IEC 62067:2001

(Main)Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements

Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements

Specifies test methods and requirements for power cable systems, cables with extruded insulation and their accessories for fixed installations, for rated voltages above 150 kV (Um = 170 kV) up to and including 500 kV (Um = 550 kV). The requirements apply to single-core cables and to their accessories for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

Câbles d'énergie à isolation extrudée et leurs accessoires pour des tensions assignées supérieures à 150 kV (Um = 170 kV) et jusqu'à 500 kV (Um = 550 kV) - Méthodes et prescriptions d'essai

Spécifie les méthodes et les prescriptions d'essai applicables aux systèmes de câbles d'énergie, comprenant les câbles à isolation extrudée et leurs accessoires pour installations fixes, pour des tensions assignées supérieures à 150 kV (Um = 170 kV) et jusqu'à 500 kV compris (Um = 550 kV). Les prescriptions sont applicables aux câbles unipolaires et à leurs accessoires, pour des conditions habituelles d'installation et de fonctionnement, mais ne le sont pas à des câbles spéciaux et à leurs accessoires comme les câbles sous-marins, pour lesquels il peut être nécessaire d'apporter des modifications aux essais normaux ou d'élaborer des conditions d'essai particulières.

General Information

- Status

- Published

- Publication Date

- 23-Oct-2001

- Technical Committee

- TC 20 - Electric cables

- Drafting Committee

- WG 16 - TC 20/WG 16

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 24-Nov-2011

- Completion Date

- 13-Feb-2026

Relations

- Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Overview

IEC 62067:2001 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies test methods and requirements for power cables with extruded insulation and their accessories. It targets fixed installations of single-core cables with rated voltages from above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV). The standard defines comprehensive guidance on electrical and mechanical testing protocols to ensure cable system reliability and performance under typical installation and operational conditions.

This standard does not cover special cable types like submarine cables, which may require modified or additional testing procedures. IEC 62067 serves as a vital reference for manufacturers, testing laboratories, utilities, and engineers involved in high-voltage power cable design, testing, installation, and maintenance. The document represents extended requirements based on prior standards such as IEC 60840, advancing the specifications for high-voltage cable systems.

Key Topics

Scope and Application

Focused on extruded insulation cables and accessories for rated voltages between 150 kV and 500 kV, ensuring suitability for fixed, typical installation environments.Test Methods

- Routine tests: Partial discharge, voltage withstand, electrical tests on cable oversheaths

- Sample tests: Conductor examination, insulation thickness measurement, capacitance and density tests, hot set tests for insulation materials

- Type tests: Electrical and non-electrical tests on complete cable systems and components to confirm design compliance

- Prequalification tests: For new cable designs or system combinations to validate performance before widespread deployment

- Post-installation tests: DC and AC voltage tests on oversheath and insulation to confirm integrity after installation

Material Requirements

Defined properties and test requirements for insulating materials such as XLPE (cross-linked polyethylene), EPR (ethylene propylene rubber), and oversheathing compounds to guarantee mechanical, electrical, and environmental durability.Voltage Designations and Test Voltages

Clear definitions of rated voltages and corresponding power, switching, and lightning impulse test levels for verifying insulation withstand capabilities.Precautions Against Water Penetration

Test procedures and design considerations aimed at preventing moisture ingress to maintain cable longevity and performance.Mechanical and Electrical Characteristics

Parameters governing cable dimension tolerances, conductor resistance, insulation thickness, and overall cable construction verified through standardized tests.

Practical Applications

IEC 62067:2001 is essential for stakeholders involved in the lifecycle of high-voltage extruded insulated power cables including:

Power Utilities

Assisting in procurement and acceptance criteria for high-voltage cable systems ensuring safe and reliable grid infrastructure.Cable Manufacturers

Guiding the design, production, and quality control procedures for extruded insulation cables and accessories to meet international standards.Testing Laboratories

Providing standardized test methods for routine, sample, type, and post-installation verification of cable system electrical and mechanical properties.Engineering Consultants and Contractors

Specifying cable system requirements, verifying adherence to test criteria, and implementing best practices for installation based on approved standards.Research and Development

Applying the standard’s test methods for new materials and system configurations to achieve compliance and innovation in high-voltage cable technology.

Related Standards

IEC 60840 – Power cables with extruded insulation and their accessories for rated voltages above 30 kV up to 150 kV: Test methods and requirements. IEC 62067 extends similar principles to higher voltage levels.

IEC 62067 Amendment 1 (2006) – Provides technical updates and clarifications enhancing test accuracy and applicability.

IEC 60287 – Electric cables - Calculation of the current rating, relevant for thermal and electrical performance validation complementing mechanical and electrical tests outlined in IEC 62067.

IEC 60332 – Tests on electric cables under fire conditions, providing complementary safety requirements.

CIGRE Technical Brochures – Offer guidance and application insights for extruded insulation cables at ultra-high voltages, supporting practical implementation of IEC 62067.

Keywords: IEC 62067, power cables, extruded insulation, high voltage cables, rated voltages above 150 kV, cable accessories, test methods, cable system requirements, electrical testing, mechanical testing, cable installation standards, high-voltage cable standards, IEC standards, power cable testing.

IEC 62067:2001 - Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements Released:10/24/2001 Isbn:2831860571

IEC 62067:2001+AMD1:2006 CSV - Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements Released:3/14/2006 Isbn:2831885396

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

IEC 62067:2001 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Power cables with extruded insulation and their accessories for rated voltages above 150 kV (Um = 170 kV) up to 500 kV (Um = 550 kV) - Test methods and requirements". This standard covers: Specifies test methods and requirements for power cable systems, cables with extruded insulation and their accessories for fixed installations, for rated voltages above 150 kV (Um = 170 kV) up to and including 500 kV (Um = 550 kV). The requirements apply to single-core cables and to their accessories for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

Specifies test methods and requirements for power cable systems, cables with extruded insulation and their accessories for fixed installations, for rated voltages above 150 kV (Um = 170 kV) up to and including 500 kV (Um = 550 kV). The requirements apply to single-core cables and to their accessories for usual conditions of installation and operation, but not to special cables and their accessories, such as submarine cables, for which modifications to the standard tests may be necessary or special test conditions may need to be devised.

IEC 62067:2001 is classified under the following ICS (International Classification for Standards) categories: 29.060.20 - Cables. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62067:2001 has the following relationships with other standards: It is inter standard links to IEC 62067:2001/AMD1:2006, IEC 62067:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62067:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Première édition

STANDARD

First edition

2001-10

Câbles d'énergie à isolation extrudée

et leurs accessoires pour des tensions

assignées supérieures à 150 kV (U = 170 kV)

m

et jusqu'à 500 kV (U = 550 kV) –

m

Méthodes et prescriptions d'essai

Power cables with extruded insulation

and their accessories for rated voltages above

150 kV (U = 170 kV) up to 500 kV (U = 550 kV) –

m m

Test methods and requirements

Numéro de référence

Reference number

CEI/IEC 62067:2001

Numérotation des publications Publication numbering

Depuis le 1er janvier 1997, les publications de la CEI As from 1 January 1997 all IEC publications are

sont numérotées à partir de 60000. Ainsi, la CEI 34-1 issued with a designation in the 60000 series. For

devient la CEI 60034-1. example, IEC 34-1 is now referred to as IEC 60034-1.

Editions consolidées Consolidated editions

Les versions consolidées de certaines publications de la The IEC is now publishing consolidated versions of its

CEI incorporant les amendements sont disponibles. Par publications. For example, edition numbers 1.0, 1.1

exemple, les numéros d’édition 1.0, 1.1 et 1.2 indiquent and 1.2 refer, respectively, to the base publication,

respectivement la publication de base, la publication de the base publication incorporating amendment 1 and

base incorporant l’amendement 1, et la publication de the base publication incorporating amendments 1

base incorporant les amendements 1 et 2. and 2.

Informations supplémentaires Further information on IEC publications

sur les publications de la CEI

Le contenu technique des publications de la CEI est The technical content of IEC publications is kept

constamment revu par la CEI afin qu'il reflète l'état under constant review by the IEC, thus ensuring that

actuel de la technique. Des renseignements relatifs à the content reflects current technology. Information

cette publication, y compris sa validité, sont dispo- relating to this publication, including its validity, is

nibles dans le Catalogue des publications de la CEI available in the IEC Catalogue of publications

(voir ci-dessous) en plus des nouvelles éditions, (see below) in addition to new editions, amendments

amendements et corrigenda. Des informations sur les and corrigenda. Information on the subjects under

sujets à l’étude et l’avancement des travaux entrepris consideration and work in progress undertaken by the

par le comité d’études qui a élaboré cette publication, technical committee which has prepared this

ainsi que la liste des publications parues, sont publication, as well as the list of publications issued,

également disponibles par l’intermédiaire de: is also available from the following:

• Site web de la CEI (www.iec.ch) • IEC Web Site (www.iec.ch)

• Catalogue des publications de la CEI • Catalogue of IEC publications

Le catalogue en ligne sur le site web de la CEI The on-line catalogue on the IEC web site

(www.iec.ch/catlg-f.htm) vous permet de faire des (www.iec.ch/catlg-e.htm) enables you to search

recherches en utilisant de nombreux critères, by a variety of criteria including text searches,

comprenant des recherches textuelles, par comité technical committees and date of publication. On-

d’études ou date de publication. Des informations line information is also available on recently

en ligne sont également disponibles sur les issued publications, withdrawn and replaced

nouvelles publications, les publications rempla- publications, as well as corrigenda.

cées ou retirées, ainsi que sur les corrigenda.

• IEC Just Published

• IEC Just Published

Ce résumé des dernières publications parues

This summary of recently issued publications

(www.iec.ch/JP.htm) est aussi disponible par

(www.iec.ch/JP.htm) is also available by email.

courrier électronique. Veuillez prendre contact

Please contact the Customer Service Centre (see

avec le Service client (voir ci-dessous) pour plus

below) for further information.

d’informations.

• Service clients

• Customer Service Centre

Si vous avez des questions au sujet de cette

If you have any questions regarding this

publication ou avez besoin de renseignements

publication or need further assistance, please

supplémentaires, prenez contact avec le Service

contact the Customer Service Centre:

clients:

Email: custserv@iec.ch

Email: custserv@iec.ch

Tél: +41 22 919 02 11

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

Fax: +41 22 919 03 00

.

NORME CEI

INTERNATIONALE IEC

INTERNATIONAL

Première édition

STANDARD

First edition

2001-10

Câbles d'énergie à isolation extrudée

et leurs accessoires pour des tensions

assignées supérieures à 150 kV (U = 170 kV)

m

et jusqu'à 500 kV (U = 550 kV) –

m

Méthodes et prescriptions d'essai

Power cables with extruded insulation

and their accessories for rated voltages above

150 kV (U = 170 kV) up to 500 kV (U = 550 kV) –

m m

Test methods and requirements

IEC 2001 Droits de reproduction réservés Copyright - all rights reserved

Aucune partie de cette publication ne peut être reproduite ni No part of this publication may be reproduced or utilized in

utilisée sous quelque forme que ce soit et par aucun procédé, any form or by any means, electronic or mechanical,

électronique ou mécanique, y compris la photocopie et les including photocopying and microfilm, without permission in

microfilms, sans l'accord écrit de l'éditeur. writing from the publisher.

International Electrotechnical Commission 3, rue de Varembé Geneva, Switzerland

Telefax: +41 22 919 0300 e-mail: inmail@iec.ch IEC web site http://www.iec.ch

CODE PRIX

Commission Electrotechnique Internationale

W

PRICE CODE

International Electrotechnical Commission

Pour prix, voir catalogue en vigueur

For price, see current catalogue

– 2 – 62067 © CEI:2001

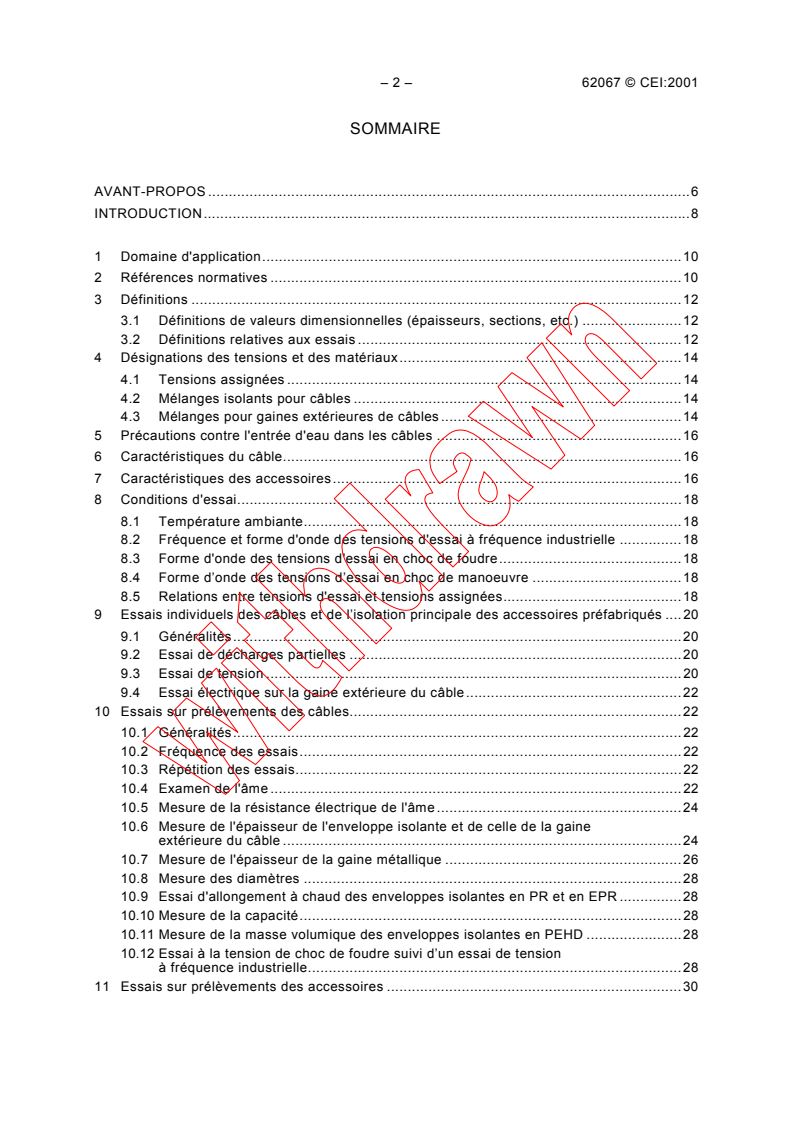

SOMMAIRE

AVANT-PROPOS .6

INTRODUCTION.8

1 Domaine d'application.10

2 Références normatives .10

3 Définitions .12

3.1 Définitions de valeurs dimensionnelles (épaisseurs, sections, etc.) .12

3.2 Définitions relatives aux essais .12

4 Désignations des tensions et des matériaux.14

4.1 Tensions assignées .14

4.2 Mélanges isolants pour câbles .14

4.3 Mélanges pour gaines extérieures de câbles .14

5 Précautions contre l'entrée d'eau dans les câbles .16

6 Caractéristiques du câble.16

7 Caractéristiques des accessoires.16

8 Conditions d'essai.18

8.1 Température ambiante.18

8.2 Fréquence et forme d'onde des tensions d'essai à fréquence industrielle .18

8.3 Forme d'onde des tensions d'essai en choc de foudre.18

8.4 Forme d’onde des tensions d’essai en choc de manoeuvre .18

8.5 Relations entre tensions d'essai et tensions assignées.18

9 Essais individuels des câbles et de l’isolation principale des accessoires préfabriqués .20

9.1 Généralités.20

9.2 Essai de décharges partielles .20

9.3 Essai de tension .20

9.4 Essai électrique sur la gaine extérieure du câble.22

10 Essais sur prélèvements des câbles.22

10.1 Généralités.22

10.2 Fréquence des essais.22

10.3 Répétition des essais.22

10.4 Examen de l'âme .22

10.5 Mesure de la résistance électrique de l'âme.24

10.6 Mesure de l'épaisseur de l'enveloppe isolante et de celle de la gaine

extérieure du câble .24

10.7 Mesure de l'épaisseur de la gaine métallique .26

10.8 Mesure des diamètres .28

10.9 Essai d'allongement à chaud des enveloppes isolantes en PR et en EPR .28

10.10 Mesure de la capacité.28

10.11 Mesure de la masse volumique des enveloppes isolantes en PEHD .28

10.12 Essai à la tension de choc de foudre suivi d’un essai de tension

à fréquence industrielle.28

11 Essais sur prélèvements des accessoires .30

62067 © IEC:2001 – 3 –

CONTENTS

FOREWORD.7

INTRODUCTION.9

1 Scope.11

2 Normative references.11

3 Definitions .13

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.) .13

3.2 Definitions concerning the tests .13

4 Voltage designations and materials .15

4.1 Rated voltages .15

4.2 Cable insulating materials.15

4.3 Cable oversheathing materials .15

5 Precautions against water penetration in cables .17

6 Cable characteristics .17

7 Accessory characteristics.17

8 Test conditions .19

8.1 Ambient temperature .19

8.2 Frequency and waveform of power frequency test voltages .19

8.3 Waveform of lightning impulse test voltage .19

8.4 Waveform of switching impulse test voltage .19

8.5 Relationship of test voltages to rated voltages.19

9 Routine tests on cables and on the main insulation of prefabricated accessories .21

9.1 General .21

9.2 Partial discharge test .21

9.3 Voltage test .21

9.4 Electrical test on oversheath of the cable .23

10 Sample tests on cables.23

10.1 General .23

10.2 Frequency of tests .23

10.3 Repetition of tests.23

10.4 Conductor examination .23

10.5 Measurement of electrical resistance of conductor .25

10.6 Measurement of thickness of insulation and cable oversheath.25

10.7 Measurement of thickness of metallic sheath .27

10.8 Measurement of diameter .29

10.9 Hot set test for XLPE and EPR insulations .29

10.10 Measurement of capacitance .29

10.11 Measurement of density of HDPE insulation .29

10.12 Lightning impulse voltage test followed by a power frequency voltage test .29

11 Sample tests on accessories.31

– 4 – 62067 © CEI:2001

12 Essais de type des systèmes de câbles.30

12.1 Généralités.30

12.2 Etendue de l'acceptation de type.30

12.3 Résumé des essais de type .32

12.4 Essais électriques sur systèmes de câble complet .32

12.5 Essais de type non électriques sur les constituants du câble et sur câble

complet .40

13 Essai de préqualification sur le système de câble.46

13.1 Domaine d’acceptation de l’essai de préqualification .46

13.2 Essai de préqualification sur système de câble complet .48

14 Essais électriques après pose.50

14.1 Essai sous tension continue de la gaine extérieure.50

14.2 Essai sous tension alternative de l’enveloppe isolante.50

Annexe A (normative) Arrondissement des nombres.64

Annexe B (normative) Méthode de mesure de la résistivité des écrans semi-

conducteurs .66

Annexe C (normative) Essai de pénétration d'eau.70

Annexe D (normative) Essais de la protection externe des jonctions enterrées.74

Bibliographie .78

Figure B.1 – Préparation des échantillons pour la mesure de la résistivité des écrans

sur âme et sur enveloppe isolante .68

Figure C.1 – Schéma de principe de l’appareillage pour l’essai de pénétration d’eau.72

Tableau 1 – Mélanges isolants pour câbles .52

Tableau 2 – Prescriptions pour tan δ pour les mélanges isolants pour câbles.52

Tableau 3 – Tensions d’essai .52

Tableau 4 – Essais de type non électriques pour mélanges pour enveloppes isolantes

et pour gaines extérieures de câbles .54

Tableau 5 – Prescriptions d'essai pour les caractéristiques mécaniques des mélanges

pour enveloppes isolantes de câbles (avant et après vieillissement) .56

Tableau 6 – Prescriptions d'essai pour les caractéristiques mécaniques des mélanges

pour gaine extérieure de câbles (avant et après vieillissement).58

Tableau 7 – Prescriptions d'essai pour les caractéristiques particulières des mélanges

pour enveloppes isolantes de câbles .60

Tableau 8 – Taux de noir de carbone des mélanges à base de polyéthylène

thermoplastique pour gaines extérieures de câbles.60

Tableau 9 – Prescriptions d'essai pour les caractéristiques particulières des mélanges

à base de PVC pour gaines extérieures de câbles .62

Tableau 10 – Tensions d’essai alternatives après pose.62

Tableau D.1 – Essais aux ondes de choc .76

62067 © IEC:2001 – 5 –

12 Type tests on cable systems .31

12.1 General .31

12.2 Range of type approval .31

12.3 Summary of type tests .33

12.4 Electrical type tests on complete cable systems .33

12.5 Non-electrical type tests on cable components and on complete cable .41

13 Prequalification test of the cable system.47

13.1 Range of prequalification test approval .47

13.2 Prequalification test on complete cable system .49

14 Electrical tests after installation.51

14.1 DC voltage test of the oversheath .51

14.2 AC voltage test of the insulation.51

Annex A (normative) Rounding of numbers.65

Annex B (normative) Method of measuring resistivity of semi-conducting screens .67

Annex C (normative) Water penetration test .71

Annex D (normative) Tests of outer protection for buried joints .75

Bibliography .79

Figure B.1 – Preparation of samples for measurement of resistivity of conductor and

insulation screens .69

Figure C.1 – Schematic diagram of apparatus for water penetration test .73

Table 1 – Insulating compounds for cables .53

Table 2 – Tan δ requirements for insulating compounds for cables .53

Table 3 – Test voltages .53

Table 4 – Non-electrical type tests for insulating and oversheathing compounds

for cables.55

Table 5 – Test requirements for mechanical characteristics of insulating compounds

for cables (before and after ageing).57

Table 6 – Test requirements for mechanical characteristics of oversheathing

compounds for cables (before and after ageing) .59

Table 7 – Test requirements for particular characteristics of insulating compounds

for cables.61

Table 8 – Carbon black content of thermoplastic polyethylene oversheathing compounds

for cables.61

Table 9 – Test requirements for particular characteristics of PVC oversheathing

compounds for cables .63

Table 10 – AC test voltages after installation .63

Table D.1 – Impulse voltage tests.77

– 6 – 62067 © CEI:2001

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

__________

CÂBLES D'ÉNERGIE À ISOLATION EXTRUDÉE ET LEURS ACCESSOIRES

POUR DES TENSIONS ASSIGNÉES SUPÉRIEURES À 150 kV (U = 170 kV)

m

ET JUSQU'À 500 kV (U = 550 kV) –

m

MÉTHODES ET PRESCRIPTIONS D'ESSAI

AVANT-PROPOS

1) La CEI (Commission Electrotechnique Internationale) est une organisation mondiale de normalisation

composée de l'ensemble des comités électrotechniques nationaux (Comités nationaux de la CEI). La CEI a

pour objet de favoriser la coopération internationale pour toutes les questions de normalisation dans les

domaines de l'électricité et de l'électronique. A cet effet, la CEI, entre autres activités, publie des Normes

internationales. Leur élaboration est confiée à des comités d'études, aux travaux desquels tout Comité national

intéressé par le sujet traité peut participer. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec la CEI, participent également aux travaux. La CEI collabore étroitement

avec l'Organisation Internationale de Normalisation (ISO), selon des conditions fixées par accord entre les deux

organisations.

2) Les décisions ou accords officiels de la CEI concernant les questions techniques représentent, dans la mesure

du possible un accord international sur les sujets étudiés, étant donné que les Comités nationaux intéressés

sont représentés dans chaque comité d’études.

3) Les documents produits se présentent sous la forme de recommandations internationales. Ils sont publiés

comme normes, spécifications techniques, rapports techniques ou guides et agréés comme tels par les

Comités nationaux.

4) Dans le but d'encourager l'unification internationale, les Comités nationaux de la CEI s'engagent à appliquer de

façon transparente, dans toute la mesure possible, les Normes internationales de la CEI dans leurs normes

nationales et régionales. Toute divergence entre la norme de la CEI et la norme nationale ou régionale

correspondante doit être indiquée en termes clairs dans cette dernière.

5) La CEI n’a fixé aucune procédure concernant le marquage comme indication d’approbation et sa responsabilité

n’est pas engagée quand un matériel est déclaré conforme à l’une de ses normes.

6) L’attention est attirée sur le fait que certains des éléments de la présente Norme internationale peuvent faire

l’objet de droits de propriété intellectuelle ou de droits analogues. La CEI ne saurait être tenue pour

responsable de ne pas avoir identifié de tels droits de propriété et de ne pas avoir signalé leur existence.

La Norme internationale CEI 62067 a été établie par le Comité d'études 20 de la CEI: Câbles

électriques.

Le texte de cette norme est issu des documents suivants:

FDIS Rapport de vote

20/482/FDIS 20/489/RVD

Le rapport de vote indiqué dans le tableau ci-dessus donne toute information sur le vote ayant

abouti à l'approbation de cette norme.

Cette publication a été rédigée selon les Directives ISO/CEI, Partie 3.

Les annexes A, B, C et D font partie intégrante de cette norme.

Le comité a décidé que le contenu de cette publication ne sera pas modifié avant 2005. A cette

date, la publication sera

• reconduite;

• supprimée;

• remplacée par une édition révisée, ou

• amendée.

62067 © IEC:2001 – 7 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

___________

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES ABOVE 150 kV (U = 170 kV)

m

UP TO 500 kV (U = 550 kV) –

m

TEST METHODS AND REQUIREMENTS

FOREWORD

1) The IEC (International Electrotechnical Commission) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of the IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, the IEC publishes International Standards. Their preparation is

entrusted to technical committees; any IEC National Committee interested in the subject dealt with may

participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. The IEC collaborates closely with the International Organization

for Standardization (ISO) in accordance with conditions determined by agreement between the two

organizations.

2) The formal decisions or agreements of the IEC on technical matters express, as nearly as possible, an

international consensus of opinion on the relevant subjects since each technical committee has representation

from all interested National Committees.

3) The documents produced have the form of recommendations for international use and are published in the form

of standards, technical specifications, technical reports or guides and they are accepted by the National

Committees in that sense.

4) In order to promote international unification, IEC National Committees undertake to apply IEC International

Standards transparently to the maximum extent possible in their national and regional standards. Any

divergence between the IEC Standard and the corresponding national or regional standard shall be clearly

indicated in the latter.

5) The IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with one of its standards.

6) Attention is drawn to the possibility that some of the elements of this International Standard may be the subject

of patent rights. The IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62067 has been prepared by IEC technical committee 20: Electric

cables.

The text of this standard is based on the following documents:

FDIS Report on voting

20/482/FDIS 20/489/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 3.

Annexes A, B, C and D form an integral part of this standard.

The committee has decided that the contents of this publication will remain unchanged until

2005. At this date, the publication will be

• reconfirmed;

• withdrawn;

• replaced by a revised edition, or

• amended.

– 8 – 62067 © CEI:2001

INTRODUCTION

En raison des développements importants des réseaux de câbles à isolation extrudée pour les

tensions supérieures à 150 kV, le Comité d’études 21 de la CIGRE a constitué un groupe de

travail (GT) 21.03 en 1990, dont les termes de référence étaient « de préparer des

recommandations pour les essais de type électriques, les essais sur prélèvements et les

essais individuels, en étendant la norme CEI 60840 (1988) jusqu’à 400 kV, et de faire des

propositions pour les essais de préqualification/développement qui doivent être effectués a

minima ».

Le GT 21.03 a indiqué que l’extension de la CEI 60840 aux tensions supérieures à 150 kV

méritait une considération particulière en raison des facteurs suivants:

– ces câbles constituent l’un des éléments essentiels des réseaux de transport et, par

conséquent, les considérations de fiabilité sont de la plus haute importance;

– ces câbles et leurs accessoires fonctionnent sous des contraintes électriques supérieures

à celles des câbles de tensions jusqu’à 150 kV et, de ce fait, ont une marge de sécurité

plus restreinte par rapport à la performance intrinsèque des liaisons par câbles;

– ces câbles et leurs accessoires ont une épaisseur d’isolation plus forte que celle des

matériels jusqu’à 150 kV et sont donc soumis à des contraintes thermomécaniques plus

fortes;

– la conception et la compatibilité des câbles et de leurs accessoires deviennent plus

difficiles avec l’accroissement des niveaux de tension des réseaux.

Les recommandations du GT 21.03 ont été publiées dans Electra n°151 en décembre 1993 et

prises en compte par la CEI en 1995 dans la préparation de la présente norme pour les

réseaux de câbles à isolation extrudée de tensions supérieures à 150 kV. La CEI a cependant

considéré que cette norme devrait aussi couvrir le niveau 500 kV. Ainsi, lors de sa réunion de

septembre 1996, le Comité d’études 21 de la CIGRE a créé un groupe ad hoc 21.18 pour

étudier l’extension des recommandations initiales au niveau 500 kV. Les recommandations

mises à jour ont été citées dans Electra n° 193 en décembre 2000 et, de nouveau, prises en

compte dans la préparation de la présente norme.

Par rapport à la CEI 60840, première édition (1988), révisée et publiée en 1999 en tant que

CEI 60840, deuxième édition, il existe une différence majeure: la CIGRE a estimé que, afin

d’obtenir des indications sur la fiabilité à long terme d’un réseau de câbles, il est nécessaire de

procéder à un essai de vieillissement accéléré de longue durée. Cet essai, dénommé «essai

de préqualification», doit être effectué sur le système complet comprenant câble, jonctions et

extrémités afin de démontrer la performance du système.

En outre, le GT 21.09 de la CIGRE, dont la tâche était d’étudier les essais après la pose des

réseaux de câbles haute tension à isolation extrudée, a publié ses recommandations dans

Electra n° 173 en août 1997. Celles-ci ont également été prises en compte dans la préparation

de la présente Norme internationale. Ces recommandations indiquent, entre autres, qu'il

convient que les essais sous tension continue soient évités sur l’isolation principale car ils sont

à la fois inefficaces et dangereux. Par contre, les essais sous tension continue sont

recommandés sur les gaines extérieures.

Une liste des références CIGRE appropriées est donnée dans la bibliographie.

62067 © IEC:2001 – 9 –

INTRODUCTION

As a result of major developments in cable systems with extruded insulation for voltages above

150 kV, CIGRE Study Committee 21 set up Working Group (WG) 21.03 in 1990. The terms of

reference of WG 21.03 were "to prepare recommendations for electrical type tests, sample and

routine tests, based on extending IEC 60840 (1988) up to 400 kV and to make proposals for

prequalification/development tests which, as a minimum, should be performed ".

WG 21.03 reported that the extension of IEC 60840 to voltages above 150 kV needed extra

consideration because of the following factors:

– such cables form part of the backbone of the transmission system and, therefore, reliability

considerations are of the highest priority;

– these cables and their accessories operate with higher electrical stresses than cables up to

150 kV and, as a result, have a smaller safety margin with respect to the intrinsic

performance boundaries of the cable system;

– such cables and accessories have a thicker insulation wall than those up to 150 kV and, as

a result, are subjected to greater thermomechanical effects;

– the design and coordination of the cables and accessories become more difficult with

increasing system voltage levels.

The recommendations of the WG 21.03 were published in Electra No. 151 in December 1993

and taken into account by IEC in 1995 in the preparation of this standard for cable systems

with extruded insulation for voltages above 150 kV. IEC considered that this new standard

should also cover the 500 kV level. Thus, at its meeting in September 1996, CIGRE Study

Committee 21 set up a Task Force 21.18 to study the extension of the initial recommendations

to the 500 kV level. The updated recommendations were cited in Electra No. 193 in December

2000 and again taken into account by IEC in the preparation of this standard.

Compared with IEC 60840, first edition (1988), revised and published in 1999 as IEC 60840

edition 2, there is a major difference: CIGRE advised that, in order to gain some indication of

the long term reliability of a cable system, it is necessary to carry out a long term accelerated

ageing test. This test, known as the "prequalification test", is to be performed on the complete

system comprising the cable, joints and terminations in order to demonstrate the performance

of the system.

In addition, CIGRE WG 21.09, given the task to study tests after installation on high-voltage

extruded insulation cable systems, published its recommendations in Electra No 173 in August

1997. In the preparation of this International Standard, account has also been taken of these

recommendations which state, among others, that d.c. tests should be avoided on the main

insulation, as they are both ineffective and dangerous. On the other hand, d.c. tests are

recommended on the oversheath.

A list of relevant CIGRE references is given in the bibliography.

– 10 – 62067 © CEI:2001

CÂBLES D'ÉNERGIE À ISOLATION EXTRUDÉE ET LEURS ACCESSOIRES

POUR DES TENSIONS ASSIGNÉES SUPÉRIEURES À 150 kV (U = 170 kV)

m

ET JUSQU'À 500 kV (U = 550 kV) –

m

MÉTHODES ET PRESCRIPTIONS D'ESSAI

1 Domaine d'application

La présente Norme internationale spécifie les méthodes et les prescriptions d'essai

applicables aux systèmes de câbles d’énergie, comprenant les câbles à isolation extrudée et

leurs accessoires pour installations fixes, pour des tensions assignées supérieures à 150 kV

(U = 170 kV) et jusqu'à 500 kV compris (U = 550 kV).

m m

Les prescriptions sont applicables aux câbles unipolaires et à leurs accessoires, pour des

conditions habituelles d'installation et de fonctionnement, mais ne le sont pas à des câbles

spéciaux et à leurs accessoires comme les câbles sous-marins, pour lesquels il peut être

nécessaire d'apporter des modifications aux essais normaux ou d’élaborer des conditions

d'essai particulières.

2 Références normatives

Les documents normatifs suivants contiennent des dispositions qui, par suite de la référence

qui y est faite, constituent des dispositions valables pour la présente Norme internationale.

Pour les références datées, les amendements ultérieurs ou les révisions de ces publications

ne s’appliquent pas. Toutefois, les parties prenantes aux accords fondés sur la présente

Norme internationale sont invitées à rechercher la possibilité d’appliquer les éditions les plus

récentes des documents normatifs indiqués ci-après. Pour les références non datées, la

dernière édition du document normatif en référence s’applique. Les membres de l’ISO et de la

CEI possèdent le registre des Normes internationales en vigueur.

CEI 60060-1:1989, Techniques des essais à haute tension – Première partie: Définitions et

prescriptions générales relatives aux essais

CEI 60183:1984, Guide pour le choix des câbles à haute tension

CEI 60228:1978, Ames des câbles isolés

CEI 60229:1982, Essais sur les gaines extérieures des câbles, qui ont une fonction spéciale

de protection et sont appliqués par extrusion

CEI 60230:1966, Essais de choc des câbles et de leurs accessoires

CEI 60332-1:1993, Essais des câbles électriques soumis au feu – Partie 1: Essais sur un

conducteur ou câble isolé vertical

CEI 60811-1-1:1993, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Partie 1: Méthodes d'application générale – Section 1: Mesure

des épaisseurs et des dimensions extérieures – Détermination des propriétés mécaniques

CEI 60811-1-2:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Première partie: Méthodes d'application générale –

Section 2: Méthodes de vieillissement thermique

CEI 60811-1-3:1993, Matériaux d’isolation et de gainage des câbles électriques – Méthodes

d’essais communes – Partie 1: Application générale – Section 3: Méthodes de détermination

de la masse volumique – Essais d'absorption d'eau – Essai de rétraction

62067 © IEC:2001 – 11 –

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES ABOVE 150 kV (U = 170 kV)

m

UP TO 500 kV (U = 550 kV) –

m

TEST METHODS AND REQUIREMENTS

1 Scope

This International Standard specifies test methods and requirements for power cable systems,

cables with extruded insulation and their accessories for fixed installations, for rated voltages

above 150 kV (U = 170 kV) up to and including 500 kV (U = 550 kV).

m m

The requirements apply to single-core cables and to their accessories for usual conditions of

installation and operation, but not to special cables and their accessories, such as submarine

cables, for which modifications to the standard tests may be necessary or special test

conditions may need to be devised.

2 Normative references

The following normative documents contain provisions which, through reference in this text,

constitute provisions of this International Standard. For dated references, subsequent

amendments to, or revision of, any of these publications do not apply. However, parties to

agreements based on this International Standard are encouraged to investigate the possibility

of applying the most recent editions of the normative documents indicated below. For undated

references, the latest edition of the normative document referred to applies. Members of ISO

and IEC maintain registers of currently valid International Standards.

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60183:1984, Guide to the selection of high-voltage cables

IEC 60228:1978, Conductors of insulated cables

IEC 60229:1982, Tests on cable oversheaths which have a special protective function and are

applied by extrusion

IEC 60230:1966, Impulse tests on cables and their accessories

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 1: Measurement of thickness and

overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 2: Thermal ageing methods

IEC 60811-1-3:1993, Insulating and sheathing materials of electric cables – Common test

methods – Part 1: General application – Section 3: Methods for determining the density –

Water absorption tests – Shrinkage test

– 12 – 62067 © CEI:2001

CEI 60811-1-4:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Première partie: Méthodes d'application générale –

Section quatre: Essais à basse température

CEI 60811-2-1:1998, Matériaux d'isolation et de gainage des câbles électriques et optiques –

Méthodes d'essais communes – Partie 2-1: Méthodes spécifiques pour les mélanges élastomères –

Essais relatifs à la résistance à l'ozone, à l'allongement à chaud et à la résistance à l'huile

CEI 60811-3-1:1985, Méthodes d’essais communes pour les matériaux d’isolation et de gainage

des câbles électriques – Troisième partie: Méthodes spécifiques pour les mélanges PVC –

Section une: Essai de pression à température élevée – Essais de résistance à la fissuration

CEI 60811-3-2:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Troisième partie: Méthodes spécifiques pour les mélanges

PVC – Section deux: Essai de perte de masse – Essai de stabilité thermique

CEI 60811-4-1:1985, Méthodes d’essais communes pour les matériaux d’isolation et de

gainage des câbles électriques – Quatrième partie: Méthodes spécifiques pour les mélanges

polyéthylène et polypropylène – Section un: Résistance aux craquelures sous contraintes dues

à l'environnement – Essai d'enroulement après vieillissement thermique dans l'air – Mesure de

l’indice de fluidité à chaud – Mesure dans le PE du taux de noir de carbone et/ou des charges

minérales

CEI 60885-3:1988, Méthodes d’essais électriques pour les câbles électriques – Troisième

partie: Méthodes d’essais pour mesures de décharges partielles sur longueurs de câbles de

puissance extrudés

3 Définitions

Pour les besoins de la présente Norme internationale, les définitions suivantes s'appliquent.

3.1 Définitions de valeurs dimensionnelles (épaisseurs, sections, etc.)

3.1.1

valeur nominale

valeur par laquelle une grandeur est dénommée et qui est souvent utilisée dans les tableaux

NOTE Régulièrement, dans cette norme, les valeurs nominales correspondent à des valeurs qui sont vérifiées par

des mesures, en tenant compte des tolérances spécifiées.

3.1.2

valeur médiane

quand plusieurs résultats d'essais sont obtenus et classés par ordre de valeurs croissantes

(ou décroissantes), valeur du milieu de la série si le nombre de valeurs disponibles est impair,

et moyenne arithmétique des deux valeurs centrales de la série si le nombre est pair

3.2 Définitions relatives aux essais

3.2.1

essais individuels

essais effectués par le fabrica

...

IEC 62067

Edition 1.1 2006-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power cables with extruded insulation and their accessories for rated voltages

above 150 kV (U = 170 kV) up to 500 kV (U = 550 kV) – Test methods

m m

and requirements

Câbles d'énergie à isolation extrudée et leurs accessoires pour des tensions

assignées supérieures à 150 kV (U = 170 kV) et jusqu'à 500 kV (U = 550 kV) –

m m

Méthodes et prescriptions d'essai

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62067

Edition 1.1 2006-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Power cables with extruded insulation and their accessories for rated voltages

above 150 kV (U = 170 kV) up to 500 kV (U = 550 kV) – Test methods

m m

and requirements

Câbles d'énergie à isolation extrudée et leurs accessoires pour des tensions

assignées supérieures à 150 kV (U = 170 kV) et jusqu'à 500 kV (U = 550 kV) –

m m

Méthodes et prescriptions d'essai

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CM

CODE PRIX

ICS 29.060.20 ISBN 2-8318-8539-6

62067 © IEC:2001+A1:2006 – 3 –

– 2 – 62067 © IEC:2001+A1:2006

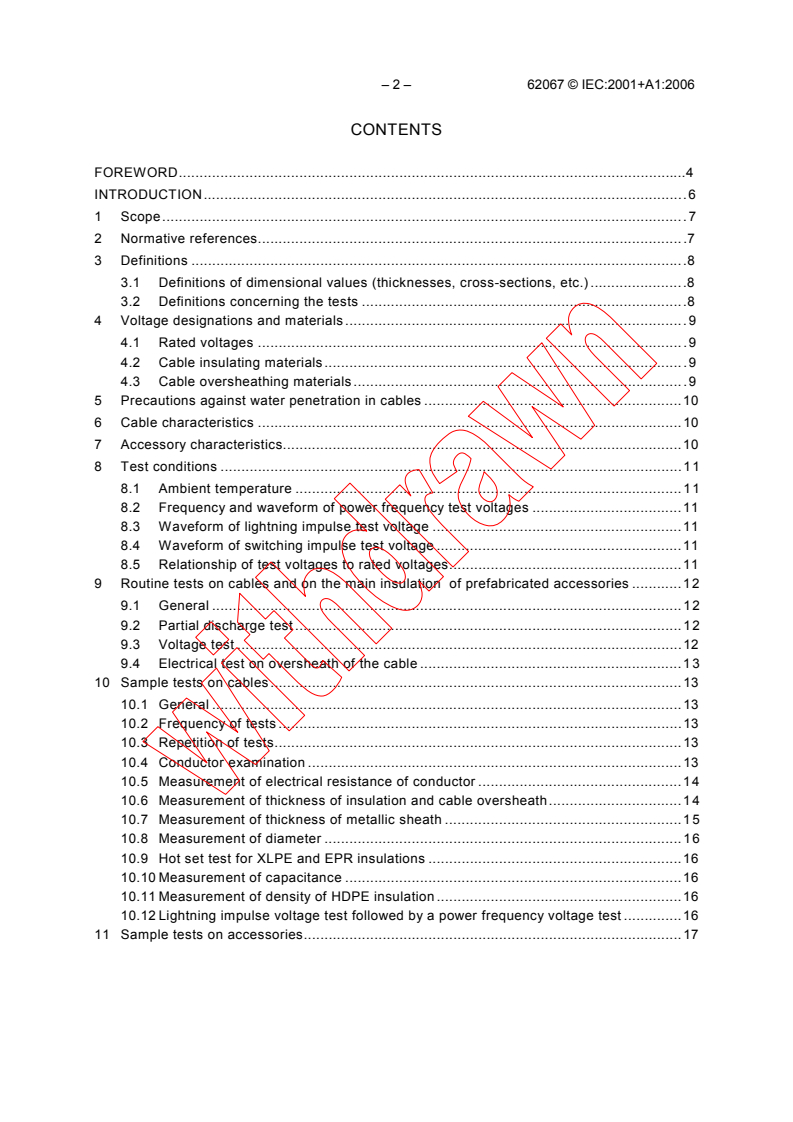

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.7

2 Normative references.7

3 Definitions .8

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.) .8

3.2 Definitions concerning the tests .8

4 Voltage designations and materials .9

4.1 Rated voltages .9

4.2 Cable insulating materials.9

4.3 Cable oversheathing materials .9

5 Precautions against water penetration in cables .10

6 Cable characteristics .10

7 Accessory characteristics.10

8 Test conditions .11

8.1 Ambient temperature .11

8.2 Frequency and waveform of power frequency test voltages .11

8.3 Waveform of lightning impulse test voltage .11

8.4 Waveform of switching impulse test voltage .11

8.5 Relationship of test voltages to rated voltages.11

9 Routine tests on cables and on the main insulation of prefabricated accessories .12

9.1 General .12

9.2 Partial discharge test .12

9.3 Voltage test .12

9.4 Electrical test on oversheath of the cable .13

10 Sample tests on cables.13

10.1 General .13

10.2 Frequency of tests .13

10.3 Repetition of tests.13

10.4 Conductor examination .13

10.5 Measurement of electrical resistance of conductor .14

10.6 Measurement of thickness of insulation and cable oversheath.14

10.7 Measurement of thickness of metallic sheath .15

10.8 Measurement of diameter .16

10.9 Hot set test for XLPE and EPR insulations .16

10.10 Measurement of capacitance .16

10.11 Measurement of density of HDPE insulation .16

10.12 Lightning impulse voltage test followed by a power frequency voltage test .16

11 Sample tests on accessories.17

62067 © IEC:2001+A1:2006 – 5 –

62067 © IEC:2001+A1:2006 – 3 –

12 Type tests on cable systems .17

12.1 General .17

12.2 Range of type approval .17

12.3 Summary of type tests .18

12.4 Electrical type tests on complete cable systems .18

12.5 Non-electrical type tests on cable components and on complete cable .22

13 Prequalification test of the cable system.25

13.1 Range of prequalification test approval .25

13.2 Prequalification test on complete cable system .26

14 Electrical tests after installation.27

14.1 DC voltage test of the oversheath .27

14.2 AC voltage test of the insulation.27

Annex A (normative) Rounding of numbers.34

Annex B (normative) Method of measuring resistivity of semi-conducting screens.35

Annex C (normative) Water penetration test .37

Annex D (normative) Tests of outer protection for buried joints .39

Bibliography .41

Figure B.1 – Preparation of samples for measurement of resistivity of conductor and

insulation screens .36

Figure C.1 – Schematic diagram of apparatus for water penetration test .38

Table 1 – Insulating compounds for cables .28

Table 2 – Tan δ requirements for insulating compounds for cables .28

Table 3 – Test voltages .28

Table 4 – Non-electrical type tests for insulating and oversheathing compounds

for cables.29

Table 5 – Test requirements for mechanical characteristics of insulating compounds

for cables (before and after ageing).30

Table 6 – Test requirements for mechanical characteristics of oversheathing

compounds for cables (before and after ageing) .31

Table 7 – Test requirements for particular characteristics of insulating compounds

for cables.32

Table 8 – Carbon black content of thermoplastic polyethylene oversheathing compounds

for cables.32

Table 9 – Test requirements for particular characteristics of PVC oversheathing

compounds for cables .33

Table 10 – AC test voltages after installation .33

Table D.1 – Impulse voltage tests.40

62067 © IEC:2001+A1:2006 – 7 –

– 4 – 62067 © IEC:2001+A1:2006

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES ABOVE 150 kV (U = 170 kV)

m

UP TO 500 kV (U = 550 kV) –

m

TEST METHODS AND REQUIREMENTS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62067 has been prepared by IEC technical committee 20: Electric

cables.

This consolidated version of IEC 62067 consists of the first edition (2001) [documents

20/482/FDIS and 20/489/RVD] and its amendment 1 (2006) [documents 20/784/FDIS and

20/802/RVD].

The technical content is therefore identical to the base edition and its amendment and has

been prepared for user convenience.

It bears the edition number 1.1.

A vertical line in the margin shows where the base publication has been modified by

amendment 1.

Annexes A, B, C and D form an integral part of this standard.

62067 © IEC:2001+A1:2006 – 9 –

62067 © IEC:2001+A1:2006 – 5 –

The committee has decided that the contents of the base publication and its amendments will

remain unchanged until the maintenance result date indicated on the IEC web site under

"http://webstore.iec.ch" in the data related to the specific publication. At this date,

the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

62067 © IEC:2001+A1:2006 – 11 –

– 6 – 62067 © IEC:2001+A1:2006

INTRODUCTION

As a result of major developments in cable systems with extruded insulation for voltages above

150 kV, CIGRE Study Committee 21 set up Working Group (WG) 21.03 in 1990. The terms of

reference of WG 21.03 were "to prepare recommendations for electrical type tests, sample and

routine tests, based on extending IEC 60840 (1988) up to 400 kV and to make proposals for

prequalification/development tests which, as a minimum, should be performed ".

WG 21.03 reported that the extension of IEC 60840 to voltages above 150 kV needed extra

consideration because of the following factors:

– such cables form part of the backbone of the transmission system and, therefore, reliability

considerations are of the highest priority;

– these cables and their accessories operate with higher electrical stresses than cables up to

150 kV and, as a result, have a smaller safety margin with respect to the intrinsic

performance boundaries of the cable system;

– such cables and accessories have a thicker insulation wall than those up to 150 kV and, as

a result, are subjected to greater thermomechanical effects;

– the design and coordination of the cables and accessories become more difficult with

increasing system voltage levels.

The recommendations of the WG 21.03 were published in Electra No. 151 in December 1993

and taken into account by IEC in 1995 in the preparation of this standard for cable systems

with extruded insulation for voltages above 150 kV. IEC considered that this new standard

should also cover the 500 kV level. Thus, at its meeting in September 1996, CIGRE Study

Committee 21 set up a Task Force 21.18 to study the extension of the initial recommendations

to the 500 kV level. The updated recommendations were cited in Electra No. 193 in December

2000 and again taken into account by IEC in the preparation of this standard.

Compared with IEC 60840, first edition (1988), revised and published in 1999 as IEC 60840

edition 2, there is a major difference: CIGRE advised that, in order to gain some indication of

the long term reliability of a cable system, it is necessary to carry out a long term accelerated

ageing test. This test, known as the "prequalification test", is to be performed on the complete

system comprising the cable, joints and terminations in order to demonstrate the performance

of the system.

In addition, CIGRE WG 21.09, given the task to study tests after installation on high-voltage

extruded insulation cable systems, published its recommendations in Electra No 173 in August

1997. In the preparation of this International Standard, account has also been taken of these

recommendations which state, among others, that d.c. tests should be avoided on the main

insulation, as they are both ineffective and dangerous. On the other hand, d.c. tests are

recommended on the oversheath.

A list of relevant CIGRE references is given in the bibliography.

62067 © IEC:2001+A1:2006 – 13 –

62067 © IEC:2001+A1:2006 – 7 –

POWER CABLES WITH EXTRUDED INSULATION AND THEIR ACCESSORIES

FOR RATED VOLTAGES ABOVE 150 kV (U = 170 kV)

m

UP TO 500 kV (U = 550 kV) –

m

TEST METHODS AND REQUIREMENTS

1 Scope

This International Standard specifies test methods and requirements for power cable systems,

cables with extruded insulation and their accessories for fixed installations, for rated voltages

above 150 kV (U = 170 kV) up to and including 500 kV (U = 550 kV).

m m

The requirements apply to single-core cables and to their accessories for usual conditions of

installation and operation, but not to special cables and their accessories, such as submarine

cables, for which modifications to the standard tests may be necessary or special test

conditions may need to be devised.

This standard does not cover transition joints between cables with extruded insulation and

paper insulated cables.

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60060-1:1989, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60183:1984, Guide to the selection of high-voltage cables

IEC 60228:1978, Conductors of insulated cables

IEC 60229:1982, Tests on cable oversheaths which have a special protective function and are

applied by extrusion

IEC 60230:1966, Impulse tests on cables and their accessories

IEC 60332-1:1993, Tests on electric cables under fire conditions – Part 1: Test on a single

vertical insulated wire or cable

IEC 60811-1-1:1993, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 1: Measurement of thickness and

overall dimensions – Tests for determining the mechanical properties

IEC 60811-1-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section 2: Thermal ageing methods

IEC 60811-1-3:1993, Insulating and sheathing materials of electric cables – Common test

methods – Part 1: General application – Section 3: Methods for determining the density –

Water absorption tests – Shrinkage test

62067 © IEC:2001+A1:2006 – 15 –

– 8 – 62067 © IEC:2001+A1:2006

IEC 60811-1-4:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 1: Methods for general application – Section Four: Tests at low temperature

IEC 60811-2-1:1998, Insulating and sheathing materials of electric and optical cables –

Common test methods – Part 2-1: Methods specific to elastomeric compounds – Ozone

resistance, hot set and mineral oil immersion tests

IEC 60811-3-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section One: Pressure test at high

temperature – Tests for resistance to cracking

IEC 60811-3-2:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 3: Methods specific to PVC compounds – Section Two: Loss of mass test –

Thermal stability test

IEC 60811-4-1:1985, Common test methods for insulating and sheathing materials of electric

cables – Part 4: Methods specific to polyethylene and polypropylene compounds – Section

One: Resistance to environmental stress cracking – Wrapping test after thermal ageing in air –

Measurement of the melt flow index – Carbon black and/or mineral content measurement in PE

IEC 60840:2004, Power cables with extruded insulation and their accessories for rated

voltages above 30 kV (U = 36 kV) up to 150 kV (U = 170 kV) – Test methods and

m m

requirements.

IEC 60885-3:1988, Electrical test methods for electric cables – Part 3: Test methods for partial

discharge measurements on lengths of extruded power cables

3 Definitions

For the purpose of this International Standard, the following definitions apply.

3.1 Definitions of dimensional values (thicknesses, cross-sections, etc.)

3.1.1

nominal value

value by which a quantity is designated and which is often used in tables

NOTE Usually, in this standard, nominal values give rise to values to be checked by measurements taking into

account specified tolerances.

3.1.2

median value

when several test results have been obtained and ordered in an increasing (or decreasing)

succession, middle value if the number of available values is odd, and mean of the two middle

values if the number is even

3.2 Definitions concerning the tests

3.2.1

routine tests

tests made by the manufacturer on each manufactured component (length of cable or

accessory) to check that the component meets the specified requirements

3.2.2

sample tests

tests made by the manufacturer on samples of complete cable or components taken from a

complete cable or accessory, at a specified frequency, so as to verify that the finished product

meets the specified requirements

62067 © IEC:2001+A1:2006 – 17 –

62067 © IEC:2001+A1:2006 – 9 –

3.2.3

type tests

tests made before supplying on a general commercial basis a type of cable system covered by

this standard, in order to demonstrate satisfactory performance characteristics to meet the

intended application. Once successfully completed, these tests need not be repeated, unless

changes are made in the cable or accessory materials, or design or manufacturing process

which might change the performance characteristics

3.2.4

prequalification test

test made before supplying on a general commercial basis a type of cable system covered by

this standard, in order to demonstrate satisfactory long term performance of the complete

cable system. The prequalification test need only be carried out once unless there is a

substantial change in the cable system with respect to material, manufacturing process, design

and design levels

NOTE A substantial change is defined as that which might adversely affect the performance of the cable system.

The supplier should provide a detailed case, including test evidence, if modifications are introduced, which are

claimed not to constitute a substantial change.

3.2.5

electrical tests after installation

tests made to demonstrate the integrity of the cable system as installed

3.3

cable system

cable with installed accessories

4 Voltage designations and materials

4.1 Rated voltages

In this standard, the symbols U , U and U are used to designate the rated voltages of cables

0 m

and accessories where these symbols have the meanings given in IEC 60183.

4.2 Cable insulating materials

This standard applies to cables insulated with the materials listed in table 1, which also

specifies for cables with each type of insulating compound the maximum operating conductor

temperatures on which the specified test conditions are based.

4.3 Cable oversheathing materials

Tests are specified for four types of oversheath, as follows:

– ST and ST based on PVC;

1 2

– ST and ST based on polyethylene.

3 7

The choice of the type of oversheath will depend on the design of the cable and the mechanical

and thermal constraints during operation.

The maximum conductor temperatures in normal operation given in IEC 60840 apply to this

standard.

62067 © IEC:2001+A1:2006 – 19 –

– 10 – 62067 © IEC:2001+A1:2006

5 Precautions against water penetration in cables

When cable systems are installed in the ground, in easily flooded galleries or in water, a radial

water impermeable barrier around the cable is recommended.

NOTE A test for radial water penetration is not currently available.

Longitudinal water barriers may also be applied, either by agreement between the purchaser

and the manufacturer or as recommended by the manufacturer, to avoid the need to replace

long sections of cable in case of damage in the presence of water.

A test for longitudinal water penetration is given in 12.5.14.

6 Cable characteristics

For the purpose of carrying out and recording the tests described in this standard, the cable

shall be identified. The following characteristics shall be known or declared.

6.1 Rated voltage: values shall be given for U , U, U (see 4.1 and 8.5).

0 m

6.2 Type of conductor, its material and nominal cross-sectional area, in square millimetres.

Presence, if any, and nature of measures taken to achieve longitudinal watertightness. If the

nominal cross-sectional area is not in accordance with IEC 60228, the d.c. conductor

resistance shall be declared.

6.3 Material and nominal thickness of insulation (see 4.2).

6.4 Type of manufacturing process for insulation system.

6.5 Presence, if any, and nature of watertightness measures in screening area.

6.6 Material and construction of metallic screen, e.g. number and diameter of wires, if any.

Material, construction and nominal thickness of metallic sheath, if any. The d.c. resistance of

the metallic screen shall be declared.

6.7 Material and nominal thickness of oversheath.

6.8 Nominal diameter over conductor (d).

6.9 Nominal diameter over complete cable (D).

6.10 Nominal capacitance between conductor and metallic screen/sheath.

7 Accessory characteristics

For the purpose of carrying out and recording the tests described in this standard, the

accessory shall be identified. The following characteristics shall be known or declared.

7.1 Conductor connectors used within the accessories shall be correctly identified with

respect to

– assembly technique;

– tooling, dies and necessary setting;

– preparation of contact surfaces, if applicable;

– type, reference number and any other identification of the connector.

62067 © IEC:2001+A1:2006 – 21 –

62067 © IEC:2001+A1:2006 – 11 –

7.2 Accessories to be tested shall be correctly identified with respect to

– name of manufacturer;

– type, designation, manufacturing date or date code;

– rated voltage (see 6.1);

– installation instructions (reference and date).

8 Test conditions

8.1 Ambient temperature

Unless otherwise specified in the details for the particular test, tests shall be carried out at an

ambient temperature of (20 ± 15) °C.

8.2 Frequency and waveform of power frequency test voltages

Unless otherwise indicated in this standard, the frequency of the alternating test voltages shall

be in the range 49 Hz to 61 Hz. The waveform shall be substantially sinusoidal. The values

quoted are r.m.s. values.

8.3 Waveform of lightning impulse test voltage

In accordance with IEC 60230, the front time of the standard lightning impulse voltage shall be

between 1 µs and 5 µs. The time to half value shall be 50 µs ± 10 µs as specified in

IEC 60060-1.

8.4 Waveform of switching impulse test voltage

In accordance with IEC 60060-1, the standard switching impulse voltage shall have a time to

peak of 250 µs ± 50 µs and a time to half value of 2 500 µs ± 1 500 µs.

8.5 Relationship of test voltages to rated voltages

Where test voltages are specified in this standard as multiples of the rated voltage U , the

value of U for the determination of the test voltages shall be as specified in table 3.

For cables and accessories of rated voltage not shown in the table, the value of U for

determination of test voltages may be the same as for the nearest rated voltage which is given,

provided that the value of U for the cable and accessory is not higher than the corresponding

m

value in the table. Otherwise, and particularly if the rated voltage is not close to one of the

values in the table, the value of U on which the test voltages are based shall be the rated

value, i.e. U divided by 3 .

The test voltages in this standard are based on the assumption that the cables and accessories

are used on systems of category A, as defined in IEC 60183.

62067 © IEC:2001+A1:2006 – 23 –

– 12 – 62067 © IEC:2001+A1:2006

9 Routine tests on cables and on the main insulation

of prefabricated accessories

9.1 General

The following tests shall be carried out on each manufactured length of cable and on the main

insulation of each prefabricated accessory, to check that the whole of each cable length and

that the main insulation of each prefabricated accessory complies with the requirements.

The order in which these tests are carried out is at the discretion of the manufacturer.

a) Partial discharge test (see 9.2).

b) Voltage test (see 9.3).

c) Electrical test on oversheath of the cable, if required (see 9.4).

The applicability of the test on the oversheath of the cable, in item c) above, when the test is

specified in the particular contract or order, depends upon the function of the oversheath in the

installation (see IEC 60229). Therefore, this test shall only be carried out when required for the

particular contract.

The main insulation of prefabricated accessories is required to undergo partial discharge and

voltage routine tests according to alternative 1), 2) or 3) below:

1) on the main insulation of prefabricated accessories installed on cable;

2) by using a host accessory into which a component of an accessory is substituted for test;

3) by using a simulated accessory rig in which the electrical stress environment of a main

insulation component is reproduced.