IEC PAS 62282-6-1:2006

(Main)Fuel cell technologies - Part 6-1: Micro fuel cell power systems - Safety

Fuel cell technologies - Part 6-1: Micro fuel cell power systems - Safety

Establishes requirements for all fuel cell power systems, units and cartridges to ensure a reasonable degree of safety for normal use, reasonably foreseeable misuse, and consumer transportation of such items. Covers fuel cell power systems, power units and fuel cartridges that are wearable or easily carried by hand, providing d.c. outputs not exceeding 60 V d.c. and power outputs not exceeding 240 VA. The contents of the corrigendum of April 2007 have been included in this copy.

General Information

- Status

- Replaced

- Publication Date

- 22-Feb-2006

- Technical Committee

- TC 105 - Fuel cell technologies

- Drafting Committee

- WG 402 - TC 105/WG 402

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 03-Mar-2010

- Completion Date

- 13-Feb-2026

Relations

- Replaced By

IEC 62282-6-100:2010 - Fuel cell technologies - Part 6-100: Micro fuel cell power systems - Safety - Effective Date

- 05-Sep-2023

- Effective Date

- 05-Sep-2023

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

IEC PAS 62282-6-1:2006 is a technical specification published by the International Electrotechnical Commission (IEC). Its full title is "Fuel cell technologies - Part 6-1: Micro fuel cell power systems - Safety". This standard covers: Establishes requirements for all fuel cell power systems, units and cartridges to ensure a reasonable degree of safety for normal use, reasonably foreseeable misuse, and consumer transportation of such items. Covers fuel cell power systems, power units and fuel cartridges that are wearable or easily carried by hand, providing d.c. outputs not exceeding 60 V d.c. and power outputs not exceeding 240 VA. The contents of the corrigendum of April 2007 have been included in this copy.

Establishes requirements for all fuel cell power systems, units and cartridges to ensure a reasonable degree of safety for normal use, reasonably foreseeable misuse, and consumer transportation of such items. Covers fuel cell power systems, power units and fuel cartridges that are wearable or easily carried by hand, providing d.c. outputs not exceeding 60 V d.c. and power outputs not exceeding 240 VA. The contents of the corrigendum of April 2007 have been included in this copy.

IEC PAS 62282-6-1:2006 is classified under the following ICS (International Classification for Standards) categories: 27.070 - Fuel cells. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC PAS 62282-6-1:2006 has the following relationships with other standards: It is inter standard links to IEC 62282-6-100:2010, IEC PAS 62282-6-1:2006/COR1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC PAS 62282-6-1:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

PUBLICLY

IEC

AVAILABLE

PAS 62282-6-1

SPECIFICATION

First edition

Pre-Standard

2006-02

Fuel cell technologies –

Part 6-1:

Micro fuel cell power systems – Safety

Reference number

IEC/PAS 62282-6-1:2006(E)

Publication numbering

As from 1 January 1997 all IEC publications are issued with a designation in the

60000 series. For example, IEC 34-1 is now referred to as IEC 60034-1.

Consolidated editions

The IEC is now publishing consolidated versions of its publications. For example,

edition numbers 1.0, 1.1 and 1.2 refer, respectively, to the base publication, the

base publication incorporating amendment 1 and the base publication incorporating

amendments 1 and 2.

Further information on IEC publications

The technical content of IEC publications is kept under constant review by the IEC,

thus ensuring that the content reflects current technology. Information relating to

this publication, including its validity, is available in the IEC Catalogue of

publications (see below) in addition to new editions, amendments and corrigenda.

Information on the subjects under consideration and work in progress undertaken

by the technical committee which has prepared this publication, as well as the list

of publications issued, is also available from the following:

• IEC Web Site (www.iec.ch)

• Catalogue of IEC publications

The on-line catalogue on the IEC web site (www.iec.ch/searchpub) enables you to

search by a variety of criteria including text searches, technical committees

and date of publication. On-line information is also available on recently issued

publications, withdrawn and replaced publications, as well as corrigenda.

• IEC Just Published

This summary of recently issued publications (www.iec.ch/online_news/ justpub)

is also available by email. Please contact the Customer Service Centre (see

below) for further information.

• Customer Service Centre

If you have any questions regarding this publication or need further assistance,

please contact the Customer Service Centre:

Email: custserv@iec.ch

Tel: +41 22 919 02 11

Fax: +41 22 919 03 00

PUBLICLY

IEC

AVAILABLE

PAS 62282-6-1

SPECIFICATION

First edition

Pre-Standard

2006-02

Fuel cell technologies –

Part 6-1:

Micro fuel cell power systems – Safety

IEC 2006 Copyright - all rights reserved

No part of this publication may be reproduced or utilized in any form or by any means, electronic or

mechanical, including photocopying and microfilm, without permission in writing from the publisher.

International Electrotechnical Commission, 3, rue de Varembé, PO Box 131, CH-1211 Geneva 20, Switzerland

Telephone: +41 22 919 02 11 Telefax: +41 22 919 03 00 E-mail: inmail@iec.ch Web: www.iec.ch

PRICE CODE

Commission Electrotechnique Internationale

XE

International Electrotechnical Commission

Международная Электротехническая Комиссия

For price, see current catalogue

– 2 – PAS 62282-6-1 © IEC:2006(E)

CONTENTS

FOREWORD. 05

1 Scope. 1H6

1.1 System boundary . 2H6

1.2 Equivalent Level of Safety . 3H7

2 Normative references . 4H7

3 Terms and definitions . 5H8

4 Materials and construction of fuel cartridge, micro fuel cell power unit and micro

fuel cell power system for portable devices. 6H11

4.1 General . 7H11

4.2 FMEA/hazard analysis. 8H11

4.3 Fuel Input. 9H11

4.4 General materials . 10H11

4.5 Selection of materials. 11H11

4.6 Vacant. 12H12

4.7 General construction . 13H12

4.8 Vacant . 14H13

4.9 Piping and fittings. 15H13

4.10 Fuel containing parts and piping systems . 16H13

4.11 Materials and construction – System . 17H14

4.12 Ignition sources. 18H14

4.13 Enclosures and acceptance strategies. 19H15

4.14 Protection against fire, explosion, corrosivity and toxicity hazard. 20H19

4.15 Protection against electrical hazards . 21H19

4.16 Fuel cell stack . 22H19

4.17 Fuel supply construction. 23H19

4.18 Protection against mechanical hazards. 24H20

4.19 Wiring material, including printed wiring . 25H22

4.20 Miscellaneous electrical equipment . 26H22

4.21 Construction of electric device components. 27H22

4.22 Protection. 28H25

5 Abnormal operation requirements and tests. 29H25

5.1 Abnormal operations and fault conditions . 30H25

6 Instructions and warnings for fuel supply cartridges, micro fuel cell power units,

and micro fuel cell power systems . 31H28

6.1 Minimum markings required on the cartridge . 32H28

6.2 Additional information required either on the cartridge or on accompanying

written information or on the system or power unit. 33H28

7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 34H28

7.1 Test conditions. 35H29

7.2 Leakage measurement of methanol and the measuring procedure. 36H29

7.3 Type tests . 37H34

Annex A (Normative) formic acid fuel cell systems . 38H49

A.1 Scope. 39H49

PAS 62282-6-1 © IEC:2006(E) – 3 –

A.2 Normative references . 40H50

A.3 Terms and definitions . 41H51

A.4 Materials and construction of fuel cartridge, micro fuel cell power unit, and micro

fuel cell power system for portable device . 42H51

A.5 Requirements of fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 43H52

A.6 Instructions and warnings for fuel supply cartridges, micro fuel cell power units,

and micro fuel cell power systems using formic acid as a fuel. 44H52

A.7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 45H52

Annex B (normative) Hydrogen stored in hydrogen absorbing metal alloy . 46H56

B.1 Scope. 47H56

B.2 Normative references . 48H57

B.3 Definitions . 49H57

B.4 Materials and construction of fuel cartridge, micro fuel cell power unit, and micro

fuel cell power system for portable devices. 50H58

B.5 Abnormal operation requirements and tests. 51H60

B.6 Instructions for fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 52H60

B.7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 53H60

Annex C (Normative) Micro reformed methanol fuel cells . 54H68

C.1 Scope. 55H68

C.2 Normative references . 56H69

C.3 Terms and definitions . 57H69

C.4 Materials and construction of fuel cartridge, micro fuel cell power unit and micro

fuel cell power system . 58H69

C.5 Requirements of fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 59H70

C.6 Instructions for fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 60H70

C.7 Type tests . 61H70

Annex D (Normative) Methanol clathrate compound. 62H74

D.1 Scope. 63H74

D.2 Normative references . 64H76

D.3 Terms and definitions . 65H76

D.4 Materials and construction of fuel cartridge, micro fuel cell power unit, and micro

fuel cell power system for portable devices. 66H76

D.5 Abnormal operation requirements and tests. 67H76

D.6 Instructions and warnings for fuel supply cartridges, micro fuel cell power units,

and micro fuel cell power systems . 68H76

D.7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 69H77

Annex E (normative) Borohydride compounds. 70H93

E.1 Scope. 71H93

E.2 Normative references . 72H95

E.3 Terms and definitions . 73H95

– 4 – PAS 62282-6-1 © IEC:2006(E)

E.4 Materials and construction of fuel cartridge, micro fuel cell power unit, and micro

fuel cell power system for portable devices. 74H97

E.5 Abnormal operation requirements and tests. 75H99

E.6 Instructions and warnings for fuel supply cartridges, micro fuel cell power units,

and micro fuel cell power systems . 76H99

E.7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 77H99

Annex F (Normative) Butane Supplement . 78H105

F.1 Scope. 79H105

F.2 Normative references . 80H106

F.3 Definitions . 81H106

F.4 Materials and construction of fuel cartridge, micro fuel cell power unit and micro

fuel cell power system for portable devices. 82H107

F.5 Requirements of fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 83H107

F.6 Instructions for fuel cartridge, micro fuel cell power unit, and micro fuel cell power

system. 84H107

F.7 Type tests for a fuel cartridge, a micro fuel cell power unit, and a micro fuel cell

power system . 85H108

PAS 62282-6-1 © IEC:2006(E) – 5 –

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

FUEL CELL TECHNOLOGIES –

Part 6-1: Micro fuel cell power systems – Safety

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

A PAS is a technical specification not fulfilling the requirements for a standard, but made

available to the public.

IEC-PAS 62282-6-1 has been processed by IEC technical committee 105: Fuel cell

technologies.

The text of this PAS is based on the This PAS was approved for

following document: publication by the P-members of the

committee concerned as indicated in

the following document

Draft PAS Report on voting

105/96/PAS 105/104/RVD

Following publication of this PAS, which is a pre-standard publication, the technical committee

or subcommittee concerned will transform it into an International Standard. Its structure will

then be adapted to the IEC rules.

This PAS shall remain valid for an initial maximum period of three years starting from

2006-02. The validity may be extended for a single three-year period, following which it shall

be revised to become another type of normative document or shall be withdrawn.

The contents of the corrigendum of April 2007 have been included in this copy.

– 6 – PAS 62282-6-1 © IEC:2006(E)

FUEL CELL TECHNOLOGIES –

Part 6-1: Micro fuel cell power systems – Safety

1 Scope

1.1 System boundary

1.1.1 This consumer safety PAS covers fuel cell power systems, power units and fuel

cartridges that are wearable or easily carried by hand, providing d.c. outputs that do not

exceed 60 V d.c. and power outputs that do not exceed 240 VA. As such, the externally

accessible circuitry is considered as circuits that are “SELV” as defined in IEC 60950-1, and

as limited power circuits if further compliance with IEC 60950-1, 2.5 is demonstrated.

Systems that have internal systems exceeding 60 V d.c. or 240 VA should be appropriately

evaluated in accordance with the separate criteria of IEC 60950-1.

1.1.2 This consumer safety PAS covers all fuel cell power systems, units and cartridges.

This PAS establishes requirements for all fuel cell power systems, units and cartridges to

ensure a reasonable degree of safety for normal use, reasonably foreseeable misuse, and

consumer transportation of such items. The cartridges covered by this PAS are not intended

to be refilled by the consumer. Cartridges refilled by the manufacturer or by trained

technicians should meet all the requirements of this PAS as unused cartridges.

1.1.3 This PAS also covers compatible and separately transported fuel storage fuel

cartridges for supplying fuel to the fuel cell power unit.

1.1.4 Fuel cell power systems that provide output levels that exceed electrical limits

specified in 1.1.1 are covered by IEC 62282-5.

1.1.5 These products are not intended for use in hazardous areas.

1.1.6 Fuels and technologies covered

1.1.6.1 This PAS includes methanol or methanol and water solutions as fuels.

1.1.6.2 This PAS includes equipment designs that include proton exchange membrane

(PEM) fuel cell stacks and direct methanol fuel cell stacks (DMFC).

1.1.6.3 This PAS includes requirements for other fuels and the associated systems in the

annexes, formatted as deviations or additional requirements to the main body of this PAS.

1.1.6.4 It is understood that all fuel cartridges, power units and fuel cell systems should

comply with applicable country and local requirements including transportation, child-

resistance, and storage, where required.

PAS 62282-6-1 © IEC:2006(E) – 7 –

Water

Mechanical

Cartridge

Primary

Thermal

Interface

(Optional)

battery

Waste

Management

Signal Interface

Heat

Internal Power Needs

Fuel Supply Fuel

Power

(Optional)

Interface

Management

Fuel Cell Interface

Or Module

Power

Fuel

Stack

Conditioning

Internal

Cartridge

Reservoir

Air

Mechanical

Management

(Optional)

Interface

Rechargeable

Fuel Cartridge Water and/or Signal

Battery or

Interface

Byproduct

Capacitor

Management

Total Control

Waste

(Optional)

System

Products and

Waste

unused fuel

Cartridge

Air

(Optional)

Micro Fuel Cell Power Unit

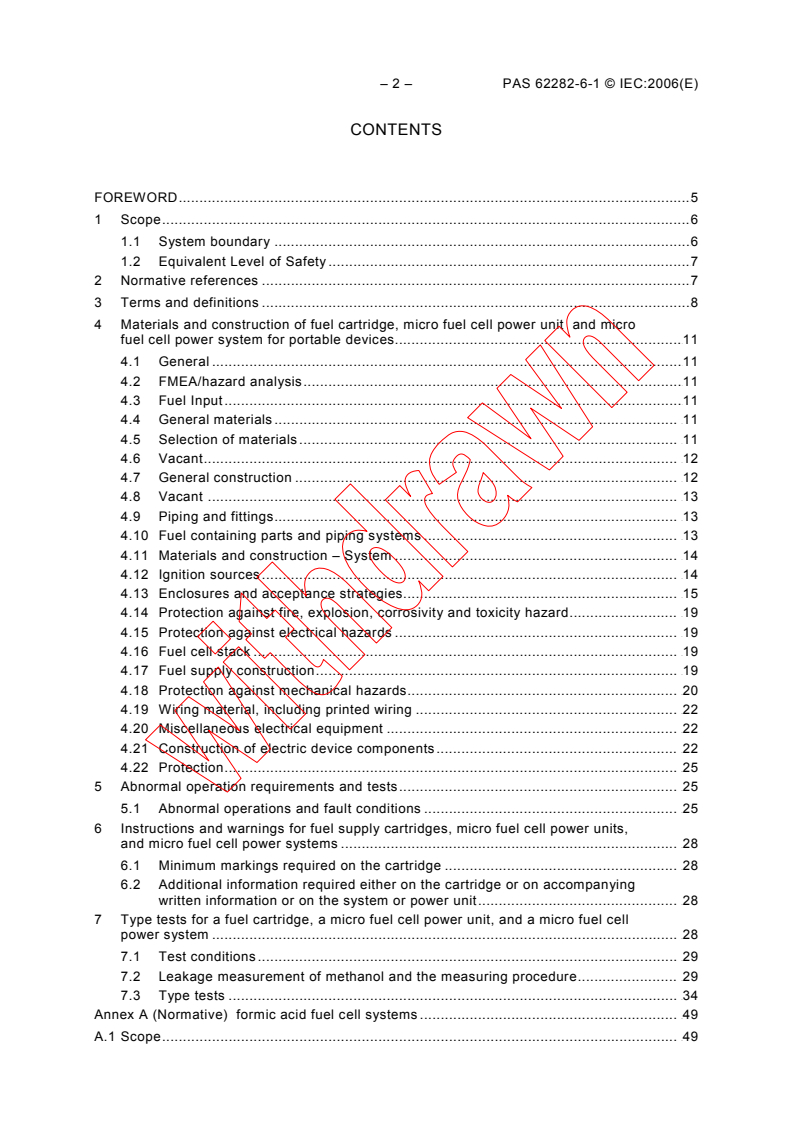

Figure 1 – Micro fuel cell power system

1.2 Equivalent Level of Safety

The requirements of this PAS are not intended to constrain innovation. The manufacturer

may consider fuels, materials, designs or constructions not specifically dealt with in this PAS.

These alternatives should be evaluated as to their ability to yield levels of safety equivalent to

those prescribed by this PAS.

2 Normative references

The following referenced documents are indispensable for the application of this PAS. For

dated references, only the edition cited applies. For undated references, the latest edition of

the referenced document (including any amendments) applies.

IEC 60079-15:2005, Electrical apparatus for explosive gas atmospheres – Part 15:

Construction, test and marking of type of protection ‘n’ electrical apparatus

IEC 60086-4:2000, Primary batteries – Part 4: Safety of lithium batteries

IEC 60695-2-11, Fire hazard testing – Part 2-11: Glowing/hot-wire based test methods –

Glow-wire flammability test method for end-products

IEC 60695-2-20, Fire hazard testing – Part 2-20: Glowing/hot-wire based test methods – Hot-

wire coil ignitability – Apparatus, test method and guidance

IEC 60695-11-10, Fire hazard testing – Part 11-10: Test flames – 50 W horizontal and vertical

flame test methods

IEC 60730-1, Automatic electrical controls for household and similar use – Part 1: General

requirements

IEC 60950-1, Information technology equipment – Safety – Part 1: General requirements

– 8 – PAS 62282-6-1 © IEC:2006(E)

IEC 61025, Fault tree analysis

IEC 61032, Protection of persons and equipment by enclosures – Probes for verification

IEC 61960, Secondary cells and batteries containing alkaline or other non-acid electrolytes –

Secondary lithium cells and batteries for portable applications

ISO 175, Plastics – Methods of test for determination of the effects of immersion in liquid

chemicals

ISO 188, Rubber, vulcanized or thermoplastic – Accelerated ageing and heat resistance tests

ISO 1817, Rubber, vulcanized – Determination of the effect of liquids

ISO 9772, Cellular plastics – Determination of horizontal burning characteristics of small

specimens subjected to a small flame

ISO 15649, Petroleum and natural gas industries – Piping

ISO 16000-3, Indoor air – Part 3: Determination of formaldehyde and other carbonyl

compounds – Active sampling method

ISO 16000-6, Indoor air – Part 6: Determination of volatile organic compounds in indoor and

test chamber air by active sampling on Tenax Ta sorbent, thermal desorption and gas

chromatography using MS/FID

ISO 16017-1, Indoor, ambient and workplace air – Part 1: Sampling and analysis of volatile

organic compounds by sorbent tube/thermal desorption/capillary gas chromatography – Part 1:

Pumped sampling

ANSI/ASME B.31.3, Process piping

3 Terms and definitions

For the purposes of this PAS, the following terms and definitions apply.

3.1

enclosure

parts of the micro fuel cell intended to be a barrier to protect, shield, and control access to the

internal components or material

3.2

fire enclosure

part of the fuel cell power unit that is intended to minimize the spread of fire or flames from

within

3.3

fuel

one of the following substances:

a) Methanol or methanol/water solution regardless of the concentration that is used to

produce electricity in the fuel cell unit

b) Formic acid

c) Hydrogen

d) Methanol clathrate compound

e) Borohydride compounds

f) Butane

PAS 62282-6-1 © IEC:2006(E) – 9 –

NOTE The methanol or methanol/water solution, is covered by the main body of the PAS. Annexes A through F

cover the other fuels.

3.4

fuel cartridge

removable article that contains and supplies fuel to the fuel cell power unit or internal

reservoir, not to be refilled by the user

3.5

insert cartridge

fuel cartridge, which has its own enclosure and is installed within the enclosure of the device

powered by the fuel cell power system

3.6

exterior cartridge

fuel cartridge, which has its own enclosure that forms a portion of the enclosure of the device

powered by the fuel cell power system

3.7

attached cartridge

fuel cartridge, which has its own enclosure that connects to the device powered by the fuel

cell power system

3.8

satellite cartridge

fuel cartridge that is intended to be connected to and removed from the fuel cell power unit to

transfer fuel to the internal reservoir inside the micro fuel cell power unit

3.9

fuel cell power unit

fuel cell power unit intended for use in a product in which service and replacement of the fuel

cell power unit will be done only by the user or by a person who has been trained to service

and repair the product

3.10

fuel supply unit, non-pressurized

cartridge in which the normal working pressure does not exceed a gauge pressure of 50 kPa

at 22 °C

3.11

fuel supply unit, pressurized

cartridge in which the normal working pressure exceeds a gauge pressure of 50 kPa at 22 °C

3.12

hazardous liquid fuel

any liquid fuel amount over 5 ml or a concentration of methanol greater than, or equal to, 4 %

by weight in water. Other hazardous fuel definitions are given in Annexes A through F

3.13

internal reservoir

structure in a fuel cell power unit that stores fuel and cannot be removed

3.14

leakage

accessible hazardous liquid fuel outside the system or cartridge

– 10 – PAS 62282-6-1 © IEC:2006(E)

3.15

limited power sources

circuits supplied by a limited power source are not considered to be a potential fire hazard

due to the limits on available power to the circuits. A limited power source is either inherently

or non-inherently limited

NOTE An inherently limited power source does not rely on a current-limiting device to meet limited power

requirements although it may rely on an impedance to limit its output. However, a non-inherently limited power

source relies upon a current-limiting device such as a fuse, etc. to meet limited power requirements.

3.16

material, toxic

any material having a toxic hazard rating of 2, moderate, in Sax’s "Dangerous Properties of

Industrial Materials" or related reference guide

3.17

mechanical enclosure

parts of the micro fuel cell intended to be a barrier to protect, shield, and control access to the

internal components or material

3.18

micro fuel cell

fuel cell power system and fuel cartridge that is wearable or easily carried by hand, providing

a d.c. output that does not exceed 60 V d.c. and power outputs that do not exceed 240 VA

3.19

no accessible liquid

consumer cannot come into physical contact with hazardous liquid fuel

3.20

no-fuel vapour loss

fuel vapour escaping from the cartridge or system of less than 0,33 g/h

3.21

no leakage

no accessible hazardous liquid fuel outside the system or cartridge

3.22

room

constructed closed environment having a 2,1 m to 2,4 m (7 ft to 8 ft) high ceiling and having a

total volume based on the intended portable fuel cell power unit application

3.23

valve, refill

component of the non-user-refillable fuel cartridge that allows refilling the cartridge only by

trained technicians

3.24

valve, shut-off

component of a fuel cartridge that controls the release of fuel

3.25

waste cartridge

cartridge that stores waste and by-products from the power unit

3.26

water cartridge

cartridge that is filled with water (no additives) to adjust fuel concentration

PAS 62282-6-1 © IEC:2006(E) – 11 –

4 Materials and construction of fuel cartridge, micro fuel cell power unit

and micro fuel cell power system for portable devices

4.1 General

4.1.1 The fuel cell power unit when coupled to the fuel cartridge shall be designed and

constructed to avoid any credible risk of fire or explosion posed by the fuel cell power system

itself or gases, vapours, liquids or other substances produced or used by the fuel cell power

system.

4.1.2 To prevent a fire or explosion hazard within the fuel cell power system, the

manufacturer shall eliminate potential ignition source(s) within areas where fuel is present (or

can be potentially released).

4.1.3 Flammable, toxic and corrosive fluids shall be kept within a closed containment

system such as within fuel piping, in a reservoir, a cartridge or similar enclosure to avoid

leakage.

4.2 FMEA/hazard analysis

4.2.1 A failure modes and effects analysis (FMEA) or equivalent reliability analysis shall be

conducted by the manufacturer to identify faults which can have safety-related consequences

and the design features that serve to mitigate those faults. The analysis shall include failures

that may result in leakage. Failures related to refilling of non-user-refillable cartridges, if

anticipated by the manufacturer or trained technicians, shall be considered.

4.2.2 Guidance can be found in IEC 61025.

4.3 Fuel Input

4.3.1 The manufacturer of the fuel cell system, power unit and/or fuel cartridges shall

specify the type and characteristics of the fuel and, if applicable, the quality and

characteristics of the fuel and water to be employed with the fuel cell power system. This

information shall be provided as part of the documentation provided with the system.

4.3.2 The fuel cell power units shall specify the fuel cartridge(s) that it is intended for. This

information shall be provided as part of the documentation provided with the fuel cell power

unit or fuel cell power system.

4.4 General materials

The materials and coating shall be resistant to corrosion under the normal transportation and

normal usage conditions over the lifespan of the product.

4.5 Selection of materials

4.5.1 Non-metallic materials such as rubber and plastics shall be selected so as to be

resistant to deterioration under their normal usage conditions over the lifespan of the product.

4.5.2 Materials employed in the fuel cell system and cartridge shall be resistant to the

affects of temperature and exposure to fuels and the effects of weather as outlined in 4.7.

4.5.3 Metallic and non-metallic materials used to construct internal or external parts of the

fuel cell power system, in particular those exposed directly or indirectly to moisture, fuel

and/or by-products in either a gas or liquid form as well as all parts and materials used to seal

or interconnect the same, e.g. welding consumables, shall be suitable for all physical,

chemical and thermal conditions which are reasonably foreseeable within the scheduled

lifetime of the equipment and for all test conditions; in particular,

– 12 – PAS 62282-6-1 © IEC:2006(E)

• they shall retain their mechanical stability with respect to strength (fatigue properties,

endurance limit, creep strength) under normal usage;

• they shall be sufficiently resistant to the chemical and physical action of the fluids that

they contain and to environmental degradation;

• the chemical and physical properties necessary for operational safety shall not be

significantly affected within the expected lifetime of the equipment;

• specifically, when selecting materials and manufacturing methods, due account shall be

taken of the material’s corrosion and wear resistance, electrical conductivity, impact

strength, ageing resistance, the effects of temperature variations, the effects arising when

materials are put together (e.g. galvanic corrosion), and the effects of ultraviolet radiation;

• where conditions of erosion, abrasion, corrosion or other chemical attack may arise,

adequate measures shall be taken to

– minimize that effect by appropriate design, e.g. additional thickness, or by appropriate

protection, e.g. use of liners, cladding materials or surface coatings, taking due

account of normal use;

– permit replacement of parts which are most affected;

– and draw attention, in the manual referred to in Clause 6, to type and frequency of

inspection and maintenance measures necessary for continued safe use; where

appropriate, it shall be indicated which parts are subject to wear and the criteria for

replacement.

4.5.4 Elastomeric materials such as gaskets and tubing in contact with fuels shall be

resistant to deterioration when in contact with those fuels and shall be suitable for the

temperatures that they are exposed to during normal use. Compliance shall be determined by

ISO 188 and ISO 1817.

4.5.5 Polymeric materials in contact with fuels shall be resistant to deterioration when in

contact with those fuels and shall be suitable for the temperature they are exposed to during

normal use. Compliance shall be determined by ISO 175.

4.6 Vacant

4.7 General construction

4.7.1 Micro fuel cell power systems shall have a safe construction that is resistant to impact

(drop), vibration, crushing, environmental changes such as temperature, moisture and

atmospheric pressure fluctuations during normal use, reasonably foreseeable misuse, and

consumer transportation of such items.

4.7.2 Connection mechanisms, including the connection between a detachable fuel cartridge

and the fuel cell system, and the electrical connection between the fuel cell module and

device, shall be designed in such a way that they cannot be attached at a wrong location or in

an incomplete state so that leakage occurs.

4.7.3 An edge projection or corner of a fuel cell power system and a fuel cartridge shall not

be sufficiently sharp to result in a risk of injury to persons during the intended use or user

maintenance.

PAS 62282-6-1 © IEC:2006(E) – 13 –

4.8 Vacant

4.9 Piping and fittings

4.9.1 Where piping systems are designed for internal pressures over 50 kPa they shall be

designed, constructed, and tested in accordance with ISO 15649 and ANSI/ASME B31.3.

4.9.2 Piping designed for operation below 50 kPa or, in accordance with the applicable

regional or national pressure equipment codes and standards not qualifying as pressure

piping, such as low-pressure water hoses, plastic tubing, or other connections to atmospheric

or low-pressure tanks and similar containers, shall be constructed of suitable materials, and

their related joints and fittings shall be designed and constructed with adequate strength and

leakage resistance to prevent unintended releases.

4.9.3 The piping shall comply dimensionally with the technical requirements given above,

and the materials shall be compatible with the intended fluids and process parameters.

4.9.4 Threaded portions shall only be allowed in cases where a leakage does not create a

hazard; e.g. air supply, cooling circuits. All other joints shall be glued, welded, brazed, or

sealed, or at least have fitting connections with a defined sealing area as specified by the

manufacturer.

4.9.5 Unions, when used in fuel gas or oxygen lines, shall be of the ground-joint type or the

flanged-joint type or sealed using an O-ring resistant to the fluid transported or of the

compression-joint type having packing resistant to the action of the fluid transported.

4.9.6 O-Rings shall be compatible with both the fluid transported and the ambient conditions

of use.

4.9.7 The design and construction of both rigid and flexible pipes and fittings shall consider

the following aspects.

4.10 Fuel containing parts and piping systems

4.10.1 Fuel-containing parts and their connections shall have adequate strength to withstand

the pressures to which they are exposed. Compliance is determined by the pressure

differential tests of 7.3.1 and the internal pressure tests of 7.3.11.

4.10.2 Connections within the piping and fuel handling parts of the system and cartridge

shall be sufficiently leaktight to prevent leakage during normal use, reasonably foreseeable

misuse, and consumer transportation. Compliance is determined by type tests 7.3.1 and

7.3.11.

4.10.3 Fuel valves

4.10.3.1 Applies to all shut-off valves, filling valves, relief valves, commercial refilling valves,

including all cartridge types.

4.10.3.2 Operating and pressure-containing parts of the shutoff valve and relief valve

assemblies shall last the life of the cartridge under normal conditions.

4.10.3.3 The fuel cartridge shall be packaged to prevent the valve from being damaged

during shipping.

4.10.3.4 The valves must have a means to prevent leakage of fuel through normal use and

storage of the cartridge.

– 14 – PAS 62282-6-1 © IEC:2006(E)

4.10.3.5 The valves shall not be susceptible to unintended actuation, or manual actuation by

a user not using tools, that results in fuel leakage. Compliance shall be checked using test

probe 11 of IEC 61032 and a force of 9,8 N.

4.10.3.6 There shall be no leakage of fuel during storage, connection, disconnection or

transferring of fuel from the cartridge to the power unit.

4.11 Materials and construction – System

The fuel cell power unit when coupled to the fuel cartridge shall be designed and constructed

to avoid any credible risk of fire or explosion posed by the fuel cell power system itself or

gases, vapours, liquids or other substances produced or used by the fuel cell power system.

4.11.1 The maximum quantity of methanol stored in the fuel cell power unit shall not be more

than 200 ml.

4.11.2 The fuel cell power system shall be protected by means (e.g. ventilation, controlled

oxidation, operating temperatures higher than the auto-ignition temperature, etc.) in such a

way that leaking fuel from or inside the fuel cell power system cannot form explosive

concentrations. The design criteria for such means (e.g. required ventilation rate) shall be

provided by the fuel cell power system manufacturer. The means shall be provided either by

the fuel cell power system manufacturer or by the manufacturer of the device powered by the

fuel cell power system.

4.11.3 Components and materials inside the fuel cell power system shall be constructed or

shall make use of such materials that propagation of fire and ignition is mitigated. The

material flammability shall be such that a sustained fire will not be supported after electrical

power and the fuel and oxidant supply have been terminated. This may be demonstrated

through the selection of materials meeting FV 0, FV 1 or FV 2 in accordance with

IEC 60695-1-1.

4.11.4 Exemptions

4.11.4.1 Membranes, or other materials within the fuel cell stack volume which comprise

less than 10 % of the total fuel cell stack mass, are considered to be of limited quantity and

are permissible without flame-spread ratings.

4.11.4.2 If the actual temperature in any location of the fuel cell power system, where a

flammable mixture may occur, is higher than the auto-ignition temperature, leakage of fuel

into the oxidant or vice versa results in immediate oxidation of the flammable fuel. Thus, it is

obvious that no major concentrations of explosive gases can accumulate. Whenever this

temperature of such high-temperature fuel cells is lower than the auto-ignition temperature,

the fuel cell power system shall be transferred into a safe state.

4.12 Ignition sources

To prevent a fire or explosion hazard within the fuel cell power system, the manufacturer shall

eliminate potential ignition source(s) within areas where fuel is present (or can be potentially

released) by ensuring that

• the surface temperatures shall not exceed 80 % of the auto-ignition temperature,

expressed in °C, of the flammable gas or vapour;

• equipment containing materials capable of catalysing the reaction of flammable fluids with

air shall be capable of suppressing the propagation of the reaction from the equipment to

the surrounding flammable atmosphere;

• electrical equipment, if subject to contact with fuel, is suitable for the area in which it is

installed.

PAS 62282-6-1 © IEC:2006(E) – 15 –

4.13 Enclosures and acceptance strategies

A fire enclosure is required when temperatures of parts under fault conditions could be

sufficient for ignition.

4.13.1 Parts requiring a fire enclosure

Except where Method 2 of 4.7.1 of IEC 60950-1 is used exclusively, or as permitted in 4.7.2.2

of IEC 60950-1, the following are considered to have a risk of ignition and, therefore, require

a fire enclosure.

4.13.1.2 Components in circuits supplied by limited power sources as specified in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...