IEC 62427:2007

(Main)Railway applications - Compatibility between rolling stock and train detection systems

Railway applications - Compatibility between rolling stock and train detection systems

Describes a procedure for mutual acceptance of rolling stock to run over specific routes. Describes the methods of measurement of interference currents, the methods of measurement of the susceptibility of train detection systems, the characterisation of traction power supplies and the procedure for acceptance. The result of the acceptance procedure is a structured justification document referred to as a "compatibility case".

Applications ferroviaires - Compatibilité entre matériel roulant et systèmes de détection de train

Décrit une procédure d'acceptation mutuelle des matériels roulants sur un itinéraire donné. Décrit les méthodes de mesure des courants d'interférence, les méthodes de mesure de la susceptibilité des systèmes de détection de train, la caractérisation des alimentations de traction ainsi que la procédure d'acceptation. Le résultat de cette procédure d'acceptation est un document de justification structuré appelé "dossier de compatibilité".

General Information

- Status

- Published

- Publication Date

- 17-Sep-2007

- Technical Committee

- TC 9 - Electrical equipment and systems for railways

- Current Stage

- DELPUB - Deleted Publication

- Start Date

- 04-Dec-2024

- Completion Date

- 29-Jul-2022

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62427:2007 is an international standard published by the International Electrotechnical Commission (IEC) that addresses the compatibility between rolling stock and train detection systems on railway networks. The standard establishes a systematic acceptance process ensuring that rolling stock operating on specific routes does not interfere with train detection systems installed on those routes.

This standard is critical for railway operators, rolling stock manufacturers, and infrastructure managers seeking to achieve safe and efficient train operations while avoiding electromagnetic interference issues. By defining procedures for measuring interference currents, assessing the susceptibility of detection systems, and characterizing traction power supplies, IEC 62427 facilitates mutual acceptance of rolling stock across different rail networks and countries.

Key Topics

Acceptance Process

IEC 62427 outlines a clear acceptance procedure involving multiple stakeholders to ensure rolling stock compatibility. This includes responsibilities, testing phases, compatibility analysis, and issuance of a formal "compatibility case" document certifying acceptance.Electromagnetic Compatibility (EMC)

The standard emphasizes the importance of evaluating electromagnetic interference caused by rail currents, electromagnetic fields, and differential voltages between train axles. It provides methods to measure and limit such interference to prevent false train detection or system failures.Characterization of Systems

Detailed characterization methodologies cover:- Train detection systems (track circuits, axle counters, wheel detectors) to evaluate their susceptibility and physical compatibility.

- Rolling stock electrical characteristics and interference emissions through defined test plans and measurements.

- Traction power supply systems (both DC and AC) and their impact on electromagnetic compatibility.

Testing and Analysis

Both laboratory simulations and on-site real railway tests are described to simulate worst-case interference scenarios, ensuring robust evaluation of compatibility.Documentation and Quality Management

The output of the acceptance process is a structured "compatibility case" that documents all analyses, results, and acceptance certificates. The standard integrates quality management practices to maintain consistency and traceability.

Applications

IEC 62427 provides practical value for:

Railway Operators and Infrastructure Managers

To evaluate and approve new or modified rolling stock for safe operation on existing routes without compromising train detection reliability.Rolling Stock Manufacturers

To design and test vehicles in compliance with electromagnetic compatibility requirements, facilitating cross-border acceptance and reducing retrofit costs.System Integrators and Testing Laboratories

For conducting standardized measurement and testing of interference currents and susceptibility parameters, ensuring interoperability.Regulators and Certification Bodies

For setting harmonized criteria and issuing acceptance certifications that conform to international best practices.

Implementation of IEC 62427 aids in overcoming technical barriers caused by diverse train detection technologies and power supply systems, especially in complex, multi-national railway environments.

Related Standards

IEC 62427 is connected to and complements other railway and electromagnetic compatibility standards including:

- EN 50238 – Railway applications focusing on electromagnetic compatibility, which IEC 62427 is based on.

- IEC 1747 – Guidelines addressing electromagnetic disturbances in railway environments.

- IEC Technical Committee 9 Standards – Covering electrical equipment and systems for railways, providing broader context in safety and interoperability.

- ISO/IEC Directives – Ensuring the alignment of IEC 62427 with international standardization processes and terminology.

For further research and applications, stakeholders should also refer to the IEC Electropedia for precise definitions related to railway electrotechnical terminology.

By adhering to IEC 62427:2007, the railway industry can enhance interoperability, improve safety margins, reduce costly modifications, and promote seamless train operations across different networks with reliable and compatible train detection systems.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

IEC 62427:2007 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Railway applications - Compatibility between rolling stock and train detection systems". This standard covers: Describes a procedure for mutual acceptance of rolling stock to run over specific routes. Describes the methods of measurement of interference currents, the methods of measurement of the susceptibility of train detection systems, the characterisation of traction power supplies and the procedure for acceptance. The result of the acceptance procedure is a structured justification document referred to as a "compatibility case".

Describes a procedure for mutual acceptance of rolling stock to run over specific routes. Describes the methods of measurement of interference currents, the methods of measurement of the susceptibility of train detection systems, the characterisation of traction power supplies and the procedure for acceptance. The result of the acceptance procedure is a structured justification document referred to as a "compatibility case".

IEC 62427:2007 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62427:2007 has the following relationships with other standards: It is inter standard links to IEC 62427:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

IEC 62427:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

IEC 62427

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Compatibility between rolling stock and train detection

systems

Applications ferroviaires – Compatibilité entre matériel roulant et systèmes de

détection de train

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by

any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either IEC or

IEC's member National Committee in the country of the requester.

If you have any questions about IEC copyright or have an enquiry about obtaining additional rights to this publication,

please contact the address below or your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de la CEI ou du Comité national de la CEI du pays du demandeur.

Si vous avez des questions sur le copyright de la CEI ou si vous désirez obtenir des droits supplémentaires sur cette

publication, utilisez les coordonnées ci-après ou contactez le Comité national de la CEI de votre pays de résidence.

IEC Central Office

3, rue de Varembé

CH-1211 Geneva 20

Switzerland

Email: inmail@iec.ch

Web: www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

ƒ Catalogue of IEC publications: www.iec.ch/searchpub

The IEC on-line Catalogue enables you to search by a variety of criteria (reference number, text, technical committee,…).

It also gives information on projects, withdrawn and replaced publications.

ƒ IEC Just Published: www.iec.ch/online_news/justpub

Stay up to date on all new IEC publications. Just Published details twice a month all new publications released. Available

on-line and also by email.

ƒ Electropedia: www.electropedia.org

The world's leading online dictionary of electronic and electrical terms containing more than 20 000 terms and definitions

in English and French, with equivalent terms in additional languages. Also known as the International Electrotechnical

Vocabulary online.

ƒ Customer Service Centre: www.iec.ch/webstore/custserv

If you wish to give us your feedback on this publication or need further assistance, please visit the Customer Service

Centre FAQ or contact us:

Email: csc@iec.ch

Tel.: +41 22 919 02 11

Fax: +41 22 919 03 00

A propos de la CEI

La Commission Electrotechnique Internationale (CEI) est la première organisation mondiale qui élabore et publie des

normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications CEI

Le contenu technique des publications de la CEI est constamment revu. Veuillez vous assurer que vous possédez

l’édition la plus récente, un corrigendum ou amendement peut avoir été publié.

ƒ Catalogue des publications de la CEI: www.iec.ch/searchpub/cur_fut-f.htm

Le Catalogue en-ligne de la CEI vous permet d’effectuer des recherches en utilisant différents critères (numéro de référence,

texte, comité d’études,…). Il donne aussi des informations sur les projets et les publications retirées ou remplacées.

ƒ Just Published CEI: www.iec.ch/online_news/justpub

Restez informé sur les nouvelles publications de la CEI. Just Published détaille deux fois par mois les nouvelles

publications parues. Disponible en-ligne et aussi par email.

ƒ Electropedia: www.electropedia.org

Le premier dictionnaire en ligne au monde de termes électroniques et électriques. Il contient plus de 20 000 termes et

définitions en anglais et en français, ainsi que les termes équivalents dans les langues additionnelles. Egalement appelé

Vocabulaire Electrotechnique International en ligne.

ƒ Service Clients: www.iec.ch/webstore/custserv/custserv_entry-f.htm

Si vous désirez nous donner des commentaires sur cette publication ou si vous avez des questions, visitez le FAQ du

Service clients ou contactez-nous:

Email: csc@iec.ch

Tél.: +41 22 919 02 11

Fax: +41 22 919 03 00

IEC 62427

Edition 1.0 2007-09

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Railway applications – Compatibility between rolling stock and train detection

systems

Applications ferroviaires – Compatibilité entre matériel roulant et systèmes de

détection de train

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

X

CODE PRIX

ICS 45.060 ISBN 2-8318-9309-7

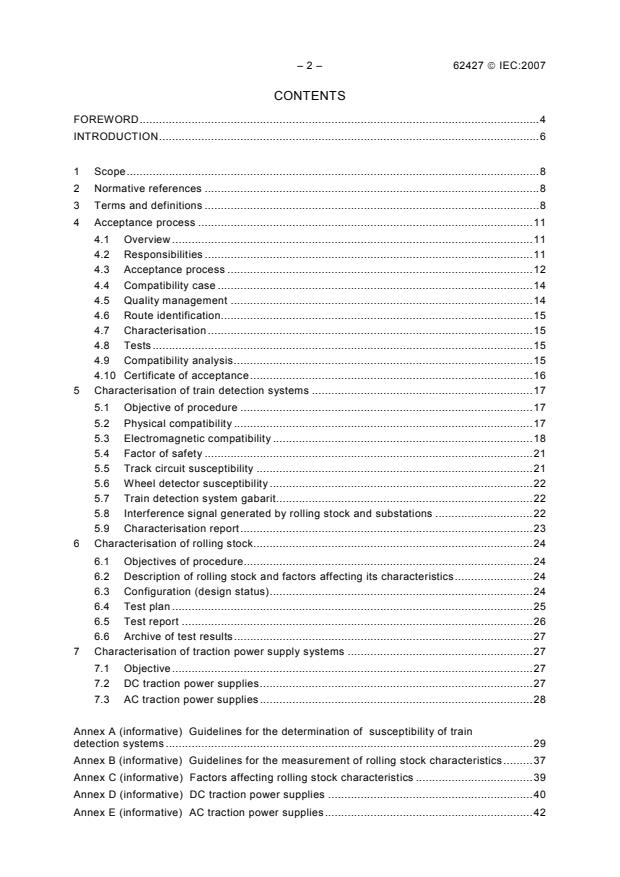

– 2 – 62427 © IEC:2007

CONTENTS

FOREWORD.4

INTRODUCTION.6

1 Scope.8

2 Normative references .8

3 Terms and definitions .8

4 Acceptance process .11

4.1 Overview .11

4.2 Responsibilities .11

4.3 Acceptance process .12

4.4 Compatibility case .14

4.5 Quality management .14

4.6 Route identification.15

4.7 Characterisation .15

4.8 Tests.15

4.9 Compatibility analysis.15

4.10 Certificate of acceptance.16

5 Characterisation of train detection systems .17

5.1 Objective of procedure .17

5.2 Physical compatibility .17

5.3 Electromagnetic compatibility .18

5.4 Factor of safety .21

5.5 Track circuit susceptibility .21

5.6 Wheel detector susceptibility .22

5.7 Train detection system gabarit.22

5.8 Interference signal generated by rolling stock and substations .22

5.9 Characterisation report.23

6 Characterisation of rolling stock.24

6.1 Objectives of procedure.24

6.2 Description of rolling stock and factors affecting its characteristics.24

6.3 Configuration (design status).24

6.4 Test plan .25

6.5 Test report .26

6.6 Archive of test results.27

7 Characterisation of traction power supply systems .27

7.1 Objective.27

7.2 DC traction power supplies.27

7.3 AC traction power supplies .28

Annex A (informative) Guidelines for the determination of susceptibility of train

detection systems .

Annex B (informative) Guidelines for the measurement of rolling stock characteristics.37

Annex C (informative) Factors affecting rolling stock characteristics .39

Annex D (informative) DC traction power supplies .40

Annex E (informative) AC traction power supplies.42

62427 © IEC:2007 – 3 –

Bibliography.45

Figure 1 – Sources of electromagnetic interference .6

Figure 2 – Parties concerned in the acceptance process.11

Figure 3 – Acceptance process .13

Figure 4 – Relationship between gabarit and permissible interference .16

Figure A.1 – Interference mechanism with rails intact .29

Figure A.2 – Interference mechanism with self-revealing broken rail .29

Figure A.3 – Interference mechanism with unrevealed broken rail.30

Figure A.4 – Double rail track circuit .30

Figure A.5 – Double rail track circuit with broken rail.31

Figure A.6 – Interference mechanism due to voltage between axles – Case 1.31

Figure A.7 – Interference mechanism due to voltage between axles – Case 2.32

Figure A.8 – Effect of inter-vehicle current .32

Figure A.9 – Equivalent circuit for Figure A.8 .33

Figure A.10 – Example of radiated interference .34

Figure A.11 – Sensitive zone of wheel detectors .35

Figure B.1 – Example of a system for the measurement of interference currents.37

Figure D.1 – Rolling stock with DC supply.41

Figure D.2 – Circulation of interference current generated by rolling stock.41

Figure D.3 – Circulation of interference current generated by the substation.41

Figure E.1 – Rolling stock and AC supply without power converter .43

Figure E.2 – Rolling stock and AC supply with power converter .43

Figure E.3 – Circulation of interference current generated by rolling stock .43

Figure E.4 – Circulation of interference current generated by the substation.44

– 4 – 62427 © IEC:2007

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

RAILWAY APPLICATIONS –

COMPATIBILITY BETWEEN ROLLING STOCK

AND TRAIN DETECTION SYSTEMS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC provides no marking procedure to indicate its approval and cannot be rendered responsible for any

equipment declared to be in conformity with an IEC Publication.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62427 has been prepared by IEC technical committee 9: Electrical

equipment and systems for railways.

It was submitted to the National Committees for voting under the Fast Track Procedure as the

following documents:

FDIS Report on voting

9/1058/FDIS 9/1088/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This document is based on EN 50238.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

62427 © IEC:2007 – 5 –

The committee has decided that the contents of this publication will remain unchanged until

the maintenance result date indicated on the IEC web site under "http://webstore.iec.ch" in the

data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – 62427 © IEC:2007

INTRODUCTION

This Standard defines a process to obtain the assurance that specific rolling stock operating

on a specific route does not interfere with train detection systems installed on this route.

Compatibility problems between train detection systems and rolling stock are a significant

obstacle to cross-acceptance of rolling stock in Europe. Unfortunately it is not possible to

establish general rules for the maximum levels of interference allowed valid for every country.

This is due to the great diversity of rolling stock, power supply and return current systems,

and train detection systems installed in Europe. This diversity leads to consideration of the

problem of compatibility of rolling stock and train detection systems for specific routes to

avoid unnecessarily restrictive specifications.

Compatibility is determined by both physical and electromagnetic considerations. With regard

to EMC, the need is not for general values for maximum levels of interference permitted, but

for convenient methods by which to specify the level of interference allowed for operation on

specific routes.

Interference may be caused by

– rail currents,

– electromagnetic fields,

– differential voltage between axles,

as shown in Figure 1.

Feeder

station

Electromagnetic field Rail current

transfer functions transfer functions

Wheel

Track circuit Others

detector

IEC 1747/07

Figure 1 – Sources of electromagnetic interference

62427 © IEC:2007 – 7 –

In practice, the susceptibility of the system is determined by

– the sensitivity of individual components of the system,

– the application of the components, i.e. the configuration of the system.

Therefore the problems concerning track circuits and axle counters or wheel detection

systems will be considered separately.

For determining the susceptibility of train detection systems, laboratory/simulation testing

methods as well as methods to conduct tests on the “real railway” are proposed. Modelling

enables worst-case conditions to be simulated. In addition, particular test sites are used

because, from experience, they are known to provide the test evidence required. Then, taking

account of the experience of the railways, it is possible to establish a general method for

determining the susceptibility of train detection systems, described in this Standard.

Before measuring the interference level on rolling stock, a sufficient knowledge of the electric

circuit diagram of the power equipment is required, e.g. switching frequencies of on-board

static converters, type of regulation used for power converters, resonant frequency of each

filter, operating limits under high and low supply voltages, downgraded modes of operation,

etc.

– 8 – 62427 © IEC:2007

RAILWAY APPLICATIONS –

COMPATIBILITY BETWEEN ROLLING STOCK

AND TRAIN DETECTION SYSTEMS

1 Scope

This International Standard describes a procedure for mutual acceptance of rolling stock to

run over specific routes. It describes the methods of measurement of interference currents,

the methods of measurement of the susceptibility of train detection systems, the

characterisation of traction power supplies and the procedure for acceptance. The result of

the acceptance procedure is a structured justification document referred to as a “compatibility

case”, which documents the evidence that the conditions for compatibility have been satisfied.

The procedure is also applied to modifications of rolling stock, traction power supply or train

detection systems which are considered to affect compatibility.

The scope of the compatibility case is restricted to the demonstration of compatibility of rolling

stock with a train detection system’s characterisation (e.g. gabarit). Train detection system in

this standard refers only to a track circuit or those using wheel detector.

2 Normative references

The following referenced documents are indispensable for the application of this document.

For dated references, only the edition cited applies. For undated references, the latest edition

of the referenced document (including any amendments) applies.

IEC 62278, Railway applications – Specification and demonstration of reliability, availability,

maintainability and safety (RAMS)

IEC 60850, Railway applications – Supply voltages of traction systems

ISO/IEC 17025, General requirements for the competence of testing and calibration

laboratories

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

accepting body

body responsible for the evaluation of the compatibility case and the issue of a certificate of

acceptance. The authority is assigned by National Law.

3.2

compatibility case

a set of documents which records the evidence demonstrating the degree of compatibility

between rolling stock, traction power supplies and train detection systems for a specific route

or specific railway network

62427 © IEC:2007 – 9 –

3.3

certificate of acceptance

written autorisation from the accepting body that the compatibility case is acceptable to allow

the new or modified systems to enter service. Relations with legislation should be determined

nationally.

3.4

degraded modes

modes of operation in the presence of faults which have been anticipated in the design of the

rolling stock. Degraded modes will normally allow the rolling stock to complete its journey

3.5

gabarit

the maximum permissible levels of interference signal, with respect to frequencies and

duration, to which a train detection system may be exposed

3.6

railway infrastructure authority

the body responsible for the safety of the track and signalling systems

3.7

right side failure

failure of a signalling system which results in a more restrictive condition for the movement of

traffic than is appropriate

3.8

rolling stock operator

body responsible for the operation and maintenance of the rolling stock

3.9

wheel detector

sensor which detects the passage of a wheel. It may be used as part of an axle counter

system or as a treadle

3.10

wrong side failure

failure of a signalling system which results in a less restrictive condition for the movement of

traffic than is appropriate

3.11

factor of safety

margin between the level of per train emissions and actual susceptibility of track circuit. It

covers safety or availability depending on whether wrong side failure or right side failure

mechanism is considered.

3.12

signalling system

assembly of sub-systems, and components connected together in an organised way to

achieve specific signalling functionality, of which train detection is a particular sub-system,

referred to as ‘system’ in the context of this standard

3.13

rolling stock

general term covering all vehicles with or without motors. For the purposes of this standard

rolling stock is equivalent to influencing unit.

[IEV 811-02-01, modified]

– 10 – 62427 © IEC:2007

3.14

traction power supply system

3.14.1

(traction) substation

installation the main function of which is to supply a contact line system and at which the

voltage of a primary supply system, and in certain cases the frequency, is transformed to the

voltage and the frequency of the contact line

[IEC 62128-1]

3.14.2

(traction) switching station

installation from which electrical energy can be distributed to different feeding sections or

from which different feeding sections can be switched on and off or can be interconnected

[IEC 62128-1]

3.14.3

feeding section

section of the traction power supply system which may be isolated from other sections or

feeders of the system by means of switching devices

[IEC 62128-1]

3.14.4

feeder

electrical connection between the contact line and a substation or a switching station

[IEC 62128-1]

3.14.5

feeding point

point at which the feeders or line feeders are connected to the contact line

[IEC 62128-1]

3.14.6

contact line

a conductor system for supplying electric energy to vehicles through current-collecting

equipment

[IEV 811-33-01]

3.15

axle counter

a system using counting points with wheel detector and a counter which detects the

occupancy of a section of track by comparing the number of axles which enter the section with

the number of axles which leave the section, parity of the numbers being necessary to give a

clear indication

[IEV 821-03-41, modified]

3.16

susceptibility

the inability of a device, equipment or system to perform without degradation in the presence

of an electromagnetic disturbance

[IEV 161-01-21, modified]

62427 © IEC:2007 – 11 –

3.17

train detection

safe recognition of the presence or absence of any trains on a defined section of the track or

at a given point

[IEC 62290-1]

3.18

track circuit

an electrical circuit of which the rails of a track section form a part, with usually a source of

current connected at one end and a detection device at the other end for detecting whether

this track section is clear or occupied by a vehicle

NOTE In a continuous signalling system, the track circuit may be used to transmit information between the ground

and the train.

[IEV 821-03-01]

4 Acceptance process

4.1 Overview

The parties concerned in the acceptance process are shown in Figure 2.

Acceptance

Railway

Industry Other authorities

infrastructure

(signalling) or operators

authority

Laboratory

Compatibility

case

Rolling stock

Industry

operator

(rolling stock)

Laboratory

Acceptance

Accepting

certificate

body

IEC 1748/07

Figure 2 – Parties concerned in the acceptance process

4.2 Responsibilities

The responsibility for demonstrating compatibility between rolling stock, train detection and

traction power supply systems, and for maintaining it over the full life cycle of the equipment,

is shared between those parties responsible for the particular railway infrastructure and the

particular rolling stock. Specific responsibilities for a given compatibility case, including the

party taking the lead role, shall be assigned as per national practice. The documentation, in

the form of a compatibility case, shall be submitted to an accepting body, and shall be

reviewed when any modification is carried out.

– 12 – 62427 © IEC:2007

4.2.1 Railway infrastructure authority

For a defined route (the application of interest), the railway infrastructure authority should

characterise all train detection systems and the traction power supply system.

4.2.2 Rolling stock operator

The rolling stock operator should characterise the interference which may be generated and

propagated by the rolling stock.

4.2.3 Accepting body

The accepting body shall review submitted documents and as a result issue a certificate of

acceptance. As part of this process, the accepting body should ensure that the compatibility

case is reviewed by experts who are qualified in accordance with national practice to assess

and evaluate it.

4.3 Acceptance process

The acceptance process is summarised in Figure 3.

62427 © IEC:2007 – 13 –

Assign responsibilities and

1)

begin compatibility case

Characterisation of

Description of rolling

train detection

3)

2) stock Description of power

system

4)

supply system

5)

Theoretical analysis

Additional

information 6)

Test plan

and/or

measurements

No

Test plan approved

by accepting body?

Yes

Testing and test

7)

report

Mandatory action

Yes

More information

needed ?

No

Optional action

Yes

No

Can a compatibility

case be made?

Modify

Submission to Modify train

Modify

power

8)

accepting body detection

rolling

supply

system?

stock?

system?

Yes

Economic and technical comparison

More information

of available solutions : selection of

needed?

optimum solution

No

No No No

Acceptance with

Acceptance with

Unrestricted

permanent restrictions?

temporary restrictions?

acceptance?

Yes Yes Yes

Yes

More information

needed?

No

Temporary

9) Restricted No

Full acceptance 9)

9) 9)

acceptance

acceptance certificate

IEC 1749/07

Figure 3 – Acceptance process

– 14 – 62427 © IEC:2007

Notes of Figure 3.

No

Title References Responsible

1) Assign responsibilities and 4.4 Compatibility case To be agreed between the

begin compatibility case parties defined in 4.1

4.6 Route identification

2) Characterisation of train 4.7 Characterisation Infrastructure manager

detection system

5 Characterisation of train detection

systems

3) Description of rolling stock 4.7 Characterisation Rolling stock operator

6 Characterisation of rolling stock

4) Description of power supply 4.7 Characterisation Infrastructure manager

system

7 Characterisation of traction power

supply systems

5) Theoretical analysis 4.9 Compatibility analysis To be agreed between the

parties defined in 4.1

6) Test plan 4.8 Tests To be agreed between the

parties defined in 4.1

6.4 Test plan

7.2.1 Test procedure

7.3.1 Test procedure

7) Testing and test report 4.8 Tests To be agreed between the

parties defined in 4.1

6.5 Test report

8) Submission to accepting body To be agreed between the

parties defined in 4.1

9) Acceptance / No certificate 4.10 Certificate of acceptance Accepting body

4.4 Compatibility case

A compatibility case shall be prepared, including but not limited to, the following:

– scope of compatibility case;

– route identification;

– characterisation of train detection systems;

– characterisation of traction power supply system;

– characterisation of rolling stock;

– assumptions made;

– test report;

– evidence of quality management;

– related compatibility cases;

– assessment of compatibility.

The compatibility case shall be submitted to an accepting body for approval.

4.5 Quality management

Quality management systems shall be in place. The importance of configuration management

should be noted.

The configuration state of the relevant infrastructure and rolling stock (including maintenance

processes and schedules) shall be recorded and referenced within the compatibility case. Any

62427 © IEC:2007 – 15 –

subsequent changes to these configurations shall lead to an examination of the continued

validity of the compatibility case.

The organisation conducting the tests shall be able to demonstrate its competence in

accordance with recognised national practice to make measurements in a traction

environment. It should preferably be certified to ISO/IEC 17025, but in any case shall have a

documented quality system in accordance with a recognised standard.

In order to maintain objectivity (e.g. in the event that tests are being conducted by a

manufacturer on equipment of his own supply) the organisation conducting tests should be

subject to an audit by the accepting body.

4.6 Route identification

In order to accept a particular rolling stock in respect of a particular route or network, the

different types and applications of train detection systems and traction power supply systems

on the route and on adjacent routes which may be affected shall be identified. In addition to

the intended operational route(s), alternative route(s) which may be required in the event of

disruption to traffic shall also be considered.

4.7 Characterisation

The characteristics of the identified systems shall be obtained in accordance with the

following clauses:

– train detection systems: 5;

– rolling stock: 6;

– power supply system: 7.

4.8 Tests

A test plan shall be prepared to deliver the compatibility criteria as described in Figure 4 and

approved by the accepting body.

Tests shall be conducted in accordance with the test plan and a test report produced to

support the compatibility case.

4.9 Compatibility analysis

In general terms, it shall be demonstrated that the rolling stock characteristics for generated

and propagated interference comply with the train detection system gabarit, under defined

operating conditions, including degraded modes. Their relationship is shown in Figure 4. The

information flow may be in either direction depending on which system is to be changed.

– 16 – 62427 © IEC:2007

TRAIN DETECTION SYSTEM SUBSTATION ROLLING STOCK

Permissible

Equipment Transfer Permissible

interference

sensitivity function interference

per on-board

source

Factor of Summation

safety rules

Total

interference

from on-board

sources

Summation

rules

ROLLING STOCK

AND SUBSTATION

Compare

Total

Gabarit

interference

IEC 1750/07

Figure 4 – Relationship between gabarit and permissible interference

Additionally, the physical characteristics of the rolling stock shall be demonstrated to be

compatible with the train detection systems.

The compatibility analysis is mandatory and shall explain the technical principles which

ensure compatibility, including (or giving reference to) all supporting evidence e.g.,

calculations, test plans and results, etc.

The method of analysis of fault modes shall be agreed between the parties listed in 4.2. If the

parties consider it to be necessary, for complex systems, reference may be made to

subclauses 4.6 and 6.3 of IEC 62278.

4.10 Certificate of acceptance

The accepting body shall review the compatibility case and issue a certificate of acceptance

to the party requesting the change.

It is recognised that characterisation of interference generated and propagated by rolling

stock can be a time consuming process, which may require a significant amount of testing

during service operations in order to refine the characteristics. Therefore, provided that the

risks to all parties can be demonstrated to be acceptable, temporary acceptance may be

given prior to full acceptance. This also allows for the identification of contributory factors

which had been overlooked in the preparation of the compatibility case.

Any temporary acceptance shall be time limited and be provided for a specific agreed

purpose, whilst additional measures to identify interference and mitigate against possible

hazards should be implemented.

62427 © IEC:2007 – 17 –

In the event that the assessment identifies either a non-compliance with the existing gabarit,

or a worsening of the existing gabarit (e.g. higher susceptibility), such that rolling stock with

existing route acceptance becomes non-compliant, then the relevant Railway Infrastructure

Authorities and rolling stock operators shall jointly determine the modifications to

infrastructure and/or rolling stock to be made and initiate acceptance processes where

applicable. If modifications are not possible or are not carried out, permanent restrictions shall

be applied. Restrictions are usually controlled by the railway infrastructure manager

(authority) unless established otherwise by national practice.

5 Characterisation of train detection systems

5.1 Objective of procedure

To ensure the correct operation of train detection systems, their physical and electromagnetic

properties shall be checked against those of the rolling stock and the traction power supply

system.

5.2 Physical compatibility

5.2.1 Track circuits

Physical compatibility, including but not limited to the following aspects, shall be considered:

– minimum track circuit length;

– minimum train length;

– maximum and minimum distance between the first and last axle of a vehicle;

– characteristics of boundary definition of jointless track circuit;

– maximum speed of trains;

– response time of track circuits;

– shunt values of track circuits;

– shunt impedance of trains, and reliability of shunting in all service conditions including the

influence of brake shoes on the shunting impedance;

– axle loads of vehicles;

– axle spacing;

– body overhang;

– track characteristics;

– substations earthing arrangements.

5.2.2 Wheel detectors

Physical compatibility, including but not limited to the following aspects, shall be considered:

– wheel geometry;

– speed of trains;

– wheel material;

– equipment which may be mistaken for a wheel, e.g. track brakes or metal assemblies

which are mounted close to the rail head.

5.2.2.1 Wheel dimensions and material

Axle counters and treadles are generally specified to detect reliably wheel types used on main

line vehicles. Other vehicle types may require special settings of the wheel detectors.

– 18 – 62427 © IEC:2007

5.2.2.2 Interfering equipment

Equipment mounted within the immediate vicinity of the rail may interfere with the reliability of

wheel detection either by fouling mechanically or due to its electromagnetic properties (see

Annex A).

This aspect of compatibility shall be assessed by testing.

5.3 Electromagnetic compatibility

This subclause describes the measurement of the gabarit of the train detection system. It

defines the general approach to be adopted, but since every installation is different in detail, it

cannot describe the whole process exactly. The compatibility case shall cover all credible

configurations and parameters. Some examples of configuration and models are given in

Annex A.

The required measurements are as follows.

5.3.1 The sensitivity of the train detection system equipment (see 5.3.3.1 for track circuits;

5.3.4.1 for wheel detectors).

5.3.2 The “transfer function” relating the interference signal at the train detection system

equipment to the interference generated by the rolling stock (see 5.3.3.2 for track circuits;

5.3.4.2 for wheel detectors).

Let the transfer function be denoted by F.

Let the interference signal at the train detection system equipment be denoted by I .

TDS

Let the interference signal generated by the rolling stock be denoted by I .

RS

The interference signal is then:

I = F × I

TDS RS

Hence I = I / F

RS TDS

The maximum permissible interference signal at the train detection system equipment I

TDSmax

is determined by the sensitivity of the train detection system equipment. Let the total

permissible interference generated by rolling stock be denoted by I . Then:

RStot

I = I / F

RStot TDSmax

Where multiple sources may contribute to the total interference signal, the permissible

interference per source shall take this into account (see 5.8).

Note that the permissible interference signal will have two values determined by the following

criteria:

– the signal which may cause the train detection system to show clear when it is in fact

occupied (a wrong side failure, i.e. a matter of safety);

– the signal which may cause the train detection system to show occupied when it is in fact

clear (a right side failure, i.e. a matter of reliability). The effect on interlocking logic shall

however be considered.

62427 © IEC:2007 – 19 –

5.3.3 Track circuits

5.3.3.1 Sensitivity and susceptibility of equipment alone

The sensitivity of the track circuit equipment itself shall be determined. In general the

susceptibility of the receiver will be more significant than that of the transmitter and will be the

determining factor in the permissible level of interference; however the susceptibility of the

transmitter shall also be checked.

Where the sensitivity of the track circuit is adjustable, it shall be measured for all the relevant

settings and in particular for the worst case settings.

The susceptibility shall be determined as follows.

5.3.3.1.1 The parameters (amplitudes, frequencies and durations) of the voltage(s),

current(s) or electro-magnetic fields which may cause the receiver to be energised, in the

absence of a signal from the transmitter, such that a “track circuit unoccupied” indication is

given.

NOTE Some types of track circuit receivers which are designed to operate with an amplitude modulated signal

may also be energised by a combination of unmodulated frequencies, and some types of track circuit receivers

which are designed to operate with a frequency modulated signal may also be energised by one or more amplitude

modulated frequencies.

5.3.3.1.2 The parameters (amplitudes, frequencies and durations) of the additional voltages,

currents or electro-magnetic fields which may de-energise the receiver, or may influence the

output signal of the transmitter, such that a “track circuit occupied” indication is given.

The above information shall be obtained from the suppliers of the track circuit equipment. If it

is not available (for example in the case of an obsolete design) it shall be obtained by

laboratory measurements.

5.3.3.2 Transfer function of track circuit as installed

The transfer function of the installed track circuit with regard to interference current shall be

determined as follows.

5.3.3.2.1 Determine the electrical equivalent circuit of the track circuit and the traction power

supply system in so far as the latter may affect the track circuit. In doing this all relevant

conductors shall be considered, including catenaries or conductor rails, cross-bonded running

rails, return conductors, impedance bonds, booster transformers, earthed structures, earth

paths, etc. Normally the “worst case” transfer function will correspond to the maximum length

track circuit.

5.3.3.2.2 Set up the equivalent circuit using a real test site or a hardware or software model.

If a model is used it shall be verified by means of comparative site tests.

5.3.3.2.3 Measure the voltage or current at the track circuit equipment terminals resulting

from a current generated by the rolling stock. The transfer function is then the ratio of the

voltage at the track circuit equipment terminals to the interference current.

NOTE 1 The value of the transfer function will depend on the position of the train with respect to the track circuit.

The worst case value should be determined.

NOTE 2 If the train has two or more on-board sources, or is composed of electric multiple unit stock, or utilises

the rails for the return current path for auxiliary power supplies (see UIC 550), it may have to be represented by

more than one current source.

5.3.3.2.4 Repeat the above tests with fault conditions applied, for example broken rails,

broken cross-bonds and broken return conductors, examples of which are shown in Annex A

(see 4.9). The “worst case” transfer function is the ratio of the highest value of interference

– 20 – 62427 © IEC:2007

voltage at the track circuit equipment terminals observed under fault conditions

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...