IEC 62679-3-2:2013

(Main)Electronic paper display - Part 3-2: Measuring method - Electro-optical

Electronic paper display - Part 3-2: Measuring method - Electro-optical

IEC 62679-3-2:2013 is restricted to electronic paper display modules using either segment, passive, or active matrix, and either monochromatic, or colour type displays. In order to achieve a useful and uniform description of the performance of these devices, specifications for commonly accepted relevant parameters are put forward. The purpose of IEC 62679-3-2 is to indicate and list the procedure-dependent parameters and to prescribe the specific methods and conditions that are to be used for their uniform numerical determination.

Afficheur de papier électronique - Partie 3-2: Méthode de mesure - Electro-optique

La CEI 62679-3-2:2013 est limitée aux modules d'affichage de papier électronique utilisant des écrans soit à segments, soit à matrice passive ou active et monochromatiques ou couleurs. Pour obtenir une description utile et uniforme des performances de ces dispositifs, des spécifications des paramètres pertinents et couramment acceptés sont fournies. L'objectif de la CEI 62679-3-2 est d'indiquer et d'énumérer les paramètres qui dépendent de la procédure, ainsi que de prescrire les méthodes et conditions spécifiques à utiliser pour en obtenir une détermination numérique uniforme.

General Information

- Status

- Published

- Publication Date

- 08-Sep-2013

- Technical Committee

- TC 110 - Electronic displays

- Drafting Committee

- WG 7 - TC 110/WG 7

- Current Stage

- PPUB - Publication issued

- Start Date

- 09-Sep-2013

- Completion Date

- 15-Sep-2013

Overview

IEC 62679-3-2:2013 is an international standard developed by the International Electrotechnical Commission (IEC) that defines the electro-optical measuring methods for electronic paper display (EPD) modules. This standard specifically applies to electronic paper displays utilizing segment, passive, or active matrix configurations, and encompasses both monochromatic and color types.

The purpose of this standard is to provide a uniform and reproducible procedure for measuring key electro-optical parameters of electronic paper displays. By specifying the exact measurement conditions and methods, it ensures consistent performance evaluation across different devices and manufacturers. IEC 62679-3-2 is part of the IEC 62679 series focusing on electronic paper displays.

Key Topics

Scope and Application: The standard covers measuring procedures for electronic paper display modules under normal operating conditions as experienced by end-users. It excludes any externally attached components such as touch panels or front-light units unless removal is impossible.

Measuring Equipment:

- Luminance meters calibrated according to the CIE 1931 photopic response V(λ) function, including spectro-radiometers or photometers with appropriate filters.

- Colorimeters such as spectro-radiometers or filter colorimeters used for accurate color evaluation.

Measurement Locations:

- For matrix displays, the standard specifies 25 spatial sampling points (P0 to P24) evenly distributed across the display active area.

- These measurement points help assess uniformity and consistency of electro-optical properties throughout the screen.

Measurement Parameters:

- Initial reflectance and luminance of the electronic paper display.

- Electro-optical response time and frame response.

- Electrical characteristics including rewriting electric energy.

- Image retention duration and power consumption during image retention.

Conditions and Procedures:

- The standard requires measurements to be performed by skilled personnel using calibrated equipment.

- All tests should emulate the display’s usual operating environment reflecting realistic usage patterns.

- Specific driving signals and measurement timelines are prescribed to ensure comparability.

Applications

IEC 62679-3-2:2013 plays a critical role in the design, testing, and quality assurance of electronic paper displays, which are increasingly used in:

E-Readers and Digital Notepads: Devices requiring sharp, low-power displays with high readability under various lighting conditions.

Electronic Shelf Labels: Retail applications where accurate reflectance and color consistency impact customer experience.

Wearable Devices and Smart Cards: Where low power consumption and reliable image retention over time are essential.

Industrial and Medical Displays: Areas demanding dependable, uniform display performance under diverse operational parameters.

Manufacturers benefit from IEC 62679-3-2 by having a standardized method to evaluate product performance and compare devices objectively. End-users are assured of consistent display quality, durability, and energy efficiency.

Related Standards

IEC 62679-3-2:2013 is part of the broader IEC 62679 series on electronic paper displays, designed to cover multiple aspects including:

Part 3-1: Future standards addressing illumination and optical measurement techniques for EPDs.

Other Parts of IEC 62679: Covering component specifications, environmental testing, and electrical interfaces.

Additionally, related standards in electronics and display technologies include:

IEC 62341 Series: For OLED displays and performance measurements.

ISO/CIE Standards: For color measurement and photometric functions.

The collaboration between IEC and ISO ensures harmonization across global standardization efforts in electronic display technologies.

By adhering to IEC 62679-3-2 measurement methods, stakeholders ensure precise, reliable, and internationally recognized evaluation of electronic paper display modules’ electro-optical performance, fostering innovation and quality in electronic display products.

Frequently Asked Questions

IEC 62679-3-2:2013 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Electronic paper display - Part 3-2: Measuring method - Electro-optical". This standard covers: IEC 62679-3-2:2013 is restricted to electronic paper display modules using either segment, passive, or active matrix, and either monochromatic, or colour type displays. In order to achieve a useful and uniform description of the performance of these devices, specifications for commonly accepted relevant parameters are put forward. The purpose of IEC 62679-3-2 is to indicate and list the procedure-dependent parameters and to prescribe the specific methods and conditions that are to be used for their uniform numerical determination.

IEC 62679-3-2:2013 is restricted to electronic paper display modules using either segment, passive, or active matrix, and either monochromatic, or colour type displays. In order to achieve a useful and uniform description of the performance of these devices, specifications for commonly accepted relevant parameters are put forward. The purpose of IEC 62679-3-2 is to indicate and list the procedure-dependent parameters and to prescribe the specific methods and conditions that are to be used for their uniform numerical determination.

IEC 62679-3-2:2013 is classified under the following ICS (International Classification for Standards) categories: 31.120 - Electronic display devices; 31.260 - Optoelectronics. Laser equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62679-3-2:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62679-3-2 ®

Edition 1.0 2013-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronic paper display –

Part 3-2: Measuring method – Electro-optical

Afficheur de papier électronique –

Partie 3-2: Méthode de mesure – Electro-optique

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et les

microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

Useful links:

IEC publications search - www.iec.ch/searchpub Electropedia - www.electropedia.org

The advanced search enables you to find IEC publications The world's leading online dictionary of electronic and

by a variety of criteria (reference number, text, technical electrical terms containing more than 30 000 terms and

committee,…). definitions in English and French, with equivalent terms in

It also gives information on projects, replaced and additional languages. Also known as the International

withdrawn publications. Electrotechnical Vocabulary (IEV) on-line.

IEC Just Published - webstore.iec.ch/justpublished Customer Service Centre - webstore.iec.ch/csc

Stay up to date on all new IEC publications. Just Published If you wish to give us your feedback on this publication

details all new publications released. Available on-line and or need further assistance, please contact the

also once a month by email. Customer Service Centre: csc@iec.ch.

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

Liens utiles:

Recherche de publications CEI - www.iec.ch/searchpub Electropedia - www.electropedia.org

La recherche avancée vous permet de trouver des Le premier dictionnaire en ligne au monde de termes

publications CEI en utilisant différents critères (numéro de électroniques et électriques. Il contient plus de 30 000

référence, texte, comité d’études,…). termes et définitions en anglais et en français, ainsi que

Elle donne aussi des informations sur les projets et les les termes équivalents dans les langues additionnelles.

publications remplacées ou retirées. Egalement appelé Vocabulaire Electrotechnique

International (VEI) en ligne.

Just Published CEI - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications de la CEI.

Just Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur

Disponible en ligne et aussi une fois par mois par email. cette publication ou si vous avez des questions

contactez-nous: csc@iec.ch.

IEC 62679-3-2 ®

Edition 1.0 2013-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Electronic paper display –

Part 3-2: Measuring method – Electro-optical

Afficheur de papier électronique –

Partie 3-2: Méthode de mesure – Electro-optique

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX T

ICS 31.120; 31.260 ISBN 978-2-8322-1044-4

– 2 – 62679-3-2 © IEC:2013

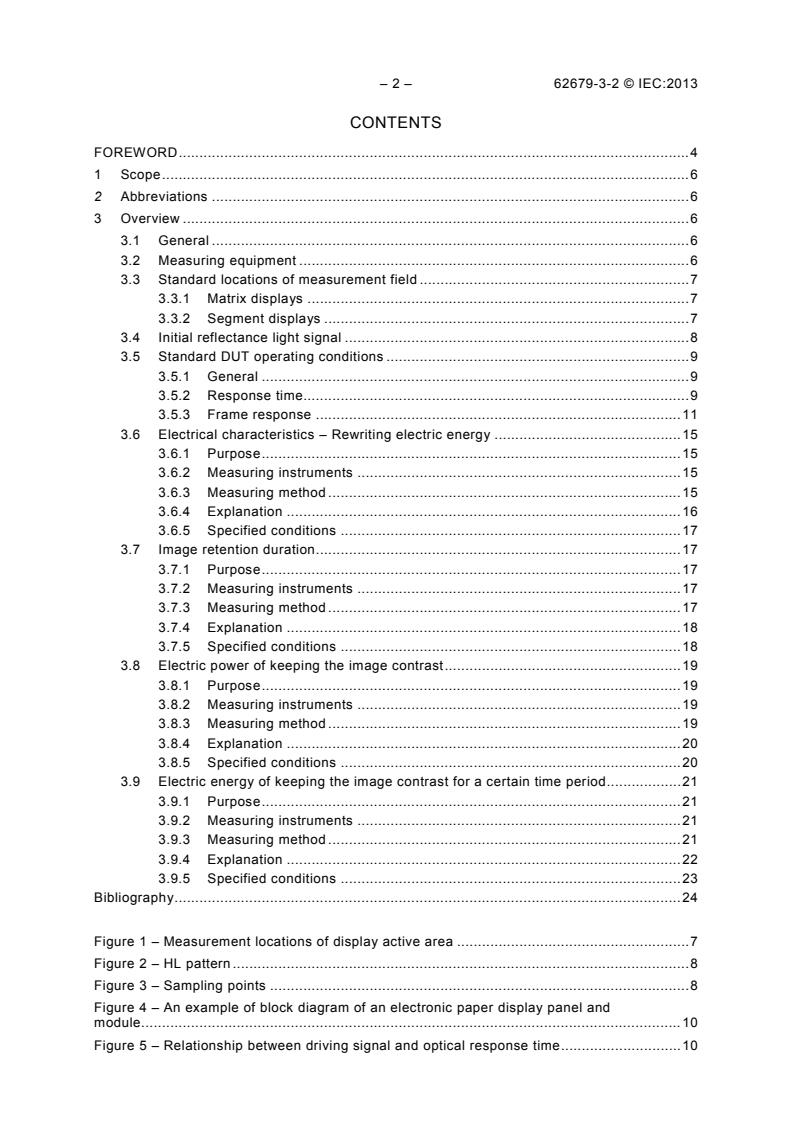

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Abbreviations . 6

3 Overview . 6

3.1 General . 6

3.2 Measuring equipment . 6

3.3 Standard locations of measurement field . 7

3.3.1 Matrix displays . 7

3.3.2 Segment displays . 7

3.4 Initial reflectance light signal . 8

3.5 Standard DUT operating conditions . 9

3.5.1 General . 9

3.5.2 Response time. 9

3.5.3 Frame response . 11

3.6 Electrical characteristics – Rewriting electric energy . 15

3.6.1 Purpose . 15

3.6.2 Measuring instruments . 15

3.6.3 Measuring method . 15

3.6.4 Explanation . 16

3.6.5 Specified conditions . 17

3.7 Image retention duration . 17

3.7.1 Purpose . 17

3.7.2 Measuring instruments . 17

3.7.3 Measuring method . 17

3.7.4 Explanation . 18

3.7.5 Specified conditions . 18

3.8 Electric power of keeping the image contrast . 19

3.8.1 Purpose . 19

3.8.2 Measuring instruments . 19

3.8.3 Measuring method . 19

3.8.4 Explanation . 20

3.8.5 Specified conditions . 20

3.9 Electric energy of keeping the image contrast for a certain time period . 21

3.9.1 Purpose . 21

3.9.2 Measuring instruments . 21

3.9.3 Measuring method . 21

3.9.4 Explanation . 22

3.9.5 Specified conditions . 23

Bibliography . 24

Figure 1 – Measurement locations of display active area . 7

Figure 2 – HL pattern . 8

Figure 3 – Sampling points . 8

Figure 4 – An example of block diagram of an electronic paper display panel and

module . 10

Figure 5 – Relationship between driving signal and optical response time . 10

62679-3-2 © IEC:2013 – 3 –

Figure 6 – An example of driving signal and frame response time (segment) . 13

Figure 7 – An example of driving signal and frame response time (matrix) . 14

Figure 8 – Checkerboard pattern . 16

Figure 9 – An example of block diagram for measuring the rewriting electric energy of

an electronic paper display module . 16

Figure 10 – Temporal characteristics of contrast ratio . 18

Figure 11 – Image contrast and driving mode. 19

Figure 12 – Image contrast, driving mode and measuring period . 22

– 4 – 62679-3-2 © IEC:2013

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

ELECTRONIC PAPER DISPLAY –

Part 3-2: Measuring method –

Electro-optical

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62679-3-2 has been prepared by IEC technical committee 110:

Electronic display devices.

The text of this standard is based on the following documents:

FDIS Report on voting

110/475/FDIS 110/502/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

A list of all parts in the IEC 62679 series, published under the general title Electronic paper

display, can be found on the IEC website.

62679-3-2 © IEC:2013 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – 62679-3-2 © IEC:2013

ELECTRONIC PAPER DISPLAY –

Part 3-2: Measuring method –

Electro-optical

1 Scope

This part of IEC 62679 series is restricted to electronic paper display modules using either

segment, passive, or active matrix, and either monochromatic, or colour type displays.

In order to achieve a useful and uniform description of the performance of these devices,

specifications for commonly accepted relevant parameters are put forward.

The purpose of this part of IEC 62679 series is to indicate and list the procedure-dependent

parameters and to prescribe the specific methods and conditions that are to be used for their

uniform numerical determination.

2 Abbreviations

DUT – Device under test

LMD – Light measuring device

PWM – Pulse width modulation

3 Overview

3.1 General

It is intended that the future IEC 62679-3-1 will cover the proper illumination method and

optical measurement method to evaluate the electro-optical property of electronic paper

display modules.

If an electronic paper display module works in combination with an external touch-key-panel

or an external front-light-unit, remove those for measuring. If it is not possible to remove

these elements, this fact shall be mentioned. However, it is not necessary to mention the

protective sheet.

It is assumed that all measurements are performed by personnel skilled in the general art of

radiometric and electrical measurements as the purpose of this paper is not to give a detailed

account of good practice in electrical and optical experimental physics. Furthermore, it is

necessary to ensure that all equipment is suitably calibrated as is known to skilled personnel

and that records of the calibration data and traceability are kept.

It is assumed that all measurements are performed under normal operation conditions as

used in the finished product by the end user unless requested otherwise. This includes the

driving signals (waveforms) of the electronic paper display panel and/or module.

NOTE An electronic paper display module consists of an electronic paper display panel (electro-optical material,

back plane, and driving circuit) and a logic circuit (see Figure 4).

3.2 Measuring equipment

Luminance meter: the devices for measuring luminance can be realized by

• a spectro-radiometer with numerical V(λ) correction

62679-3-2 © IEC:2013 – 7 –

• a photometer with filter adaption to V(λ)

where V(λ) is the photopic response, as defined by the CIE 1931 standard observer in

CIE/ISO 10527:1991.

Colorimeter: devices for measuring colour can be realized by

• spectro-radiometer with numerical evaluation (spectrophotometer),

• filter-colorimeter

3.3 Standard locations of measurement field

3.3.1 Matrix displays

P23 P24 P9 P10 P11

P22 P8 P1 P2 P12

P21 P7 P0 P3 P13

P20 P6 P5 P4 P14

P19 P18 P17 P16 P15

(1/10)H

(3/10)H

(5/10)H

IEC 2137/13

NOTE Standard measurement positions are at the centres of all rectangles P0 to P24. Height and width of each

rectangle are 20 % of display active area height and width respectively.

Figure 1 – Measurement locations of display active area

Luminance, spectral distribution and/or tristimulus measurements may be taken at several

specified positions on the DUT surface. To this end, the front view of the display is divided

into 25 identical imaginary rectangles (see Figure 1). Unless otherwise specified,

measurements are carried out in the centre of each rectangle. Care shall be taken that the

measuring spots on the display do not overlap. Positioning of the measuring spot on the thus

prescribed positions in the x and y axis shall be to within 7 % of V and H respectively (where

V and H denote the length of the display active area in the x and y axis respectively).

While scanning the position of the measuring spot over the surface of the DUT, the polar

angles shall stay fixed.

Any deviation from the above-described standard positions shall be added to the detail

specification.

3.3.2 Segment displays

Standard measurement positions are the same as those prescribed for the matrix displays

above. However, for segment displays, all measurements shall be performed at the centre of

a segment and the chosen segment should be as close as possible to the centre of the

designated rectangle. Thus, when measurements on position Pi (i = 0 to 24) are requested,

(5/10)V

(3/10)V

(1/10)V

H

– 8 – 62679-3-2 © IEC:2013

the geometrical centre of the segment closest to the centre of box Pi should be used for

positioning of the detector.

Any deviation from the above-described standard positions shall be mentioned.

3.4 Initial reflectance light signal

Measuring method:

Send an HL pattern (see Figure 2) that has a 50 % cover ratio to an electronic paper display

module by using a pattern generator and a driving circuit. Stop driving that electronic paper

display module (do not send any command nor data). Select one proper physical condition of

lighting and measuring method. Measure 5 points each (see Figure 3) in both areas of high

and low reflected optical signal. Calculate the average of those 5 points to obtain the initial

reflectance of Ref and Ref . Calculate the initial contrast, CR , from Ref and Ref .

max min i max min

CR = Ref /Ref

i min max

IEC 2138/13

The 'black' area shall have the lowest reflected optical signal while the 'white' area shall have the highest reflected

optical signal.

Figure 2 – HL pattern

Sampling point

1/8V 1/8V 1/8V 1/8V 1/8V 1/8V 1/8V 1/8V

½ V ½ V

IEC 2139/13

Figure 3 – Sampling points

¼H ¼H ¼H ¼H

62679-3-2 © IEC:2013 – 9 –

3.5 Standard DUT operating conditions

3.5.1 General

Depending on the physics of some electronic paper display module types, optical properties of

these modules vary with the direction of observation (i.e. viewing-direction). Therefore it

should be understood that for the determination of several of the parameters below, proper

(mechanical) control and specification of the viewing direction is necessary. The normal

viewing direction should be the default viewing direction, and the LMD aligned perpendicular

to the DUT surface, unless stated otherwise. For viewing direction dependence, the process

that will be described in IEC 62679-3-1 can be followed.

All light sources used for illumination of the DUT during the measurement shall be constant in

illuminance and spectrum at least over the time-period of measurements that are related to

each other in the evaluation (e.g. bright and dark state of a display for contrast evaluation).

The luminance or illuminance of the arrangement used for illumination of the DUT shall be

constant within ± 1 %, and shall not exhibit short-term fluctuations (e.g. ripple, PWM, etc.).

Measurements shall be started after the DUT, the source illumination, and measuring

instruments achieve stability. Constant and correct temperature of the DUT shall be verified.

The module being tested shall be physically prepared for testing. It should be thermostatically

controlled for stable operation during a specified period being less than one hour. If the

control period is less than one hour, stable temperature shall be verified. Testing shall be

conducted under nominal conditions of driving signal (voltage, current, waveform). Any

deviation from the standard device operation conditions shall be added to the detail

specification.

3.5.2 Response time

3.5.2.1 Purpose

This method is used for the determination of the time needed to change from high to low

reflected optical signal (light to dark) or from low to high reflected optical signal (dark to light)

by application of the driving voltage.

By convention, the response of an electronic paper display module to an increase in driving

voltage is called ‘turn-high’ whereas the relaxation following a decrease of the driving voltage

is called ‘turn-low’. While this definition is straightforward in the case of segment- and low-

resolution displays, it is significantly more complicated in the case of high resolution matrix

displays, due to the complexity of data processing.

In order to measure a meaningful response time for the electronic paper display module, it is

recommended to evaluate a response time for the actual driving signal for an electronic paper

panel of that display. This requires having access to the electrical signal that is applied to the

electronic paper display panel.

3.5.2.2 Measurement equipment

An LMD with sufficient frequency response, a power supply, a driving signal generator, a

trigger signal generator, and a recorder.

3.5.2.3 Measurement method

The measurements are performed in the dark room under standard measuring conditions.

Drive the DUT according to the display driving method and measure the reflection-time

transition (see Figure 5). For segment display, drive only one segment. For matrix display,

drive multiple pixels at the same time.

– 10 – 62679-3-2 © IEC:2013

Driving power supply

Driving circuit

Logic circuit

Electronic paper display panel

Electronic paper display module

IEC 2140/13

Figure 4 – An example of block diagram of an electronic

paper display panel and module

T T

1 2

Y Y

T T

p1 p2

100% 100%

90% 90%

10% 10%

0% 0%

t t

t t

1 2

Driving Driving

Signal Signal

Driving Driving

for module for module

Driving Driving

for panel for panel

t t

IEC 2141/13

T – time from start of the module driving signal until panel reaches 10% of reflected optical signal

T – time from start of the module driving signal until panel reaches 90% of reflected optical signal

T – time from start of the panel driving signal until panel reaches 10% of reflected optical signal

p1

T – time from start of the panel driving signal until panel reaches 90% of reflected optical signal

p2

t – time needed to change the reflected optical signal of the panel from 90% to 10%

t – time needed to change the reflected optical signal of the panel from 10% to 90%

Figure 5 – Relationship between driving signal and optical response time

62679-3-2 © IEC:2013 – 11 –

a) Select one of the standard measuring systems and set the DUT.

b) Use the measurement circuits system as shown in Figure 4, and measure response time.

The electrical signal of the detector, which is positioned in the design-viewing direction at

position P0 (see Figure 1), is measured at the recorder. The display is driven by an invertible

plain field signal from a signal generator. Upon inverting, the signal goes from start level to

end level without displaying any intermediate level on the display. The frequency of inversion

shall be low enough to allow the display to obtain optical equilibrium in each of the two states.

A trigger signal is sent to the recorder upon inversion of the reflected optical signal at position

P0. The luminance meter measures the optical response. Ripples in the detected signal due

to effects that are not relevant (e.g. originating from the display frame-frequency) shall be

eliminated from the response. The reflected optical signal in the LIGHT mode is chosen as

100 % and in the DARK mode as 0 %.

3.5.2.4 Explanation

• The time from the start of the module driving signal until the panel reaches 90 % or 10 %

of the reflected optical signal is called ‘module response time’.

• The time from the start of the module driving signal until the panel reaches 10 % of the

reflected optical signal (from HIGH to LOW) is T .

• The time from the start of the module driving signal until the panel reaches 90 % of the

reflected optical signal (from LOW to HIGH) is T .

• The time from the start of the panel driving signal until the panel reaches 90 % or 10 % of

the reflected optical signal is called ‘panel response time’.

• The time from the start of the panel driving signal until the panel reaches 10 % (from HIGH

to LOW) of the reflected optical signal is T .

p1

• The time from the start of the panel driving signal until the panel reaches 90 % (from LOW

to HIGH) of the reflected optical signal is T .

p2

• The time needed to change the reflected light signal of the panel from 90 % to 10 % or

from 10 % to 90 % is called ‘fall time’,t or ‘rise time’,t .

1 2

NOTE 0 % is the minimum reference reflected optical signal level, and 100% is the maximum reference reflected

optical signal.

3.5.2.5 Specified conditions

The records of the measurement shall be made to describe deviations from the standard

measurement conditions and include the following information:

• selected standard measuring system and its related conditions;

• driving signals (waveforms, voltage);

• measurement equipment and detector specifications;

• if not measuring the ‘panel response time’, note that.

3.5.3 Frame response

3.5.3.1 Purpose

This method is used for the assessment of the frame response time of both segment and

matrix electronic paper display modules. This response includes any stabilization period used

by the device after the initial leading edge of the drive signal to create the frame.

3.5.3.2 Measurement equipment

Same as in 3.5.2.2.

– 12 – 62679-3-2 © IEC:2013

3.5.3.3 Measurement method

Measure the transition period from the displaying of the highest to the lowest reflected optical

signal, and the lowest to the highest reflected optical signal. If the DUT requires a certain kind

of process, such as a stabilizing process before writing the actual data to the DUT with a

certain signal, start measuring by inputting that signal (see Figure 6). Normally the driving

signals (waveforms) of the electronic paper display module are used. If these driving signals

include a preliminary process such as ‘Reset’ or ‘stabilization’ before writing the actual image

data to the module, start measuring the response times T or T from the start of that process.

1 2

For the matrix display, measure that period by changing pattern A to pattern B or pattern B to

pattern A (see Figure 7). The measuring location Pf is the last changed location in the

standard measuring locations shown in Figure 7.

Other measuring methods follow 3.5.2.3.

62679-3-2 © IEC:2013 – 13 –

Y

Y

100% 100%

90% 90%

10% 10%

0%

0%

t t

T

T

1 2

Driving Driving

signal signal

Driving Driving

t t

IEC 2142/13

Y

100%

90%

10%

0%

t

T

Driving

signal

Driving

t

With stabilizing process

Y

100%

90%

10%

0%

t

T

Driving

signal Driving

t

With stabilizing process

IEC 2143/13

Y – reflected optical signal

t – time

Figure 6 – An example of driving signal and frame response time (segment)

– 14 – 62679-3-2 © IEC:2013

Measuring point

Y

Y

100% 100%

Pattern A 90% 90%

10% 10%

0%

0%

t t

T

1 T

Driving Driving

signal signal

Pattern B Driving Driving

t t

Without stabilizing process

IEC 2144/13

Y

100%

90%

10%

0%

t

T

Driving

signal

Driving

t

With stabilizing process (HIGH->LOW)

Y

100%

90%

10%

0%

t

T

Driving

Signal

Driving

t

With stabilizing process (LOW->HIGH)

IEC 2145/13

Y – reflected optical signal

t – time

Figure 7 – An example of driving signal and frame response time (matrix)

3.5.3.4 Explanation

To change from the highest reflection to the lowest reflection, the time needed for the

reflected optical signal to change from 100 % to 10 % (T ) is measured. To change from the

62679-3-2 © IEC:2013 – 15 –

lowest reflection to the highest reflection, the time needed for the reflected optical signal to

change from 0 % to 90 % (T ) is measured.

If the driving signals (waveform) of the DUT include a preliminary process such as

‘stabilization’ or ‘Reset’ to change from the highest reflection to the lowest reflection, the time

needed for the reflected optical signal to change from 100 % to 10 % including reset time (T )

is measured, and to change the lowest reflection to the highest reflection, the time needed for

the reflected optical signal to change from 0 % to 90 % including reset time (T ) is measured.

When measuring T the 10% threshold has to be crossed in the direction from higher to lower

reflected optical signal, and when measuring T the 90% threshold has to be crossed in the

direction from lower to higher reflected optical signal, at the end of the stabilization period.

3.5.3.5 Specified condition

The records of the measurement shall be made to describe deviations from the standard

measurement conditions and include the following information:

• selected standard measuring system and its related conditions;

• driving signals (waveforms, voltage);

• measurement equipment and detector specifications;

• if use is made of the term switching-time or (dynamic) response time, explanation of use

shall be given in the detail specification and deviations from prescribed nomenclature in

3.5.3.4 shall be given when using other names for any of these times;

• if the DUT shows another transition during a changing state, show that transition, perform

a similar measurement and define T , T , t , and t accordingly;

1 2 1 2

• for a matrix display module, describe the location of Pl (the last changed location that

shows a transition).

3.6 Electrical characteristics – Rewriting electric energy

3.6.1 Purpose

This method is applied to the measurements of electric energy for an electronic paper display

module, especially rewriting.

3.6.2 Measuring instruments

Rewriting electric energy is measured by using an LMD (luminance meter or colorimeter), a

driving power supply, a driving circuit, a pattern generator, voltage meters with timestamp,

and current meters with timestamp.

3.6.3 Measuring method

The measurements are performed under the standard measuring conditions. Send a

checkerboard pattern that has a 50 % covering ratio (see Figure 8) by using a pattern

generator and a driving circuit (pattern A in Figure 8). Then, send a reversed checkerboard

pattern (pattern B in Figure 8). Measure the electric energy during changing (rewriting) from

pattern A to pattern B. Both pattern A and pattern B should have the same contrast ratio

measured by a standard method. The actual rewriting process is dependent on each display.

Using a measuring circuit (shown in Figure 9), measure the electric energy during rewriting

from pattern A to pattern B. Electric energy is measured by voltage V , V , current I , I and

1 2 1 2

duration t.

Testing shall be conducted under nominal conditions of driving signal (voltage, current,

waveform).

– 16 – 62679-3-2 © IEC:2013

PPatattterernn A A PPatattterernn B B

IEC 2146/13

Figure 8 – Checkerboard pattern

Driving power supply

V V GND

1 2

I t Current I t

1 2

V t

V t

Voltage

Logic circuit Driving circuit

Electronic paper display panel

IEC 2147/13

Key

I , I – current

1 2

V , V – voltage

1 2

Figure 9 – An example of block diagram for measuring

the rewriting electric energy of an electronic paper display module

3.6.4 Explanation

3.6.4.1 Rewriting electric energy

Rewriting electric energy for the electric paper display module in each circuit is calculated

using the following formulae:

t

The electric energy of logic circuit W = V I dt (1)

1 1 1

∫

62679-3-2 © IEC:2013 – 17 –

t

The electric energy of electronic paper display driving circuit W = V I dt (2)

2 2 2

∫

The total rewriting electronic energy in the display module W = W + W (3)

1 2

where

V is the voltage

I is the current

W is the electric energy

If the logic circuit and the driving circuit are not separated, measure the compound current,

the superposed voltage and the time to calculate the total rewriting electric energy. In this

case, note the use of that method.

3.6.4.2 Maximum electric energy for rewriting

Adjust the conditions for the electronic paper display module driving current and driving

voltage which are specified in the detailed specification for the maximum electric energy. In

these conditions, the measured individual and the total electric energy are defined as the

corresponding maximum electric energy.

3.6.5 Specified conditions

In case of measuring under non standard conditions, specify what that is, such as:

• measuring conditions, such as the physical condition of light source and/or receptacle,

and/or the related required detail information (such as angle of incidence);

• in case of using a non standard checkerboard pattern, because of a physical limitation of

display(s), note the detailed information about used pattern, size, covering ratio (black

ratio);

• in case measurements using pattern A and/or pattern B have a different contrast ratio (if

the contrast ratio of used pattern is not 100% black nor 100% white), note the contrast

ratio of those patterns and the measured electric energy.

3.7 Image retention duration

3.7.1 Purpose

This method is applied to the measurement of the image retention duration of an electronic

paper display module.

3.7.2 Measuring instruments

Image retention duration is measured by using an LMD (luminance meter or colorimeter), a

driving power supply, a driving circuit, a pattern generator, and a timer.

3.7.3 Measuring method

The measurements are performed under the standard measuring conditions.

not instantly but after a fixed waiting period, for example 3 s.

Measure CR

i

Set the electronic paper display module with either pattern A or pattern B under the standard

condition. Measure the time t when the contrast of that electronic paper display module

becomes 80 % of CR . If required, other durations such as t for 60 % of CR , or t for 40 %

i 60 i 40

can be used.

of CR

i

– 18 – 62679-3-2 © IEC:2013

NOTE To test the usability requirements, if possible, it can be useful to measure the time t when the electric

x

paper display becomes barely readable by visual evaluation.

Figure 10 shows the relationship between contrast CR , and duration t .

x x

Contrast ratio

CR 1,0

i

CR = 0,8 × CR 0,8

80 i

CR = 0,X × CR 0,X

x i

CR = 0,Y × CR 0,Y

y i

Time

t t t

80 X Y

IEC 2148/13

Figure 10 – Temporal characteristics of contrast ratio

3.7.4 Explanation

The image retention duration is measured by using the following methods:

Initial contrast CR = Ref / Ref (4)

i max min

80 % of CR CR = 0,8 × CR (5)

80 i

NOTE CR in Figure 10 is normalized.

Image retention period: t time period from the start to when the contrast of that electronic

paper display module becomes 80 % of Cr .

i

Image retention period: t time period from the start to when the contrast of that electronic

Y

paper display module becomes Y % of CR .

i

3.7.5 Specified conditions

In case of not following the standard measuring method, specify what that is, such as:

• measuring conditions, such as the physical condition of light source and/or receptacle,

and/or the related required detail information (such as angle of incident);

62679-3-2 © IEC:2013 – 19 –

• in case of using a non standard checkerboard pattern, because of a physical limitation of

display(s), note the detailed information about the said pattern, size, and cover ratio

(black ratio);

• if measured from several CR (because of the characteristics of measuring the electronic

i

paper display module), record each CR in conjunction with t , t , t for each CR ;

i 80 60 40 i

• measuring conditions and retention conditions (environmental),

• if t is not measurable (the electronic paper display module never reaches CR within a

80 80

reasonable period), measure at a much higher contrast ratio, such as 95% or 90% of CR ,

i

and note those, such as t or t .

95 90

3.8 Electric power of keeping the image contrast

3.8.1 Purpose

This method is applied to the measurement of the electric power to keep the image contrast.

3.8.2 Measuring instruments

The electric power of keeping the image contrast is measured by using an LMD (luminance

meter or colorimeter), a driving power supply, a pattern generator, a voltage meter with

timestamp, and a current meter with timestamp.

3.8.3 Measuring method

The measurement is performed under the standard measuring conditions. Write the standard

image pattern (Figure 8) by using driving signals and a pattern generator with the

measurement circuit in Figure 9. The initial contrast ratio is calculated from the measured

reflectance ratio and called CR . After a non driving duration send electronic signal(s) in order

i

to ensure that the electronic paper display module has the same contrast CR . Measure the

i

required electronic power and required duration. (See Figure 11)

Contrast Ratio

CR 1,0

i

CR = 0,8 × CR 0,8

80 i

Non driving

Driving Non driving

t t

h d

Time

IEC 2149/13

Figure 11 – Image contrast and driving mode

– 20 – 62679-3-2 © IEC:2013

3.8.4 Explanation

The electric power of keeping the image contrast is defined as the electric energy required to

keep an electronic paper display module at the initial contrast condition after holding the

image for a certain period. That power is measured by using the driving duration (t ), the

d

current and voltage in order to bring back the contrast to the initial contrast ratio (CR ), which

i

is gradually decayed with the image retention duration.

Measure the powers for each portion as in the following formulae, and sum up to the total

power.

Power for the logic circuit P =W / ( t + t ) (6)

1 1 h d

t

d

W = V I dt (7)

1 1 1

∫

Power for the driving circuit P =W / ( t + t ) (8)

2 2 h d

t

d

W = V I dt (9)

2 2 2

∫

Total power of the electronic paper display module P =P + P (10)

1 2

where

V is the voltage

I is the current

P is the power

W is the electric energy

If the power for the logic circuit and the driving circuit cannot be measured separately,

measure the total power consumption, and use that as the power of that electronic paper

display module.

3.8.5 Specified conditions

In case of not following the standard measuring method, specify what that is, such as:

• measuring conditions, such as the physical condition of the light source and/or receptacle,

and/or the related required detailed information (such as angle of incidence);

• in case of using a non standard checkerboard pattern, because of a physical limitation of

display(s), note the detailed information about the said pattern, size, and cover ratio (black

ratio);

values (because of characteristics of the measuring

• if measured from several CR

i

electronic paper display module), record each CR in conjunction with t , t , t for each

i 80 60 40

;

CR

i

• measuring conditions and holding conditions (environmental);

• if the electronic paper display module never reaches CR within a certain period, note

that.

62679-3-2 © IEC:2013 – 21 –

3.9 Electric energy of keeping the image contrast for a certain time period

3.9.1 Purpose

This method is applied to the measurement of electric energy to keep the image contrast for a

certain time period

3.9.2 Measuring instruments

The electric energy of keeping the image contrast for a certain time period is measured by

using an LMD (luminance meter or colorimeter), a driving power supply, a pattern generator, a

voltage meter, a current meter, and a timer.

3.9.3 Measuring method

The measurement is performed under the standard measuring conditions. Write the standard

image pattern (Figure 8) by using driving signals and a pattern generator with the

measu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...