EN 16601-60:2014

(Main)Space project management - Cost and schedule management

Space project management - Cost and schedule management

The requirements specified herein apply to, and affect the customer and supplier at all levels.

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

Raumfahrt-Projektmanagement - Kosten- und Zeitplanmanagement

Die in dieser Norm festgelegten Anforderungen betreffen und gelten für Kunden und Lieferanten auf allen Ebenen.

Diese Norm darf auf die speziellen Merkmale und Vorgaben eines Raumfahrt-Projekts nach ECSS S ST 00 ausgelegt werden.

Management des projets spatiaux - Maîtrise des coûts et des délais

Vodenje vesoljskih projektov - 60. del: Vodenje stroškov in časovnih rokov

Zahteve, navedene v tem dokumentu, veljajo za stranke in dobavitelje na vseh ravneh. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Publication Date

- 19-Aug-2014

- Withdrawal Date

- 27-Feb-2015

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5 - Space

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Mar-2020

- Completion Date

- 03-Mar-2020

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

Overview

EN 16601-60:2014 - “Space project management - Part 60: Cost and schedule management” is a CEN European Standard derived from ECSS-M‑ST‑60C. Published in 2014, it defines requirements and good practices for planning, controlling and reporting project costs and schedules for space systems. The requirements apply to customers and suppliers at all levels and may be tailored to specific project characteristics in conformance with ECSS‑S‑ST‑00.

Key topics and technical requirements

The standard provides structured, practical guidance across these technical areas:

- Project structure

- Work Breakdown Structure (WBS), Cost Breakdown Structure (CBS), Business Agreement Structure and Country/Company Structure (CCS) to align technical, financial and contractual views.

- Business agreement and contract types

- Treatment of fixed‑price, cost‑reimbursement, and ceiling‑price contracts, plus Contract Change Notice (CCN) procedures.

- Risk management interfaces

- Integration of risk registers and lessons‑learned into cost and schedule control.

- Schedule management

- Schedule definition (activities, sequencing, milestones, resource allocation), baseline and working schedules, performance evaluation (critical path), and schedule reporting (Gantt, milestone trend charts).

- Cost management

- Cost estimating methods, Development Cost Plan (DCP), payment and milestone plans, audited rates, currency/exchange handling, price variation mechanisms, inventory control.

- Cost control and forecasting

- Baseline cost plans, Estimate at Completion (EAC) and Estimate to Completion (ETC), financial audit interfaces and reporting requirements.

- Reporting and tools

- Standardized cost and manpower reports, inventory records and recommended reporting systems.

Applications

EN 16601-60:2014 is intended to be used to:

- Establish and enforce cost and schedule governance on space projects (satellites, launchers, payloads, ground systems).

- Define contractual cost and schedule interfaces between agencies, prime contractors and subcontractors.

- Implement baseline control, forecasting (EAC/ETC) and milestone‑based payment mechanisms.

- Integrate schedule performance and cost reporting into program reviews, risk mitigation and change control.

Who should use this standard

- Space program and project managers

- Cost controllers, schedulers and contract managers

- Systems engineers and subcontracting leads

- Procurement and finance teams at space agencies, primes and suppliers

Related standards

- EN 16601-10 (Project planning and implementation)

- EN 16601-80 (Risk management)

- ECSS‑S‑ST‑00‑01 (ECSS glossary)

EN 16601-60:2014 supersedes EN 13290‑7:2001 and is intended to be tailored for specific projects in line with ECSS system requirements.

Keywords: EN 16601-60:2014, space project management, cost and schedule management, cost breakdown structure, baseline schedule, estimate at completion, ECSS, CEN.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16601-60:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space project management - Cost and schedule management". This standard covers: The requirements specified herein apply to, and affect the customer and supplier at all levels. This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

The requirements specified herein apply to, and affect the customer and supplier at all levels. This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

EN 16601-60:2014 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16601-60:2014 has the following relationships with other standards: It is inter standard links to EN 13290-7:2001, EN 13290-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16601-60:2014 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16601-60:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Raumfahrt-Projektmanagement - Teil 60: Kosten- und ZeitplanmanagementManagement des projets spatiaux - Partie 60: Maîtrise des coûts et des délaisSpace project management - Part 60: Cost and schedule management49.140Vesoljski sistemi in operacijeSpace systems and operations03.100.40Raziskave in razvojResearch and developmentICS:Ta slovenski standard je istoveten z:EN 16601-60:2014SIST EN 16601-60:2014en,fr,de01-november-2014SIST EN 16601-60:2014SLOVENSKI

STANDARDSIST EN 13290-7:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16601-60

August 2014 ICS 49.140 Supersedes EN 13290-7:2001

English version

Space project management - Part 60: Cost and schedule management

Management des projets spatiaux - Partie 60: Maîtrise des coûts et des délais

Raumfahrt-Projektmanagement - Teil 60: Kosten- und Zeitplanmanagement This European Standard was approved by CEN on 14 December 2013.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2014 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16601-60:2014 E SIST EN 16601-60:2014

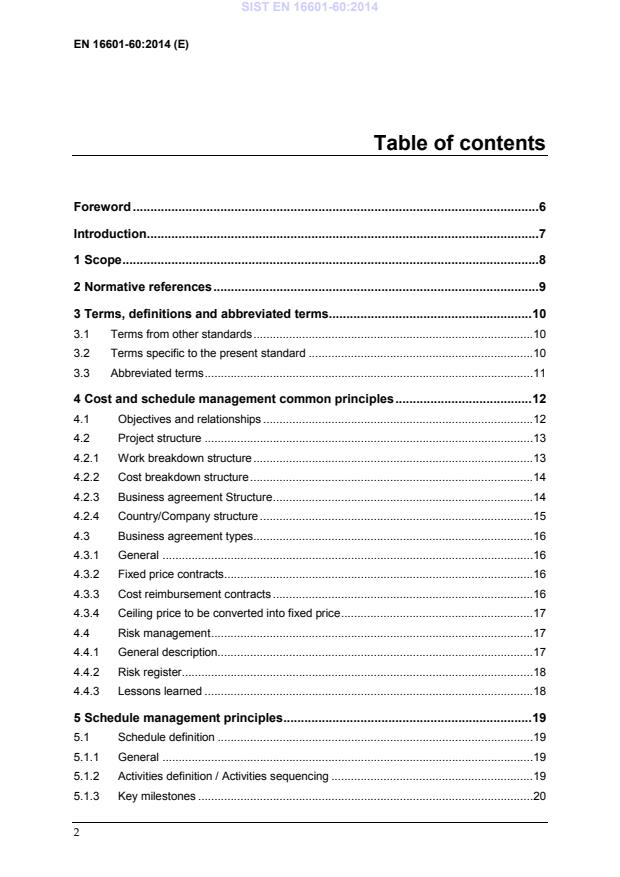

Figures Figure 4-1: Overall functional analysis . 13 Figure 4-2: Business agreement structure example . 15 SIST EN 16601-60:2014

Tables Table Q-1 : Cost estimate method vs. project phase . 79

• cost targets, • timely completion, and • technical performance. To this end, costs and activities are planned and actively controlled, with special care being given to the identification of critical situations that can lead to an adverse impact on the project cost and schedule, so that the relevant recovery actions can be proposed. SIST EN 16601-60:2014

This standard may be tailored for the specific characteristics and constraints of a space project in conformance with ECSS-S-ST-00.

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system – Glossary of terms EN 16601-10 ECSS-M-ST-10 Space project management – Project planning and implementation EN 16601-80 ECSS-M-ST-80 Space project management – Risk management

estimate (cost) at completion

estimate (cost) to completion

3.2 Terms specific to the present standard 3.2.1 cost reimbursement contract generic type of business agreement in which payments are depending upon incurred costs 3.2.2 cost estimating process helping in the determination of the expected costs of a project 3.2.3 critical path chain of activities critical to the timely completion of the project 3.2.4 direct manpower cost manpower cost charged to the project using the agreed rates 3.2.5 economic conditions reference period of time during which a set of financial elements (e.g. hourly rates and overheads) are applicable NOTE

Reference economic conditions are those prevailing when the decision to commit to the project is taken. Current economic conditions are the conditions prevailing when the service is provided. 3.2.6 fixed price contract generic type of business agreement in which payments are defined in the business agreement in the form of milestone payment plan(s), and depend upon the achievement of the relevant contractual milestones SIST EN 16601-60:2014

Meaning AIV assembly, integration and verification CBCP current baseline cost plan CBS cost breakdown structure CCN contract change notice CCS country/company structure CIL critical items list CPM critical path method CR cost reimbursement CWP control work package DCP development cost plan DIL deliverable items list EAC estimate at completion EC economic conditions ETC estimate to completion FP fixed price FFP firm fixed price G&A general & administrative MPP milestone payment plan MTA milestone trend analysis MTC milestone trend chart OBCP original baseline cost plan PDM precedence diagram method PMAC payment milestone achievement certificate PEF price escalation formula PSS procedure standard specification PT product tree WBS work breakdown structure SIST EN 16601-60:2014

Figure 4-1: Overall functional analysis 4.2 Project structure 4.2.1 Work breakdown structure A general introduction into the Work Breakdown Structure (WBS) is provided in ECSS-M-ST-10. In the specific context of Cost and Schedule management, the WBS is used as a common tool in the project, assisting its participants in: • Conducting tender comparisons and business agreement negotiations; • Optimizing the distribution of work amongst the different suppliers; • Monitoring the schedule of the project: A network of events (e.g. start, complete) and activities (e.g. design, develop and operate) takes place. The logical relationships between the activities allow the producing and completing of the WBS deliverables. Resources (e.g. labour skill, and materials) and responsible organizations (e.g. mechanical engineering department, fabrication department, supplier) can then be identified for each activity. The scope and complexity of the work and the management needs for schedule visibility influence the frequency of schedule reporting and their associated levels of detail.

Cost management WBS / Business agreement Project schedule (baseline & current)

Constraints and risks Resource development plan Cost and schedule project plan Performance

report OBCP / CBCP

and MPP Cost estimates (EAC and ETC) Task definition, duration and sequencing Schedule management Schedule report (progress status, performances, delivery and trends) Project milestones CBS and CCS (+geo return) Inventory control plan Audit Geographical distribution CCN Financial elements (Company cost element data sheet, Company price breakdown forms, Manpower and price summary, Work package manpower and cost plan, Price variation mechanism) Report (Performance measurement, Contract close out report, payment and commitment status report, Inventory record) SIST EN 16601-60:2014

To perform data reporting, the WBS is broken down into work-packages. All defined work-packages reflect the total work scope. Any reporting to the customer is performed using Control work-packages, which are agreed between the customer and the supplier and reflected in the corresponding business agreement. All defined Control work-packages also reflect the total work scope. 4.2.2 Cost breakdown structure The Cost Breakdown Structure (CBS) defines a set of cost categories used to break down all the costs of the project. It provides a common framework for all cost management activities among suppliers for the same project.

The total cost planned for each work package is broken down per cost category (e.g. labour, non-labour, subcontracts). For each cost category, the distinction between direct and indirect costs is identified by each supplier to the customer.

4.2.3 Business agreement Structure A Business Agreement Structure is a specific type of organization chart, the purpose of which is to identify the project reporting relationships between the respective customers and suppliers. It shows which suppliers are responsible for which work packages, as depicted in Figure 4-2.

Supplier 1 Service Module Supplier 6

Electrical system

Supplier 2 Payload Module Supplier 3 AIV Supplier 4

Risk Magt Supplier 5

PA support Supplier 9 Structure Supplier 11

Propulsion

Supplier 7

Structure

Supplier 8

EGSE

Supplier 10

Reflector

Prime Contractor

Figure 4-2: Business agreement structure example By relating work packages in the WBS to business agreements in the Business Agreement Structure, contractual responsibilities can be traced. It facilitates the cost management process by providing the means to ensure that all impacts (e.g. liability, financial, technical or schedule) of a change in the business agreement are properly assessed at all levels of the contractual hierarchy (see Figure 4-3).

Figure 4-3: Business agreement structure schematic 4.2.4 Country/Company structure The Country/Company Structure (CCS) shows the relationships between each company's business agreement for a project and the countries in which the corresponding work is performed. By identifying the relationships between work packages in the WBS and business agreements in the CCS, reports can be generated to illustrate how each supplier’s work is distributed per country, e.g. for geographical return purposes. In the case of projects where it is simple to identify the countries in which the works are performed, the CCS is combined with the Business Agreement Structure.

Prime level Sub-level 1 OBS Sub-level 2 Sub-level n WBS SIST EN 16601-60:2014

4.3.2 Fixed price contracts a. Firm fixed price: the price of the business agreement is not subject to any adjustment or revision by reason of the actual costs incurred by the supplier in the performance of his business obligations. b. Fixed price with variation: the price of the business agreement is not subject to any adjustment or revision by reason of the actual costs incurred by the supplier in the performance of his business obligations, except for the update to current economic conditions by applying an agreed price variation mechanism. c. Fixed unit price: the price of the business agreement is defined per unit price of the various supplies and services. 4.3.3 Cost reimbursement contracts a. Cost plus fixed fee: it is a cost-reimbursement type of business agreement which provides for the payment of a fixed fee to the supplier. Its implementation mechanism is described in the business agreement and generally includes the following elements: a target cost for the whole project; the above-mentioned fixed fee, which does not vary with actual cost; a cost sharing scheme, defining applicable incentives and penalties depending on how the actual cost spent for the whole project compares with agreed target cost. b. Cost plus incentive fee: it is a cost-reimbursement type of business agreement which provides for the payment of a target fee, which is the fee to be paid to the supplier if the business agreement is executed in accordance with targets specified in the business agreement. Its amount is adjusted depending on whether the supplier’s execution of the project is below or above the specifications fixed for the above-mentioned targets. c. Time and material: it is a cost-reimbursement type of business agreement of which the price is determined on the basis of the following elements: average hourly rates or hourly rates per category, including direct as well as indirect charges, general administrative overhead and profit, either for personnel or for the hire of facilities including operating personnel; SIST EN 16601-60:2014

Developing a network of activities, milestones and relationships between them allows for effective schedule analysis, risk evaluation and mitigation. The identification of the critical path helps to anticipate the definition of corrective measures on such critical activities so as to avoid schedule drift. Schedule reporting, including critical path, between supplier and customer provides the necessary overall visibility of the project status at any time. 5.1.2 Activities definition / Activities sequencing The network of activities is derived from the agreed Work Breakdown Structure (WBS). The activities are put in sequence linked by relationships reflecting the logical dependencies that exist between the activities. Project activity overall logic is described in a technical manner in the System Engineering Management Plan (see ECSS-E-ST-10) and Design and Development Plan (see ECSS-M-ST-10). A duration is estimated for each network of activities. Duration estimation is commonly based on a mixture of previous experiences, expert opinions, supplier information and common sense. The risk analysis process provides valuable input to define the required schedule contingencies. Schedule contingencies are usually allocated to the last activity within a project phase or sub-project phase. Once the activity identification, network logic and durations have been performed and the customer requirements (e.g. key milestones) duly taken into account, the resulting network is analysed using an agreed project calendar taking into account working hours, working days and company holidays and available critical resources such as personnel, machines, tools and facilities. This iterative process results in a schedule that is validated, logical, complete and compliant with the business agreement. SIST EN 16601-60:2014

By this means, critical periods of under-load or over-load are identified in advance, and non-critical activities can be rescheduled to suit the availabilities. During the process of schedule development all critical resources are taken into account.

During the project lifetime, the supplier uses the current working schedule and the updated resource allocation for such internal processes as: • capacity planning, • progress measurement methods, and • booking of critical resources like tooling, machines and facilities. For cost reimbursement contracts, the overall resource allocation is used as input for the development cost plan (see clause 6.3.2). 5.2 Schedule control 5.2.1 Baseline schedule The baseline schedule describes the activities and their sequences that meet the project objectives for timely completion of the project or project phase. It is developed by the supplier and agreed by the contractual parties and is the reference for schedule reporting and performance measurement. The baseline schedule is coherent with the agreed product tree and describes the flow of the work as defined in the WBS. SIST EN 16601-60:2014

As a minimum, the baseline schedule contains: • key milestones,

• descriptions of the activities, • start and finish dates of activities, • duration of activities, and • identification of the critical path activities. The baseline schedule is included in the project business agreement. The impact of any agreed change on schedule dates and logic is included in the updated version of the baseline schedule. 5.2.2 Current working schedule The current working schedule documents the actual status of completed and planned activities and of the planned activity sequence. For completed activities, actual dates are given and for future activities the planned dates are used. The current schedule identifies the most realistic view of the project status given by the supplier to the customer, and hence does not necessarily reflect an agreed and accepted project status. The current working schedule is identical in its structure, level of detail and content, to the baseline schedule (see clause 5.2.1). It conforms to the principles described in clause 5.1. At the start of the project, the baseline schedule is identical to the working schedule, as no progress has been made (both schedules show only the planned status of the project). As the project progresses, the current working schedule can differ from the baseline schedule due to the progress made, reflected by updating the status of activities and the activity sequence. The current working schedule reflects the following information: • up-to-date status of activities; • up-to-date status of key milestones; • suppliers’ procurement status. The comparison between the current working schedule and the baseline schedule forms the basis for the overall project progress assessment. If the current working schedule shows delays against the baseline schedule, the necessary corrective actions are identified, assessed and implemented so as to converge back to the baseline schedule. SIST EN 16601-60:2014

Figure 5-1: Gantt chart example The evolution of the planned dates for key milestones within the project lifetime results in a trend analysis, which is one key method of assessing the project status. Different representations of trend analysis exist, of which the following are two examples: A Milestone Trend Chart (MTC) allows the performing of milestone trend analysis (MTA). In an MTC, the dates of milestones are drawn in a graph versus the reporting dates of the schedule. The slope of the graph indicates whether the considered milestone progresses consistently (zero slope), is delayed (positive slope) or accelerated (negative slope). Figure 5-2 shows one example of an MTC illustration with a number of milestones. SIST EN 16601-60:2014

Figure 5-2: Milestone trend chart example Figure 5-3 shows an example of a Milestone List. A concise overview of the project is obtained through a “traffic light” presentation by comparing the baseline and current working schedule for each identified milestone. In the following list the traffic light is defined as: • green: on schedule with more than 10 days margin • yellow: current date within +/- 10 days of baseline date • red: current date more than 10 days later than baseline MilestoneBaselineCurrentFinish of development1/ Jun 048/ Jun 04Design review1/ Nov 0410/ Oct 04Start manufacturing1/ Feb 0525/ Jan 05Delivery1/ Jul 0520/ Aug 05 Figure 5-3: Milestone list example SIST EN 16601-60:2014

• Activities completed, together with their actual finish date; • Forecast completion dates for activities in progress; • Validity assessment of the defined sequences, relationships and constraints of planned activities. Evolution of major project events selected as key milestones are reported in conjunction with the above information and is commonly presented in the form of a milestone trend

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...