EN 1504-5:2004

(Main)Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 5: Concrete injection

Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 5: Concrete injection

This part of this document specifies requirements and conformity criteria for the identification, performance (including durability aspects) and safety of injection products for the repair and protection of concrete structures, used for:

- force transmitting filling of cracks, voids and interstices in concrete (category F, see 3.1);

- ductile filling of cracks, voids and interstices in concrete (category D, see 3.1);

- swelling fitted filling of cracks, voids and interstices in concrete (category S, see 3.1).

The performance requirements in this part of this document may not be applicable to highly specialised applications in extreme environmental conditions, e.g. cryogenic use, nor do they cover specialised circumstances such as accidental impact, e.g. due to traffic or ice, or earthquake loading, where specific performance requirements will apply.

This part of this document does not cover:

- the treatment of cracks by widening them and sealing them with an elastomeric sealing compound;

- external filling of cavities, that is the placement of product outside the structure (generally within the surrounding foundation soils, or at the interface between the structure and the soil). This is covered by EN 12715, under contact grouting [1];

- preliminary injection works, if necessary, to temporarily stop water passage during waterproofing injection.

Produkte und Systeme für den Schutz und die Instandsetzung von Betontragwerken - Definitionen, Anforderungen, Qualitätsüberwachung und Beurteilung der Konformität - Teil 5: Injektion von Betonbauteilen

Der vorliegende Teil dieses Dokuments legt Anforderungen und Konformitätskriterien für die Identitätsprüfung,

die Leistung (einschließlich Aspekten der Dauerhaftigkeit) und die Sicherheit von Rissfüllstoffen für die

Instandsetzung und den Schutz von Betontragwerken fest, die für Folgendes verwendet werden:

- kraftschlüssiges Füllen von Rissen, Hohlräumen und Fehlstellen in Beton (Kategorie F, siehe 3.1);

- dehnbares Füllen von Rissen, Hohlräumen und Fehlstellen in Beton (Kategorie D, siehe 3.1);

- quellfähiges Füllen von Rissen, Hohlräumen und Fehlstellen in Beton (Kategorie S, siehe 3.1).

Die Anforderungen des vorliegenden Teils dieses Dokuments sind nicht auf besondere Anwendungen unter

extremen Umweltbedingungen, wie z. B. Einsatz bei Tieftemperaturen, anwendbar; auch decken sie keine

besonderen Bedingungen, wie z. B. zufällige Einwirkungen ab, die z. B. durch Verkehr, Eis oder Erdbeben

verursacht sind, wobei für diese Fälle besondere Leistungsanforderungen bestehen.

Der vorliegende Teil dieses Dokuments gilt nicht für:

- Erweitern und Versiegeln von Rissen mit elastomerer Dichtungsmasse;

- das Füllen der Hohlräume von außen, d. h. das Aufbringen des Rissfüllstoffes außerhalb des Tragwerkes

(im Allgemeinen im Boden, der das Fundament umgibt, oder zwischen Tragwerk und Boden). Hierfür gilt

die EN 12715 (Füllen durch Abdichtungsinjektion) abgedeckt;

- Injektionen, sofern erforderlich, für die vorübergehende Verminderung der Wasserzufuhr während der

Injektion zum Zwecke der Herstellung der Wasserdichtheit.

Produits et systèmes pour la protection et la réparation des structures en béton - Définitions, prescriptions, maîtrise de la qualité et évaluation de la conformité - Partie 5 : Produits et systèmes d'injection du béton

La présente norme spécifie les exigences et les critères de conformité pour l'identification, les performances (y compris les aspects durabilité) et la sécurité des produits et systèmes utilisés pour la réparation des structures en béton en procédant à un remplissage interne des fissures et cavités par injection, gravité ou capillarité ) .

Il faut également prendre en compte la conformité à toutes les réglementations de sécurité destinées à protéger les personnes et l'environnement.

L'injection est utilisée pour éviter les effets nocifs des vides et fissures dans le béton.

Pour obtenir l'étanchéité et donc l'étanchéité à l'eau.

Pour éviter la pénétration d'agents agressifs susceptibles de provoquer la corrosion des armatures métalliques.

Pour renforcer la structure en renforçant le béton.

La présente norme ne couvre pas

¾ le traitement des fissures en les élargissant et en les scellant à l'aide d'un produit élastique tel qu'un produit d'étanchéité pour joints ;

¾ le remplissage externe des cavités qui consiste à placer le produit à l'extérieur de la structure (en général dans les sols de fondation environnants ou à l'interface entre la structure et le sol).

Proizvodi in sistemi za zaščito in popravilo betonskih konstrukcij – Definicije, zahteve, kontrola kakovosti in ovrednotenje skladnosti – 5. del: Injektiranje betona

General Information

- Status

- Withdrawn

- Publication Date

- 14-Dec-2004

- Withdrawal Date

- 09-Apr-2013

- Technical Committee

- CEN/TC 104 - Concrete ( performance, production, placing and compliance criteria )

- Drafting Committee

- CEN/TC 104/SC 8/WG 4 - Injection products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Apr-2013

- Completion Date

- 10-Apr-2013

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 17-Apr-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 196-3:2016 - Methods of testing cement - Part 3: Determination of setting times and soundness - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1504-5:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 5: Concrete injection". This standard covers: This part of this document specifies requirements and conformity criteria for the identification, performance (including durability aspects) and safety of injection products for the repair and protection of concrete structures, used for: - force transmitting filling of cracks, voids and interstices in concrete (category F, see 3.1); - ductile filling of cracks, voids and interstices in concrete (category D, see 3.1); - swelling fitted filling of cracks, voids and interstices in concrete (category S, see 3.1). The performance requirements in this part of this document may not be applicable to highly specialised applications in extreme environmental conditions, e.g. cryogenic use, nor do they cover specialised circumstances such as accidental impact, e.g. due to traffic or ice, or earthquake loading, where specific performance requirements will apply. This part of this document does not cover: - the treatment of cracks by widening them and sealing them with an elastomeric sealing compound; - external filling of cavities, that is the placement of product outside the structure (generally within the surrounding foundation soils, or at the interface between the structure and the soil). This is covered by EN 12715, under contact grouting [1]; - preliminary injection works, if necessary, to temporarily stop water passage during waterproofing injection.

This part of this document specifies requirements and conformity criteria for the identification, performance (including durability aspects) and safety of injection products for the repair and protection of concrete structures, used for: - force transmitting filling of cracks, voids and interstices in concrete (category F, see 3.1); - ductile filling of cracks, voids and interstices in concrete (category D, see 3.1); - swelling fitted filling of cracks, voids and interstices in concrete (category S, see 3.1). The performance requirements in this part of this document may not be applicable to highly specialised applications in extreme environmental conditions, e.g. cryogenic use, nor do they cover specialised circumstances such as accidental impact, e.g. due to traffic or ice, or earthquake loading, where specific performance requirements will apply. This part of this document does not cover: - the treatment of cracks by widening them and sealing them with an elastomeric sealing compound; - external filling of cavities, that is the placement of product outside the structure (generally within the surrounding foundation soils, or at the interface between the structure and the soil). This is covered by EN 12715, under contact grouting [1]; - preliminary injection works, if necessary, to temporarily stop water passage during waterproofing injection.

EN 1504-5:2004 is classified under the following ICS (International Classification for Standards) categories: 91.080.40 - Concrete structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1504-5:2004 has the following relationships with other standards: It is inter standard links to EN 1504-5:2013, EN ISO 3251:2019, EN 14498:2004, EN 445:2007, EN 196-3:2016, EN 12618-1:2003, EN 1543:1998, EN 12190:1998, EN 15459:2007, EN 1242:2013, EN 12618-2:2004, EN ISO 3219-1:2021, EN 14068:2003, EN 1504-1:1998, EN ISO 527-1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1504-5:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/128. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1504-5:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 5: Concrete injectionProduits et systemes pour la protection et la réparation des structures en béton - Définitions, prescriptions, maîtrise de la qualité et évaluation de la conformité - Partie 5 : Produits et systemes d'injection du bétonProdukte und Systeme für den Schutz und die Instandsetzung von Betontragwerken - Definitionen, Anforderungen, Qualitätsüberwachung und Beurteilung der Konformität - Teil 5: Injektion von Betonbauteilen91.080.40Betonske konstrukcijeConcrete structuresICS:SIST EN 1504-5:2005enTa slovenski standard je istoveten z:EN 1504-5:200401-februar-2005SIST EN 1504-5:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1504-5December 2004ICS 91.080.40English versionProducts and systems for the protection and repair of concretestructures - Definitions, requirements, quality control andevaluation of conformity - Part 5: Concrete injectionProduits et systèmes pour la protection et la réparation desstructures en béton - Définitions, exigences, maîtrise de laqualité et évaluation de la conformité - Partie 5 : Produits etsystèmes d'injection du bétonProdukte und Systeme für den Schutz und dieInstandsetzung von Betontragwerken - Definitionen,Anforderungen, Qualitätsüberwachung und Beurteilung derKonformität - Teil 5: Injektion von BetonbauteilenThis European Standard was approved by CEN on 9 July 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1504-5:2004: E

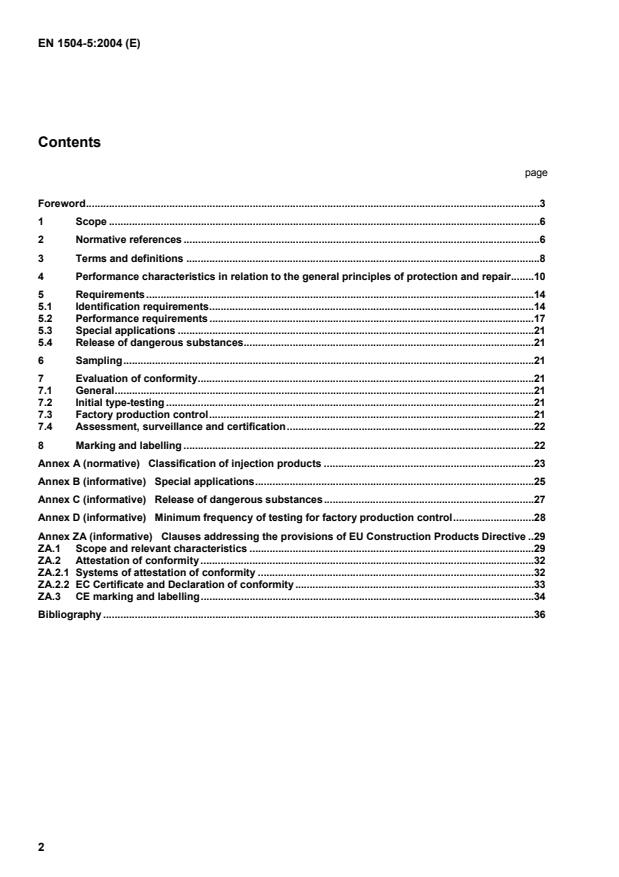

Classification of injection products.23 Annex B (informative)

Special applications.25 Annex C (informative)

Release of dangerous substances.27 Annex D (informative)

Minimum frequency of testing for factory production control.28 Annex ZA (informative)

Clauses addressing the provisions of EU Construction Products Directive.29 ZA.1 Scope and relevant characteristics.29 ZA.2 Attestation of conformity.32 ZA.2.1 Systems of attestation of conformity.32 ZA.2.2 EC Certificate and Declaration of conformity.33 ZA.3 CE marking and labelling.34 Bibliography.36

1)

To be published. 2)

ENV 1504-9 will have to be modified when adopted as EN to reflect the published texts of parts 2 to 8 and part 10.

3.2 injection product formulated with reactive polymer binder (P) product where the hardening is related to the curing of a reactive polymer binder. The reactive part of a polymer binder involved in the hardening of the binder is the functional group 3.3 injection product formulated with hydraulic binder (H) product where the hardening is related to the hydration reaction of an hydraulic binder

flowing water through the crack. NOTE The manufacturer should indicate the moisture state or states with which the product is compatible, based on the results of the injectability and other relevant performance tests specified in Clause 4.

Adhesion by slant shear strength (H, P) ‘ Volumetric shrinkage (P)

Bleeding (H)

Volume change (H)

Glass transition temperature (P) ‘ Chloride content (H) ‘ WORKABILITY CHARACTERISTICS Injectability into dry medium

crack widths: 0,1 mm – 0,2 mm – 0,3 mm): determination of injectability and splitting test (H, P) crack widths: 0,5 mm – 0,8 mm or where EN 1771 is not suitable : covered by: adhesion by tensile bond strength (H, P)

Injectability into non dry medium crack widths: 0,1 mm – 0,2 mm – 0,3 mm: determination of injectability and splitting test (H, P) crack widths: 0,5 mm – 0,8 mm or where EN 1771 is not suitable: covered by: adhesion by tensile bond strength (H, P)

Viscosity (P)

Time of efflux (H)

REACTIVITY CHARACTERISTICS Workable time (H, P)

Tensile strength development for polymers (P)

Setting time (H)

DURABILITY Adhesion by tensile bond strength after thermal and wet-drying cycles (H, P)

Compatibility with concrete (H, P)

For all intended uses. ‘ For certain intended uses. (H) Injection product formulated with hydraulic binder. (P) Injection product formulated with reactive polymer binder.

performance characteristics Performance characteristics Method 1.4 Intended use BASIC CHARACTERISTICS Adhesion and elongation capacity of ductile injection products (P)

Watertightness (P) ‘ Glass transition temperature (P) ‘ WORKABILITY CHARACTERISTICS Injectability into dry medium (P) crack widths: 0,1 mm – 0,2 mm – 0,3 mm:

determination of injectability (P) crack widths: 0,5 mm – 0,8 mm or where EN 1771 is not suitable Injection between concrete tiles (P)

Injectability into non dry medium (P) crack widths: 0,1 mm – 0,2 mm – 0,3 mm: determination of injectability (P) crack widths: 0,5 mm – 0,8 mm or where EN 1771 is not suitable: injection between concrete tiles (P)

Viscosity (P)

Expansion ratio and evolution (P) ‘ REACTIVITY CHARACTERISTICS Workable time (P)

DURABILITY Compatibility with concrete (P)

For all intended uses. ‘ For certain intended uses. (P) Injection product formulated with reactive polymer binder.

performance characteristics Performance characteristics Method 1.4 Intended use BASIC CHARACTERISTICS Watertightness (P)

Corrosion behaviour (P) ‘ WORKABILITY CHARACTERISTICS Viscosity (P)

Expansion ratio and rate by water storage (P)

REACTIVITY CHARACTERISTICS Workable life (P)

DURABILITY Sensitivity to water: expansion ratio caused by water storage (P)

Sensitivity to wet-drying cycles (P)

Compatibility with concrete (P)

For all intended uses. ‘ For certain intended uses. (P) Injection product formulated with reactive polymer binder. 5 Requirements 5.1 Identification requirements The manufacturer shall undertake selected representative initial identification tests for the product or system as specified in Tables 2.a and 2.b. These tests may be used to confirm the composition of the product at any time. Acceptable tolerances are given in Tables 2.a and 2.b.Test records shall be held by the manufacturer.

* Related to the functional group

Epoxy equivalent EN 1877-1 ± 5

Amine functions EN 1877-2 ± 6

Hydroxyl value EN 1240 ± 10

Isocyanate content EN 1242 ± 10

Other functional group To be determined, according to the nature of the functional group

* Specific weight EN ISO 2811 (Part 1 or Part 2) ± 3 * Infrared analysis EN 1767 The positions and relative intensities of the main absorption bands shall match those of the reference spectrum. Freshly mixed product

* Viscosity EN ISO 3219 ± 20

Viscosity shall be measured 5 min after mixing of the product has been completed.

The separate components of the product shall be maintained at a constant temperature of (21 ± 2) °C before mixing. The temperature of the freshly mixed product shall be measured and recorded before the viscosity is measured.

For products that harden in less than 5 min, viscosity shall be measured on unmixed components.

* Pot life EN ISO 9514 ± 20

The test shall be performed at three conditioning and test temperatures: 21 °C and the minimum and maximum use temperatures recommended by the manufacturer, with a tolerance of ± 2 °C.

NOTE Definition 3.4 applies.

* Determination of volatile and non volatile matter EN ISO 3251 ± 5 "to be continued"

* Tensile strength, elongation and elastic modulus (F, D) EN ISO 527-1 ± 20

EN ISO 527-2

The test shall be performed after 7 days conditioning under the standard conditions for injection products formulated with reactive polymer binder, which are poured on to a non-adherent substrate to a thickness of 3 mm.

* Strength properties (S) A compressive load is applied with a speed

of 100 mm/min on the product specimen, obtained from the pot life test, with a stamp ∅ 20 mm provided by a conical head (angle: 60°); the load/deformation curve is reported. The test is performed after 24 h conditioning under the standard conditions. ± 20 Table 2.b — Identificatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...