EN 1504-10:2017

(Main)Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 10: Site application of products and systems and quality control of the works

Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 10: Site application of products and systems and quality control of the works

This part of EN 1504 gives requirements for:

- substrate condition before and during application of systems and products;

- storage of systems and products;

- structural stability during preparation, protection and repair;

- methods of protection and repair;

- quality control for execution of work;

- maintenance of the structure.

Produkte und Systeme für den Schutz und die Instandsetzung von Betonbauteilen - Definitionen, Anforderungen, Qualitätsüberwachung und Beurteilung der Konformität - Teil 10: Anwendung von Produkten und Systemen auf der Baustelle, Qualitätsüberwachung der Ausführung

Dieser Teil von EN 1504 enthält Anforderungen zur

- Vorbereitung des Untergrundes vor und während der Aufbringung von Systemen und Produkten;

- Lagerung von Systemen und Produkten;

- Tragfähigkeit während Vorbereitung, Schutz und Instandsetzung;

- Verfahren zum Schutz und zur Instandsetzung;

- Qualitätssicherung der Ausführung;

- Instandhaltung des Tragwerks.

Produits et systèmes pour la protection et la réparation des structures en béton - Définitions, exigences, maîtrise de la qualité et évaluation de la conformité - Partie 10 : Application sur site des produits et systèmes et contrôle de la qualité des travaux

La présente partie de l’EN 1504 définit les exigences relatives :

— à l’état du support avant et pendant l’application des systèmes et des produits ;

— au stockage des systèmes et des produits ;

— à la stabilité structurale pendant la préparation, la protection et la réparation ;

— aux méthodes de protection et de réparation ;

— au contrôle de la qualité pour l’exécution des travaux ;

— à la maintenance de la structure.

Proizvodi in sistemi za zaščito in popravilo betonskih konstrukcij - Definicije, zahteve, kontrola kakovosti in ovrednotenje skladnosti - 10. del: Uporaba proizvodov in sistemov na terenu in kontrola kakovosti del

Ta del standarda EN 1504 podaja zahteve za:

– stanje podlage pred in med uporabo sistemov ter proizvodov;

– skladiščenje sistemov in proizvodov;

– stabilnost konstrukcije med pripravo, zaščito in popravilom;

– metode zaščite in popravila;

– kontrola kakovosti za izvedbo del;

– vzdrževanje konstrukcije.

Ti vidiki vključujejo vplive na zdravje in varnost, delovno okolje, okolje ter gospodarstvo.

General Information

- Status

- Published

- Publication Date

- 10-Oct-2017

- Withdrawal Date

- 29-Apr-2018

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Jun-2023

- Completion Date

- 04-Jun-2023

Relations

- Effective Date

- 18-Oct-2017

- Effective Date

- 18-Oct-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 12390-2:2019 - Testing hardened concrete - Part 2: Making and curing specimens for strength tests - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10080:2005 - Steel for the reinforcement of concrete - Weldable reinforcing steel - General - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1504-10:2017 - part of the EN 1504 series - sets requirements for the site application of products and systems used to protect and repair concrete structures, and for the quality control of the works. The standard covers pre‑application substrate condition, storage, structural stability during works, approved methods of protection and repair, in‑process and final quality control, and ongoing maintenance. It also includes informative Annexes that describe field test methods for surface cleanliness, surface roughness and microcracking.

Key topics and technical requirements

- Substrate condition before and during application: inspection, acceptable surface condition, and control of microcracks are required to ensure durable bonding and performance.

- Storage and handling: guidance on storage of products and systems prior to application to maintain conformity.

- Structural stability: requirements for ensuring safety and stability of the structure during preparation, protection and repair operations.

- Methods of protection and repair: guidance on a wide range of interventions (e.g., coatings, membranes, surface bandaging of cracks, transferring cracks to joints, erection of external panels, electrochemical chloride extraction, prestressing) and references to product‑specific EN parts.

- Quality control for execution: defined execution classes, mandatory tests and observations (e.g., bond tests, pull‑out/core tests, electrical resistivity, inspection for microcracks) and a summary test table for in‑process and final verification.

- Maintenance: requirements for post‑repair care and scheduled maintenance to safeguard long‑term performance.

- Informative test methods: Annex B (cleanliness), Annex C (saw‑teeth profile surface roughness), Annex D (degree of microcracking).

Practical applications and users

EN 1504-10:2017 is intended for:

- Contractors and applicators executing on‑site concrete protection and repair works

- Structural and civil engineers specifying repair strategies and verification criteria

- QA/QC inspectors and testing laboratories performing site tests and acceptance checks

- Manufacturers and system suppliers preparing guidance and demonstrations of conformity

- Asset owners and facility managers who need assurance of durable repair and maintenance plans

Typical applications include repair and strengthening of bridges, tunnels, parking structures, marine works and industrial facilities where durable protection against ingress, corrosion and structural degradation is required.

Related standards

EN 1504-10:2017 is part of the EN 1504 series. Relevant referenced standards include other EN 1504 parts (Parts 1–9), EN 1542 (bond testing), EN 12504-3 (pull‑out/core testing), EN 14487 series (sprayed mortar/concrete) and EN ISO 8501-1 (steel cleaning) among others. Use this part together with product‑specific EN parts to create complete specifications for site execution and quality control.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1504-10:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Products and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 10: Site application of products and systems and quality control of the works". This standard covers: This part of EN 1504 gives requirements for: - substrate condition before and during application of systems and products; - storage of systems and products; - structural stability during preparation, protection and repair; - methods of protection and repair; - quality control for execution of work; - maintenance of the structure.

This part of EN 1504 gives requirements for: - substrate condition before and during application of systems and products; - storage of systems and products; - structural stability during preparation, protection and repair; - methods of protection and repair; - quality control for execution of work; - maintenance of the structure.

EN 1504-10:2017 is classified under the following ICS (International Classification for Standards) categories: 91.080.40 - Concrete structures. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1504-10:2017 has the following relationships with other standards: It is inter standard links to EN 1504-10:2003/AC:2005, EN 1504-10:2003, EN 12190:1998, EN 1504-5:2013, EN 13395-2:2002, EN 206:2013+A2:2021, EN 13670:2009, EN 12390-2:2019, EN 1008:2002, EN 10080:2005, EN 16242:2012, EN ISO 2808:2019, EN ISO 21920-3:2022, EN 1504-8:2016, EN 1504-7:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1504-10:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Produkte und Systeme für den Schutz und die Instandsetzung von Betontragwerken - Definitionen, Anforderungen, Qualitätsüberwachung und Beurteilung der Konformität - Teil 10: Anwendung von Produkten und Systemen auf der Baustelle, Qualitätsüberwachung der AusführungProduits et systèmes pour la protection et la réparation de structures en béton - Définitions, prescriptions, maîtrise de la qualité et évaluation de la conformité - Partie 10: Application sur site des produits et systèmes et contrôle de la qualité des travauxProducts and systems for the protection and repair of concrete structures - Definitions, requirements, quality control and evaluation of conformity - Part 10: Site application of products and systems and quality control of the works91.080.40Betonske konstrukcijeConcrete structures01.040.91Gradbeni materiali in gradnja (Slovarji)Construction materials and building (Vocabularies)ICS:Ta slovenski standard je istoveten z:EN 1504-10:2017SIST EN 1504-10:2017en01-december-2017SIST EN 1504-10:2017SLOVENSKI

STANDARDSIST EN 1504-10:2004/AC:2005SIST EN 1504-10:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1504-10

October

t r s y ICS

{ sä r z rä v r Supersedes EN

s w r væ s rã t r r uEnglish Version

Products and systems for the protection and repair of concrete structures æ Definitionsá requirementsá quality control and evaluation of conformity æ Part

s rã Site application of products and systems and quality control of the works Produits et systèmes pour la protection et la réparationdes structures en béton æ Définitionsá exigencesá maîtrise de la qualité et évaluation de la conformité æ Partie

s r ã Application sur site des produits et systèmes et contrôle de la qualité des travaux

Produkte und Systeme für den Schutz und die Instandsetzung von Betonbauteilen æ Definitionená Anforderungená Qualitätsüberwachung und Beurteilung der Konformität æ Teil

s rã Anwendung von Produkten und Systemen auf der Baustelleá Qualitätsüberwachung der Ausführung This European Standard was approved by CEN on

t x July

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w r væ s rã t r s y ESIST EN 1504-10:2017

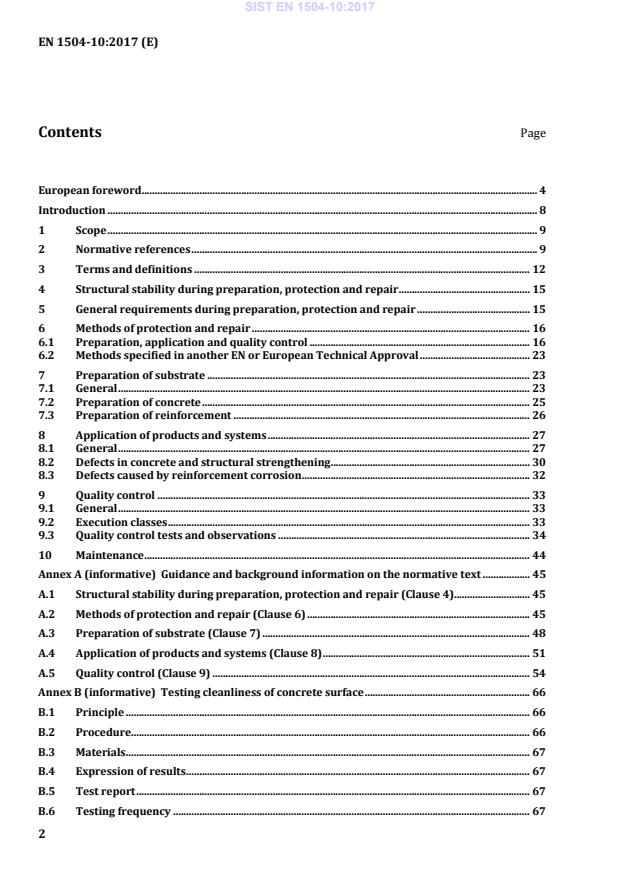

European foreword . 4 Introduction . 8 1 Scope . 9 2 Normative references . 9 3 Terms and definitions . 12 4 Structural stability during preparation, protection and repair . 15 5 General requirements during preparation, protection and repair . 15 6 Methods of protection and repair . 16 6.1 Preparation, application and quality control . 16 6.2 Methods specified in another EN or European Technical Approval . 23 7 Preparation of substrate . 23 7.1 General . 23 7.2 Preparation of concrete . 25 7.3 Preparation of reinforcement . 26 8 Application of products and systems . 27 8.1 General . 27 8.2 Defects in concrete and structural strengthening . 30 8.3 Defects caused by reinforcement corrosion . 32 9 Quality control . 33 9.1 General . 33 9.2 Execution classes . 33 9.3 Quality control tests and observations . 34 10 Maintenance . 44 Annex A (informative)

Guidance and background information on the normative text . 45 A.1 Structural stability during preparation, protection and repair (Clause 4). 45 A.2 Methods of protection and repair (Clause 6) . 45 A.3 Preparation of substrate (Clause 7) . 48 A.4 Application of products and systems (Clause 8) . 51 A.5 Quality control (Clause 9) . 54 Annex B (informative)

Testing cleanliness of concrete surface . 66 B.1 Principle . 66 B.2 Procedure. 66 B.3 Materials . 67 B.4 Expression of results . 67 B.5 Test report . 67 B.6 Testing frequency . 67 SIST EN 1504-10:2017

Testing surface roughness through the saw-teeth profile method . 68 C.1 Principle . 68 C.2 Definitions . 68 C.3 Procedure . 68 C.4 Apparatus . 70 C.5 Expression of result . 70 C.6 Test report . 70 C.7 Testing frequency . 71 Annex D (informative)

Testing degree of microcracking of concrete surfaces . 72 D.1 Principle . 72 D.2 Procedure . 72 D.3 Apparatus . 73 D.4 Expression of result . 73 D.5 Test report . 73 D.6 Testing frequency . 74 Bibliography . 75

depth of approximately 2 mm 3.2 bond adhesion of the applied product or system to the substrate 3.3 cement grout mixture of cement, water and in some cases admixtures and fillers 3.4 cementitious repair products and systems hydraulic or polymer hydraulic mortars, concretes and grouts 3.5 coating product and/or system for the treatment of concrete to produce a continuous protective layer on the surface 3.6 extent of microcracking total length of microcracks within a defined area Note 1 to entry: The area is defined in Annex D. 3.7 dew point temperature at which water vapour condenses SIST EN 1504-10:2017

Note 1 to entry: The pores and capillaries are internally coated, but they are not filled. There is no measurable film on the surface of the concrete. 3.11 hydraulic mortars and hydraulic concrete (CC) mortars or concrete based on a hydraulic binder which is blended together with graded aggregates and may include admixtures and additions which, when mixed with water, set by hydrated reaction 3.12 impregnation product for the treatment of concrete to reduce the surface porosity and to strengthen the surface

Note 1 to entry: The pores and capillaries are partially or totally filled. This treatment usually leads to a discontinuous, thin film on the concrete surface. 3.13 mechanical removal removal of substrate by percussive or abrasive means 3.14 micro crack crack too small to be seen with the unaided eye Note 1 to entry: Annex D defines 0,03 mm as a minimum width. 3.15 mortars and concrete hydraulic, polymer hydraulic and polymer mortar and concrete 3.16 non-selective hydrodemolition removal of concrete to a selected depth by using high pressure water techniques 3.17 polymer hydraulic cement mortars and concrete (PCC) hydraulic mortars or concrete modified by the addition of a polymer 3.18 polymer mortars and polymer concretes (PC) blended mixture of polymer binder and graded aggregate which set by polymerisation reaction SIST EN 1504-10:2017

Note 1 to entry: High pressure is usually in the range of 80 MPa to 120 MPa. 3.35 water-pressure cleaning method for cleaning, abrading or shallow removal of concrete using a stream of pressure water ejected from a nozzle at high velocity

Note 1 to entry: Pressure is usually in the range of 10 MPa to 70 MPa. 3.36 wavelength

distance between two consecutive maximum values in a regular saw-tooth curve characterizing the roughness of the substrate surface 3.37 wet on wet application of a cementitious mortar or concrete onto the surface of a similar material which has set but not hardened 4 Structural stability during preparation, protection and repair Safety and structural stability before, during and after repair shall be maintained in accordance with EN 1504-9. Any period required for gain of strength of the repair products and systems shall be a part of the duration of the repair. 5 General requirements during preparation, protection and repair Consideration should be given to the: a) chemical, electrochemical and physical condition of the substrate and any contaminants, b) the ability of the structure to accept loading, movement and vibration during protection and repair, c) ambient conditions, d) the characteristics of the materials contained in the structure, and e) the characteristics of the protection and repair products and systems. The following requirements shall be met: SIST EN 1504-10:2017

The following methods satisfy the principle of reducing or preventing the ingress of adverse agents e.g. water, other liquids, vapour gas such as carbon dioxide, chemicals such as chlorides and biological agents. 1.1 Hydrophobic impregnation

This method is to apply a product to prevent or reduce the passage of water by lining the surface pores with material with hydrophobic properties. 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 1.2 Impregnation

This method is to apply a product to reduce the surface porosity and to strengthen the surface by partly or totally filling the pores and capillaries. 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 1.3 Coating

This method is to apply a product to the surface of the concrete to prevent the passage of agents. 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.7 9.1, 9.2 1.4 Surface bandaging of cracks See A.2.1 in informative Annex A. 1.5 Filling of cracks

a

This method is to fill cracks to protect against ingress. 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.2, 8.2.5, 8.2.6 9.1, 9.2 1.6 Transferring cracks into joint See A.2.1 1.7 Erecting external panels See 6.2 1.8 Applying membranes See 6.2

Methods to satisfy principle 2 – Moisture control The following methods satisfy the principle of adjusting and maintaining the moisture content in the concrete between a specified range of values. SIST EN 1504-10:2017

This method is to apply a product to reduce the penetration of water and other agents into the treated concrete by lining the surface pores with materials with hydrophobic properties. 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 2.2 Impregnation This method is to apply a product to reduce the surface porosity and to strengthen the surface by partly or totally filling the pores and capillaries. 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 2.3 Coating

This method is to apply a product to the surface of the concrete to prevent the passage of water or water vapour. 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.7 9.1, 9.2 2.4 Erecting external panels See 6.2 2.5 Electrochemical treatment See 6.2

Methods to satisfy principle 3 – Concrete restoration The following methods satisfy the principle of restoring the original concrete of an element of the structure to the originally specified shape and function. Restoring the concrete structure by replacing part of it. 3.1 Hand-applied mortar This method is to apply manually a repair mortar to the prepared concrete surface. 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4, 7.2.5 8.1, 8.2.1, 8.2.2, 8.2.5 9.1, 9.2 3.2 Recasting with concrete or mortar This method is to proceed to concrete repair with the form and pour method. 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4, 7.2.5 and EN 13670 8.1, 8.2.1, 8.2.4, 8.2.5 and EN 206 and EN 13670 9.1, 9.2 3.3 Spraying concrete or mortar This method is to proceed to concrete repair using mechanically spray method. 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4, 7.2.5 and EN 13670 and EN 14487-1, EN 14487-2 and EN 1504-3 8.1, 8.2.1, 8.2.3, 8.2.5 and EN 13670 and EN 14487-1, EN 14487-2: and EN 1504-3 9.1, 9.2 3.4 Replacing elements See 6.2 SIST EN 1504-10:2017

Methods to satisfy principle 4 – Structural strengthening

The following methods satisfy the principle of increasing or restoring the structural load bearing capacity of an element of the concrete structure. 4.1 Adding or replacing embedded or external reinforcing steel bars 7.1, 7.3.1, 7.3.2, 8.2.1, 8.3.2 8.1, 8.2.8, 8.3.1, 8.3.3, EN 13670 and EN 10080 9.1, 9.2 4.2 Installing bonded rebars in preformed or drilled holes in the concrete Adding reinforcement anchored in pre-formed or drilled holes 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.8, 8.3.1, 8.3.3 9.1, 9.2 4.3 Bonding plate reinforcement

This method is to bond the strengthening plates externally to an element of the concrete structure. 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4, 7.2.5 8.1, 8.2.1, 8.2.6, 8.2.9 9.1, 9.2 4.4 Adding mortar or concrete

This method is to bond additional mortar or concrete to the concrete structure. 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4, 7.2.5 8.1, 8.2.1, 8.2.2, 8.2.3, 8.2.4, 8.2.5 9.1, 9.2 4.5 Injecting cracks, voids or interstices

This method is to inject the concrete with appropriate fluid. 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.2, 8.2.5, 8.2.6 9.1, 9.2 4.6 Filling cracks, voids or interstices 7.1, 7.2.1, 7.2.2 8.1, 8.2.1, 8.2.2, 8.2.5, 8.2.6b 9.1, 9.2 4.7 Prestressing (post tensioning) See 6.2

Methods to satisfy principle 5 – Increasing physical resistance

The following methods satisfy the principle of increasing resistance to physical or mechanical attack. SIST EN 1504-10:2017

This method is to increase the physical resistance with surface coatings 7.1, 7.2.1, 7.2.2, 7.2.4, 7.2.5 8.1, 8.2.1, 8.2.7 9.1, 9.2 5.2 Impregnation This method is to increase the physical resistance with impregnation 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 5.3 Adding mortar or concrete This method is to increase the physical resistance by adding mortar or concrete 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4 8.1, 8.2.1, 8.2.2, 8.2.3, 8.2.4, 8.2.5 9.1, 9.2

Methods to satisfy principle 6 – Resistance to chemicals

The following methods satisfy the principle of increasing resistance of the concrete surface to deterioration by chemical attack. Reducing the penetration of chemical agents into treated concrete to prevent or reduce deterioration due to chemical attack. 6.1 Coating

This method is to reduce penetration of chemical agents into treated concrete to prevent or reduce deterioration using protective coating 7.1, 7.2.1, 7.2.2, 7.2.4 8.1, 8.2.1, 8.2.7 9.1, 9.2 6.2 Impregnation This method is to increase the chemical resistance of the concrete with impregnation 7.1, 7.2.1, 7.2.2 8.1, 8.2.7 9.1, 9.2 6.3 Adding mortar or concrete This method is to increase the chemical resistance by adding mortar or concrete 7.1, 7.2.1, 7.2.2, 7.2.3, 7.2.4 8.1, 8.2.1, 8.2.2, 8.2.3, 8.2.4, 8.2.5 9.1, 9.2

Methods to satisfy principle 7 – Preserving or restoring passivity

The following methods satisfy the principle of creati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...