IEC 62321-4:2013

(Main)Determination of certain substances in electrotechnical products - Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS

Determination of certain substances in electrotechnical products - Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS

IEC 62321-4:2013 describes the use of four test methods for mercury in polymers, metals and electronics, namely CV-AAS (cold vapour atomic absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES (inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled plasma mass spectrometry) as well as several procedures for preparing the sample solution from which the most appropriate method of analysis can be selected by experts.

It has the status of a horizontal standard in accordance with IEC Guide 108.

Détermination de certaines substances dans les produits électrotechniques - Partie 4: Mercure dans les polymères, métaux et produits électroniques par CV-AAS, CV-AFS, ICP-OES et ICP-MS

IEC 62321-4:2013 describes the use of four test methods for mercury in polymers, metals and electronics, namely CV-AAS (cold vapour atomic absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES (inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled plasma mass spectrometry) as well as several procedures for preparing the sample solution from which the most appropriate method of analysis can be selected by experts.

It has the status of a horizontal standard in accordance with IEC Guide 108.

General Information

- Status

- Published

- Publication Date

- 18-Jun-2013

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 19-Jun-2013

- Completion Date

- 30-Jun-2013

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62321-4:2013 is an international horizontal standard published by the International Electrotechnical Commission (IEC) that focuses on the determination of mercury content in electrotechnical products. This standard addresses mercury in polymers, metals, and electronic components, outlining test methods based on advanced spectrometric and analytical techniques. It forms part 4 of the IEC 62321 series, which deals with the analysis of certain substances in electrical and electronic equipment to support regulatory compliance and environmental protection.

The standard specifies four analytical methods for mercury detection:

- CV-AAS (Cold Vapour Atomic Absorption Spectrometry)

- CV-AFS (Cold Vapour Atomic Fluorescence Spectrometry)

- ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry)

- ICP-MS (Inductively Coupled Plasma Mass Spectrometry)

In addition, IEC 62321-4:2013 provides detailed sample preparation procedures, ensuring robust and accurate mercury quantification across different material matrices including polymers and metals commonly found in electronic products.

Key Topics

- Scope and Purpose: Defines mercury determination in polymers, metals, and electronic components to ensure compliance with international regulations restricting hazardous substances.

- Test Methods: Detailed procedures for CV-AAS, CV-AFS, ICP-OES, and ICP-MS, enabling selection of the most appropriate analytical technique depending on the sample type and measurement requirements.

- Sample Preparation: Includes wet digestion, microwave digestion, and thermal decomposition-gold amalgamation methods to prepare samples for precise mercury analysis.

- Calibration and Quality Control: Guidelines on calibration curve development, reagent blanks, method detection limits (LOD), and quantification limits (LOQ) to maintain analytical integrity.

- Precision and Accuracy: Statistical data on repeatability and reproducibility to validate method consistency.

- Environmental and Regulatory Relevance: Supports manufacturers and test labs in addressing mercury restrictions in electronic products in line with global directives such as RoHS (Restriction of Hazardous Substances).

Applications

IEC 62321-4:2013 is essential for:

- Manufacturers of electrical and electronic products aiming to monitor and control mercury content in their materials to ensure regulatory compliance and environmental safety.

- Testing laboratories conducting standardized mercury analysis using recognized spectrometric methods, enhancing the reliability of their test results.

- Environmental and regulatory authorities ensuring that electrotechnical products entering the market meet hazardous substance limits to minimize environmental and human health risks.

- Quality assurance teams within electronics industries implementing mercury testing within supplier audits and product inspection processes.

- Research and development units focusing on material safety assessment and innovation in low-mercury or mercury-free electronics.

By following IEC 62321-4, stakeholders can achieve consistent, comparable, and internationally accepted results that facilitate market access and reduce environmental impact.

Related Standards

IEC 62321-4:2013 is part of the broader IEC 62321 series that covers determination methods for certain hazardous substances in electronics, including:

- IEC 62321-1: Introduction and overview of test methods for various restricted substances.

- IEC 62321-5: Cadmium determination by various methods.

- IEC 62321-6: Determination of phthalates.

- IEC 62321-7: Methods for polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE).

- IEC 62321-8: Determination of hexavalent chromium.

Together, these standards provide a comprehensive framework for hazardous substance assessment in electrotechnical products, complementing regulations such as RoHS, WEEE, and REACH. Compliance with IEC 62321-4 supports environmental stewardship and fosters global harmonization in chemical safety controls for the electronics industry.

Keywords: IEC 62321-4, mercury determination, polymers, metals, electronics, electrotechnical products, CV-AAS, CV-AFS, ICP-OES, ICP-MS, mercury testing, hazardous substances, electrical and electronic equipment, standardized analysis, environmental compliance, RoHS, Hg content analysis

Buy Documents

IEC 62321-4:2013 - Determination of certain substances in electrotechnical products - Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS

IEC 62321-4:2013+AMD1:2017 CSV - Determination of certain substances in electrotechnical products - Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS Released:7/13/2017 Isbn:9782832246016

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Sponsored listings

Frequently Asked Questions

IEC 62321-4:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS". This standard covers: IEC 62321-4:2013 describes the use of four test methods for mercury in polymers, metals and electronics, namely CV-AAS (cold vapour atomic absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES (inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled plasma mass spectrometry) as well as several procedures for preparing the sample solution from which the most appropriate method of analysis can be selected by experts. It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-4:2013 describes the use of four test methods for mercury in polymers, metals and electronics, namely CV-AAS (cold vapour atomic absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES (inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled plasma mass spectrometry) as well as several procedures for preparing the sample solution from which the most appropriate method of analysis can be selected by experts. It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-4:2013 is classified under the following ICS (International Classification for Standards) categories: 13.020.01 - Environment and environmental protection in general; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-4:2013 has the following relationships with other standards: It is inter standard links to IEC 62321-4:2013/AMD1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62321-4:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-4 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS,

ICP-OES and ICP-MS

Détermination de certaines substances dans les produits électrotechniques –

Partie 4: Mercure dans les polymères, métaux et produits électroniques par

CV-AAS, CV-AFS, ICP-OES et ICP-MS

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62321-4 ®

Edition 1.0 2013-06

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS,

ICP-OES and ICP-MS

Détermination de certaines substances dans les produits électrotechniques –

Partie 4: Mercure dans les polymères, métaux et produits électroniques par

CV-AAS, CV-AFS, ICP-OES et ICP-MS

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020; 43.040.10 ISBN 978-2-83220-841-0

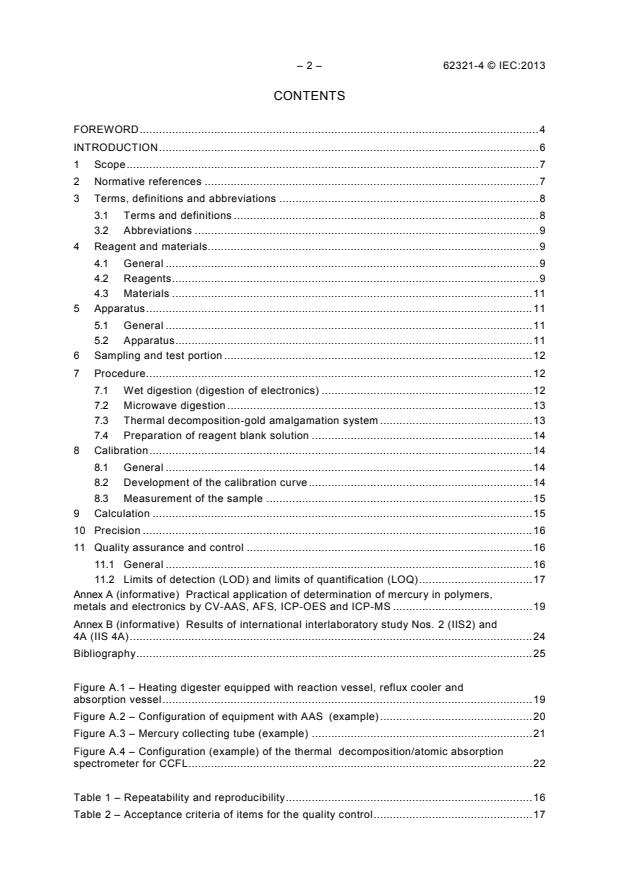

– 2 – 62321-4 © IEC:2013

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviations . 8

3.1 Terms and definitions . 8

3.2 Abbreviations . 9

4 Reagent and materials. 9

4.1 General . 9

4.2 Reagents . 9

4.3 Materials . 11

5 Apparatus . 11

5.1 General . 11

5.2 Apparatus . 11

6 Sampling and test portion . 12

7 Procedure. 12

7.1 Wet digestion (digestion of electronics) . 12

7.2 Microwave digestion . 13

7.3 Thermal decomposition-gold amalgamation system . 13

7.4 Preparation of reagent blank solution . 14

8 Calibration . 14

8.1 General . 14

8.2 Development of the calibration curve . 14

8.3 Measurement of the sample . 15

9 Calculation . 15

10 Precision . 16

11 Quality assurance and control . 16

11.1 General . 16

11.2 Limits of detection (LOD) and limits of quantification (LOQ) . 17

Annex A (informative) Practical application of determination of mercury in polymers,

metals and electronics by CV-AAS, AFS, ICP-OES and ICP-MS . 19

Annex B (informative) Results of international interlaboratory study Nos. 2 (IIS2) and

4A (IIS 4A) . 24

Bibliography . 25

Figure A.1 – Heating digester equipped with reaction vessel, reflux cooler and

absorption vessel . 19

Figure A.2 – Configuration of equipment with AAS (example) . 20

Figure A.3 – Mercury collecting tube (example) . 21

Figure A.4 – Configuration (example) of the thermal decomposition/atomic absorption

spectrometer for CCFL. 22

Table 1 – Repeatability and reproducibility . 16

Table 2 – Acceptance criteria of items for the quality control . 17

62321-4 © IEC:2013 – 3 –

Table 3 – Method detection limit = t × s . 18

n–1

Table A.1 – Program for microwave digestion (example) of samples (power output for

five vessels). 20

Table B.1 – Statistical data for TD(G)-AAS . 24

Table B.2 – Statistical data for CV-AAS . 24

Table B.3 – Statistical data for CV-AFS . 24

Table B.4 – Statistical data for ICP-OES . 24

– 4 – 62321-4 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 4: Mercury in polymers, metals and electronics

by CV-AAS, CV-AFS, ICP-OES and ICP-MS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62321-4 has been prepared by IEC technical committee 111:

Environmental standardization for electrical and electronic products and systems.

It has the status of a horizontal standard in accordance with IEC Guide 108.

The first edition of IEC 62321:2008 was a 'stand alone' standard that included an Introduction,

an overview of test methods, a mechanical sample preparation as well as various test method

clauses.

This first edition of IEC 62321-4 is a partial replacement of IEC 62321, forming a structural

revision and replacing Clause 7 and Annex E.

Future parts in the IEC 62321 series will gradually replace the corresponding clauses in

IEC 62321:2008. Until such time as all parts are published, however, IEC 62321:2008 remains

valid for those clauses not yet re-published as a separate part.

62321-4 © IEC:2013 – 5 –

The text of this standard is based on the following documents:

FDIS Report on voting

111/299/FDIS 111/309/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62321 series can be found on the IEC website under the general

title: Determination of certain substances in electrotechnical products

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 62321-4 © IEC:2013

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adaptation of regulations

affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated diphenyl

ethers (PBDEs)) in electrotechnical products, is a source of concern in current and proposed

regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this International Standard should be familiar with normal

laboratory practice. This standard does not purport to address all of the safety

problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national

regulatory conditions.

62321-4 © IEC:2013 – 7 –

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 4: Mercury in polymers, metals and electronics

by CV-AAS, CV-AFS, ICP-OES and ICP-MS

1 Scope

This part of IEC 62321 describes test methods for mercury in polymers, metals and

electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS.

This standard specifies the determination of the levels of mercury (Hg) contained in

electrotechnical products. These materials are polymers, metals and electronics (e.g. printed

wiring boards, cold cathode fluorescent lamps, mercury switches). Batteries containing Hg

should be handled as described in [1] . The interlaboratory study has only evaluated these

test methods for plastics, other matrices were not covered.

This standard refers to the sample as the object to be processed and measured. What the

sample is or how to get to the sample is defined by the entity carrying out the tests. Further

guidance on obtaining representative samples from finished electronic products to be tested

for levels of regulated substances may be found in IEC 62321-2. It is noted that the selection

and/or determination of the sample may affect the interpretation of the test results.

This standard describes the use of four methods, namely CV-AAS (cold vapour atomic

absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES

(inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled

plasma mass spectrometry) as well as several procedures for preparing the sample solution

from which the most appropriate method of analysis can be selected by experts.

Analysis by CV-AAS, CV-AFS, ICP-OES and ICP-MS allows the determination of the target

element, mercury, with high precision (uncertainty in the low per cent range) and/or high

sensitivity (down to the µg/kg level). The test procedures described in this standard are

intended to provide the highest level of accuracy and precision for concentrations of mercury

in the range from 4 mg/kg to 1 000 mg/kg. The procedures are not limited for higher

concentrations.

For direct analysis, using thermal decomposition-gold amalgamation in conjunction with

CV-AAS (TD(G)-AAS) can be also applied for mercury analysis without sample digestion,

although the detection limits are higher than other methods due to the reduced sample size.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1, Determination of levels of certain substances in electrotechnical products –

Part 1: Introduction and overview

______________

Figures in square brackets refer to the bibliography.

– 8 – 62321-4 © IEC:2013

IEC 62321-2, Determination of levels of certain substances in electrotechnical products –

Part 2: Disassembly, disjointment and mechanical sample preparation

IEC 62321-3-1, Determination of certain substances in electrotechnical products – Part 3-1:

Screening – Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence

spectrometry

IEC 62554, Sample preparation for measurement of mercury level in fluorescent lamps

ISO 3696, Water for analytical laboratory use – Specification and test methods

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62321-1 as well as

the following, apply.

3.1.1

accuracy

closeness of agreement between a test result and an accepted reference value

3.1.2

blank calibration solution

calibration solution without analyte

3.1.3

calibration standard

substance in solid or liquid form with known and stable concentration(s) of the analyte(s) of

interest used to establish instrument response (calibration curve) with respect to analyte(s)

concentration(s)

3.1.4

calibration solution

solution used to calibrate the instrument prepared either from (a) stock solution(s) or from a

(certified) reference material

3.1.5

certified reference material

reference material, accompanied by documentation issued by an authoritative body and

providing one or more specified property values with associated uncertainties and

traceabilities using valid precedures

3.1.6

laboratory control sample

known matrix spiked with compound(s) representative of the target analytes, used to

document laboratory performance

[SOURCE: US EPA SW-846] [2]

3.1.7

reagent blank solution

prepared by adding to the solvent the same amounts of reagents as those added to the test

sample solution (same final volume)

______________

To be published.

62321-4 © IEC:2013 – 9 –

3.1.8

stock solution

solution with accurately known analyte concentartion(s), prepared from “pure chemicals”

3.1.9

test portion

quantity of material drawn from the test sample (or from the laboratory sample if both are the

same) and on which the test or observation is actually carried out

[SOURCE ISO 6206:1979] [3]

3.1.10

test sample solution

solution prepared with the test portion of the test sample according to the appropriate

specifications such that it can be used for the envisaged measurement

3.2 Abbreviations

CRM Certified reference material

CCFL Cold cathode fluorescent lamp

CCV Continuing calibration verification

CV-AAS Cold vapour atomic absorption spectrometry

CV-AFS Cold vapour atomic fluorescence spectrometry

LCS Laboratory control sample

LOD Limits of detection

LOQ Limits of quantification

MDL Method detection limit

TD(G)-AAS Thermal decomposition – Gold amalgamation – Atomic absorption spectrometry

NOTE TD(G)-AAS is commonly referred to as a direct mercury analysis or DMA technique.

4 Reagent and materials

4.1 General

For the determination of elements at trace level, the reagents shall be of adequate purity.

Contamination can be a major source of error when working in the 1 ng range with the

instruments. Cautious handling of the apparatus and careful technique will minimize this

problem. Therefore, only grade 1 water (4.2 a) shall be used. Care shall be taken that all

materials in contact with the water are Hg-free.

Chemicals used for sample preparation can be a major source of contamination. Only

reagents that are mercury-free shall be used. It is therefore highly recommended that the

blank values of the reducing agents and the other chemicals be measured before using them

for sample preparation.

4.2 Reagents

The following reagents are used:

a) Water: Grade 1, as defined in ISO 3696, shall be used for preparation and dilution of all

sample solutions.

b) Nitric acid (concentrated nitric acid): ρ(HNO ) = 1,4 g/ml , a mass fraction of 65 %, trace

metal grade.

c) Nitric acid, a mass fraction of 50 %, trace metal grade.

d) Nitric acid, 0,5 mol/l, trace metal grade.

– 10 – 62321-4 © IEC:2013

e) Nitric acid, a mass fraction of 1 %, trace metal grade.

f) Nitric acid, a mass fraction of 1,5 %, trace metal grade.

g) Nitric acid, a mass fraction of 5 % , trace metal grade.

h) Fluoroboric acid: HBF a mass fraction of 50 %, trace metal grade (for microwave

4,

digestion).

i) Hydrogen peroxide: H O a mass fraction of 30 %, trace metal grade (for microwave

2 2,

digestion).

j) Stock solution with 1 000 mg/L of mercury, trace metal grade.

k) Potassium tetrahydridoborate (potassium borohyride): KBH , trace metal grade.

l) Potassium permanganate: KMnO , a mass fraction of 5 % solution, trace metal grade.

Dissolve 5 g of potassium permanganate in 100 ml of water (4.2 a).

m) Sodium tetrahydridoborate (sodium borohydride), NaBH , trace metal grade.

n) Sodium hydroxide, NaOH trace metal grade.

o) Hydrogen tetrachloroaurate (Ⅲ) tetra hydrate, HAuCl ・ 4H2O trace metal grade.

p) Internal standard stock solution, trace metal grade:

– Internal standard elements that do not interfere with the target element are used for

ICP-OES and ICP-MS. Also, the presence of these internal standard elements in the

sample solution shall be at negligible levels. Sc, In, Tb, Lu, Re, Rh, Bi and Y may be

used as internal standard elements.

– For use with ICP-OES, Sc or Y is recommended. The recommended concentration is

1 000 mg/L.

– For use with ICP-MS, Rh is recommended. The recommended concentration is

1 000 µg/l.

q) Reducing agent for CV-AAS: a mass fraction of 3 % NaBH in a mass fraction of 1 %

NaOH.

Dissolve 10,0 g sodium hydroxide (4.2 n) into approximately 700 ml of water (4.2 a) in a

beaker and stir until dissolved. Add 30,0 g of sodium tetrahydridoborate powder (4.2 m)

into the beaker and stir until dissolved. Finally transfer to a 1 l volumetric flask and fill up

to the mark with water (4.2 a) and filter. Prepare daily.

Reductant solution containing sodium tetrahydridoborate in a sodium hydroxide solution is

recommended. If the available mercury hydride system is incompatible with this reductant,

tin (II) chloride or stannous sulfate can be used instead. The instructions given in the

operator’s manual for the instrument should be followed.

r) Reducing agent for CV-AFS: a mass fraction of 1 % (m/v) KBH in a mass fraction of

0,05 % NaOH.

Dissolve 0,50 g sodium hydroxide (4.2 n) into approximately 700 ml of water (4.2 a) in a

beaker and stir until dissolved. Add 10,0 g of potassium tetrahydridoborate (4.2 k) into the

beaker and stir until dissolved. Finally transfer to a 1 l volumetric flask and fill up to the

mark with water (4.2 a) and filter. Prepare daily.

Reductant solution containing potassium tetrahydridoborate in a sodium hydroxide solution

is recommended. If the available mercury hydride system is incompatible with this

reductant, tin (II) chloride or stannous sulfate can be used instead. The instructions given

in the operator’s manual for the instrument should be followed.

s) Gold preservation stock solution for mercury (1 ml = 100 µg): it is recommended

purchasing as high purity prepared solution of AuCl in dilute hydrochloric acid matrix.

t) Diatomaceous earth

Analytical grade reagents may be used as an alternative except when utilizing ICP-MS

methods.

62321-4 © IEC:2013 – 11 –

4.3 Materials

Materials include:

a) Mercury collector for thermal–decomposition-gold amalgamation system

A solution of 1 g of hydrogen tetrachloroaurate(Ⅲ) tetra hydrate (4.2 o) in 20 ml to 30 ml

of water (4.2 a) is added to 3 g of 420 µm to 590 µm diatomaceous earth, which is then

mixed until homogeneous. After being dried at approximately 80 °C, the collector is loaded

into a tube furnace and heated for 30 min at around 800 °C in flowing air.

5 Apparatus

5.1 General

In general, the collection and storage of glassware are a critical part of mercury analysis,

regardless of the type of sample to be analysed. Because of the sensitivity of the mercury

analysis techniques described, each individual sampling step shall be carried out with great

care.

Beakers, pipettes, volumetric flasks, etc. are all major sources of metal contamination. It is

essential to use mercury-free plastic or quartz glassware for sample handling.

All sampling, storage and manipulation apparatus shall be mercury free. Soak all glassware in

50 % nitric acid (4.2 c) for 24 h at room temperature, and then rinse thoroughly with water

(4.2 a).

For measurements by ICP-OES and ICP-MS, the memory effect occurs in cases where high

concentrations of mercury are introduced. Dilution of the sample solution is required for high

levels of mercury. If the memory effect is not decreased by dilution, thorough washing of the

equipment is required.

5.2 Apparatus

The following apparatus shall be used:

a) Analytical balance capable of measuring accurately to 0,000 1 g.

For wet digestion as described in 7.1:

b) Heating digester equipped with reaction vessels, reflux coolers and absorption vessels

(for the digestion of metals and electronics).

c) Glass fibre filter 0,45 µm.

For microwave digestion as described in 7.2:

d) Microwave sample preparation system equipped with a sample holder and high-pressure

polytetrafluoroethylene/tetrafluoroethylene modified (PTFE/TFM) or perfluoro alkoxyl

alkane resin /tetrafluoroethylene modified (PFA/TFM) or other vessels based on

fluorocarbon materials (for the digestion of metals containing significant amounts of silicon

(Si), zirconium (Zr), hafnium (Hf), titanium (Ti), tantalum (Ta), niobium (Nb) or tungsten

(W), and for plastics).

e) Glass microfibre filter (borosilicate glass), pore size: 0,45 µm and a suitable filter cup.

f) Volumetric flasks such as 25 ml, 250 ml , etc. (PTFE-PFA equipment or glassware).

Where appropriate, other types of volumetric equipment with acceptable precision and

accuracy can be used as alternatives to volumetric flasks.

g) Pipettes such as 1 ml, 2 ml, 5 ml, 10 ml, etc. (PTFE-PFA equipment or glassware).

h) Micropipettes such as 200 µl, 500 µl, 1 000 µl, etc.

i) Plastic containers for standards and digestion solutions. (PTFE-PFA equipment).

j) Cold vapour atomic absorption spectrometer (CV-AAS).

– 12 – 62321-4 © IEC:2013

k) Cold vapour atomic fluorescence spectrometer (CV-AFS).

l) Inductively coupled plasma optical emission spectrometer (ICP-OES).

m) Inductively coupled plasma mass spectrometer (ICP-MS).

n) Argon gas with a purity of at least 99,99 %.

o) Thermal decomposition-gold amalgamation system.

6 Sampling and test portion

The different test methods, which can be used as alternatives according to this standard,

need different amounts of sample to obtain the required quality of results.

In the case of electronics, the sample shall first be destroyed mechanically by appropriate

means (e.g. grinding, milling, mill cutting with LN -cooling due to volatility of mercury) before

chemical dissolution of the powder can start. To ensure representative sample taking at this

stage, a certain particle size as a function of the starting amount of sample is required (see

IEC 62321-2).

For the determination of mercury in fluorescent self ballasted lamps, single capped compact

florescent multi lamps and linear fluorescent lamps, follow the instructions given in IEC 62554.

If using a thermal decomposition-gold amalgamation system, samples should be milled in a

ball mill and homogenized in advance. Difficult samples, like metals, to be ground as finely as

possible. Put 50 mg to 200 mg of the sample into a sample boat. If using an additive, spread

0,5 g in a thin layer over the surface of the sample boat, evenly spread the sample over the

additive, and then cover the sample with 2 g of additive.

It is recommended to analyse aqueous sample solutions containing mercury preferably

directly after sample preparation. If this is not possible, it is highly recommended stabilizing

the solutions in an adequate way, and to store the solutions no longer than 28 days at

ambient temperature.

7 Procedure

7.1 Wet digestion (digestion of electronics)

Wet digestion is recommended for the digestion of metals and electronics, with the exception

of metals containing significant amounts of Si, Zr, Hf, Ti, Ta, Nb or W. For these materials and

for polymers, microwave digestion, as described in 7.2, is recommended.

a) Weigh 1 g of a sample to the nearest 0,1 mg into the reaction vessel and 30 ml

concentrated nitric acid (4.2 b) is added. (When the available sample amount is 500 mg or

less, refer to the instructions given in 7.2 a).

The vessel is equipped with a reflux cooler and an absorption vessel (on top of the reflux

cooler – see Figure A.1) containing 10 ml 0,5 mol/l nitric acid (4.2 d). A temperature

program is then started to digest the samples for 1 h at room temperature and for 2 h at

90 °C.

After cooling to room temperature, the contents of the absorption tube are placed in the

reaction vessel and the solution obtained is transferred to a 250 ml volumetric flask (5.2 f)

and filled with 5 % nitric acid (4.2 g) to the mark (if the sample is digested completely).

b) For ICP-OES and ICP-MS measurements, the sample solution obtained may be diluted

with water (4.2 a) to the appropriate concentration levels for measurements. Add 250 µl of

internal standard (4.2 p) for a volume of 250 ml before filling to the mark.

c) If the sample is not completely digested (e.g. printed wiring boards), the sample is filtered

with a filter (5.2 e) and the solid residue is washed four times with 15 ml 5 % nitric acid

62321-4 © IEC:2013 – 13 –

(4.2 g). The solution obtained is transferred to a 250 ml volumetric flask (5.2 f) and filled

with 5 % nitric acid (4.2 g) to the mark.

d) Any sample residues shall be separated by a centrifuge or a filter. The residues shall be

tested by appropriate measurements (e.g. XRF, alkali fusion method, other acid digestion

methods, etc.) to confirm the absence of target elements. The instruction for XRF is given

in IEC 62321-3-1.

7.2 Microwave digestion

Microwave digestion is recommended for the following materials:

– metals containing significant amounts of Si, Zr, Hf, Ti, Ta, Nb or W,

– polymers,

in cases where the available sample amount is smaller than 500 mg.

It is highly recommended that the same sample amounts and the same type of samples be

weighed in one digestion run.

NOTE 1 Mercury can be determined in the same solution with Pb and Cd obtained in a closed system for acid

decomposition, as described in IEC 62321-5 [4].

a) Weigh, 0,1 g of a sample to the nearest 0,1 mg into a PTFE-TFM or PFA-TFM vessel. Add

5 ml of concentrated nitric acid (4.2 b), 1,5 ml 50 % HBF solution (4.2 h), 1,5 ml 30 %

H O (4.2 i) and 1 ml water (4.2 a). Close the vessel and digest the sample in the

2 2

microwave oven following a digestion program specified in advance. An example of a

suitable microwave program is given in Annex A.

NOTE 2 If HBF is not available in sufficient purity, HF may be used as an alternative.

Hydrogen peroxide should only be added when the reactive components of the sample are

known. Hydrogen peroxide may react rapidly and violently with easily oxidizable materials

and should not be added if the sample contains large quantities of easily oxidizable

organic constituents.

b) Cool the vessel to room temperature (approximately 1 h). Open the vessel, filter the

solution with filter (5.2 e) into a 25 ml flask (5.2 f), wash with water (4.2 a) and fill to mark

with water (4.2 a).

c) Any sample residues shall be separated by a centrifuge or filter. The residues shall be

checked by appropriate measurements (e.g. XRF, alkali fusion method, other acid

digestion methods, etc.) to confirm the absence of target elements. The instruction for

XRF is given in IEC 62321-3-1.

The resulting concentrated solutions may be measured directly by ICP-OES and ICP-MS, i.e.

the digestion solution may be analysed without any further sample preparation. When using

CV-AAS and CV-AFS, the mercury is reduced to its elemental state before it is analysed.

7.3 Thermal decomposition-gold amalgamation system

The procedure should be performed as follows, but also follow the instruction manual of the

relevant instruments for details on their operation:

a) Place the sample vessel charged with a sample in position in the automatic sample

changer.

b) Set the predetermined temperature ramp program and raise the temperature of the

sample heating furnace.

c) The mercury, mercury compounds and combustion product gases generated from the

sample will be decomposed in the decomposition furnace containing the catalyst and then

scrubbed and dehumidified in the gas washing bottle and the dehumidifier bottle.

– 14 – 62321-4 © IEC:2013

d) The mercury and other gases are introduced into the mercury collecting tube, where only

mercury is trapped in the form of amalgam, and any other gases discharged through the

switching valve.

e) The mercury collecting tube is heated at a constant temperature of 350 °C to 600 °C, and

the generated mercury introduced into the absorption cell or the fluorescence cell. The

height or area of the absorption peak or the fluorescence intensity is then measured at a

wavelength of 253,7 nm.

7.4 Preparation of reagent blank solution

The procedure is identical to that of sample preparation and is carried out concurrently but

without the sample.

8 Calibration

8.1 General

All analyses require that a calibration curve shall be prepared to cover the appropriate

concentration range. Calibration solutions are prepared by diluting the stock solution (4.2 j)

with 1,5 % nitric acid (4.2 f). When internal standard methods (ICP-OES and ICP-MS) are

used, the appropriate amounts of solution for the internal standard stock solutions (4.2 p) are

added.

Prepare a reagent blank solution of 1,5 % nitric acid (4.2 f) and at least three calibration

solutions in graduated amounts in the appropriate range of the linear part of the calibration

curve.

Calibration solutions shall be stored in mercury-free plastic containers. The stock solution (4.2

j) is usually stable for at least a year, whereas calibration solutions shall be prepared daily.

The stability of mercury calibration solutions can be severely affected by adsorption on the

walls of the storage vessel. Therefore, it is recommended that mercury calibration solutions

be stabilized by the addition of a few drops of 5 % KMnO (4.2 l) solution.

NOTE A 1 % gold (Au) solution can also be used instead of potassium permanganate.

8.2 Development of the calibration curve

The spectrometers are prepared for quantification with a reagent blank solution and a

minimum of three calibration solutions.

a) CV-AAS

1) The readings for the absorbance of the target element mercury are determined. The

calibration curve obtained shows the relationship between the absorbance of mercury

and its concentration.

2) The recommended wavelength and examples of workable instrument parameters are

listed in Clause A.3.

b) CV-AFS

1) The readings for the fluorescence intensity of the target element mercury are

determined. The calibration curve obtained shows the relationship between the

fluorescence intensity of mercury and its concentration.

2) The recommended wavelength and examples of workable instrument parameters are

listed in Clause A.3.

c) ICP-OES

The readings for the emission intensity of the target element mercury and those of the

internal standard are determined. The calibration curve obtained shows the relationship

62321-4 © IEC:2013 – 15 –

between the ratio of emission intensities of mercury and those of the internal standard to

the concentration of mercury.

The recommended wavelength for mercury and examples of workable instrument

parameters are listed in Clause A.3.

d) ICP-MS

The readings for the mass/charge (m/z) intensity of the target element mercury and those

of the internal standard are determined. The calibration curve obtained shows the

relationship between the intensity ratio of the m/z of mercury and that of the internal

standard to the concentration of mercury.

The recommended m/z ratios for mercury and examples of workable instrument

parameters are listed in Clause A.3.

e) TD(G)-AAS

Four or five calibration solutions, including a blank calibration solution, are placed directly

into the sample boats using a micro pipette while changing the amount but ensuring it is

within the working measurement range, and measured in the same manner as samples. A

calibration curve is then derived from the relationship between the amounts of mercury

and indicated values. For example, in the case of a sample’s mercury concentration being

around 10 mg/kg, use 50 µl, 100 µl, 150 µl and 200 µl of 100 µg/ml stock solution for

measurement and develop a calibration curve from the results obtained.

8.3 Measurement of the sample

After development of the calibration curve, the reagent blank solution and the test sample

solutions are measured. If the sample concentration is above the range of the concentration

curve, the solution shall be diluted with 1 % nitric acid (4.2 e) to the range of the calibration

curve and measured again.

Measurement precision and baseline drift shall be checked with a standard substance,

calibration solution, etc. and a blank calibration solution at regular intervals (such as every 10

samples) and after the last sample.

If the sample is diluted to the range of calibration, it should be ensured that the internal

standard concentration in the diluted sample solution is adjusted to the standard solution.

9 Calculation

The concentration measured in 8.3 is the concentration of mercury in the sample solution. The

concentration of mercury in the sample is calculated from the following formula:

(A − A )

1 2

c = ×V (2)

m

where

c is the concentration of mercury in the sample in µg/g;

A is the concentration of mercury in the sample solution in mg/l;

A is the concentration of mercury in the reagent blank solution in mg/l;

V is the total volume for the sample solution in ml which depends on

– the type of digestion carried out (250 ml for wet digestion, 25 ml for microwave

digestion),

– the type of the particular series of dilutions used;

m is the measured quantity of the sample in g.

– 16 – 62321-4 © IEC:2013

10 Precision

When the values of two independent single test results, obtained using the same method on

identical test material in the same laboratory by the same operator using the same equipment

within a short interval of time, lie within the range of the mean val

...

IEC 62321-4 ®

Edition 1.1 2017-07

CONSOLIDATED

VERSION

VERSION

CONSOLIDÉE

colour

inside

NORME HORIZONTALE

HORIZONTAL STANDARD

Determination of certain substances in electrotechnical products –

Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS,

ICP-OES and ICP-MS

Détermination de certaines substances dans les produits électrotechniques –

Partie 4: Mercure dans les polymères, métaux et produits électroniques par

CV-AAS, CV-AFS, ICP-OES et ICP-MS

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and definitions clause of

IEC publications issued between 2002 and 2015. Some

IEC Customer Service Centre - webstore.iec.ch/csc entries have been collected from earlier publications of IEC

If you wish to give us your feedback on this publication or TC 37, 77, 86 and CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues entre 2002 et 2015. Plus certaines

entrées antérieures extraites des publications des CE 37, 77,

Service Clients - webstore.iec.ch/csc 86 et CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62321-4 ®

Edition 1.1 2017-07

CONSOLIDATED

VERSION

VERSION

CONSOLIDÉE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS,

ICP-OES and ICP-MS

Détermination de certaines substances dans les produits électrotechniques –

Partie 4: Mercure dans les polymères, métaux et produits électroniques par

CV-AAS, CV-AFS, ICP-OES et ICP-MS

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020; 43.040.10 ISBN 978-2-8322-4601-6

IEC 62321-4 ®

Edition 1.1 2017-07

REDLINE VERSION

VERSION REDLINE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 4: Mercury in polymers, metals and electronics by CV-AAS, CV-AFS,

ICP-OES and ICP-MS

Détermination de certaines substances dans les produits électrotechniques –

Partie 4: Mercure dans les polymères, métaux et produits électroniques par

CV-AAS, CV-AFS, ICP-OES et ICP-MS

– 2 – IEC 62321-4:2013+AMD1:2017 CSV

© IEC 2017

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions and abbreviations . 8

3.1 Terms and definitions . 8

3.2 Abbreviations . 9

4 Reagent and materials. 9

4.1 General . 9

4.2 Reagents . 9

4.3 Materials . 11

5 Apparatus . 11

5.1 General . 11

5.2 Apparatus . 11

6 Sampling and test portion . 12

7 Procedure. 12

7.1 Wet digestion (digestion of electronics) . 12

7.2 Microwave digestion . 13

7.3 Thermal decomposition-gold amalgamation system . 13

7.4 Preparation of reagent blank solution . 14

8 Calibration . 14

8.1 General . 14

8.2 Development of the calibration curve . 14

8.3 Measurement of the sample . 15

9 Calculation . 15

10 Precision . 16

11 Quality assurance and control . 17

11.1 General . 17

11.2 Limits of detection (LOD) and limits of quantification (LOQ) . 18

Annex A (informative) Practical application of determination of mercury in polymers,

metals and electronics by CV-AAS, AFS, ICP-OES and ICP-MS . 20

Annex B (informative) Results of international interlaboratory study Nos. 2 (IIS2)

and 4A (IIS 4A) . 25

Bibliography . 26

Figure A.1 – Heating digester equipped with reaction vessel, reflux cooler and

absorption vessel . 20

Figure A.2 – Configuration of equipment with AAS (example) . 21

Figure A.3 – Mercury collecting tube (example) . 22

Figure A.4 – Configuration (example) of the thermal decomposition/atomic absorption

spectrometer for CCFL. 23

Table 1 – Repeatability and reproducibility . 17

Table 2 – Acceptance criteria of items for the quality control . 18

© IEC 2017

Table 3 – Method detection limit = t × s . 19

n–1

Table A.1 – Program for microwave digestion (example) of samples (power output

for five vessels) . 21

Table B.1 – Statistical data for TD(G)-AAS . 25

Table B.2 – Statistical data for CV-AAS . 25

Table B.3 – Statistical data for CV-AFS . 25

Table B.4 – Statistical data for ICP-OES . 25

– 4 – IEC 62321-4:2013+AMD1:2017 CSV

© IEC 2017

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 4: Mercury in polymers, metals and electronics

by CV-AAS, CV-AFS, ICP-OES and ICP-MS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been prepared

for user convenience.

IEC 62321-4 edition 1.1 contains the first edition (2013-06) [documents 111/299/FDIS and

111/309/RVD] and its amendment 1 (2017-07) [documents 111/414/CDV and 111/431/RVC].

In this Redline version, a vertical line in the margin shows where the technical content is

modified by amendment 1. Additions are in green text, deletions are in strikethrough red text. A

separate Final version with all changes accepted is available in this publication.

© IEC 2017

International Standard IEC 62321-4 has been prepared by IEC technical committee 111:

Environmental standardization for electrical and electronic products and systems.

It has the status of a horizontal standard in accordance with IEC Guide 108.

The first edition of IEC 62321:2008 was a 'stand alone' standard that included an Introduction, an

overview of test methods, a mechanical sample preparation as well as various test method clauses.

This first edition of IEC 62321-4 is a partial replacement of IEC 62321, forming a structural

revision and replacing Clause 7 and Annex E.

Future parts in the IEC 62321 series will gradually replace the corresponding clauses in IEC

62321:2008. Until such time as all parts are published, however, IEC 62321:2008 remains valid for

those clauses not yet re-published as a separate part.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62321 series can be found on the IEC website under the general title:

Determination of certain substances in electrotechnical products

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date, the

publication will be

reconfirmed,

withdrawn,

replaced by a revised edition, or

amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62321-4:2013+AMD1:2017 CSV

© IEC 2017

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adaptation of regulations

affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated diphenyl

ethers (PBDEs)) in electrotechnical products, is a source of concern in current and proposed

regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this International Standard should be familiar with normal

laboratory practice. This standard does not purport to address all of the safety

problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national

regulatory conditions.

© IEC 2017

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 4: Mercury in polymers, metals and electronics

by CV-AAS, CV-AFS, ICP-OES and ICP-MS

1 Scope

This part of IEC 62321 describes test methods for mercury in polymers, metals and

electronics by CV-AAS, CV-AFS, ICP-OES and ICP-MS.

This standard specifies the determination of the levels of mercury (Hg) contained in

electrotechnical products. These materials are polymers, metals and electronics (e.g. printed

wiring boards, cold cathode fluorescent lamps, mercury switches). Batteries containing Hg

should be handled as described in [1] . The interlaboratory study has only evaluated these

test methods for plastics, other matrices were not covered.

This standard refers to the sample as the object to be processed and measured. What the

sample is or how to get to the sample is defined by the entity carrying out the tests. Further

guidance on obtaining representative samples from finished electronic products to be tested

for levels of regulated substances may be found in IEC 62321-2. It is noted that the selection

and/or determination of the sample may affect the interpretation of the test results.

This standard describes the use of four methods, namely CV-AAS (cold vapour atomic

absorption spectrometry), CV-AFS (cold vapour atomic fluorescence spectrometry) ICP-OES

(inductively coupled plasma optical emission spectrometry), and ICP-MS (inductively coupled

plasma mass spectrometry) as well as several procedures for preparing the sample solution

from which the most appropriate method of analysis can be selected by experts.

Analysis by CV-AAS, CV-AFS, ICP-OES and ICP-MS allows the determination of the target

element, mercury, with high precision (uncertainty in the low per cent range) and/or high

sensitivity (down to the µg/kg level). The test procedures described in this standard are

intended to provide the highest level of accuracy and precision for concentrations of mercury

in the range from 4 mg/kg to 1 000 mg/kg. The procedures are not limited for higher

concentrations.

For direct analysis, using thermal decomposition-gold amalgamation in conjunction with

CV-AAS (TD(G)-AAS) can be also applied for mercury analysis without sample digestion,

although the detection limits are higher than other methods due to the reduced sample size.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1, Determination of levels of certain substances in electrotechnical products –

Part 1: Introduction and overview

______________

Figures in square brackets refer to the bibliography.

– 8 – IEC 62321-4:2013+AMD1:2017 CSV

© IEC 2017

IEC 62321-2, Determination of levels of certain substances in electrotechnical products –

Part 2: Disassembly, disjointment and mechanical sample preparation

IEC 62321-3-1, Determination of certain substances in electrotechnical products – Part 3-1:

Screening – Lead, mercury, cadmium, total chromium and total bromine by X-ray fluorescence

spectrometry

IEC 62554, Sample preparation for measurement of mercury level in fluorescent lamps

ISO 3696, Water for analytical laboratory use – Specification and test methods

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62321-1 as well as

the following, apply.

3.1.1

accuracy

closeness of agreement between a test result and an accepted reference value

3.1.2

blank calibration solution

calibration solution without analyte

3.1.3

calibration standard

substance in solid or liquid form with known and stable concentration(s) of the analyte(s) of

interest used to establish instrument response (calibration curve) with respect to analyte(s)

concentration(s)

3.1.4

calibration solution

solution used to calibrate the instrument prepared either from (a) stock solution(s) or from a

(certified) reference material

3.1.5

certified reference material

reference material, accompanied by documentation issued by an authoritative body and

providing one or more specified property values with associated uncertainties and

traceabilities using valid precedures

3.1.6

laboratory control sample

known matrix spiked with compound(s) representative of the target analytes, used to

document laboratory performance

[SOURCE: US EPA SW-846] [2]

3.1.7

reagent blank solution

prepared by adding to the solvent the same amounts of reagents as those added to the test

sample solution (same final volume)

______________

To be published.

© IEC 2017

3.1.8

stock solution

solution with accurately known analyte concentartion(s), prepared from “pure chemicals”

3.1.9

test portion

quantity of material drawn from the test sample (or from the laboratory sample if both are the

same) and on which the test or observation is actually carried out

[SOURCE ISO 6206:1979] [3]

3.1.10

test sample solution

solution prepared with the test portion of the test sample according to the appropriate

specifications such that it can be used for the envisaged measurement

3.2 Abbreviations

CRM Certified reference material

CCFL Cold cathode fluorescent lamp

CCV Continuing calibration verification

CV-AAS Cold vapour atomic absorption spectrometry

CV-AFS Cold vapour atomic fluorescence spectrometry

LCS Laboratory control sample

LOD Limits of detection

LOQ Limits of quantification

MDL Method detection limit

TD(G)-AAS Thermal decomposition – Gold amalgamation – Atomic absorption spectrometry

NOTE TD(G)-AAS is commonly referred to as a direct mercury analysis or DMA technique.

4 Reagent and materials

4.1 General

For the determination of elements at trace level, the reagents shall be of adequate purity.

Contamination can be a major source of error when working in the 1 ng range with the

instruments. Cautious handling of the apparatus and careful technique will minimize this

problem. Therefore, only grade 1 water (4.2 a) shall be used. Care shall be taken that all

materials in contact with the water are Hg-free.

Chemicals used for sample preparation can be a major source of contamination. Only

reagents that are mercury-free shall be used. It is therefore highly recommended that the

blank values of the reducing agents and the other chemicals be measured before using them

for sample preparation.

4.2 Reagents

The following reagents are used:

a) Water: Grade 1, as defined in ISO 3696, shall be used for preparation and dilution of all

sample solutions.

b) Nitric acid (concentrated nitric acid): ρ(HNO ) = 1,4 g/ml , a mass fraction of 65 %, trace

metal grade.

c) Nitric acid, a mass fraction of 50 %, trace metal grade.

d) Nitric acid, 0,5 mol/l, trace metal grade.

– 10 – IEC 62321-4:2013+AMD1:2017 CSV

© IEC 2017

e) Nitric acid, a mass fraction of 1 %, trace metal grade.

f) Nitric acid, a mass fraction of 1,5 %, trace metal grade.

g) Nitric acid, a mass fraction of 5 % , trace metal grade.

h) Fluoroboric acid: HBF a mass fraction of 50 %, trace metal grade (for microwave

4,

digestion).

i) Hydrogen peroxide: H O a mass fraction of 30 %, trace metal grade (for microwave

2 2,

digestion).

j) Stock solution with 1 000 mg/L of mercury, trace metal grade.

k) Potassium tetrahydridoborate (potassium borohyride): KBH , trace metal grade.

l) Potassium permanganate: KMnO , a mass fraction of 5 % solution, trace metal grade.

Dissolve 5 g of potassium permanganate in 100 ml of water (4.2 a).

m) Sodium tetrahydridoborate (sodium borohydride), NaBH , trace metal grade.

n) Sodium hydroxide, NaOH trace metal grade.

o) Hydrogen tetrachloroaurate (Ⅲ) tetra hydrate, HAuCl ・ 4H2O trace metal grade.

p) Internal standard stock solution, trace metal grade:

– Internal standard elements that do not interfere with the target element are used for

ICP-OES and ICP-MS. Also, the presence of these internal standard elements in the

sample solution shall be at negligible levels. Sc, In, Tb, Lu, Re, Rh, Bi and Y may be

used as internal standard elements.

– For use with ICP-OES, Sc or Y is recommended. The recommended concentration is

1 000 mg/L.

– For use with ICP-MS, Rh is recommended. The recommended concentration is

1 000 µg/l.

q) Reducing agent for CV-AAS: a mass fraction of 3 % NaBH in a mass fraction of 1 %

NaOH.

Dissolve 10,0 g sodium hydroxide (4.2 n) into approximately 700 ml of water (4.2 a) in a

beaker and stir until dissolved. Add 30,0 g of sodium tetrahydridoborate powder (4.2 m)

into the beaker and stir until dissolved. Finally transfer to a 1 l volumetric flask and fill up

to the mark with water (4.2 a) and filter. Prepare daily.

Reductant solution containing sodium tetrahydridoborate in a sodium hydroxide solution is

recommended. If the available mercury hydride system is incompatible with this reductant,

tin (II) chloride or stannous sulfate can be used instead. The instructions given in the

operator’s manual for the instrument should be followed.

r) Reducing agent for CV-AFS: a mass fraction of 1 % (m/v) KBH in a mass fraction of

0,05 % NaOH.

Dissolve 0,50 g sodium hydroxide (4.2 n) into approximately 700 ml of water (4.2 a) in a

beaker and stir until dissolved. Add 10,0 g of potassium tetrahydridoborate (4.2 k) into the

beaker and stir until dissolved. Finally transfer to a 1 l volumetric flask and fill up to the

mark with water (4.2 a) and filter. Prepare daily.

Reductant solution containing potassium tetrahydridoborate in a sodium hydroxide solution

is recommended. If the available mercury hydride system is incompatible with this

reductant, tin (II) chloride or stannous sulfate can be used instead. The instructions given

in the operator’s manual for the instrument should be followed.

s) Gold preservation stock solution for mercury (1 ml = 100 µg): it is recommended

purchasing as high purity prepared solution of AuCl in dilute hydrochloric acid matrix.

t) Diatomaceous earth

Analytical grade reagents may be used as an alternative except when utilizing ICP-MS

methods.