prEN IEC 60695-5-2:2026

(Main)Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance of test methods

Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance of test methods

Preskušanje požarne ogroženosti - 5-2. del: Poškodbe zaradi korozijskega učinka izžarevanja ognja - Povzetek in relevantnost preskusnih metod

General Information

- Status

- Not Published

- Publication Date

- 09-Aug-2027

- Technical Committee

- CLC/SR 89 - Fire hazard testing

- Current Stage

- 4020 - Enquiry circulated - Enquiry

- Start Date

- 16-Jan-2026

- Due Date

- 31-Oct-2024

- Completion Date

- 16-Jan-2026

Overview

prEN IEC 60695-5-2:2026, titled Fire hazard testing – Part 5-2: Corrosion damage effects of fire effluent – Summary and relevance of test methods, is an essential standard developed by the International Electrotechnical Commission (IEC) with CENELEC involvement. It addresses the evaluation of the corrosive effects that fire effluents exert on materials, components, and electrotechnical products by summarizing established laboratory test methods. Assessing and mitigating corrosion caused by fire effluent is vital for ensuring the safety, performance, and longevity of electrical and electronic systems exposed to fire scenarios.

The standard is used widely across industries to guide the selection and implementation of test methods for understanding the risks of corrosion-related failures post-fire. It emphasizes the importance of linking laboratory test results to real-world fire situations and the relevance of each method for specific materials and product applications. This document is highly relevant for safety professionals, engineers, manufacturers of electrical equipment, test laboratories, and compliance authorities.

Key Topics

Assessment of Corrosivity

Summarizes and evaluates main test methods for determining the corrosivity of fire effluent, focusing on established international, national, and industry standards.Types of Test Methods

- Determination of halogen acid in combustion gases

- Evaluation of acidity and conductivity of combustion gas solutions

- Testing copper corrosion in compliance with ASTM D 2671

- Cone corrosimeter method to measure metal loss

Classification Criteria

Test methods are classified by:- Nature of the specimen (finished product or material sample)

- Physical fire model implemented

- Direct or indirect corrosivity measurement approach

Relevance and Usefulness

Provides guidance on the suitability and limitations of each test, helping product committees and engineers select appropriate test methods for their specific context.Repeatability and Reproducibility

Discusses available data and interlaboratory comparisons where applicable.

Applications

Product and Material Safety Assessment

Used by manufacturers to evaluate the fire corrosion risk of electrical and electronic products, including printed circuit boards, cables, and switchboards, to prevent post-fire failures.Compliance and Certification

Essential reference for achieving regulatory compliance with fire safety and material standards in Europe and internationally.Design and Material Selection

Assists design engineers in selecting materials with acceptable performance against corrosion from fire by-products.Laboratory Testing

Provides up-to-date, science-based procedures for laboratories conducting fire effluent corrosion testing, ensuring consistency and reliability of results.Industry Sectors

Valuable in sectors including electrical engineering, telecommunications, construction (building materials), transportation (rail, automotive, aerospace), and data centers.

Related Standards

For a comprehensive approach to fire hazard and corrosion testing, consider these associated standards:

- IEC 60695-4: Fire hazard testing – Terminology concerning fire tests

- IEC 60695-5-1: Corrosion damage effects of fire effluent - General guidance

- IEC 60754-1: Test for halogen acid gas evolved during combustion of cables

- IEC 60754-2: Tests on gases evolved during combustion of materials from cables - Determination of acidity (by pH measurement) and conductivity

- ASTM D 2671: Standard Test Methods for Heat-Shrinkable Tubing for Electrical Use

- ISO 13943: Fire safety – Vocabulary

Understanding and applying prEN IEC 60695-5-2 aids organizations in managing fire risk, ensuring robust performance of critical infrastructure, and supporting a safer built environment through the reliable assessment of corrosion damage due to fire effluent. For those working with electrotechnical products, adherence to this standard raises the bar for fire hazard testing and post-fire resilience.

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

NSF International

Global independent organization facilitating standards development and certification.

UL Solutions

Global safety science company with testing, inspection and certification.

Sponsored listings

Frequently Asked Questions

prEN IEC 60695-5-2:2026 is a draft published by CLC. Its full title is "Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance of test methods". This standard covers: Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance of test methods

Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance of test methods

prEN IEC 60695-5-2:2026 is classified under the following ICS (International Classification for Standards) categories: 13.220.99 - Other standards related to protection against fire; 19.020 - Test conditions and procedures in general; 29.020 - Electrical engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN IEC 60695-5-2:2026 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2026

Preskušanje požarne ogroženosti - 5-2. del: Poškodbe zaradi korozijskega učinka

izžarevanja ognja - Povzetek in relevantnost preskusnih metod

Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and

relevance of test methods

Ta slovenski standard je istoveten z: prEN IEC 60695-5-2:2026

ICS:

13.220.99 Drugi standardi v zvezi z Other standards related to

varstvom pred požarom protection against fire

19.020 Preskuševalni pogoji in Test conditions and

postopki na splošno procedures in general

29.020 Elektrotehnika na splošno Electrical engineering in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

89/1641/CDV

COMMITTEE DRAFT FOR VOTE (CDV)

PROJECT NUMBER:

IEC 60695-5-2 ED2

DATE OF CIRCULATION: CLOSING DATE FOR VOTING:

2026-01-16 2026-04-10

SUPERSEDES DOCUMENTS:

89/1614/CD, 89/1638/CC

IEC TC 89 : FIRE HAZARD TESTING

SECRETARIAT: SECRETARY:

Germany Mr Bernd Komanschek

OF INTEREST TO THE FOLLOWING COMMITTEES: HORIZONTAL FUNCTION(S):

TC 10,TC 14,TC 20,SC 22F,SC 23A,TC 46,TC 61,SC

86A,TC 99,TC 104,TC 112,SC 121A,ACOS

ASPECTS CONCERNED:

Safety

SUBMITTED FOR CENELEC PARALLEL VOTING NOT SUBMITTED FOR CENELEC PARALLEL VOTING

Attention IEC-CENELEC parallel voting

The attention of IEC National Committees, members of

CENELEC, is drawn to the fact that this Committee Draft

for Vote (CDV) is submitted for parallel voting.

The CENELEC members are invited to vote through the

CENELEC online voting system.

This document is still under study and subject to change. It should not be used for reference purposes.

Recipients of this document are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

Recipients of this document are invited to submit, with their comments, notification of any relevant “In Some

Countries” clauses to be included should this proposal proceed. Recipients are reminded that the CDV stage is the

final stage for submitting ISC clauses. (SEE AC/22/2007 OR NEW GUIDANCE DOC).

TITLE:

Fire hazard testing - Part 5-2: Corrosion damage effects of fire effluent - Summary and relevance

of test methods

PROPOSED STABILITY DATE: 2029

NOTE FROM TC/SC OFFICERS:

this electronic file, to make a copy and to print out the content for the sole purpose of preparing National Committee

positions. You may not copy or "mirror" the file or printed version of the document, or any part of it, for any other

purpose without permission in writing from IEC.

IEC CDV 60695-5-2 © IEC 2025

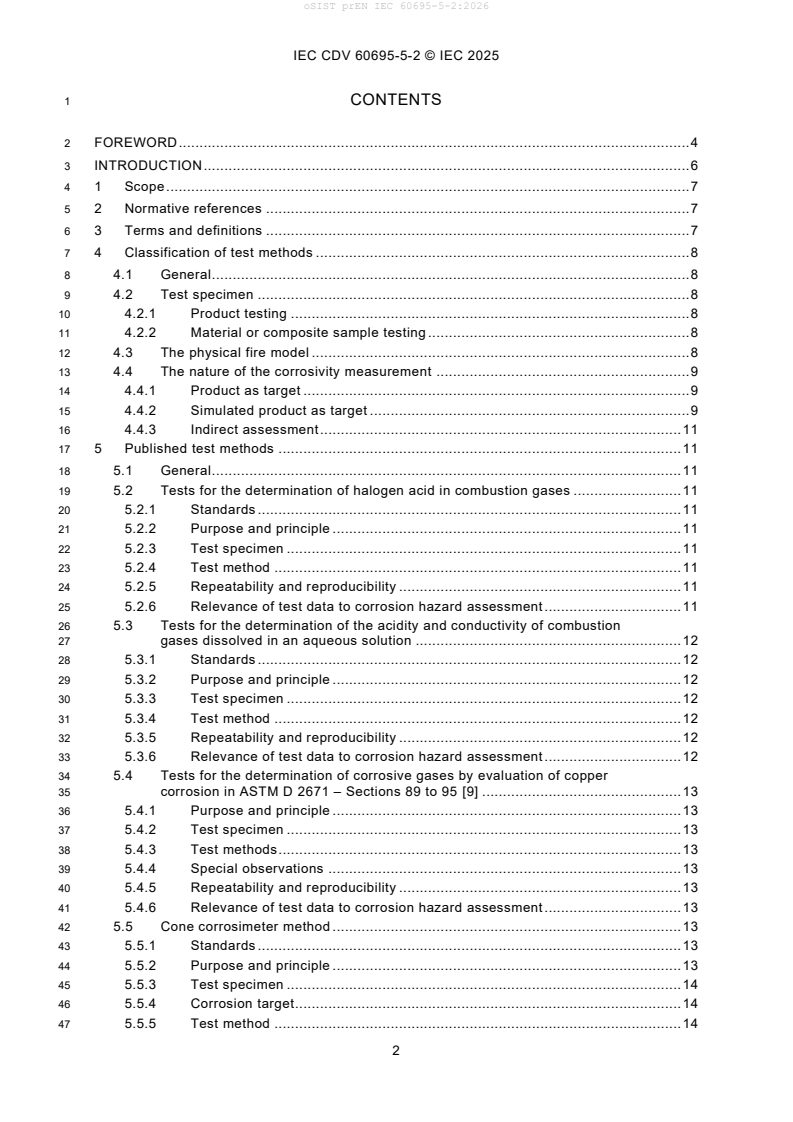

1 CONTENTS

2 FOREWORD . 4

3 INTRODUCTION . 6

4 1 Scope . 7

5 2 Normative references . 7

6 3 Terms and definitions . 7

7 4 Classification of test methods . 8

8 4.1 General . 8

9 4.2 Test specimen . 8

10 4.2.1 Product testing . 8

11 4.2.2 Material or composite sample testing . 8

12 4.3 The physical fire model . 8

13 4.4 The nature of the corrosivity measurement . 9

14 4.4.1 Product as target . 9

15 4.4.2 Simulated product as target . 9

16 4.4.3 Indirect assessment . 11

17 5 Published test methods . 11

18 5.1 General . 11

19 5.2 Tests for the determination of halogen acid in combustion gases . 11

20 5.2.1 Standards . 11

21 5.2.2 Purpose and principle . 11

22 5.2.3 Test specimen . 11

23 5.2.4 Test method . 11

24 5.2.5 Repeatability and reproducibility . 11

25 5.2.6 Relevance of test data to corrosion hazard assessment . 11

26 5.3 Tests for the determination of the acidity and conductivity of combustion

27 gases dissolved in an aqueous solution . 12

28 5.3.1 Standards . 12

29 5.3.2 Purpose and principle . 12

30 5.3.3 Test specimen . 12

31 5.3.4 Test method . 12

32 5.3.5 Repeatability and reproducibility . 12

33 5.3.6 Relevance of test data to corrosion hazard assessment . 12

34 5.4 Tests for the determination of corrosive gases by evaluation of copper

35 corrosion in ASTM D 2671 – Sections 89 to 95 [9] . 13

36 5.4.1 Purpose and principle . 13

37 5.4.2 Test specimen . 13

38 5.4.3 Test methods . 13

39 5.4.4 Special observations . 13

40 5.4.5 Repeatability and reproducibility . 13

41 5.4.6 Relevance of test data to corrosion hazard assessment . 13

42 5.5 Cone corrosimeter method . 13

43 5.5.1 Standards . 13

44 5.5.2 Purpose and principle . 13

45 5.5.3 Test specimen . 14

46 5.5.4 Corrosion target . 14

47 5.5.5 Test method . 14

IEC CDV 60695-5-2 © IEC 2025

48 5.5.6 Special observation . 15

49 5.5.7 Repeatability and reproducibility . 15

50 5.5.8 Relevance of test data to corrosion hazard assessment . 15

51 6 Overview of methods and relevance of data . 15

52 Annex A (informative) Acidity and conductivity of aqueous solutions – Test methods . 18

53 Annex B (informative) Determination of repeatability and reproducibility –

54 Comparative tests of solutions of combustion gases . 19

55 Bibliography . 23

57 Figure 1 – Schematic drawing of a typical corrosion target of defined metal thickness …….15

59 Table 1 – Characteristics of fire stages (from Table 1 in ISO 19706:2011) . 10

60 Table 2 – Overview of corrosivity test methods . 17

61 Table A.1 – Test methods for the measurement of acidity and conductivity of aqueous

62 solutions obtained after bubbling combustion effluent through water . 18

63 Table B.1 – Determination of repeatability and reproducibility – Comparative pH tests

64 on solutions of combustion gases . 20

65 Table B.2 – Determination of repeatability and reproducibility – Comparative resistivity

66 tests on solutions of combustion gases . 20

67 Table B.3 – Results obtained on brominated polycarbonate . 22

IEC CDV 60695-5-2 © IEC 2025

70 INTERNATIONAL ELECTROTECHNICAL COMMISSION

71 ____________

73 FIRE HAZARD TESTING –

75 Part 5-2: Corrosion damage effects of fire effluent –

76 Summary and relevance of test methods

78 FOREWORD

79 1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

80 all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

81 co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

82 in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

83 Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC Publication(s)”). Their

84 preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

85 may participate in this preparatory work. International, governmental and non-governmental organizations liaising

86 with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

87 Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

88 2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

89 consensus of opinion on the relevant subjects since each technical committee has representation from all

90 interested IEC National Committees.

91 3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

92 Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

93 Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

94 misinterpretation by any end user.

95 4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

96 transparently to the maximum extent possible in their national and regional publications. Any divergence between

97 any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

98 5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

99 assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

100 services carried out by independent certification bodies.

101 6) All users should ensure that they have the latest edition of this publication.

102 7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

103 members of its technical committees and IEC National Committees for any personal injury, property damage or

104 other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

105 expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

106 Publications.

107 8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

108 indispensable for the correct application of this publication.

109 9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

110 rights. IEC shall not be held responsible for identifying any or all such patent rights.

111 International Standard IEC 60695-5-2 has been prepared by IEC technical committee 89: Fire

112 hazard testing.

113 It has the status of a basic safety publication in accordance with IEC Guide 104 and

114 ISO/IEC Guide 51.

115 The text of this International Standard is based on the following documents:

FDIS Report on voting

89/XXXX/FDIS 89/YYYY/RVD

117 Full information on the voting for its approval can be found in the report on voting indicated in

118 the above table.

119 This document was drafted in accordance with ISO/IEC Directives, Part 2.

120 This International Standard is to be read in conjunction with IEC 60695-5-1.

IEC CDV 60695-5-2 © IEC 2025

121 A list of all parts in the IEC 60695 series, published under the general title Fire hazard testing,

122 can be found on the IEC website.

123 IEC 60695-5 consists of the following parts:

124 Part 5-1: Corrosion damage effects of fire effluent - General guidance

125 Part 5-2: Corrosion damage effects of fire effluent – Summary and relevance of test methods

126 The committee has decided that the contents of this document will remain unchanged until the

127 stability date indicated on the IEC website under webstore.iec.ch in the data related to the

128 specific document. At this date, the document will be

129 • reconfirmed,

130 • withdrawn,

131 • replaced by a revised edition, or

132 • amended.

133 The National Committees are requested to note that for this document the stability date is 2029.

IEC CDV 60695-5-2 © IEC 2025

135 INTRODUCTION

136 In the design of an electrotechnical product the risk of fire and the potential hazards associated

137 with fire need to be considered. In this respect the objective of component, circuit and

138 equipment design, as well as the choice of materials, is to reduce the risk of fire to a tolerable

139 level even in the event of reasonably foreseeable (mis)use, malfunction or failure.

140 IEC 60695-1-10 [1] , IEC 60695-1-11 [2], and IEC 60695-1-12 [3] provide guidance on how this

141 is to be accomplished.

142 Fires involving electrotechnical products can also be initiated from external non -electrical

143 sources. Considerations of this nature are dealt with in an overall fire hazard assessment.

144 The aim of the IEC 60695 series is to save lives and property by reducing the number of fires

145 or reducing the consequences of the fire. This can be accomplished by:

146 • trying to prevent ignition caused by an electrically energised component part and, in the

147 event of ignition, to confine any resulting fire within the bounds of the enclosure of the

148 electrotechnical product.

149 • trying to minimise flame spread beyond the product’s enclosure and to minimise the harmful

150 effects of fire effluents including heat, smoke, and toxic or corrosive combustion products.

151 All fire effluent is corrosive to some degree and the level of potential to corrode depends on the

152 nature of the fire, the combination of combustible materials involved in the fire, the nature of

153 the substrate under attack, and the temperature and relative humidity of the environment in

154 which the corrosion is taking place. There is no evidence that fire effluent from electrotechnical

155 products offers greater risk of corrosion damage than the fire effluent from other products such

156 as furnishings, building materials, etc.

157 The performance of electrical and electronic components can be adversely affected by

158 corrosion damage when subjected to fire effluent. A wide variety of combinations of small

159 quantities of effluent gases, smoke particles, moisture and temperature may provide conditions

160 for electrical component or system failures from breakage, overheating or shorting.

161 Evaluation of potential corrosion damage is particularly important for high value and safety-

162 related electrotechnical products and installations.

163 Technical committees responsible for the products will choose the test(s) and specify the level

164 of severity.

165 The study of corrosion damage requires an interdisciplinary approach involving chemistry,

166 electricity, physics, mechanical engineering, metallurgy and electrochemistry. In the

167 preparation of this part of IEC 60695, all of the above have been considered.

168 IEC 60695-5-1 defines the scope of the guidance and indicates the field of application.

169 IEC 60695-5-2 provides a summary of test methods including relevance and usefulness.

Numbers in square brackets refer to the bibliography.

IEC CDV 60695-5-2 © IEC 2025

172 FIRE HAZARD TESTING –

174 Part 5-2: Corrosion damage effects of fire effluent –

175 Summary and relevance of test methods

179 1 Scope

180 This part of IEC 60695 summarises the test methods that are used in the assessment of the

181 corrosivity of fire effluent. It presents a brief summary of test methods in common use, either

182 as international standards, national or industry standards. It includes special observations on

183 their relevance, for electrotechnical products and their materials, to real fire scenarios and gives

184 recommendations on their use.

185 2 Normative references

186 The following documents are referred to in the text in such a way that some or all of their content

187 constitutes requirements of this document. For dated references, only the edition cited applies.

188 For undated references, the latest edition of the referenced document (including any

189 amendments) applies.

190 IEC 60695-4, Fire hazard testing – Part 4: Terminology concerning fire tests

191 IEC 60695-5-1, Fire hazard testing – Part 5-1: Corrosion damage effects of fire effluent -

192 General guidance

193 ISO 13943:2017, Fire safety – Vocabulary

194 3 Terms and definitions

195 For the purposes of this document, the terms and definitions given in IEC 60695-4 and

196 ISO 13943:2017 (some of which are reproduced below) apply.

197 3.1

198 corrosion damage

199 physical and/or chemical damage or impaired function caused by chemical action

200 [SOURCE: ISO 13943:2017, 3.69]

201 3.2

202 corrosion target

203 sensor used to determine the degree of corrosion damage (3.1), under specified test conditions

204 Note 1 to entry: This sensor may be a product, a component. It may also be a reference material or object used to

205 simulate the behaviour of a product or a component.

206 [SOURCE: ISO 13943:2017, 3.70]

207 3.3

208 fire effluent

209 all gases and aerosols, including suspended particles created by combustion or pyrolysis (3.6)

210 and emitted to the environment

211 [SOURCE: ISO 13943:2017, 3.123]

212 3.4

213 fire scenario

214 qualitative description of the course of a fire with respect to time, identifying key events that

215 characterize the studied fire and differentiate it from other possible fires

IEC CDV 60695-5-2 © IEC 2025

216 Note 1 to entry: See fire scenario cluster (ISO 13943:2017, 3.154) and representative fire scenario

217 (ISO 13943:2017, 3.153).

218 Note to entry: It typically defines the ignition and fire growth processes, the fully developed fire stage, the fire decay

219 stage, and the environment and systems that will impact on the course of the fire.

220 Note to entry: Unlike deterministic fire analysis, where fire scenarios are individually selected and used as design

221 fire scenarios, in fire risk assessment, fire scenarios are used as representative fire scenarios within fire scenario

222 clusters.

223 [SOURCE: ISO 13943:2017, 3.152]

224 3.5

225 physical fire model

226 laboratory process, including the apparatus, the environment and the fire test procedure

227 intended to represent a certain phase of a fire

228 [SOURCE: ISO 13943:2017, 3.298]

229 3.6

230 pyrolysis

231 chemical decomposition of a substance by the action of heat

232 Note 1 to entry: Pyrolysis is often used to refer to a stage of fire before flaming combustion has begun.

233 Note 2 to entry: In fire science, no assumption is made about the presence or absence of oxygen.

234 [SOURCE: ISO 13943:2017, 3.316]

235 3.7

236 smoke

237 visible part of a fire effluent (3.3)

238 [SOURCE: ISO 13943:2017, 3.347]

239 4 Classification of test methods

240 4.1 General

241 The test methods included in this document can generally be classified according to the

242 following three criteria:

243 a) the nature of the test specimen which is burnt;

244 b) the physical fire model used in the test;

245 c) the nature of the measurement of corrosivity.

246 4.2 Test specimen

247 4.2.1 Product testing

248 The test specimen is a manufactured product or a representative portion of a product. Examples

249 include a printed circuit board, a switchboard, a computer or a cable.

250 4.2.2 Material or composite sample testing

251 The test specimen is a basic material (solid or liquid), or composite of materials.

252 4.3 The physical fire model

253 Test methods use a wide variety of heat sources and geometries. The amount, the rate of

254 production and the corrosive nature of fire effluent released from a given material or product is

255 not an inherent property of that material or product, but is critically dependent on the conditions

256 under which that material or product is burnt. In a fire scenario or a fire test, the chemical nature

257 of the fuel, the decomposition temperature and the amount of ventilation are the main variables

258 which affect the composition of fire effluent.

259 It is critical to show that the test conditions defined in a standardized test method are relevant

260 to, and replicate, the desired stage of a real fire. ISO has published a general classification of

261 fire stages in ISO 19706:2011, shown in Table 1. The important factors affecting effluent

262 production are oxygen concentration, irradiance and temperature.

IEC CDV 60695-5-2 © IEC 2025

263 4.4 The nature of the corrosivity measurement

264 4.4.1 Product as target

265 The corrosion target is a manufactured product or a representative portion of a product, which

266 can be represented by a test specimen. Examples include: printed wiring boards, switchboards,

267 washing machines and computers.

268 The corrosion damage effects of fire effluent on the product can be assessed by degradation of

269 function as determined by inspection or measurement.

270 4.4.2 Simulated product as target

271 When a simulated product is used as the target, the corrosion target is typically a reference

272 circuit, a thin sheet of metal or a metal mirror. The corrosion damage effects of fire effluent on

273 the target can be assessed by changes in appearance, mass or measurements of mechanical,

274 physical or electrical characteristics.

IEC CDV 60695-5-2 © IEC 2025

275 Table 1 – Characteristics of fire stages (from Table 1 in ISO 19706:2011)

Max. temperature Oxygen volume

Heat flux to

100[CO ]

[CO] 2

Fuel/air

fuel surface

C %

Fire stage equivalence [CO2]

[CO2]+[CO]

ratio (plume)

v/v

kW/m Fuel surface Upper layer Entrained Exhausted

% efficiency

1 Non-flaming

a self-sustaining not

d

450 to 800 25 to 85 20 20 – 0,1 to 1 50 to 90

(smouldering) applicable

b oxidative pyrolysis

a

b c c

from externally applied – 300 to 600 20 20 1

radiation

c anaerobic pyrolysis

b c c

from externally applied – 100 to 500 0 0 1

radiation

d e

2 Well-ventilated flaming 0 to 60 350 to 650 50 to 500 20 20 1 0,05 95

f

3 Underventilated flaming

a small, localized fire,

generally in a poorly

a

0 to 30 300 to 600 50 to 500 15 to 20 5 to 10 1 0,2 to 0,4 70 to 80

ventilated

compartment

g h i

b post-flashover fire 50 to 150 350 to 650 600 15 5 1 0,1 to 0,4 70 to 90

a

The upper limit is lower than for well-ventilated flaming combustion of a given combustible.

b

The temperature in the upper layer of the fire room is most likely determined by the source of the externally applied radiati on and room geometry.

c

There are few data, but for pyrolysis this ratio is expected to vary widely depending on the material chemistry and the local ventilation and thermal conditions.

d

The fire’s oxygen consumption is small compared to that in the room or the inflow, the flame tip is below the hot gas upper l ayer or the upper layer is not yet significantly

vitiated to increase the CO yield significantly, the flames are not truncated by contact with another object, and the burning rate is controlled by the availability of fuel.

e

The ratio can be up to an order of magnitude higher for materials that are fire-resistant. There is no significant increase in this ratio for equivalence ratios up to 0,75, and

between 0,75 and 1, some increase in this ratio may occur.

f

The fire’s oxygen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...