IEC 62868-1:2020

(Main)Organic light emitting diode (OLED) Light sources for general lighting - Safety - Part 1: General requirements and tests

Organic light emitting diode (OLED) Light sources for general lighting - Safety - Part 1: General requirements and tests

IEC 62868-1:2020 specifies general safety requirements of OLED products for use on DC supplies up to 1000 V or AC supplies up to 1000 V at 50 Hz or 60 Hz for indoors and similar general lighting purposes.

This document applies to any OLED light sources which are not covered by IEC 62868-2 (all parts).

This first edition cancels and replaces IEC 62868 published in 2014.

Sources lumineuses électroluminescentes organiques (OLED) destinées à l’éclairage général - Sécurité - Partie 1: Exigences générales et essais

L'IEC 62868-1:2020 spécifie les exigences générales de sécurité des produits OLED destinés à être utilisés avec des alimentations en tension continue jusqu’à 1000 V ou avec des alimentations en tension alternative jusqu’à 1000 V à 50 Hz ou 60 Hz, pour l’éclairage général intérieur ou similaire.

Le présent document s’applique aux sources lumineuses OLED qui ne sont pas couvertes par l’IEC 62868-2 (toutes les parties).

Cette première édition annule et remplace l'IEC 62868 parue en 2014.

General Information

- Status

- Published

- Publication Date

- 13-May-2020

- Technical Committee

- SC 34A - Electric light sources

- Drafting Committee

- WG 3 - TC 34/SC 34A/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 14-May-2020

- Completion Date

- 05-Jun-2020

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62868-1:2020 (consolidated edition 1.1 with Amendment 1) specifies general safety requirements and test methods for organic light emitting diode (OLED) light sources intended for general indoor lighting. It covers OLED tiles, panels and modules (rigid substrates and simple devices without active electronics) for use on DC or AC supplies up to 1 000 V (50 Hz / 60 Hz). This Part 1 sets the common baseline of safety requirements where specific product types are not covered by IEC 62868‑2 series parts.

Key topics and requirements

The standard defines mandatory subjects and test areas to verify safe construction and operation of OLED light sources, including:

- Scope and definitions for OLED light sources (tiles, panels, modules).

- Marking: required content, location, durability and legibility of labels.

- Construction & mechanical strength: general construction rules, vibration and mechanical tests.

- Internal short-circuit: methods to provoke and evaluate internal faults.

- Insulation and electrical tests: insulation resistance, electric strength and creepage/clearance requirements.

- Thermal stress: thermal performance and heat resistance requirements for components and assemblies.

- Resistance to dust, moisture and corrosion: environmental robustness considerations.

- Fire and heat resistance: resistance to ignition, flame and excessive heat.

- Photobiological safety: assessment related to human exposure to OLED emissions.

- Terminals, earthing and connections: safety of user-accessible parts, protective earthing, screws and current-carrying parts.

- Information for luminaire design: guidance for integrators to safely combine OLED sources into luminaires (referenced Annex B).

(Annexes include OLED panel construction examples, test methods for internal short circuits and classification guidance.)

Applications and users

IEC 62868‑1 is intended for:

- OLED manufacturers designing tiles, panels and modules for general indoor lighting.

- Product safety and compliance engineers performing safety assessments and type testing.

- Test laboratories and certification bodies executing the specified mechanical, electrical and thermal tests.

- Luminaire designers and integrators who use OLED sources as components (compatibility with IEC 60598 luminaires).

- Component suppliers and R&D teams ensuring new OLED designs meet baseline safety expectations.

Related standards

- IEC 62868‑2 (series): Part‑specific requirements for particular OLED product types (when published).

- IEC 60598 (luminaires): integration guidance for OLED light sources used as luminaires components.

- Other referenced IEC electrical safety and photobiological standards (see normative references).

Keywords: IEC 62868-1:2020, OLED light sources, OLED panels, OLED modules, safety requirements, electrical tests, thermal stress, photobiological safety, general lighting.

Buy Documents

IEC 62868-1:2020+AMD1:2025 CSV - Organic light emitting diode (OLED) Light sources for general lighting - Safety - Part 1: General requirements and tests Released:2/24/2025 Isbn:9782832702789

IEC 62868-1:2020 - Organic light emitting diode (OLED) Light sources for general lighting - Safety - Part 1: General requirements and tests Released:5/14/2020 Isbn:9782832283097

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62868-1:2020 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Organic light emitting diode (OLED) Light sources for general lighting - Safety - Part 1: General requirements and tests". This standard covers: IEC 62868-1:2020 specifies general safety requirements of OLED products for use on DC supplies up to 1000 V or AC supplies up to 1000 V at 50 Hz or 60 Hz for indoors and similar general lighting purposes. This document applies to any OLED light sources which are not covered by IEC 62868-2 (all parts). This first edition cancels and replaces IEC 62868 published in 2014.

IEC 62868-1:2020 specifies general safety requirements of OLED products for use on DC supplies up to 1000 V or AC supplies up to 1000 V at 50 Hz or 60 Hz for indoors and similar general lighting purposes. This document applies to any OLED light sources which are not covered by IEC 62868-2 (all parts). This first edition cancels and replaces IEC 62868 published in 2014.

IEC 62868-1:2020 is classified under the following ICS (International Classification for Standards) categories: 29.140.99 - Other standards related to lamps. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62868-1:2020 has the following relationships with other standards: It is inter standard links to IEC 62868:2014, IEC 62868-1:2020/AMD1:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62868-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62868-1 ®

Edition 1.1 2025-02

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

Organic light emitting diode (OLED) Light sources for general lighting – Safety –

Part 1: General requirements and tests

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews, graphical symbols and the glossary.

committee, …). It also gives information on projects, replaced With a subscription you will always have access to up to date

and withdrawn publications. content tailored to your needs.

IEC Just Published - webstore.iec.ch/justpublished

Electropedia - www.electropedia.org

Stay up to date on all new IEC publications. Just Published

The world's leading online dictionary on electrotechnology,

details all new publications released. Available online and once

containing more than 22 500 terminological entries in English

a month by email.

and French, with equivalent terms in 25 additional languages.

Also known as the International Electrotechnical Vocabulary

IEC Customer Service Centre - webstore.iec.ch/csc

(IEV) online.

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62868-1 ®

Edition 1.1 2025-02

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

Organic light emitting diode (OLED) Light sources for general lighting – Safety –

Part 1: General requirements and tests

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.140.99 ISBN 978-2-8327-0278-9

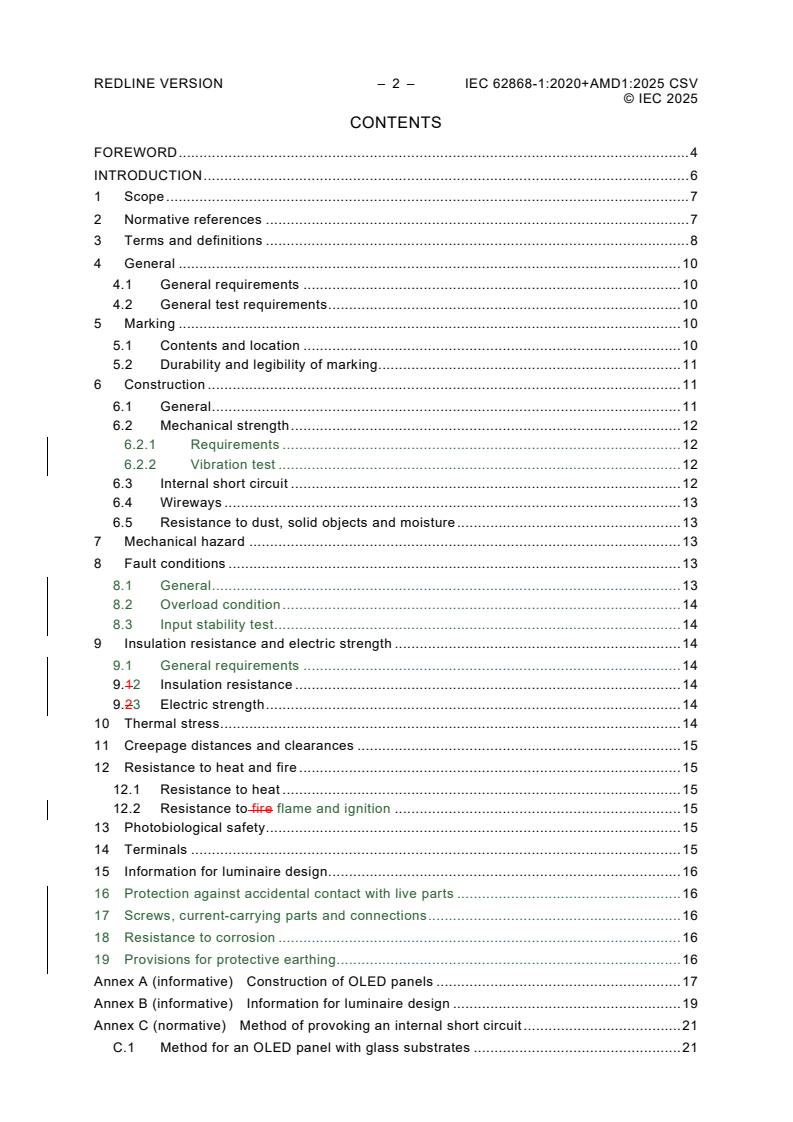

REDLINE VERSION – 2 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General . 10

4.1 General requirements . 10

4.2 General test requirements . 10

5 Marking . 10

5.1 Contents and location . 10

5.2 Durability and legibility of marking . 11

6 Construction . 11

6.1 General . 11

6.2 Mechanical strength . 12

6.2.1 Requirements . 12

6.2.2 Vibration test . 12

6.3 Internal short circuit . 12

6.4 Wireways . 13

6.5 Resistance to dust, solid objects and moisture . 13

7 Mechanical hazard . 13

8 Fault conditions . 13

8.1 General . 13

8.2 Overload condition . 14

8.3 Input stability test . 14

9 Insulation resistance and electric strength . 14

9.1 General requirements . 14

9.12 Insulation resistance . 14

9.23 Electric strength . 14

10 Thermal stress . 14

11 Creepage distances and clearances . 15

12 Resistance to heat and fire . 15

12.1 Resistance to heat . 15

12.2 Resistance to fire flame and ignition . 15

13 Photobiological safety . 15

14 Terminals . 15

15 Information for luminaire design . 16

16 Protection against accidental contact with live parts . 16

17 Screws, current-carrying parts and connections . 16

18 Resistance to corrosion . 16

19 Provisions for protective earthing. 16

Annex A (informative) Construction of OLED panels . 17

Annex B (informative) Information for luminaire design . 19

Annex C (normative) Method of provoking an internal short circuit . 21

C.1 Method for an OLED panel with glass substrates . 21

© IEC 2025

C.2 Method for an OLED panel with flexible plastic substrates . 21

Annex D (informative) Overview of the OLED lighting system consisting

of OLED panel or module OLED lighting system overview . 22

Annex E (informative) Classification of OLED modules . 24

E.1 Power supply classification . 24

E.2 Installation method classification . 24

Bibliography . 25

Figure A.1 – Schematic diagram of OLED tile for lighting . 17

Figure A.2 – Schematic diagram of OLED panel (Example 1) for lighting . 17

Figure A.3 – Schematic diagram of OLED panel (Example 2) for lighting . 18

Figure A.4 – Schematic diagram of OLED panel (Example 3) for lighting . 18

Figure D.1 – Schematic diagram of OLED lighting system consisting of OLED panel or

module . 23

Table 1 – Contents and location of marking . 11

REDLINE VERSION – 4 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) LIGHT

SOURCES FOR GENERAL LIGHTING – SAFETY –

Part 1: General requirements and tests

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) IEC draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). IEC takes no position concerning the evidence, validity or applicability of any claimed patent rights in

respect thereof. As of the date of publication of this document, IEC had not received notice of (a) patent(s),

which may be required to implement this document. However, implementers are cautioned that this may not

represent the latest information, which may be obtained from the patent database available at

https://patents.iec.ch. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 62868-1 edition 1.1 contains the first edition (2020-05) [documents 34A/2177/FDIS

and 34A/2185/RVD] and its amendment 1 (2025-02) [documents 34A/2421/FDIS and

34A/2433/RVD].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

© IEC 2025

International Standard IEC 62868-1 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This first edition cancels and replaces IEC 62868 published in 2014.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62868 series, published under the general title Organic light

emitting diode (OLED) light sources for general lighting – Safety, can be found on the IEC

website.

In this document, the following print types are used:

– requirements: roman type,

– test specifications: italic type,

– notes: smaller roman type.

The committee has decided that the contents of this document and its amendment will remain

unchanged until the stability date indicated on the IEC website under webstore.iec.ch in the

data related to the specific document. At this date, the document will be

• reconfirmed,

• withdrawn, or

• revised.

REDLINE VERSION – 6 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

INTRODUCTION

This part of IEC 62868 provides a set of general safety requirements and tests of OLED light

sources which are applicable to general indoor lightings. This document specifies the

requirements and tests for simple OLED light sources which do not include active electronic

components and consist of rigid substrates. It applies to the common requirements and tests

to verify the safety of all types of OLED light sources such as OLED modules and flexible

OLED panels. This document applies to OLED panels and tiles which consist of rigid

substrates. It also applies to any OLED light sources which are not specified in IEC 62868-2

(all parts) .

The parts which make up the IEC 62868-2 series, in referring to any clauses of this document,

specify the extent of application of this document; they also include additional requirements

and tests as necessary.

Where the requirements of any clauses of this document are referred to in the various parts

that make up the IEC 62868-2 series by the phrase "The requirements of Clause n of

IEC 62868-1 apply", this phrase will be interpreted as meaning that all requirements of the

clauses in question of this document apply, except any which are clearly inapplicable to a

particular type of OLED light source covered by the Part n of the IEC 62868-2 series

concerned.

The safety requirements of this document are intended to ensure that electrical lightings

constructed in accordance with this document do not endanger the safety of users or

properties when the light sources are properly installed, maintained and used in applications.

Particular requirements and tests for OLED light sources which include any active electronic

components and consist of flexible substrate will be the subject of a separate standard, as the

need arises.

___________

Under preparation. Stage at the time of publication IEC AFDIS 62868-2-1:2020, IEC AFDIS 62868-2-2:2020 and

IEC ACDV 62868-2-3:2020.

© IEC 2025

ORGANIC LIGHT EMITTING DIODE (OLED) LIGHT

SOURCES FOR GENERAL LIGHTING – SAFETY –

Part 1: General requirements and tests

1 Scope

This part of IEC 62868 specifies general safety requirements of OLED products for use on DC

supplies up to 1000 V or AC supplies up to 1000 V at 50 Hz or 60 Hz for indoors and similar

general lighting purposes.

This document applies to any OLED light sources which are not covered by IEC 62868-2 (all

parts).

NOTE 1 Only test methods for DC operated OLED light sources are provided in this document. Provisions for AC

operated OLED products are under consideration.

NOTE 2 The construction of OLED tiles and panels is illustrated in Figure A.1 to Figure A.4 in Annex A.

NOTE 3 The OLED lighting system consisting of OLED panels or modules is illustrated in Annex D.

NOTE 4 This document applies to OLED light sources (tiles, panels, modules) which are composed of OLED

luminaires or OLED lamps, and it is intended so that the OLED light source in accordance with this document fits in

IEC 60598 (all parts) as a component of lighting equipment, in combination with other components.

NOTE 5 Where an appropriate Part 2 of IEC 62868 for an OLED light source does not exist, the nearest

applicable Part 2 of IEC 62868 can be used as a guide to the requirements and tests.

This part of IEC 62868 specifies general safety requirements of organic light emitting diode

(OLED) light sources (tiles, panels and modules and OLED lamps) for use on DC supplies up

to 1 000 V or AC supplies up to 1 000 V at 50 Hz or 60 Hz for indoors and similar general

lighting purposes.

Where an appropriate part of the IEC 62868-2 series for an OLED light source does not exist,

the applicable part with the nearest configuration of the IEC 62868-2 series can be used as a

guide to the requirements and tests in conjunction with this document.

NOTE 1 The OLED lighting system consisting of OLED panels or modules is illustrated in Annex D.

NOTE 2 This document applies to OLED light sources (tiles, panels, modules and lamps), and it is intended so

that the OLED light source in accordance with this document fits in the IEC 60598 series as a component of

lighting equipment, in combination with other components.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60598-1:20142020, Luminaires – Part 1: General requirements and tests

IEC 60598-1:2014/AMD1:2017

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

REDLINE VERSION – 8 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

IEC 60598 (all parts), Luminaires

IEC 60838-2-2, Miscellaneous lampholders – Part 2-2: Particular requirements – Connectors

for LED-modules

IEC 62504, General lighting – Light emitting diode (LED) products and related equipment –

Terms and definitions

IEC TR 62854:2014, Sharp edge testing apparatus and test procedure for lighting equipment –

Tests for sharpness of edge

IEC TS 62972, General lighting – Organic light emitting diode (OLED) products and related

equipment – Terms and definitions

ISO 4046-4:2016, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper and

board grades and converted products

3 Terms and definitions

For the purpose of this document, the terms and definitions given in IEC 62504 and

IEC TS 62972 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

organic light emitting diode

OLED

light emitting semiconductor consisting of an electroluminescent zone made of organic

compounds, situated between two electrodes

Note 1 to entry: This note applies to the French language only.

3.2

OLED tile

smallest functional OLED light source which cannot be separated into smaller OLED lighting

elements containing at least one contact ledge with at least one positive and one negative

pole for connection to the electrical power supply

3.3

OLED panel

independently operable unit OLED product light source containing an OLED tile and means of

connection to the electrical supply

Note 1 to entry: An OLED panel may have a connector, PCB (printed circuit board), passive electronic

components and optionally a frame.

3.4

OLED module

assembly of one or more OLED panels and active electronic components

Note 1 to entry: The classification of OLED modules is given in Annex E.

© IEC 2025

3.5

semi-integrated OLED module

OLEDsi module

OLED module which carries the control unit of the controlgear, and is operated by the

separated power supply of the controlgear

3.6

integrated OLED module

OLEDi module

OLED module incorporating controlgear and any additional elements necessary for stable

operation of the light source, designed for direct connection to the supply voltage

3.7

integral OLED module

OLED module, designed to form a non-replaceable part component of a luminaire

Note 1 to entry: Refer to Annex D.

3.8

built-in OLED module

OLED module, designed to form a replaceable part component to be built into a luminaire and

into a module, a box, an enclosure or the like and not intended to be mounted outside a

luminaire

Note 1 to entry: Refer to Annex D.

3.9

independent OLED module

OLED module, designed for being mounted or placed separately from a luminaire, from an

additional box or enclosure or the like

Note 1 to entry: The independent OLED module provides all the necessary protection with regard to safety

according to its classification and marking.

Note 2 to entry: An example of an independent OLED module is a system where the OLED module is connected

via a glass fibre with the luminaire head.

Note 1 to entry: Refer to Annex D.

Note 2 to entry: Independent OLED light sources can be considered as an OLED luminaire.

3.10

rated value

quantity value for a characteristic of a product light source for specific operating conditions

with the values and the conditions specified in the relevant standard, or assigned by the

manufacturer or responsible vendor

3.11

type test

test or series of tests made on a type test sample for the purpose of checking compliance of

the design of a given product light source with the requirements of the relevant standard

3.12

stabilization

keeping of an OLED product light source switched on under

specified electrical input to obtain stable operation

Note 1 to entry: The mentioned operation can be photometric or electrical under specified conditions in the

relevant test clause.

REDLINE VERSION – 10 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

3.13

dark spot

small area remarkably darker than the surrounding light output area on the OLED product light

source

Note 1 to entry: A dark spot can be due to lower current density or an open circuit in that area.

3.14

internal short circuit

unintentional conductive path between the OLED anode and OLED cathode localized on a

small area

Note 1 to entry: An internal short circuit can look like a dark spot. It can lead to a significant heat generation in

that area.

4 General

4.1 General requirements

An OLED product light source shall be designed and manufactured in such a way as to

operate safely during its intended use and not to cause any danger to persons and the

environment.

In case of a failure of an OLED product light source it shall fail safely.

Reference to an OLED product also includes reference to OLED tiles in the requirements and

tests of this document.

4.2 General test requirements

Tests according to this document are type tests.

The tests, unless otherwise specified, are carried out at an ambient temperature of 25 °C ±

5 °C.

The tests shall be conducted at the rated current with a tolerance of 1 % unless otherwise

specified in this document.

The OLED product light source under test shall be mounted in accordance with the

manufacturer’s installation instructions. If more than one way of mounting is specified, the

most onerous way shall be chosen for each test. For electrical tests, this is the position

leading to the largest heat build-up of the light emitting surface. The orientation of the OLED

product light source shall be maintained during the entire test.

Integral OLED light sources shall be regarded as integral components of luminaires according

to IEC 60598-1:2020, 0.5.1.

In addition to the requirements of this document, independent OLED light sources shall

comply with the IEC 60598 series.

5 Marking

5.1 Contents and location

Marking of the OLED product light source shall be done in accordance with Table 1.

© IEC 2025

Table 1 – Contents and location of marking

Packaging or product

Parameters Product

datasheet or leaflet

Manufacturer (or responsible vendor) or Mandatory Mandatory

trademark

Polarity (in case of DC power supply) Mandatory

Neutral or earthing terminal Mandatory

Model number or production code Mandatory Mandatory

Rated current or rated current range Mandatory

Rated voltage or rated voltage range Mandatory

Rated power Mandatory

Type of power supply (DC or AC) and frequency Mandatory

Shape and dimension Mandatory

Connecting information Mandatory

Mounting instruction Mandatory

Operating temperature range Mandatory

IP number Mandatory

Information for luminaire design Mandatory

The connecting information shall include methods of mechanical and electrical connection.

The information of the electrical connection may include the type of driver.

For marking of the IP number, symbols for degree of protection shall be in accordance with

Section 3 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017 IEC 60598-1:2020.

5.2 Durability and legibility of marking

Marking shall be durable and legible.

Compliance is checked by visual inspection and (for marking on the OLED product) by trying

to remove the marking by rubbing the area lightly by hand for 15 s with a piece of smooth

cloth, dampened with water.

Compliance is checked by the following.

1) Presence and legibility of the marking required in 5.1 – by visual inspection.

2) The durability of the marking is checked by trying to remove it by rubbing lightly for 15 s

with a piece of cloth soaked in water. After the test, the marking shall be legible, marking

labels shall not be easily removable and they shall show no curling.

3) Availability of information required in 5.1 – by visual inspection.

6 Construction

6.1 General

Wood, cotton, silk, paper and similar fibrous material shall not be used as insulation.

Compliance is checked by inspection.

REDLINE VERSION – 12 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

6.2 Mechanical strength

6.2.1 Requirements

The OLED product panel shall have sufficient mechanical strength which shall be checked in

accordance with 6.2.2.

6.2.2 Vibration test

The OLED light source shall have sufficient mechanical strength.

The following vibration test shall be performed.

Compliance is checked by the vibration test.

For the vibration test, the OLED product light source shall be mounted in accordance with 4.2.

A sinusoidal vibration test is conducted in accordance with IEC 60068-2-6 with the following

parameters:

– displacement: 0,35 mm;

– acceleration: 50 m/s ;

– frequency range: 10 Hz to 500 Hz;

– axes of vibration: 3;

– duration: 3 × 10 cycles (10 times per axis).

After completion of the vibration test, the OLED product light source shall be operated for

15 min under the conditions specified in 4.2.

Compliance is checked as follows:

After the test, the OLED product light source is checked by inspection. Any splintered or

broken glass is not accepted. Fire, smoke or flammable gas shall not be produced. The OLED

product light source shall have no loosened parts which could impair safety.

Electrical contacts which could not be touched before the vibration test (e.g. those in OLED

products in accordance with Figure A.3 and Figure A.4) shall not have become accessible

after the test.

6.3 Internal short circuit

An OLED product light source with internal short circuit shall not cause any hazard.

The following internal short test shall be performed.

Compliance is checked by the internal short test.

An internal short circuit shall be provoked intentionally in the OLED product light source under

test in accordance with instructions given by the manufacturer or in accordance with a method

described in Annex C. The location of this internal short circuit shall be close to the edge of

the light output area at around 2 mm distance.

Before starting the test, the test sample of the OLED product light source shall not be

operated.

© IEC 2025

The test sample of the OLED product light source shall be operated at the rated current for 30

min for testing.

If the test sample does not generate an internal short circuit during the test operation, the

internal short circuit test shall be repeated with the same sample.

If none of the methods described in the manufacturer’s instructions and Annex C generate an

internal short circuit after three attempts, the test sample passes the test.

Compliance: An OLED product light source passes this test if there is no emission of flames

or molten material during the test. Any hot material from the sample shall not ignite a tissue

paper, as specified in 4.187 of ISO 4046-4:2016, spread below the OLED product light source.

Any splintered or broken glass is not accepted.

6.4 Wireways

Wireways shall be smooth and free from sharp edges, burrs, flashes and the like, which might

cause abrasion of the insulation of the wiring. Parts such as sharp-edged screws shall not

protrude into wireways.

Compliance is checked by inspection and, if necessary, by dismantling and reassembling the

luminaire.

6.5 Resistance to dust, solid objects and moisture

If an IP number is rated, the OLED product light source shall comply with Section 9 of

IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017 IEC 60598-1:2020.

NOTE IP numbers for degrees of protection are explained in IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017, Annex J.

7 Mechanical hazard

An OLED product light source with glass edges or corners shall be free from sharp edges or

points that could create hazards during installation, normal operation or maintenance.

An OLED product light source with thin metal foil or thin plastic film shall have protections

against sharp edges or points that could create hazards during installation, normal operation,

or maintenance.

Compliance is checked by inspection and means of the sharp edge tester in accordance with

IEC TR 62854.

8 Fault conditions

8.1 General

An OLED product light source shall not impair safety under fault conditions that may occur

during the intended use. The following overpower test shall be performed.

Compliance is checked by the overpower test.

The overpower fault condition test shall be conducted at an ambient temperature of (25 °C

± 5) °C unless otherwise specified by the manufacturer or responsible vendor. The

temperature shall be maintained within ±2 °C during the test.

Compliance is checked by the overload test.

REDLINE VERSION – 14 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

8.2 Overload condition

The OLED product light source shall be operated with rated current and the power monitored

(at the input side) and the input power shall be increased until 150 % of the rated current or

power is reached. The test shall be continued for 15 min.

Compliance is checked by inspection. An OLED product light source passes this fault test if

there is no emission of flames or molten material during the test. Any hot material from the

sample shall not ignite a tissue paper, as specified in 4.187 of ISO 4046-4:2016, spread

below the OLED product light source. Any splintered or broken glass is not accepted.

8.3 Input stability test

The OLED light source shall be operated with the rated current. The input power and voltage

shall be monitored at the input side. The test shall be continued for 15 min.

Compliance is checked as follows:

The voltage shall remain within the range of the rated voltage ±10 % during the test.

9 Insulation resistance and electric strength

9.1 General requirements

The requirements of IEC 60598-1:2020, 10.1 and 10.2 apply.

9.19.2 Insulation resistance

The requirements of 10.2.1 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017

IEC 60598-1:2020, 10.2.1 apply.

3 Electric strength

9.29.

The requirements of 10.2.2 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017

IEC 60598-1:2020, 10.2.2 apply.

10 Thermal stress

OLED products light sources shall sustain thermal stress.

The thermal stress test shall be conducted at a specified ambient temperature in a climate

chamber. The temperature shall be any convenient temperature in the range between 60 °C

and 70 °C. The temperature shall be maintained within ±2 °C during the stabilization and test.

The OLED product light source shall be operated with rated current. After stabilization, the

test shall be continued for 60 min.

Compliance is checked by inspection. An OLED product light source passes this test if no

failure occurs. In case of performance failure, an OLED product light source is considered to

pass this test, if no fire, smoke or flammable gas is produced. Any splintered or broken glass

is not accepted.

11 Creepage distances and clearances

Section 11 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017 applies to individual

OLED products.

© IEC 2025

The requirements of IEC 60598-1:2020, Section 11 apply to individual OLED light sources.

12 Resistance to heat and fire

12.1 Resistance to heat

An OLED product light source shall have sufficient heat resistance. The exterior of the

insulation material should have a function of protection against an electric shock and have

heat resistance.

External parts of insulating material providing protection against electric shock, and parts of

insulating material retaining live parts in position shall be sufficiently resistant to heat using a

ball pressure test in accordance with 13.2.1 of IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017.

The ball pressure test does not have to be applied to plastic parts of an OLED product light

source which provide supplementary insulation.

Compliance is checked by the ball pressure test in accordance with 13.2.1 of

IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017.

12.2 Resistance to fire flame and ignition

Parts of insulating material retaining live parts in position, and external parts of insulating

material providing protection against electric shock shall be resistant to flame and ignition.

Compliance is checked by the test of 13.3 of IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017 for materials other than ceramic.

The test specimen is the entire OLED product light source.

If the specimen is too small to be tested in a manner mentioned above, the foregoing test

shall apply to separated specimens which are made of the same material and are at least

30 mm , each having a thickness identical to the smallest thickness of the OLED product light

source.

13 Photobiological safety

Most OLED products are not expected to reach a level of UV, infrared or blue light hazard that

requires marking, but high power OLED products may create a blue light hazard.

Photobiological safety requirements and tests of high power OLED light sources are under

consideration.

OLED light sources are not expected to reach a level of UV, infrared or blue light hazard that

requires marking, or measurement.

14 Terminals

For screw terminals, the requirements of Section 14 of IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017 shall be used, if applicable.

For screwless terminals, the requirements of Section 15 of IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017 shall be used, if applicable.

For connectors, the requirements of IEC 60838-2-2 shall be used, if applicable.

REDLINE VERSION – 16 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

15 Information for luminaire design

Information is given in Annex B.

16 Protection against accidental contact with live parts

The requirements of IEC 61347-1:2015, Clause 10 and IEC 61347-1:2015/AMD1:2017,

Clause 10 apply.

17 Screws, current-carrying parts and connections

The requirements of IEC 61347-1:2015, Clause 14 and IEC 61347-1:2015/AMD1:2017,

Clause 14 apply.

18 Resistance to corrosion

The requirements of IEC 61347-1:2015, Clause 19 apply.

19 Provisions for protective earthing

The requirements of IEC 61347-1:2015, Clause 8 and IEC 61347-1:2015/AMD1:2017,

Clause 8 apply.

Delete Annex A and Annex E.

© IEC 2025

Annex A

(informative)

Construction of OLED panels

Figure A.1 to Figure A.4 provide schematic diagrams of OLED tiles and panels.

NOTE The front view is given on the left and the rear view on the right. The OLED tile is the most elementary

OLED product light source consisting of a substrate, encapsulation, OLED stack and metal ledge without a printed

circuit board (PCB), electrical connecting parts, and casing.

Figure A.1 – Schematic diagram of OLED tile for lighting

NOTE The front view is given on the left and the rear view on the right. The OLED panel (Example 1) consists of

an OLED tile and PCB or flexible PCB for electrical contacts, and electrical connecting parts.

Figure A.2 – Schematic diagram of OLED panel (Example 1) for lighting

REDLINE VERSION – 18 – IEC 62868-1:2020+AMD1:2025 CSV

© IEC 2025

NOTE The front view is given on the left and the rear view on the right. The OLED panel (Example 2) consists of

an OLED tile, wires and soldering pads for electrical contacts, and external casing.

Figure A.3 – Schematic diagram of OLED panel (Example 2) for lighting

NOTE The front view is given on the left and the rear view on the right. The OLED panel (Example 3) consists of

an OLED tile, a PCB or a flexible PCB for electrical contacts, and external casing.

Figure A.4 – Schematic diagram of OLED panel (Example 3) for lighting

© IEC 2025

Annex B

(informative)

Information for luminaire design

Internal short circuits can pose a risk to users and should be considered when designing

luminaires incorporating OLED products light sources.

An internal short circuit has a resistance significantly lower than that of the organic

electroluminescent layers. This alters the current distribution through the OLED product light

source and usually leads to a significantly increased current density at the location of the

internal short circuit. As a result, (parts of) the OLED product light source will no longer emit

light.

The internal short circuit typically has a non-zero residual resistance. Due to this residual

resistance power is consumed in the internal short circuit resulting in significant heat

generation. Local temperatures in excess of 100 °C can be observed and are maintained until

the OLED product light source is no longer powered.

If a constant current power supply is used, the voltage drop across the OLED will typically be

lowered, reducing total power consumption. If a constant voltage power supply is used, the

current will typically be increased until it is limited by the power supply or until the voltage

drop across the internal short circuit matches that of the OLED product light source under

normal operation, generally increasing power consumption significantly.

Temperatures created by a short circuit can be measured for example by applying a

thermocouple to the OLED product light source at the location of the short circuit. Internal

short circuits can be created for this purpose by the procedure described in 6.3. A

thermocouple should be applied after the short is generated but before the OLED product light

source is powered for the first time.

NOTE Temperatures measured in this way can differ from temperatures that occur in products light sources under

fault conditions as the method of generating an artificial internal short circuit differs from faults in actual products

light sources.

Possible risks from internal short circuits include:

– burns or scalds from touching the hot spot;

– ignition of flammable materials in the vicinity of the OLED product light source;

– ignition of flammable materials placed on the OLED product light source by users;

– faults of other components due to operation under abnormal conditions;

– splinters, melting material, etc. covered in 6.3.

Luminaire designers should assess the risk that is posed by such an internal short circuit. The

following should be taken into consideration:

– knowledge of users about OLED product light source fault conditions compared with

conventional lamps (OLED products light sources are often touchable in normal operation

but may be hot in fault conditions);

– appearance (visibility) of internal short circuit to user;

– accessibility of OLED product light source and internal short circuit;

– temperature increase from internal short circuits compared to normal operating

temperatures of the OLED product light source;

– temperature generated by internal short c

...

IEC 62868-1 ®

Edition 1.0 2020-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Organic light emitting diode (OLED) light sources for general lighting – Safety –

Part 1: General requirements and tests

Sources lumineuses à diodes électroluminescentes organiques (OLED)

destinées à l’éclairage général – Sécurité –

Partie 1: Exigences générales et essais

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62868-1 ®

Edition 1.0 2020-05

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Organic light emitting diode (OLED) light sources for general lighting – Safety –

Part 1: General requirements and tests

Sources lumineuses à diodes électroluminescentes organiques (OLED)

destinées à l’éclairage général – Sécurité –

Partie 1: Exigences générales et essais

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.140.99 ISBN 978-2-8322-8309-7

– 2 – IEC 62868-1:2020 © IEC 2020

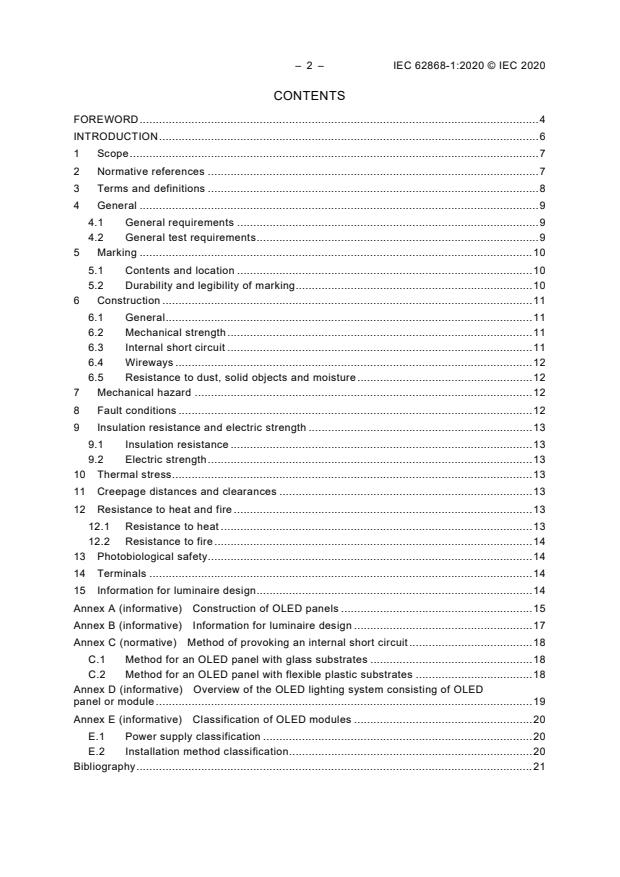

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 General . 9

4.1 General requirements . 9

4.2 General test requirements . 9

5 Marking . 10

5.1 Contents and location . 10

5.2 Durability and legibility of marking . 10

6 Construction . 11

6.1 General . 11

6.2 Mechanical strength . 11

6.3 Internal short circuit . 11

6.4 Wireways . 12

6.5 Resistance to dust, solid objects and moisture . 12

7 Mechanical hazard . 12

8 Fault conditions . 12

9 Insulation resistance and electric strength . 13

9.1 Insulation resistance . 13

9.2 Electric strength . 13

10 Thermal stress . 13

11 Creepage distances and clearances . 13

12 Resistance to heat and fire . 13

12.1 Resistance to heat . 13

12.2 Resistance to fire . 14

13 Photobiological safety . 14

14 Terminals . 14

15 Information for luminaire design . 14

Annex A (informative) Construction of OLED panels . 15

Annex B (informative) Information for luminaire design . 17

Annex C (normative) Method of provoking an internal short circuit . 18

C.1 Method for an OLED panel with glass substrates . 18

C.2 Method for an OLED panel with flexible plastic substrates . 18

Annex D (informative) Overview of the OLED lighting system consisting of OLED

panel or module . 19

Annex E (informative) Classification of OLED modules . 20

E.1 Power supply classification . 20

E.2 Installation method classification . 20

Bibliography . 21

Figure A.1 – Schematic diagram of OLED tile for lighting . 15

Figure A.2 – Schematic diagram of OLED panel (Example 1) for lighting . 15

Figure A.3 – Schematic diagram of OLED panel (Example 2) for lighting . 16

Figure A.4 – Schematic diagram of OLED panel (Example 3) for lighting . 16

Figure D.1 – Schematic diagram of OLED lighting system consisting of OLED panel or

module . 19

Table 1 – Contents and location of marking . 10

– 4 – IEC 62868-1:2020 © IEC 2020

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ORGANIC LIGHT EMITTING DIODE (OLED) LIGHT

SOURCES FOR GENERAL LIGHTING – SAFETY –

Part 1: General requirements and tests

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62868-1 has been prepared by subcommittee 34A: Lamps, of IEC

technical committee 34: Lamps and related equipment.

This first edition cancels and replaces IEC 62868 published in 2014.

The text of this International Standard is based on the following documents:

FDIS Report on voting

34A/2177/FDIS 34A/2185/RVD

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62868 series, published under the general title Organic light

emitting diode (OLED) light sources for general lighting – Safety, can be found on the IEC

website.

In this document, the following print types are used:

– requirements: roman type,

– test specifications: italic type,

– notes: smaller roman type.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data related

to the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62868-1:2020 © IEC 2020

INTRODUCTION

This part of IEC 62868 provides a set of general safety requirements and tests of OLED light

sources which are applicable to general indoor lightings. This document specifies the

requirements and tests for simple OLED light sources which do not include active electronic

components and consist of rigid substrates. It applies to the common requirements and tests

to verify the safety of all types of OLED light sources such as OLED modules and flexible

OLED panels. This document applies to OLED panels and tiles which consist of rigid

substrates. It also applies to any OLED light sources which are not specified in IEC 62868-2

(all parts) .

The parts which make up the IEC 62868-2 series, in referring to any clauses of this document,

specify the extent of application of this document; they also include additional requirements

and tests as necessary.

Where the requirements of any clauses of this document are referred to in the various parts

that make up the IEC 62868-2 series by the phrase "The requirements of Clause n of

IEC 62868-1 apply", this phrase will be interpreted as meaning that all requirements of the

clauses in question of this document apply, except any which are clearly inapplicable to a

particular type of OLED light source covered by the Part n of the IEC 62868-2 series

concerned.

The safety requirements of this document are intended to ensure that electrical lightings

constructed in accordance with this document do not endanger the safety of users or

properties when the light sources are properly installed, maintained and used in applications.

Particular requirements and tests for OLED light sources which include any active electronic

components and consist of flexible substrate will be the subject of a separate standard, as the

need arises.

___________

Under preparation. Stage at the time of publication IEC AFDIS 62868-2-1:2020, IEC AFDIS 62868-2-2:2020 and

IEC ACDV 62868-2-3:2020.

ORGANIC LIGHT EMITTING DIODE (OLED) LIGHT

SOURCES FOR GENERAL LIGHTING – SAFETY –

Part 1: General requirements and tests

1 Scope

This part of IEC 62868 specifies general safety requirements of OLED products for use on DC

supplies up to 1000 V or AC supplies up to 1000 V at 50 Hz or 60 Hz for indoors and similar

general lighting purposes.

This document applies to any OLED light sources which are not covered by IEC 62868-2 (all

parts).

NOTE 1 Only test methods for DC operated OLED light sources are provided in this document. Provisions for AC

operated OLED products are under consideration.

NOTE 2 The construction of OLED tiles and panels is illustrated in Figure A.1 to Figure A.4 in Annex A.

NOTE 3 The OLED lighting system consisting of OLED panels or modules is illustrated in Annex D.

NOTE 4 This document applies to OLED light sources (tiles, panels, modules) which are composed of OLED

luminaires or OLED lamps, and it is intended so that the OLED light source in accordance with this document fits in

IEC 60598 (all parts) as a component of lighting equipment, in combination with other components.

NOTE 5 Where an appropriate Part 2 of IEC 62868 for an OLED light source does not exist, the nearest

applicable Part 2 of IEC 62868 can be used as a guide to the requirements and tests.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their

content constitutes requirements of this document. For dated references, only the edition

cited applies. For undated references, the latest edition of the referenced document (including

any amendments) applies.

IEC 60598-1:2014, Luminaires – Part 1: General requirements and tests

IEC 60598-1:2014/AMD1:2017

IEC 60068-2-6:2007, Environmental testing – Part 2-6: Tests – Test Fc: Vibration (sinusoidal)

IEC 62504, General lighting – Light emitting diode (LED) products and related equipment –

Terms and definitions

IEC TR 62854:2014, Sharp edge testing apparatus and test procedure for lighting equipment –

Tests for sharpness of edge

IEC TS 62972, General lighting – Organic light emitting diode (OLED) products and related

equipment – Terms and definitions

ISO 4046-4:2016, Paper, board, pulps and related terms – Vocabulary – Part 4: Paper and

board grades and converted products

– 8 – IEC 62868-1:2020 © IEC 2020

3 Terms and definitions

For the purpose of this document, the terms and definitions given in IEC 62504 and

IEC TS 62972 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

organic light emitting diode

OLED

light emitting semiconductor consisting of an electroluminescent zone made of organic

compounds, situated between two electrodes

Note 1 to entry: This note applies to the French language only.

3.2

OLED tile

smallest functional OLED light source which cannot be separated into smaller OLED lighting

elements containing at least one contact ledge with at least one positive and one negative

pole for connection to the electrical power supply

3.3

OLED panel

independently operable unit OLED product containing an OLED tile and means of connection

to the electrical supply

Note 1 to entry: An OLED panel may have a connector, PCB (printed circuit board), passive electronic

components and optionally a frame.

3.4

OLED module

assembly of one or more OLED panels and active electronic components

Note 1 to entry: The classification of OLED modules is given in Annex E.

3.5

semi-integrated OLED module

OLEDsi module

OLED module which carries the control unit of the controlgear, and is operated by the

separated power supply of the controlgear

3.6

integrated OLED module

OLEDi module

OLED module incorporating controlgear and any additional elements necessary for stable

operation of the light source, designed for direct connection to the supply voltage

3.7

integral OLED module

OLED module, designed to form a non-replaceable part of a luminaire

3.8

built-in OLED module

OLED module, designed to form a replaceable part to be built into a luminaire, a box, an

enclosure or the like and not intended to be mounted outside a luminaire

3.9

independent OLED module

OLED module, designed for being mounted or placed separately from a luminaire, from an

additional box or enclosure or the like

Note 1 to entry: The independent OLED module provides all the necessary protection with regard to safety

according to its classification and marking.

Note 2 to entry: An example of an independent OLED module is a system where the OLED module is connected

via a glass fibre with the luminaire head.

3.10

rated value

quantity value for a characteristic of a product for specific operating conditions with the values

and the conditions specified in the relevant standard, or assigned by the manufacturer or

responsible vendor

3.11

type test

test or series of tests made on a type test sample for the purpose of checking compliance of

the design of a given product with the requirements of the relevant standard

3.12

stabilization

keeping of an OLED product switched on under specified electrical input

to obtain stable operation

Note 1 to entry: The mentioned operation can be photometric or electrical under specified conditions in the

relevant test clause.

3.13

dark spot

small area remarkably darker than the surrounding light output area on the OLED product

Note 1 to entry: A dark spot can be due to lower current density or an open circuit in that area.

3.14

internal short circuit

unintentional conductive path between the OLED anode and OLED cathode localized on a

small area

Note 1 to entry: An internal short circuit can look like a dark spot. It can lead to a significant heat generation in

that area.

4 General

4.1 General requirements

An OLED product shall be designed and manufactured in such a way as to operate safely

during its intended use and not to cause any danger to persons and the environment.

In case of a failure of an OLED product it shall fail safely.

Reference to an OLED product also includes reference to OLED tiles in the requirements and

tests of this document.

4.2 General test requirements

The tests, unless otherwise specified, are carried out at an ambient temperature of 25 °C ±

5 °C.

– 10 – IEC 62868-1:2020 © IEC 2020

The tests shall be conducted at the rated current with a tolerance of 1 % unless otherwise

specified in this document.

The OLED product under test shall be mounted in accordance with the manufacturer’s

installation instructions. If more than one way of mounting is specified, the most onerous way

shall be chosen for each test. For electrical tests, this is the position leading to the largest

heat build-up of the light emitting surface. The orientation of the OLED product shall be

maintained during the entire test.

5 Marking

5.1 Contents and location

Marking of the OLED product shall be done in accordance with Table 1.

Table 1 – Contents and location of marking

Packaging or product

Parameters Product

datasheet or leaflet

Manufacturer (or responsible vendor) or Mandatory Mandatory

trademark

Polarity (in case of DC power supply) Mandatory

Neutral or earthing terminal Mandatory

Model number or production code Mandatory Mandatory

Rated current or rated current range Mandatory

Rated voltage or rated voltage range Mandatory

Rated power Mandatory

Type of power supply (DC or AC) and frequency Mandatory

Shape and dimension Mandatory

Connecting information Mandatory

Mounting instruction Mandatory

Operating temperature range Mandatory

IP number Mandatory

Information for luminaire design Mandatory

The connecting information shall include methods of mechanical and electrical connection.

The information of the electrical connection may include the type of driver.

For marking of the IP number, symbols for degree of protection shall be in accordance with

Section 3 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017.

5.2 Durability and legibility of marking

Marking shall be durable and legible.

Compliance is checked by visual inspection and (for marking on the OLED product) by trying

to remove the marking by rubbing the area lightly by hand for 15 s with a piece of smooth

cloth, dampened with water.

6 Construction

6.1 General

Wood, cotton, silk, paper and similar fibrous material shall not be used as insulation.

Compliance is checked by inspection.

6.2 Mechanical strength

The OLED product shall have sufficient mechanical strength.

The following vibration test shall be performed.

Compliance is checked by the vibration test.

For the vibration test, the OLED product shall be mounted in accordance with 4.2.

A sinusoidal vibration test is conducted in accordance with IEC 60068-2-6 with the following

parameters:

– displacement: 0,35 mm;

– acceleration: 50 m/s ;

– frequency range: 10 Hz to 500 Hz;

– axes of vibration: 3;

– duration: 3 × 10 cycles (10 times per axis).

After completion of the vibration test, the OLED product shall be operated for 15 min under

the conditions specified in 4.2.

Compliance:

After the test, the OLED product is checked by inspection. Any splintered or broken glass is

not accepted. Fire, smoke or flammable gas shall not be produced. The OLED product shall

have no loosened parts which could impair safety.

Electrical contacts which could not be touched before the vibration test (e.g. those in OLED

products in accordance with Figure A.3 and Figure A.4) shall not have become accessible

after the test.

6.3 Internal short circuit

An OLED product with internal short circuit shall not cause any hazard.

The following internal short test shall be performed.

Compliance is checked by the internal short test.

An internal short circuit shall be provoked intentionally in the OLED product under test in

accordance with instructions given by the manufacturer or in accordance with a method

described in Annex C. The location of this internal short circuit shall be close to the edge of

the light output area at around 2 mm distance.

Before starting the test, the test sample of the OLED product shall not be operated.

– 12 – IEC 62868-1:2020 © IEC 2020

The test sample of the OLED product shall be operated at the rated current for 30 min for

testing.

If the test sample does not generate an internal short circuit during the test operation, the

internal short circuit test shall be repeated with the same sample.

If none of the methods described in the manufacturer’s instructions and Annex C generate an

internal short circuit after three attempts, the test sample passes the test.

Compliance: An OLED product passes this test if there is no emission of flames or molten

material during the test. Any hot material from the sample shall not ignite a tissue paper, as

specified in 4.187 of ISO 4046-4:2016, spread below the OLED product. Any splintered or

broken glass is not accepted.

6.4 Wireways

Wireways shall be smooth and free from sharp edges, burrs, flashes and the like, which might

cause abrasion of the insulation of the wiring. Parts such as sharp-edged screws shall not

protrude into wireways.

Compliance is checked by inspection and, if necessary, by dismantling and reassembling the

luminaire.

6.5 Resistance to dust, solid objects and moisture

If an IP number is rated, the OLED product shall comply with Section 9 of IEC 60598-1:2014

and IEC 60598-1:2014/AMD1:2017.

NOTE IP numbers for degrees of protection are explained in IEC 60598-1:2014 and

IEC 60598-1:2014/AMD1:2017, Annex J.

7 Mechanical hazard

An OLED product with glass edges or corners shall be free from sharp edges or points that

could create hazards during installation, normal operation or maintenance.

An OLED product with thin metal foil or thin plastic film shall have protections against sharp

edges or points that could create hazards during installation, normal operation, or

maintenance.

Compliance is checked by inspection and means of the sharp edge tester in accordance with

IEC TR 62854.

8 Fault conditions

An OLED product shall not impair safety under fault conditions that may occur during the

intended use.

The following overpower test shall be performed.

Compliance is checked by the overpower test.

The overpower test shall be conducted at an ambient temperature of 25 °C ± 5 °C unless

otherwise specified by the manufacturer or responsible vendor. The temperature shall be

maintained within ±2 °C during the test.

The OLED product shall be operated with rated current and the power monitored (at the input

side) and the input power shall be increased until 150 % of the rated current or power is

reached. The test shall be continued for 15 min.

Compliance is checked by inspection. An OLED product passes this fault test if there is no

emission of flames or molten material during the test. Any hot material from the sample shall

not ignite a tissue paper, as specified in 4.187 of ISO 4046-4:2016, spread below the OLED

product. Any splintered or broken glass is not accepted.

9 Insulation resistance and electric strength

9.1 Insulation resistance

The requirements of 10.2.1 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017 apply.

9.2 Electric strength

The requirements of 10.2.2 of IEC 60598-1:2014 and IEC 60598-1:2014/AMD1:2017 apply.

10 Thermal stress

OLED products shall sustain thermal stress.

The thermal stress test shall be conducted at a specified ambient temperature in a climate

chamber. The temperature shall be any convenient temperature in the range between 60 °C

and 70 °C. The temperature shall be maintained within ±2 °C during the stabilization and test.

The OLED product shall be operated with rated current. After stabilization, the test shall be

continued for 60 min.

Compliance is checked by inspection. An OLED product passes this test if no failure occurs.