EN 15715:2009

(Main)Thermal insulation products - Instructions for mounting and fixing for reaction to fire testing - Factory made products

Thermal insulation products - Instructions for mounting and fixing for reaction to fire testing - Factory made products

This standard specifies instructions for mounting and fixing for reaction to fire testing of factory made thermal insulation products.

Wärmedämmstoffe - Einbau- und Befestigungsbedingungen für die Prüfung des Brandverhaltens - Werkmäßig hergestellte Wärmedämmstoffe

Diese Europäische Norm legt Anweisungen für Montage und Befestigung von fabrikmäßig hergestellten Dämmprodukten in der Brandverhaltensprüfung fest.

Produits isolants thermiques - Instructions de montage et de fixation pour l'essai de réaction au feu - Produits isolants thermiques manufacturés

La présente Norme européenne spécifie des instructions de montage et de fixation pour l’essai de réaction au feu de produits isolants thermiques manufacturés.

Toplotnoizolacijski proizvodi - Navodila za vgradnjo in pritrjevanje za preskuse odziva na ogenj - Tovarniško izdelani proizvodi

Ta evropski standard določa navodila za vgradnjo in pritrjevanje za preskuse odziva na ogenj tovarniško izdelanih termoizolacijskih proizvodov.

General Information

- Status

- Published

- Publication Date

- 03-Nov-2009

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88 - Thermal insulating materials and products

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13963:2014 - Jointing materials for gypsum boards - Definitions, requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 1182:2020 - Reaction to fire tests for products - Non-combustibility test (ISO 1182:2020) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15715:2009 - Thermal insulation products: Instructions for mounting and fixing for reaction to fire testing (factory made products) is a CEN European Standard that specifies how factory-made thermal insulation products must be mounted and fixed when subjected to reaction-to-fire tests. The standard ensures reproducible laboratory conditions so that fire performance test results (ignitability, spread, heat release) are comparable and valid for product assessment and classification.

Key topics and requirements

- Scope & principle: Defines the purpose and testing principle for mounting specimens to assess reaction to fire.

- Product and installation parameters: Lists required parameters to be recorded (material type, thickness, geometry) and installation conditions affecting test outcomes.

- Mounting and fixing rules: Detailed instructions on how to mount and mechanically fix specimens for:

- Ignitability tests (EN ISO 11925-2) - single-flame exposure methods.

- Single Burning Item (SBI) tests (EN 13823) - room-corner test assessing heat release and flaming behavior.

- Standardised assemblies: Procedures for testing products installed in assemblies that simulate end-use applications (walls, façades, roofs, pipes).

- Field of application / validity: Guidance on the applicability of test results across product families and similar installations.

- Product-specific annexes: Annex A contains product-specific mounting parameters and tables for a wide range of materials (mineral wool, EPS, XPS, PUR/PIR, phenolic foam, cellular glass, wood-based insulants, elastomeric foams, calcium silicate, polyethylene foam, etc.).

Applications and who uses it

- Manufacturers use EN 15715 to prepare specimens and test reports that reliably reflect in-service fire behaviour and to support CE marking or product declarations.

- Test laboratories follow the standard to ensure consistent mounting and fixing procedures during EN ISO 11925-2 and EN 13823 testing.

- Certification bodies and regulators use the standardised test set-up as part of assessment and product classification workflows.

- Specifiers, architects and installers rely on test-based fire performance data produced using EN 15715 to select suitable thermal insulation for building envelopes, façades, roofs and services insulation where reaction-to-fire performance is critical.

Related standards

- EN ISO 11925-2 - Ignitability (single-flame exposure)

- EN 13823 - Single Burning Item (SBI) test

- Often used together with fire classification standards from the EN 13501 family for assigning reaction-to-fire classes.

EN 15715:2009 is essential for ensuring repeatable, reliable reaction-to-fire test results for factory-made thermal insulation products and for translating laboratory data into practical, code-compliant product information.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15715:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products - Instructions for mounting and fixing for reaction to fire testing - Factory made products". This standard covers: This standard specifies instructions for mounting and fixing for reaction to fire testing of factory made thermal insulation products.

This standard specifies instructions for mounting and fixing for reaction to fire testing of factory made thermal insulation products.

EN 15715:2009 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15715:2009 has the following relationships with other standards: It is inter standard links to EN ISO 11925-2:2026, EN ISO 1716:2018, EN ISO 11925-2:2020, EN 13963:2014, EN 13238:2010, EN 13823:2020+A1:2022, EN 508-1:2021, EN 520:2004+A1:2009, EN ISO 1182:2020, EN 13501-1:2018, EN 13172:2024, EN ISO 9229:2007, EN 14304:2009, EN 14307:2015, EN 14305:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15715:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15715:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi - Navodila za vgradnjo in pritrjevanje za preskuse odziva na ogenj - Tovarniško izdelani proizvodiWärmedämmstoffe - Einbau- und Befestigungsbedingungen für die Prüfung des Brandverhaltens - Werkmäßig hergestellte WärmedämmstoffeProduits isolants thermiques - Instructions de montage et de fixations pour l'essai de réaction au feu - Produits isolants thermiques manufacturésThermal insulation products - Instructions for mounting and fixing for reaction to fire testing - Factory made products91.100.60Thermal and sound insulating materials13.220.50Požarna odpornost gradbenih materialov in elementovFire-resistance of building materials and elementsICS:Ta slovenski standard je istoveten z:EN 15715:2009SIST EN 15715:2010en,fr,de01-april-2010SIST EN 15715:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15715

November 2009 ICS 91.100.60 English Version

Thermal insulation products - Instructions for mounting and fixing for reaction to fire testing - Factory made products

Produits isolants thermiques - Instructions de montage et de fixations pour l'essai de réaction au feu - Produits isolants thermiques manufacturés

Wärmedämmstoffe - Einbau- und Befestigungsbedingungen für die Prüfung des Brandverhaltens - Werkmäßig hergestellte Wärmedämmstoffe This European Standard was approved by CEN on 29 September 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15715:2009: ESIST EN 15715:2010

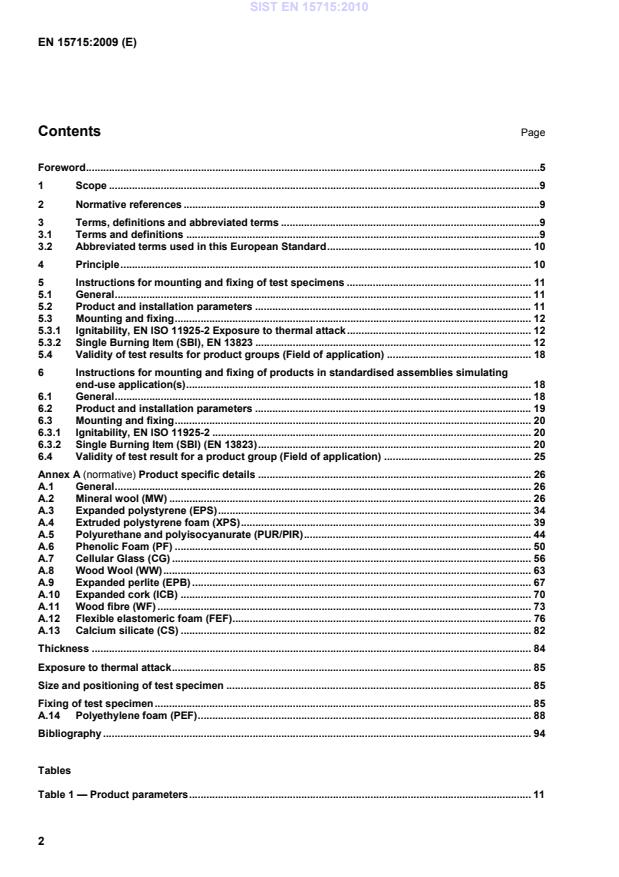

Tables Table 1 — Product parameters . 11 SIST EN 15715:2010

Table A.1 — Product parameters for MW – flat products, when tested as placed on the market or in standard test configuration of assemblies . 26 Table A.2 — Installation parameters for MW – flat products, as placed on the market . 29 Table A.3 — Product parameters for MW – pipe insulation products, as placed on the market . 30 Table A.4 — Installation parameters for MW – pipe insulation products, as placed on the market . 31 Table A.5 — Installation parameters for MW –

flat products in standard test configuration of assemblies, simulating end-use applications . 32

Table A.6 — Product parameters for EPS – flat products,

when tested as placed on the market

or in standard test configuration of assemblies . 34 Table A.7 — Installation parameters for EPS – flat products as placed on the market . 35 Table A.8 — Product parameters for

EPS

– pipe insulation products, as placed on the market . 36 Table A.9 — Installation parameters for EPS – pipe insulation products, as placed on the market . 37 Table A.10 — Installation parameters for EPS

–

flat products in standard test configuration of assemblies, simulating end-use applications . 38

Table A.11 — Product parameters for XPS – flat products when tested as placed on the market or in standard test configuration of assemblies . 39 Table A.12— Installation parameters for XPS

–

flat products as placed on the market . 40 Table A.13 — Product parameters for XPS

– pipe insulation products, as placed on the market . 41 Table A.14 — Installation parameters for XPS – pipe insulation products, as placed on the market . 42 Table A.15 — Installation parameters for XPS

– flat products in standard test configuration of assemblies, simulating end-use applications . 43

Table A.16 — Product parameters for PUR/PIR – flat products when tested as placed on the market or in standard test configuration of assemblies. 44 Table A.17 — Installation parameters for PUR/PIR – flat products, as placed on the market . 45 Table A.18 — Product parameters for PUR/PIR – pipe insulation products, as placed on the market . 46 Table A.19 — Installation parameters for PUR/PIR - pipe insulation products, as placed on the market . 47 Table A.20 — Installation parameters for PUR/ PIR – flat products in standard test configuration of assemblies, simulating end-use applications . 48

Table A.21 — Product parameters for PF – flat products, when tested as placed on the market or in standard test configuration of assemblies . 50 Table A.22 — Installation parameters for PF – flat products, as placed on the market . 51 Table A.23 — Product parameters for PF – pipe insulation products, as placed on the market . 52 Table A.24 — Installation parameters for PF – pipe insulation products, as placed on the market. 53 Table A.25 — Installation parameters for PF

– flat products in standard test configuration of assemblies, simulating end-use applications . 54

Table A.26 — Product parameters for CG – flat products when tested as placed on the market

or in standard test configuration of assemblies . 56 Table A.27 — Installation parameters for CG – flat products, as placed on the market . 58 Table A.28 — Product parameters for CG – pipe insulation productsa, as placed on the market . 59 Table

A.29 — Installation parameters for CG- linear pipe thermal insulation . 60 Table A.30— Installation parameters for CG

— flat products, in standard test configuration of assemblies

simulating end-use applications . 61

Table A.31 — Product parameters for WW

—

flat products, when tested as placed on the market or in standard test configuration of assemblies . 63 Table A.31 (continued) . 64 Table A.32 — Installation parameters WW — flat products, as placed on the market . 65 SIST EN 15715:2010

simulating end-use applications . 66

Table A.34 — Product parameters for EPB – flat products, when tested as placed on the market or in standard test configuration of assemblies . 67 Table A.35— Installation parameters for EPB – flat products, as placed on the market . 68 Table A.36— Installation parameters for EPB – flat products in standard test configuration of assemblies

simulating end-use applications . 69

Table A.37 — Product parameters for ICB flat products, when tested as placed on the market or in standard test configuration of assemblies . 70 Table A. 38— Installation parameters for ICB – flat products, as placed on the market . 71 Table A.39 — Installation parameters for ICB – flat products in standard test configuration of assemblies

simulating end-use applications . 72

Table A.40 — Product parameters for WF – flat products, when tested as placed on the market or in standard test configuration of assemblies . 73 Table A.41— Installation parameters for WF – flat products, as placed on the market . 74 Table A.42— Installation parameters for WF – flat products, in standard test configuration of assemblies

simulating end-use applications . 75

Table A.43 — Product parameters for FEF – flat products, when tested as placed on the market or in standard test configuration of assemblies . 76 Table A.44 — Installation parameters for FEF – flat products, as placed on the market . 77 Table A.45 — Product parameters for FEF – pipe insulation products, as placed on the market . 78 Table A.46 — Installation parameters for FEF – pipe insulation products, as placed on the market . 79 Table A.47 — Installation parameters for FEF – for flat products in standard test configuration of assemblies

simulating end-use applications . 80

Table A.48 — Product parameters for CS – flat products when tested as placed on the market or in standard test configuration of assemblies . 82 Table A.49 — Installation Parameters for CS – flat products as placed on the market . 83 Table A.50 – Product parameters for CS – pipe insulation products, as placed on the market. 84 Table A.51 – Installation parameters for CS – pipe insulation products, as placed on the market . 85 Table A.52 — Installation parameters for CS – flat products in standard test configuration of assemblies

simulating end-use applications . 86

Table A.53 — Product parameters for PEF, flat products when tested as placed on the market or in standard test configuration of assemblies . 88 Table A.54 — Installation parameters for PEF flat products, as placed on the market . 89 Table A.55 — Product parameters for PEF – pipe insulation products as placed on the market . 90 Table A.56 — Installation parameters for PEF – pipe insulation products as placed on the market . 91 Table A.57 — Installation parameters for PEF – for flat products in standard test configuration of assemblies

simulating end-use applications . 92

Figures

Figure 1 — Installation of specimen according to EN 13823 . 15 Figure 2 — Principle of positioning of minimum mechanical fixings . 16 Figure 3 — Joint arrangement for a product tested uncovered (front view) . 16 Figure 4 — Schematic drawings of the mounting of the test specimens in the SBI in the case of 25 mm insulation thickness . 17 Figure 5 — Fixing corrugated steel sheet (New figure is being drawn) . 24

CEN/TC 88 have proposed to set the date of withdrawal (dow) of national standards which conflict with this European Standard 21 months after availability. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Clause TitleAlignment4.2.xxa) Reaction to fire Addition to Title: of the product as placed on the market New text: Reaction to fire classification of the product, as placed on the market, shall be determined in accordance with EN 13501-1 and the basic Mounting and Fixing rules given in EN 15715:2009.

NOTE 1

This classification is compulsory and always included in the CE Marking label.

Detailed information about the test conditions and the field of application of the classification as stated in the reaction to fire classification report shall be given in the manufacturer's literature.

Manufacturers declaring Euroclass A1 without further test shall demonstrate by testing in accordance with EN 13820 that the products do not contain more than 1,0 % by weight of organic matter.

NOTE 2

The commission decision 96/603/EC of 4 October 1996 amended by the commission Decision 00/605/EC of 26 September 2000 gives the list of products to be considered as reaction to fire class Euroclass A1 without the need for testing.

4.3.xx a)

New Clause Title: Reaction to fire of product in standardized assemblies simulating end-use applications. Text: Reaction to fire classification of products in standardized assemblies simulating end-use applications excluding pipe insulation, shall be determined in accordance with EN 13501-1 and the basic Mounting and Fixing rules given in EN 15715:2009.

This classification offers the opportunity to give a complementary and optional declaration on reaction to fire for standard test configurations of assemblies which include the insulation product.

The number of the selected test configuration of assembly (Table 5 of EN 15715:2009) which is used in the test shall be quoted with the Euroclass.

Detailed information about the test conditions and the field of application of the classification as stated in the reaction to fire classification report shall be given in the manufacturer's literature.

5., Table 7 Test methods, Table 7.

4.2xxa) Add: Under "specific conditions", column 5, "See Clause 5 of EN 15715:2009"

Add: 4.3.xx Across columns 2, 3 and 4 add: see EN 13501-1 column 5 add see Clause 6 of EN 15715:2009.

Clause 8 by:

Products conforming to this standard shall be marked clearly, either on the product or on the label or on the packaging, with the following information:

product name or other identifying characteristic; name or identifying mark of the manufacturer or his authorised representative;

address of the manufacturer or his authorised representative;

shift or time of production or traceability code;

reaction to fire class of the product as placed on the market.

This classification shall be identified with the designation "product" after the classification.

If tests on standardised assemblies have been performed according to Clause 6 of EN 15715:2009, then the reaction to fire classification shall be added and identified with the designation "standardised assembly no. x" after the classification. This information shall be kept distinct from the CE marking.

The number of the standardised assembly is taken from Table 5 of EN 15715:2009. Reference to manufacturer's literature (ML) for further information:

declared thermal resistance;

declared thermal conductivity;

nominal thickness;

designation code as given in Clause 6; nominal length; nominal width; type of facing, if any; number of pieces and area in the package, as appropriate.

NOTE : For CE marking and labelling see ZA.3.

Figure xa): Example of additional voluntary information. a) Number depends on the relevant product standard.

Any other voluntary information on the product such as:

Reaction to fire for standardised assembly No. 1, 2, 3, 4

Voluntary marks

(ISO 1716:2002) EN ISO 9229:2007, Thermal insulation — Vocabulary (ISO 9229:2007) EN ISO 11925-2, Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame — Part 2: single-flame source test (ISO 11925-2:2002) 3 Terms, definitions and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 9229:2007 and the following apply. 3.1.1 asymmetrical thermal insulation product product that has no plane of symmetry in the thickness SIST EN 15715:2010

insulation product designed to fit around pipes NOTE From fire respective "pipe insulation" is considered as linear product.

3.1.4 product as placed on the market insulation product complying with the scope of this standard (product itself)

3.6 product parameter aspect of a product (e.g. thickness, composition, density), which may vary and which may or may not have an influence on the test performance 3.2 Abbreviated terms used in this European Standard

CWFT Classification Without Further Testing

PCS Pouvoir Calorifique Supérieur (engl.: gross heat of combustion)

SBi

Single Burning item 4 Principle The reaction to fire classification (Euroclasses) shall be determined in accordance with EN 13501-1, respecting the test conditions laid down in this standard. The classification for the product as placed on the market is without any non-integrated installation means, e.g. glues, sealants. Thermal insulation products shall be tested in accordance with Clause 5 of this standard. This classification is compulsory and shall be included in the marking and labelling. Detailed information about the test conditions and the field of application of the classification as stated in the reaction to fire classification report shall be given in the manufacturer’s literature and in the declaration of conformity. Additional and optional reaction to fire tests of standardised assemblies simulating end-use applications, excluding pipe-insulation and which incorporate thermal insulation products, may be performed according to Clause 6 of this standard. This additional test data will allow the manufacturer the opportunity to give a complementary and optional declaration (where required) on reaction to fire for a standardised end-use application/assembly which includes the insulation product. The number of the selected test configuration of the assembly (Table 5) that is used shall be quoted with the Euroclass. Detailed information about the test conditions and the field of application of the classification as stated in the reaction to fire classification report shall be given in the manufacturer’s literature. This information shall be kept distinct from the CE marking when labelling products. NOTE 1 In respect of the standardised assemblies, it is understood that the manufacturer of the thermal insulation cannot take responsibility for the quality of the installation, neither for the way the insulation is installed.

NOTE 2 For pipe insulation, especially since the variety of end-uses, no standardised assemblies have been defined. Instructions for mounting and fixing of test specimens. SIST EN 15715:2010

This clause gives instructions for mounting and fixing for reaction to fire testing of thermal insulation products as placed on the market (product itself) and includes the field of application of the test results in 5.4.

This subclause is related to 4.2 in the main body of the product standards, e.g. EN 13162 or EN 14303. 5.2 Product and installation parameters Tables 1 and 2 give the parameters that have to be taken into account when determining a product’s reaction to fire performance and the field of application of the test results. The following tables are valid for both, flat products and pipe insulation. NOTE 1 Ageing or washing procedures are Not applicable for the test specimens. NOTE 2 Prefabricated shapes, e.g. elbows, T-pieces shall be deemed to have the same fire classification as tested products of the same product group.

Table 1 — Product parameters Product Parameters EN ISO 1182 (class A1 and A2) EN ISO 1716 (class A1 and A2) EN 13823 (class A1 to D) EN ISO 11925-2 (class B to E) All products

Thickness — — X X Density X — X X Type of product X X X X Additional properties for faced and/or coated thermal insulation products Type of facing(s) or coating(s) — X X X Thickness/area weight of facing(s) or coating(s) — X X X Type and amount of adhesive for facing(s) or coating(s) — X X X Asymmetry — — X X

Size and positioning of test specimen X — Product orientation and geometry

X X Fixing of test specimen

X — a) For pipe insulation only

5.3 Mounting and fixing 5.3.1 Ignitability, EN ISO 11925-2 Exposure to thermal attack The product shall be tested directly exposed to the thermal attack. Both surface and edge shall be exposed to the flame. If a product is produced with closed edges, the closed edge shall be exposed to the flame. 5.3.1.1 Substrate The test specimen, cut from the product samples including their facings and/or coatings, shall be mounted in the test apparatus without a substrate. 5.3.1.2 Product orientation and geometry Homogeneous products and products with the same facing or coating on both sides shall be tested on one face only.

If the product surfaces are not the same or the product is asymmetrical, two options are open for declaration: either the worse test result will be used to declare the reaction to fire class of the product (valid for both faces exposed); or a declaration of the reaction to fire class of each face is made, provided that the identification of the faces is clearly visible in the marking and labelling of the product. In case of a Euroclass F declaration for one of the faces, no test needs be performed on that face. 5.3.2 Single Burning Item (SBI), EN 13823 5.3.2.1 Exposure to thermal attack The product shall be tested directly exposed to the thermal attack. SIST EN 15715:2010

For Euroclass A1 classification a calcium silicate substrate is compulsory. Gypsum plaster board, steel, and wooden particle board substrates such as defined in EN 13238 are permitted to be used instead.

The test conditions and limit to the applicability of the classification shall be given in the declaration of conformity, in the classification report and in the manufacturer’s technical literature. 5.3.2.3 Air gaps/cavities The test specimen (product itself) shall be mounted in the test apparatus without an air gap/cavity (neither between the product and substrate nor between substrate and backing board). 5.3.2.4 Joints/ edges The general test shall be done with one vertical and one horizontal joint in the long wing. Alternatively, testing can be done either with a horizontal or a vertical joint. Positioning of the joints shall be in accordance with EN 13823. Testing with a vertical and a horizontal joint in the same test reflects a worst case situation and gives the widest field of application. Test specimens taken from product samples that are small shall be arranged in the test apparatus such that the joints required by EN 13823 are in the correct places. Other joints, resulting from the product size, may also be present. All joints (in the corner and at the long wing) shall be installed without a flashing or a sealant and tightly closed. Products shall be mounted with the edges as existing; results from testing with butt edges are valid for all types of edges. If a horizontal or vertical joint is used, the test conditions and field of application of the classification shall be given in the declaration/certification of conformity, in the classification report and in the manufacturer’s technical literature. 5.3.2.5 Size and positioning of the test specimen The size of the test specimens is given in EN 13823. The test specimens shall be cut from the product sample including its facings or coatings. Positioning of the test specimens shall meet the following conditions: 5.3.2.4 shall be taken into account; products having larger dimensions than the SBI test specimens shall be cut to size; products having smaller dimensions than the SBI test specimen shall be mounted in such a way that installation of full size products is started at the bottom corner line between both wings and joints; the specimens installed on the short wing shall cover (on their thickness) those installed at the long wing with a butt joint, see Figure 1; the maximum thickness of the test specimen including the substrate that can be installed in the SBI is 200 mm. SIST EN 15715:2010

Dimensions in mm

Key: 1 Backing Board 2 Substrate 3 Vertical joint 4 Horizontal joint 5 Product Figure 1 — Installation of specimen according to EN 13823 SIST EN 15715:2010

Figure 2 — Principle of positioning of minimum mechanical fixings

Figure 3 — Joint arrangement for a product tested uncovered (front view)

5.3.2.8 Fixing of pipe insulation test specimens 5.3.2.8.1 Dimensions of specimens Products that can be tested in the SBI are pipe insulation with an inside diameter of 22 mm and a thickness of 25 mm to 75 mm. Each individual thickness in that range 25 mm to 75 mm may be tested and classified if desired. The test data for 25 mm thickness is also valid for smaller thicknesses. The following principles apply: 1) The product shall always be tested at 25 mm thickness, or at the nearest available greater thickness. Products only available at thicknesses below 25 mm shall be tested multi-layered to reach or exceed 25 mm. 2) For product thicknesses larger than 25 mm but smaller than 50 mm: The actual maximum

thickness shall also be tested. The worst case results apply for all product thicknesses up to the maximum tested. This means that two thicknesses are tested. 3) For product thicknesses larger than 50 mm and up to 75 mm: The maximum thickness and the dimension closest to 50 mm shall also be tested. The worst case results apply for all product thicknesses up to the maximum tested. This means that three thicknesses are tested. 4) For product thicknesses larger than 75 mm:

as 3), but the maximum thickness tested is 75 mm. Test data on pipe-insulation with a bore of 22 mm is deemed to cover all other bores. Test data on pipe-insulation with a thickness of 75 mm is deemed to cover products of larger thickness. Pipe-insulation and insulation for cylindrical ducts with an outer diameter larger than 300 mm and insulation products intended to be used on flat surfaces shall be tested as flat specimens. SIST EN 15715:2010

5.3.2.8.2 Mounting of test specimen Pipe insulation shall be mounted on steel pipes. The steel pipes shall have an outside diameter of 21,3 mm and a wall thickness of 2,5 mm to 2,6 mm. NOTE Steel pipes produced according to ISO 65. The steel pipes shall have a length of 1 500 mm and be mounted vertically in the SBI trolley. The steel pipes shall be closed at one end to prevent convection, but for safety reasons care should be taken not to seal the pipe completely. The pipes shall be mounted in such a way that there is a gap of 25 mm between the outside pipe insulation surfaces of the adjacent pipe and between the outside insulation surface and the backing board. As many pipes as possible shall be mounted on each wing in the SBI. For the insulation thickness of 25 mm the number of pipes is five on the short wing and ten on the long wing. For the insulation thickness of 50 mm the number of pipes is three on the short wing and six on the long wing; for the insulation thickness of 75 mm the number of pipes is two on the short wing and five on the long wing. The steel pipes shall be mounted in such a way that their position is fixed for the duration of the test. Figure 4 shows a schematic drawing of the mounting in the SBI. Dimensions in mm

a) Front view Key: 1 Backing board 2 Burner 3 U-profile

b) Top view

Figure 4 — Schematic drawings of the mounting of the test specimens in the SBI in the case of 25 mm insulation thickness SIST EN 15715:2010

5.3.2.8.4 Backing board The backing board shall be positioned behind the test specimens at a distance of 25 mm from the outside surface of the specimen. 5.3.2.8.5 Fixing of the pipe insulation on the steel pipes Pipe insulation, shall be mounted in the SBI test without any fixings, except where the products may be able to slide down during the test. These types of products shall be fixed at the top of each specimen using steel wire. Pipe insulation of which the joints are adhered in end-use shall be mounted with adhered joints, faced to the burner in the SBI test. Pipe insulation with mechanically held longitudinal joints shall be arranged with one joint on each pipe facing the burner

5.4 Validity of test results for product groups (Field of application) The manufacturer is responsible for the grouping of his products according to EN 13172, the relevant product standard, and this standard. The validity of the test result for a product group is determined by the product and installation parameters with the requirements given in Annex A. Ancillaries used on site are not part of the product group and shall not be part of the test report

for the reaction to fire classification. 6 Instructions for mounting and fixing of products in standardised assemblies simulating end-use application(s) 6.1 General

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...