used by authorities for legal type-approval

purposes.

NOTE In the various vocabularies and standards, different terms are used for "incandescent lamp"

(IEV 845-07-04) and "discharge lamp" (IEV 845-07-17). In this standard, "filament lamp" and "discharge lamp" are

used. However, where only “lamp” is written both types are meant, unless the context clearly shows that it applies

to one type only.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050(845):1987, International Electrotechnical Vocabulary (IEV) – Chapter 845: Lighting

IEC 60068-2-6:1995, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal) –

Basic safety publication

IEC 60068-2-47:1999, Environmental testing – Part 2-47: Test methods – Mounting of

components, equipment and other articles for vibration, impact and similar dynamic tests

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 60809, Lamps for road vehicles – Dimensional, electrical and luminous requirements

ISO 5344:1980, Electrodynamic test equipment for generating vibration – Methods of describ-

ing equipment characteristics

– 8 – 60810 CEI:2003

3 Termes et définitions

Pour les besoins du présent document, les définitions suivantes s'appliquent, ainsi que celles

qui sont données dans la CEI 60050(845) et la CEI 60809.

3.1

durée de vie

totalité du temps (exprimé en heures) pendant lequel une lampe a fonctionné avant d’être

hors d’usage. Une lampe à filament est considérée comme telle selon l’un ou l’autre des

critères suivants:

a) la fin de vie est l’instant où se produit la défaillance du filament;

b) la fin de vie d’une lampe à deux filaments est l’instant où se produit la défaillance de l’un

ou l’autre des filaments, si la lampe est essayée selon un cycle d’allumage impliquant le

fonctionnement alterné des deux filaments

3.2

durée de vie caractéristique

T

constante de la distribution de Weibull indiquant le temps au bout duquel 63,2 % du nombre

de lampes essayées, du même type, ont atteint la fin de leur durée de vie individuelle

3.3

durée B3

constante de la distribution de Weibull indiquant le temps au bout duquel 3 % du nombre de

lampes essayées, du même type, ont atteint la fin de leur durée de vie individuelle

3.4

maintien du flux lumineux

rapport entre le flux lumineux d'une lampe, à un instant donné de sa vie, et son flux lumineux

initial, la lampe ayant fonctionné dans des conditions spécifiées

3.5

flux lumineux initial

flux lumineux d’une lampe mesuré après le vieillissement spécifié à l’Annexe C de la

CEI 60809 pour les lampes à filament ou à l’Annexe D de la présente norme pour les lampes

à décharge

3.6

valeur assignée

valeur d'une caractéristique spécifiée, pour le fonctionnement d'une lampe, à la tension

d'essai et/ou à d'autres conditions spécifiées

3.7

température limite du pincement

température maximale admissible au pincement, afin d'assurer à une lampe une performance

satisfaisante en service

3.8

température limite de soudure

température maximale admissible de la soudure afin d'assurer à une lampe une performance

satisfaisante en service

3.9

encombrement maximal d'une lampe

contour délimitant le volume à réserver, pour la lampe, dans l'appareil correspondant

60810 IEC:2003 – 9 –

3 Terms and definitions

For the purpose of this document, the following definitions apply, in addition to the definitions

in IEC 60050(845) and IEC 60809.

3.1

life

total time (expressed in hours) during which a lamp has been operated before it becomes

useless. For filament lamps, it is considered to be so according to one of the following criteria:

a) the end of life is the time when the filament fails;

b) the life of a dual-filament lamp is the time until either filament fails, if the lamp is tested in

a switching cycle involving alternative operation of both filaments

3.2

characteristic life

T

constant of the Weibull distribution indicating the time up to which 63,2 % of a number of

tested lamps of the same type have ended their individual lives

3.3

life B3

constant of the Weibull distribution indicating the time during which 3 % of a number of the

tested lamps of the same type have reached the end of their individual lives

3.4

lumen maintenance

ratio of the luminous flux of a lamp at a given time in its life to its initial luminous flux, the

lamp being operated under specific conditions

3.5

initial luminous flux

luminous flux of a lamp measured after the ageing specified in Annex C of IEC 60809 for

filament lamps or in Annex D of this standard for discharge lamps

3.6

rated value

value of a characteristic specified for operation of a lamp at test voltage and/or other specified

conditions

3.7

pinch temperature limit

maximum admissible pinch temperature to ensure satisfactory lamp performance in service

3.8

solder temperature limit

maximum admissible solder temperature to ensure satisfactory lamp performance in service

3.9

maximum lamp outline

contour limiting the space to be reserved for the lamp in the relevant equipment

– 10 – 60810 CEI:2003

3.10

lampe pour usage intensif

lampe déclarée comme telle par le fabricant ou le vendeur responsable, et qui doit satisfaire

aux conditions d'essais d'environnement sévères spécifiées dans le Tableau B.2 de la

présente norme en complément des prescriptions spécifiées dans la CEI 60809

4 Prescriptions et conditions d’essai relatives aux lampes à filament

4.1 Fonctions principales et interchangeabilité

Les lampes à filament doivent satisfaire à la CEI 60809.

4.2 Résistance à la torsion

Le culot doit être solide et fermement fixé à l'ampoule.

La conformité est vérifiée avant et après l'essai de durée, en soumettant la lampe à filament

aux couples de torsion suivants:

lampes à filament avec culots à baïonnette

- pour les chemises de diamètre 9 mm: 0,3 Nm*

- pour les chemises de diamètre 15 mm: 1,5 Nm*

- pour les chemises de diamètre 20 mm: 3,0 Nm*

lampes à filament avec culots à vis

- pour les chemises de diamètre 10 mm: 0,8 Nm*.

Le couple de torsion ne doit pas être appliqué brusquement, mais doit augmenter progres-

sivement de 0 à la valeur spécifiée.

Les valeurs sont basées sur un niveau de non-conformité de 1 %.

4.3 Durée de vie caractéristique T

La durée T, mesurée sur un échantillonnage d'essai, d'au moins 20 lampes à filament, doit

être d'au moins 96 % de la valeur assignée donnée dans le Tableau 3.

La conformité est vérifiée par les essais de durée prescrits à l'Annexe A.

4.4 Durée B3

La durée B3 ne doit pas être inférieure à la valeur assignée donnée dans le Tableau 3.

La conformité est vérifiée par les essais de durée prescrits à l'Annexe A.

Le nombre de lampes à filament hors service avant la durée requise ne doit pas dépasser les

valeurs du Tableau 1.

———————

*

A l'étude.

60810 IEC:2003 – 11 –

3.10

heavy-duty lamp

lamp declared as such, by the manufacturer or responsible vendor, which shall comply with

the heavy-duty test conditions specified in Table B.2 of this standard in addition to the

requirements specified in IEC 60809

4 Requirements and test conditions for filament lamps

4.1 Basic function and interchangeability

Filament lamps shall comply with IEC 60809.

4.2 Torsion strength

The cap shall be strong and firmly secured to the bulb.

Compliance is checked before and after the life test by submitting the filament lamp to the

following torque values:

filament lamps with bayonet caps

*

− with 9 mm shell-diameter: 0,3 Nm ;

− with 15 mm shell-diameter: 1,5 Nm*;

− with 20 mm shell-diameter: 3,0 Nm*;

filament lamps with screw caps

− with 10 mm shell-diameter: 0,8 Nm*.

The torque shall not be applied suddenly but shall be increased progressively from 0 to the

specified amount.

Values are based on a non-compliance level of 1 %.

4.3 Characteristic life T

The life T measured on a test quantity of at least 20 filament lamps shall be at least 96 % of

the rated value, given in Table 3.

Compliance is checked by life tests as prescribed in Annex A.

4.4 Life B3

The life B3 shall not be less than the rated value given in Table 3.

Compliance is checked by life tests as prescribed in Annex A.

The number of filament lamps failing before the required time shall not exceed the values in

Table 1.

———————

*

Under consideration.

– 12 – 60810 CEI:2003

Tableau 1 – Conditions de conformité pour la durée B3

Nombre de lampes

Limite d'acceptation

à filament essayées

23 à 35 2

36 à 48 3

49 à 60 4

61 à 74 5

75 à 92 6

4.5 Maintien du flux lumineux

Le maintien du flux ne doit pas être inférieur à la valeur assignée donnée dans le Tableau 4.

Cette valeur est basée sur un niveau de non-conformité de 10 %.

4.6 Résistance aux vibrations et aux chocs

Dans le cas où la durée pratique est influencée par des vibrations ou des chocs, les

méthodes d'essai et procédures décrites dans l'Annexe B doivent être utilisées afin d'évaluer

la performance.

Les lampes à filament sont considérées comme ayant entièrement satisfait à l'essai de

vibrations aléatoires à large bande ou à bande étroite, tel qu'il est décrit à l'Annexe B, si elles

continuent à fonctionner pendant et après l'essai.

Le nombre de lampes à filament défaillantes lors de l'un des essais ne doit pas dépasser les

valeurs du Tableau 2 (valeurs basées sur un NQA de 4 %).

Tableau 2 – Conditions de conformité pour l'essai de vibrations

Nombre de lampes

Limite d'acceptation

à filament essayées

14 à 20 2

21 à 32 3

33 à 41 4

42 à 50 5

51 à 65 6

4.7 Résistance de l'ampoule en verre

Dans le cas où les ampoules sont affaiblies par une manipulation mécanique lors de leur

assemblage dans un matériel, les méthodes d'essai et procédures définies dans l'Annexe C

doivent être utilisées afin d'évaluer la performance. Les ampoules doivent supporter la force

de compression spécifiée.

60810 IEC:2003 – 13 –

Table 1 – Conditions of compliance for life B3

Number of

Acceptance number

filament lamps tested

23 to 35 2

36 to 48 3

49 to 60 4

61 to 74 5

75 to 92 6

4.5 Lumen maintenance

The lumen maintenance shall be not less than the rated value given in Table 4. This value is

based on a non-compliance level of 10 %.

4.6 Resistance to vibration and shock

In the event of service life being influenced by vibration or shock, the test methods and

schedules detailed in Annex B shall be used to assess the performance.

The filament lamps are deemed to have satisfactorily completed the wideband or narrowband

random vibration test as described in Annex B, if they continue to function during and after

the test.

The number of filament lamps failing one of the tests shall not exceed the values in Table 2

(values are based on the AQL of 4 %).

Table 2 – Conditions of compliance for the vibration test

Number of

Acceptance number

filament lamps tested

14 to 20 2

21 to 32 3

33 to 41 4

42 to 50 5

51 to 65 6

4.7 Glass-bulb strength

In the event of bulbs being impaired by mechanical handling for their assembly in equipment,

the test methods and schedules defined in Annex C shall be used to assess the performance.

The bulbs have to withstand the specified compression strength.

– 14 – 60810 CEI:2003

5 Feuilles de caractéristiques des lampes à filament

5.1 Valeurs des durées de vie assignées et du maintien du flux lumineux

des lampes à filament pour véhicules routiers, essayées dans les conditions

prescrites à l'Annexe A

Tableau 3 – Valeurs des durées de vie assignées, en fonctionnement continu

Lampe à filament Type 12 V 24 V

Feuilles de

Tension B3 T Tension B3 T

caractéristiques

d'essai d'essai

Catégorie

n° V h h V h h

60809-IEC-2110 R2 13,2 90 250 28,0 90 250

a a

60809-IEC-2120 H4 13,2 350 700 28,0

180 500

60809-IEC-2125 H6 14,0 (A l'étude) 300 – – –

60809-IEC-2305 H5 14,0 (A l'étude) 100 – – –

a a

60809-IEC-2310 H1 13,2 150 400 28,0

90 250

60809-IEC-2320 H2 13,2 90 250 28,0 90 250

a a

60809-IEC-2330 H3 13,2 150 400 28,0

90 250

b b b b

60809-IEC-3110 P21/5W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

b b b b

60809-IEC-3120 P21/4W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

a a

60809-IEC-3310 P21W 13,5 120 320 28,0

60 160

a a

60809-IEC-3320 R5W 13,5 100 300 28,0

80 225

a a

60809-IEC-3330 R10W 13,5 100 300 28,0

80 225

a a

60809-IEC-3340 T4W 13,5 300 750 28,0

120 350

a a

60809-IEC-4110 C5W 13,5 350 750 28,0

120 350

60809-IEC-4120 C21W 13,5 40 110 28,0 – –

a a

60809-IEC-4310 W3W 13,5 500 1 500 28,0

400 1 100

a a

60809-IEC-4320 W5W 13,5 200 500 28,0

120 350

NOTE 1 Les valeurs indiquées sont des exigences minimales. En fonction de spécifications particulières des

clients, différentes valeurs peuvent être obtenues, par exemple: durée de vie plus courte avec un flux lumineux

plus élevé ou durée de vie plus longue avec un maintien de flux lumineux inférieur. Ceci sera négocié entre les

fabricants de lampes à filament et leurs clients.

a

Valeurs améliorées à l'étude.

b

Filament de forte puissance.

c

Filament de faible puissance.

60810 IEC:2003 – 15 –

5 Filament lamp data

5.1 Rated life and lumen-maintenance values for road vehicle filament lamps tested

under conditions as prescribed in Annex A

Table 3 – Rated life values for continuous operation

Filament lamp Type 12 V 24 V

Data sheet Category Test B3 T Test B3 T

Nos. V h h V h h

60809-IEC-2110 R2 13,2 90 250 28,0 90 250

a a

60809-IEC-2120 H4 13,2 350 700 28,0

180 500

(Under

60809-IEC-2125 H6 14,0 300 – – –

consideration)

(Under

60809-IEC-2305 H5 14,0 100 – – –

consideration)

a a

60809-IEC-2310 H1 13,2 150 400 28,0

90 250

60809-IEC-2320 H2 13,2 90 250 28,0 90 250

a a

60809-IEC-2330 H3 13,2 150 400 28,0

90 250

b b b b

60809-IEC-3110 P21/5W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

b b b b

60809-IEC-3120 P21/4W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

a a

60809-IEC-3310 P21W 13,5 120 320 28,0

60 160

a a

60809-IEC-3320 R5W 13,5 100 300 28,0

80 225

a a

60809-IEC-3330 R10W 13,5 100 300 28,0

80 225

a a

60809-IEC-3340 T4W 13,5 300 750 28,0

120 350

a a

60809-IEC-4110 C5W 13,5 350 750 28,0

120 350

60809-IEC-4120 C21W 13,5 40 110 28,0 – –

a a

60809-IEC-4310 W3W 13,5 500 1 500 28,0

400 1 100

a a

60809-IEC-4320 W5W 13,5 200 500 28,0

120 350

NOTE 1 The values indicated are minimum requirements. Depending on some particular customers'

specifications, different values may be obtained, i.e. shorter life/higher luminous flux or longer life/lower lumen

maintenance. This has to be negotiated between filament lamp manufacturers and their customers.

a

Extended values are under consideration.

b

High-wattage filament.

c

Low-wattage filament.

– 16 – 60810 CEI:2003

Tableau 4 – Valeurs assignées de la maintenance du flux lumineux,

en fonctionnement continu

Lampe à filament Type 12 V 24 V

Feuilles de Tension Maintien Tension Maintien

caractéristiques d'essai du flux lumineux d'essai du flux lumineux

Catégorie

n° V h % V h %

c c

60809-IEC-2110 R2 13,2 85 28,0 85

55 55

d 70 28,0 d 70

110 110

c c

60809-IEC-2120 H4 13,2 85 85

110 110

d d

85 28,0 85

225 225

c

60809-IEC-2125 H6 14,0 85 –– –

d

60809-IEC-2305 H5 14,0 75 85 – – –

60809-IEC-2310 H1 13,2 170 90 28,0 170 90

60809-IEC-2320 H2 13,2 170 90 28,0 170 90

60809-IEC-2330 H3 13,2 170 90 28,0 170 90

a a

60809-IEC-3110 P21/5W 13,5 70 28,0 70

110 110

b b

70 70

750 750

a

60809-IEC-3120 P21/4W 13,5 70 28,0 (A l'étude) (A l'étude)

b

70 (A l'étude) (A l'étude)

60809-IEC-3310 P21W 13,5 110 70 28,0 110 70

60809-IEC-3320 R5W 13,5 150 70 28,0 150 70

60809-IEC-3330 R10W 13,5 150 70 28,0 150 70

60809-IEC-3340 T4W 13,5 225 70 28,0 225 70

60809-IEC-4110 C5W 13,5 225 60 28,0 225 60

60809-IEC-4120 C21W 13,5 75 60 – – –

60809-IEC-4310 W3W 13,5 750 60 28,0 750 60

60809-IEC-4320 W5W 13,5 225 60 28,0 225 60

NOTE 1 Les valeurs indiquées sont des exigences minimales. En fonction de spécifications particulières des

clients, différentes valeurs peuvent être obtenues, par exemple: durée de vie plus courte avec un flux lumineux

plus élevé ou durée de vie plus longue avec un maintien de flux lumineux inférieur. Ceci sera négocié entre les

fabricants de lampes à filament et leurs clients.

NOTE 2 Les valeurs de maintien du flux lumineux pour des temps d'opération prolongés sont à l'étude.

a

Filament de forte puissance.

b

Filament de faible puissance.

c

Filament route.

d

Filament croisement.

60810 IEC:2003 – 17 –

Table 4 – Rated lumen-maintenance values for continuous operation

Filament lamp Type 12 V 24 V

Data sheet Category Test Lumen maintenance Test Lumen maintenance

Nos.

V h % V h %

c c

60809-IEC-2110 R2 13,2 85 28,0 85

55 55

d d

70 28,0 70

110 110

c c

60809-IEC-2120 H4 13,2 85 85

110 110

d d

85 28,0 85

225 225

c

60809-IEC-2125 H6 14,0 85 –– –

d

60809-IEC-2305 H5 14,0 75 85 – – –

60809-IEC-2310 H1 13,2 170 90 28,0 170 90

60809-IEC-2320 H2 13,2 170 90 28,0 170 90

60809-IEC-2330 H3 13,2 170 90 28,0 170 90

a a

60809-IEC-3110 P21/5W 13,5 70 28,0 70

110 110

b b

70 70

750 750

a

60809-IEC-3120 P21/4W 13,5 110 70 28,0 (Under (Under

consideration) consideration)

b

750 70 (Under (Under

consideration) consideration)

60809-IEC-3310 P21W 13,5 110 70 28,0 110 70

60809-IEC-3320 R5W 13,5 150 70 28,0 150 70

60809-IEC-3330 R10W 13,5 150 70 28,0 150 70

60809-IEC-3340 T4W 13,5 225 70 28,0 225 70

60809-IEC-4110 C5W 13,5 225 60 28,0 225 60

60809-IEC-4120 C21W 13,5 75 60 – – –

60809-IEC-4310 W3W 13,5 750 60 28,0 750 60

60809-IEC-4320 W5W 13,5 225 60 28,0 225 60

NOTE 1 The values indicated are minimum requirements. Depending on some particular customers'

specifications, different values may be obtained, i.e. shorter life/higher luminous flux or longer life/lower lumen

maintenance. This has to be negotiated between filament lamp manufacturers and their customers.

NOTE 2 Lumen-maintenance values for extended operation times are under consideration.

a

High-wattage filament.

b

Low-wattage filament.

c

Main or upper beam filament.

d

Dipped or lower beam filament.

– 18 – 60810 CEI:2003

6 Prescriptions et conditions d’essai relatives aux lampes à décharge

6.1 Fonctions principales et interchangeabilité

Les lampes à décharge doivent satisfaire aux prescriptions techniques de la CEI 60809.

6.2 Résistance mécanique

6.2.1 Fixation de l’ampoule au culot

L’ampoule doit être solidement fixée au culot. La conformité est vérifiée au moyen de l’essai

de fléchissement de l’ampoule conduit conformément à l’Annexe E.

6.2.2 Fixation de fil au culot (le cas échéant)

Si un fil est fixé au culot, cette fixation doit résister à une force de traction de 60 N. La force

doit être appliquée dans la direction du fil (droit).

6.3 Durée de vie caractéristique T

Pour les lampes à décharge D1S, D2S, D1R et D2R, la durée T mesurée sur un échantillon

d’essai d’au moins 20 lampes ne doit pas être inférieure à la valeur déclarée par le fabricant,

laquelle doit être d’au moins 3 000 h. La conformité est vérifiée par les essais prescrits à

l’Annexe D.

6.4 Durée B3

Pour les lampes à décharge D1S, D2S, D1R et D2R, la durée B3 mesurée sur un échantillon

d’essai d’au moins 20 lampes ne doit pas être inférieure à la valeur déclarée par le fabricant,

laquelle doit être d’au moins 1 500 h. La conformité est vérifiée par les essais prescrits à

l’Annexe D.

6.5 Maintien du flux lumineux

Pour les lampes à décharge D1S, D2S, D1R et D2R, le maintien du flux lumineux doit être

d’au moins 60 % du flux lumineux initial. La conformité est vérifiée par les essais prescrits à

l’Annexe D.

Les valeurs sont basées sur un niveau de non-conformité de 10 %.

6.6 Résistance aux vibrations et aux chocs

Dans le cas où la durée pratique est influencée par des vibrations ou des chocs, les

méthodes

...

IEC 60810

Edition 3.1 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lamps for road vehicles – Performance requirements

Lampes pour véhicules routiers – Prescriptions de performances

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 60810

Edition 3.1 2008-10

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Lamps for road vehicles – Performance requirements

Lampes pour véhicules routiers – Prescriptions de performances

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CL

CODE PRIX

ICS 29.140.99 ISBN 978-2-88910-300-3

– 2 – 60810 © IEC:2003+A1:2008

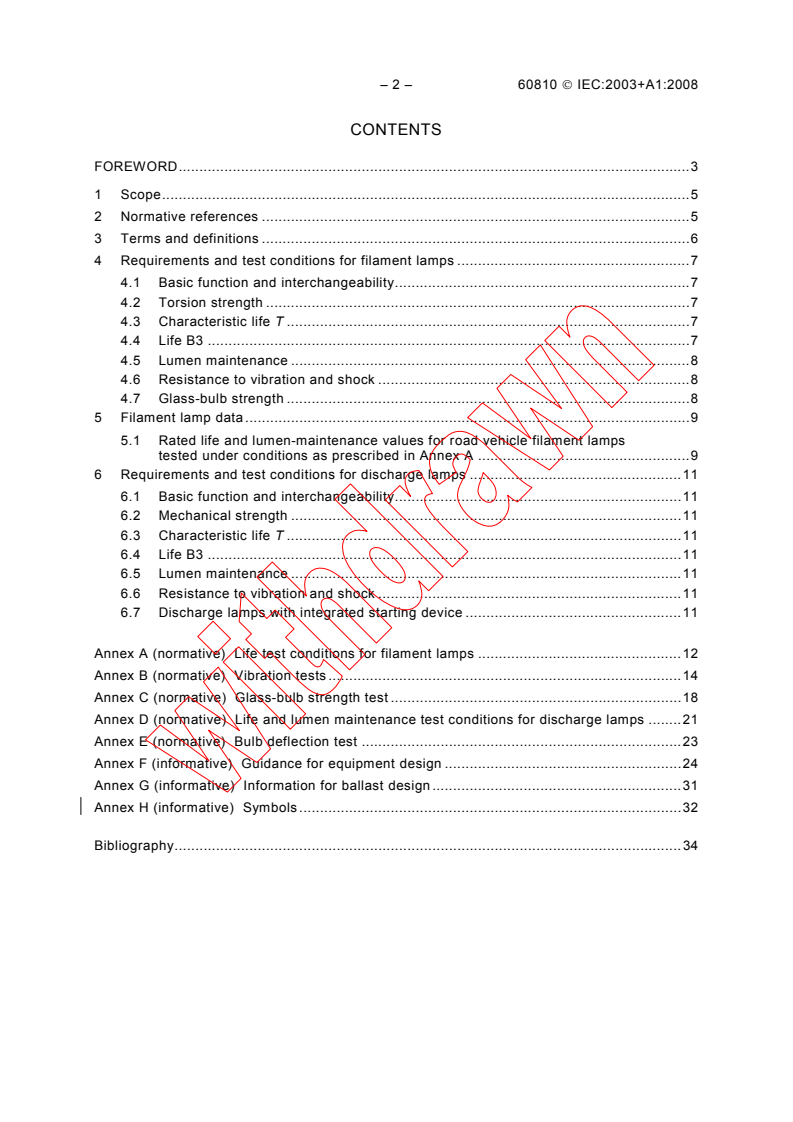

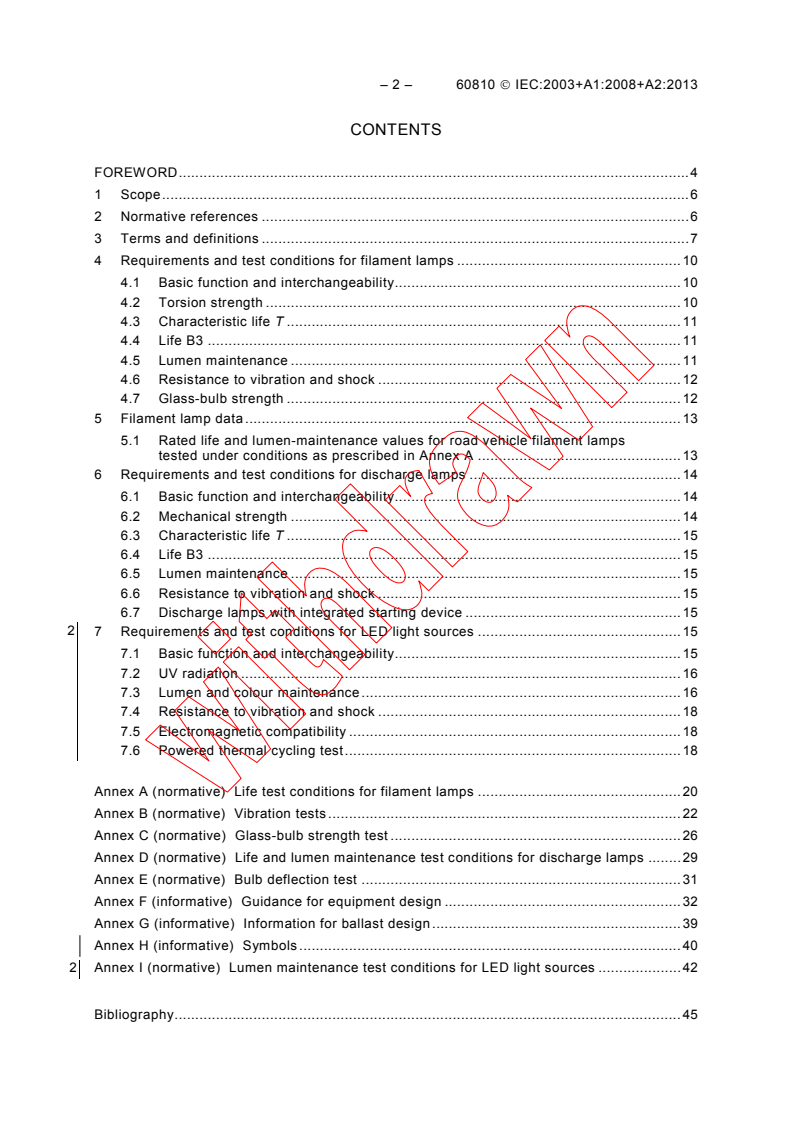

CONTENTS

FOREWORD.3

1 Scope.5

2 Normative references .5

3 Terms and definitions .6

4 Requirements and test conditions for filament lamps .7

4.1 Basic function and interchangeability.7

4.2 Torsion strength .7

4.3 Characteristic life T .7

4.4 Life B3 .7

4.5 Lumen maintenance .8

4.6 Resistance to vibration and shock .8

4.7 Glass-bulb strength .8

5 Filament lamp data.9

5.1 Rated life and lumen-maintenance values for road vehicle filament lamps

tested under conditions as prescribed in Annex A .9

6 Requirements and test conditions for discharge lamps .11

6.1 Basic function and interchangeability.11

6.2 Mechanical strength .11

6.3 Characteristic life T .11

6.4 Life B3 .11

6.5 Lumen maintenance .11

6.6 Resistance to vibration and shock .11

6.7 Discharge lamps with integrated starting device .11

Annex A (normative) Life test conditions for filament lamps .12

Annex B (normative) Vibration tests.14

Annex C (normative) Glass-bulb strength test .18

Annex D (normative) Life and lumen maintenance test conditions for discharge lamps .21

Annex E (normative) Bulb deflection test .23

Annex F (informative) Guidance for equipment design .24

Annex G (informative) Information for ballast design.31

Annex H (informative) Symbols.32

Bibliography.34

60810 © IEC:2003+A1:2008 – 3 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

LAMPS FOR ROAD VEHICLES –

PERFORMANCE REQUIREMENTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 60810 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This consolidated version of IEC 60810 consists of the third edition (2003) [documents

34A/1031/FDIS and 34A/1034/RVD] and its amendment 1 (2008) [documents 34A/1244/CDV

and 34A/1283/RVC].

The technical content is therefore identical to the base edition and its amendment and has

been prepared for user convenience.

It bears the edition number 3.1.

A vertical line in the margin shows where the base publication has been modified by

amendment 1.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

– 4 – 60810 © IEC:2003+A1:2008

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

60810 © IEC:2003+A1:2008 – 5 –

LAMPS FOR ROAD VEHICLES –

PERFORMANCE REQUIREMENTS

1 Scope

This International Standard is applicable to replaceable lamps (filament lamps and discharge

lamps) to be used in headlamps, fog-lamps and signalling lamps for road vehicles. It is

especially applicable to those lamps which are listed in IEC 60809. However, the standard

may also be used for other lamps falling under the scope of this standard, as well as for future

developments, e.g. such where the light is produced by light emitting diodes (LED).

It specifies requirements and test methods for the measurement of performance charac-

teristics such as lamp life, lumen maintenance, torsion strength, glass bulb strength and

resistance to vibration and shock. Moreover, information on temperature limits, maximum

lamp outlines and maximum tolerable voltage surges is given for the guidance of lighting and

electrical equipment design.

For some of the requirements given in this standard, reference is made to data given in

tables. For lamps not listed in such tables, the relevant data are supplied by the lamp

manufacturer or responsible vendor.

The performance requirements are additional to the basic requirements specified in

IEC 60809. They are, however, not intended to be used by authorities for legal type-approval

purposes.

NOTE In the various vocabularies and standards, different terms are used for "incandescent lamp"

(IEV 845-07-04) and "discharge lamp" (IEV 845-07-17). In this standard, "filament lamp" and "discharge lamp" are

used. However, where only “lamp” is written both types are meant, unless the context clearly shows that it applies

to one type only.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 60050(845):1987, International Electrotechnical Vocabulary (IEV) – Chapter 845: Lighting

IEC 60068-2-6:1995, Environmental testing – Part 2: Tests – Test Fc: Vibration (sinusoidal) –

Basic safety publication

IEC 60068-2-47:1999, Environmental testing – Part 2-47: Test methods – Mounting of

components, equipment and other articles for vibration, impact and similar dynamic tests

IEC 60410:1973, Sampling plans and procedures for inspection by attributes

IEC 60809, Lamps for road vehicles – Dimensional, electrical and luminous requirements

ISO 5344:1980, Electrodynamic test equipment for generating vibration – Methods of describ-

ing equipment characteristics

– 6 – 60810 © IEC:2003+A1:2008

3 Terms and definitions

For the purpose of this document, the following definitions apply, in addition to the definitions

in IEC 60050(845) and IEC 60809.

3.1

life

total time (expressed in hours) during which a lamp has been operated before it becomes

useless. For filament lamps, it is considered to be so according to one of the following criteria:

a) the end of life is the time when the filament fails;

b) the life of a dual-filament lamp is the time until either filament fails, if the lamp is tested in

a switching cycle involving alternative operation of both filaments

3.2

characteristic life

T

constant of the Weibull distribution indicating the time up to which 63,2 % of a number of

tested lamps of the same type have ended their individual lives

3.3

life B3

constant of the Weibull distribution indicating the time during which 3 % of a number of the

tested lamps of the same type have reached the end of their individual lives

3.4

lumen maintenance

ratio of the luminous flux of a lamp at a given time in its life to its initial luminous flux, the

lamp being operated under specific conditions

3.5

initial luminous flux

luminous flux of a lamp measured after the ageing specified in Annex C of IEC 60809 for

filament lamps or in Annex D of this standard for discharge lamps

3.6

rated value

value of a characteristic specified for operation of a lamp at test voltage and/or other specified

conditions

3.7

pinch temperature limit

maximum admissible pinch temperature to ensure satisfactory lamp performance in service

3.8

solder temperature limit

maximum admissible solder temperature to ensure satisfactory lamp performance in service

3.9

maximum lamp outline

contour limiting the space to be reserved for the lamp in the relevant equipment

60810 © IEC:2003+A1:2008 – 7 –

3.10

heavy-duty lamp

lamp declared as such, by the manufacturer or responsible vendor, which shall comply with

the heavy-duty test conditions specified in Table B.2 of this standard in addition to the

requirements specified in IEC 60809

4 Requirements and test conditions for filament lamps

4.1 Basic function and interchangeability

Filament lamps shall comply with IEC 60809.

4.2 Torsion strength

The cap shall be strong and firmly secured to the bulb.

Compliance is checked before and after the life test by submitting the filament lamp to the

following torque values:

filament lamps with bayonet caps

*

− with 9 mm shell-diameter: 0,3 Nm ;

− with 15 mm shell-diameter: 1,5 Nm*;

− with 20 mm shell-diameter: 3,0 Nm*;

filament lamps with screw caps

− with 10 mm shell-diameter: 0,8 Nm*.

The torque shall not be applied suddenly but shall be increased progressively from 0 to the

specified amount.

Values are based on a non-compliance level of 1 %.

4.3 Characteristic life T

The life T measured on a test quantity of at least 20 filament lamps shall be at least 96 % of

the rated value, given in Table 3.

Compliance is checked by life tests as prescribed in Annex A.

4.4 Life B3

The life B3 shall not be less than the rated value given in Table 3.

Compliance is checked by life tests as prescribed in Annex A.

The number of filament lamps failing before the required time shall not exceed the values in

Table 1.

———————

*

Under consideration.

– 8 – 60810 © IEC:2003+A1:2008

Table 1 – Conditions of compliance for life B3

Number of

Acceptance number

filament lamps tested

23 to 35 2

36 to 48 3

49 to 60 4

61 to 74 5

75 to 92 6

4.5 Lumen maintenance

The lumen maintenance shall be not less than the rated value given in Table 4. This value is

based on a non-compliance level of 10 %.

4.6 Resistance to vibration and shock

In the event of service life being influenced by vibration or shock, the test methods and

schedules detailed in Annex B shall be used to assess the performance.

The filament lamps are deemed to have satisfactorily completed the wideband or narrowband

random vibration test as described in Annex B, if they continue to function during and after

the test.

The number of filament lamps failing one of the tests shall not exceed the values in Table 2

(values are based on the AQL of 4 %).

Table 2 – Conditions of compliance for the vibration test

Number of

Acceptance number

filament lamps tested

14 to 20 2

21 to 32 3

33 to 41 4

42 to 50 5

51 to 65 6

4.7 Glass-bulb strength

In the event of bulbs being impaired by mechanical handling for their assembly in equipment,

the test methods and schedules defined in Annex C shall be used to assess the performance.

The bulbs have to withstand the specified compression strength.

60810 © IEC:2003+A1:2008 – 9 –

5 Filament lamp data

5.1 Rated life and lumen-maintenance values for road vehicle filament lamps tested

under conditions as prescribed in Annex A

Table 3 – Rated life values for continuous operation

Filament lamp Type 12 V 24 V

Data sheet Category Test B3 T Test B3 T

Nos. V h h V h h

60809-IEC-2110 R2 13,2 90 250 28,0 90 250

a a

60809-IEC-2120 H4 13,2 350 700 28,0

180 500

(Under

60809-IEC-2125 H6 14,0 300 – – –

consideration)

(Under

60809-IEC-2305 H5 14,0 100 – – –

consideration)

a a

60809-IEC-2310 H1 13,2 150 400 28,0

90 250

60809-IEC-2320 H2 13,2 90 250 28,0 90 250

a a

60809-IEC-2330 H3 13,2 150 400 28,0

90 250

b b b b

60809-IEC-3110 P21/5W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

b b b b

60809-IEC-3120 P21/4W 13,5 28,0

60 160 60 160

c c c c

600 1 600 600 1 600

a a

60809-IEC-3310 P21W 13,5 120 320 28,0

60 160

a a

60809-IEC-3320 R5W 13,5 100 300 28,0

80 225

a a

60809-IEC-3330 R10W 13,5 100 300 28,0

80 225

a a

60809-IEC-3340 T4W 13,5 300 750 28,0

120 350

a a

60809-IEC-4110 C5W 13,5 350 750 28,0

120 350

60809-IEC-4120 C21W 13,5 40 110 28,0 – –

a a

60809-IEC-4310 W3W 13,5 500 1 500 28,0

400 1 100

a a

60809-IEC-4320 W5W 13,5 200 500 28,0

120 350

NOTE 1 The values indicated are minimum requirements. Depending on some particular customers'

specifications, different values may be obtained, i.e. shorter life/higher luminous flux or longer life/lower lumen

maintenance. This has to be negotiated between filament lamp manufacturers and their customers.

a

Extended values are under consideration.

b

High-wattage filament.

c

Low-wattage filament.

– 10 – 60810 © IEC:2003+A1:2008

Table 4 – Rated lumen-maintenance values for continuous operation

Filament lamp Type 12 V 24 V

Data sheet Category Test Lumen maintenance Test Lumen maintenance

Nos.

V h % V h %

c c

60809-IEC-2110 R2 13,2 85 28,0 85

55 55

d d

70 28,0 70

110 110

c c

60809-IEC-2120 H4 13,2 85 85

110 110

d d

85 28,0 85

225 225

c

60809-IEC-2125 H6 14,0 85 – – –

d

60809-IEC-2305 H5 14,0 75 85 – – –

60809-IEC-2310 H1 13,2 170 90 28,0 170 90

60809-IEC-2320 H2 13,2 170 90 28,0 170 90

60809-IEC-2330 H3 13,2 170 90 28,0 170 90

a a

60809-IEC-3110 P21/5W 13,5 70 28,0 70

110 110

b b

70 70

750 750

a

60809-IEC-3120 P21/4W 13,5 110 70 28,0 (Under (Under

consideration) consideration)

b

750 70 (Under (Under

consideration) consideration)

60809-IEC-3310 P21W 13,5 110 70 28,0 110 70

60809-IEC-3320 R5W 13,5 150 70 28,0 150 70

60809-IEC-3330 R10W 13,5 150 70 28,0 150 70

60809-IEC-3340 T4W 13,5 225 70 28,0 225 70

60809-IEC-4110 C5W 13,5 225 60 28,0 225 60

60809-IEC-4120 C21W 13,5 75 60 – – –

60809-IEC-4310 W3W 13,5 750 60 28,0 750 60

60809-IEC-4320 W5W 13,5 225 60 28,0 225 60

NOTE 1 The values indicated are minimum requirements. Depending on some particular customers'

specifications, different values may be obtained, i.e. shorter life/higher luminous flux or longer life/lower lumen

maintenance. This has to be negotiated between filament lamp manufacturers and their customers.

NOTE 2 Lumen-maintenance values for extended operation times are under consideration.

a

High-wattage filament.

b

Low-wattage filament.

c

Main or upper beam filament.

d

Dipped or lower beam filament.

60810 © IEC:2003+A1:2008 – 11 –

6 Requirements and test conditions for discharge lamps

6.1 Basic function and interchangeability

Discharge lamps shall comply with the technical requirements of IEC 60809.

6.2 Mechanical strength

6.2.1 Bulb-to-cap connection

The bulb shall be strongly secured to the cap. Compliance is checked by means of the bulb

deflection test conducted in accordance with Annex E.

6.2.2 Cable-to-cap connection (if any)

If the cable has a fixed connection to the cap, it shall withstand a pulling force of 60 N. The

force shall be applied in the direction of the (straight) cable.

6.3 Characteristic life T

For the D1S, D2S, D1R and D2R discharge lamps, the life T measured on a test quantity of at

least 20 lamps shall be not less than the value declared by the manufacturer, which shall be

at least 3 000 h. Compliance is checked by tests as prescribed in Annex D.

6.4 Life B3

For the D1S, D2S, D1R and D2R discharge lamps, the life B3 measured on a test quantity of

at least 20 lamps shall be not less than the value declared by the manufacturer, which shall

be at least 1 500 h. Compliance is checked by tests as prescribed in Annex D.

6.5 Lumen maintenance

For the D1S, D2S, D1R and D2R discharge lamps, the lumen maintenance shall be at least

60 % of the initial luminous flux. Compliance is checked by tests prescribed in Annex D.

Values are based on a non-compliance level of 10 %.

6.6 Resistance to vibration and shock

In the event of service life being influenced by vibration and shock, the test methods and

schedules in Annex B shall be used to assess the performance.

The discharge lamps are deemed to have satisfactorily completed the wideband or

narrowband random vibration test as described in Annex B, if they continue to function during

and after the test. Moreover, the position of the electrodes shall comply with the dimensional

requirements as prescribed in the relevant standard.

Values are based on a non-compliance level of 4 %.

NOTE It is necessary to take care to protect service employees. See the note to Clause D.3.

6.7 Discharge lamps with integrated starting device

For discharge lamps of category D1S and D1R, the starting device may be built into the cap

of the lamp. The total weight of the lamp shall not exceed 120 g. Information for ballast design

is given in Annex G.

– 12 – 60810 © IEC:2003+A1:2008

Annex A

(normative)

Life test conditions for filament lamps

A.1 Ageing

Filament lamps shall be aged at their test voltage for approximately 1 h. For dual-filament

lamps, each filament shall be aged separately. Filament lamps which fail during the ageing

period shall be omitted from the test results.

A.2 Test voltage

Measurements shall be carried out at the test voltage specified in Clause 5 of this standard

which shall be a stable d.c. or a.c. voltage with a frequency between 40 Hz and 60 Hz.

NOTE The test voltage is deemed to be stable when the momentary fluctuations do not exceed 1 % and the

deviation of the average over the test period does not exceed 0,5 % of the specified value.

A.3 Operating position

Filament lamps shall be operated on a vibration-free test rack with both lamp axis and

filament(s) horizontal. In the special case of double-filament lamps which include a shield, this

shall be under the dipped or lower-beam filament (H-H line horizontal). In the case of filament

lamps with an axial filament, the longer filament support shall be positioned above the

filament.

A.4 Switching cycle

A.4.1 Single-filament lamps

A.4.1.1 Filament lamps for continuous operation

Filament lamps shall be switched off twice daily for periods of not less than 15 min, such

periods not being considered as part of the life.

A.4.1.2 Filament lamps for intermittent operation

Filament lamps for intermittent operation as used in stop-lamps and flashing direction

indicators shall be operated in the following switching cycle:

− 15 s on for intermittent (flashing) operation;

− 15 s off;

− flashing frequency: 90/min;

− on/off ratio 1:1.

The whole flashing operation time is considered as life.

60810 © IEC:2003+A1:2008 – 13 –

A.4.2 Dual-filament lamps for headlamps

The filaments shall be operated alternately according to the following cycle and starting with

the lower beam filament:

− dipped or lower-beam filament: 15 h on/45 min off;

− main or upper-beam filament: 7,5 h on/45 min off.

The end of the life is determined by failure of either filament.

The off periods are not considered as part of the life.