IEC 62321-3-1:2013

(Main)Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry

Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry

IEC 62321-3-1:2013 describes the screening analysis of five substances, specifically lead (Pb), mercury (Hg), cadmium (Cd), total chromium (Cr) and total bromine (Br) in uniform materials found in electrotechnical products, using the analytical technique of X-ray fluorescence (XRF) spectrometry.

IEC 62321-3-1:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

Détermination de certaines substances dans les produits électrotechniques - Partie 3-1: Méthodes d'essai - Plomb, du mercure, du cadmium, du chrome total et du brome total par laspectrométrie par fluorescence X

L'IEC 62321-3-1:2013 décrit des procédures d'analyse de détection de cinq substances, spécifiquement le plomb (Pb), le mercure (Hg), le cadmium (Cd), le chrome total (Cr) et le brome total (Br) dans des matériaux uniformes utilisés dans les produits électrotechniques en utilisant la technique d'analyse de spectrométrie par fluorescence X (XRF).

L'IEC 62321-3-1:2013 a le statut de norme horizontale conformément au Guide IEC 108.

General Information

- Status

- Published

- Publication Date

- 18-Jun-2013

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Jun-2013

- Completion Date

- 30-Jun-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62321-3-1:2013 is an international standard published by the International Electrotechnical Commission (IEC) that defines a standardized screening method for detecting hazardous substances in electrotechnical products. Specifically, it covers the quantitative screening of lead (Pb), mercury (Hg), cadmium (Cd), total chromium (Cr), and total bromine (Br) in uniform materials using X-ray fluorescence (XRF) spectrometry. As a horizontal standard according to IEC Guide 108, it applies broadly across various electrotechnical materials and supports compliance with environmental and safety regulations.

This standard outlines a fast, non-destructive testing approach enabling manufacturers, testing laboratories, and regulatory bodies to identify restricted substances efficiently during product evaluation processes. The use of XRF spectrometry provides reliable elemental analysis necessary for ensuring electrotechnical products meet critical environmental directives such as RoHS (Restriction of Hazardous Substances).

Key Topics

- Scope and Purpose: Provides screening analysis methodology for hazardous elements in homogeneous materials of electrical/electronic products.

- Test Principle: Utilizes X-ray fluorescence spectrometry, a non-destructive technique detecting elemental composition through emitted X-ray spectra.

- Tested Substances: Focus on Pb, Hg, Cd, total Cr, and total Br due to their regulatory importance and environmental impact.

- Sampling Approaches:

- Non-destructive: Direct surface analysis without altering the test object.

- Destructive: If surface heterogeneity exists, samples may be prepared by grinding or other means for uniformity.

- Apparatus and Calibration: Details requirements for XRF spectrometers, calibration protocols, and quality control to ensure accurate detection limits.

- Precision and Repeatability: Statistical data to guide test reproducibility and reliability across multiple material matrices such as ABS, PE, PVC, and PC/ABS.

- Test Reporting: Specifies necessary documentation standards for test results ensuring traceability and compliance auditing.

- Practical Guidelines: Includes annexes with real-world examples and advice on interpreting XRF screening results in diverse applications.

Applications

IEC 62321-3-1:2013 is essential for manufacturers and compliance testing labs involved in:

- Environmental Compliance: Screening electrotechnical components to meet RoHS and similar legislation limiting hazardous substances.

- Quality Control in Production: Rapid verification of raw materials and finished products to ensure absence or acceptable levels of lead, mercury, cadmium, chromium, and bromine.

- Material Selection and Recycling: Assessing material composition to enhance sustainable product design and support recycling programs.

- Supplier Auditing: Validating materials provided by suppliers conform to international hazardous substance regulations.

- Product Safety Certification: Providing accurate substance concentration data critical for safety and environmental certification processes.

By employing the standardized XRF-based screening methodology, organizations optimize compliance workflows, reduce testing costs, and promote environmentally responsible electrical and electronic product manufacturing.

Related Standards

- IEC 62321 Series: Covers the broader scope of determination methods for controlled substances in electrotechnical products, including chemical digestion and instrumental analysis techniques.

- RoHS Directive (EU 2011/65/EU): Sets legal limits on hazardous substances in electrical and electronic equipment, aligning with IEC 62321 test methods.

- IEC Guide 108: Defines the horizontal standard status pertinent to the uniform application of IEC 62321-3-1 across the electrotechnical sector.

- ISO 3613 and ISO 11426: Other international standards offering complementary methodologies for trace element analysis.

IEC 62321-3-1:2013 facilitates a harmonized, efficient approach to screening dangerous substances by X-ray fluorescence spectrometry-empowering stakeholders in the electrotechnical industry to uphold safety, environmental sustainability, and regulatory compliance globally.

Buy Documents

IEC 62321-3-1:2013 - Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry Released:6/19/2013

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Sponsored listings

Frequently Asked Questions

IEC 62321-3-1:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 3-1: Screening - Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence spectrometry". This standard covers: IEC 62321-3-1:2013 describes the screening analysis of five substances, specifically lead (Pb), mercury (Hg), cadmium (Cd), total chromium (Cr) and total bromine (Br) in uniform materials found in electrotechnical products, using the analytical technique of X-ray fluorescence (XRF) spectrometry. IEC 62321-3-1:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-3-1:2013 describes the screening analysis of five substances, specifically lead (Pb), mercury (Hg), cadmium (Cd), total chromium (Cr) and total bromine (Br) in uniform materials found in electrotechnical products, using the analytical technique of X-ray fluorescence (XRF) spectrometry. IEC 62321-3-1:2013 has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-3-1:2013 is classified under the following ICS (International Classification for Standards) categories: 13.020.01 - Environment and environmental protection in general; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-3-1:2013 has the following relationships with other standards: It is inter standard links to IEC PAS 62596:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62321-3-1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-3-1 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 3-1: Screening – Lead, mercury, cadmium, total chromium and total bromine

by X-ray fluorescence spectrometry

Détermination de certaines substances dans les produits électrotechniques –

Partie 3-1: Méthodes d'essai – Plomb, du mercure, du cadmium, du chrome total

et du brome total par la spectrométrie par fluorescence X

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62321-3-1 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 3-1: Screening – Lead, mercury, cadmium, total chromium and total bromine

by X-ray fluorescence spectrometry

Détermination de certaines substances dans les produits électrotechniques –

Partie 3-1: Méthodes d'essai – Plomb, du mercure, du cadmium, du chrome total

et du brome total par la spectrométrie par fluorescence X

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020; 43.040.10 ISBN 978-2-83220-839-7

– 2 – 62321-3-1 © IEC:2013

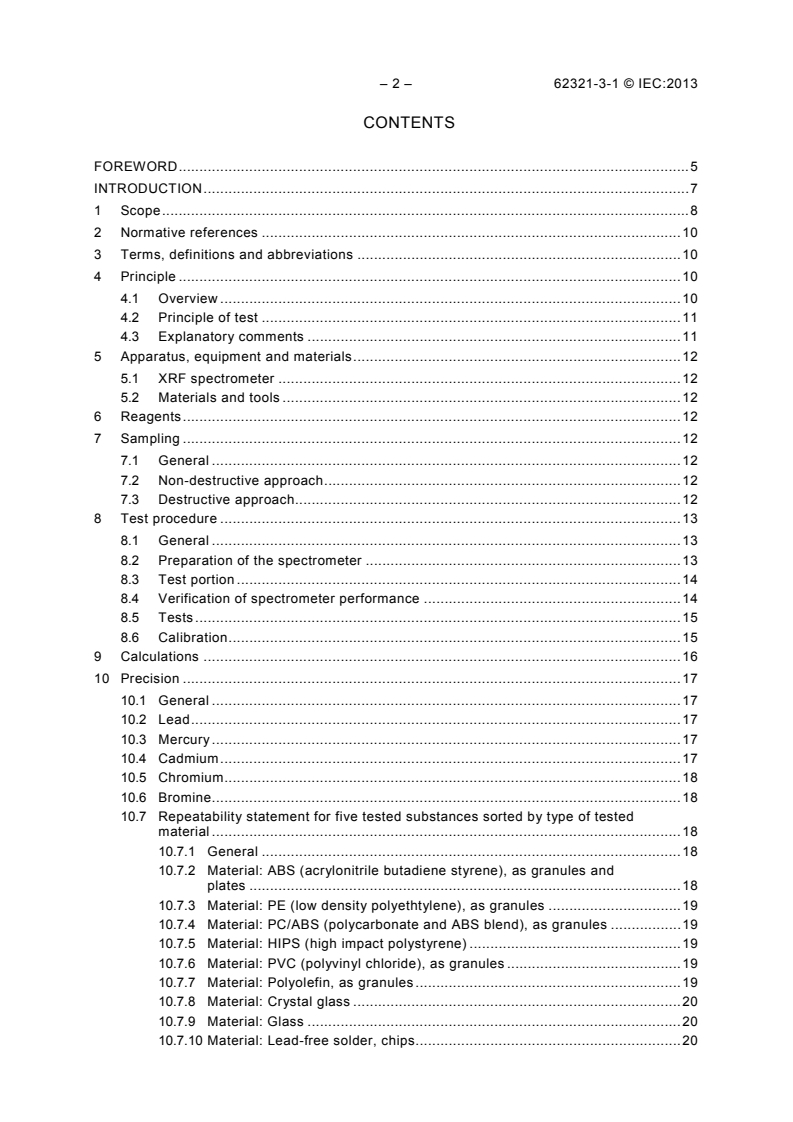

CONTENTS

FOREWORD . 5

INTRODUCTION . 7

1 Scope . 8

2 Normative references . 10

3 Terms, definitions and abbreviations . 10

4 Principle . 10

4.1 Overview . 10

4.2 Principle of test . 11

4.3 Explanatory comments . 11

5 Apparatus, equipment and materials . 12

5.1 XRF spectrometer . 12

5.2 Materials and tools . 12

6 Reagents . 12

7 Sampling . 12

7.1 General . 12

7.2 Non-destructive approach . 12

7.3 Destructive approach. 12

8 Test procedure . 13

8.1 General . 13

8.2 Preparation of the spectrometer . 13

8.3 Test portion . 14

8.4 Verification of spectrometer performance . 14

8.5 Tests . 15

8.6 Calibration . 15

9 Calculations . 16

10 Precision . 17

10.1 General . 17

10.2 Lead . 17

10.3 Mercury . 17

10.4 Cadmium . 17

10.5 Chromium . 18

10.6 Bromine. 18

10.7 Repeatability statement for five tested substances sorted by type of tested

material . 18

10.7.1 General . 18

10.7.2 Material: ABS (acrylonitrile butadiene styrene), as granules and

plates . 18

10.7.3 Material: PE (low density polyethtylene), as granules . 19

10.7.4 Material: PC/ABS (polycarbonate and ABS blend), as granules . 19

10.7.5 Material: HIPS (high impact polystyrene) . 19

10.7.6 Material: PVC (polyvinyl chloride), as granules . 19

10.7.7 Material: Polyolefin, as granules . 19

10.7.8 Material: Crystal glass . 20

10.7.9 Material: Glass . 20

10.7.10 Material: Lead-free solder, chips . 20

62321-3-1 © IEC:2013 – 3 –

10.7.11 Material: Si/Al Alloy, chips . 20

10.7.12 Material: Aluminum casting alloy, chips . 20

10.7.13 Material: PCB – Printed circuit board ground to less than 250 µm . 20

10.8 Reproducibility statement for five tested substances sorted by type of tested

material . 20

10.8.1 General . 20

10.8.2 Material: ABS (Acrylonitrile butadiene styrene), as granules and

plates . 21

10.8.3 Material: PE (low density polyethtylene), as granules . 21

10.8.4 Material: PC/ABS (Polycarbonate and ABS blend), as granules . 21

10.8.5 Material: HIPS (high impact polystyrene) . 21

10.8.6 Material: PVC (polyvinyl chloride), as granules . 22

10.8.7 Material: Polyolefin, as granules . 22

10.8.8 Material: Crystal glass . 22

10.8.9 Material: Glass . 22

10.8.10 Material: Lead-free solder, chips . 22

10.8.11 Material: Si/Al alloy, chips . 22

10.8.12 Material: Aluminum casting alloy, chips . 22

10.8.13 Material: PCB – Printed circuit board ground to less than 250 µm . 22

11 Quality control . 23

11.1 Accuracy of calibration . 23

11.2 Control samples . 23

12 Special cases . 23

13 Test report . 23

Annex A (informative) Practical aspects of screening by X-ray fluorescence

spectrometry (XRF) and interpretation of the results . 25

Annex B (informative) Practical examples of screening with XRF . 31

Bibliography . 40

Figure B.1 – AC power cord, X-ray spectra of sampled sections . 32

Figure B.2 – RS232 cable and its X-ray spectra . 33

Figure B.3 – Cell phone charger shown partially disassembled . 34

Figure B.4 – PWB and cable of cell phone charger . 35

Figure B.5 – Analysis of a single solder joint on a PWB . 36

Figure B.6 – Spectra and results obtained on printed circuit board with two collimators . 36

Figure B.7 – Examples of substance mapping on PWBs . 38

Figure B.8 – SEM-EDX image of Pb free solder with small intrusions of Pb (size = 30 µm) . 39

Table 1 – Tested concentration ranges for lead in materials . 8

Table 2 – Tested concentration ranges for mercury in materials . 9

Table 3 – Tested concentration ranges for cadmium in materials . 9

Table 4 – Tested concentration ranges for total chromium in materials . 9

Table 5 – Tested concentration ranges for total bromine in materials . 9

Table 6 – Recommended X-ray lines for individual analytes . 14

Table A.1 – Effect of matrix composition on limits of detection of some controlled

elements . 26

– 4 – 62321-3-1 © IEC:2013

Table A.2 – Screening limits in mg/kg for regulated elements in various matrices . 27

Table A.3 – Statistical data from IIS2 . 29

Table A.4 – Statistical data from IIS4 . 30

Table B.1 – Selection of samples for analysis of AC power cord . 32

Table B.2 – Selection of samples (testing locations) for analysis after visual inspection

– Cell phone charger. 34

Table B.3 – Results of XRF analysis at spots (1) and (2) as shown in Figure B.6 . 37

62321-3-1 © IEC:2013 – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 3-1: Screening – Lead, mercury, cadmium, total chromium

and total bromine by X-ray fluorescence spectrometry

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62321-3-1 has been prepared by IEC technical committee 111:

Environmental standardization for electrical and electronic products and systems.

It has the status of a horizontal standard in accordance with IEC Guide 108.

The first edition of IEC 62321:2008 was a 'stand alone' standard that included an introduction,

an overview of test methods, a mechanical sample preparation as well as various test method

clauses.

This first edition of IEC 62321-3-1 is a partial replacement of IEC 62321:2008, forming a

structural revision and generally replacing Clauses 6 and Annex D.

Future parts in the IEC 62321 series will gradually replace the corresponding clauses in

IEC 62321:2008. Until such time as all parts are published, however, IEC 62321:2008 remains

valid for those clauses not yet re-published as a separate part.

– 6 – 62321-3-1 © IEC:2013

The text of this standard is based on the following documents:

FDIS Report on voting

111/298/FDIS 111/308/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62321 series can be found on the IEC website under the general

title: Determination of certain substances in electrotechnical products

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

62321-3-1 © IEC:2013 – 7 –

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adaptation of regulations

affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated diphenyl

ethers (PBDEs)) in electrotechnical products, is a source of concern in current and proposed

regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this International Standard should be familiar with normal

laboratory practice. This standard does not purport to address all of the safety

problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national

regulatory conditions.

– 8 – 62321-3-1 © IEC:2013

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 3-1: Screening – Lead, mercury, cadmium, total chromium

and total bromine by X-ray fluorescence spectrometry

1 Scope

Part 3-1 of IEC 62321 describes the screening analysis of five substances, specifically lead

(Pb), mercury (Hg), cadmium (Cd), total chromium (Cr) and total bromine (Br) in uniform

materials found in electrotechnical products, using the analytical technique of X-ray

fluorescence (XRF) spectrometry.

It is applicable to polymers, metals and ceramic materials. The test method may be applied to

raw materials, individual materials taken from products and “homogenized” mixtures of more

than one material. Screening of a sample is performed using any type of XRF spectrometer,

provided it has the performance characteristics specified in this test method. Not all types of

XRF spectrometers are suitable for all sizes and shapes of sample. Care should be taken to

select the appropriate spectrometer design for the task concerned.

The performance of this test method has been tested for the following substances in various

media and within the concentration ranges as specified in Tables 1 to 5.

Table 1 – Tested concentration ranges for lead in materials

Substance/

Lead

element

Medium/material tested

Unit of

a b d

ABS PE Low- Al, Lead- Ground Crystal PVC Poly-

Parameter

measure

c

alloy Al-Si free PWB glass olefine

steel alloy solder

Concentration

15,7 14 190 22 000 390

or 380 to

e

mg/kg to to 30 to 174 to 240 000 to

concentration 640

954 108 930 23 000 665

range tested

a

Acrylonitrile butadiene styrene.

b

Polyethylene.

c

Printed wiring board.

d

Polyvinyl chloride.

e

This lead concentration was not detectable by instruments participating in tests.

62321-3-1 © IEC:2013 – 9 –

Table 2 – Tested concentration ranges for mercury in materials

Substance/element Mercury

Medium/material tested

Parameter Unit of measure

a b

ABS PE

Concentration or concentration range

mg/kg 100 to 942 4 to 25

tested

a

Acrylonitrile butadiene styrene.

b

Polyethylene.

Table 3 – Tested concentration ranges for cadmium in materials

Substance/element Cadmium

Medium/material tested

Parameter Unit of measure

a b

Lead-free solder ABS PE

Concentration or concentration

c

mg/kg 3 10 to 183 19,6 to 141

range tested

a

Acrylonitrile butadiene styrene.

b

Polyethylene.

c

This cadmium concentration was not detectable by instruments participating in tests.

Table 4 – Tested concentration ranges for total chromium in materials

Substance/element Chromium

Medium/material tested

Unit of

Low-

Parameter

Al, Al-Si

measure a b

ABS PE alloy Glass

alloy

steel

Concentration or

concentration range mg/kg 16 to 944 16 to 115 240 130 to 1 100 94

tested

a

Acrylonitrile butadiene styrene.

b

Polyethylene.

Table 5 – Tested concentration ranges for total bromine in materials

Substance/element Bromine

Medium/material tested

Unit of

Parameter

measure c a d b

HIPS , ABS PC/ABS PE

Concentration or concentration

mg/kg 25 to 118 400 800 to 2 400 96 to 808

range tested

a

Acrylonitrile butadiene styrene.

b

Polyethylene.

c

High impact polystyrene.

d

Polycarbonate and ABS blend.

These substances in similar media outside of the specified concentration ranges may be

analysed according to this test method; however, the performance has not been established

for this standard.

– 10 – 62321-3-1 © IEC:2013

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1, Determination of certain substances in electrotechnical products – Part 1:

Introduction and overview

IEC 62321-2, Determination of certain substances in electrotechnical products – Part 2:

Disassembly, disjointment and mechanical sample preparation

IEC/ISO Guide 98-1, Uncertainty of measurement – Part 1: Introduction to the expression of

uncertainty in measurement

3 Terms, definitions and abbreviations

For the purposes of this document, the terms, definitions and abbreviations given in

IEC 62321-1 and IEC 62321-2 apply.

4 Principle

4.1 Overview

The concept of 'screening' has been developed to reduce the amount of testing. Executed as

a predecessor to any other test analysis, the main objective of screening is to quickly

determine whether the screened part or section of a product:

– contains a certain substance at a concentration significantly higher than its value or values

chosen as criterion, and therefore may be deemed unacceptable;

– contains a certain substance at a concentration significantly lower than its value or values

chosen as criterion, and therefore may be deemed acceptable;

– contains a certain substance at a concentration so close to the value or values chosen as

criterion that when all possible errors of measurement and safety factors are considered,

no conclusive decision can be made about the acceptable absence or presence of a

certain substance and, therefore, a follow-up action may be required, including further

analysis using verification testing procedures.

This test method is designed specifically to screen for lead, mercury, cadmium, chromium and

bromine (Pb, Hg, Cd, Cr, Br) in uniform materials, which occur in most electrotechnical

products. Under typical circumstances, XRF spectrometry provides information on the total

quantity of each element present in the sample, but does not identify compounds or valence

states of the elements. Therefore, special attention shall be paid when screening for

chromium and bromine, where the result will reflect only the total chromium and total bromine

present. The presence of Cr(VI) or the brominated flame retardants PBB or PBDE shall be

confirmed by a verification test procedure. When applying this method to electronics “as

received”, which, by the nature of their design, are not uniform, care shall be taken in

interpreting the results. Similarly, the analysis of Cr in conversion coatings may be difficult

due to the presence of Cr in substrate material and/or because of insufficient sensitivity for Cr

in typically very thin (several hundred nm) conversion coating layers.

Screening analysis can be carried out by one of two means:

___________

To be published.

62321-3-1 © IEC:2013 – 11 –

• non-destructively – by directly analysing the sample “as received”;

• destructively – by applying one or more sample preparation steps prior to analysis.

In the latter case, the user shall apply the procedure for sample preparation as described in

IEC 62321-2. This test method will guide the user in choosing the proper approach to sample

presentation.

4.2 Principle of test

The representative specimen of the object tested is placed in the measuring chamber or over

the measuring aperture of the X-ray fluorescence spectrometer. Alternatively, a measuring

window/aperture of a handheld, portable XRF analyser is placed flush against the surface of

the object tested. The analyser illuminates the specimen for a preselected measurement time

with a beam of X rays which in turn excite characteristic X rays of elements in the specimen.

The intensities of these characteristic X rays are measured and converted to mass fractions

or concentrations of the elements in the tested sample using a calibration implemented in the

analyser.

The fundamentals of XRF spectrometry, as well as practical aspects of sampling for XRF, are

covered in detail in [1, 2 and 3].

4.3 Explanatory comments

To achieve its purpose, this test method shall provide rapid, unambiguous identification of the

elements of interest. The test method shall provide at least a level of accuracy that is

sometimes described as semi-quantitative, i.e. the relative uncertainty of a result is typically

30 % or better at a defined level of confidence of 68 %. Some users may tolerate higher

relative uncertainty, depending on their needs. This level of performance allows the user to

sort materials for additional testing. The overall goal is to obtain information for risk

management purposes.

This test method is designed to allow XRF spectrometers of all designs, complexity and

capability to contribute screening analyses. However, the capabilities of different XRF

spectrometers cover such a wide range that some will be relatively inadequate in their

selectivity and sensitivity while others will be more than adequate. Some spectrometers will

allow easy measurement of a wide range of sample shapes and sizes, while others, especially

research-grade WDXRF units, will be very inflexible in terms of test portions.

Given the above level of required performance and the wide variety of XRF spectrometers

capable of contributing useful measurements, the requirements for the specification of

procedures are considerably lower than for a high-performance test method for quantitative

determinations with low estimates of uncertainty.

This test method is based on the concept of a performance based measurement system.

Apparatus, sample preparation and calibration are specified in this standard in relatively

general terms. It is the responsibility of the user to document all procedures developed in the

laboratory that uses the test method. The user shall establish a written procedure for all cases

denoted in this method by the term “work instructions”.

The user of this test method shall document all relevant spectrometer and method

performance parameters.

WARNING 1 Persons using the XRF test method shall be trained in the use of XRF

spectrometers and the related sampling requirements.

WARNING 2 Xrays are hazardous to humans. Care shall be taken to operate the equipment

in accordance with both the safety instructions provided by the manufacturer and the

applicable local health and occupational safety regulations.

– 12 – 62321-3-1 © IEC:2013

5 Apparatus, equipment and materials

5.1 XRF spectrometer

An XRF spectrometer consists of an X-ray excitation source, a means of reproducible sample

presentation, an X-ray detector, a data processor and a control system [4, 5 and 6]:

a) source of X-ray excitation – X-ray tube or radio-isotope sources are commonly used;

b) X-ray detector (detection subsystem) – Device used to convert the energy of an X-ray

photon to a corresponding electric pulse of amplitude proportional to the photon energy.

5.2 Materials and tools

All materials used in the preparation of samples for XRF measurements shall be shown to be

free of contamination, specifically by the analytes of this test method. This means that all

grinding materials, solvents, fluxes, etc. shall not contain detectable quantities of Pb, Hg, Cd,

Cr and/or Br.

Tools used in the handling of samples shall be chosen to minimize contamination by the

analytes of this test method as well as by any other elements. Any procedures used to clean

the tools shall not introduce contaminants.

6 Reagents

Reagents, if any, shall be of recognized analytical grade and shall not contain detectable

quantities of Pb, Hg, Cd, Cr and/or Br.

7 Sampling

7.1 General

It is the responsibility of the user of this test method to define the test sample using

documented work instructions. The user may choose to define the test sample in a number of

ways, either via a non-destructive approach in which the portion to be measured is defined by

the viewing area of the spectrometer, or by a destructive approach in which the portion to be

measured is removed from the larger body of material and either measured as is, or

destroyed and prepared using a defined procedure.

7.2 Non-destructive approach

The user of this test method shall:

a) establish the area viewed by the spectrometer and place the test sample within that area,

taking care to ascertain that no fluorescent X-rays will be detected from materials other

than the defined test portion. Usually, the area viewed by the spectrometer is a section of

a plane delineated by the shape and boundary of the measuring window of the instrument.

The area of the test sample viewed by the spectrometer shall be flat. Any deviation from

the flat area requirement shall be documented;

b) make sure that a repeatable measurement geometry with a repeatable distance between

the spectrometer and the test portion is established;

c) document the steps taken to disassemble a larger object to obtain a test portion.

7.3 Destructive approach

The following points shall be taken into account in the destructive approach:

62321-3-1 © IEC:2013 – 13 –

a) the user shall create and follow a documented work instruction for the means of

destruction applied to obtain the test portion, as this information is critical for correct

interpretation of the measurement results;

b) a procedure that results in a powder shall produce a material with a known or controlled

particle size. In cases where the particles have different chemical, phase or mineralogical

compositions, it is critical to reduce their size sufficiently to minimize differential

absorption effects;

c) in a procedure that results in a material being dissolved in a liquid matrix, the quantity and

physical characteristics of the material to be dissolved shall be controlled and documented.

The resulting solution shall be completely homogeneous. Instructions shall be provided to

deal with undissolved portions to ensure proper interpretation of the measured results.

Instructions shall be provided for presentation of the test portion of the solution to the X-

ray spectrometer in a repeatable manner, i.e. in a liquid cell of specified construction and

dimensions;

d) in a procedure that results in a sample material being fused or pressed in a solid matrix,

the quantity and physical characteristics of the sample material shall be controlled and

documented. The resulting solid (fused or pressed pellet) shall be completely uniform.

Instructions shall be provided to deal with unmixed portions to ensure proper

interpretation of the measured results.

8 Test procedure

8.1 General

The test procedure covers preparation of the X-ray spectrometer, preparation and mounting of

test portions and calibration. Certain instructions are presented in general terms due to the

wide range of XRF equipment and the even greater variety of laboratory and test samples to

which this test method will be applied. However, a cardinal rule that applies without exception

to all spectrometers and analytical methods shall be followed; that is that the calibration and

sample measurements be performed under the same conditions and using the same sample

preparation procedures.

In view of the wide range of XRF spectrometer designs and the concomitant range of

detection capabilities, it is important to understand the limitation of the chosen instrument.

Certain designs may be incapable of detecting or accurately determining the composition of a

very small area or very thin samples. As a consequence, it is imperative that users carefully

establish and clearly document the performance of the test method as implemented in their

laboratories. One goal is to prevent false negative test results.

8.2 Preparation of the spectrometer

Prepare the spectrometer as follows:

a) switch on the instrument and prepare it for operation according to the manufacturer’s

manual. Allow the instrument to stabilize as per guidelines established by the

manufacturer or laboratory work instructions;

b) set the measurement conditions to the optimum conditions previously established by the

manufacturer or the laboratory.

Many instruments available on the market are already optimized and preset for a particular

application, and therefore this step might not be necessary. Otherwise, the laboratory should

establish optimum operating conditions for each calibration. Choices should be made to

optimize sensitivity and minimize spectral interferences. Excitation conditions may vary by

material, analyte and X-ray line energy. A list of recommended analytical X-ray lines is given

in Table 6. Detection system settings should optimize the compromise between sensitivity and

energy resolution. Guidance can usually be found in the instrument manual and in literature

on X-ray spectrometry [1, 2 and 3].

– 14 – 62321-3-1 © IEC:2013

a

Table 6 – Recommended X-ray lines for individual analytes

Analyte Preferred line Secondary line

Lead (Pb) L –M (Lβ ) L –M (Lα )

2 4 1 3 4,5 1,2

Mercury (Hg) L –M (Lα )

3 4,5 1,2

b

Cadmium (Cd) K–L (Kα )

2,3 1,2

Chromium (Cr) K–L (Kα )

2,3 1,2

Bromine (Br) K–L (Kα ) K–M (Kβ )

2,3 1,2 2,3 1,3

a

Other X-ray line choices may provide adequate performance. However, when deciding on alternative

analytical lines one should be aware of possible spectral interferences from other elements present in the

sample (e.g. BrKα on PbLα or AsKα on PbLα lines; see Clause A.2 b) for more typical examples).

b

K–L (Kα ) means that there are actually two transitions to the K shell, i.e. one from the L shell which

2,3 1,2 2

generates Kα X-rays and another from the L shell that generates Kα X- rays. However, since both energies

2 3 1

are very close, energy dispersive spectrometers cannot distinguish them and so they are analysed as one

combined K α energy.

1,2

8.3 Test portion

The creation of a test portion is described in Clause 7.

In the case of destructive sample preparation, measure the mass and dimensions of the test

portion as required by the calibration method and the work instruction established by the

laboratory to ensure repeatable sampling. The location of the test portion shall also be documented

in relation to its origin on the electrotechnical product.

8.4 Verification of spectrometer performance

Spectrometer performance shall be verified as follows:

a) Users shall provide objective evidence of the performance of the method as implemented

in their laboratories. This is necessary to enable the users and their customers to

understand the limitations of the method and to make decisions using the results of

analyses. Critical aspects regarding the performance of the method are as follows:

• sensitivity for each analyte;

• spectral resolution;

• limit of detection;

• demonstration of measured area;

• repeatability of sample preparation and measurement;

• accuracy of calibration, which will be checked according to Clause 10.

Given the variety of spectrometers and the associated software operating systems, it is

acceptable for the users to obtain this information in their own laboratory using their own

procedures or as a service provided by the manufacturer. It is important to obtain

verification of spectrometer and method performance when the method is implemented.

Evidence of the maintenance of performance may be obtained through the use of control

charts or by repeating the measurements and calculations made at the time of

implementation;

b) Spectrometer sensitivity is used as a figure of merit to compare spectrometers and to

ensure that a meaningful calibration is possible.

c) Spectral resolution is important to ensure that the analyte and interfering spectral lines are

handled correctly in the collection of data and in the calibration. For the purposes of this

standard, the correction of line overlaps is considered as part of the spectrometer

calibration.

d) The limit of detection, LOD, shall be estimated for each set of operating conditions

employed in the test method using Equation (1) below:

62321-3-1 © IEC:2013 – 15 –

LOD = 3σ (1)

where

LOD is the limit of detection (LOD) for given analyte expressed in units of concentration;

σ is the standard deviation of the results of multiple determinations using a blank

material. Standard deviation is usually estimated using a small (but not less than

seven) number of determinations, in which case the symbol, s (the unbiased

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...