IEC 61010-2-011:2019

(Main)Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-011: Particular requirements for refrigerating equipment

Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-011: Particular requirements for refrigerating equipment

IEC 61010-2-011:2019 specifies particular safety requirements for the following types a) to c) of electrical equipment and their accessories, wherever they are intended to be used, whenever that equipment incorporates refrigerating systems as an integral part of, or separate from, the equipment and the equipment is in direct control of the refrigerating system. This document details all the requirements when up to 150 g of flammable refrigerant are used per stage of a refrigerating system. Additional requirements beyond the current scope of this document apply if a refrigerant charge of flammable refrigerant exceeds this amount.

a) Electrical test and measurement equipment

This is equipment which by electromagnetic means tests, measures, indicates or records one or more electrical or physical quantities, also non-measuring equipment such as signal generators, measurement standards, power supplies for laboratory use, transducers, transmitters, etc.

b) Electrical industrial process-control equipment

This is equipment which controls one or more output quantities to specific values, with each value determined by manual setting, by local or remote programming, or by one or more input variables.

c) Electrical laboratory equipment

This is equipment which measures, indicates, monitors, inspects or analyses materials, or is used to prepare materials, and includes in vitro diagnostic (IVD) equipment. This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) introduction of new defined terms or modified terms to align with Part 2-012 and other source documents. Editorial changes to use small capitals only for defined terms. Note the difference of defined term in 4.3.2.101 and abnormal operation in 11.7.104.3 and 11.7.104.5;

c) clarifications for cooling tests in 4.4.2.10;

d) changes pertaining to the accurate employment of the following terms: temperature, operating temperature, application temperature, controlled temperature, room ambient and ambient temperature;

e) use of defined term to replace cooling system;

f) move text of 4.4.2.101 to 4.3.2.101, since the purpose of as defined, is to simulate failure of the ambient conditions of 1.4.1 but not of the of the equipment;

g) use of the term equipment to replace unit, apparatus, appliance, where applicable;

h) in 5.1.2 dd) for high and low sides for each stage are required only under ;

i) use of defined term to replace normal operation;

j) use of defined term to replace user.

It has the status of a group safety publication in accordance with IEC Guide 104.

Exigences de sécurité pour appareils électriques de mesurage, de régulation et de laboratoire - Partie 2-011: Exigences particulières pour appareils de réfrigération

L'IEC 61010-2-011:2019 spécifie les exigences de sécurité particulières pour les types a) à c) suivants d'appareils électriques et leurs accessoires, quel que soit l'endroit dans lequel ils sont destinés à être utilisés, lorsque ces appareils comportent des systèmes frigorifiques, que ces derniers fassent partie intégrante des appareils ou qu'ils soient séparés des appareils, et que les appareils sont sous la commande directe du système frigorifique. Le présent document décrit de manière détaillée toutes les exigences correspondant à l'utilisation d'une quantité de fluide frigorigène inflammable allant jusqu'à 150 g par étage d'un système frigorifique. Lorsqu'une charge de fluide frigorigène inflammable dépasse cette quantité, des exigences supplémentaires hors du domaine d'application du présent document s'appliquent.

a) Appareils électriques d'essai et de mesurage

Il s'agit d'appareils qui, par des moyens d'ordre électromagnétique, mesurent, indiquent ou enregistrent une ou plusieurs grandeurs électriques ou physiques, ainsi que des appareils non-mesureurs tels que générateurs de signaux, étalons de mesure, alimentations de puissance de laboratoire, transducteurs, transmetteurs, etc.

b) Appareils électriques de contrôle de procédés industriels

Il s'agit d'appareils qui règlent une ou plusieurs grandeurs de sortie selon des valeurs spécifiques, chaque valeur étant déterminée par réglage manuel, par programmation locale ou à distance, ou par une ou plusieurs variables d'entrée.

c) Appareils électriques de laboratoire

Il s'agit d'appareils qui mesurent, indiquent, surveillent, inspectent ou analysent des matériaux, ou qui servent à préparer des matériaux, y compris les appareils de diagnostic in vitro (DIV). Cette deuxième édition annule et remplace la première édition parue en 2016. Cette édition constitue une révision technique. Cette édition inclut les modifications techniques majeures suivantes par rapport à l'édition précédente:

a) alignement sur les modifications apportées par l'Amendement 1 de l'IEC 61010-1:2010;

b) introduction de nouveaux termes et définitions ou modification de termes pour s'aligner sur la Partie 2-012 et d'autres documents de base. Modifications rédactionnelles permettant d'utiliser les petites majuscules uniquement pour les termes définis. Noter la différence entre "(3.107) utilisé en 4.3.2.101 et "fonctionnement anormal" en 11.7.104.3 et 11.7.104.5;

c) clarifications relatives aux essais de refroidissement en 4.4.2.10;

d) modifications relatives à l'emploi précis des termes suivants: "température d'application", "", "température du local" et "température ambiante";

e) utilisation du terme défini "pour remplacer "système de refroidissement";

f) déplacement du texte de 4.4.2.101 à 4.3.2.101, en ce sens que le tel que défini consiste à simuler une défaillance des conditions ambiantes au 1.4.1, mais pas une de l'appareil;

g) utilisation du terme "appareil" ("equipment" en anglais) pour remplacer le terme "unité", le cas échéant;

h) les de 5.1.2 dd) des côtés haute et basse pression pour chaque étage du sont exigées uniquement en ;

i) utilisation du terme défini "" pour remplacer "fonctionnement normal";

j) utilisation du terme défini "" pour remplacer "utilisateur".

Elle a le statut d'une publication groupée de sécurité conformément au Guide IEC 104.

General Information

- Status

- Published

- Publication Date

- 21-Mar-2019

- Technical Committee

- TC 66 - Safety of measuring, control and laboratory equipment

- Drafting Committee

- MT 17 - TC 66/MT 17

- Current Stage

- PPUB - Publication issued

- Start Date

- 22-Mar-2019

- Completion Date

- 11-Apr-2019

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 61010-2-011:2019 specifies particular safety requirements for refrigerating equipment that is part of electrical equipment for measurement, control and laboratory use. It applies where the equipment (electrical test & measurement, industrial process-control, or laboratory/IVD equipment) incorporates a refrigerating system and the equipment directly controls that system. The standard covers refrigerant charges of flammable refrigerant up to 150 g per stage; larger charges require additional requirements outside this Part 2‑011 scope. This is Edition 2.0 (2019) and is used together with the latest IEC 61010‑1.

Key topics and technical requirements

IEC 61010-2-011 supplements IEC 61010‑1 by adding refrigerating‑specific rules. Main topics include:

- Scope and definitions for refrigerating systems and controlled/ambient temperatures (alignment with Part 1 and Part 2‑012).

- Tests: cooling performance tests, leakage and rupture assessments, and motor‑compressor temperature/pressure tests.

- Protection requirements: protection against electric shock, mechanical hazards, spread of fire, and HAZARDS from fluids and solid foreign objects.

- Temperature and heat resistance: maximum temperature limits for motor‑compressors and components.

- Gases and explosion: safeguards for liberated gases, flammability parameters and explosion/implosion risks (annexes provide guidance).

- Components and piping: requirements and parameters for pressure vessels, tubing and piping (incl. referenced parameters in informative annexes).

- Marking and documentation: required labels, information for equipment containing flammable refrigerants, and user/operator instructions.

- Safety interlocks and risk assessment: provisions for interlocks and guidance to perform RISK assessment for refrigerating systems.

- Annexes: informative and normative annexes cover leakage/rupture, hazards, component/piping requirements, and marking for flammable refrigerants.

Significant technical updates in the 2019 edition include alignment with Amendment 1 to IEC 61010‑1, clarified terminology, refined cooling tests, and standardized use of defined terms.

Practical applications and who uses this standard

IEC 61010-2-011 is used by:

- Manufacturers of laboratory equipment, environmental chambers, medical/IVD devices and test instruments that include refrigerating systems.

- Product safety engineers and compliance teams preparing CE/CB/other conformity evidence.

- Test labs and certification bodies performing safety testing and assessments for refrigerating equipment.

- Design engineers specifying compressors, piping and safety interlocks for small-charge systems (≤150 g flammable refrigerant per stage).

It helps ensure safe design, testing, marking, and documentation to mitigate electrical, mechanical, thermal and flammability hazards.

Related standards

- IEC 61010‑1 (general safety requirements for measurement, control and laboratory equipment) - Part 1 is normative and must be used in conjunction with Part 2‑011.

- IEC 61010‑2‑010 and IEC 61010‑2‑012 (related Part 2 standards for heating and combined heating/refrigerating systems).

Keywords: IEC 61010-2-011, refrigerating equipment safety, flammable refrigerant, laboratory equipment safety, refrigerating system requirements, IEC standard.

REDLINE IEC 61010-2-011:2019 - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-011: Particular requirements for refrigerating equipment Released:3/22/2019 Isbn:9782832267264

IEC 61010-2-011:2019 - Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-011: Particular requirements for refrigerating equipment

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

IEC 61010-2-011:2019 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Safety requirements for electrical equipment for measurement, control, and laboratory use - Part 2-011: Particular requirements for refrigerating equipment". This standard covers: IEC 61010-2-011:2019 specifies particular safety requirements for the following types a) to c) of electrical equipment and their accessories, wherever they are intended to be used, whenever that equipment incorporates refrigerating systems as an integral part of, or separate from, the equipment and the equipment is in direct control of the refrigerating system. This document details all the requirements when up to 150 g of flammable refrigerant are used per stage of a refrigerating system. Additional requirements beyond the current scope of this document apply if a refrigerant charge of flammable refrigerant exceeds this amount. a) Electrical test and measurement equipment This is equipment which by electromagnetic means tests, measures, indicates or records one or more electrical or physical quantities, also non-measuring equipment such as signal generators, measurement standards, power supplies for laboratory use, transducers, transmitters, etc. b) Electrical industrial process-control equipment This is equipment which controls one or more output quantities to specific values, with each value determined by manual setting, by local or remote programming, or by one or more input variables. c) Electrical laboratory equipment This is equipment which measures, indicates, monitors, inspects or analyses materials, or is used to prepare materials, and includes in vitro diagnostic (IVD) equipment. This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010; b) introduction of new defined terms or modified terms to align with Part 2-012 and other source documents. Editorial changes to use small capitals only for defined terms. Note the difference of defined term in 4.3.2.101 and abnormal operation in 11.7.104.3 and 11.7.104.5; c) clarifications for cooling tests in 4.4.2.10; d) changes pertaining to the accurate employment of the following terms: temperature, operating temperature, application temperature, controlled temperature, room ambient and ambient temperature; e) use of defined term to replace cooling system; f) move text of 4.4.2.101 to 4.3.2.101, since the purpose of as defined, is to simulate failure of the ambient conditions of 1.4.1 but not of the of the equipment; g) use of the term equipment to replace unit, apparatus, appliance, where applicable; h) in 5.1.2 dd) for high and low sides for each stage are required only under ; i) use of defined term to replace normal operation; j) use of defined term to replace user. It has the status of a group safety publication in accordance with IEC Guide 104.

IEC 61010-2-011:2019 specifies particular safety requirements for the following types a) to c) of electrical equipment and their accessories, wherever they are intended to be used, whenever that equipment incorporates refrigerating systems as an integral part of, or separate from, the equipment and the equipment is in direct control of the refrigerating system. This document details all the requirements when up to 150 g of flammable refrigerant are used per stage of a refrigerating system. Additional requirements beyond the current scope of this document apply if a refrigerant charge of flammable refrigerant exceeds this amount. a) Electrical test and measurement equipment This is equipment which by electromagnetic means tests, measures, indicates or records one or more electrical or physical quantities, also non-measuring equipment such as signal generators, measurement standards, power supplies for laboratory use, transducers, transmitters, etc. b) Electrical industrial process-control equipment This is equipment which controls one or more output quantities to specific values, with each value determined by manual setting, by local or remote programming, or by one or more input variables. c) Electrical laboratory equipment This is equipment which measures, indicates, monitors, inspects or analyses materials, or is used to prepare materials, and includes in vitro diagnostic (IVD) equipment. This second edition cancels and replaces the first edition published in 2016. This edition constitutes a technical revision. This edition includes the following significant technical changes with respect to the previous edition: a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010; b) introduction of new defined terms or modified terms to align with Part 2-012 and other source documents. Editorial changes to use small capitals only for defined terms. Note the difference of defined term in 4.3.2.101 and abnormal operation in 11.7.104.3 and 11.7.104.5; c) clarifications for cooling tests in 4.4.2.10; d) changes pertaining to the accurate employment of the following terms: temperature, operating temperature, application temperature, controlled temperature, room ambient and ambient temperature; e) use of defined term to replace cooling system; f) move text of 4.4.2.101 to 4.3.2.101, since the purpose of as defined, is to simulate failure of the ambient conditions of 1.4.1 but not of the of the equipment; g) use of the term equipment to replace unit, apparatus, appliance, where applicable; h) in 5.1.2 dd) for high and low sides for each stage are required only under ; i) use of defined term to replace normal operation; j) use of defined term to replace user. It has the status of a group safety publication in accordance with IEC Guide 104.

IEC 61010-2-011:2019 is classified under the following ICS (International Classification for Standards) categories: 19.080 - Electrical and electronic testing. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 61010-2-011:2019 has the following relationships with other standards: It is inter standard links to IEC 61010-2-011:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 61010-2-011:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 61010-2-011 ®

Edition 2.0 2019-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 61010-2-011 ®

Edition 2.0 2019-03

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

GROUP SAFETY PUBLICATION

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 19.080 ISBN 978-2-8322-6726-4

– 2 – IEC 61010-2-011:2019 RLV © IEC 2019

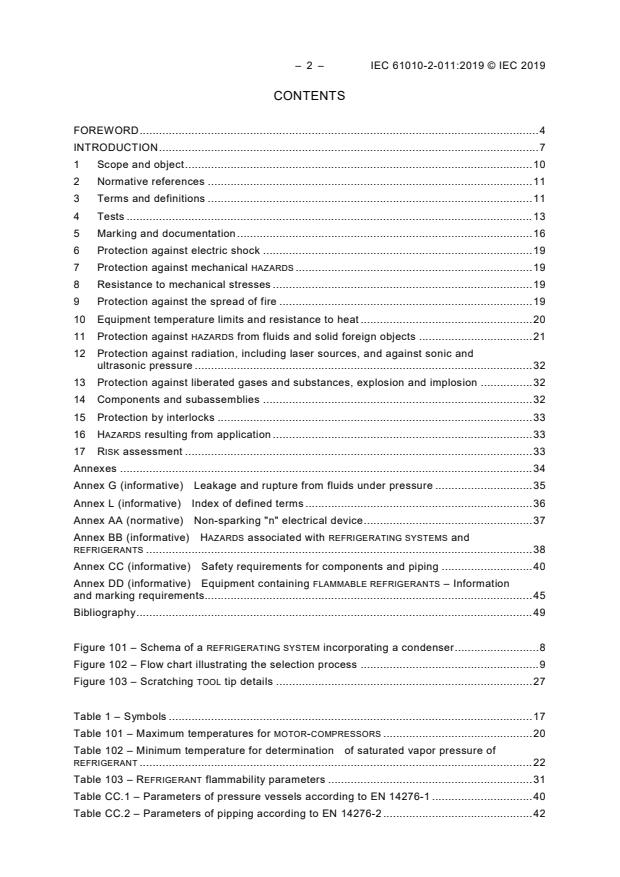

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope and object . 10

2 Normative references . 11

3 Terms and definitions . 11

4 Tests . 13

5 Marking and documentation . 16

6 Protection against electric shock . 19

7 Protection against mechanical HAZARDS . 20

8 Resistance to mechanical stresses . 20

9 Protection against the spread of fire . 20

10 Equipment temperature limits and resistance to heat . 20

11 Protection against HAZARDS from fluids and solid foreign objects . 22

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 33

13 Protection against liberated gases and substances, explosion and implosion . 33

14 Components and subassemblies . 33

15 Protection by safety interlocks . 33

16 HAZARDS resulting from application . 33

17 RISK assessment . 34

Annexes . 35

Annex G (informative) Leakage and rupture from fluids under pressure . 36

Annex L (informative) Index of defined terms . 37

Annex AA (normative) Non-sparking "n" electrical apparatus device . 38

Annex BB (informative) HAZARDS associated with REFRIGERATING SYSTEMS and

REFRIGERANTS . 39

Annex CC (informative) Safety requirements for components and piping . 41

Annex DD (informative) Equipment containing FLAMMABLE REFRIGERANTS – Information

and marking requirements. 46

Bibliography . 50

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a condenser . 8

Figure 102 – Flow chart illustrating the selection process . 9

Figure 103 – Scratching TOOL tip details . 28

Table 1 – Symbols . 17

Table 101 – Maximum temperatures for MOTOR-COMPRESSORS . 21

Table 102 – Minimum temperature for determination of saturated vapor pressure of

REFRIGERANT . 23

Table 103 – REFRIGERANT flammability parameters . 31

Table CC.1 – Parameters of pressure vessels according to EN 14276-1 . 41

Table CC.2 – Parameters of pipping according to EN 14276-2 . 43

Table CC.3 – Component and piping requirements . 44

Table CC.4 – Minimum wall thickness for copper and steel tubing . 45

Table DD.1 – Quantity of Group A2/A3 REFRIGERANT per occupied space . 49

– 4 – IEC 61010-2-011:2019 RLV © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition. A vertical bar appears in the margin wherever a change

has been made. Additions are in green text, deletions are in strikethrough red text.

International Standard IEC 61010-2-011 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

It has the status of a group safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) introduction of new defined terms or modified terms to align with Part 2-012 and other

source documents. Editorial changes to use small capitals only for defined terms. Note the

difference of defined term ABNORMAL OPERATION (3.107) in 4.3.2.101 and abnormal

operation in 11.7.104.3 and 11.7.104.5;

c) clarifications for cooling tests in 4.4.2.10;

d) changes pertaining to the accurate employment of the following terms: temperature,

operating temperature, application temperature, CONTROLLED TEMPERATURE, room ambient

and ambient temperature;

e) use of defined term REFRIGERATING SYSTEM to replace cooling system;

f) move text of 4.4.2.101 to 4.3.2.101, since the purpose of ABNORMAL OPERATION, as defined,

is to simulate failure of the ambient conditions of 1.4.1 but not of the SINGLE FAULT

CONDITION of the equipment;

g) use of the term equipment to replace unit, apparatus, appliance, where applicable;

h) in 5.1.2 dd) PS for high and low sides for each REFRIGERANT stage are required only under

NORMAL CONDITION;

i) use of defined term NORMAL CONDITION to replace normal operation;

j) use of defined term OPERATOR to replace user.

The text of this International Standard is based on the following documents:

CDV Report on voting

66/676/CDV 66/683/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61010 series, published under the general title Safety

requirements for electrical equipment for measurement, control, and laboratory use, can be

found on the IEC website.

This Part 2-011 is to be used in conjunction with the latest edition of IEC 61010-1. It was

established on the basis of the third edition (2010) and its Amendment 1 (2016), hereinafter

referred to as Part 1.

This Part 2-011 supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for REFRIGERATING

EQUIPMENT.

Where a particular subclause of Part 1 is not mentioned in this Part 2-011, that subclause

applies as far as is reasonable. Where this Part 2-011 states "addition", "modification",

– 6 – IEC 61010-2-011:2019 RLV © IEC 2019

"replacement", or "deletion", the relevant requirement, test specification, or note in Part 1

should be adapted accordingly.

In this standard:

1) the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in Clause 3: SMALL

ROMAN CAPITALS.

2) subclauses, figures, tables and notes which are additional to those in Part 1 are numbered

starting from 101. Additional annexes are lettered starting from AA and additional list

items are lettered from aa).

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

This Part 2-011, in conjunction along with Part 2-010 and Part 2-012, taken together,

addresses the specific HAZARDS associated with the heating and cooling of materials by

equipment which are segregated and are organized as follows:

IEC 61010-2-010 Specifically addresses the HAZARDS associated with equipment

incorporating heating systems.

IEC 61010-2-011 Specifically addresses the HAZARDS associated with equipment

incorporating REFRIGERATING SYSTEMS.

IEC 61010-2-012 Specifically addresses the HAZARDS associated with equipment

incorporating both heating and REFRIGERATING SYSTEMS that interact

with each other such that the combined heating and REFRIGERATING

SYSTEM yield additional or more severe HAZARDS for the two systems

than if treated separately. It also addresses the HAZARDS associated

with the treatment of materials by other factors like irradiation,

excessive humidity, CO and mechanical movement.

Guidance for the application of the correct Part 2 standard(s)

When the equipment includes only a material heating system, and no REFRIGERATING SYSTEM

or other environmental factors apply, then Part 2-010 applies without needing Part 2-011 or

Part 2-012. Similarly, when the equipment includes only a REFRIGERATING SYSTEM, and no

material heating system or other environmental factors apply, then Part 2-011 applies without

needing Part 2-010 or Part 2-012. However, when the equipment incorporates both a material

REFRIGERATING SYSTEM or the materials being treated in the intended

heating system, and a

application introduce significant heat into the REFRIGERATING SYSTEM, a determination should

be made as to whether the interaction between the two systems will generate additional or

more severe HAZARDS than if the systems were evaluated separately (application CONTROLLED

TEMPERATURE, see flow chart of Figure 102 for selection process). If the interaction of the

heating and cooling functions yields no additional or more severe HAZARDS then both

Part 2-010 and Part 2-011 apply for their respective functions. Conversely, if additional or

more severe HAZARDS results from the combining of the heating and cooling functions, or if the

equipment incorporates additional material treatment factors, then Part 2-012 applies, but not

Part 2-010 or Part 2-011.

What HAZARDS are applicable for a REFRIGERATING SYSTEM?

The typical HAZARDS for a REFRIGERATING SYSTEM (see Figure 101) consisting of a MOTOR-

COMPRESSOR, a condenser, an expansion device and an evaporator include but are not

limited to:

MOTOR-

– The excess of temperature of the low-pressure side (return temperature) to the

COMPRESSOR is higher than admissible. A MOTOR-COMPRESSOR incorporates a REFRIGERANT

cooled motor and it should be established that the maximum temperatures of low-pressure

side under least favourable condition do not exceed the insulation RATINGS within the

motor.

– The excess of pressure of the low-pressure side at the inlet to the MOTOR-COMPRESSOR is

higher than admissible. The housing of the MOTOR-COMPRESSOR is exposed to this

pressure and so the design RATING of the MOTOR-COMPRESSOR housing should

accommodate the worst-case pressures whilst providing the correct safety margin for a

pressure vessel.

– The excess of temperature of the high-pressure side to the condenser is higher than

admissible. The temperatures of the high-pressure side under the most unfavourable

– 8 – IEC 61010-2-011:2019 RLV © IEC 2019

conditions may can present a temperature HAZARD if the OPERATOR is exposed, or an

electrical HAZARD if insulation is degraded.

– The excess of pressure of the high-pressure side to the condenser is higher than

REFRIGERANT components downstream of the MOTOR-COMPRESSOR up to

admissible. The

the expansion device are exposed to this pressure and so the design RATING of these

components should accommodate the worst case pressures whilst providing the correct

safety margin for a pressure vessel.

– The maximum application CONTROLLED TEMPERATURES where the heat is being extracted

from, may impact the maximum temperature of the low-pressure side to the MOTOR-

COMPRESSOR as well as present a temperature HAZARD if the OPERATOR is exposed, or an

electrical HAZARD if insulation is degraded. Whether this application CONTROLLED

TEMPERATURE is derived from an integral heating function of the device or from the heat

dissipated from the material being cooled, the impact under worst-case conditions should

be evaluated.

– The current draw of the equipment should be established when including the worst-case

running conditions of the REFRIGERATING SYSTEM including any defrost cycles that may

apply.

The worst-case conditions should be determined for the equipment and will include both the

least favourable NORMAL USE conditions as well as the most unfavourable testing results under

SINGLE FAULT CONDITIONS.

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a condenser

The selection process is illustrated in the following flow chart (see Figure 102).

Figure 102 – Flow chart illustrating the selection process

– 10 – IEC 61010-2-011:2019 RLV © IEC 2019

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

1 Scope and object

This clause of Part 1 is applicable, except as follows:

1.1.1 Equipment included in scope

Replacement:

Replace the first second paragraph by the following:

This group safety publication is primarily intended to be used as a product safety standard for

the products mentioned in the scope, but shall also be used by technical committees in the

preparation of their publications for products similar to those mentioned in the scope of this

standard, in accordance with the principles laid down in IEC guide 104 and ISO/IEC Guide 51.

This Part 2 of IEC 61010 specifies particular safety requirements for the following types

a) to c) of electrical equipment and their accessories, wherever they are intended to be used,

whenever that equipment incorporates REFRIGERATING SYSTEMS whether as an integral part of,

or remote to separate from, the equipment and the equipment is in direct control of the

REFRIGERATING SYSTEM.

This document details all the requirements when up to 150 g of FLAMMABLE REFRIGERANT are

used per stage of a REFRIGERATING SYSTEM. Additional requirements beyond the current scope

of this document apply if a REFRIGERANT charge of FLAMMABLE REFRIGERANT exceeds this

amount.

Addition:

Add the following text after the last paragraph:

NOTE 101 Examples for REFRIGERATING EQUIPMENT include, but are not limited to, laboratory equipment such as

laboratory refrigerators, freezers, refrigerated display cabinets, etc.

If It is possible that all or part of the equipment falls within the scope of one or more other

Part 2 standards of IEC 61010 as well as within the scope of this standard, it should also

meet. In that case, the requirements of those other Part 2 standards will also apply. In

particular, if equipment is intended to be used as a centrifuge, it should meet the

requirements of IEC 61010-2-020 apply. However, when the equipment incorporates a

refrigerating system and a heating function where the combination of the two introduces

additional or more severe HAZARDS than if treated separately, then the application of it is

possible that IEC 61010-2-012 should be considered is applicable instead of this Part 2-011.

See further information in the flow chart (Figure 102) for the selection process and guidance

in the Introduction.

1.1.2 Equipment excluded from scope

Addition:

Add the following new item after item j):

or equipment incorporating:

aa) a transcritical REFRIGERANT SYSTEM (system that uses CO ) or a system that uses

ammonia (NH ) as the REFRIGERANT.

1.2 Object

1.2.1 Aspects included in scope

Replacement:

Replace the first paragraph by the following:

The object of this document is to ensure that the design and methods of construction of

REFRIGERATING EQUIPMENT provide adequate protection for OPERATORS, bystanders, trained

service personnel, and the surrounding area against the specific HAZARDS that relate to

REFRIGERATING SYSTEMS.

Addition:

Add the following note after the existing note:

NOTE 101 A list of HAZARDS typically associated with REFRIGERATING SYSTEMS and REFRIGERANTS is included in

Annex BB.

2 Normative references

This clause of Part 1 is applicable, except as follows:

Addition:

Add the following references to the list:

IEC 60079-15:2010, Explosive atmospheres – Part 15: Equipment protection by type of

protection "n"

IEC 60335-2-34:2012, Household and similar electrical appliances – Safety – Part 2-34:

Particular requirements for motor-compressors

IEC 60335-2-34:2012/AMD1:2015

IEC 60335-2-34:2012/AMD2:2017

UL 471:2010, Commercial Refrigerators and Freezers

ISO 7010, Graphical symbols – Safety colours and safety signs – Registered safety signs

3 Terms and definitions

This clause of Part 1 is applicable, except as follows:

Addition:

Add the following new terms and definitions:

– 12 – IEC 61010-2-011:2019 RLV © IEC 2019

3.101

REFRIGERATING EQUIPMENT

test, measurement, control or laboratory equipment that incorporates a REFRIGERATING SYSTEM

either as an integral part of or remote to separate from the equipment

3.102

REFRIGERATING SYSTEM

factory assembled unit for performing part of the refrigerant cycle (compression and

condensation) comprising one or more refrigerant compressors with motors, condensers,

liquid receivers (where required), interconnecting pipe work and ancillary equipment

combination of interconnected REFRIGERANT-containing parts constituting one closed

REFRIGERANT circuit in which the REFRIGERANT is circulated for the purpose of extracting and

rejecting heat

[SOURCE: ISO 5149-1:2014, 3.1.9, modified – The term in brackets "(heat pump)", the words

"(heating and cooling)", and the note to entry, have been omitted.]

3.103

FLAMMABLE REFRIGERANT

REFRIGERANT with a flammability classification of group 2 or 3 in accordance with ISO 5149-1

and ISO 817

Note 1 to entry: For REFRIGERANT blends which have more than one flammability classification, either the most

unfavourable classification is taken for the purpose of this definition or the blend itself is evaluated for flammability

in accordance with ISO 817.

3.104

HPCO

HIGH PRESSURE CUT-OUT

pressure-actuated device that is designed to stop the operation of the pressure generator

Note 1 to entry: This note applies to the French language only.

3.105

MAXIMUM ALLOWABLE PRESSURE

PS

maximum allowable pressure as determined by the collated test results detailed in 11.7

maximum pressure for which the equipment is designed, as specified by the manufacturer

Note 1 to entry: This note applies to the French language only.

[SOURCE: ISO 5149-1:2014, 3.3.3]

3.106

SOAKED TEMPERATURE CONDITION

environmental temperature condition when all the temperatures in the equipment under test

(EUT) equal to ±2 °C of the test room ambient temperature

Note 1 to entry: This note applies to the French language only.

3.107

ABNORMAL OPERATION

operation of a REFRIGERATING SYSTEM EQUIPMENT with a limited RATED ambient temperature

range in ambient temperature conditions outside that limitation but within the temperature

limits of 1.4.1

3.108

REFRIGERANT

fluid used for heat transfer in a REFRIGERATING SYSTEM, which absorbs heat at a low

temperature and a low pressure of the fluid and rejects heat at a higher temperature and a

higher pressure of the fluid, usually involving changes of state of the fluid

[SOURCE: ISO 5149-1:2014, 3.7.9, modified – The note has been removed.]

3.109

CONTROLLED TEMPERATURE

temperature where the evaporator is located and to which the low-pressure side of the

equipment is exposed, as a result of heat transfer either by active heating or from the

application system or specimen

Note 1 to entry: For heat pump systems, where a four-way valve is used to shift between heating and cooling, the

function of the condenser and evaporator is exchanged.

3.110

LOWER EXPLOSIVE LIMIT

LEL

concentration of flammable gas or vapour in air, below which an explosive gas atmosphere

will not be formed

Note 1 to entry: This note applies to the French language only.

[SOURCE: IEC 60050-426:2008, 426-02-09]

3.111

MOTOR-COMPRESSOR

refrigerating subassembly consisting of the mechanical mechanism of the compressor and the

motor, both of which are enclosed in the same sealed housing, with no external shaft seals,

and with the motor operating in a REFRIGERANT atmosphere with or without oil

Note 1 to entry: The housing may be permanently sealed, such as by welding or brazing (hermetic MOTOR-

COMPRESSOR), or may be sealed by gasketted joints (semi-hermetic MOTOR-COMPRESSOR). A TERMINAL box, a

TERMINAL boxcover, and other electrical components or an electronic control system may be included.

[SOURCE: IEC 60335-2-34:2012, 3.101, modified – "appliance" has been replaced by

"refrigerating subassembly" and note 2 has been removed.]

3.112

CONDENSING UNIT

specific refrigerating subassembly combination for a given REFRIGERANT, consisting of one or

more MOTOR-COMPRESSORS, condensers, liquid receivers (when required) and the regularly

furnished accessories

[SOURCE: ISO 5149-1:2014, 3.4.5, modified – The definition has been adapted for the

specific case of refrigerating equipment.]

4 Tests

This clause of Part 1 is applicable, except as follows:

4.3 Reference test conditions

4.3.1 Environmental conditions

Addition:

– 14 – IEC 61010-2-011:2019 RLV © IEC 2019

Add the following text after item d):

Since the operating temperatures, pressures and current draws for a REFRIGERATING SYSTEM

are significantly impacted by ambient temperatures in a non-linear way, linear extrapolation of

test data is not possible. Therefore tests to establish temperatures, pressures, and current

draws of a REFRIGERATING SYSTEM shall be conducted under the following environmental

conditions:

aa) an ambient temperature of 40 °C;

bb) a relative humidity not exceeding the limits of 1.4.1 d).

If the equipment is RATED by the manufacturer to operate in extended environmental

conditions as defined by 1.4.2 or a more restricted environment condition in accordance with

1.4.1, note 2, then these conditions will define the settings for 4.3.1 aa) or 4.3.1 bb).

When the REFRIGERATING SYSTEM is water cooled, the temperature of the water supply shall be

the maximum as specified by the manufacturer (see 5.4.3) with the worst case water pressure

as specified by the manufacturer.

If a restricted environment condition in accordance with 1.4.1, note 2, is employed then the

test of 4.43.2.101 applies.

4.3.2 State of equipment

4.3.2.1 General

Addition:

Add the following text after the first paragraph:

When measuring temperatures, pressures and current draws of equipment incorporating a

REFRIGERATING SYSTEM the tests shall be started from a SOAKED TEMPERATURE CONDITION when

all pressures have fully equalized. Tests at the extremes of the input voltage (±10 %) shall

start under these voltage conditions and achieve a stable state but need not start from a

SOAKED TEMPERATURE CONDITION. Safety protective devices shall not operate during this test.

Addition:

Add the following new subclause:

4.3.2.101 ABNORMAL OPERATION to simulate the failure of the controlled environment

For REFRIGERATING EQUIPMENT intended to operate in a restricted environment and tested in

accordance with 4.3.1 this additional test of ABNORMAL OPERATION shall apply to simulate the

failure of the controlled environment in the installation.

Having determined the worst case test condition for the temperature and pressure tests under

10.4.1 the equipment is run under these conditions until a steady state has been achieved.

The test environment is then increased to the limits from 1.4.1 for normal environmental

conditions (40 °C, up to 50 % RH) and the equipment is allowed to stabilize, and the

maximum temperatures and pressures are recorded. The operation of protective devices is

permitted during this test. If steady state conditions are not possible due to the operation of

protective devices then the maximum values recorded for this test shall be either:

– the maximum temperatures and pressures at the point of operation of non-resettable or

manually resettable devices. The manually resettable device does not need to be reset

during this test; or

– the maximum temperatures and pressures achieved after the cycling of auto-resetting

protective devices. Cycling shall continue until it is clear that successive cycles will not

develop higher maximum values.

4.4.2 Application of fault conditions

4.4.2.10 Cooling

Replacement:

Replace the text with the following:

For cooling not associated with the cooling of the REFRIGERATING SYSTEM:

a) air-holes with filters shall be closed;

b) forced cooling by motor-driven fans shall be stopped;

c) cooling by circulation of water or other coolant shall be stopped.

REFRIGERATING SYSTEM:

For cooling associated with t1he cooling of the

d) Condenser fan stall test – for an air cooled REFRIGERATING SYSTEM

Each condenser fan shall be stalled one at a time unless a single fault could disable all

condenser fans simultaneously, or with the condenser airflow restricted, whichever is the

worst case, until maximum stabilized pressure is attained or until representative maximum

temperatures are attained under cycling load. The temperatures and pressures shall be

monitored at short intervals throughout the test for the pressures to ensure that peak

pressures are captured. This test is conducted at a room an ambient temperature of

25 °C ± 3 °C.

e) Condenser water failure test – for a water cooled REFRIGERATING SYSTEM

The REFRIGERATING SYSTEM is to shall be operated with the condensing water shut off and

also, or with the condensing water restricted whichever is the worst case, until maximum

stabilized temperatures are attained or until representative maximum temperatures are

attained under cycling load. The temperatures and pressures shall be monitored at short

intervals throughout the test for the pressures to ensure that peak pressures are captured.

This test is conducted at a room an ambient temperature of 25 °C ± 3 °C.

f) Condenser fins shall be blocked to simulate clogging with dust etc.

If a manual reset HPCO is relied upon to limit the peak pressure during tests d) or e) or f), then

it shall be reset manually within 6 s of operation for 10 cycles.

If an automatic reset HPCO is relied upon to limit the peak pressure during tests d) or e) or f),

then it shall be permitted to cycle automatically until it can be demonstrated that peak

temperatures and pressures have been achieved.

If it can be demonstrated that an HPCO will operate during tests d) or e) or f), the manufacturer

may can elect to waive this test, but will set the PS for the high and low side of the MOTOR-

COMPRESSOR to the RATING of the HPCO.

For units equipment with both air-cooled and water-cooled condensers, only one can be

faulted at a time unless the customer is permitted to run either the air-cooled or water-cooled

condenser (the design incorporates a redundant cooling option for the condenser).

For a cascade REFRIGERATING SYSTEM, if a heat exchanger from the first stage system acts as

a condenser to the second stage system, then the manufacturer may can elect to run each

condenser stage individually under the tests of d) or e) or f) accordingly. In this case,

disabling the first stage system is considered to simulate the second stage running under a

stalled fan or condenser water failure test test condition of d) or e).

– 16 – IEC 61010-2-011:2019 RLV © IEC 2019

Addition:

Add the following new subclauses:

4.4.2.101 Extreme operating ambient abnormal (ABNORMAL OPERATION)

For REFRIGERATING EQUIPMENT intended to operate in a restricted environment and tested in

accordance with 4.3.1 then this additional test of ABNORMAL OPERATION shall apply to simulate

the failure of the controlled environment in the installation.

Having determined the worst case test condition for the temperature and pressure tests under

10.4.1 the unit is run under these conditions until a steady state has been achieved. The test

environment is then increased to the limits from 1.4.1 for Normal environmental conditions

(40 °C, up to 50 % RH) and the unit is allowed to stabilize and the maximum temperatures

and pressures are recorded. The operation of protective devices is permitted during this test.

If steady state conditions are not possible due to the operation of protective devices then the

maximum values recorded for this test shall be either:

– the maximum temperatures and pressures at the point of operation of non-resettable or

manually resettable device. The manually resettable device does not need to be reset

during this test; or

– the maximum temperatures and pressures achieved after the cycling of auto-resetting

protective devices. Cycling shall continue until it is clear that successive cycles will not

develop higher maximum values.

4.4.2.102 4.4.2.101 Uncontrolled cooling test

Temperature controllers shall be overridden to produce uncontrolled cooling. This applies

regardless of whether the controller controls the temperature of the equipment, heat transfer

medium or material being processed.

4.4.3.1 General

Addition:

Add a second new paragraph the following paragraph after the first paragraph:

Due Owing to the time it may can take to achieve stable conditions for a REFRIGERATING

SYSTEM, the duration of single fault tests may can be longer than 4 h unless it is clear that

stable conditions have been maintained for at least 1 h.

5 Marking and documentation

This clause of Part 1 is applicable, except as follows:

5.1.2 Identification

Addition:

Add the following new items after the note following item b):

aa) the total mass of REFRIGERANT for each separate REFRIGERANT circuit;

bb) for a single component REFRIGERANT, at least one of the following:

– the chemical name,

– the chemical formula,

– the REFRIGERANT number,

cc) for a blended REFRIGERANT, at least one of the following:

– the chemical name and nominal proportion of each of its components,

– the chemical formula and nominal proportion of each of its components,

– the REFRIGERANT number and nominal proportion of each of its components,

– the REFRIGERANT number of the REFRIGERANT blend,

NOTE 101 REFRIGERANT numbers are quoted in accordance with ISO 817 or other REFRIGERANT classification

standard, for example ANSI/ASHRAE 34.

dd) MAXIMUM ALLOWABLE PRESSURE (PS) under NORMAL CONDITION, high- and low-pressure

sides for each REFRIGERANT stage.

NOTE 102 The collation of the test results that define PS is detailed in 11.7.101.

5.1.3 MAINS supply

Replacement:

Replace the conformity statement as follows:

Conformity is checked by inspection and by measurement of the power or input current to

check the marking of 5.1.3 c). The measurement is made with the equipment in the condition

of maximum power consumption, but to exclude any initial inrush current, it is not made until

the current has stabilized (usually after 1 min). Transients are ignored. For REFRIGERATING

EQUIPMENT, the impact of extreme ambient temperatures and the interaction of any defrost

mode need to be evaluated in determining the condition of maximum power consumption.

Addition:

Add the following new symbols to Table 1:

Table 1 – Symbols

Number Symbol Reference Description

ISO 7010-W010 Warning; low temperature/freezing conditions, frostbite

(2011-05) HAZARD (MOD)

ISO 7010-W021

102 Warning; flammable material

(2011-05)

ISO 7010-W011

103 Warning; slippery surface

(2011-05)

ISO 7010-W024

104 Warning; crushing of hands

(2011-05)

5.2 Warning markings

Replacement:

Replace the first paragraph with the following:

– 18 – IEC 61010-2-011:2019 RLV © IEC 2019

Warning markings specified in this standard shall meet the following requirements.

Replace item a) by the following:

a) the perpendicular height of the triangle for all warning symbols shall be at least 15 mm.

The height of text shall be at least 1,8 mm, depending on the size of the equipment, the

legibility during NORMAL USE and the space available for the symbol. Symbols and text

shall have clear contrast in colour with the background.

Addition:

Add the following new paragraph after the last paragraph (before the conformity statement):

Warning markings or symbols for particular HAZARDS, which exist or develop only when

performing installation or maintenance of the equipment, shall be marked and visible only

when executing this particular maintenance. For example, the marking of the type of

FLAMMABLE REFRIGERANT and of the flammable insulation blowing gas, shall be visible when

gaining access to the MOTOR-COMPRESSORs, and, in the case of equipment with a remote

REFRIGERANT CONDENSING UNIT, the pipe connections. Symbol 102 of Table 1 shall be placed

on the nameplate of the unit equipment near the declaration of the REFRIGERANT type and

charge information. It shall be visible after installation of the REFRIGERATING EQUIPMENT.

5.4 Documentation

This clause of Part 1 is applicable, except as follows:

5.4.1 General

Replacement:

Replace item d) by the following:

d) the information specified in 5.4.2 to 5.4.6, 5.4.101 and 5.4.102;

5.4.3 Equipment Installation

Replacement:

Replace the note with the following text:

NOTE 1 It is recommended to add A statement in the documentation for the installation can be added to indicate

that the safety of any system incorporating the equipment is the responsibility of the assembler of the system.

Add the following new note:

NOTE 2 101 In the US, equipment containing FLAMMABLE REFRIGERANT is required to have additional instructions

– see informative Annex DD.

5.4.4 Equipment operation

Addition:

Add the following new item after 5.4.4 j):

aa) information to allow safe access during use, including identification of trip and slip

HAZARDS (see also 7.3.101 and 16.101).

Addition:

Add the following new subclauses:

5.4.101 Additional instructions for equipment with a separate REFRIGERANT

CONDENSING UNIT and intended for connection to a water supply

For equipment with a separate REFRIGERANT CONDENSING UNIT, the instructions shall include a

statement containing the substance of the following:

The installation of the REFRIGERATING EQUIPMENT and the REFRIGERANT CONDENSING UNIT shall

only be made by the manufacturer's service personnel or similarly skilled person.

The information provided with the REFRIGERATING EQUIPMENT with a separate REFRIGERANT

shall include

CONDENSING UNIT

– information on the type of separate REFRIGERANT CONDENSING UNIT to w

...

IEC 61010-2-011 ®

Edition 2.0 2019-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

Exigences de sécurité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-011: Exigences particulières pour APPAREILS DE REFRIGERATION

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform Electropedia - www.electropedia.org

The advanced search enables to find IEC publications by a The world's leading online dictionary on electrotechnology,

variety of criteria (reference number, text, technical containing more than 22 000 terminological entries in English

committee,…). It also gives information on projects, replaced and French, with equivalent terms in 16 additional languages.

and withdrawn publications. Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Glossary - std.iec.ch/glossary

details all new publications released. Available online and 67 000 electrotechnical terminology entries in English and

once a month by email. French extracted from the Terms and Definitions clause of

IEC publications issued since 2002. Some entries have been

IEC Customer Service Centre - webstore.iec.ch/csc collected from earlier publications of IEC TC 37, 77, 86 and

If you wish to give us your feedback on this publication or CISPR.

need further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Electropedia - www.electropedia.org

webstore.iec.ch/advsearchform Le premier dictionnaire d'électrotechnologie en ligne au

La recherche avancée permet de trouver des publications IEC monde, avec plus de 22 000 articles terminologiques en

en utilisant différents critères (numéro de référence, texte, anglais et en français, ainsi que les termes équivalents dans

comité d’études,…). Elle donne aussi des informations sur les 16 langues additionnelles. Egalement appelé Vocabulaire

projets et les publications remplacées ou retirées. Electrotechnique International (IEV) en ligne.

IEC Just Published - webstore.iec.ch/justpublished Glossaire IEC - std.iec.ch/glossary

Restez informé sur les nouvelles publications IEC. Just 67 000 entrées terminologiques électrotechniques, en anglais

Published détaille les nouvelles publications parues. et en français, extraites des articles Termes et Définitions des

Disponible en ligne et une fois par mois par email. publications IEC parues depuis 2002. Plus certaines entrées

antérieures extraites des publications des CE 37, 77, 86 et

Service Clients - webstore.iec.ch/csc CISPR de l'IEC.

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 61010-2-011 ®

Edition 2.0 2019-03

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

GROUP SAFETY PUBLICATION

PUBLICATION GROUPÉE DE SÉCURITÉ

Safety requirements for electrical equipment for measurement, control, and

laboratory use –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

Exigences de sécurité pour appareils électriques de mesurage, de régulation et

de laboratoire –

Partie 2-011: Exigences particulières pour APPAREILS DE REFRIGERATION

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 19.080 ISBN 978-2-8322-6658-8

– 2 – IEC 61010-2-011:2019 © IEC 2019

CONTENTS

FOREWORD . 4

INTRODUCTION . 7

1 Scope and object . 10

2 Normative references . 11

3 Terms and definitions . 11

4 Tests . 13

5 Marking and documentation . 16

6 Protection against electric shock . 19

7 Protection against mechanical HAZARDS . 19

8 Resistance to mechanical stresses . 19

9 Protection against the spread of fire . 19

10 Equipment temperature limits and resistance to heat . 20

11 Protection against HAZARDS from fluids and solid foreign objects . 21

12 Protection against radiation, including laser sources, and against sonic and

ultrasonic pressure . 32

13 Protection against liberated gases and substances, explosion and implosion . 32

14 Components and subassemblies . 32

15 Protection by interlocks . 33

16 HAZARDS resulting from application . 33

17 RISK assessment . 33

Annexes . 34

Annex G (informative) Leakage and rupture from fluids under pressure . 35

Annex L (informative) Index of defined terms . 36

Annex AA (normative) Non-sparking "n" electrical device . 37

Annex BB (informative) HAZARDS associated with REFRIGERATING SYSTEMS and

REFRIGERANTS . 38

Annex CC (informative) Safety requirements for components and piping . 40

Annex DD (informative) Equipment containing FLAMMABLE REFRIGERANTS – Information

and marking requirements. 45

Bibliography . 49

Figure 101 – Schema of a REFRIGERATING SYSTEM incorporating a condenser . 8

Figure 102 – Flow chart illustrating the selection process . 9

Figure 103 – Scratching TOOL tip details . 27

Table 1 – Symbols . 17

Table 101 – Maximum temperatures for MOTOR-COMPRESSORS . 20

Table 102 – Minimum temperature for determination of saturated vapor pressure of

REFRIGERANT . 22

Table 103 – REFRIGERANT flammability parameters . 31

Table CC.1 – Parameters of pressure vessels according to EN 14276-1 . 40

Table CC.2 – Parameters of pipping according to EN 14276-2 . 42

Table CC.3 – Component and piping requirements . 43

Table CC.4 – Minimum wall thickness for copper and steel tubing . 44

Table DD.1 – Quantity of Group A2/A3 REFRIGERANT per occupied space . 48

– 4 – IEC 61010-2-011:2019 © IEC 2019

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SAFETY REQUIREMENTS FOR ELECTRICAL EQUIPMENT

FOR MEASUREMENT, CONTROL, AND LABORATORY USE –

Part 2-011: Particular requirements for REFRIGERATING EQUIPMENT

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC

Publication(s)"). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 61010-2-011 has been prepared by IEC technical committee 66:

Safety of measuring, control and laboratory equipment.

It has the status of a group safety publication in accordance with IEC Guide 104.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) alignment with changes introduced by Amendment 1 of IEC 61010-1:2010;

b) introduction of new defined terms or modified terms to align with Part 2-012 and other

source documents. Editorial changes to use small capitals only for defined terms. Note the

difference of defined term ABNORMAL OPERATION (3.107) in 4.3.2.101 and abnormal

operation in 11.7.104.3 and 11.7.104.5;

c) clarifications for cooling tests in 4.4.2.10;

d) changes pertaining to the accurate employment of the following terms: temperature,

operating temperature, application temperature, CONTROLLED TEMPERATURE, room ambient

and ambient temperature;

e) use of defined term REFRIGERATING SYSTEM to replace cooling system;

ABNORMAL OPERATION, as defined,

f) move text of 4.4.2.101 to 4.3.2.101, since the purpose of

is to simulate failure of the ambient conditions of 1.4.1 but not of the SINGLE FAULT

CONDITION of the equipment;

g) use of the term equipment to replace unit, apparatus, appliance, where applicable;

h) in 5.1.2 dd) PS for high and low sides for each REFRIGERANT stage are required only under

NORMAL CONDITION;

NORMAL CONDITION to replace normal operation;

i) use of defined term

j) use of defined term OPERATOR to replace user.

The text of this International Standard is based on the following documents:

CDV Report on voting

66/676/CDV 66/683/RVC

Full information on the voting for the approval of this International Standard can be found in

the report on voting indicated in the above table.

This document has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts of the IEC 61010 series, published under the general title Safety

requirements for electrical equipment for measurement, control, and laboratory use, can be

found on the IEC website.

This Part 2-011 is to be used in conjunction with the latest edition of IEC 61010-1. It was

established on the basis of the third edition (2010) and its Amendment 1 (2016), hereinafter

referred to as Part 1.

This Part 2-011 supplements or modifies the corresponding clauses in IEC 61010-1 so as to

convert that publication into the IEC standard: Particular requirements for REFRIGERATING

EQUIPMENT.

Where a particular subclause of Part 1 is not mentioned in this Part 2-011, that subclause

applies as far as is reasonable. Where this Part 2-011 states "addition", "modification",

"replacement", or "deletion", the relevant requirement, test specification, or note in Part 1

should be adapted accordingly.

In this standard:

1) the following print types are used:

– requirements and definitions: in roman type;

– NOTES: in smaller roman type;

– conformity and tests: in italic type;

– terms used throughout this standard which have been defined in Clause 3: SMALL

ROMAN CAPITALS.

2) subclauses, figures, tables and notes which are additional to those in Part 1 are numbered

starting from 101. Additional annexes are lettered starting from AA and additional list

items are lettered from aa).

– 6 – IEC 61010-2-011:2019 © IEC 2019

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under "http://webstore.iec.ch" in the data related to

the specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

INTRODUCTION

This Part 2-011, along with Part 2-010 and Part 2-012, taken together, address the specific

HAZARDS associated with the heating and cooling of materials by equipment and are organized

as follows:

IEC 61010-2-010 Specifically addresses the HAZARDS associated with equipment

incorporating heating systems.

IEC 61010-2-011 Specifically addresses the HAZARDS associated with equipment

incorporating REFRIGERATING SYSTEMS.

IEC 61010-2-012 Specifically addresses the HAZARDS associated with equipment

incorporating both heating and REFRIGERATING SYSTEMS that interact

with each other such that the combined heating and REFRIGERATING

SYSTEM yield additional or more severe HAZARDS for the two systems

than if treated separately. It also addresses the HAZARDS associated

with the treatment of materials by other factors like irradiation,

excessive humidity, CO and mechanical movement.

Guidance for the application of the correct Part 2 standard(s)

When the equipment includes only a material heating system, and no REFRIGERATING SYSTEM

or other environmental factors apply, then Part 2-010 applies without needing Part 2-011 or

Part 2-012. Similarly, when the equipment includes only a REFRIGERATING SYSTEM, and no

material heating system or other environmental factors apply, then Part 2-011 applies without

needing Part 2-010 or Part 2-012. However, when the equipment incorporates both a material

REFRIGERATING SYSTEM or the materials being treated in the intended

heating system, and a