IEC 62321-7-1:2015

(Main)Determination of certain substances in electrotechnical products - Part 7-1: Hexavalent chromium - Presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protected coatings on metals by the colorimetric method

Determination of certain substances in electrotechnical products - Part 7-1: Hexavalent chromium - Presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protected coatings on metals by the colorimetric method

IEC 62321-7-1:2015 describes a boiling water extraction procedure intended to provide a qualitative determination of the presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protection coatings on metallic samples. In this procedure, when Cr(VI) in a sample is detected below the 0,10 g;cm2 LOQ (limit of quantification), the sample is considered to be negative for Cr(VI). Since Cr(VI) may not be uniformly distributed in the coating even within the same sample batch, a ;grey zone; between 0,10 g;cm2 and 0,13 g;cm2 has been established as ;inconclusive; to reduce inconsistent results due to unavoidable coating variations. In this case, additional testing may be necessary to confirm the presence of Cr(VI). When Cr(VI) is detected above 0,13 g;cm2, the sample is considered to be positive for the presence of Cr(VI) in the coating layer.

It has the status of a horizontal standard in accordance with IEC Guide 108.

Détermination de certaines substances dans les produits électrotechniques - Partie 7-1: Chrome hexavalent - Présence de chrome hexavalent (Cr(VI)) dans les revêtements incolores et colorés de protection anticorrosion appliqués sur les métaux à l'aide de la méthode colorimétrique

L'IEC 62321-7-1:2015 décrit une procédure d'extraction à l'eau bouillante destinée à assurer une détermination qualitative de la présence de chrome hexavalent (Cr(VI)) dans les revêtements incolores et colorés de protection anticorrosion d'échantillons métalliques. Dans la présente procédure, lorsque du chrome hexavalent est détecté sur un échantillon selon une valeur inférieure à 0,10 g/cm2 de la limite de quantification (LOQ), l'échantillon est considéré comme négatif au chrome hexavalent. Dans la mesure où le chrome hexavalent peut ne pas être uniformément réparti sur le revêtement, et ce même au sein du même lot d'échantillons, une "zone grise" comprise entre 0,10 g/cm2 et 0,13 g/cm2 a été établie comme "non concluante" pour réduire l'incohérence des résultats due à des variations inévitables de revêtement. Dans ce cas, des essais supplémentaires peuvent être nécessaires pour confirmer la présence de chrome hexavalent. Si du chrome hexavalent est détecté selon une valeur supérieure à 0,13 g/cm2, l'échantillon est considéré comme positif dans le cadre de la présence de chrome hexavalent dans la couche de revêtement.

Elle a le statut de norme horizontale conformément au Guide IEC 108.

General Information

- Status

- Published

- Publication Date

- 15-Sep-2015

- Technical Committee

- TC 111 - Environmental standardization for electrical and electronic products and systems

- Drafting Committee

- WG 3 - TC 111/WG 3

- Current Stage

- PPUB - Publication issued

- Start Date

- 16-Sep-2015

- Completion Date

- 31-Aug-2015

Overview

IEC 62321-7-1:2015 is an international standard developed by the International Electrotechnical Commission (IEC) focusing on the determination of hexavalent chromium (Cr(VI)) in electrotechnical products. This part of the IEC 62321 series specifies a qualitative colorimetric method using a boiling water extraction procedure to detect the presence of hexavalent chromium in colourless and coloured corrosion-protected coatings on metal surfaces.

Hexavalent chromium is a substance of environmental and health concern due to its toxicity and carcinogenic properties. The standard provides a reliable methodology to assess whether Cr(VI) is present above certain threshold limits in corrosion-protection coatings applied to metallic substrates, ensuring safety and regulatory compliance across global markets.

Key Topics

Scope and Objective: IEC 62321-7-1:2015 targets the qualitative detection of Cr(VI) in corrosion-protection coatings on metals using a colorimetric method. It helps verify if coatings contain Cr(VI) above defined concentration limits, especially in electrotechnical products.

Testing Procedure:

The standard outlines a boiling water extraction process wherein the metallic sample’s coatings undergo extraction to release hexavalent chromium compounds. The subsequent colorimetric analysis detects and semi-quantitatively measures Cr(VI) levels.Detection Limits and Interpretation:

- Below 0.10 µg/cm² (limit of quantification - LOQ): Sample is considered negative for Cr(VI).

- Between 0.10 µg/cm² and 0.13 µg/cm²: Results are inconclusive (grey zone) due to inherent coating variability; further testing recommended.

- Above 0.13 µg/cm²: Sample is positive for Cr(VI) presence in the coating.

Sampling and Calibration:

The standard provides detailed procedures for sample preparation, including handling coated screws or metallic parts, as well as guidelines for instrument calibration using traditional or permanent calibration instruments ensuring result accuracy and reproducibility.Quality Assurance:

Guidelines for verifying colorimetric instrument performance and ensuring limits of detection (LOD) and quantification (LOQ) meet standard requirements form an integral part of the test method to assure consistent and valid test outcomes.

Applications

Electrotechnical Industry Compliance:

Manufacturers and testing laboratories utilize IEC 62321-7-1 to assess corrosion-protection coatings on metal parts within electrical and electronic equipment, ensuring products meet global environmental regulations that restrict hazardous substances like hexavalent chromium.Environmental Safety:

The standard aids in identifying hazardous chromium compounds in coatings, promoting safer disposal and recycling practices for electrotechnical product wastes in compliance with regional legislations.Quality Control in Production:

Production facilities can apply this testing method for routine monitoring of coating processes to minimize or eliminate the use of Cr(VI), preventing contamination and ensuring product safety.Regulatory Testing:

IEC 62321-7-1 serves as a harmonized global reference method for laboratories carrying out conformance testing under environmental directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals).

Related Standards

IEC 62321 Series:

This standard is part of the broader IEC 62321 framework which addresses the determination of various hazardous substances (including lead, cadmium, mercury, and certain flame retardants) in electrotechnical products. It complements other parts focusing on different chemicals and testing methods for comprehensive compliance.IEC Guide 108:

IEC 62321-7-1 holds the status of a horizontal standard aligned with IEC Guide 108, indicating its cross-sector applicability within the electrotechnical industry.International and Regional Environmental Regulations:

Test methods in this standard support compliance with environmental safety laws and directives worldwide concerning hazardous substances in electrical and electronic equipment.

Keywords: IEC 62321-7-1, hexavalent chromium detection, Cr(VI) colorimetric method, corrosion-protected coatings, electrotechnical products testing, hazardous substances, environmental compliance, boiling water extraction, limit of quantification, IEC standards for electronics.

Buy Documents

IEC 62321-7-1:2015 - Determination of certain substances in electrotechnical products - Part 7-1: Hexavalent chromium - Presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protected coatings on metals by the colorimetric method

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Sponsored listings

Frequently Asked Questions

IEC 62321-7-1:2015 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Determination of certain substances in electrotechnical products - Part 7-1: Hexavalent chromium - Presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protected coatings on metals by the colorimetric method". This standard covers: IEC 62321-7-1:2015 describes a boiling water extraction procedure intended to provide a qualitative determination of the presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protection coatings on metallic samples. In this procedure, when Cr(VI) in a sample is detected below the 0,10 g;cm2 LOQ (limit of quantification), the sample is considered to be negative for Cr(VI). Since Cr(VI) may not be uniformly distributed in the coating even within the same sample batch, a ;grey zone; between 0,10 g;cm2 and 0,13 g;cm2 has been established as ;inconclusive; to reduce inconsistent results due to unavoidable coating variations. In this case, additional testing may be necessary to confirm the presence of Cr(VI). When Cr(VI) is detected above 0,13 g;cm2, the sample is considered to be positive for the presence of Cr(VI) in the coating layer. It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-7-1:2015 describes a boiling water extraction procedure intended to provide a qualitative determination of the presence of hexavalent chromium (Cr(VI)) in colourless and coloured corrosion-protection coatings on metallic samples. In this procedure, when Cr(VI) in a sample is detected below the 0,10 g;cm2 LOQ (limit of quantification), the sample is considered to be negative for Cr(VI). Since Cr(VI) may not be uniformly distributed in the coating even within the same sample batch, a ;grey zone; between 0,10 g;cm2 and 0,13 g;cm2 has been established as ;inconclusive; to reduce inconsistent results due to unavoidable coating variations. In this case, additional testing may be necessary to confirm the presence of Cr(VI). When Cr(VI) is detected above 0,13 g;cm2, the sample is considered to be positive for the presence of Cr(VI) in the coating layer. It has the status of a horizontal standard in accordance with IEC Guide 108.

IEC 62321-7-1:2015 is classified under the following ICS (International Classification for Standards) categories: 13.020.01 - Environment and environmental protection in general; 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62321-7-1:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62321-7-1 ®

Edition 1.0 2015-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 7-1: Hexavalent chromium – Presence of hexavalent chromium (Cr(VI)) in

colourless and coloured corrosion-protected coatings on metals by the

colorimetric method

Détermination de certaines substances dans les produits électrotechniques –

Partie 7-1: Chrome hexavalent – Présence de chrome hexavalent (Cr(VI)) dans

les revêtements incolores et colorés de protection anticorrosion appliqués sur

les métaux à l'aide de la méthode colorimétrique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 15

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 60 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

15 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

La recherche avancée permet de trouver des publications IEC Plus de 60 000 entrées terminologiques électrotechniques, en

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62321-7-1 ®

Edition 1.0 2015-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

HORIZONTAL STANDARD

NORME HORIZONTALE

Determination of certain substances in electrotechnical products –

Part 7-1: Hexavalent chromium – Presence of hexavalent chromium (Cr(VI)) in

colourless and coloured corrosion-protected coatings on metals by the

colorimetric method

Détermination de certaines substances dans les produits électrotechniques –

Partie 7-1: Chrome hexavalent – Présence de chrome hexavalent (Cr(VI)) dans

les revêtements incolores et colorés de protection anticorrosion appliqués sur

les métaux à l'aide de la méthode colorimétrique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 13.020; 43.040.10 ISBN 978-2-8322-2895-1

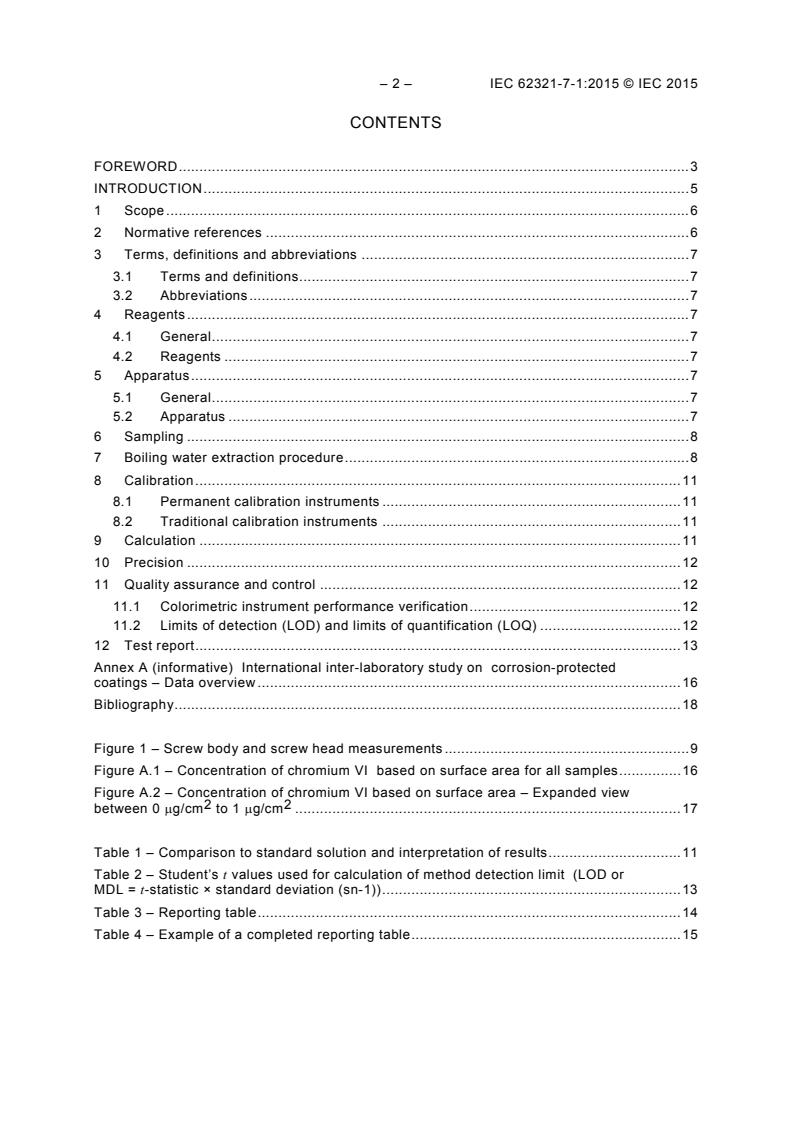

– 2 – IEC 62321-7-1:2015 © IEC 2015

CONTENTS

FOREWORD . 3

INTRODUCTION . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviations . 7

3.1 Terms and definitions . 7

3.2 Abbreviations . 7

4 Reagents . 7

4.1 General . 7

4.2 Reagents . 7

5 Apparatus . 7

5.1 General . 7

5.2 Apparatus . 7

6 Sampling . 8

7 Boiling water extraction procedure . 8

8 Calibration . 11

8.1 Permanent calibration instruments . 11

8.2 Traditional calibration instruments . 11

9 Calculation . 11

10 Precision . 12

11 Quality assurance and control . 12

11.1 Colorimetric instrument performance verification . 12

11.2 Limits of detection (LOD) and limits of quantification (LOQ) . 12

12 Test report . 13

Annex A (informative) International inter-laboratory study on corrosion-protected

coatings – Data overview . 16

Bibliography . 18

Figure 1 – Screw body and screw head measurements . 9

Figure A.1 – Concentration of chromium VI based on surface area for all samples . 16

Figure A.2 – Concentration of chromium VI based on surface area – Expanded view

2 2

between 0 µg/cm to 1 µg/cm . 17

Table 1 – Comparison to standard solution and interpretation of results . 11

Table 2 – Student’s t values used for calculation of method detection limit (LOD or

MDL = t-statistic × standard deviation (sn-1)) . 13

Table 3 – Reporting table . 14

Table 4 – Example of a completed reporting table . 15

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 7-1: Hexavalent chromium – Presence of hexavalent chromium (Cr(VI))

in colourless and coloured corrosion-protected coatings

on metals by the colorimetric method

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62321-7-1 has been prepared by IEC technical committee 111:

Environmental standardization for electrical and electronic products and systems.

It has the status of a horizontal standard in accordance with IEC Guide 108.

The first edition of IEC 62321:2008 was a 'stand-alone' standard that included an introduction,

an overview of test methods, a mechanical sample preparation as well as various test method

clauses.

This first edition of IEC 62321-7-1 is a partial replacement of IEC 62321:2008, forming a

structural revision and generally replacing informative Annex B.

Future parts in the IEC 62321 series will gradually replace the corresponding clauses in

IEC 62321:2008. Until such time as all parts are published, however, IEC 62321:2008 remains

valid for those clauses not yet re-published as a separate part.

– 4 – IEC 62321-7-1:2015 © IEC 2015

The text of this standard is based on the following documents:

FDIS Report on voting

111/380/FDIS 111/393/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62321 series can be found on the IEC website under the general

title: Determination of certain substances in electrotechnical products.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC website under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

The widespread use of electrotechnical products has drawn increased attention to their impact

on the environment. In many countries this has resulted in the adaptation of regulations

affecting wastes, substances and energy use of electrotechnical products.

The use of certain substances (e.g. lead (Pb), cadmium (Cd) and polybrominated

diphenylethers (PBDE’s)) in electrotechnical products is a source of concern in current and

proposed regional legislation.

The purpose of the IEC 62321 series is therefore to provide test methods that will allow the

electrotechnical industry to determine the levels of certain substances of concern in

electrotechnical products on a consistent global basis.

WARNING – Persons using this International Standard should be familiar with normal

laboratory practice. This standard does not purport to address all of the safety

problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national

regulatory conditions.

– 6 – IEC 62321-7-1:2015 © IEC 2015

DETERMINATION OF CERTAIN SUBSTANCES

IN ELECTROTECHNICAL PRODUCTS –

Part 7-1: Hexavalent chromium – Presence of hexavalent chromium (Cr(VI))

in colourless and coloured corrosion-protected coatings

on metals by the colorimetric method

1 Scope

This part of IEC 62321 describes a boiling water extraction procedure intended to provide a

qualitative determination of the presence of hexavalent chromium (Cr(VI)) in colourless and

coloured corrosion-protection coatings on metallic samples.

Due to its highly reactive nature, the concentration of Cr(VI) in a corrosion-protection coating

can change drastically with time and storage conditions. Since storage conditions prior to

sample submission are not often known or provided with the samples, this procedure

determines the presence of Cr(VI) based on the levels detected in the coatings at the time of

testing. For testing of freshly coated samples, a minimum waiting period of 5 days (after the

coating process) is necessary to ensure the coatings have stabilized. This waiting period

allows potential post-process oxidation of Cr(III) to Cr(VI) to occur prior to testing.

The presence of Cr(VI) is determined by the mass of Cr(VI) per surface area of the coating,

in µg/cm . This approach is preferred since corrosion-protection coating weights are often

difficult to measure accurately after production. From a coating technology perspective, the

industry as a whole has transitioned to either using the non-Cr(VI) based chemistries – where

little to no Cr(VI) should be present – or using the traditional Cr(VI) based chemistries –

where significant levels of Cr(VI) are present and can be detected reliably. Given this industry

shift, the presence or absence of Cr(VI) is often sufficient for compliance testing purposes.

In this procedure, when Cr(VI) in a sample is detected below the 0,10 µg/cm LOQ (limit of

quantification), the sample is considered to be negative for Cr(VI). Since Cr(VI) may not be

uniformly distributed in the coating even within the same sample batch, a “grey zone” between

2 2

0,10 µg/cm and 0,13 µg/cm has been established as “inconclusive” to reduce inconsistent

results due to unavoidable coating variations. In this case, additional testing may be

necessary to confirm the presence of Cr(VI). When Cr(VI) is detected above 0,13 µg/cm , the

sample is considered to be positive for the presence of Cr(VI) in the coating layer.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 62321-1, Determination of certain substances in electrotechnical products – Part 1:

Introduction and overview

IEC 62321-2, Determination of certain substances in electrotechnical products – Part 2:

Disassembly, disjointment and mechanical sample preparation

ISO 78-2, Chemistry – Layouts for standards – Part 2: Methods of chemical analysis

ISO 3696, Water for analytical laboratory use – Specification and test methods

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 62321-1 apply.

3.2 Abbreviations

For the purposes of this document, the abbreviations given in IEC 62321-1 apply.

4 Reagents

4.1 General

Use only reagents of recognized analytical grade, unless otherwise specified.

4.2 Reagents

The following reagents shall be used:

a) 1,5-diphenylcarbazide, analytical reagent grade.

b) Potassium dichromate (K Cr O ) stock solution: in a glass container, weigh (5.2 a)) and

2 2 7

dissolve 0,113 g of K Cr O (analytical reagent grade, dried at 100 °C for 1 h before use)

2 2 7

in water (4.2 f)) and dilute with water (4.2 f)) to the mark of a 1,000 ml volumetric flask

(5.2 e)). Cap or stopper the container tightly. The shelf life of this solution is one year.

Cr O ) equivalent comparison standard solutions, 0,10 µg/cm

c) Potassium dichromate (K

2 2 7

and 0,13 µg/cm : in this method, the 0,10 µg/ml and 0,13 µg/ml standards are equivalent

2 2 2

to 0,10 µg/cm and 0,13 µg/cm , respectively. Prepare the 0,10 µg/cm equivalent

comparison standard by pipetting (5.2 f)) 2,5 ml of the K Cr O stock solution (4.2 b)) into

2 2 7

a 1,000 ml volumetric flask and dilute to mark. Prepare the 0,13 µg/cm comparison

standard by pipetting (5.2 f)) 3,3 ml of the K Cr O stock solution (4.2 b)) into a 1,000 ml

2 2 7

volumetric flask (5.2 e)) and dilute to mark.

d) Acetone, analytical reagent grade.

e) Orthophosphoric acid (H PO ) solution (mass fraction of 75 %), analytical reagent grade.

3 4

f) Water: Grade 1 specified in ISO 3696, which shall be free of interferences.

5 Apparatus

5.1 General

All re-usable labware (glass, quartz, polyethylene, polytetrafluoroethylene (PTFE), etc.)

including the sample containers shall be soaked overnight in laboratory-grade detergent and

water, rinsed with water, and soaked for 4 h or more in HNO (volume fraction of 20%) or in a

mixture of dilute acids (HNO :HCl:H O = 1:2:9 by volume) followed by rinsing with water (4.2

3 2

f)). Alternative cleaning procedures are permitted, provided adequate cleanliness can be

demonstrated through the analysis of method blanks.

5.2 Apparatus

The following items shall be used for the analysis:

a) Analytical balance with an accuracy of 0,10 mg.

b) Thermometer or other temperature measurement device capable of measuring up to

100 °C.

– 8 – IEC 62321-7-1:2015 © IEC 2015

c) Colorimetric instrument: either a spectrophotometer for use at 540 nm providing a light

path of 1 cm or longer; or a filter photometer providing a light path of 1 cm or longer and

equipped with a greenish-yellow filter having maximum transmittance near 540 nm.

d) Boiling chips.

e) Volumetric glassware: Class A or equivalent of acceptable precision and accuracy.

Alternative volumetric equipment (e.g. automatic dilutors) with equivalent precision and

accuracy can be used.

f) Assorted calibrated pipettes: Class A glassware or other with equivalent precision and

accuracy.

g) Borosilicate glass or quartz beaker with a volume graduation of 250 ml, or equivalent.

h) Heating device: capable of maintaining boiling of the extraction solution.

i) Filter membranes (0,45 µm), cellulose-based or polycarbonate types preferred.

j) Silicon carbide (SiC) grinding paper with 800 grit size, or equivalent.

k) Watch glass.

6 Sampling

Samples shall not be stored in environments where oxidation of Cr(III) to Cr(VI) can occur.

Samples shall be stored at ambient conditions upon arrival until the start of testing. Ambient

conditions are defined as 45 % RH to 75 % RH (relative humidity) and temperature between

15 °C and 35 °C.

In some cases, disassembly or mechanical disjointment may be necessary to obtain samples

for testing; refer to IEC 62321-2 for sample preparation.

Prior to the test, the sample surface shall be free of all contaminants, fingerprints and stains.

If the surface is coated with thin oil, the oil shall be removed prior to the test by using a clean,

soft laboratory wipe wetted with a suitable solvent, or by rinsing the surface with a suitable

solvent at ambient temperature. The samples shall not be subject to forced drying at

temperature in excess of 35 °C. Treatment in alkaline solutions shall not be performed as

corrosion-protection coatings are broken down by alkalis.

If there is a polymer coating on a sample surface, gentle abrasion with a fine grinding paper

(5.2 j)) may be performed to expose the corrosion protection layer for extraction; however,

care shall be taken not to remove the entire corrosion protection coating beneath the polymer

coating. Other top coat removal methods may be applied if they are shown to be of equal or

greater effectiveness.

Since Cr(VI) is toxic to human beings, all potential Cr(VI)-containing samples and reagents

used in the method shall be handled with appropriate precautions. Solutions or waste material

containing Cr(VI) shall be disposed of properly. For example, ascorbic acid or other reducing

agents can be used to reduce Cr(VI) to Cr(III) prior to disposal.

7 Boiling water extraction procedure

The boiling water extraction procedure is as follows:

a) Prepare the test solution as follows: dissolve 0,5 g of diphenylcarbazide (4.2 a)) in 50 ml

of acetone (4.2 d)). Dilute slowly, while stirring, with 50 ml of water (4.2 f)) (rapid mixing

may result in precipitation of diphenylcarbazide). For maximum stability, store this test

solution under refrigeration at 7 °C ± 2 °C in an amber glass bottle. Discard when the

solution becomes discoloured.

2 2

b) The sample to be tested should have a surface area of 50 cm ± 5 cm . For fasteners or

samples with smaller surface area, use a suitable number of samples to obtain the total

2 2

required surface area. In cases where obtaining a total surface area of 50 cm ± 5 cm is

not possible, a reduced total sample surface area may be used by reducing the water

extraction volume, while maintaining the same surface area to extraction volume ratio

2 2

(1 cm :1 ml). A minimum surface area of 25 cm is recommended. Similarly, a higher

sample surface area can be used by keeping the same ratio. The type of adjustment shall

be recorded in the final report.

The surface area of complex geometry samples can be estimated according to its

manufacturing specifications (e.g. mechanical drawings) if available, or by using its

dimensions and shape. For example: a flat-headed countersunk screw may be considered

as one metal cylinder (the screw body) adjacent to one metal cone (the screw head), as

shown in Figure 1.

H H

h b

IEC

Figure 1 – Screw body and screw head measurements

Estimated surface area of the screw body:

S = 2π R H + π(R ) (1)

b b b b

where

S is the estimated surface area of the screw body;

b

R is the radius of the screw body;

b

H is the height of the screw body.

b

Estimated surface area of the screw head:

2 2 2

S =πR (H +R ) +πR (2)

h h h h h

where

S is the estimated surface area of the screw head;

h

R is the top radius of the screw head;

h

H is the height of the screw head.

h

Total estimated surface area of the screw:

S = S + S (3)

t h b

where

S is the total estimated surface area of the screw.

t

NOTE The German Fastener Association, Deutscher Schraubenverband E.V. (DSV), offers a surface area

program for fastener surface area calculation via the International Material Data System (IMDS). Limitations of

this tool are documented within the program and users shall ensure this tool is applicable to the sample of

interest.

c) Add boiling chips (5.2 d)) and 50 ml of water (4.2 f)) to a beaker with volume graduation

(5.2 g)). Bring the water (4.2 f)) to boiling temperature (5.2 b) and 5.2 h)) for at least 10

min to deoxygenate the water; maintain the water volume by covering the beaker (5.2 g))

with a watch glass (5.2 k)). After boiling for at least 10 min, totally immerse the sample

into the boiling water. Cover the beaker (5.2 g)) with a watch glass (5.2 k)). Extract the

sample for 10 min ± 0,5 min once boiling is resumed. If necessary, add water (4.2 f)) to

ensure sample is totally submerged during the extraction. Remove the sample and allow

the resulting solution to cool to ambient temperature. The solution should be colourless

R

h

R

b

– 10 – IEC 62321-7-1:2015 © IEC 2015

and free of precipitate. Adjust the volume to 50 ml. If the solution is milky or has a

precipitate, filter the solution through a membrane filter (5.2 i)) into a dry beaker (5.2 g))

and adjust the volume back to 50 ml.

d) Add 1 ml of orthophosphoric acid solution (4.2 e)) and mix well. Pour 25 ml of the solution

using a graduated cylinder (5.2 e)) into another dry beaker (5.2 g)). Add 1 ml test solution

(7 a)), mix, and observe the colour. After a 10 min reaction time, a red to violet colour

indicates the presence of Cr(VI). The remaining portion of the extract will serve as the

blank.

e) If there is a colour interference (e.g. from a coating dye), a correction against the blank

shall be performed. Transfer a portion of the sample solution to an absorption cell (5.2 c)).

Measure the absorbance at 540 nm against the blank (7 d)) with the colorimetric

instrument (5.2 c)). Make three measurements and take the average as the final

absorbance of the sample. In some cases, depending on the type of spectrometer used,

the correction for the blank may have to be made manually in the collected data.

f) Place 50 ml of the 0,10 µg/cm equivalent comparison standard solution (4.2 c)) in a

beaker (5.2 g)). Add 1 ml of orthophosphoric acid solution (4.2 e)) and mix well. Add 2 ml

test solution (7 a)), mix, and wait 10 min for colour development. Measure the absorbance

three times as above. Take the average of three measurements as the final absorbance of

the standard solution.

g) Place 50 ml of the 0,13 µg/cm equivalent comparison standard solution (4.2 c)) in a

suitable beaker (5.2 g)). Add 1 ml of orthophosphoric acid solution (4.2 e)) and mix well.

Add 2 ml test solution (7 a)), mix, and wait 10 min for colour development. Measure the

absorbance three times as above. Take the average of three measurements as the final

absorbance of the standard solution.

h) If the absorbance value obtained in 7 d) or 7 e) is less than absorbance of the

0,10 µg/cm equivalent comparison standard solution (4.2 c)) obtained in 7 f), the sample

is considered to be negative for Cr(VI) (see Table 1).

i) If the absorbance value obtained in 7 d) or 7 e) is in between the values of the

2 2

0,10 µg/cm and 0,13 µg/cm equivalent comparison standard solutions (4.2 c)) obtained

in 7 f) and 7 g), the sample is in the “grey zone” where the presence or absence of Cr(VI)

in the sample is inconclusive (see Table 1).

j) If the absorbance value obtained in 7 d) or 7 e) is greater than the absorbance value of

the 0,13 µg/cm equivalent comparison standard solution (4.2 c)) obtained in 7 g), the

sample is considered to be positive for Cr(VI) (see Table 1).

In the case where the sample colour after the colorimetric reaction is significantly more

intense than the 0,13 µg/cm equivalent comparison standard such that the result can clearly

be determined as positive for Cr(VI), measurement via a colorimetric instrument is not

necessary. However, the report shall clearly state that the result is significantly above

0,13 µg/cm based on visual observation and no colorimetric measurement was performed.

Colorimetric measurement shall be performed if the Cr(VI) is not clearly above 0,13 µg/cm .

Table 1 – Comparison to standard solution and interpretation of results

Colorimetric result Qualitative result

(Cr(VI) concentration)

The sample solution is ˂ the 0,10 µg/cm equivalent The sample is negative for Cr(VI) − The Cr(VI)

comparison standard solution concentration is below the limit of quantification. The

coating is considered a non-Cr(VI) based coating

The sample solution is ≥ the 0,10 µg/cm and ≤ the The result is considered to be inconclusive –

Unavoidable coating variations may influence the

0,13 µg/cm equivalent comparison standard solutions

determination.

Recommendation: if addition samples are available,

perform a total of 3 trials to increase sampling surface

area. Use the averaged result of the 3 trials for the

final determination.

The sample solution is ˃ the 0,13 µg/cm equivalent The sample is positive for Cr(VI) − The Cr(VI)

comparison standard solution concentration is above the limit of quantification and

the statistical margin of error. The sample coating is

considered to contain Cr(VI)

8 Calibration

8.1 Permanent calibration instruments

Colorimetric instruments designed specifically for hexavalent chromium detection at 540 nm

may have a permanent calibration provided by the manufacture and no further calibration is

needed. Refer to the manufacturer’s instructions to ensure that the instrument is functioning

properly and its working range is appropriate for this analysis.

8.2 Traditional calibration instruments

8.2.1 Traditional colorimetric instrument calibration shall be conducted using a blank and

three standard solutions at a minimum. The standard solution concentrations shall bracket the

two equivalent comparison standard solution concentrations (0,10 µg/ml and 0,13 µg/ml).

8.2.2 Zero the colorimetric instrument with the 0,0 µg/ml blank standard and save this

solution to re-zero the instrument before reading samples and standards.

8.2.3 Read the standard solutions. Construct a calibration curve and determine a line

equation by plotting absorbance values (ordinate or y-axis) against µg/ml of Cr(VI) (abscissa

or x-axis) for each standard including the 0,0 µg/ml standard.

8.2.4 The calibration curve (linear fit with zero intercept) shall have a correlation coefficient

≥ 0,995 or a new curve shall be built.

8.2.5 Calibration curves can be used for up to one month from initial generation.

9 Calculation

The concentration of Cr(VI) shall be calculated according to Equation (4):

(C −B)×V

C(VI) = ×DF (4)

A

where

C(VI) is the sample coating concentration of chromium (VI) (µg/cm );

– 12 – IEC 62321-7-1:2015 © IEC 2015

C is the sample solution concentration of chromium (VI) reading (µg/ml);

B is the concentration of reagent blank for sample preparation (µg/ml);

V is the volume of extract (ml);

A is the sample surface area (cm );

DF is the dilution factor (if no dilution is made, DF = 1).

10 Precision

Since the qualitative nature of this method does not lend itself to quantitative repeatability and

reproducibility statements (see ISO 78-2:1999, Annex B), the precision statements below

have been gleaned from 111/320/INF [1] .

• Seven laboratories submitted triplicate results and one laboratory submitted duplicate

results collected from a metal plate coated with hexavalent chromium (IIS4B-A1). All 23

results were positive for the presence of hexavalent chromium (˃ 0,13 µg/cm ).

• Eight laboratories submitted triplicate results collected from a metal screw coated with

hexavalent chromium (IIS4B-D4). All 24 results were positive for the presence of

hexavalent chromium (˃ 0,13 µg/cm ).

• Eight laboratories submitted triplicate results collected from a metal plate coated with

trivalent chromium (IIS4B-B2). Twenty (20) results were negative for the presence of

hexavalent chromium (< 0,10 µg/cm ), 3 results were inconclusive for the presence of

2 2

hexavalent chromium (≥ 0,10 µg/ cm and ≤ 0,13 µg/cm ) and one result was positive for

the presence of hexavalent chromium (˃ 0,13 µg/cm ).

• Eight laboratories submitted triplicate results collected from a metal screw coated with

trivalent chromium (IIS4B-E5). All 24 results were negative for the presence of hexavalent

chromium (< 0,10 µg/cm ).

• Eight laboratories submitted triplicate results collected from a metal plate coated without

any chromium (IIS4B-C3). All 24 results were negative for the presence of hexavalent

chromium (< 0,10 µg/cm ). See Annex A for supporting data.

11 Quality assurance and control

11.1 Colorimetric instrument performance verification

11.1.1 Regardless of the instrument type, a performance verification using the two

equivalent comparison standard solutions shall be carried out prior to sample measurements

and at the end of each sample sequence to ensure the instrument is functioning properly.

11.1.2 In the event that either of the equivalent comparison standard solutions measured

prior to sample measurements result in concentrations that differ from the expected values

(0,10 µg/ml and 0,13 µg/ml) by more than 15 %, the calibration shall be re-measured.

11.1.3 In the event that either of the equivalent comparison standard solutions measured at

the end of instrumental sequence result in concentrations that differ from the expected values

by more than 15 %, the calibration and all of the samples in the sequence shall be re-

measured.

11.2 Limits of detection (LOD) and limits of quantification (LOQ)

In its simplest form, a limit of detection (LOD) or method detection limit (MDL) is typically

described as the lowest amount or concentration of analyte in a test sample that can be

reliably differentiated from zero for a given measurement system.

______________

Numbers in square brackets refer to the Bibliography

Instrument detection limits represent an instrument’s ability to differentiate low concentrations

of analytes from “zero” in a blank or standard solution, and are commonly used by

manufacturers to demonstrate the measurement capability of a system (e.g. atomic absorption

spectrometer). While instrument detection limits are useful, they are often considerably lower

than a limit of detection representing a complete analytical method measurement process.

Complete analytical method detection limits are most appropriately determined experimentally

by performing replicate, independent measurements on low-level or fortified sample matrices

carried out through the entire test procedure, including sample digestion or extraction. A

minimum of six replicates and analyte concentrations of 3 to 5 times the estimated method

detection limit have been suggested as suitable for this analysis. The complete method

detection limit for an entire test procedure is determined by multiplying the standard deviation

of the replicates by an appropriate factor. The International Union of Pure and Applied

Chemistry (IUPAC) recommends a factor of 3 for a minimum of six replicates, while the United

States Environmental Protection Agency (US EPA) utilizes a one-sided confidence interval

with the multiplier equal to Student’s t value chosen for the number of replicates and the level

of confidence (e.g. t = 3,36 for six replicates for 99 % confidence).

All analyses used to calculate an MDL should be consecutive. The LOD or MDL was

determined using the appropriate Student’s t values and t-statistic shown in Table 2.

Table 2 – Student’s t values used for calculation of method detection limit

(LOD or MDL = t-statistic × standard deviation (sn-1))

Student’s t-statistic

Number of samples

(99 % confidence)

6 3,36

7 3,14

8 3,00

9 2,90

10 2,82

The limit of quantification (LOQ) or estimated quantification limit for a given measurement

system is typically described as the lowest concentration that can be reliably determined

within specified or acceptable limits of precision during routine laboratory operating conditions.

The acceptable precision limit is often defined as 10 % relative standard deviation or simply

expressed as a fixed multiple (2 to 10) of the method detection limit.

12 Test report

Clause 12 specifies which information is to be included in the test report and shall require

information on at least the following aspects of the test:

a) the sample;

b) the International Standard used (including its year of publication);

c) the method used (if the standard includes several);

d) the limit of detection (LOD) or limit of quantification (LOQ);

e) any deviations from the procedure (e.g. surface area, extract volume, etc.);

f) any unusual features observed;

g) the date of the test;

h) the numeric result(s) in 2 significant figures, following the format laid out in Table 3 and

the text within Table 3 that correspond to the numeric result(s).

– 14 – IEC 62321-7-1:2015 © IEC 2015

Visual comparison is only allowed in the case of a positive Cr(VI) determination. Otherwise,

the numeric result (in µg/cm ) shall be stated in the report.

Table 3 – Reporting table

Colorimetric results

Sample Cr(VI)

Sample identification (in mass per surface Results

concentration is:

area, µg/cm )

Sample name Numeric result obtained The sample is negative for

˂ 0,10 µg/cm

from colorimetric Cr(VI) − The Cr(VI)

measurement and concentration is below the

Equation (4)

limit of quantification. The

coating is considered a

non-Cr(VI) based coating.

Or

The result is considered to

≥ 0,10 µg/cm and

be inconclusive –

≤ 0,13 µg/cm

unavoidable coating

variations may influence

the determination.

Recommendation: if

addition samples are

available, perform a total

of 3 trials to increase

sampling surface area, use

the averaged result of the

3 trials for the final

determination.

Or

The sample is positive for

˃ 0,13 µg/cm

Cr(VI) − The Cr(VI)

concentration is above the

limit of quantification and

the statistical margin of

error. The sample coating

is considered to contain

Cr(VI).

Or

Sample name Sample solution is ˃ 0,13 µg/cm The sample is positive for

significantly more intense Cr(VI) based on visual

comparison only. No

than the 0,13 µg/cm

colorimetric measurement

equivalent comparison

was performed. (Visual

standard

comparison is allowed only

in the case of a positive

Cr(VI) determination, and

the actual value in µg/cm

is not required).

Table 4 shows examples of reporting with test results:

Sample N° 1: 0,060 µg/cm

Sample N° 2: 0,19 µg/cm

Sample N° 3: 0,11 µg/cm

Sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...