EN 416-2:2006

(Main)Single burner gas-fired overhead radiant tube heaters for non-domestic use - Part 2: Rational use of energy

Single burner gas-fired overhead radiant tube heaters for non-domestic use - Part 2: Rational use of energy

This European Standard specifies the requirements and test methods for the rational use of energy of non-domestic gas fired overhead radiant tube heaters incorporating a single burner system under the control of an automatic burner control system, referred to in the body of the text as 'appliances'.

This standard is applicable to Type A2, A3, B12, B13, B22, B23, B42, B43, B52, B53, C12, C13, C32 and C33 appliances intended for use in other than domestic dwellings, in which the supply of combustion air and/or the evacuation of the products of combustion is achieved by mechanical means located upstream of the draught diverter, if provided.

This standard is not applicable to:

a) appliances designed for use in a domestic dwelling;

b) outdoor appliances;

c) appliances of heat input in excess of 120 kW (based on the net calorific value of the appropriate reference test gas);

d) appliances having fully pre-mixed gas and air burners in which :

1) either the gas and all the combustion air are brought together just before the level of the combustion zone; or

2) pre-mixing of the gas and all combustion air is carried out in a part of the burner upstream of the combustion zone.

This standard is applicable to appliances which are intended to be type tested. Requirements for appliances which are not intended to be type tested need to be subject to further consideration.

Gasgeräte-Heizstrahler - Dunkelstrahler mit einem Brenner mit Gebläse für gewerbliche und industrielle Anwendung - Teil 2: Rationelle Energienutzung

Diese Europäische Norm enthält die Anforderungen und Prüfmethoden für die rationelle Energienutzung von Dunkelstrahlern mit einem einzigen Brenner mit Gebläse mit Überwachung durch einen Gasfeuerungs-automaten (im folgenden Text als 'Geräte' bezeichnet).

Diese Europäische Norm gilt für Geräte der Arten A2, A3, B12, B13, B22, B23, B42, B43, B52, B53, C12, C13, C32 und C33, die für gewerbliche und industrielle Anwendung vorgesehen sind und bei denen die Zufuhr der Verbrennungsluft und/oder die Abführung der Verbrennungsprodukte mit mechanischen Mitteln erfolgt, die vor der Strömungssicherung angeordnet sind, wenn eine solche vorgesehen ist.

Diese Europäische Norm gilt nicht für:

a) Geräte, die für eine Verwendung in Wohnungen gedacht sind;

b) Geräte, die für eine Verwendung im Freien gedacht sind;

c) Geräte mit einer Wärmebelastung über 120 kW (bezogen auf den Heizwert des jeweiligen Normprüfgases);

d) Geräte mit Brennern mit kompletter Gas- und Luftvormischung, bei denen

1) entweder das Gas und die gesamte Verbrennungsluft kurz vor der Verbrennungszone zusammengeführt werden; oder

2) das Vormischen des Gases mit der gesamten Verbrennungsluft in einem Teil des Brenners vor der Verbrennungszone erfolgt.

Diese Norm ist anwendbar für Geräte, die für eine Typprüfung vorgesehen sind. Anforderungen an Geräte, die nicht für eine Typprüfung vorgesehen sind, benötigen weitere Überlegungen.

Tubes radiants suspendus à monobrûleur à usage non domestique utilisant les combustibles gazeux - Partie 2 : Utilisation rationnelle de l'énergie

Stropna cevna sevala s plinskim gorilnikom za nestanovanjske prostore – 2. del: Smotrna raba energije

General Information

- Status

- Withdrawn

- Publication Date

- 06-Jun-2006

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 180 - Non-domestic gas-fired overhead radiant heaters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Oct-2019

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 416-2:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Single burner gas-fired overhead radiant tube heaters for non-domestic use - Part 2: Rational use of energy". This standard covers: This European Standard specifies the requirements and test methods for the rational use of energy of non-domestic gas fired overhead radiant tube heaters incorporating a single burner system under the control of an automatic burner control system, referred to in the body of the text as 'appliances'. This standard is applicable to Type A2, A3, B12, B13, B22, B23, B42, B43, B52, B53, C12, C13, C32 and C33 appliances intended for use in other than domestic dwellings, in which the supply of combustion air and/or the evacuation of the products of combustion is achieved by mechanical means located upstream of the draught diverter, if provided. This standard is not applicable to: a) appliances designed for use in a domestic dwelling; b) outdoor appliances; c) appliances of heat input in excess of 120 kW (based on the net calorific value of the appropriate reference test gas); d) appliances having fully pre-mixed gas and air burners in which : 1) either the gas and all the combustion air are brought together just before the level of the combustion zone; or 2) pre-mixing of the gas and all combustion air is carried out in a part of the burner upstream of the combustion zone. This standard is applicable to appliances which are intended to be type tested. Requirements for appliances which are not intended to be type tested need to be subject to further consideration.

This European Standard specifies the requirements and test methods for the rational use of energy of non-domestic gas fired overhead radiant tube heaters incorporating a single burner system under the control of an automatic burner control system, referred to in the body of the text as 'appliances'. This standard is applicable to Type A2, A3, B12, B13, B22, B23, B42, B43, B52, B53, C12, C13, C32 and C33 appliances intended for use in other than domestic dwellings, in which the supply of combustion air and/or the evacuation of the products of combustion is achieved by mechanical means located upstream of the draught diverter, if provided. This standard is not applicable to: a) appliances designed for use in a domestic dwelling; b) outdoor appliances; c) appliances of heat input in excess of 120 kW (based on the net calorific value of the appropriate reference test gas); d) appliances having fully pre-mixed gas and air burners in which : 1) either the gas and all the combustion air are brought together just before the level of the combustion zone; or 2) pre-mixing of the gas and all combustion air is carried out in a part of the burner upstream of the combustion zone. This standard is applicable to appliances which are intended to be type tested. Requirements for appliances which are not intended to be type tested need to be subject to further consideration.

EN 416-2:2006 is classified under the following ICS (International Classification for Standards) categories: 97.100.20 - Gas heaters. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 416-2:2006 has the following relationships with other standards: It is inter standard links to ENV 1259-1:1994, ENV 1259-3:1996, ENV 1259-2:1996, EN 17175:2019, EN 416:2019, EN 416-1:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 416-2:2006 is associated with the following European legislation: EU Directives/Regulations: 2009/142/EC, 90/396/EEC; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 416-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Single burner gas-fired overhead radiant tube heaters for non-domestic use - Part 2: Rational use of energyStropna cevna sevala s plinskim gorilnikom za nestanovanjske prostore – 2. del: Smotrna raba energijeTubes radiants suspendus a monobruleur a usage non domestique utilisant les combustibles gazeux - Partie 2 : Utilisation rationnelle de l'énergieGasgeräte-Heizstrahler - Dunkelstrahler mit einem Brenner mit Gebläse für gewerbliche und industrielle Anwendung - Teil 2: Rationelle EnergienutzungTa slovenski standard je istoveten z:EN 416-2:2006SIST EN 416-2:2006en,fr,de97.100.20ICS:SIST ENV 1259-3:1996SIST ENV 1259-2:1996SIST ENV 1259-1:19961DGRPHãþDSLOVENSKI

STANDARDSIST EN 416-2:200601-september-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 416-2June 2006ICS 97.100.20Supersedes ENV 1259-1:1994, ENV 1259-2:1996, ENV1259-3:1996

English VersionSingle burner gas-fired overhead radiant tube heaters for non-domestic use - Part 2: Rational use of energyTubes radiants suspendus à monobrûleur à usage nondomestique utilisant les combustibles gazeux - Partie 2 :Utilisation rationnelle de l'énergieGasgeräte-Heizstrahler - Dunkelstrahler mit einem Brennermit Gebläse für gewerbliche und industrielle Anwendung -Teil 2: Rationelle EnergienutzungThis European Standard was approved by CEN on 16 March 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 416-2:2006: E

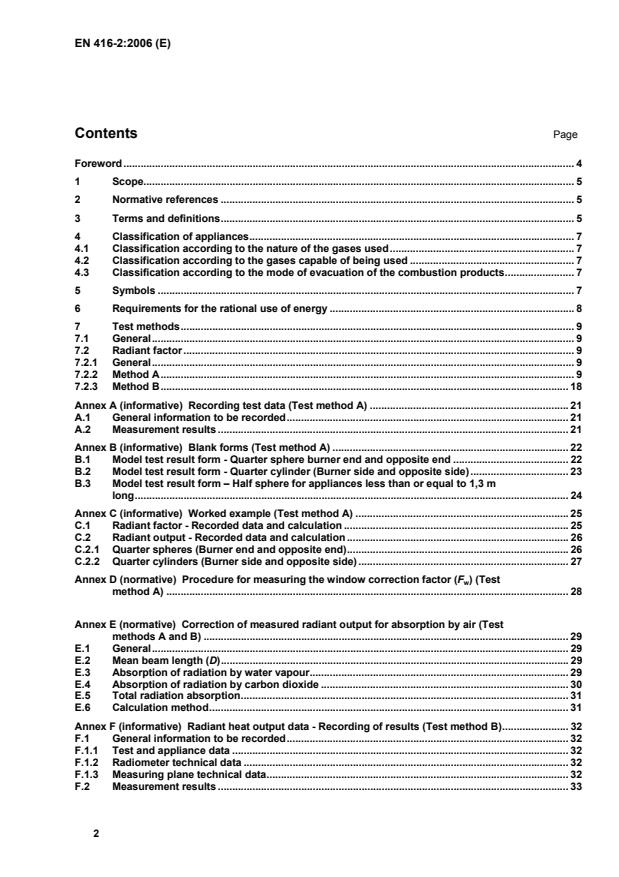

Page Foreword.4 1 Scope.5 2 Normative references.5 3 Terms and definitions.5 4 Classification of appliances.7 4.1 Classification according to the nature of the gases used.7 4.2 Classification according to the gases capable of being used.7 4.3 Classification according to the mode of evacuation of the combustion products.7 5 Symbols.7 6 Requirements for the rational use of energy.8 7 Test methods.9 7.1 General.9 7.2 Radiant factor.9 7.2.1 General.9 7.2.2 Method A.9 7.2.3 Method B.18 Annex A (informative)

Recording test data (Test method A).21 A.1 General information to be recorded.21 A.2 Measurement results.21 Annex B (informative)

Blank forms (Test method A).22 B.1 Model test result form - Quarter sphere burner end and opposite end.22 B.2 Model test result form - Quarter cylinder (Burner side and opposite side).23 B.3 Model test result form – Half sphere for appliances less than or equal to 1,3 m long.24 Annex C (informative)

Worked example (Test method A).25 C.1 Radiant factor - Recorded data and calculation.25 C.2 Radiant output - Recorded data and calculation.26 C.2.1 Quarter spheres (Burner end and opposite end).26 C.2.2 Quarter cylinders (Burner side and opposite side).27 Annex D (normative)

Procedure for measuring the window correction factor (Fw) (Test method A).28

Annex E (normative)

Correction of measured radiant output for absorption by air (Test methods A and B).29 E.1 General.29 E.2 Mean beam length (D).29 E.3 Absorption of radiation by water vapour.29 E.4 Absorption of radiation by carbon dioxide.30 E.5 Total radiation absorption.31 E.6 Calculation method.31 Annex F (informative)

Radiant heat output data - Recording of results (Test method B).32 F.1 General information to be recorded.32 F.1.1 Test and appliance data.32 F.1.2 Radiometer technical data.32 F.1.3 Measuring plane technical data.32 F.2 Measurement results.33

Worked example (Test method B).35 G.1 General information.35 G.2 Radiometer technical data.35 G.3 Measuring plane technical data.35 G.4 Measurement results.36 G.4.1 Test information.36 G.4.2 Test ambient conditions.36 G.4.3 Gas/heat input data.36 G.4.4 Flue gas data.36 G.4.5 Absorption of water vapour and CO2 data.37 G.4.6 Irradiation measurement data.37 Annex H (informative)

Radiometer design (Test method B).40 H.1 Principle radiometer design features.40 H.2 Radiometer technical design.41 H.3 Pyro-electric detector.41 Annex I (normative)

Radiometer calibration (Test method B).42 I.1 Radiometer calibration.42 I.1.1 General.42 I.1.2 Black Body calibration method.42 I.2 Worked example.43 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU directives.45

Part 1: Safety 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in Clause 3 of EN 416-1: 1999 apply together with the following. 3.1 radiation reference plane flat horizontal surface bounded by the lower edge of the reflector or, in the case where radiant parts project below this lower edge of the reflector, the flat horizontal surface touching the lowest radiant part (see Figure 1)

1 Reflector 2 Reference plane Figure 1 — Radiation reference plane 3.2 irradiance (E) radiant power per unit area (W/m2) incident upon a surface 3.3 radiant factor (Rf) heat emitted by the appliance through the radiation reference plane divided by the net heat input of the test gas 3.4 measuring plane (Test method B only) plane parallel to the radiation reference plane and 100 mm ± 3 mm below it 3.5 measuring grid (Test method B only) regular arrangement in the measuring plane of straight lines running parallel and perpendicular to the longitudinal axis of the appliance with sufficient precision (± 1 mm). The nodal points of the measuring grid are located at the points of intersection of these lines (see Figure 2) such that the distance between all adjacent nodes points on these lines is 100 mm ± 2 mm

1 Heater 2 Nodal point 3 Measuring cell Fij Figure 2 — Measuring grid (Test method B) 4 Classification of appliances 4.1 Classification according to the nature of the gases used The requirements of 4.1 of EN 416-1:1999 apply. 4.2 Classification according to the gases capable of being used The requirements of 4.2 of EN 416-1:1999 apply. 4.3 Classification according to the mode of evacuation of the combustion products The requirements of 4.3 of EN 416-1:1999 apply. 5 Symbols The symbols shown in Table 1 are used in this standard. Table 1 — Symbols Symbol Title Unit 2COα Coefficient in equation for kco2 kPa-1 m-1 2HOα Coefficient in equation for kmo kPa-1 m-1 2COA Absorption factor of carbon dioxide — 2HOA Absorption factor of water vapour — a Reflector length mm ATOT Radiant correction factor for water vapour and CO2 in air (see Annex E) — b Reflector width mm c Distance between two nodal points parallel with the longitudinal axis mm

— E Actual irradiance from overhead radiant heater W/m2 Ea Actual irradiance output by appliance in air W/m2 Eij Irradiance of the appliance measured at the nodal points of the measurement W/m2 ifE Average irradiance over the measurement grid Fij W/m2 Fw Window correction factor — Hi Net calorific value of the test gas (at 15 °C, 1013,25 mbar, dry gas)

W h/m3 2COk Coefficient in equation for emission factor of carbon dioxide kPa-1 m-1 2HOk Coefficient in equation for emission factor of water vapour kPa-1 m-1 L Length of reference surface cylinder m N Number of arc positions along the half cylinder (see Figure 2) — n Coefficient in equations for 2COk and 2HOk — P2CO Partial pressure of carbon dioxide in ambient air kPa 2HOP Partial pressure of water vapour in ambient air kPa pmax,H20 Saturated vapour pressure mbar p Gas supply pressure mbar pa Atmospheric pressure mbar pW Saturation vapour pressure of fuel gas at temperature tg mbar Qm Measured heat input based on the net calorific value of the test gas W Q(R)C Radiant output after correction for absorption of radiation in air W Q(R)M Measured radiant output W R Radius to radiometer from centre of reference plane m Rf Radiant factor — S Radiometer sensitivity µV/(W/m2)tA Ambient air temperature °C tg Gas temperature at measuring point °C ts Sensor temperature °C U Sensor voltage v V Gas volume input at test conditions m3/h Vb Sensor voltage recorded with radiation shield in place µV Vt Sensor voltage recorded without radiation shield in place µV Vo Gas volume rate under reference conditions (at 15 °C, 1013,25 mbar, dry gas) m3/h OH2ε Emissivity of water — 6 Requirements for the rational use of energy When mounted horizontally in accordance with the manufacturer’s instructions and measured by one of the methods given in 7.2 the radiant factor of the appliance, adjusted to the nominal heat input, shall be in accordance with the values given in Table 2.

Table 2 — Radiant factor for appliances mounted horizontally Class Radiant Factor 1 > 0,4

to

≤ 0,5 2 > 0, 5

1 A test at the maximum nominal heat input need not be applied if it is known that the lowest radiant output is achieved at the minimum nominal heat input.

The radius of the metal arc shall be within the range given in Figure 3. NOTE It is important to check that the maximum irradiance does not exceed the maximum value allowed for the instrument. 20º40º60º80º100º120º140º160º180º90º0º70º50º30º10ºR12432 Key

1 Removable radiation shield 2 Radiometer 3 Parallel 4 Meridian R Radius measured from the arc centre to the surface of the radiometer.

The radius shall be in the range 1,54 m to 1,88 m.

For any one measurement, the radius shall not vary by more than ± 20 mm Figure 3 — Test rig (Test method A) Test equipment shall: a) for an appliance with a length of more than 1,3 m, provide adjustment to allow the arc centre to coincide with either end of the reference plane; b) for an appliance with a length of 1,3 m or less, make the arc centre coincident with the centre of the reference plane (see Figure 1);

f) if appropriate, provide a guide rail to position the arc along the length of the appliance. 215 + - 5 mm3451> 270 mm> 270 mm Key

1 Radiation shield 2 Sensor 3 Reflective aluminium sheet 4 15 mm insulation (e.g. Rockwool or Polystyrene) 5 Matt black non-reflective surface Figure 4 — Radiation shield (Test method A) 7.2.2.2.2 Measurement apparatus 7.2.2.2.2.1 Sensor characteristics Sensors used shall : a) have a sensitivity factor that does not change by more than ± 3 % in an ambient temperature range of 15 °C to 30 °C; b) have a sensitivity that is constant either in the wavelength range 0,8 µm to 40 µm, or in another wavelength range which shall be stated in the test report (see 7.2.2.5)2); c) have a span angle ≥ 170 °C.

There shall not be a large variation in sensitivity with a change in the radiation angle of incidence;

2) This may be necessary for the purposes of calibration.

170º150º130º110º90º70º50º30º10º90º70º50º30º10ºL/N½L/NL/NLL/NL/NL/N12ADetail A3½

Key

1 Meridian 2 Parallel 3 Identification of sensor positions A Sensor position L Reference surface cylinder length N Number of arc positions along the cylinder length a)

Integrating surface (Test method A) – Appliance greater than 1,3 m in length

1 Meridian 2 Parallel 3 Sensor position notation A Sensor position b)

Integrating surface (Test method A) – Appliance less than 1,3 m in length Figure 5 — Appliance integrating surface (Test method A) 7.2.2.3 Working area Working areas shall: a) have walls and ceilings that are isolated from exterior influences (e.g. sunlight through windows and other heating equipment); b) have interior surfaces treated so as to reduce spurious radiation reflection (e.g. matt non-reflective surfaces);

in the case of an appliance of length greater than 1,3 m to a quarter cylinder plus two quarter hemispheres (the result shall be multiplied by two). 7.2.2.4.2 Measurement Connect each sensor to a millivoltmeter of the potentiometric type, electronic type or electronic device with an input impedance of at least 1 MΩ and a sensitivity of 1 µV. Make the measurements in a still atmosphere with the appliance in thermal equilibrium when operating under the adjustment conditions described in 7.2.2.1. NOTE It is important to measure the outside temperature of the instrument to ensure it is not being overheated. The measurement points shall be situated at the intersection of the parallels and the meridians (see Figures 5a) and 5b)) such that: a) for an appliance less than or equal to 1,3 m long, the measurement point shall be on the hemisphere and the intersections shall be at meridians 0°, 20°, 40° etc, up to 180°, with parallels 10°, 30°, 50° etc. up to 90° (See Figure 5b)); b) for an appliance of length greater than 1,3 m, the measurement point shall be on the half hemisphere (see Figure 5a)), the intersections at the extremities shall be at meridians 10°, 30°, 50° etc. up to 170°, with parallels 10°, 30°, 50° etc. up to 90°.

On the half cylinder required for a reference surface of length L for a number of measurements N, the intersections shall be at the points given by Expression (1). 35(21).2'2'2'2LLLNLNNNN−

(1) where : L is the reference surface length;

(2) where : Vt is the sensor voltage recorded without the radiation shield in place in µV; Vb is the sensor voltage recorded with the radiation shield in place in µV; Fw is the window correction factor; S is the radiometer sensitivity in µV/(W/m2). b) integrating over the envelope of each quarter sphere and quarter cylinder to obtain the energy received from the appliance and its contribution to the radiant output (see Annexes A and B). c) determining the measured radiant output (Q(R)M), using Equation 3 or 4 as appropriate : 1) for an appliance less than or equal to 1,3 m long : Q(R)M =

Q(R)5

(3) where : Q(R)5

is the radiant output of the hemisphere in W. 2) for an appliance of length greater than 1,3 m : Q(R)M =

Q(R)1+

Q(R)2 +

Q(R)3

+

Q(R)4

(4) where : Q(R)1 is the radiant output of the quarter sphere (burner end) in W; Q(R)2 is the radiant output of the quarter sphere (opposite end) in W; Q(R)3 is the radiant output of the quarter cylinder (burner side) in W; Q(R)4 is the radiant output of the quarter cylinder (opposite side) in W. d) measure the heat input to the appliance (Qm) using Equation (5) :

(5) where :

Vo is the gas volume rate under reference conditions in m3/h;

Hi is the net calorific value of the test gas in Wh/m3; and

Vo

=V

()()−+×+25,101315,27315,288wagpppt

where :

V is the gas volume input at the test conditions in m3/h ;

p is the gas supply pressure mbar;

pa is the atmospheric pressure in mbar;

pw is the saturation vapour pressure of the fuel gas at temperature tg in °C;

tg

is the gas temperature at the measuring point in °C NOTE 1 Qm is derived from the gas volume flow rate under reference conditions and the net calorific value of the gas used for testing, utilising the units specified in Clause 5.

Equation (6) is not the same as that given in EN 416-1 for the calculation of the nominal heat input, which is not appropriate in this instance. e) calculate the radiant factor (R f) using Equation (6) (see Annex A). m)R(fCQQR=

(6) where : Q(R)c is the radiant output after correction for the absorption of radiation in air in W; Qm is the measured heat input based on the net calorific value of the test gas in W; and (R)M(R)cTOT1-QQA=

where :

ATOT is the radiant correction factor for water vapour and CO2 in air NOTE 2 For the calculation of ATOT see Annex E.

The requirements given in Clause 6 shall be satisfied. 7.2.2.5 Test report In view of the complexity of the test, it is recommended that test results are recorded in a test report (see Annexes A, B and C for examples).

NOTE An example of a proved and tested radiometer design is given in Annex H. 7.2.3.2.2 Mechanical test equipment Test equipment shall: a) if it is mechanical equipment, enable the appliance to be suspended horizontally in accordance with the requirements of 7.1; and

b) provide a stable mobile test arrangement enabling the radiometer to be adjusted accurately in the measuring plane.

NOTE Adjustment may be achieved by hand or automatically. 7.2.3.2.3 Radiometer measurement positions Before commencing the test, the first and last node points (measurement points) shall be established where the parallel and perpendicular lines intersect. This is achieved by measuring the irradiance at the edge of the reflector and the crossover points or nodes are where irradiation is smaller than 1 % of the maximum measured value under the appliance. The radiometer shall be positioned at the nodal points of the measurement grid (see Figure 2). 7.2.3.3 Working area The test shall be carried out in a working area having a floor with a non-reflecting surface. 7.2.3.4 Test procedure 7.2.3.4.1 Measuring principle Radiant output is determined by means of a radiometric method in which the irradiance in the measuring plane is measured and the measured values are integrated over the area of the measuring grid.

7.2.3.4.2 Measuring method The radiometer is placed at each of the nodal points specified in 3.5 with a maximum deviation (for each of the three axes) of 3 mm and a measurement of the irradiance is taken as soon as the reading is stable. The radiometer axis shall not incline by more than 2° from the perpendicular. NOTE It is recommended that the measuring sequence is recorded using an automatic system. 7.2.3.5 Calculation of radiant output The radiant output (Q(R)M) corresponds to the sum of all the products between the individual node surface and the arithmetic mean of the measured values of the irradiance of the four nodes forming each node surface (Figure 2). The appliance irradiance (Eij) measured at the nodes is given by Equation (7). Eij = U/S

W/m2

(7) where :

U is the sensor voltage in µV;

S is the radiometer sensitivity in µV/W/m2 and the average appliance irradiance (ijE) measured at the nodes is given by Equation (8). 4,1,,11,1jijijijiijEEEEE+++=−−−− W/m2

(8) where : ()ni.,2,1∈ and

()kj.,2,1∈ The radiant output (Q(R)M) is then given by Equation (9). ()()()()∑====×=kjnijiMREFQ11ijij)(

(9) where :

Fij is the area of the measurement cell in m2 (see Figure 2);

ijEis the average irradiance of the measurement cell Fij in W/m2

Vo

=V

()()−+×+25,101315,27315,288wagpppt NOTE This heat input is derived from the gas volume flow rate under reference conditions and the net calorific value of the gas used for testing, utilising the units specified in Clause 5. The equation is not the same as that given in EN 416-1 for the calculation of the nominal heat input, which is not appropriate in this instance.

7.2.3.7 Calculation of radiant factor The radiant factor (Rf) of the appliance is given by Equation (6). (R)cfMQRQ= and : (R)M(R)cTOT1-QQA= The requirements of Clause 6 shall be satisfied. 7.2.3.8 Test report In view of the complexity of the test, it is recommended that test results are recorded in a test report (see Annex F for examples).

Recording test data (Test method A) A.1 General information to be recorded Equipment type : ______________________

Model : ______________________________ Supplier : ____________________________

Manufacturer : ________________________ Appliance category : ___________________

Reference gas : _______________________ Technician : __________________________

Test date :____________________________ Nominal heat input : _________________ kW

Measured heat input (QM) : ____________ W Ambient air relative humidity : ____________

Air temperature (before) : _____________ °C

Flue gas temperature (before) : ________ °C Air temperature (after) : _______________ °C

Flue gas temperature (after) : __________ °C Flue gas (O2 or CO2) (before) : ___________

Flue gas (O2 or CO2) (after) : _____________ Quarter sphere/cylinder radius : ________ m

Radiometer sensitivity : __________ µV/W/m2 Tube length (L) : ____________________ m

Number of cylinder arc positions (N) : ______ L/N : ______________________________ m

ATOT : _______________________________ A.2 Measurement results Measurement position Test measurement (W) Quarter sphere (burner end) Q(R)1

Quarter sphere (opposite end) Q(R)2

Quarter cylinder (burner side) Q(R)3

Quarter Cylinder (opposite side) Q(R)4

Total Q(R)M (= Q(R)1+ Q(R)2+ Q(R)3+ Q(R)4)

Measured radiant output (Q(R)M) for an appliance less than or equal to 1,3 m long

= Q(R5) ______W Radiant output (Q(R)c) after correction for absorption of radiation in air :

Q(R )c

= Q(R)M /(1 - ATOT )

=

________________ W

Radiant factor (Rf) :

Rf

= Q(R)c /QM

=

_______________

Blank forms (Test method A) B.1 Model test result form - Quarter sphere burner end and opposite end Quarter sphere (burner end) (Q(R)1) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µV Cαβ∆cosα1/SFw

W/(m2/µV) E=Σi.Cαβ.∆cosα1/SFw W/m2

10° 30°50° 70° 90° 110°130°150°170°

90°

0,5 0,347

70°

1 0,327

50°

1 0,266

30°

1 0,174

10°

1 0,060

Total

ΣE

Name : Date : The radiant output (Q(R)1) over the surface of the quarter sphere is given by : 21)R(9REQ×=∑_________ W Quarter sphere (Opposite end) (Q (R)2) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µV Cαβ∆cosα1/SFw

W/(m2/µV) E=Σi.Cαβ.∆cosα1/SFw W/m2

10° 30°50° 70° 90° 110°130°150°170°

90°

0,5 0,347

70°

1 0,327

50°

1 0,266

30°

1 0,174

10°

1 0,060

Total

ΣE

Name : Date : The radiant output (Q(R)2) over the surface of the quarter sphere is given by : 22)R(9REQ×=∑_________ W

Quarter cylinder (Burner side) (Q(R)3) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µV Cαβ1/SFw

W/(m2/µV) E=Σi.Cαβ.1/SFw W/m2

Pos 1 Pos 2 Pos 3 Pos 4 Pos 5 Pos 6 Pos 7 Pos 8 Pos N

90°

0,5

70°

50°

30°

10°

Total

ΣE

Name : Date : The radiant output (Q(R)3) over the surface of the quarter cylinder is given by : 25,43)(RLNEQR×=∑ = ___________ W

Quarter cylinder (Opposite side) (Q(R)4) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µV Cαβ1/SFw

W/(m2/µV) E=Σi.Cαβ.1/SFw W/m2

Pos 1 Pos 2 Pos 3 Pos 4 Pos 5 Pos 6 Pos 7 Pos 8 Pos N

90°

0,5

70°

50°

30°

10°

Total

ΣE

Name : Date : The radiant output (Q(R)4) over the surface of the quarter cylinder is given by : 25,44)(RLNEQR×=∑ = ___________ W

Half sphere (Q(R)5) Radiometer position on

radius

arc (α parallel)Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius

arc, α and β meridians

µV Σi µV Cαβ ∆cosα 1/SFw W/(m2/ µV)E=Σi.Cαβ.1/ SFw W/m2

0° 20° 40° 60° 80° 100°120°140°160°180° 200°220°240° 260°280° 300° 320° 340°

90°

0,5 0,347 70°

1 0,327 50°

1 0,266 30°

1 0,174 10°

1 0,06

Total E

Name : Date : The radiant output (Q(R)5) over the surface of the hemisphere is given by : 25)(218REQR×=∑ = ___________ W

Worked example (Test method A) C.1 Radiant factor - Recorded data and calculation Equipment type : Radiant tube

Model : 000 Supplier : ABC

Manufacturer : XYZ Appliance category : I2H

Reference gas : G 20 Technician : WG

Test date : 05-04-94 Nominal heat input : 19,50 kW

Measured heat input (QM) : 19 156 W Ambient air relative humidity : ____________

Air temperature (before) : 23,2 °C

Flue gas temperature (before) : 221 °C Air temperature (after) : 23,5 °C

Flue gas temperature (after) : 223 °C Flue gas (O2 or CO2) (before) : 5,6

Flue gas (O2 or CO2) (after) : 5,7 Quarter sphere/cylinder radius : 1,65 m

Radiometer sensitivity : 8.2 µV/(W/m2) Tube length (L) : 4,8 m

Number of cylinder arc positions (N) : 6 L/N : 0,8 m

ATOT : 0,048

Measurement position Test measurement (W) Quarter sphere (burner end) Q(R)1 1 537,27 Quarter sphere (opposite end) Q(R)2 641,64 Quarter cylinder (burner side) Q(R)3 3 524,52 Quarter Cylinder (opposite side) Q(R)4 4316,41 Total Q(R)M (= Q(R)1+ Q(R)2+ Q(R)3+ Q(R)4) 10 019,84 Radiant output (Q(R)C) after correction for absorption of radiation in air :

Q(R)C

= Q(R)M /(1 - ATOT )

=

10 019,84/(1-0,048) = 10 525,24 W

Radiant factor (Rf) :

Rf

= Q(R)C /QM

=

10 525,24/19 156 = 0,5494

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µVCαβ∆cosα1/SFw

W/(m2/µV) E=Σi.Cαβ.∆cosα1/SFw W/m2

10° 30°50° 70° 90° 110°130°150°170°

90° 129 140167 161 151 15315516716113240.50,3470,122 28,0370° 1271 1084924 513 497 6369381131137183651 0,3270,122 333,7150° 1485 14371226 1283 1069 1690169314261605129141 0,2660,122 419,0930° 2620 22342071 1947 1935 2524299936544201242051 0,1740,122 513,8210° 3071 29022895 2841 2758 3042346239073947288251 0,06 0,122 211,00

Total

ΣE 1 505,65

Name : WG Date : 05-04-94 The radiant output (Q(R)1) over the surface of the quarter sphere is given by : 21)R(9REQ×=∑ = 1537,27 W

Quarter sphere (Opposite end) (Q(R)2) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µVCαβ∆cosα1/SFw

W/(m2/µV) E=Σi.Cαβ.∆cosα1/SFw W/m2

10° 30°50° 70° 90° 110°130°150°170°

90° 89 100114 114 110 97 91 80 59 854 0,50,3470,122 18,0870° 562 538457 449 335 27738745043838931 0,3270,122 155,3150° 628 643762 773 549 51348350759154491 0,2660,122 176,8330° 1396 11731018 1037 853 8238361026105392151 0,1740,122 195,6210° 1156 12441331 1330 1210 1093114011651315112841 0,06 0,122 211,00

Total

ΣE 628,44

Name : WG Date : 05-04-94 The radiant output (Q(R)2) over the surface of the quarter sphere is given by : 22)R(9REQ×=∑ 641,64 W

Quarter cylinder (Burner side) (Q(R)3) Radiometer position on radius

α (arc parallel) Radiometer reading i (having subtracted the voltage from spurious irradiance) at position of radius arc ,

β meridian µV ΣI µVCαβ1/SFw

W/(m2/µV) E=Σi.Cαβ.1/SFw W/m2

Pos 1 Pos 2 Pos 3 Pos 4 Pos 5 Pos 6 Pos 7 Pos 8 Pos N

90° 144 144 149 137 1008660

2242 0,50,122 136,7670° 1842 2164 1991 1606 1126715

9444 1 0,122 1152,1750° 2538 2830 2521 1976 1396939

122001 0,122 1488,4030° 3294 3984 3656 3015 22431542

177341 0,122 2163,5510° 3684 4560 4148 3446 24911723

199921 0,122 24

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...